WINDS OF CHANGE

CEAT SENIORS' DESIGN PROJECT GOES UP IN STILLWATER

2019

On The Cover 20

Seven Oklahoma State University engineering students’ senior design project, a wind turbine, was installed in downtown Stillwater in April. Other projects were displayed at the Senior Design Expo, which brought together seniors from all the schools in the College of Engineering, Architecture and Technology, in ENDEAVOR. (Photo by Kristi Wheeler)

Alumni Update

32

Lee Easton has two bachelor’s degrees, four companies and a full-time engineering job — he knows what it means to work hard.

34

Ruth Spivey, OSU’s first female electrical engineering graduate, went through a lot to achieve her career success.

Research

36

Dr. Imraan Faruque is studying bees which could help autonomous drones better work as cohesive units.

38

Two OSU researchers have a new proposal for rebuilding America’s interstate infrastructure for the 21st century.

42 OSU’s College of Engineering, Architecture and Technology and College of Arts and Sciences are playing a role in research on dolphins.

3 Dean’s Letter

7 Seniors of Significance

15 College Heads

30 CEAT Bytes

56 Scholarships

58 Donors

64 Hall of Fame

DEAN, COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

Paul Tikalsky, Ph.D., P.E., F.ASCE, F.ACI, EACR

MARKETING MANAGER

Kristi Wheeler

LEAD WRITER

Jeff Hopper

UNIVERSITY EDITOR

Dorothy L. Pugh

ART DIRECTOR

Paul V. Fleming

PHOTOGRAPHY

Phil Shockley, Gary Lawson, CEAT Staff

IMPACT is a publication of the Oklahoma State University College of Engineering, Architecture and Technology and is designed to provide information on college activities and accomplishments while fostering communication among the CEAT family and friends. WWW.CEAT.OKSTATE.EDU

The office of publication for IMPACT is 307 Whitehurst, Stillwater, OK 74078-1024. © 2019, IMPACT. All rights reserved.

Oklahoma State University, in compliance with Title VI and VII of the Civil Rights Act of 1964, Executive Order 11246 as amended, and Title IX of the Education Amendments of 1972 (Higher Education Act), the Americans with Disabilities Act of 1990, and other federal and state laws and regulations, does not discriminate on the basis of race, color, national origin, genetic information, sex, age, sexual orientation, gender identity, religion, disability, or status as a veteran, in any of its policies, practices or procedures. This provision includes, but is not limited to admissions, employment, financial aid, and educational services. The Director of Equal Opportunity, 408 Whitehurst, OSU, Stillwater, OK 74078-1035; Phone 405-744-5371; email: eeo@okstate. edu has been designated to handle inquiries regarding non-discrimination policies. Any person (student, faculty, or staff) who believes that discriminatory practices have been engaged in based on gender may discuss his or her concerns and file informal or formal complaints of possible violations of Title IX with OSU’s Title IX Coordinator 405-744-9154.

This publication, issued by Oklahoma State University as authorized by the College of Engineering, Architecture and Technology, was printed by Royle Printing, at a cost of $6,388/4M/Aug 2019/job #8807.

38 54 74

…

Plus

32 34 38

42

IN THIS ISSUE OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 1

ONLINE Reaching Students Around the World! 100% Online Graduate Programs in: Also Offering Undergraduate and Graduate Online Courses in: Advance your education today! 405-744-5146 ceatonline.okstate.edu • Engineering and Technology Management (M.S.) • Electrical and Computer Engineering (M.S.) • Fire Safety and Explosion Protection (M.S.) • Industrial Engineering and Management (M.S.) • Fire and Emergency Management (M.S. & Ph.D.) • Architecture • Construction Management Technology • Electrical and Computer Engineering • Electrical Engineering Technology • Engineering Sciences • Fire and Emergency Management • Fire Protection and Safety Technology • General Engineering • Industrial Engineering and Management • Material Sciences and Engineering • Mechanical Engineering Technology ENGINEERING EDUCATION Flexible Setting · Accessible · Quality Instruction · Affordable ONLINE LEARNING College of Engineering, Architecture and Technology

From the Dean

Dear Friends and Alumni, The College of Engineering, Architecture and Technology is accelerating with levels of change and transformation not seen since its founding more than 120 years ago. Interdisciplinary and hands-on learning with advanced analytic tools and laboratories is leading to more complex projects, entrepreneurial experiences and student competition victories.

The Grand Challenges Scholars program launched in 2015 with leading engineering programs around the world. This year, OSU’s Grand Challenges Scholars team was selected to compete at the Grand Challenges summit in London, joining four other major universities as the American team. OSU students also came out on top of the USAF Aerospace Propulsion challenge, the regional concrete canoe competition and a flurry of other competitions this year.

We awarded more than 1,050 degrees this year, a 40 percent growth in engineering bachelor’s degrees in five years, despite a net loss in annual state support of more than $4,500 per graduate. We have worked with students, administration and alumni to continue to deliver world-class engineers and design professionals. By expanding our facilities, accelerating our online options and offering degree minors, undergraduate research opportunities and honors degrees, we are pushing forward in creating leaders for the next generation of industry.

The ENDEAVOR lab and initiative opened in September 2018 to transform the undergraduate experience with large-scale, hands-on labs with entrepreneurial manufacturing space for student ideas and dreams. There is no change agent like it in the world. Faculty members are redesigning curriculum to better use the integrated capabilities, and students are being trained to prototype their own ideas to build their own future. I invite you to come to campus to see that future.

Our CEAT students traveled to northern Thailand, Cambodia and Vietnam to see the contextual solutions of technical problems around the world. Others traveled to Japan, Korea, Spain, China and Mexico to gain international experience before graduation.

We are experiencing more students graduating in four years, coming in better prepared for the rigors of CEAT degrees, retaining beyond the first year at the highest levels in decades, and engaging in undergraduate research and community service every day. It is exciting to be at OSU and in the College of Engineering, Architecture and Technology.

We continue to need alumni and friends to invest in the next generation. Consider a $1,000 donation to the CEAT Scholarship fund, that would be matched by the OSU Foundation for Engineering, to give OSU students the best chance to change the world. You might also consider joining the CEAT Dean’s Club, which recognizes distinguished supporters who have given $5,000 annually to the CEAT Fund or Scholars Fund or more than $250,000 in their lifetime. Dean’s Club members have a $2,500 scholarship in their name funded by the OSU Foundation for Engineering and meet with the dean about new ideas, legislative initiatives and help with the strategic direction of the college.

On behalf of OSU and CEAT, I hope you enjoy the IMPACT of OSU. The college could not be at the forefront of innovation without the accomplishments and investments of alumni, friends and industry partners like you.

GO POKES!

Paul Tikalsky Dean College of Engineering, Architecture and Technology

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 3

“I have one principle: If the worst thing I can get is a ‘no,’ that can’t kill me, and that has pushed me to try everything.”

4 IMPACT 2019

— MUWANIKA JDIOBE

It Takes a Village

Uganda’s Jdiobe credits CEAT support for his success at OSU

Muwanika Jdiobe’s first trip out of his native Uganda came in his pursuit of his degrees in mechanical and aerospace engineering at Oklahoma State University.

It would be a long trip, but his life had already been full of arduous challenges.

At 13, Jdiobe found himself taking care of his three younger siblings after their parents died. As the eldest, he became responsible for finding food and paying for school and health care for his family. He would sometimes go hungry to ensure his siblings’ well-being, he said. But nothing stopped him from staying optimistic.

Or becoming educated. Throughout his high school years, he participated in his school’s science fairs. Being from an area with few supplies, he did not have many tools or resources for his projects — but he still managed to create an alternating generator to make hydroelectric power.

Jdiobe said he always had a curiosity about airplanes, and his teachers pushed him to learn more. He discovered online that mechanical and aerospace engineers are responsible for making airplanes.

After doing more research, Jdiobe found that Africa did not offer this type of educational program. He looked at universities around the U.S. and thought OSU offered the best engineering program with a low cost of tuition.

“Everyone thought I was crazy that I wanted to leave my village and study in America,” Jdiobe said. “I had never even seen an airplane in real life, and that acted as my motivation to come to Stillwater.”

Early Hurdle

Originally, he was sponsored by a community member in Uganda who paid for him to attend OSU. But within his first semester of school, his sponsor unexpectedly died, leaving Jdiobe no way to cover his school, housing or food costs. He was lost and did not know where to go or who to turn to for help.

“I have been the instrumental communication for [Jdiobe] and was fortunate to be at the right place at the right time to help him,” said Regina Henry, coordinator of immigration for OSU

International Students and Scholars. “Community members of Stillwater and donors to OSU were generous enough to donate money to him to ensure that he was able to get tuition and finish his schooling.”

Throughout the 43 years that Henry has been in her position, she has seen multiple students forced to return home due to insufficient funds. She said she believes it has been a miracle for Jdiobe to stay at OSU.

“All of the community is rooting for [Jdiobe] and

ACADEMIC HONORS

In his senior year alone, Muwanika Jdiobe racked up several academic honors:

■ One of 15 Outstanding Seniors at OSU. The OSU Alumni Association recognizes seniors who excel through academic achievement; campus and community activities; athletic or extracurricular honors or awards; scholarships and work ethic.

■ O ne of 43 Seniors of Significance

■ A member of the top 1 percent of OSU’s class of 2019, which includes all six undergraduate colleges

■ An Outstanding Senior of CEAT.

his family in Uganda,” Henry said. “Members of his church, friends and professors have all been doing whatever they can to help him pursue an education, so he can enjoy his time in the United States.”

Wanting to get as much out of OSU as he could, he became a senator for residential life his first semester. He remained a senator with the OSU Student Government Association all four of his years at OSU. In the 2016-2017 school year, he was selected as the outstanding senator. In the

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 5

STORY MARK SCALMANINI | PHOTOS GARY LAWSON AND COURTESY OF MUWANIKA JDIOBE

2017-2018, Jdiobe became the central region ambassador for the National Association of Engineering Student Councils, which encompasses Oklahoma, Kansas, Texas, Arkansas and Missouri. He served as the secretary general of the African Student Organization at OSU. He also served as a CEAT Student Council member for four years.

