PORTFOLIO

Brendan Tyler Hall

XL L M S Contents Community. 02 03 01 04 healing. Artistry. SYstems. PP Personality. 05

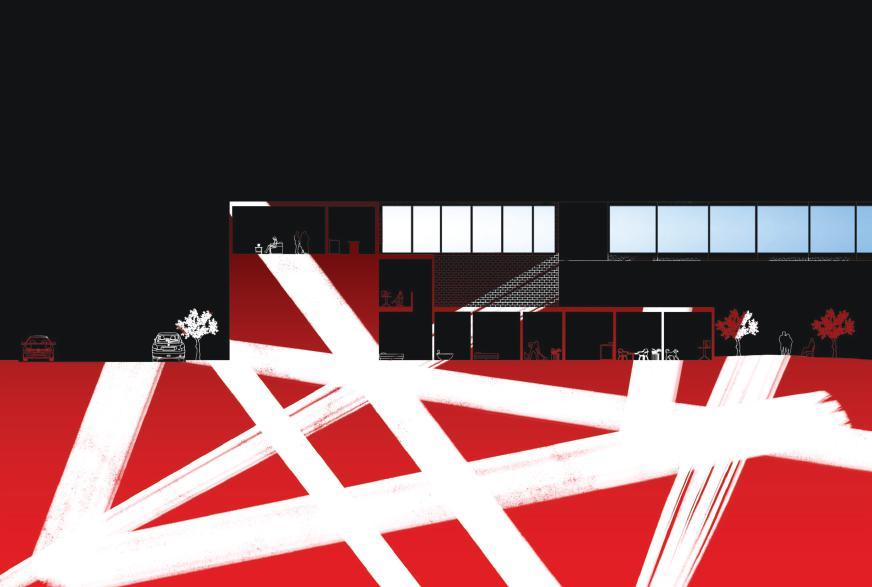

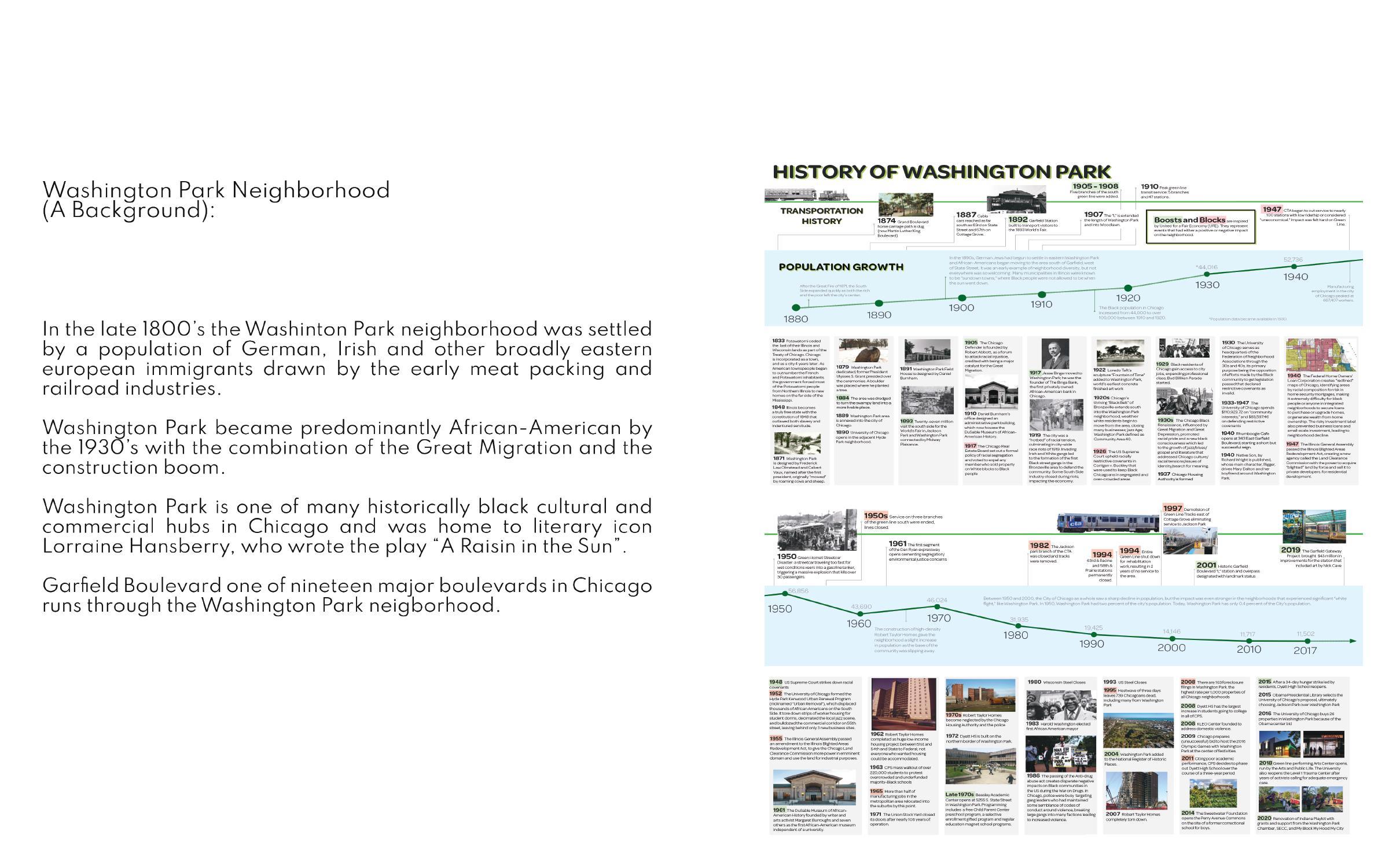

