25 minute read

mobility

Rethinking curitiba’s urban mobility

The city of Curitiba in Brazil has a long history of sustainable development planning, and is responsible for creating concepts that helped shape the urban landscape, such as the creation of the Bus Rapid Transit (BRT). This is considered an urban mobility solution that redefined the adoption of wheel transportation modal, an idea pioneered by Curitiba. It has been spread and implemented in different cities worldwide, guaranteeing the capital of Paraná a seal for its innovativeness. However, in times when the consequences of climate change has proved to be a reality, there is a need for a new qualitative leap. Urban mobility is largely responsible for the emission of greenhouse gases in Curitiba: in the 2013 inventory statistics, it accounts for 72% of emissions.

Curitiba’s institutional framework is strongly concerned with public transportation and environmental issues. There is an awareness regarding the need for coming up with disruptive proposals in relation to the current model of public transport concession, as well as the logic behind the city’s mobility, in order to reduce emissions. The starting discussions point to the construction of a sustainable mobility system – Mobility as a Service (MaaS) – that is accessible on demand, and also combines shared mobility, autonomy and electrification with integrated systems for energy, public transportation and infrastructure.

The current concession for public transportation in Curitiba expires in 2025; therefore, there are exactly six years left to develop a new, more sustainable model for mobility, and to create a favorable environment for its implementation. The current fleet consists of 1639 buses: 8.5% of this fleet is composed of Euro II vehicles, acquired between 1996 and 2003; 87.6% consists of Euro III vehicles, acquired from 2004 to 2011; and, from 2012 on, the Euro V vehicles were incorporated to the system, representing 3.9% of the fleet. The fleet also comprises 62 buses with

low-emission technology, of which 26 are bi-articulated and 06 are articulated buses that run on B100 biodiesel, as well as 30 hybrid buses, 2 of which also operate with B100 biodiesel. The city’s goal is to obtain a public transportation concession model which allows the total replacement of the fleet’s energy matrix, from diesel to a low carbon-emission technology, in Curitiba and in the metropolitan region. The city’s objectives also include the structuring of a metropolitan management body responsible for the transportation system within the MaaS perspective.

The total amount of emission attributed to public transportation in the last inventory was equivalent to 129,212 ton CO2eq, which represents 4% of all transportation emissions, or 6%, if other means of transportation, other than land transport, are considered – of these, air transport is quite representative. Such a percentage allows the identification of the high contribution of individual transportation to greenhouse gas emissions in Curitiba. Although public transportation’s 6% contribution may seem insignificant percentage-wise, public authorities are not exempt from the responsibility to invest in public transportation and new technologies. Not only it is their role to promote society’s engagement with the environmental cause; but also, only with new concepts for mass transportation it is possible to increase the attractiveness of the public transportation system and, consequently, decrease the widespread use of individual transportation.

There is much interesting information regarding this theme and it may well be a success case for the city, including as a vector of economic development. If the government does indeed move forward with the creation of a national electromo-

bility platform, Curitiba has the right conditions to be one of the references. From the economic perspective, 56.4% (data from 2016) of the portfolio of Curitiba’s product exports are tied to the automobile and engineering industries, and thus, there are excellent assets installed for the development of an electromobility platform. Recently, the Federation of Industries of the State of Paraná (FIEP) inaugurated a Technology Center for hybrid and electric vehicles. This Center accelerates the modernization of industries in the country, especially in Curitiba and its metropolitan region, and trains professionals through short-, medium- and long-term courses, in addition to undergraduate and graduate technical courses for electromobility and hybrids.