Jdiobe worked in Parker Hall’s Living Learning Program as a mentor to CEAT freshmen. By becoming engrossed in the campus community and having constant interaction with CEAT students, faculty and staff, Jdiobe strengthened his relationships and networking at OSU.

Academic Opportunities

Jdiobe’s academic and leadership excellence have won him numerous scholarships. He has been chosen as a Grand Challenges Scholar from 2017 to 2019 and a Wentz Research Scholar during the 2018-2019 school year.

“I have been able to watch [Jdiobe] focus on his research and apply it personally to his community,” said Amanda Williams, Grand Challenges Scholars Program director. “It is fulfilling to watch him utilize what he has learned in the classroom and put it to use by benefiting his home country of Uganda.”

In the Grand Challenges Scholars Program, Jdiobe has taken advantage of every resource and opportunity available, Williams said, succeeding beyond the program’s expectations, putting others’ needs before his own, she added.

In addition, Jdiobe does research for two professors.

The past four years, he has been working for Dr. Tyler Ley, structural engineering professor, processing samples of concrete for about 20 hours of research a week.

“Dr. Ley has always offered me work in the research lab,” Jdiobe said. “I was given an amazing opportunity, being led to him and have done my best to exceed his expectations in research.”

He also does research for Dr. Jamey Jacob, mechanical and aerospace engineering professor, academic adviser and Grand Challenges Scholar adviser. There, he has established a platform of scientific studies about unmanned aerial vehicles. The platform is used to collect scientific information for studies and retrieve data from a UAV in the air to water below and vice versa for about five hours a week conducting research for Jacob.

Jdiobe is receiving some funds from research. He keeps a small portion for himself and sends money to his siblings in Uganda for food, education and health care. Since 2015, he has not seen any of his family.

“[Jdiobe] has a growth mindset and if something doesn’t work, he learns from it and goes about it another way,” Williams said. “I have enjoyed seeing what life is like through his eyes.”

OSU staff and faculty have noticed Jdiobe’s work ethic and drive. He is constantly thinking of how he can make a difference and make a change to improve everyone’s quality of life, Henry said. He is living proof that anyone can do anything, she added.

“I believe that I am one of the people who has been able to max out what CEAT has to offer,” Jdiobe said. “I have done research, taken advantage of scholarship and leadership opportunities. Every single thing CEAT has to offer, I have tried to get it. I have one principle: If the worst thing I can get is a ‘no,’ that can’t kill me, and that has pushed me to try everything. I think that CEAT, and OSU at large, have offered me all aspects to benefit from.”

Jdiobe said he has no regrets about coming to OSU, adding that he is grateful to the many people here who contributed to his successes.

“In Africa, we have a saying that it takes a village to raise a child,” Jdiobe said. “And OSU CEAT has been my village to raise me up.”

Next up for Jdiobe: entering graduate school for a master’s degree in mechanical and aerospace engineering.

“Despite not seeing my friends and siblings in years, I want to continue to further my education, because it is my dream,” Jdiobe said. “As someone from an impoverished country, I can acknowledge the gap between developed and underdeveloped countries. I would love to take the challenge and opportunity to take my unique experience and build UAV systems in developing countries to boost their safety against terrorism. I want to develop low-cost drones that would give people intelligence to reduce terrorism ambushes. Regardless of where I will be, that is one thing I want to accomplish and is the whole reason I want to get my master’s degree.”

6 IMPACT 2019

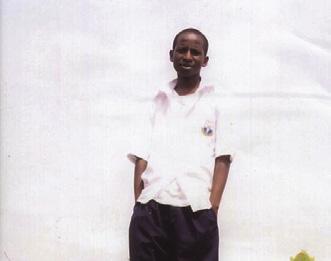

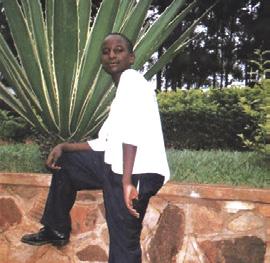

Muwanika Jdiobe home in Uganda in 2009 (left), and in 2011 (right).

Top Honors

CEAT seniors recognized with awards

Fourteen CEAT seniors were named Oklahoma State University Seniors of Significance by the OSU Alumni Association. The award recognizes students who have excelled in scholarship, leadership and service to campus and the community, and have brought distinction to OSU.

Seven of them — Madeline Hawkins, Muwanika Jdiobe, Rebecca Lane, Jasmyn Lee, Rachael Indah Merkel, Joanna Quiah and Colton Tubbs — were also named 2019 Outstanding Seniors by the OSU Alumni Association. The award recognizes seniors who excel through academic achievement; campus and community activities; academic, athletic or extracurricular honors or awards; scholarships and work ethic during their time at OSU.

Rebecca Lane

Chemical Engineering Beulah, Colorado

Jasmyn Lee

Civil and Environmental Engineering

Lawton, Oklahoma

Madeline Hawkins

Industrial Engineering and Management Carrollton, Texas

Muwanika Jdiobe

Mechanical and Aerospace Engineering Jinja, Uganda

Rachael Indah Merkel

Mechanical Engineering Stillwater

Joanna Quiah

Biosystems Engineering

Edmond, Oklahoma

Colton Tubbs

Mechanical Engineering Hartshorne, Oklahoma

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 7

CEAT Dean Paul Tikalsky, left, and OSU President Burns Hargis, right, with the CEAT Seniors of Significance. Front row, from left: Cardin Hart, Luke MacNaughton, Muwanika Jdiobe and Rachael Indah Merkel; middle row: Sarah Desharnais, Madeline Hawkins, Jasmyn Lee, Joanna Quiah and Rebecca Lane; back row: Colton Tubbs, Patrick Steichen, Conner Blatt, Blake Giles, and Adam Morgan.

Chasing Dreams

W.W. Allen scholarship opportunity offers bright future to freshman from Bartlesville

As far back as he can remember, Fernando Gomez-Moran has enjoyed working with his hands, from building Lego set to toy cars.

The summer before his seventh-grade year in his hometown of Bartlesville, Oklahoma, his mother enrolled him in the Boys and Girls Club, where he stayed while his parents were at work. As the summer progressed, he experienced many opportunities through the organization to figure out what truly interested him.

“Our program is structured in such a way that we have the kids get involved in as many different things as we can,” said Jason Barta, chief executive officer of the Bartlesville Boys and Girls Club. “It is our goal with every child to help them discover their talents.”

Gomez-Moran reiterated that "the Boys and Girls Club taught me that being unique is what has the ability to change the world."

In middle school, he decided to take a technical education course.

“My middle school offered a technical education course, and in it we worked on different projects, like Rube Goldberg machines, which helped me express my imagination and turn my thoughts into physical matter. I think that is where my passion for engineering really stems,” Gomez-Moran said.

After Barta did a community presentation on the Boys and Girls Club, he wanted to get the word out about the W.W. Allen Boys and Girls Club Scholarship.

The scholarship, funded by W. Wayne Allen, retired CEO and chairman of Phillips Petroleum Co., benefits Boys and Girls Club members in high school who wish to pursue an engineering education.

Barta reached out to Karen Lowe-Alton, the executive director of the Lowe Family Young Scholars Program, which Gomez-Moran has been involved in since 2012. The Lowe Family program assists academically promising, economically disadvantaged students in the Bartlesville Public School System.

“Jason approached me to see if we had any Boys and Girls Club members, who were also Lowe Family Young Scholars, who were interested in engineering,” Lowe-Alton said. “I mentioned Fernando, and I mentioned to Fernando that he should inquire about this scholarship.”

Barta asked Gomez-Moran if he would be willing to help with Oklahoma State University’s College of Engineering, Architecture and Technology STEM summer camp.

STORY DAKOTA KEITH | PHOTOS COURTESY OF FERNANDO GOMEZ-MORAN

“My personal goals while at OSU are to gain knowledge and to learn how to use that knowledge for myself and the community and people who supported me through some of the roughest times of my life.”

8 IMPACT 2019

— FERNANDO GOMEZ-MORAN

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 9

10 IMPACT 2019

“I met with Fernando and his parents not only about the scholarship, but his availability to help out with our summer program,” Barta said. “We encourage our teen club members to apply for jobs at the Boys and Girls Club working with our younger members. Fernando is such a wonderful role model to other kids; we felt it would be a wonderful opportunity for him to have a positive impact on others.”

The CEAT summer camp, Engineering Adventure, uses the Bartlesville Boys and Girls Club as a host site.

As an Engineering Adventure camp staff member, Gomez-Moran assisted in conducting the camp, where students in kindergarten through fifth grade learn engineering design principles with interactive and fun projects based on hands-on STEM activities.

Gomez-Moran was already seriously considering attending OSU when Amanda Williams, CEAT Scholar development manager, contacted him about everything the university could offer him, from scholarships to the educational opportunities in CEAT.

“Before I worked at the summer camp, I attended CEAT Discovery Days at the beginning of the summer between my junior and senior year of high school, and I got to see the classrooms,” Gomez-Moran said. CEAT Discovery Days gives high school students the opportunity to explore various engineering disciplines through activities and presentations.

“Then, I attended the Society of Hispanic Professional Engineers (SHPE) Discovery Days, and I got to see the ENDEAVOR lab,” he added. “It is outstanding that a college will invest in its undergraduate students and build a multimilliondollar building to help them with their research.”

The offer of an incredible opportunity — the W.W. Allen Boys and Girls Club Scholars Program — really sealed the deal on the university GomezMoran ultimately chose.

This OSU scholarship program awards incoming freshmen $15,000 per year for up to four years of study toward a bachelor’s degree in engineering.

“Scholars participate in enrichment activities and travel together,” Williams said. “In addition to the $15,000, he will receive $2,000 to participate in enrichment activities and $3,000 for international travel.”

Gomez-Moran was also selected as a CEAT Scholar. To qualify, students must have applied to OSU, have a minimum 31 ACT score and 3.75 GPA and interview with a faculty member and a current scholar to assess their character, leadership abilities and affinity for engineering.

“I have been given an incredible opportunity,” Gomez-Moran said, adding he plans to make good use of his time at OSU.

“My personal goals while at OSU are to gain knowledge and to learn how to use that knowledge for myself and the community and people who supported me through some of the roughest times of my life,” Gomez-Moran said.