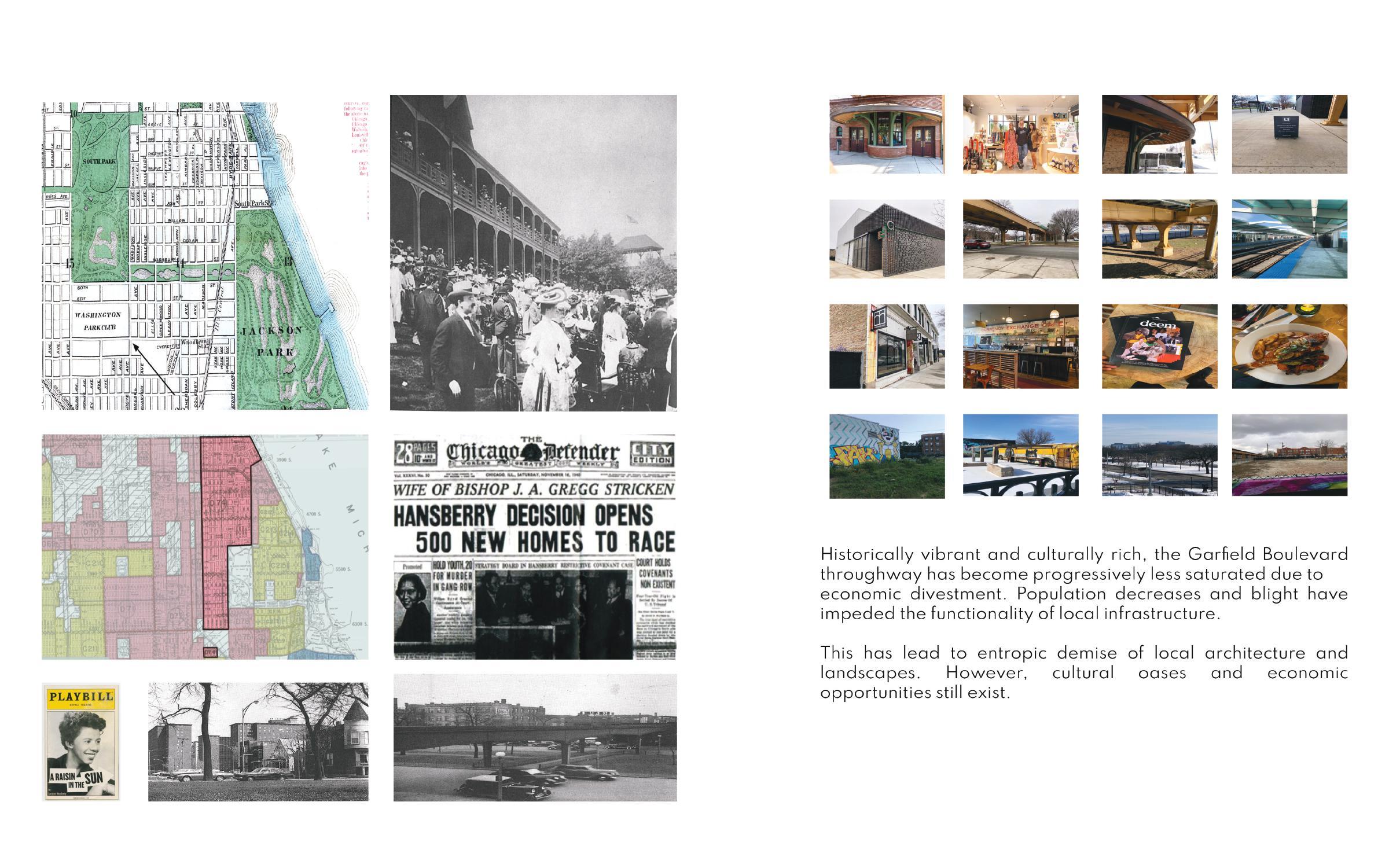

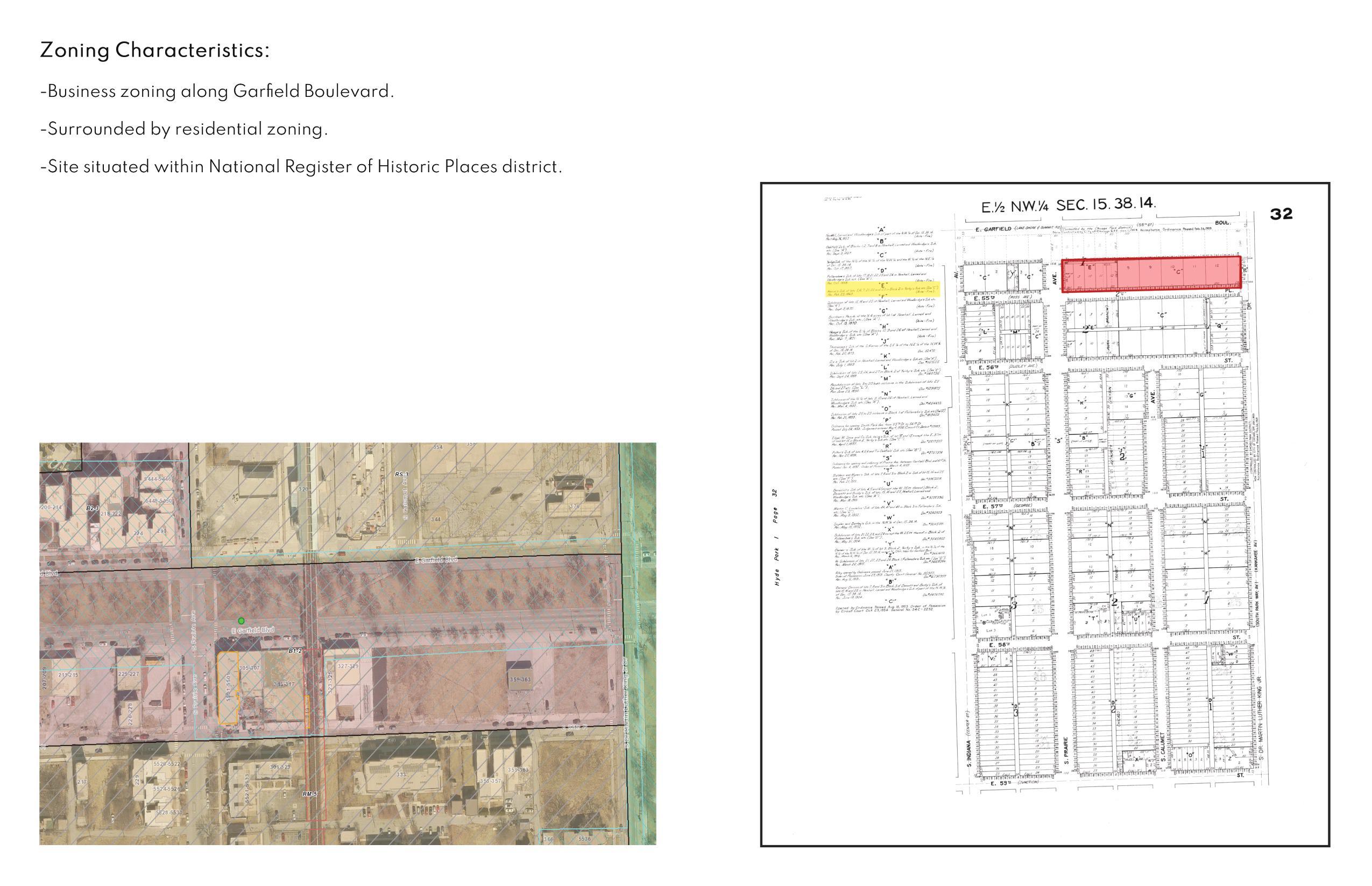

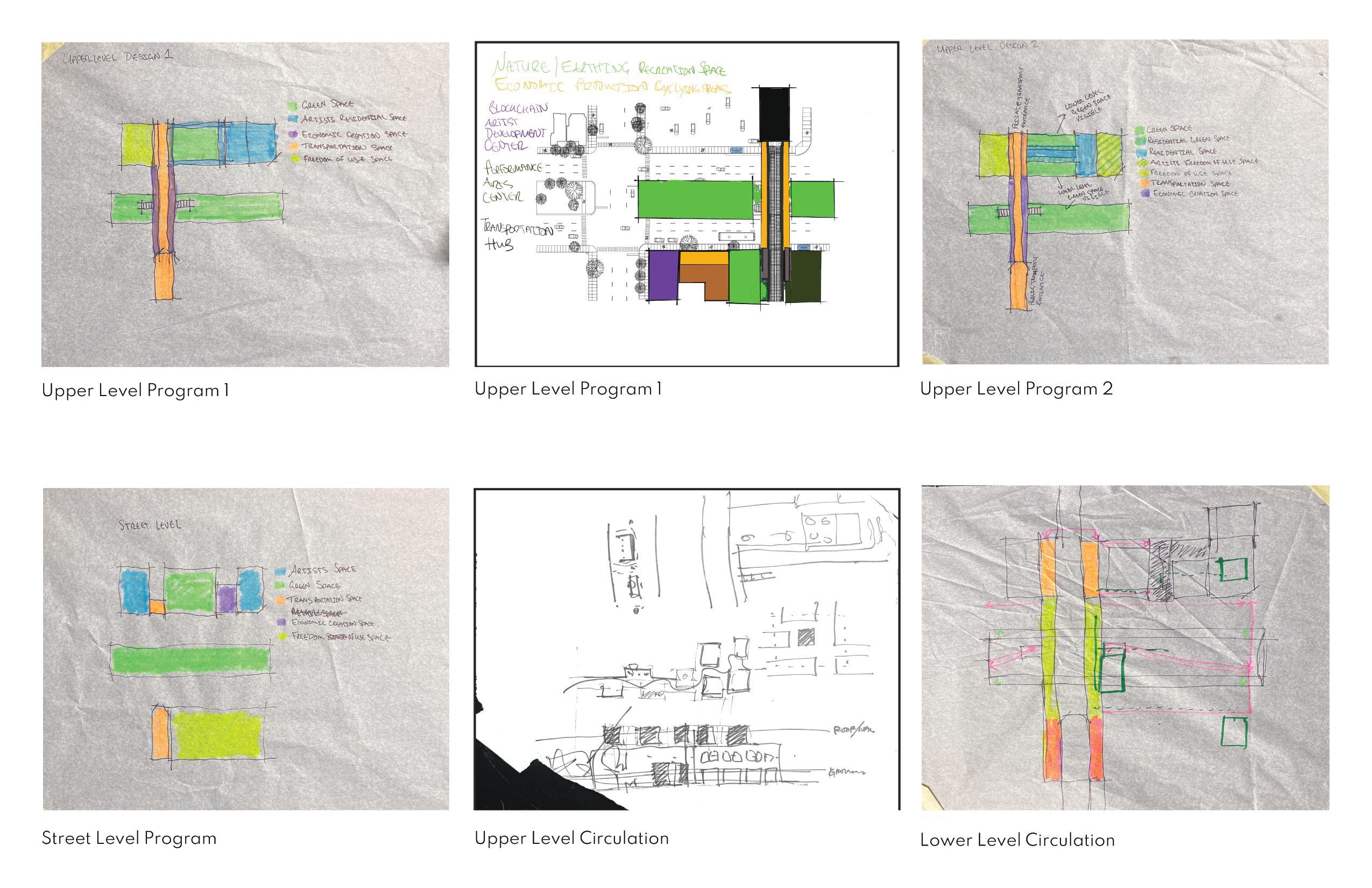

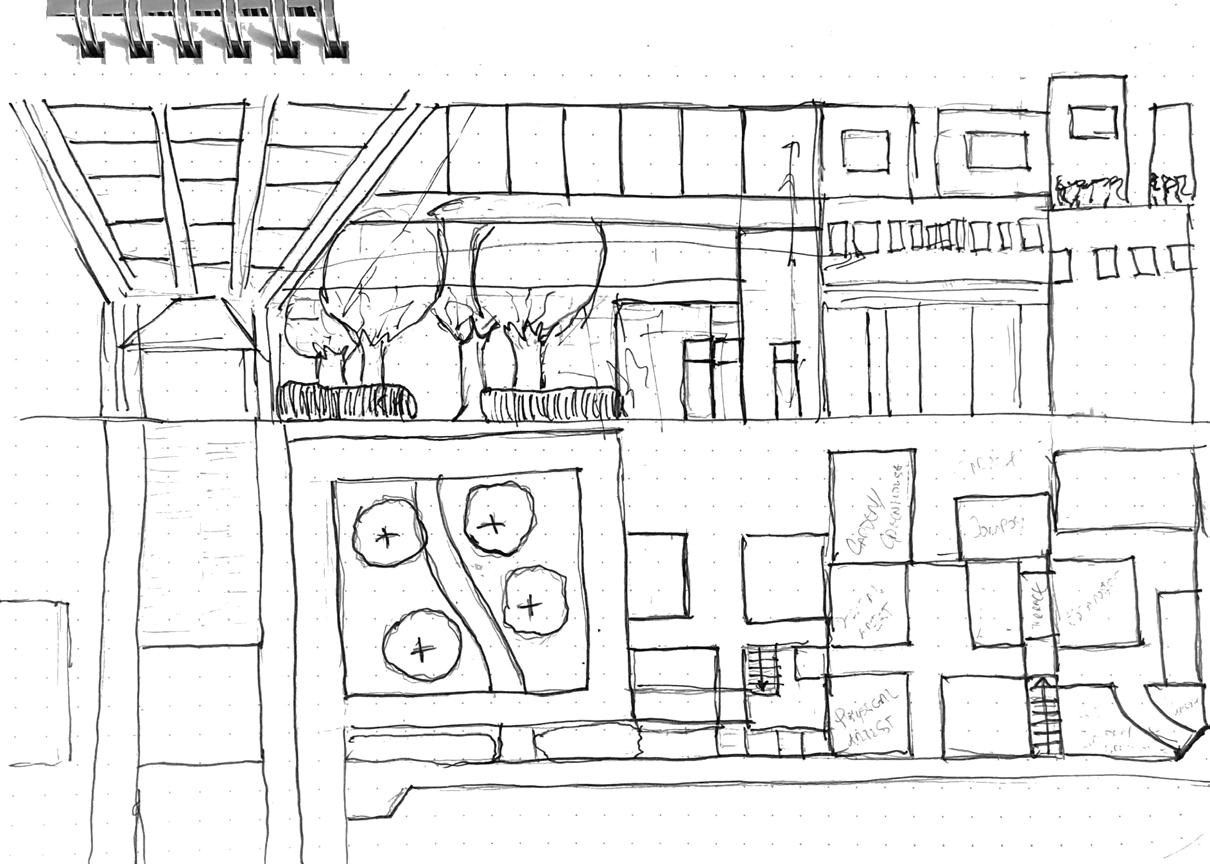

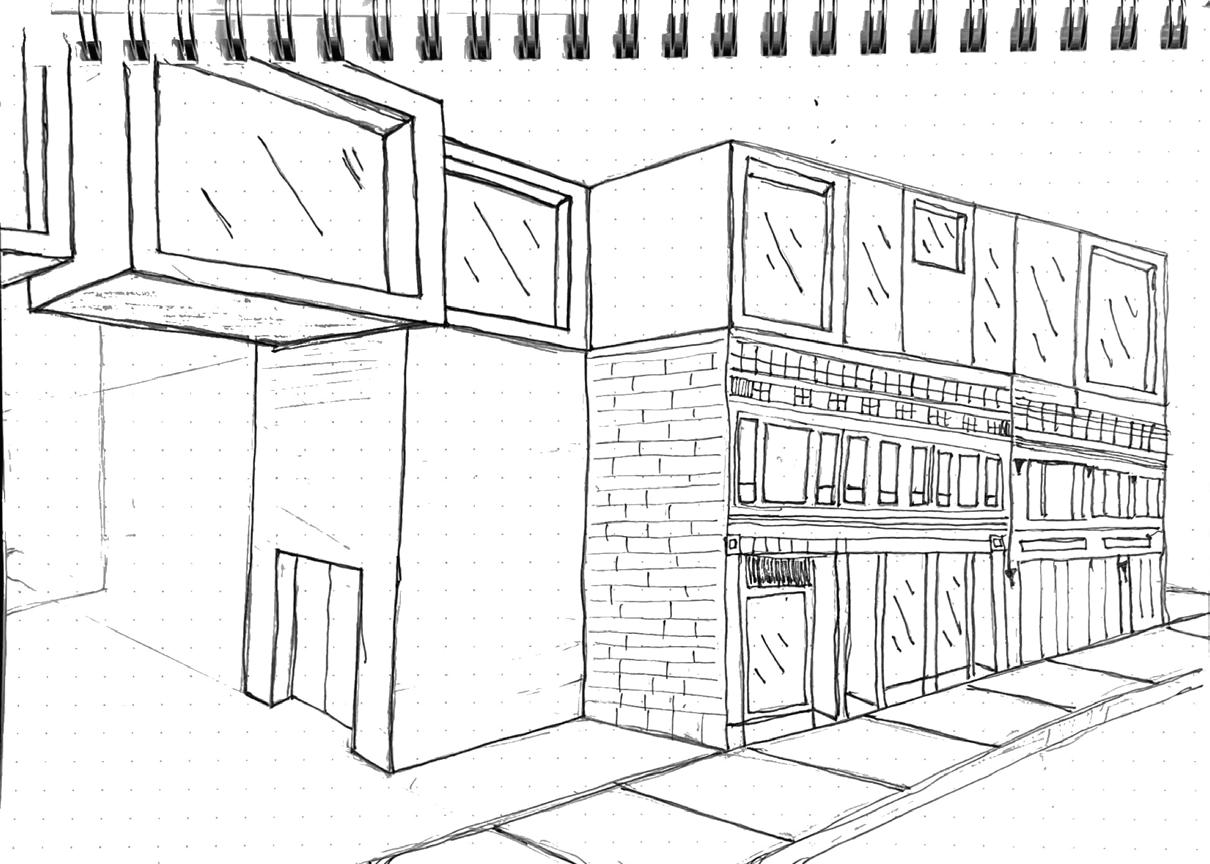

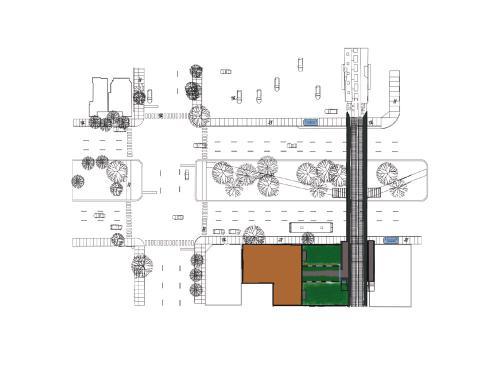