The proposal to insert modals with low carbon emissions has been studied in the city since the 1980s, through the proposal for the system’s electrification via the insertion of the Trolleybus, a bus with electrical energy by overhead contact lines. Since then, various alternatives have been studied, such as the implementation of VLT, Monorail and Metro; however, despite the proven efficiency, these actions were postponed due to their high costs of implementation. The first study, focused on electric buses (without catenaries), started in 1998, through a partnership between the Municipal Government of Curitiba and the Fiat automaker. In 2009, B100 vehicles that ran on 100% soy oil were implemented. In 2010, the city began testing hybrid buses (battery and diesel) in partnership with Volvo, which make up the fleet to this day. Volvo electric plug-in hybrid systems were also tested, and an agreement for the development of an articulated hybrid vehicle was signed between the Swedish and the local companies in 2014. On this same year, the Chinese BYD tested its fully electric articulated bus In addition to mass transit vehicles, other projects focused on the use of electric cars in the (i) City Hall’s fleet (Itaipu Binacional, Aliança Renault-Nissan and CEIIA, Ecoelectric Project, 2014) and (ii) electric taxi (BYD, City Hall and URBS, 2015).

Curitiba is part of the Ministry of Regional Development’s Electromobility and has been indicating the need to compose a multidisciplinary

work team, integrated with city technicians, with

the objective of reviewing its transportation system, both in terms of the service supply and of the concession model. There is an imperative need for the support of: consultants specialized in financial economic modeling, with know-how in public transportation and public management; professionals qualified for legal issues, especially Brazilian legislation regarding the issue of public concessions; and professionals involved in environmental and transportation technology, focusing on carbon emissions. Also important is the expertise in governance models for the new intended modeling, as well as the creation of a methodology that values the social gains origi-

Jéssica Serra de Freitas

Janaina Camile Pasqual Lofhagen

nated from the new proposal (improvement in air quality, in the inhabitants’ health, etc.).

Such actions would provide opportunities for the requalification of the public transportation system, contributing to the reduction of urban mobility conflicts, in addition, providing a case study to guide urban mobility policy guidelines.

Important Links/ References:

MINISTÉRIO DO MEIO AMBIENTE (MMA). Mobilidade Sustentável. 2018. Disponível em <https://www.mma.gov.br/ cidades-sustentaveis/urbanismo-sustentavel/mobilidade-sus-

tentável.html> Acesso em 13 de junho de 2019.

MINISTÉRIO DO MEIO AMBIENTE (MMA). Plano Setorial de Transporte e de Mobilidade Urbana para Mitigação e Adaptação à Mudança do Clima (PSTM). 2013. Disponível em <https://www.mma.gov.br/images/arquivo/80076/Transporte.pdf> Acesso em 24 de junho de 2019.

MINISTÉRIO DOS TRANSPORTES. Plano Setorial de Mobili-

dade e Transporte para Mitigaçã o e Adaptaçã o à s Mudanças Climáticas. 2013. Disponível em <https://www.mma.gov.br/ images/arquivo/80076/Transporte.pdf> Acesso em 30 de

RUNGE, C. F., SENAUER, B.The ethanol bubble. 2007. Foreign Affairs Journal and Folha de Sã o Paulo. Disponível em <http:// www1.folha.uol.com.br/folha/mundo/ult94u106159.shtml>

Acesso em 30 de junho de 2019.

U.S. ENERGY INFORMATION ADMINISTRATION (EIA). Different types of energy sources (or fuels) are used for transportation in the United States. 2016. Disponível em <http://www. eia.gov/energyexplained/?page=us_energy_transportation> Acesso em 25 de julho de 2019.

INSTITUTO AMBIENTAL DO PARANÁ (IAP). Inventário Estadual de Emissões Atmosféricas de Poluentes. 2013. Disponível em < http://www.iap.pr.gov.br/arquivos/File/Monitoramento/INVENTARIO/INVENTARIO_ESTADUAL_DE_EMISSOES_ ATM_versaofinal.pdf> Acesso em 5 de agosto de 2019.

Combined production of high Yield BioCNG and biofertilizer

Introduction:

Biogas has emerged as a strong contender of renewable technology to convert agricultural, animal, industrial and municipal wastes into electricity, and transport fuels. Current total biogas production in India stood at 2.07 billion m3/year. This is quite low compared to its biogas potential, which is estimated to be in the range of 29–48 billion m3/year. Current Indian biogas system utilizes predominantly cow dung, food wastes, and poultry litter wastes.