“I plan on graduating college and entering graduate school prepared to use everything I previously learned to research and develop technology that will better the world and humankind in its quest for greater efficiency and productivity.”

After graduation, Gomez-Moran would like to start his career with an aviation company such as Boeing, Lockheed Martin or Northrop Grumman before moving on to an automaker such as Subaru, Porsche, Ferrari or Lamborghini.

Gomez-Moran said he hopes his future career will allow him to support charities that ensure that the next generation of students are prepared to be educated.

“I have the best opportunity and empowerment at OSU to achieve my dreams,” Gomez-Moran said.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 11

Broader Experiences

Study abroad trips open eyes and minds for OSU faculty and students

In 2007, Keith Teague took his first trip to Asia, visiting industries and political groups in Vietnam to discuss economic development and education. Today, Teague, a professor in the school of electrical and computer engineering at OSU, leads study abroad trips each year to Japan.

“People in different parts of the world deal with being engineers in different ways,” Teague said. “So there are differences in the way they practice and in the way products are designed and manufactured. There are differences in cultural aspects of this, too. In Japan, so much focus is on the community as opposed to the individual, whereas here is much different. Needs are much different. If you go to another country, they have different social, political and cultural needs than we do here.

“I think it’s very important for students to see there’s more to the world than just us.”

Nick Overacker took advantage of the opportunity to study abroad during his college career. Overacker graduated in the fall of 2018 with

a degree in electrical and computer engineering from OSU. He cited his curiosity for bringing him to ECE and leading him to a minor in Japanese.

“With electronics, I felt there was this huge part of the world around me that I didn’t understand, and I wanted to learn what the secrets were to that,” he said. “When I started studying Japanese, I actually didn’t know anything about the culture. During my second year of studying the language, I became involved in the Japanese Student Association. Through that, I made a lot of Japanese friends and got very close to a lot of them. OSU has usually fewer than 20 Japanese students on campus at one time. So I was able to get to know all of them. It made me very interested in going to Japan.”

In 2016, Overacker did just that, spending 13 months as an exchange student in Japan.

“The way people interact with each other and with their environment, and generally every aspect of their life in Japan is just very different than in the United States,” he said. “It gave me a completely

The CEAT Japan study abroad students, Dr. Norb Delatte (left) and Dr. Keith Teague (far right) along with several Japanese students visited the Kiyomizudera Temple, meaning "Pure Water Temple," in Kyoto, Japan.

STORY CEAT MARKETING | PHOTOS COURTESY OF KEITH TEAGUE

12 IMPACT 2019

new outlook and showed me a different way to live life. I gained marketable language skills and insights on ways to live life. I don’t have to just follow what’s prescribed for me here. I can choose the best of everything I know. And I feel like I gained some insight on different markets, the way people interact with products and technology in other countries.”

Overacker “definitely” recommends studying abroad.

“It’s going to be easier as a student than afterward. You don’t have a summer break or a year to take off for something like that, after graduating,” he said. “There’s a lot of funding available, which a lot of people don’t realize. People often say ‘I want to study abroad but I can’t afford it.’ I was someone who couldn’t afford to go to school in the first place. I came to school on the funding available,

and I went abroad on much more funding that was available. Before I went, I applied for several study abroad scholarships, some at OSU and some outside. I recommend everyone apply to as many scholarships as they can. I ended up going with $30,000 in funding.”

Since graduating, Overacker accepted a position at Wavetech LLC in Stillwater, which was founded in 2011 by Dr. John O’Hara, an assistant professor in ECE. The company participates in cutting-edge research and provides practical, customer-oriented services in engineering. O’Hara recruited Overacker at a robotics event on campus.

Samer Elkhalid, a May 2018 graduate in electrical and computer engineering, also did a study abroad trip. Growing up, he was fascinated with digital devices, especially computers, and enjoyed anime and video games. Those gave him a

Himeji Castle in Himeji, Japan is considered the best remaining example of Japanese castle architecture. CEAT Japan study abroad students visited and explored the castle.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 13

fascination with Japanese culture, and he fulfilled his dream of visiting Japan on a study abroad trip with Teague and Dr. Norb Delatte in May 2017.

“I loved every bit of it! We got to go sightseeing on many cultural tours seeing many castles, shrines and temples,” Elkhalid said. “We went on various business tours, including a trip to Sony World Headquarters in Tokyo, which was my personal favorite business trip. And we got to have some time to ourselves exploring the various cities we went to such as Tokyo, Osaka, Negoya and Hiroshima.”

The experience changed Elkhalid’s education in the United States.

"Going on this trip was like a dream come true! I definitely have a wider perspective of how a different culture can operate,” he said. “Learning about the importance of teamwork can go a long way. One big thing that I noticed about the Japanese while I was there is that they are very efficient and hard-working. It’s like they are a very homogeneous society, and every individual does what they can to be a productive member of the society. After my trip, I felt more willing to give help and be more of a volunteer to my senior design partners, and at the same time, be willing to receive help from them.”

Teague has spent many years building relationships with contacts in Asia to make the study abroad trips educational as well as fun. The itinerary includes tours of Mitsubishi Heavy Industries, Takenaka R&D Institute and Toyota, as well as cultural visits to Hiroshima, Miyajima Island and Kyoto.

“I think they’re tremendous experiences and I think there are a lot of students that don’t realize what they’re missing,” Teague said. “If we can help convince them that this is the sort of thing they ought to try at least once in their life, I think many of them would get something out of it they may not even know they’re missing.”

Since graduating from OSU, Elkhalid accepted a job as a software engineer at Epiroc Drilling Solutions.

“People in different parts of the world deal with being engineers in different ways. I think it’s very important for students to see there’s more to the world than just us.”

( )

— DR. KEITH TEAGUE

14 IMPACT 2019

Students visited the Meiji Shrine, an iconic Shinto shrine located in Tokyo.

COLLEGE HEADS

Norb Delatte, P.E., F.ACI, F.ASCE Professor and Head M.R. Lohmann

Endowed Chair; Civil and Environmental Engineering

Jeffrey L. Young , P.E., F.IEEE Professor and Head OSURF Endowed Chair; Engineering Electrical and Computer Engineering

Suzanne Bilbeisi, AIA Professor and Head Centennial Professor of Architecture; School of Architecture

John Veenstra , P.E., BCEE Professor and Head Decker Dawson Chair; Biosystems and Agricultural Engineering

Geir Hareland Professor and Head; Continental Resources Chair; Chemical Engineering

Sunderesh Heragu

Regents Professor and Head; Donald and Cathey Humphreys Chair; Industrial Engineering and Management

Dan Fisher Professor and Head

Albert H. Nelson Jr. Chair; Mechanical and Aerospace Engineering

Young Chang , P.E., CFPS Professor and Head; Engineering Technology

Paul J. Tikalsky CEAT Dean

Randy Seitsinger Associate Dean, Academic Affairs

Chuck Bunting Associate Dean of Research Ed Kirtley Assistant Dean of Engineering Extension

Raman Singh

Paul J. Tikalsky CEAT Dean

Randy Seitsinger Associate Dean, Academic Affairs

Chuck Bunting Associate Dean of Research Ed Kirtley Assistant Dean of Engineering Extension

Raman Singh

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 15

Associate Dean of Engineering, OSU-Tulsa; Director, Helmerich Research Center

Jostling for Jobs

CEAT Career Fair draws record number of employers

More companies than ever before turned out to recruit students at the CEAT Career Fair last September.

Oklahoma State University’s College of Engineering, Architecture and Technology Student Council members, alongside OSU Career Services staff, hosted the annual event for students seeking jobs and internships.

About 2,200 students — 2,000 of them CEAT students — connected with leaders in the science, technology, engineering and math industries. The CEAT Career Fair is the largest career fair at OSU and is often recognized nationally, according to OSU Career Services.

Wade Witcher, a chemical engineering sophomore, was co-coordinator of the career fair, which drew 244 companies.

“We looked at the 2015, 2016 and 2017 career fairs to see if the same companies would return,” Witcher said. “If any companies didn’t come back, we tried to the best of our ability to get them back for this year.”

The CEAT Student Council had increased the price for career fair spots. Witcher said he wanted to bring more profit for CEAT Student Council by selling out Gallagher-Iba, and that’s exactly what they were able to accomplish.

“CEAT Student Council keeps all the profit from the career fair and places it into our operating budget,” said Maddie Hawkins, CEAT Student Council president and an industrial engineering and management senior. “We offer co-sponsorships to clubs and organizations for their events throughout the year, so their memberships can have the best.”

As president, Hawkins said it is one of her goals to try to give back as much as she can to the students while she is serving on CEAT Student Council. CEAT Student Council gives over half of the profit made from the career fair back to CEAT clubs.

“We want to build camaraderie between the students and recruiters to ensure they have the best experience they can at the career fair,” Hawkins said. “We try to focus on the benefit to the students the most.”

Many students wanted to see specific companies at the career fair, which led Witcher to chase those the students wanted.

Co-chair Nathan Hodges and CEAT Career Services Coordinator Andrea Haken also worked on the fair.

“CEAT does a great job at providing all aspects of the industry to its students,” said Haken. “Students have more options, and it opens the door to more opportunities that they can take advantage of.”

Haken said she helped oversee the career fair coordinators to navigate and troubleshoot problems. She helped recruit companies, but her main role was to prepare the students to be ready in all situations at the career fair.

“I review résumés, develop interview skills and teach how to talk with recruiters,” Haken said.

“At the CEAT Career Fair, industry leaders are searching for CEAT students, knowing what they are capable of,” Hodges said.

STORY MARK SCALMANINI | PHOTOS GARY LAWSON

“We want … to ensure (students) have the best experience they can at the career fair.”

