5 minute read

FEATURES It Makes Sense

Mike Hobson Founder & MD

Sleepsense International specialises in helping brands and retailers develop and launch new product propositions within the bedding category. Their unique approach to outsourcing streamlines the entire process, making it more efficient and cost-effective.

“As a third-party white label bedding company, we take care of everything from product development and sourcing to branding, packaging and shipping,” said Mike Hobson, Founder and Managing Director at Sleepsense International. “Our goal is to help our clients bring their vision to life and reach their target audience with high-quality, innovative bedding products.

“I first looked at the bedding industry after working for some of the biggest bed manufacturers in the UK and it was so fragmented in terms of buying and supply chain with customers having to use five to six suppliers to buy one type of pillow, for example latex, wool, natural or foam.

“There had to be a simpler way to serve the trade. This is why Sleepsense International was created. We’ve designed our model to be able to offer our customers a truly one stop shop –with a min MOQ of just one box delivered direct and with a choice of over 100 pillows all stocked with us. With choices from major brands like Sleepeezee, Airsprung, Mammoth, Millbrook and Pillowheadzz, plus many more, we really are a one stop shop.”

Sleepsense has partnered with a number of bed brands, as highlighted above, but their platform extends outside of the UK too. “We have partnered with some truly amazing bed brands here in the UK and are proud to have such great quality products and brands to offer to our customers,” Mike continued.

“We also have our international business where we offer both branded and bespoke products from the USA to Australia from our showroom here in Midsomer Norton, to our international showroom in Macedonia.”

As part of their bespoke service, Sleepsense can help in a number of ways, from product design, pricing, distribution and sales. Furthermore, the process of creating a bespoke product is simple, as Mike says: “We begin with a full consultation to understand your needs, goals and target audience. Our team will listen to your ideas and provide expert guidance to help you create the perfect product architecture for your brand.

“Our team will then work with you to create a detailed brief that outlines your product requirements and specifications. We will use this brief to create and build a product architecture tailored to your needs, ensuring that every aspect of your product line is aligned with your brand values and target audience.

“Our in-house design team will create graphic artworks for your products and in-store requirements, taking care of every detail to ensure that your products look and feel exactly as you envisioned.”

Another key element in the process is the ongoing support throughout and after creation. Sleepsense has a dedicated account support team, which is tasked to make sure the whole process runs smoothly and, most importantly, the customer is happy.

“Our dedicated account support team will be with you every step of the way, from the initial brief to the final launch and ongoing support. We will ensure that you receive timely updates and regular samples to ensure that your product line meets your expectations,” Mike said.

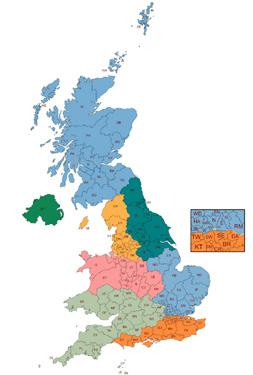

None of this could be achieved without the support of their amazing team both here in the UK and abroad, which is headed up by Stuart Page, Global Sales Director, and supported by Clare Gibbons, Global PA. In fact, three members of Sleepsense International’s sales team where recently recognised as ‘Best Agent’ award winners in the Big Furniture Awards, as voted by the furnishing industry.

“Our dedicated sales team in the UK, three of whom recently one an agent of the year accolade, showcase our full product range. They would be happy to come and see you soon, so do get in touch and drop them a line,” Mike added. “We are also delighted with our Irish distribution partners Irwin’s who showcase all the brands in their showroom in Belfast.

“At SleepSense International, we are committed to providing exceptional service and delivering products of the highest quality. Our team of experts has years of experience in the bedding industry and a deep understanding of market trends and consumer preferences. Contact us today to learn more about our bespoke design services and how we can help your brand stand out.”