India Biomass resources: India has 141 Million hectares of arable land producing over 700 Million tons/annum of biomass – estimated surplus of 150 million tons/annum and another 50 million hectares of arable land is under mono cropping potential for short cycle cellulosic biomass. Cattle dung is estimated to be around 1000 million tons/annum from 300 million cows & buffaloes. Another 8 million tons per annum is from 500 million poultry birds. As well Indian urban population is reaching 550 milliion, which would generate more than 100 Million tons per annum of MSW. Utilizing these resources consciously can meet target of 29 to 48 billion m3/year. One important sector to be developed and improved in Indian transport sector is the diesel consumption segment. Diesel demand has reached a record high in 2019 in the country, resulting in intervention by government wherein it is consciously giving more importance to renewable energy sector to conserve the use of fossil fuels(ref) and increase country’s self-reliability. Even though, Indian economy took beating due to COVID 19 , and hopefully there will be upswing in 2021. The same trend of 2019 could be expected likely in case of diesel consumption, and that adversely impact the Indian economy. In this context, India need to reconsider developing efficiency in terms of bio-economic transport fuels; there are several options in form of bio-CNG, bio-ethanol, bio-hydrogen and bio-diesel / green diesel. These fuels should be encouraged to build sustainable local economy. This will improve the economic and environment situation in both urban and rural economy as well increase the job opportunities in rural sector by providing stable income to farmers. This will also help achieve the target of cleaner energy mix, clean environment and of reduced CO2 emissions. India as well has policies for biogas (CBG) under Priority Sector Lending to provide

expedited financial assistance to new projects. India has as well encouraged policy incentives to produce Bio-CNG as vehicular fuel; a minimum of 6000 cum biogas plants is required for 2400 kg Bio-CNG having buyback arrangement from oil marketing companies under SATAT program. Although government has good policies, there are barriers in terms of shortfall of robust supply chain for ambitious Indian target.

To reach target of renewable bio economy of Bio-CNG, growing high yield biomass crops is necessary in land scarce and densely populated country. In that context, we are exploring Napier grass which looks very promising alternative biomass-crop for Indian situation

Napier grass for biogas: Pennisetum purpureum and related hybrids (also known as Napier grass / Elephant grass / Uganda grass) are the species of perennial tropical grass native to the African grasslands. Advantages are low water and nutrient requirements, and therefore can make use of otherwise uncultivated lands. After planting, Napier grass grows vigorously and can reach 4 meters in 3 months. The stems of Napier grass are less juicy and highly fibrous. Napier grass is fast growing and has high annual productivity that depends on the climatic conditions, especially temperature and rainfall. Yields range from 120 to 180 Dry Matter/ha/year depending on the fertilizer inputs. In 1953, a cross was made in India between Napier and Bajra which is more succulent, leafy, fine-textured, palatable and drought resistant to combine these qualities with high yielding potential of Napier grass.

The primary product of Hybrid Napier Co4 grass

(for simplicity elsewhere in this document referred to as Napier grass) which can be used for animal fodder and production of biogas. It is a perennial grass that can be retained on field for 3 - 5 years. Napier is harvested for the first time after planting of 75 days. Subsequent harvest is done after 45 days of regrowth period or when the plants attain a height of 1½ meters. Annually, at least 6 to 8 cuts are possible. The fodder must be cut closer to the ground level for more profuse tilling. Napier grass has the best palatability and the highest nutritive value 45 days after harvesting and this is the envisaged plantation cycle.