16 IMPACT 2019

— MADDIE HAWKINS ( )

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 17

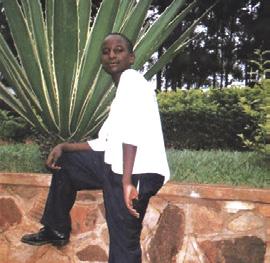

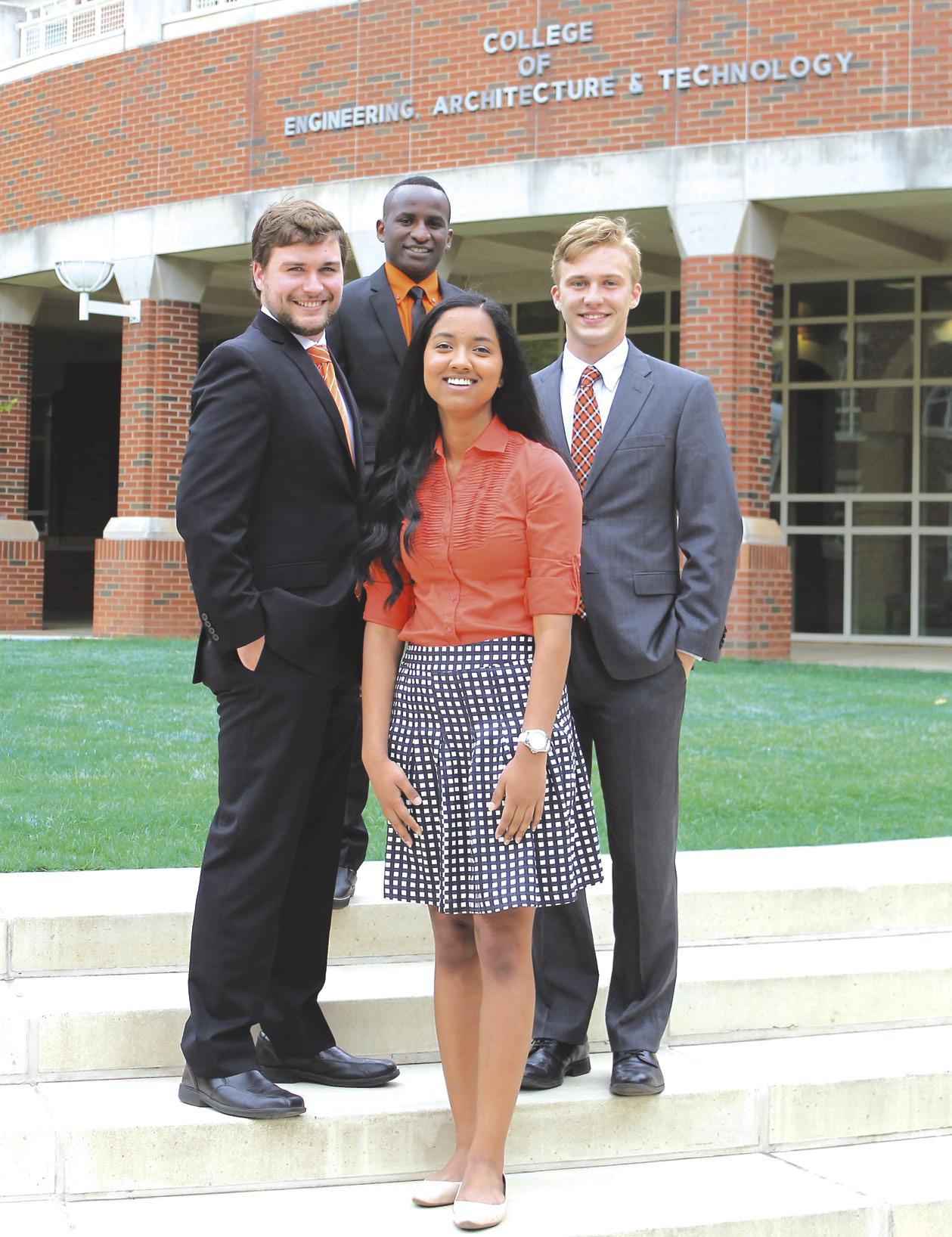

The members of OSU’s Grand Challenges team are (from left) Christian Griffith, Muwanika Jdiobe, Angela Peter and Jackson Moore.

The members of OSU’s Grand Challenges team are (from left) Christian Griffith, Muwanika Jdiobe, Angela Peter and Jackson Moore.

“… It is not just about the competition. This is about finding solutions to the challenges threatening the existence of humanity.”

18 IMPACT 2019

— MUWANIKA JDIOBE

Tackling a Grand Challenge

OSU team set to represent the U.S. in global competition

For the first time, a group of engineering students in Oklahoma State University’s College of Engineering, Architecture and Technology will represent the United States in a business plan competition at the 2019 Global Grand Challenges Summit in London.

The team is tackling the challenge of sustaining a global population of 10 billion, which the United Nations says will be reached by 2050. The OSU proposal calls for the advanced integration of technology into agriculture.

The team includes Christian Griffith, mechanical and aerospace engineering; Muwanika Jdiobe, mechanical and aerospace engineering; Jackson Moore, mechanical and aerospace engineering; and Angela Peter, chemical engineering.

Their idea is to utilize sensors underneath and on the surface of the ground, along with additional sensors on unmanned aerial vehicles to collect data from the air. This will allow them to analyze the soil and help farmers know where they need to fertilize and what crops would be best suited to that specific area, so that farmers could grow more crops at a lower cost. Crops can be too expensive to grow for many in underdeveloped countries.

OSU has one of the leading agricultural programs in the nation and conducts extensive research in this area. The team has access to that research and knowledge as well as opportunities for collaborating with some of the top minds in the field, empowering them to tackle the challenge effectively. Team members worked together, each handling different aspects of the project. Griffith focused on data analytics, Moore and Jdiobe focused on the sensors, while Peter focused on the customer discovery side of it, interviewing farmers from India and Uganda.

“Engineering problems are not just scientific problems; they are people problems,” Griffith said. “There were a lot more personable aspects than I expected out of what I thought was solely a research and business competition. It showed that we have the power to change lives.”

“We focused on how using unmanned aerial vehicles could be used to increase yield in the fields of Uganda.” Peter said. “This program is all about innovation, engineering and entrepreneurship. The work is very interdisciplinary in nature and involves making something new from what we have learned in our core courses. This project is greater in scope than our normal class work, and being able to use what I have learned and

applying it in the real world has been very rewarding. Learning and understanding the struggles of farmers in Uganda has helped us gain global awareness of struggles that exist outside of our personal spheres. I have grown in my collaborative and leadership skills, and developed my interpersonal communication skills. It has been very exciting to be the first team from OSU to make it this far.”

Moore saw this as an opportunity to unite two interests.

“I did research as a freshman research scholar and have a minor in entrepreneurship so the GCSP gives me the opportunity to combine the two interests,” Moore said. “I’ve grown in my public speaking experience, and I have been able to learn how to balance jobs and personalities with a group.”

Amanda Williams, coordinator of CEAT scholarships, felt this project had special meaning for Jdiobe.

“Muwanika is from Uganda,” Williams said. "He was telling us stories about when he was a child his family couldn’t afford to send food for lunches while attending school. It really does affect not just their health, but also their knowledge and learning abilities. Being able to solve this issue was very personal to him.”

Jdiobe said being a part of the competition is great, but, for him, it’s about so much more. “This is about finding solutions to the challenges threatening the existence of humanity, with the increasing world population and few resources, humanity is at stake, and therefore, it is upon all of us to make this world sustainable and better for all generations.”

PGA Tour star Rickie Fowler fully funds the Grand Challenges Scholarship Program in CEAT. While the golfer was not an engineering student, he has always loved tinkering and the technology side of things. He wanted to support students with a similar mindset.

CEAT Dean Paul Tikalsky presented the program to Fowler’s agent, noting “the students in a program like this would be like-minded because they’re very hands on with their research.” Fowler loved the idea that it was an extra component outside of the classroom and not just a scholarship — he is giving an experience, as well as money.

“The Grand Challenges were created in 2009, and OSU submitted a proposal to join in 2016,” Williams said. “As soon as a student applies to be a part of the program and is accepted, they are expected to continue until they graduate. Most students will have to start part of the program components before they apply. Having the program here at OSU helps us offer more opportunities for the students. They can focus a little more on what their passions are.”

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 19

STORY KRISTI WHEELER | PHOTO DAKOTA KEITH

WINDS OF CHANGE

First Senior Design Expo including all CEAT schools propels ENDEAVOR toward a successful interdisciplinary future.

The key mission behind the College of Engineering, Architecture and Technology’s ENDEAVOR lab is to unite the various elements of the college in interdisciplinary projects.

The Senior Design Expo brought that mission to life in April.

“The Senior Design Expo was the vision of Dr. Jeffrey Young and Dr. Dan Fisher to showcase the work of our students,” CEAT Dean Paul Tikalsky said.

Previously, CEAT’s senior design showcases were hosted by individual academic units with little interaction between them, said Young, department head for the School of Electrical and Computer Engineering.

“Oftentimes, the showcases were not well advertised,” he said. “In short, the larger community outside of the unit did not know much about what our students were capable of doing. That insular operation also left interdisciplinary projects as a side thought,” Young said.

“ENDEAVOR gave us the opportunity to create the expo and to invest significantly in interdisciplinary senior design,” he said.

The trial run for a full interdisciplinary exhibition came in the form of the School of Mechanical and Aerospace Engineering and the School of Electrical and Computer Engineering joining forces to host a 19-project senior design expo in the center in fall 2018.

“We started modestly in the fall 2018 semester with just ECE and MAE participating,” Young said. “One semester later, we had buy-in from all CEAT units.”

The spring of 2019 brought together all six schools of engineering, the School of Architecture and the Division of

Engineering Technology to showcase their seniors’ capstone projects. More than 85 projects, many interdisciplinary in nature, were featured throughout expo day in ENDEAVOR, the 72,000-square-foot hallmark of CEAT.

Planning

Any large-scale event of this nature takes preparation, and many of the senior design projects were actually completely assembled in the facility.

“ENDEAVOR’s continuous challenge is to provide the resources and assistance for each department to follow the best path forward,” said Dr. Brad Rowland, the center’s manager of operations. “The ENDEAVOR team provides fantastic support. Our student employees really stepped up to support the design teams’ use of our makerspaces and laboratories that were supporting expo design efforts as early as February 2019.”

The ENDEAVOR Heat Exchanger Stand senior design team was an example of a project that was completely assembled in the building.

“It was fantastic being able to build our project in ENDEAVOR,” said team member Caleb Austin, a mechanical and aerospace engineering senior. “We didn’t have to outsource to a different area to build our project. All of the tools and the workspace were available to build our project from the ground up without having to use multiple areas.