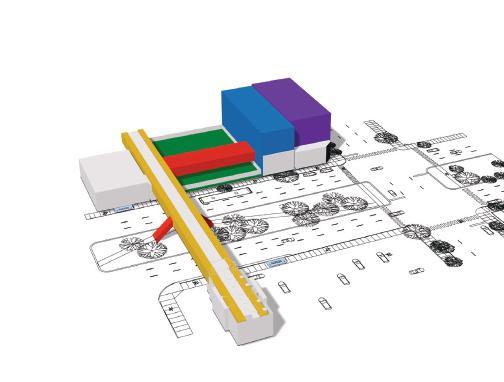

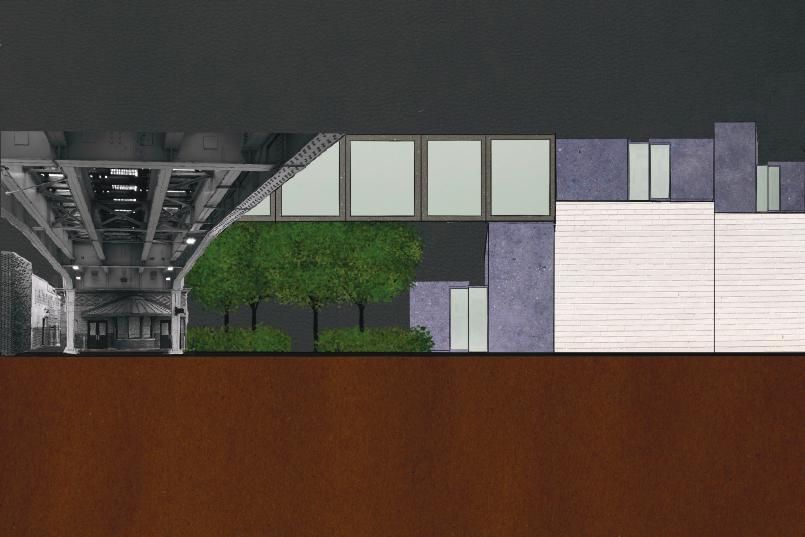

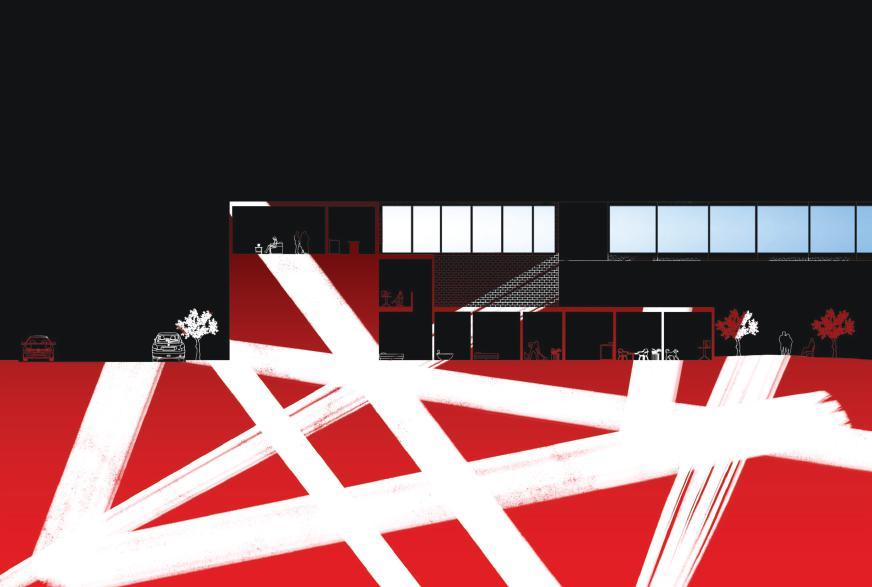

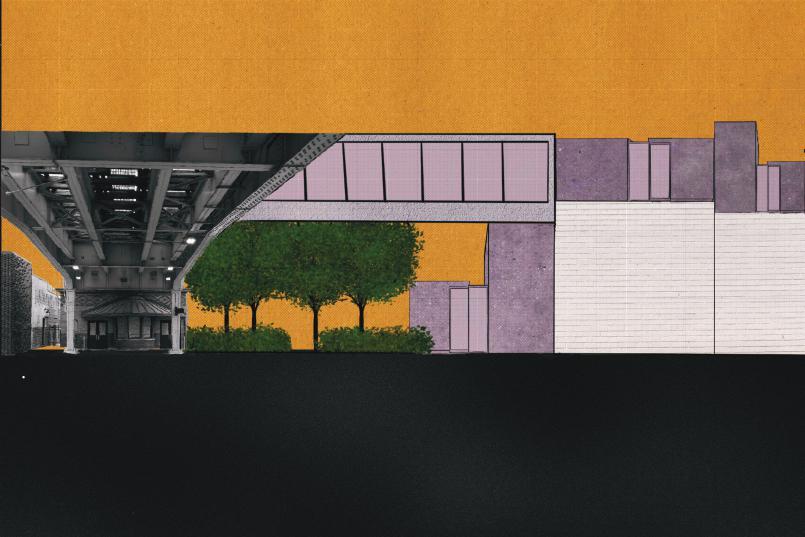

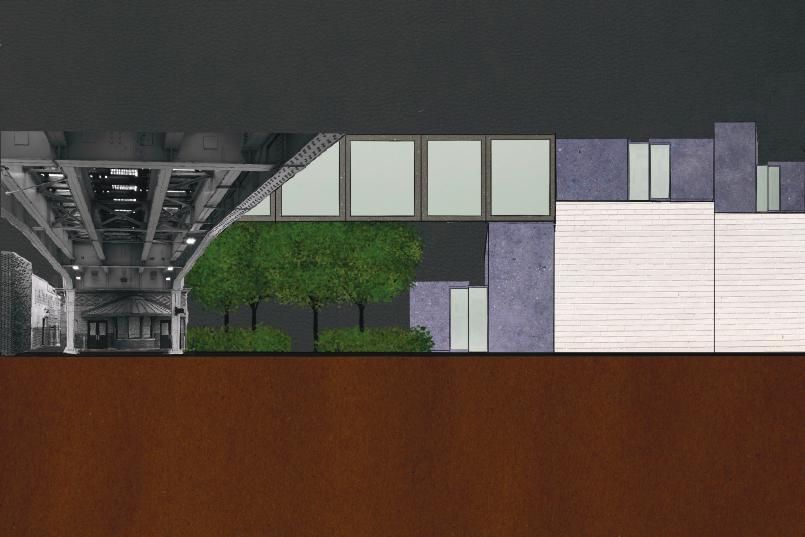