Hybrid Napier grass has a harvest of 450 tons/ha/ year of fresh matter (FM) on average if it is cultivated as a single crop. This is 56 tons of green fodder per hectare per harvest (cut) having nearly 20 to 23 % Dry Matter (DM) content. Napier can be cultivated as a single crop or intercrop with other fodder with a higher protein content or food crops. Harvesting is done continuously evthe grass. Nitrogen fertilizer is applied after every harvest and the grass is irrigated every 10 days. Cultivation is carried out continuous to keep the soil healthy and to control the weeds. protrudes out of the soil. One hectare of Napier grass produces about 1.4 million stem cuttings during the first harvest which can be propagated on another 125 hectares of land. Our strategy is to proceed with stem cuttings in order to expand our plantation on other land plots. Another expansion strategy which will be explored is to supply stem cuttings to contract farmers, support them with inputs, management and technical back-up and buy Napier silage from them at predetermined price less provided inputs.

When the clumps of Napier grass become too big, they are thinned (quartering) producing ery 45 days for up to 5 years without replanting

“seedlings” called slips for grass propagation. Like stem cuttings, the slips will be used to expand our own plantations. Napier grass slips can also be made by growing stem cuttings in pods and transplanting them to the fields when they have developed roots and stems. This reduces plant mortality associated with propagation through stem cuttings.

Napier grass is cut for silage after harvesting. This is meant to reduce nutrient loses during feeding and to facilitate transportation and storage if there is such a need.

Napier grass propagates vegetative by cutting stems consisting of at least 2 nodes and planting them with one node in the ground while the other

Dry matter

Silage can be packed in propylene jumbo bags and sold fresh to the farmers. The proposed method is “cut & carry” which means the grass is harvested, cut for silage and sold for fodder; no stocks of Na23 % pier fodder are kept at the farm.

Crude Protein

Calcium

Phosphorus

Oxalates (Max) 15.71%

0.88 %

0.24 %

2.97 % Napier grass silage has all nutrients needed by livestock. Research has shown that Napier silage increases milk production in dairy cattle and weight gain in feedlot cattle.

Table 1 shows an approximate nutritional value of hybrid Napier Co4 grasses.

Digestibility 58.00 % (without pretreatment)

Table 1 Source: Pasture Division, VRI, 2004 Hybrid Napier grass has the highest yield among all perennial forages and therefore gives the farmers the best value for money. Napier grass has a competitive edge over other fodder

Hybrid Napier Grass

Napier Grass Silage

products in price, quality and availability, farmers can avail more than 100000 rupees per acre per year which is much better prospect compared to conventional biocrops such as paddy, sugarcane, tobacco, ragi, ground nut etc.

High yield biogas and bioCNG from Napier grass:Napier grass consists of moisture content of 77.74 % and ash approximately 3.18%. Based on the ultimate analysis from Thailand lab, the carbon, Hydrogen, nitrogen and Oxygen are 44.19 %, 6%, 2 % and 43.8 % respectively. Approximately carbon to Nitrogen ratio fits to 22, this is reasonable to develop mono-substrate bio-digestion after introducing pre-treatment strategies. Napier grass has protein, cellulose, lignin and hemi cellulose. As per chemical composition is concerned, there are certain challenges to convert all without good pre-treatment technology. There is very common as matured dilute acid, alkaline or hot-water pre-treatment technologies prevail in pulp and paper industries. The proposed methodology combine strategy to improve the digestibility of cellulosic biomass by converting to more Napier Grass Stem Cutting Napier Grass Fodder

soluble sugars from the hemicellulose and cellulose part. As well our digester technology can be modularized with combining sequential stages after pre-treatment strategies with or without phase separation. The reactor design for anaerobic digestion is combined configuration of CSTR and UASB with novelty in internal baffle design for increasing microbial population. With this design modifications including three stage configurations, it can achieve high degree of conversion of cellulosic biomass. The target is to increase the biogas yield from a conventional CSTR digester which can yield 108 to 163 m3/ton of biogas. Thus, technology has high degree confidence of achieving with well controlled and designed- baffle biofilm reactor. A high degree conversion can also be provided with higher organic load by moving from mesophilic digester to thermophilic digestion; however, there is energy penalty of up to 15 % thermal energy consumption, which need to be supplied by burning portion of biogas.