“We got to utilize lab equipment that we didn’t formerly have access to. ENDEAVOR is a major upgrade from what undergrads had to work with and is a leading edge in senior design.”

STORY DAKOTA KEITH | PHOTOS PHIL SHOCKLEY AND KRISTI WHEELER

20 IMPACT 2019

Members of the hypogravity simulator project prepare a demonstration at the CEAT Senior Design Expo.

Students from the Wind Turbine/ Sculpture/Light Show interdisciplinary design team prepare to install their 40-foot tall wind-energy project in downtown Stillwater.

Members of the hypogravity simulator project prepare a demonstration at the CEAT Senior Design Expo.

Students from the Wind Turbine/ Sculpture/Light Show interdisciplinary design team prepare to install their 40-foot tall wind-energy project in downtown Stillwater.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 21

The 40-foot wind turbine was installed in downtown Stillwater in April.

Still, some projects were built elsewhere on campus.

“The units of CEAT look at design support resources that are needed for each project,” Rowland said. “Based on the support required to complete the project determines where those projects will be built. Most instrumentation, additive manufacturing and assembly are done in ENDEAVOR.”

Counting Down

As students began the final assembly of their projects days ahead of the event, it would be the first time that some would see completed senior design projects from units outside their own.

“For the first time ever, as far as I know, individual unit silos are being torn down by bringing all CEAT units under one roof to celebrate CEAT-wide senior design activities,” Young said.

From Austin’s perspective the expo is like a grown-up science fair.

“The Senior Design Expo has created a platform where someone with no initial interest in our college can come see something cool and walk through the door to find out more.” Austin said. “It creates a platform where someone with no initial interest in our college can see something cool and walk through the door to find out more. It creates interest in what the college is providing for its students.”

The expo drew a varied audience, with family and friends as well as interested campus and community members attending.

The students enjoyed the benefits of a senior design expo that brought the units together, as well as offered opportunities for them to work with others from across the college.

“Being on an interdisciplinary team has been such a positive experience,” said Carson Dickerson, a member of the Wind Turbine, Sculpture and Light Show interdisciplinary senior design team and an electrical and computer engineering senior. “I got to see the strengths of mechanical engineering majors mixed with the strengths of

“(The Senior Design Expo) will become a CEAT signature event that shines a spotlight on who we are and what we do.”

( ) 22 IMPACT 2019

— DR. JEFFREY YOUNG

electrical engineering majors, and I got to see the benefits of those two groups working together.”

Real-World Taste

Working on interdisciplinary projects represents an elevation in education that is closer to the challenges that students will face after graduation, Tikalsky said.

“Working on an interdisciplinary project has given me such a realworld experience,” Dickerson agreed. “Throughout our project we experienced setbacks, dead dates and we worked with individuals outside of the school.”

Caleb Austin’s team did not include students outside the mechanical

and aerospace engineering program, but he still found the value in an interdisciplinary expo.

“Every project in every industry will be interdisciplinary,” he said. “You are not going to be working with just mechanical engineers. This expo allows us to share knowledge with other units.”

The expo will continue to be a work in progress, Young said, adding he expects it to expand and innovate on previous successes. However, the expo has already proven its value.

“It brings together graduates, prospective employers, prospective students, parents, members of the press, OSU leadership, Regents, public servants, alumni, advisory board

members and friends under one roof to see what our amazing students are able to do. It will become a CEAT signature event that shines a spotlight on who we are and what we do,” Young said.

Dean Tikalsky reflected on whether ENDEAVOR was accomplishing its mission of becoming an interdisciplinary design space for undergraduate students.

“ENDEAVOR has taken its first steps toward its goal.”

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 23

STORY

24 IMPACT 2019

KRISTI WHEELER | PHOTOS PHIL SHOCKLEY AND COURTESY OF DIANA RODRIGUEZ

STRONG

A MIND

Injured at OSU’s Homecoming parade, Diana Rodriguez takes her mother’s advice to heart

"Not only will I graduate, but I will walk — hopefully in heels — across the stage,” Diana Rodriguez said.

That might not sound like an extraordinary goal, but for Rodriguez, who suffered a broken spine, broken left leg and ankle, internal bleeding and head trauma in the 2015 Homecoming crash at Oklahoma State University, it’s just that — extraordinary.

Rodriguez, a native of Colombia, was a graduate teaching assistant on a Fulbright Scholarship, working on her doctorate in industrial engineering and management at OSU’s College of Engineering, Architecture and Technology. She was focusing her research on the application of quantitative models in humanitarian logistics, targeting recovery activities to better help affected people get to a “new” normal life. While she was working on her doctorate, her husband Cristian was also working on earning a master’s degree and Ph.D. in civil engineering.

October 24, 2015

That morning of Homecoming, Rodriguez made a snap decision to take her 22-month-old toddler, Jacob, “on an adventure.” Cristian wasn’t a fan of large crowds, so it would be just her and her son at the parade. The pair set off and eventually ended up sitting on Main Street, just south of Hall of Fame.

Jacob, a student at the Child Development Laboratory, wanted to see the fire truck. He had seen it often at the campus fire station and couldn’t wait to see it in the parade.

A moment later, everything changed. “I heard a terrible noise and turned my head to see human bodies and debris flying everywhere,” Rodriguez said. “And a car heading straight toward me and my baby.

“I didn’t have time to stand up to run, so I grabbed Jacob and threw him down on the ground to the right side of me,” she said. She shielded him with her body to protect him from the car that was about to plow into them.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 25

Diana Rodriguez poses with her husband, Cristian, son Jacob and daughter Emily.

GIVING THANKS

Diana Rodriguez didn’t survive and succeed on her own. There is a long list of people she wanted to thank for helping her and her family.

“My family had great support from the IEM department and the OSU and the Stillwater community,” she said, continuing with her list:

“Marshall Dock, our friend who was with Cristian and Jacob while I was in surgery. Anne Terry, our angel who we consider Jacob’s and Emily’s ‘American grandma,’ Dr. (Sunderesh) Heragu, Dr. (Manjunath) Kamath, Dr. (Baski) Balasundaram, Dr. (Ricki) Ingalls, Dr. (Jennifer) Glenn, Laura Brown, Dianna Ross, Heather and Phil Lewis, the Civil Engineering department, the CDL, the International Student Office, Karen Sebring, Regina Henry, the OSU health center, (Todd) Green, M.D., Mike Skouby, Lance Rice, the Family Resource Center, Enrique Sanchez, Stillwater Medical Center and its Foundation (and head) Scott Petty, Dr. Leva Swim, Facilities Management Energy Services, Cristian’s family, my family … so many people helped us. There is not enough space to mention all of them!

“I do not have enough words to tell all the people who helped us thank you. I hope these special people see this story so they know how much they mean to me and to my family. They are angels. It was just the three of us, and we could not have gotten through this without everyone’s support.”

She felt the vehicle run over her before losing consciousness briefly. When she came to, she was able to sit up despite her injuries.

“I saw Jacob next to me, crying. I don’t know how, but I was able to grab him and put him on my lap. He was terrified, but he only had a few scratches on his face and arms. At that moment, I remembered what my mom used to tell me before she passed away. She told me that your mind should always be stronger than everything. My only focus was on Jacob.”

Sheer panic, confusion and chaos reigned at the scene. Rodriguez managed to console Jacob and another child who was lying beside her with a broken leg. Her own leg was mangled, and her back was in excruciating pain.

“I could no longer sit because the pain was unbearable, so I had to lie down,” Rodriguez said. “When people asked me where I was hurt, I don’t know why, but I started talking in Spanish, and no one could understand me.”

An “angel,” Mickey, was comforting her while another man fluent in Spanish was helping her communicate.

Cristian arrived shortly after that. He was distraught and couldn't understand what happened.

“I remember at that moment, I thought if I’m going to die, it’s okay because Jacob is with Cristian now,” Rodriguez said.

She was alert and able to talk, so medics transported other patients who appeared to be worse off — it ended up taking over an hour for her to get to the hospital in an ambulance.

At Stillwater Medical Center, doctors discovered her spine was broken, she had internal bleeding, and her leg was shattered in multiple areas. She had to be transported via helicopter to St. John’s Medical Center in Tulsa for treatment. After one week in St. John’s and three weeks in the rehab unit at Stillwater Medical Center, Rodriguez was able to go home.

Over the next four years, she endured four surgeries and years of physical therapy. They would be a challenging four years for her family, but there would be bright spots, as well.

26 IMPACT 2019

At the scene of the Homecoming crash on the morning of Oct. 25, 2015.

On September 25, 2017, the couple welcomed daughter Emily to the world. Like her big brother, she attends the Child Development Laboratory on campus. “She’s another miracle because my injuries were still so bad,” Rodriguez said.

“I know it is amazing that I survived. I know it’s amazing that Jacob survived. I know it’s amazing that we had a daughter during all of this. But it’s so sad that four people died. They were not so lucky to have a happy ending. We have a happy ending, but the families who lost Nash, Nikita, Bonnie and Marvin do not. I think about them every single day. I also think about all the other survivors and their families whose lives were changed forever.”

Still Moving Forward

It has taken Rodriguez longer than she originally anticipated, but she aims to graduate with her doctorate in fall 2019.

“I learned that it’s good to set goals, but sometimes you have to be flexible,” she said. “Every morning I look at something I have framed in my bedroom. It says, ‘We must be willing to get rid of the life we planned, so as to have the life that is waiting for us,’ by Joseph Campbell. I knew if I put my mind to it, I would do it.”

That strong mind advice from her mom holds a special place for Rodriguez. Each day is a challenge as she continues to heal. In spite of the tragedy, pain, sadness and loss, she will accomplish what she set out to do when she receives her Ph.D.

“For me, the true hero in all of this is Cristian,” Rodriguez said. “He is my hero. He took care of our son, our home and me. He had to take care of everything.”

Rodriguez hopes to stay in Stillwater after she graduates. They are an OSU family of four now, and she sees this as their home. Cristian is a utilities engineer for Facilities Management Energy Services. Diana dreams of working in improvement processes and optimization or perhaps teaching engineering students to develop soft skills. She can also see herself possibly working in a hospital setting, improving processes for patients.