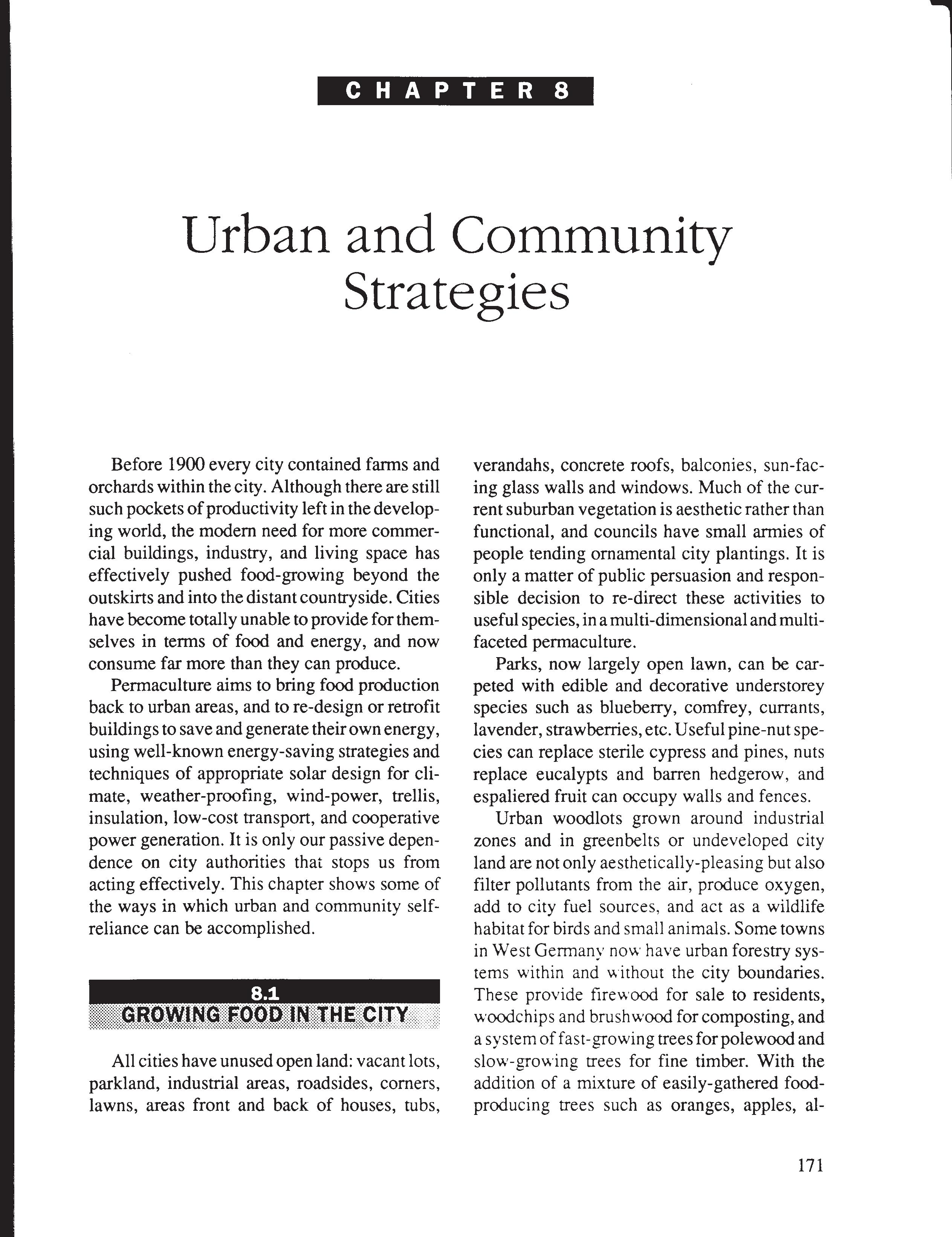

a place for Artistry

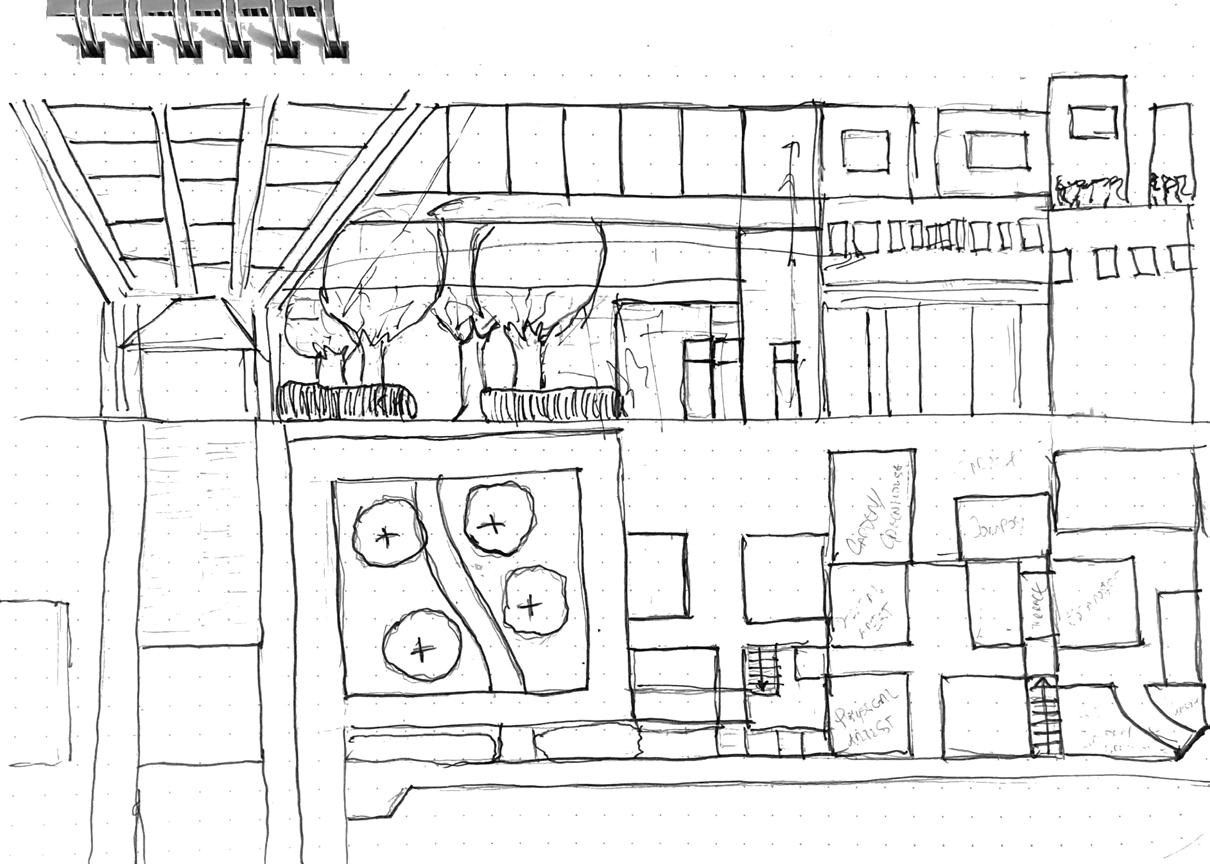

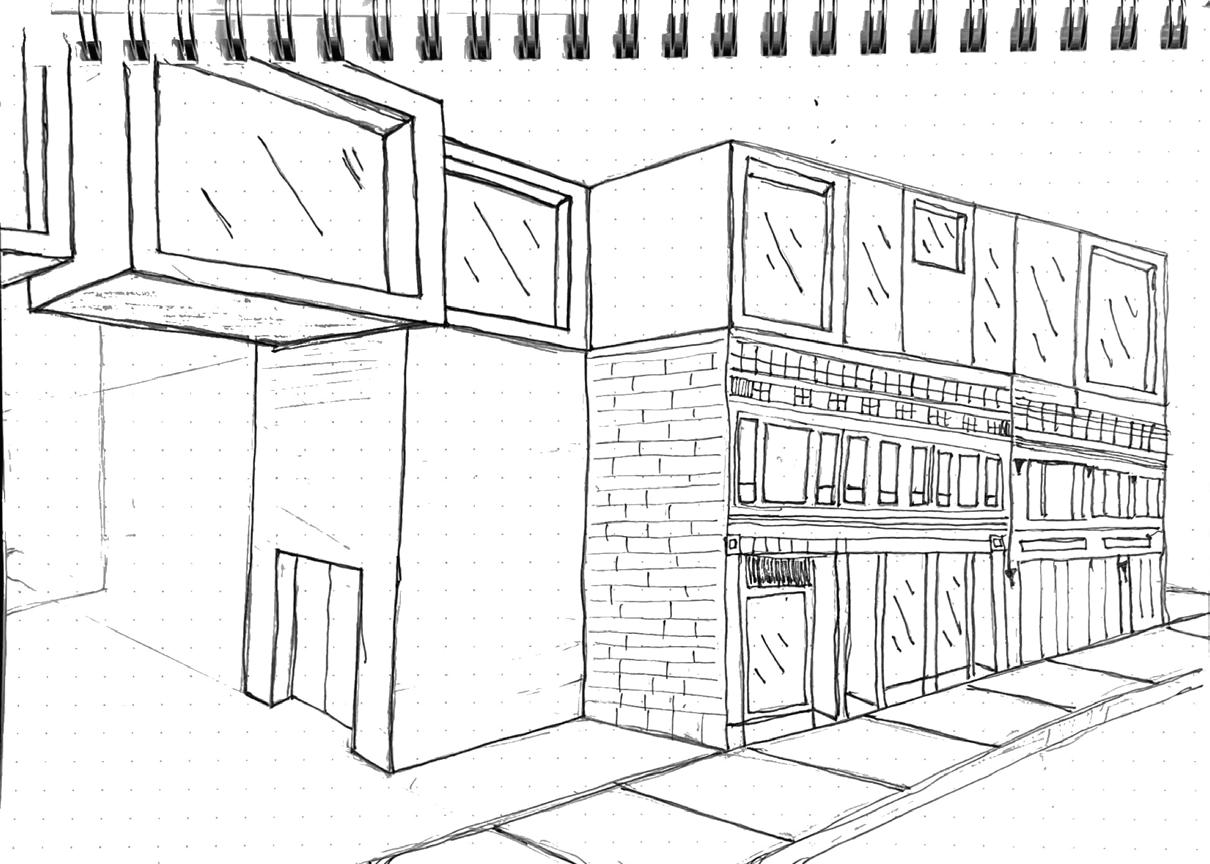

Revitalizing the neighborhood through adaptive reuse and rudimentary design.

