3 minute read

Manufacturers going green

GREEN GOING

Darren Casseytakes a look at some of the car industry’s most eco-friendly advances

Climate change is a hot topic in the car industry and manufacturers are racing to bring electric cars and plug-in hybrids to market to reduce exhaust emissions.

But it’s not just the powertrain that’s been the focus. Many manufacturers have also been working to make the whole car-building process more eco-friendly, whether it’s the materials used inside or the production process itself.

Here, we take a look at some of the ways that cars are getting greener.

Mini Strip

The Mini Strip is a one-off concept car built in collaboration with fashion designer Paul Smith. Based on the firm’s Electric Hatch, it prioritises sustainability above all else.

Features include a body that hasn’t been painted, except for a film to protect it from corrosion, recycled perspex for the panoramic roof, all but the necessary interior trim removed and cork used throughout.

Although the Mini Strip will remain as a concept, the British firm says it can be used as a ‘catalyst for more sustainable use of resources in automotive design’.

Bentley of the future

Bentley is a luxury car firm, and it has made it its mission to make sure the cars it builds in the future are more sustainable. In 2019, it revealed the EXP 100 GT concept car, which is an autonomous electric vehicle.

But everything about its construction had sustainability in mind. For example, some of the furnishings used a dyeing process that strives to achieve zero discharge of chemicals into the environment, while others come from a material called Vegea, which uses the by-products of winemaking. It also uses wood from naturally felled trees.

Volvo’s wool interiors

Volvo has been one of the manufacturers most committed to electrifying its line-up, but it’s also focused on sustainability elsewhere.

We’ve become used to seeing synthetic or ‘vegan’ leather alternatives from a variety of manufacturers, but Volvo offers a unique poly-wool upholstery.

It’s a blend that’s 30 per cent wool and 70 per cent recycled polyester that’s available as a nocost extra on some of the firm’s vehicles.

Eco-friendly production

Pretty much every major car manufacturer has announced plans to electrify its range and set targets for carbon-neutral production at its factories. This is being achieved in various ways, such as powering factories with renewable energy.

Toyota builds more cars than anyone else globally, so improvements can have a major impact at its factories. Measures include using water-based paints on cars, removing pollutants before they’re released through smokestacks, cleaning wastewater on-site before it’s released and growing forests inside its factory sites.

Last year, the Japanese company announced plans to build a ‘prototype city of the future’ at the base of Mount Fuji.

It will be fully connected and powered by hydrogen fuel cells.

Seaqual Yarn

Volvo isn’t the only manufacturer experimenting with interesting eco materials. Last year, Fiat became the first carmaker to use Seaqual yarn for its seat upholstery, with the Cupra Born’s bucket seats also using the material.

Seaqual is an initiative based in Italy that focuses on fighting plastic pollution in the ocean. Its yarn product is made of 100 per cent recycled material, with about 10 per cent coming from upcycled marine litter.

Synthetic fuel

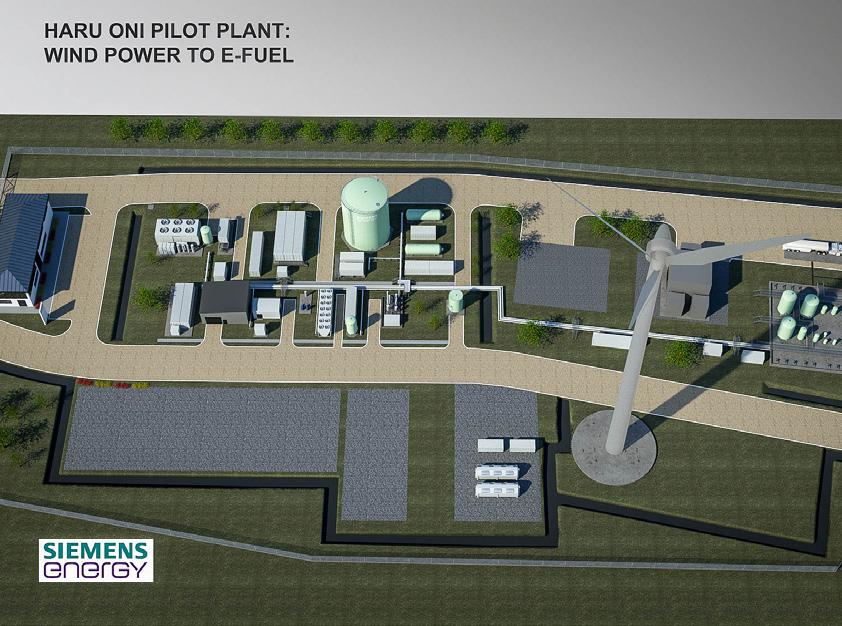

Although electric vehicles are considered the future, there are some alternatives being worked on. One example is hydrogen cars, but a less- talked-about alternative is synthetic fuel.

Also known as eFuels, they are essentially no different from the petrol and diesel that come from crude oil, but instead they are produced from CO2 and hydrogen using renewable energy.

Porsche and Siemens are two big companies working together on this technology. Although they admit that currently it’s more efficient to use that renewable energy to charge an electric vehicle, eFuels are a sustainable way to fuel the millions of petrol and diesel vehicles currently on the world’s roads.