“For me, the true hero in all of this is Cristian. He is my hero. He took care of our son, our home and me. He had to take care of everything.”

— DIANA RODRIGUEZ

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 27

CEAT by the Numbers

50%

of all CEAT students graduate with zero student loan debt

58

CEAT students receive scholarships each year

More than 1,200 Faculty

162 Full professors

$2.4M

2,144 Underrepresented students enrolled in scholarships were available for the 2018-2019 academic year

4,578 Student enrollments

non-debt financial aid awarded to CEAT students

CEAT researchers received over $16.6M

Over $27M in R&D funding last year

Over 350

undergraduate and graduate students participate in CEAT research each year

Educating students from 42 U.S. States & 48

Countries

Ranked 16

in the nation by U.S. News and World Report for Best Online Engineering Graduate Degree Programs

Industry magazine recognizes Ley’s fervor for concrete

Dr. Tyler Ley’s passion for concrete has propelled him into the spotlight in his industry. Ley, a professor of civil and environmental engineering at OSU, has now been named among the “Most Influential People in the Concrete Industry” by Concrete Construction magazine.

Ley has published over 200 educational videos on his YouTube channel that have been viewed more than 533,000 times by more than 7,700 subscribers. His channel is about concrete, “the greatest material in the world,” as he calls it.

“I am passionate about concrete,” Ley says on his YouTube introduction. “I think concrete is one of the most underappreciated wonders, and I am excited about helping others learn about it.”

Concrete Construction magazine has been serving the industry for more than 50 years.

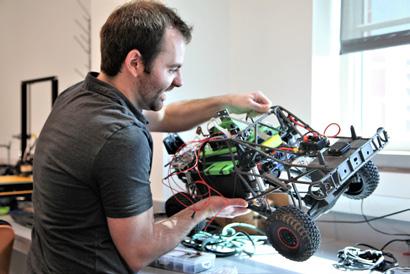

OSU wins FAA approval to fly drone swarm

Oklahoma State University’s Unmanned Systems Research Institute was the first in the country to receive approval from the FAA to fly an unmanned fixed-wing aircraft swarm within national airspace. Current FAA regulations require one pilot and one set of controls for every unmanned aircraft. This flight authorization will permit a single pilot — along with visual observers for safety — to operate a swarm of up to 20 fixed-wing unmanned aircraft.

Dr. Jamey Jacob, professor of mechanical and aerospace engineering and director of the institute, said

research started four years ago to prove that flying a swarm of unmanned fixed-wing aircraft was possible.

The unique configuration developed by OSU researchers creates a “swarm of swarms” where groups of unmanned aircraft fly within smaller flocks as part of a larger swarm, communicating with a local group leader that coordinates flights with the overall swarm formation. The research could benefit environmental and infrastructure monitoring, agriculture, package delivery, national security, airspace operations and weather research.

Jacob said unmanned aircraft swarms could gather information about thunderstorms not currently available. Aircraft flying in formation could gather data about temperature, pressure and humidity. A swarm of unmanned aircraft could also map a wildfire, providing a comprehensive picture of its movement and intensity. Using a swarm could also save money. A group of aircraft measuring gas levels around an industrial plant, for example, could complete a job in hours that would take a single pilot and aircraft days.

CEAT BYTES

30 IMPACT 2019

Kak to receive top honor from India

Subhash Kak, Regents Professor Emeritus in electrical and computer engineering at Oklahoma State University, will receive the Padma Shri award from the president of India, the India Ministry of Home Affairs recently announced.

The Padma awards are India’s highest civilian awards, recognizing distinguished contributions in the arts, education, industry, literature, science, sports, medicine, social service and public affairs.

Technology winners from outside India have included Bill Gates of Microsoft in 2015, and former Cisco Systems CEO John Chambers and Adobe CEO Shantanu Narayen in 2019.

Kak joined OSU in 2007 as head of the computer science department before transferring to electrical and computer engineering in 2014. His research focus is in artificial intelligence, cryptography, neural networks and quantum information. He has developed new codes for computing and cryptography, worked on a variety of problems on data and network security, and he is the originator of one of the two methods of quantum cryptography. He retired from OSU in January.

Industrial center

marks 1,000th audit

Late last year, a crowd turned out to celebrate a milestone by OSU’s Industrial Assessment Center.

On Dec. 4, 2018, the celebration marking the center’s 1,000th industrial assessment/energy audit drew team members, acting and retired faculty, OSU administrators and officials from the U.S. Department of Energy, Rutgers University and Wichita State University. The industrial assessment/energy audit was performed the following day at ASCO Aerospace.

The IAC helps small and medium-size manufacturers save energy, improve productivity and reduce waste with no-cost technical assessments. For more information about OSU’s IAC, visit iac.okstate.edu.

OSU’s Stine wins $1.5M grant

Computer engineering professor and Earl and Carolyn Glimp Professor of Engineering James Stine has been awarded the first phase of a threeyear, $1,504,372 research grant from the U.S. Air Force to design low-energy, high performance, application-specific computer architecture.

The award is part of the Air Force’s Future Autonomous Battlespace RF with Integrated Communications Project, a transformative communication program appropriate for access/area denial environments. The goal is to provide combat-ready, cyber-hardened, power-efficient embedded computer architectures.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 31

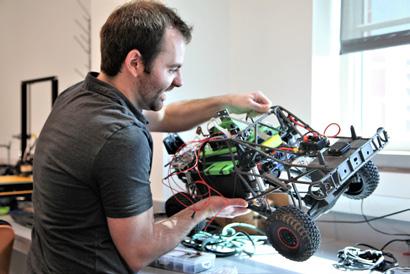

Outside the Box

Alumnus Lee Easton credits OSU for his success-oriented work ethic

Oklahoma State University

alumnus Lee Easton is a man of many hats. With two bachelor’s degrees, four companies and a full-time engineering job, he knows what it means to work hard. He developed this mindset as a student in the School of Electrical and Computer Engineering at OSU.

Easton tried several different majors at OSU before ultimately finding his place in ECE.

“I did some reading and soulsearching to ultimately find that I wanted to do things that would leave behind a positive impact and inspire others the way that I had been inspired,” Easton said. “I felt like technology was the best route to take.”

Easton felt he had to work twice as hard as his classmates to keep up in college. But he believes that made him a better person.

“Halfway through my sophomore year of college, I switched to ECE,” Easton said. “From then on, for the next four years of school, I was on campus from 8 a.m. to 12 a.m. every single day — yes, 16-hour days. I eventually just got used to this and realized this is what it would take for me to keep up.

“I saw graduation as the end goal and thought of living a normal life with eight-hour workdays. Oh, how I was wrong — it's the life of an entrepreneur. All that being said, I would have never developed this work ethic if it hadn’t had been for the switch into the ECE program.”

One of Easton’s first impressions of ECE was a hands-on learning experience that seemed tailored to his learning style.

Easton remembers his intro to engineering class fondly. “We built Styrofoam boats with a single electric motor. The goal was to split into teams and design the best craft to make it the furthest distance. Right off the bat, we were learning about teamwork, design practices, budget, timeline and documentation. These are all skills that are important in any career. For me, it was the hands-on learning practices like this that made the School of Electrical and Computer Engineering stand out over the others. Now I visit campus, and I see the ENDEAVOR Lab. Why would anyone not want to go here?”

Easton graduated with two bachelor’s degrees in computer engineering and electrical engineering in May 2014.

Since graduating, Easton has had a full-time engineering job at ConocoPhillips and founded four companies. His two favorite companies are Aerovision.io and ModernBlox. Aerovision.io is a tech-based marketing company that helps businesses around Tulsa collect data on their processes and converts that data into cost-saving opportunities.

At ModernBlox, Easton (vice president) designs and builds commercial and residential properties

STORY CEAT MARKETING | PHOTOS COURTESY OF LEE EASTON

ALUMNI 32 IMPACT 2019

out of shipping containers with two other OSU alumni, Ben Loh and Swapneel Deshpande.

“I almost switched my major in college to architecture. ModernBlox has helped me scratch that itch,” Easton said. “We recently built a 1,600-squarefoot custom car garage out of five 40-foot shipping containers for a client in Tulsa who collects classic cars. We called it #AutoBlox. We have done projects from Tulsa all the way to Detroit, Michigan, and Atlanta, Georgia.”

Easton said the quality that most differentiates the School of Electrical and Computer Engineering is its people.

“I had the best experience developing great relationships with my professors and my classmates,” he said. “This was probably the best part of the whole college experience for me. The ECE department felt like my second family. I could walk into any professor’s office any time I wanted to ask a question.”

For future and current ECE students, Easton stresses the importance of building relationships.

“Now that I am out of college, I cannot stress how important networking is,” he said. “Relationships have proven to be so important in the past four years of my life after graduating from OSU. I simply would not be where I am today if it weren’t for some of the amazing people I’ve met along the way.”

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 33

Engineering Success

OSU'S first female graduate in her field credits her ability to adjust

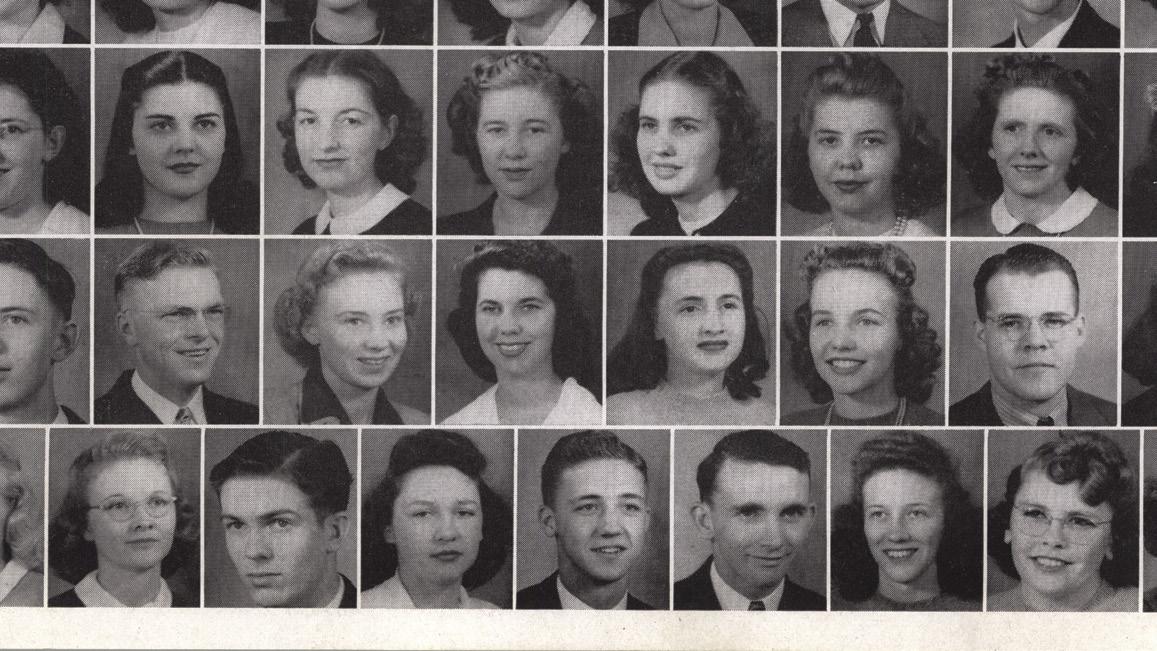

Adapt. Ruth Spivey has taken that word to heart throughout her 94 years. But when she graduated from OSU more than 70 years ago, adapting wasn’t a choice. It was a requirement.