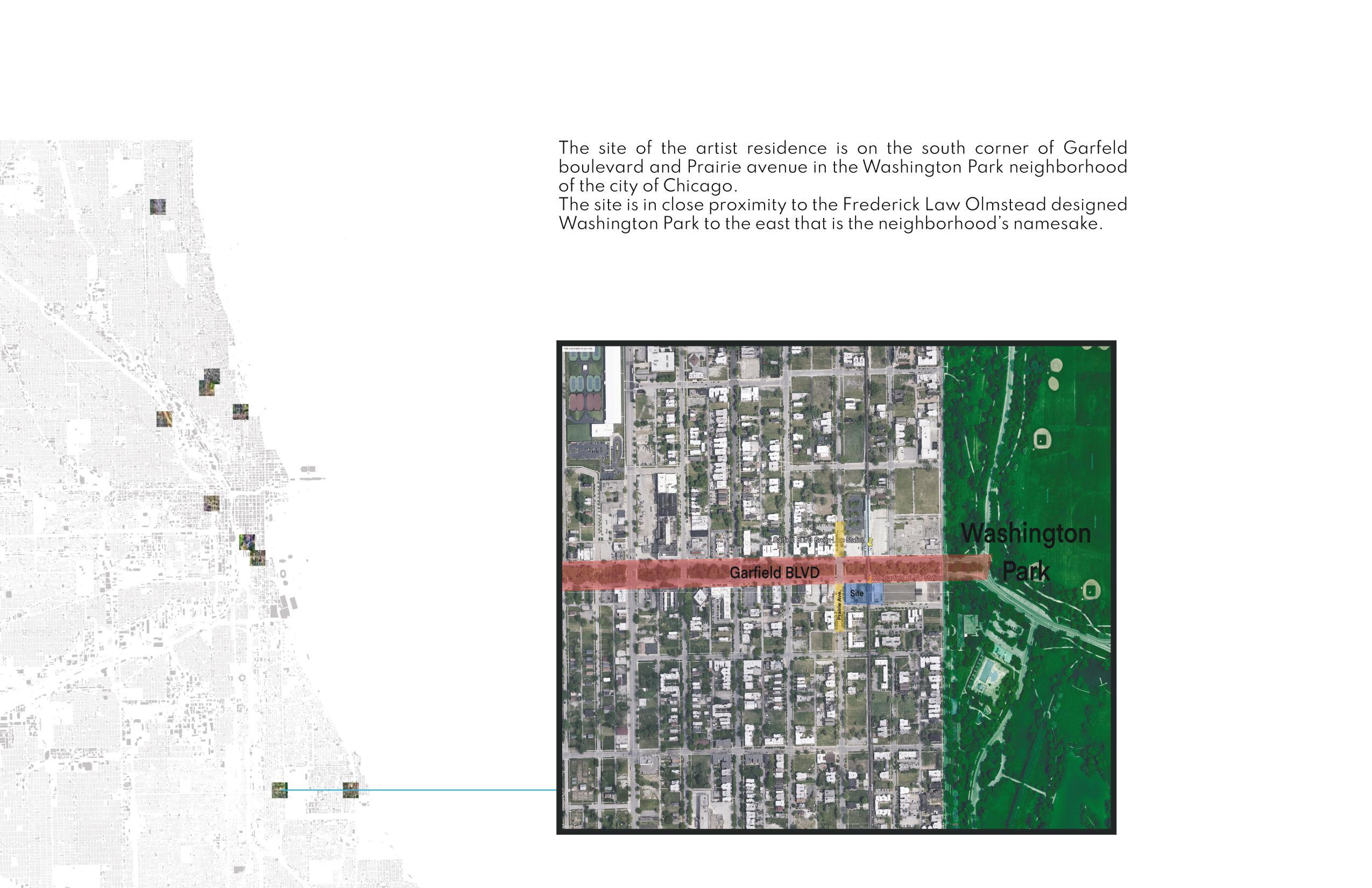

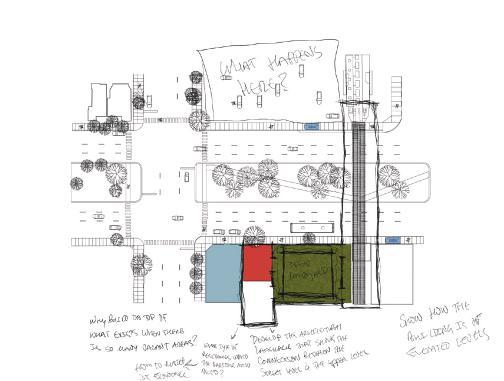

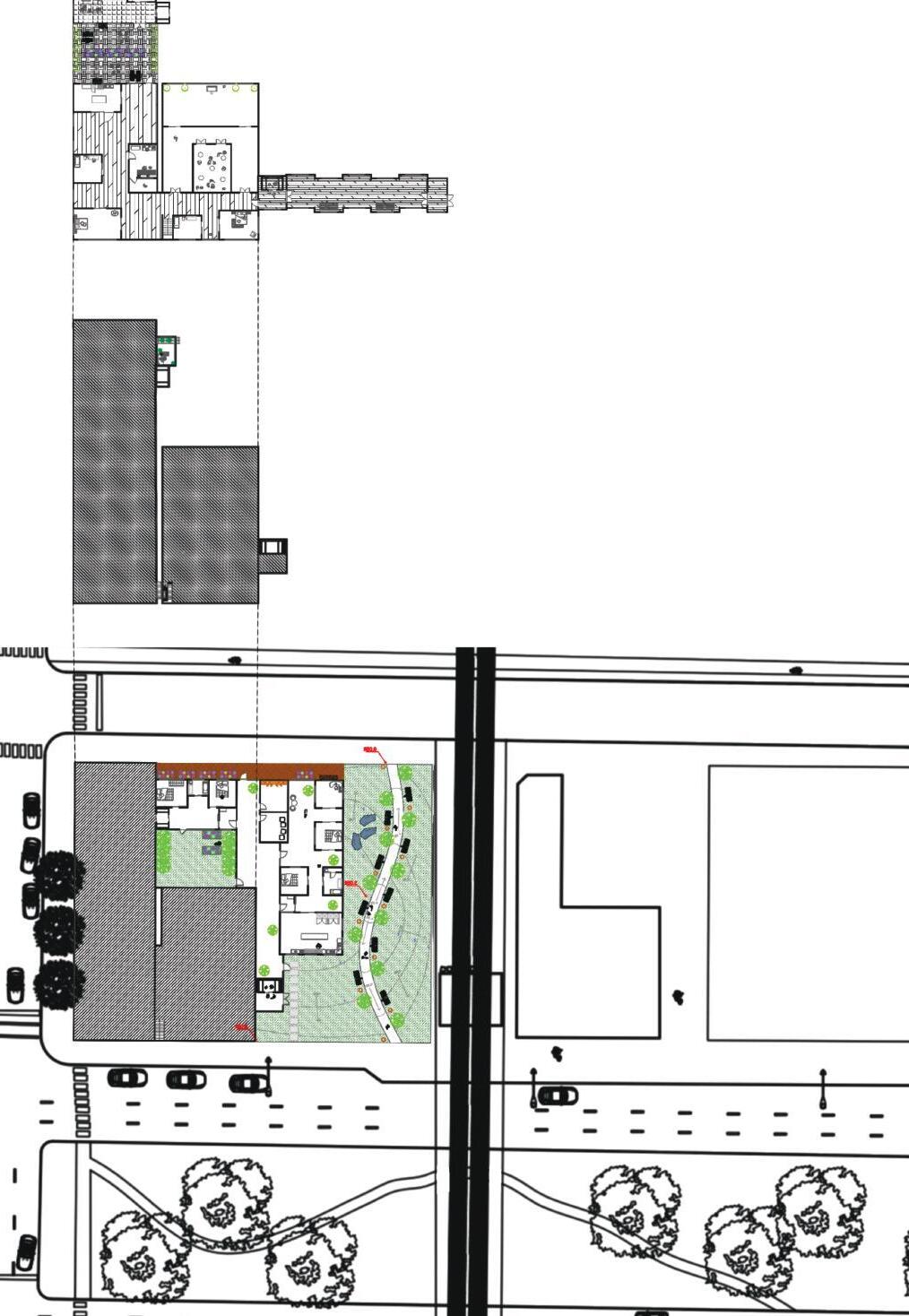

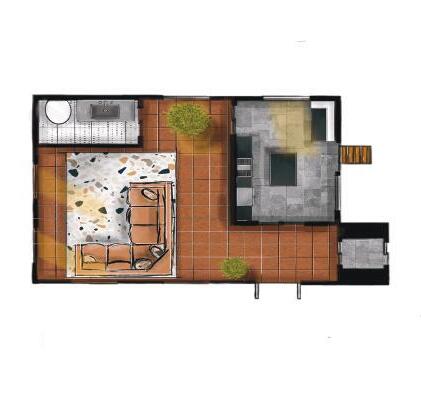

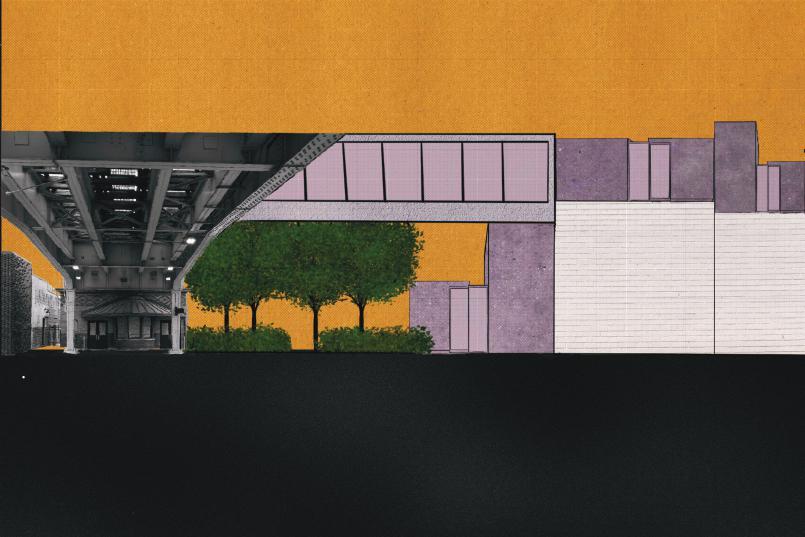

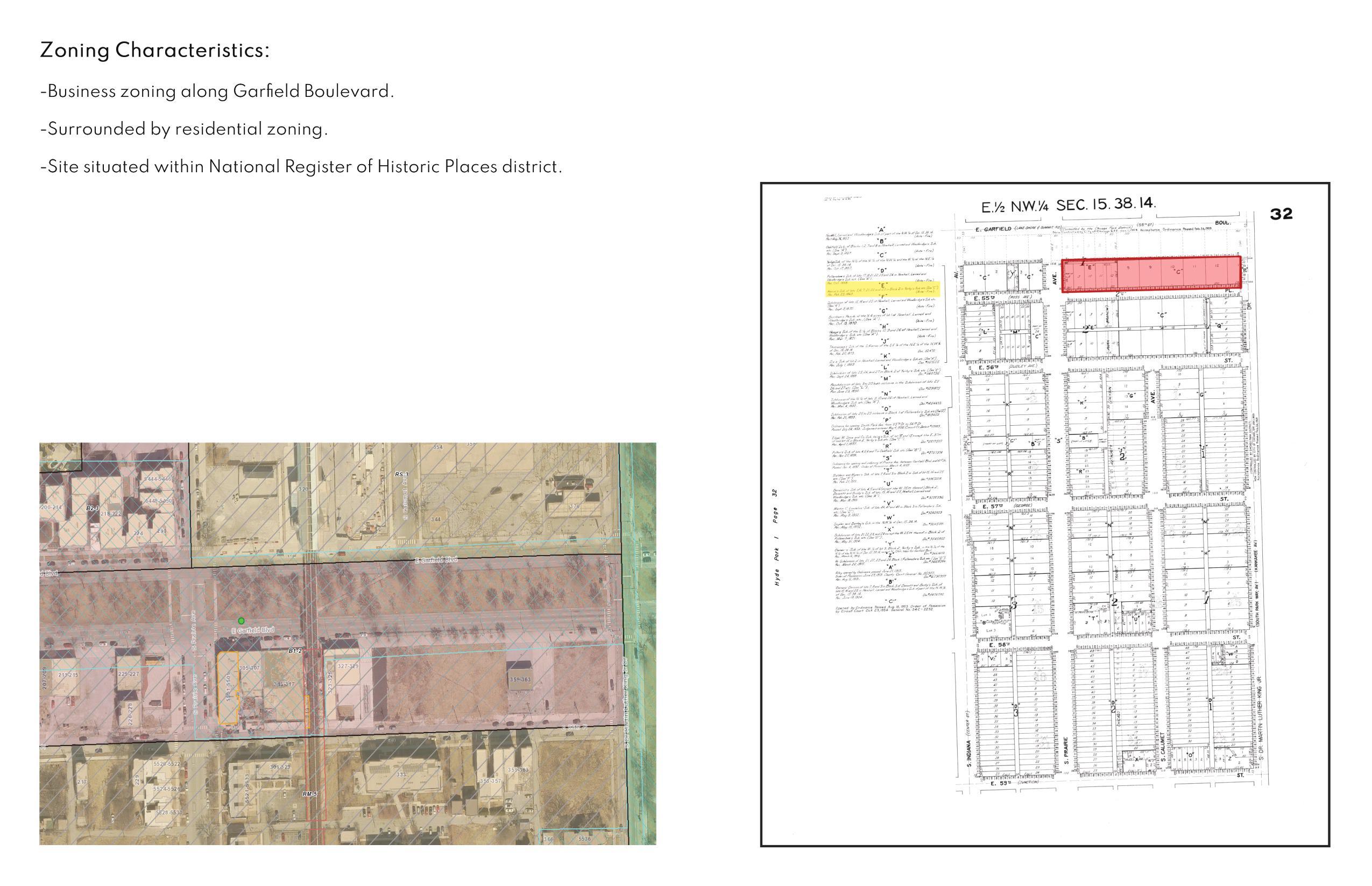