Biofertilizer: It is also proposed innovation to recover digestate slurry effluents after third stage

Advantages of innovative biodigester configuration

Conventional

With pre-treatment

With high surface reactor

Three stage biodigester coupled with high surface reactor m3 biogas/ton of Napier grass

108

118

126.8

163

of biodigester reactor using chemical process technology to crystallize ammonia rich effluent (NH4+) with phosphorous effluents using convention crystallization process technology. Fertilizer recovered can be combined with dried sludge to increase the NPK values in the digestate compost and sold to agriculture customer.

D. Hari Babu

Author Conclusion: • Innovative process technology is proposed for demonstration to encourage the farmers for growing napier grass with buy back Arrangement with the Bio-CNG Industry. • This innovation is proposed to hydrolyse with sugar.

thermal coupled acid hydrolysis for solubilizing

• Innovation also proposes solar coupled hydrolysis process reduce the hot water energy consumption. • Three stage conversion innovation also proposes more than 50% higher yield from the base conventional biodigester , i.e. from 108 to 163 m3 of biogas per ton of raw napier grass.

Rajesh S Kempegowda

Author

Present status and essence of standards in the Indian biogas ecosystem

Biogas plants have been existent in India since several decades. As an interesting fact, Biogas - a globally accepted clean fuel, actually finds its origin in India and was discovered in the mid-eighteenth century and gradually emerged as the technology of choice for bridging the energy deficit situation in rural hinterlands. However, over the last decade, it has evolved to encompass a wider role from Waste to Energy perspective too.

In other words, the biogas technology that was earlier put to use for essentially treating cow dung anaerobically as a substrate; the scope has now widened to treat other organics like municipal solid waste [organic fraction], food & vegetable waste, agro-harvest residues and industrial wastes from slaughter house, diary residue, food processing units, and so on. Indeed, the change towards treating a wider array of feedstocks in contemporary scenario has occurred with a lot of modification in the production methods. It now incorporates various technologies for pre-treatment of feedstock, a wide array of technology for digestion, purification and upgradation, and efficient utilisation of biogas or its upgraded forms. Not to be forgotten, various technologies pertaining to recovery of by-products such as organic manure and Carbon Dioxide are becoming more common in upcoming biogas/biomethane projects. Furthermore, it’s worthwhile to note that the contemporary technologies are ephemeral in nature and are continuously evolving in pursuit to improve the efficacy and yields from plants.

Nevertheless, in global comparison, the present biogas advancement of India is moving at a relatively slow pace in terms of rate of technology adaptation and its widespread acceptability as a business case. Among many reasons, one crucial aspect for slow adaptation rate is the absence of a level play-

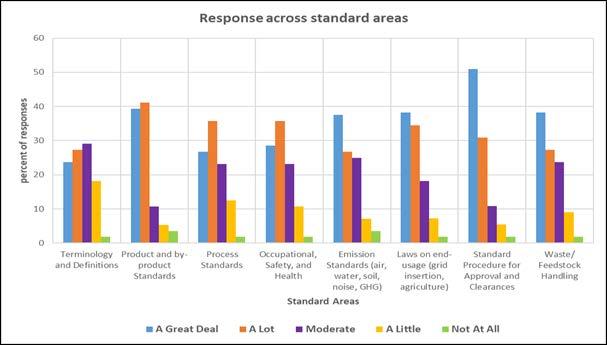

ing field, in form of standards, for participants in the biogas ecosystem. A survey by Indian Biogas Association amongst its members, representing the entire spectrum of biogas value chain, clearly reinstates this fact. Over ninety percent of the surveyed participants strongly considered that unavailability of standards in the biogas/bio-CNG industry is the major deterrent for non-realization of industry’s true potential. Furthermore, in the survey, few predefined sub-areas/domains with need for standardization were identified. Participants were asked to earmark the sub-areas/domains, lack of whose standardization, jeopardizes their business opportunity in the industry. The obtained survey results are graphically portrayed on Page No. 37.