Spivey was born in Ripley, Oklahoma, and eventually moved to Stillwater with her parents. She was always fascinated by math and science.

“I was kind of a weird little kid,” Spivey said. “I can remember before I started school, I wanted boys’ toys. My loving grandfather bought me a little steam engine and an electric train. I was always interested in that sort of thing.”

This fascination led Spivey to attend OSU (then Oklahoma A&M College) as an electrical engineering student during World War II.

“My classes were very small because most of the guys got drafted,” Spivey said. “I think that was one of the reasons I did fairly well. The classes were so small, and I got a lot of individual attention.”

At OSU, Spivey was a member of Sigma Delta, an organization designed to stimulate interest and encourage scholastic achievement of the women enrolled in engineering through closer association and mutual assistance.

“We supported each other,” Spivey said. “If we felt overwhelmed, we would boost each other up.”

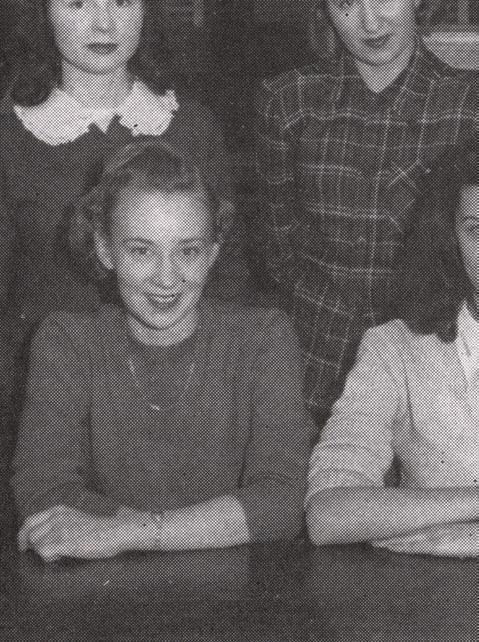

Spivey graduated in 1945 as the first woman to earn an electrical engineering degree from OSU.

Before she began her career, Spivey received some advice from a mechanical engineering professor that stuck with her.

“He told me I was entering a man’s world. Adapt. Don’t try to change it,” she said.

While working her first job as a test engineer for General Electric, Spivey met her husband, Frank. The couple would have three children together: Margaret, Harold and Patricia.

Marriage and having children led to more adapting as Spivey continued to pursue her career.

“Back in that day, women could not work if they were pregnant,” Spivey said. “There were periods of time when I didn’t get a chance to work. Also, after we got married, Frank and I couldn’t work in the same building for GE.”

None of this stopped Spivey from taking jobs across the country for the next five decades as the family moved because of Frank’s position.

STORY WILL CARR | PHOTOS OSU ALUMNI ASSOCIATION

“I think it is extremely important to work on something you are excited about. It’s not hard to get along with people if everyone is excited and shares a common goal.”

ALUMNI 34 IMPACT 2019

One of Spivey’s proudest accomplishments was doing the surveying and assisting with the location map for the Interstate 10 bypass around Benson, Arizona, while she worked for the Arizona Highway Department.

Eventually, Spivey would land multiple positions for the U.S. Air Force in San Antonio. She worked for the Air Force in civil service for over 25 years, including as head of the base closure division for Air Educations and Training Command, in charge of nearly 50 other engineers.

“I never felt like the men who worked for me were uncomfortable,” Spivey said. “I just treated them like I would have liked to have been treated.”

Upon retiring from civil service for the Air Force, Spivey was classified as a GS14 — the second-highest civilian rank.

Spivey now lives in a retirement home in New Braunfels, Texas, where she continues to support the university she loves. She hopes she can inspire women to reach for their goals.

“I think it is extremely important to work on something you are excited about,” Spivey said. “It’s not hard to get along with people if everyone is excited and shares a common goal.”

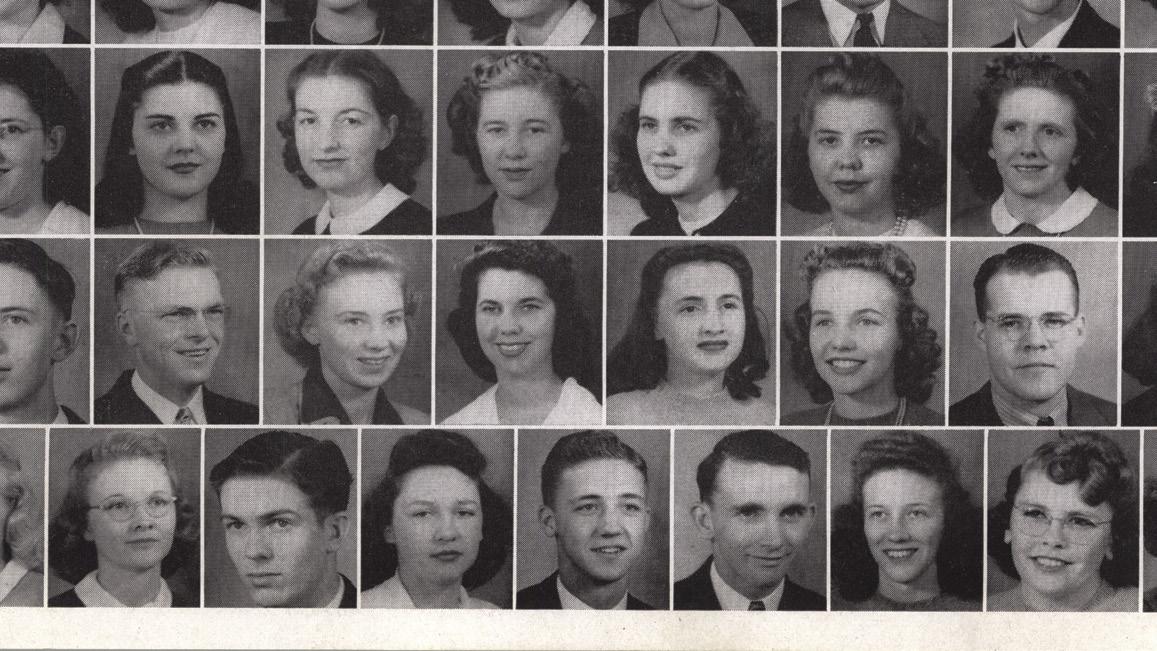

Ruth Spivey (lower left) poses with members of Sigma Delta in 1945.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 35

Lessons From Bees

OSU researchers are seeking hints on swarming behaviors from insects

Imagine seeing swarms of drones quickly fly over the path of a miles-long tornado looking at heat signatures for signs of life. Or unmanned, aerial vehicles autonomously lining up to enter a home window while searching for victims.

An Oklahoma State University researcher is in the early stages of studying groups of honey bees in hopes of determining if their flight paths could be useful in a wide variety of industries, including helping future swarms of autonomous drones better work as cohesive units.

Dr. Imraan Faruque, mechanical and aerospace engineering assistant professor and director of the autonomous physics group at OSU, is thrilled to be doing the research with

help from a few students and a postdoctoral researcher.

“We will be collecting experimental flight data in crowded assemblies, both body trajectories and wing motions, which will provide a powerful validation tool to test our theoretical models against,” Faruque said.

The Office of Naval Research selected Faruque as one of 25 earlycareer professionals for its 2019 Young Investigator Program. The award comes with up to $750,000 in funding over three years.

Faruque’s project, titled Insect Group/Swarm Behaviors and their Relation to Individual Feedback Models, will contribute to the Office of Naval Research’s Science of Autonomy program.

“In this project, we will extend my theoretical and experimental neural function extraction work from individuals to groups and swarms of insects. This will allow us to address some challenges in practical aerial swarms by studying how insects use their limited neural resources to achieve robust, autonomous, group and swarm behaviors,” he said. “Many insects don’t see the world like you and I do. They sort of see this blurry, out-offocus version. What they are actually responsive to is motion patterns.”

Sophomore Ethan Lane is fascinated with bees and had his own hives as a youth in Lawton, Oklahoma.

“Almost every insect has something unique about it that we can use and leverage to improve our technology,” Lane said. “It is already there; we just have to go and study it.”

RESEARCH STORY DAVID BITTON | PHOTOS PHIL SHOCKLEY AND DR. IMRAAN FARUQUE 36 IMPACT 2019

Dr. Imraan Faruque (above and below) works with honey bees.

During the spring semester, Lane built a tunnel that bees could fly through so they could be studied and recorded.

“The first task was to figure out what size the tunnel needed to be,” Lane said. “If a bee is feeling too confined, it will walk. If the tunnel is too big, the bee won’t be in a controlled trajectory. We settled on an 8-inch by 8-inch ‘Y’ maze that allows the bee to leave the hive and then split left or right.”

The goal is to study the detailed mechanics of in-flight interactions as insects navigate spatial decision making tasks. For example, deciding which tunnel to exit based on learned positive or negative responses to color and other visual stimulus and how those interactions change as more members are introduced.