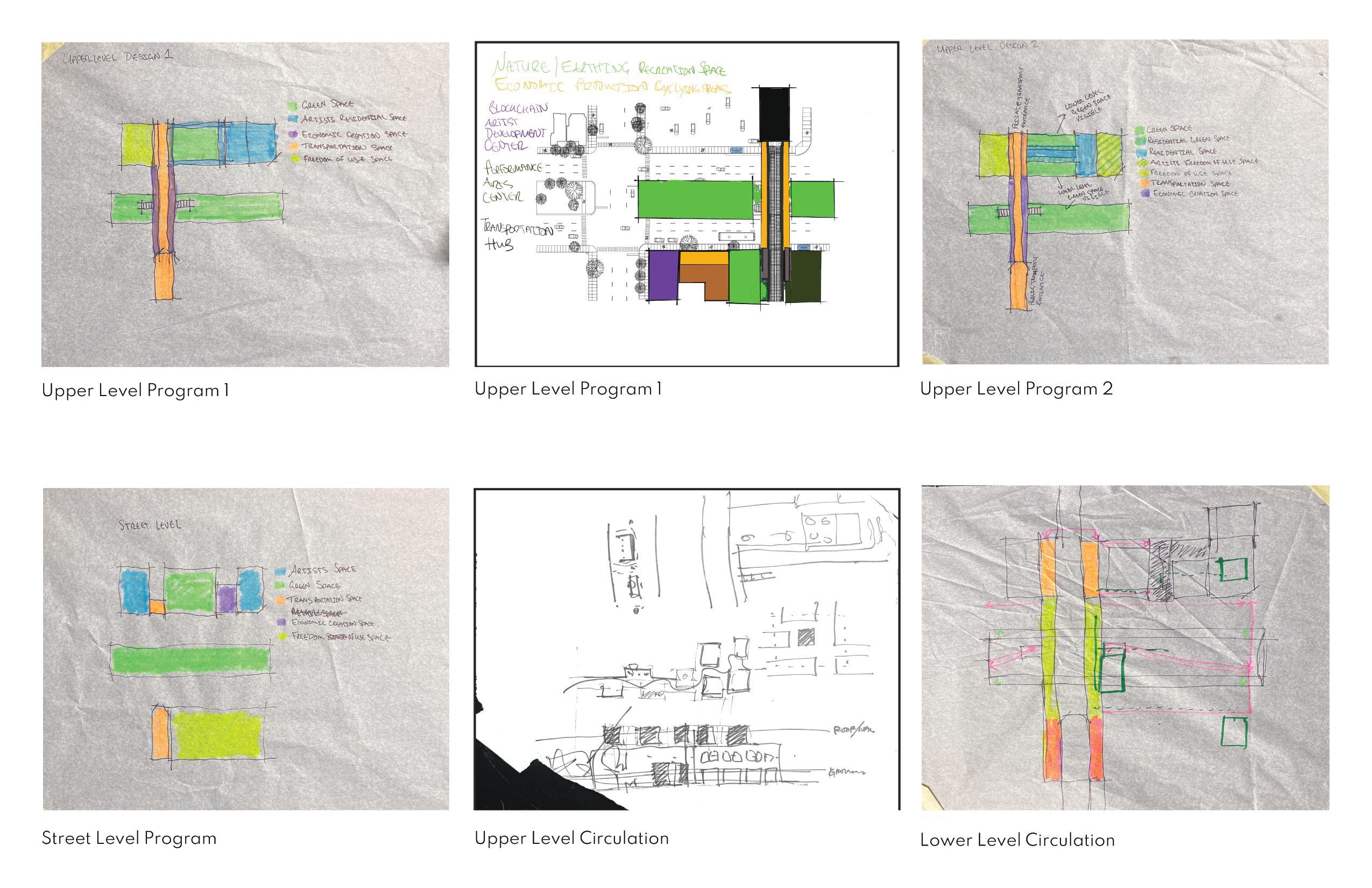

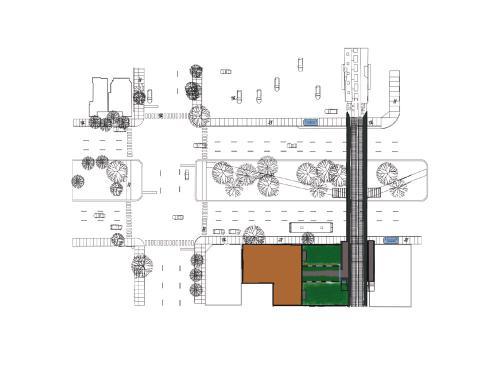

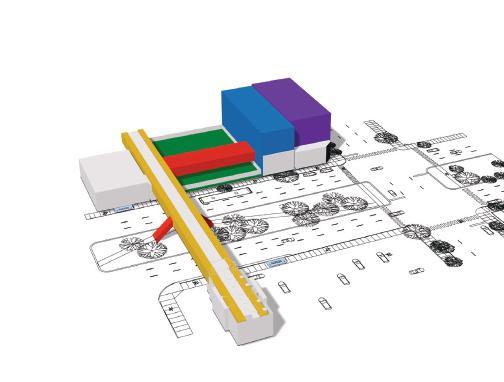

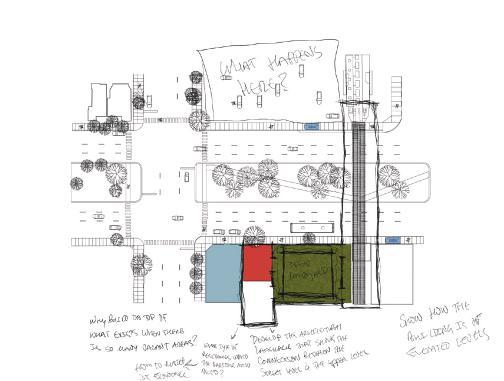

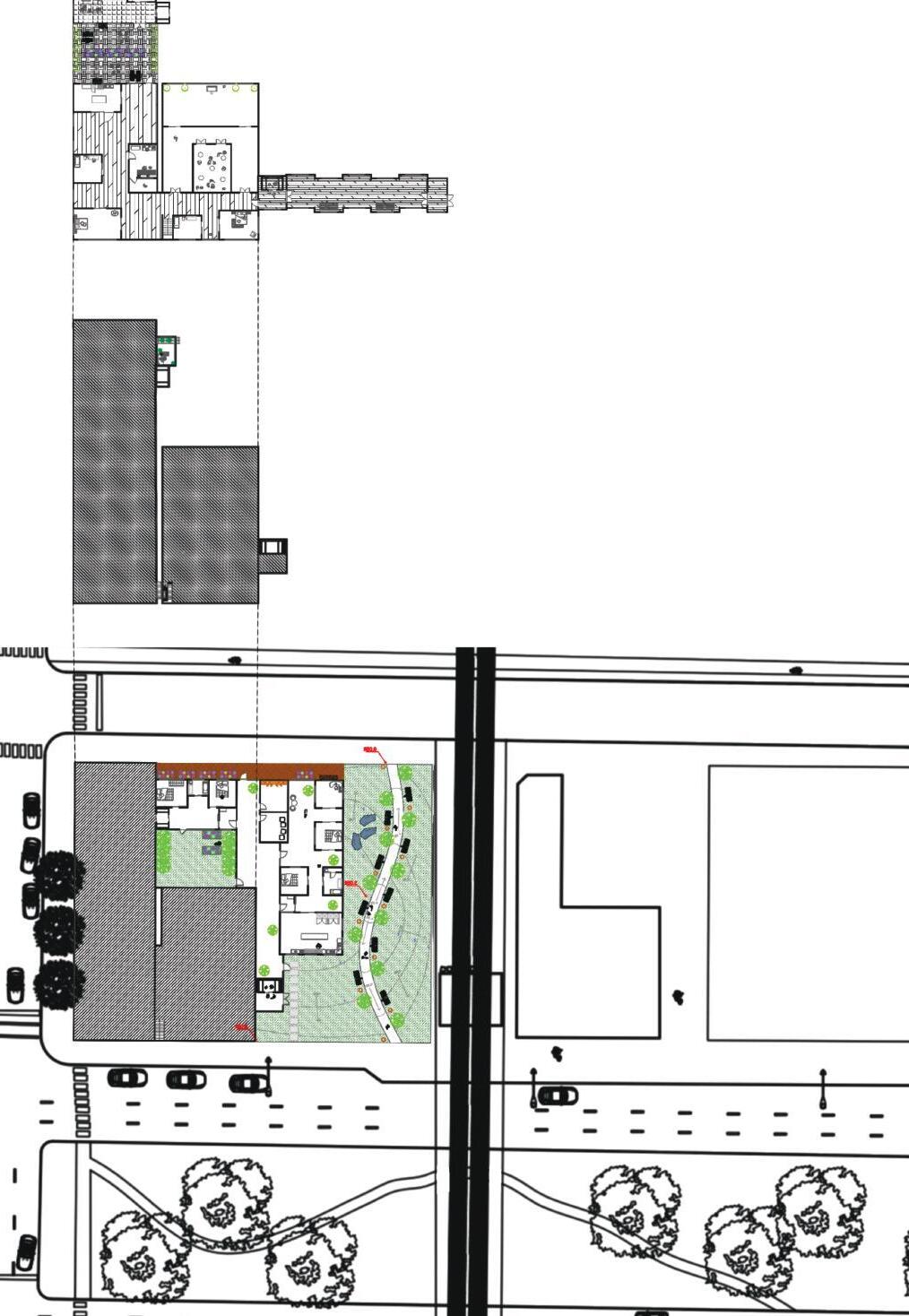

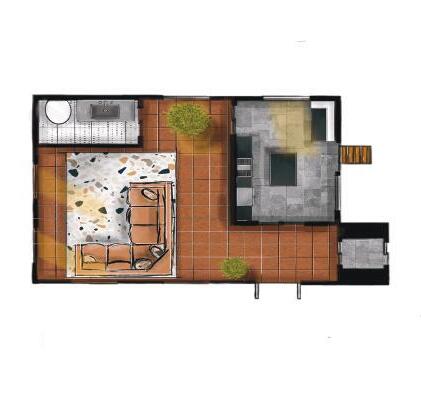

Utilizing an existing residency program for artists and business owners at the “Arts Block” on the corner of Garfield Boulevard and Prairie Avenue in Washington Park, the development seeks to explore a residence for the artists by building upon existing structure and making use of an adjacent vacant lot.