Survey participants’ response to the question: “Please select the appropriate option for the beneath listed areas of standardization, lack of which, jeopardizes your presence in the biogas/bio-CNG industry?”

Clearly, considering the survey participants’ response to be the representative sample of stakeholders in the biogas industry, the above plot shows the wider consent for a need towards standardization across all these identified domains. As depicted, majority agreed that defined and documented set of rules, in form of standards, should be available in areas such as- terminologies & definitions, specification of product, operation process, Occupation, Safety and Health (OSH), Emission norms, laws on end- usage of products, approvals and clearance processes, and handling of waste (feedstock to biogas plants). Availability of standards in these identified domains shall provide uniformity, which amongst many others shall accrue the following crucial benefits: - Allow worldwide acceptance of Indian Market for application of the product, process, or equipment, - Removal of technical barriers with swift technology transfer, - Promote quality use of biogas, its upgraded form and related equipment, and also augment the R&D space, - Providing uniform guidelines for approving regulatory authorities and sanctioning of the permissions, and - Facilitating unequivocal regimes thus ensuring hassle free compliance to the legal requirement.

The benefits shall ultimately lead to an improved transparency in the ecosystem, gain in promoter’s confidence, and steeper economic growth for the industry. Exploring further into the existing set of standards encompassing the Indian biogas/ biomethane ecosystem, which can be segmented as per different recognised scales of biogas plants by MNRE, (the central coordinating ministry for biogas), the following could be observed.

Small-scale biogas plants Courtesy, the Government’s initiative, India is currently running one of the most diverse and biggest renewable energy programmes pertaining to small scale (household-based biogas plants) known as the NNBOMP (New National Biogas and Organic Manure Program). Since the early twentieth century, MNRE has fine-tuned the program and rationalised the related subsidy scheme; by strengthening the institutional framework at state and district level and devising the standard tender documents for calling bids for implementation of the set target. Certain biogas plants models (fixed dome type, and floating dome type), which are IS marked (meeting Standard code of practices from Indian Standards Institution commonly known as ISI as approved by BIS) are recognised by the MNRE, and eligible for its subsidy scheme under the NNBOMP. Additionally, there are various other MNRE approved models under fixed, floating, pre-fabricated and bag type, which are also accepted for availing the subsidy under NNBOMP. Also, for safe, efficient and economic utilization of the biogas obtained from biogas plants, IS specifications for biogas stoves and their spare parts need to be adhered upon. Such stoves are marked with an ISI mark. This applies across any scale of biogas plant using cooking stove for end usage of the cleaner fuel.

Medium-sized and Large-scale biogas plants Under the biogas power generation (Off-Grid) and thermal application program of MNRE, decentralized power generation plants (3-250 KW) along with equivalent thermal/cooling capacity applications are promoted. In order to be applicable for subsidy, the implementation guideline from MNRE cites that equipment needed in biogas plants such as engines, generator sets, gas scrubbers, energy meter, flow meters, etc. wherever applicable should conform to standards brought by BIS and ISO. However, as on date, there aren’t any concrete standards published by BIS pertaining to the same. Furthermore, the guideline also cites that the included equipment in the project should meet all the requirements of Pollution Control Boards including Water and Air Pollution (prevention and Control) Acts and Noise Pollution Act. Then, for the larger scale projects under MNRE’s programme on Waste to Energy from urban, industrial, agricultural Residues and MSW, there isn’t any eligibility criterion on technology selection. Within this programme, biomethanation is an accepted technology type but, there isn’t any particular mentioned specification or standards, which the biomethanation technology needs to comply upon. However, the produced bio-CNG (enriched biogas) should meet the specification for biomethane as per the available BIS standard. Also, storage of the produced biomethane at higher pressure in cascades is typically done to increase the stored energy density and related economical transportation; the vessels used to store and transport should meet the standards prescribed by Petroleum Explosive and Safety Organization (PESO) under Ministry of Commerce and Industry (MoCI)”