“Anything that we want to model on the bee and study about its flight, we won’t have to wait for these things to happen — we can tell the bee to turn left, and we can get video of that turn,” Lane said.

The lab is equipped with nearinfrared lighting and four video cameras capable of recording at least 9,000 frames per second in 1080 highdefinition quality.

Doctorate student Arif Billah, from Bangladesh, is focused on analyzing the footage and drawing conclusions.

“We are trying to learn how bees communicate between each other and how they make decisions,” Billah said. “Once we know more about them, we can apply our own form of robotic bees to control how they behave.”

That’s right: OSU is working on a prototype for a fake bee.

“Part of my job as an adviser is to figure out what students are curious about and figure out a way to make that society-relevant in a way that solves some of today’s big challenges,” Faruque said. “I want people who are passionate working on a particular problem. This is a process where you need that selfdiscovery and that motivation. You sort of need to have your own curiosity.”

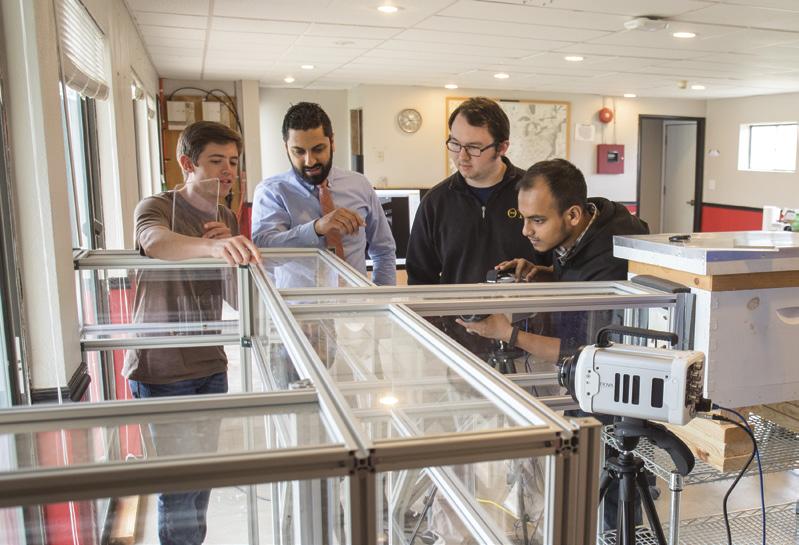

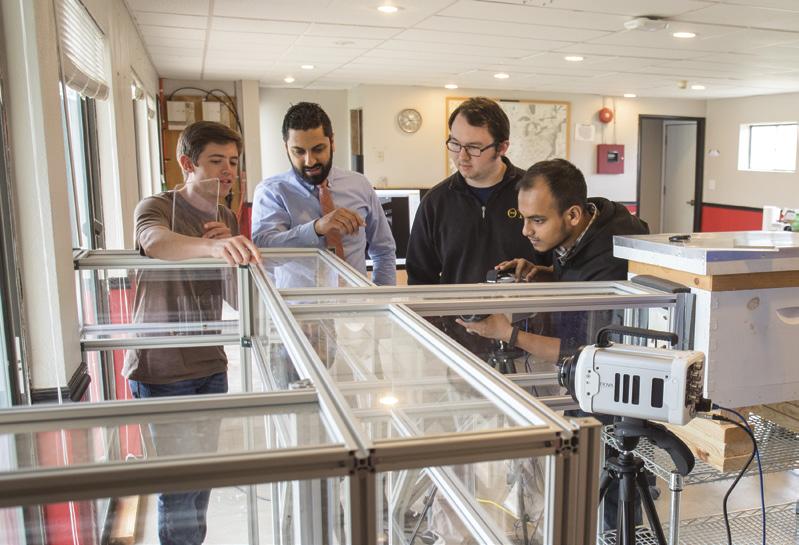

Researching bees leads to new insights. Top: Ethan Lane, Dr. Imraan Faruque, Austin Rolen, and Arif Billah work on an 8-inch tunnel for honey bees to fly in while being studied and recorded. Bottom: A queen and attendant bees are moved from a transition cage to a new hive off McElroy Road.

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 37

“(The autonomous truck corridor) … is a transformational opportunity.”

(

RESEARCH

— DR. PAUL TIKALSKY

)

38 IMPACT 2019

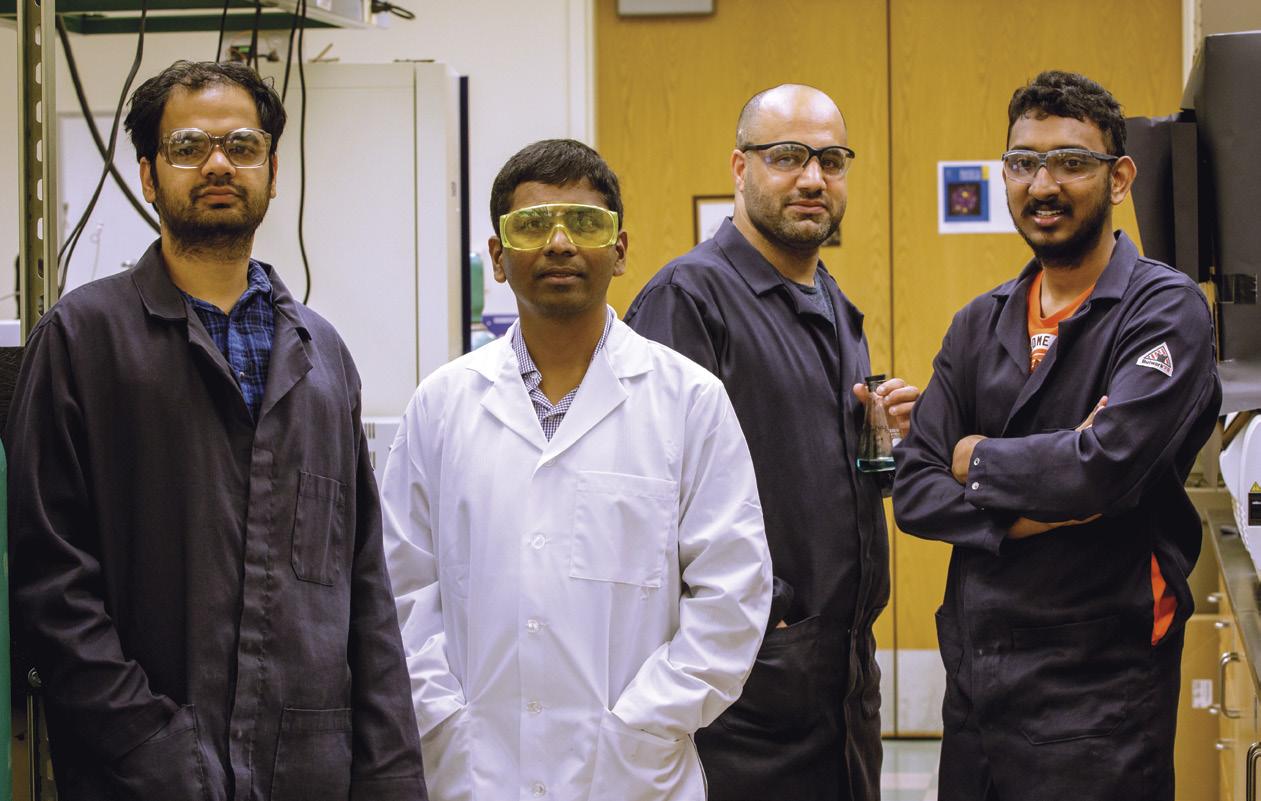

STORY DAVID BITTON | PHOTOS GARY LAWSON, PHIL SHOCKLEY AND NICOLA MOTOR CO.

Real Truck Lanes

Tikalsky and Ley propose building autonomous truck corridors to support 21st century transportation needs

Imagine an interstate highway system with less traffic, better safety and longer-lasting roadways.

That’s what two Oklahoma State University researchers are developing while tackling how to rebuild America’s interstate infrastructure for the 21st century.

“I have dedicated my life to improving roads and bridges,” said Dr. Tyler Ley, structural engineering professor in OSU’s School of Civil and Environmental Engineering. “Our roads are in pitiful shape.”

Proposed Solution

Ley and Dr. Paul Tikalsky, dean of OSU’s College of Engineering, Architecture and Technology, are proposing building independent roads next to existing highways for autonomous and electric-powered self-driving freight trucks, calling the lanes autonomous truck corridors.

These separate lanes could hold much more weight, allow autonomous trucks to travel at higher speeds, save energy by traveling closer together and provide trucking companies with a reliable way to move their products. Overhead electric and fiberoptic lines would power and monitor the trucks.

Benefits could include quicker and more reliable delivery times and lower greenhouse gas emissions.

“The technology needed to make all this happen already exists,” Tikalsky said.

Tikalsky has worked on a wide variety of transportation and infrastructure projects throughout his career and sees the Midwest and southern Plains as the freight, energy, trade, transportation and information backbone of the nation. He has met with the Senate Appropriations Committee in Washington, D.C., to propose the autonomous truck corridor.

“We aren’t the only ones thinking about this, but someone has to start it,” Tikalsky said. “It is time for a national effort to build cohesive and enduring infrastructure corridors that provide our nation with economic and sustainable transportation, and utility and information corridors that drive commerce and security for the next century.”

Partnership

OSU has partnered with Pennsylvania State University and University of North CarolinaCharlotte to help the autonomous truck corridor become a reality. One of the group’s proposals is to create a University Transportation Center in Stillwater, where experts from private industry, government agencies and academia would work together to do just that.

“This corridor will require a new way of thinking in the design, operation, maintenance

Nicola’s Tre model (left) is a fully-electric and hydrogen fuel cell electric day cab semi truck.

DR. TYLER LEY

OSU COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY 39

and financing of transportation infrastructure,” Tikalsky said. “Our team has written support from dozens of companies, four DOTs (departments of transportation) and turnpike authorities. People who think this is 10 or 20 years out could be grossly mistaken. We could build 100 to 200 miles within a few seasons.”

Tikalsky has suggested building an autonomous truck corridor on Interstate 44 between Oklahoma City and Tulsa to show that the concept works with existing technology.