SCOTLAND: Graham Dixon 07711548093 - gdixon@dxn.org.uk

NORTH EAST: Ian Crowther 0793034077 - icagencies@btinternet.com

NORTH WEST: James Leach 07779335801 - james@jrlagencies.co.uk

MIDLANDS: Richard Jackson 07790252868 - rjagencies@outlook.com

SOUTH WEST: Colin Boyce 07876198938 - colin@thefurnitureandbedagent.com

SOUTH EAST: Clive Loe 07561609364 - cliveloe@btinternet.com

EAST ANGLIA: Gary Birch 07903187719 - birchtwins@me.com

IRELAND: Irwin Textiles - Andrew Hughes 07713052220 - a.hughes@ra-irwin-co-uk

Spinks & Black

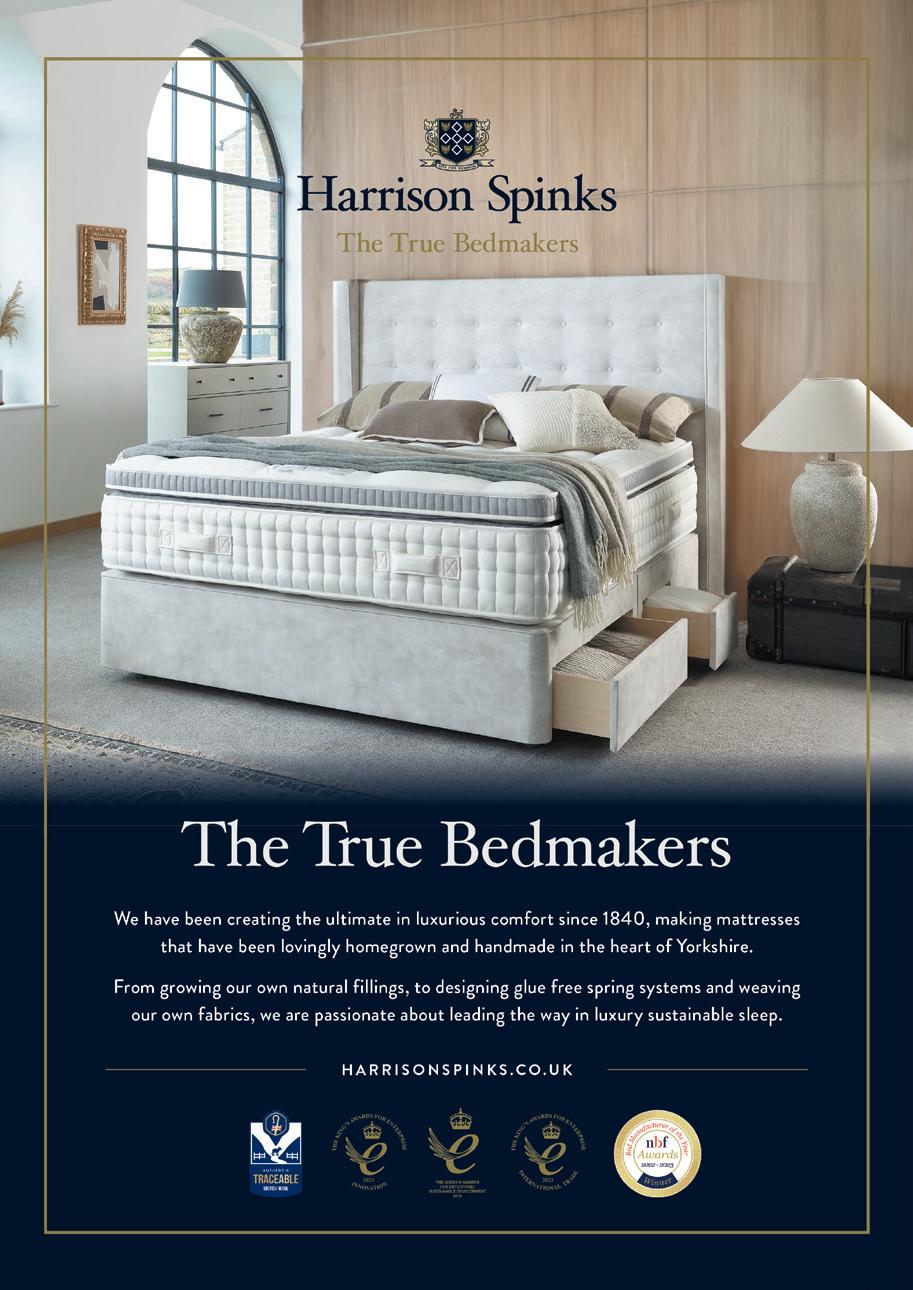

Family-owned luxury bedmaker, Harrison Spinks, has created a new British-made collection with long-standing partner Feather & Black, which features a new range of mattresses containing natural and responsibly sourced British fillings.

The premium range boasts 10 models, with the latest three mattresses recently unveiled in the range – Bennett no turn, Marlowe quilted and Conrad Ortho –luxuriously layered with British wool directly from farm to factory.

For superior comfort, there is an option to add an additional 5,000 spring count mattress topper, designed to provide an extra layer of comfort. The sumptuous natural fillings and additional layer of pocket springs creates a flexible, supportive surface for the ultimate sleep experience.

For the fabrics, the fifth generation bedmaker has partnered with fellow Yorkshire-based manufacturers Abraham Moon & Sons and Camira Fabrics which have both been producing natural and eco-friendly materials in the heart of West Yorkshire for more than 150 years.

The result is a premium patterned fabric option using quality, British-made textiles made from deluxe 100% wool.

Customers can choose from different levels of firmness for their mattress, which will feature Harrison Spinks’ industry leading Cortec™ spring technology, offering instantly adaptive support in a glue-free, recyclable spring system. Similarly, the new collection includes a style available in orthopaedic very firm tension, providing highly individualised support for an enhanced sleep experience.

As an official partner of British Wool, all wool that goes into Harrison Spinks’ mattresses is completely traceable from UK farms, with each mattress made with natural and British fillings, including blends of ethically sourced hemp and flax, while being glue-free and FR chemical treatment-free.

Nick Booth, Managing Director at Harrison Spinks said: “We’re delighted to have been able to partner with Feather & Black once again on this exciting new premium range. This new collection incorporates our innovative Cortec technology, uses British and natural fillings and, as with all our beds, each mattress is recyclable and British-made.

“We love the fact that Feather & Black customers will be able to sleep soundly, not only on a bed which is adaptive for premium comfort, but also knowing that they’re supporting the local economy by buying a British made product.”

Laura Burnett, Furniture & Homewares

Buyer at Feather & Black, said: “This new range showcases the vast selection of great quality materials we have here in Britain, as well as a high standard of manufacturing that is both innovative and responsibly developed.

“We’re always excited to work with Harrison Spinks and we love the amount of variety available in this new collection, from premium British fillings and springs to the inclusion of top-quality British-made fabrics from Yorkshire-based brands.

“Local sourcing and ethical production have been at the forefront of these designs, demonstrating the key values for both Feather & Black and our longterm business partner Harrison Spinks.” www.harrisonspinks.co.uk / www.featherandblack.com