Now looking into involvement of other Ministries, the Ministry of Petroleum and Natural Gas (MoPNG), in particular, is now deeply entrenched in the biogas ecosystem, through its Biofuel Policy 2018. The policy talks about increasing usage of biofuels in the energy and transportation sectors of the country in the coming decade. It aims to utilize, develop and promote domestic feedstock and its utilization for production of biofuels thereby increasingly substitute fossil fuels in a sustainable way. However, the policy doesn’t mention compliance to any particular standards. May be in due course, easy access to existing Natural Gas Grid infrastructure and insertion of biomethane into the grid will call for few relevant standards to be set by the Petroleum and Natural Gas Regulatory Board (PNGRB), a body under the MoPNG.

Likewise, several other ministries have their set of frameworks which has a role to play in the biogas/ bio-CNG ecosystem. For instance, the Department of Fertilizer under Ministry of Agriculture and Farmer Welfare (MoAFW) have incorporated necessary standards in the Fertilizer Control Order (FCO) to recognise bio-slurry, a by-product from biogas/ bio-CNG plant, as an organic fertilizer. Presently in FCO, forms of organic fertilizer that get recognition are Vermicompost, City compost, Organic Manure, bio-enriched organic manure and

the phosphate rich organic manure (PROM). Also, Ministry of Road Transport and Highways (MoRTH) have amended the Central Motor Vehicles Rules, 1989 and included the provisions for usage of upgraded biogas, in the form of bio-CNG, in motor vehicles, provided its meeting the fuel specification as per prescribed specification of biomethane from BIS. Under the Environment protection initiatives, the Ministry of Environment, Forest and Climate Change (MoEFCC) has notified the revised Solid Waste Management SWM Rules, 2016, which are to be considered as guidelines but, not exactly standards.

It’s quite evident that there are several Ministries involved in this industry. But, the non-harmonised nature of the frameworks from individual Ministries has always led to inadequacy of required support to the industry. So, this leads us to one of the major challenges in attempting to formulate standards on aforementioned sub-areas/domains. That, it’s not at all easy to comprehensively look into all the different existing regulatory frameworks from numerous Ministries and other authorities, which more often do not tend to crisscross into each other.

In the journey towards formulating standards, the best way to go about is to begin with taking cues from worldwide available standards on biogas. The ISO committee is already working in tandem with many other countries on developing and further fine tuning of these worldwide minimum required standards. Now, with this as the starting dot and keeping cognizance of the specifics of inter-ministerial regulatory frameworks, the onward course of standard formulation across identified sub-areas/domains can be carried out. The process may include: formation of working groups (WG) across each identified sub-area/domain, conducting organising focused group discussions- ensuring adequate representation of inter-ministry officials in each WG, followed by drafting of standards. As a more holistic approach, detailed value chain analysis of the biogas industry should be carried out and regulatory/ legal frameworks relevant to each block of the value chain should be assessed. This will lead to identification of the existing Inter-Ministerial frameworks influencing the biogas ecosystem. In other words, harmonization of formulated standards with existing inter-ministerial frameworks is extremely essential for its wider acceptance.

While, it remains imperative that standards across domains should be formed at the earliest in best interest of the development of the biogas industry in India. However, forming standards in itself shall not be enough. We have already seen the instance of inappropriate implementation of the highly promising RPO/REC regime leading to numerous circumspect investors now averse to foray into prospective renewable projects. Several earlier installed renewable projects, both in solar and non-solar category, which were built on the premise of this regime have suffered abysmally due to its inadequate implementation. Thus, along with formulation of appropriate standards; structuring an adept monitoring body for testing its “on ground” acceptability and implementation, and periodic revisions to ascertain that it meets the contemporary requirement, are also quintessential for success of the industry in long-term.

Mr. Abhijeet Mukherjee

Project Head Indian Biogas Association