01

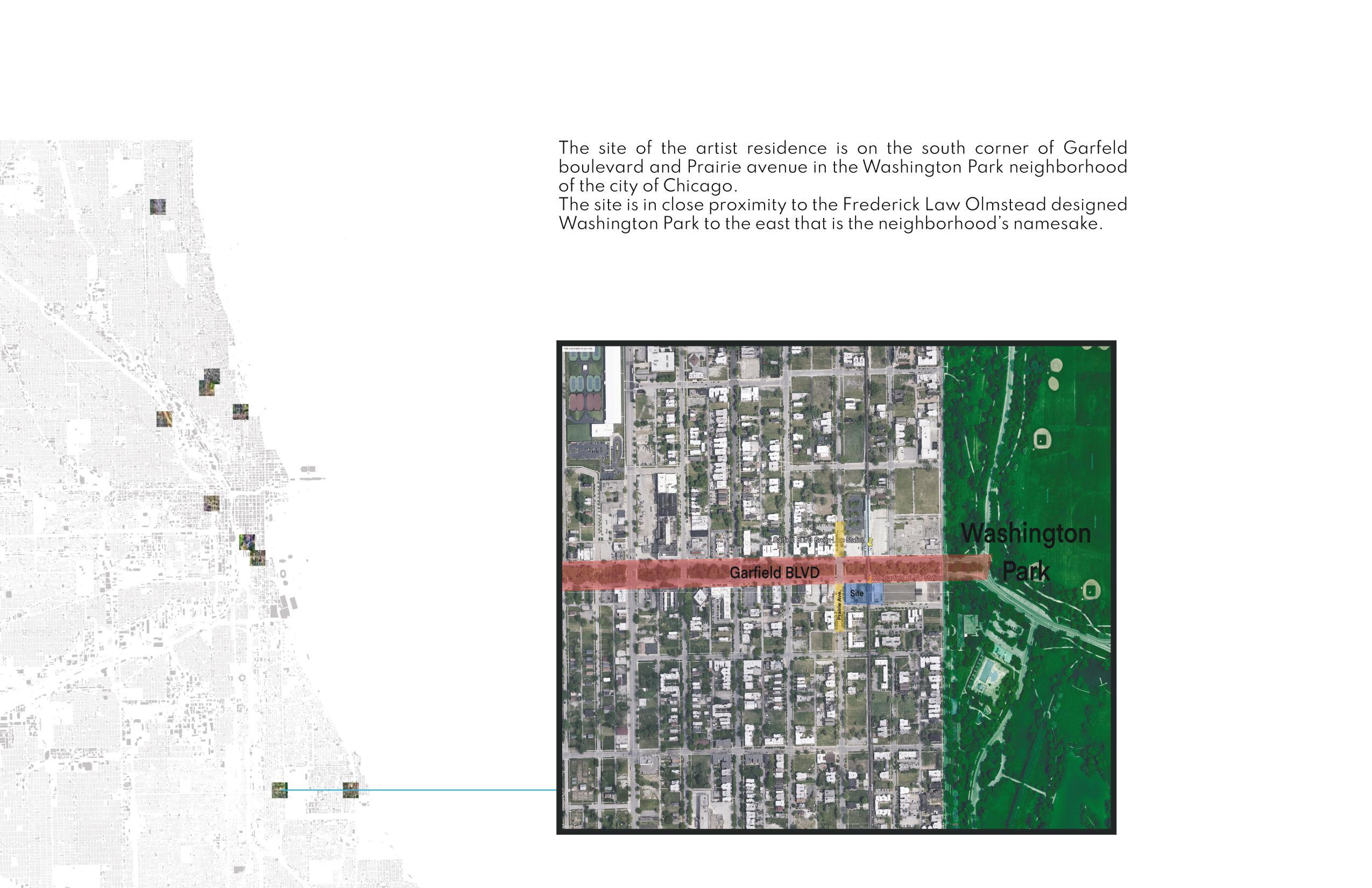

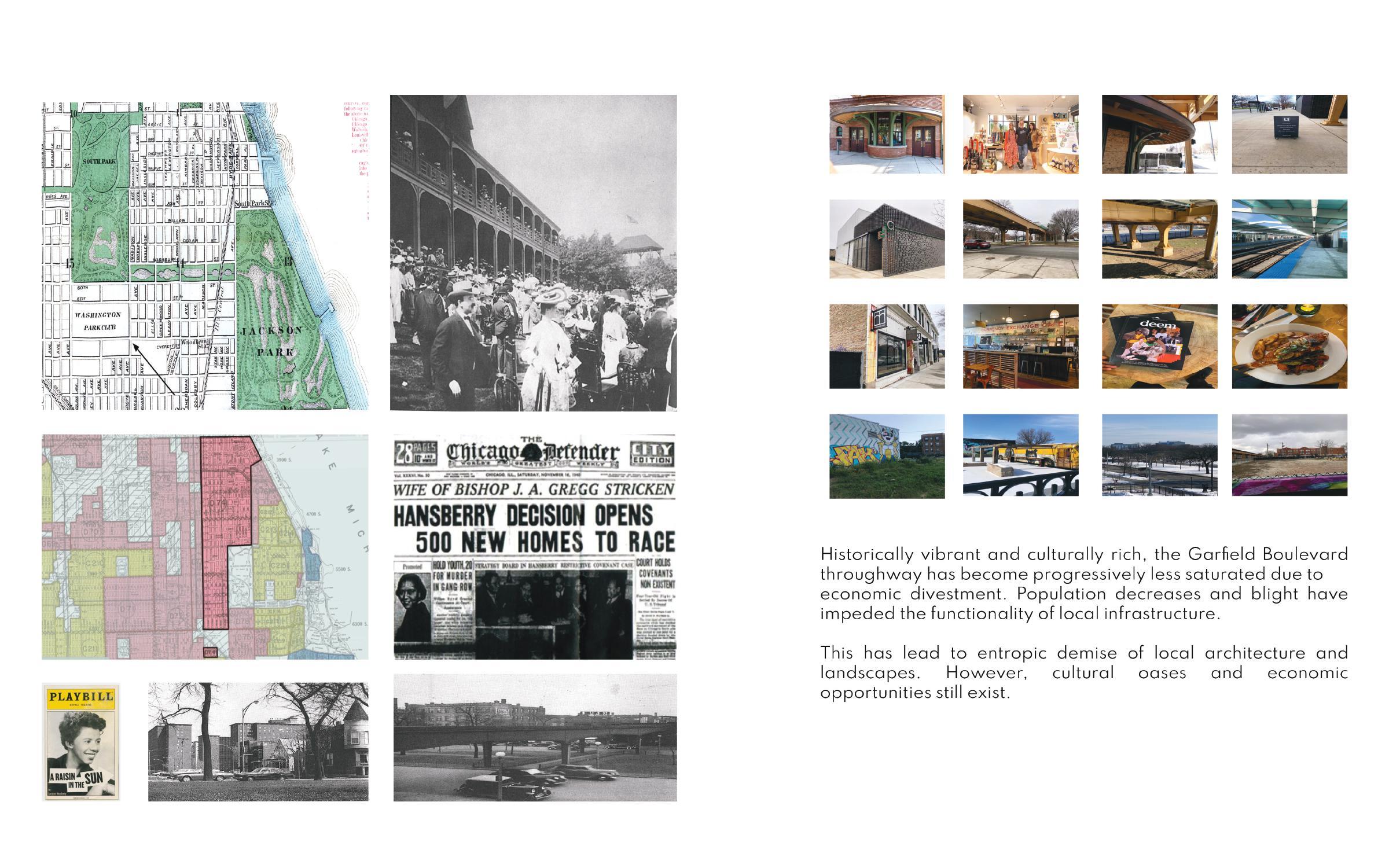

The site of the artist residence is on the south corner of Garfield boulevard and Prairie avenue in the Washinton Park neighborhood of the city of Chicago. The site is in close proximity to the Frederick Law Olmsted designed Washington Park to the east that is the neighborhood’s namesake.

Ground Floor 1st Floor 2nd Floor 3.05ft 0.05ft 0.05ft

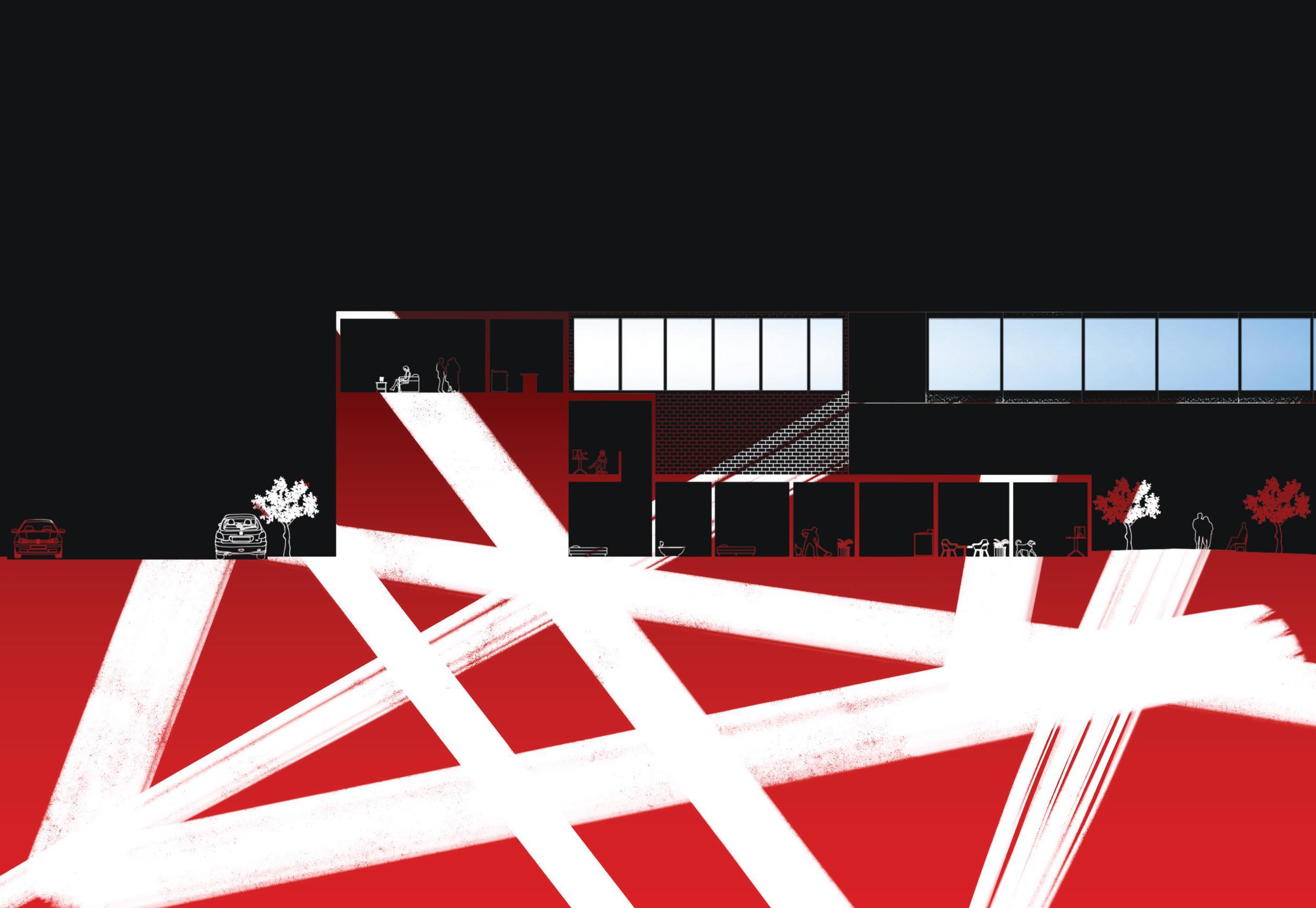

A Place For healing

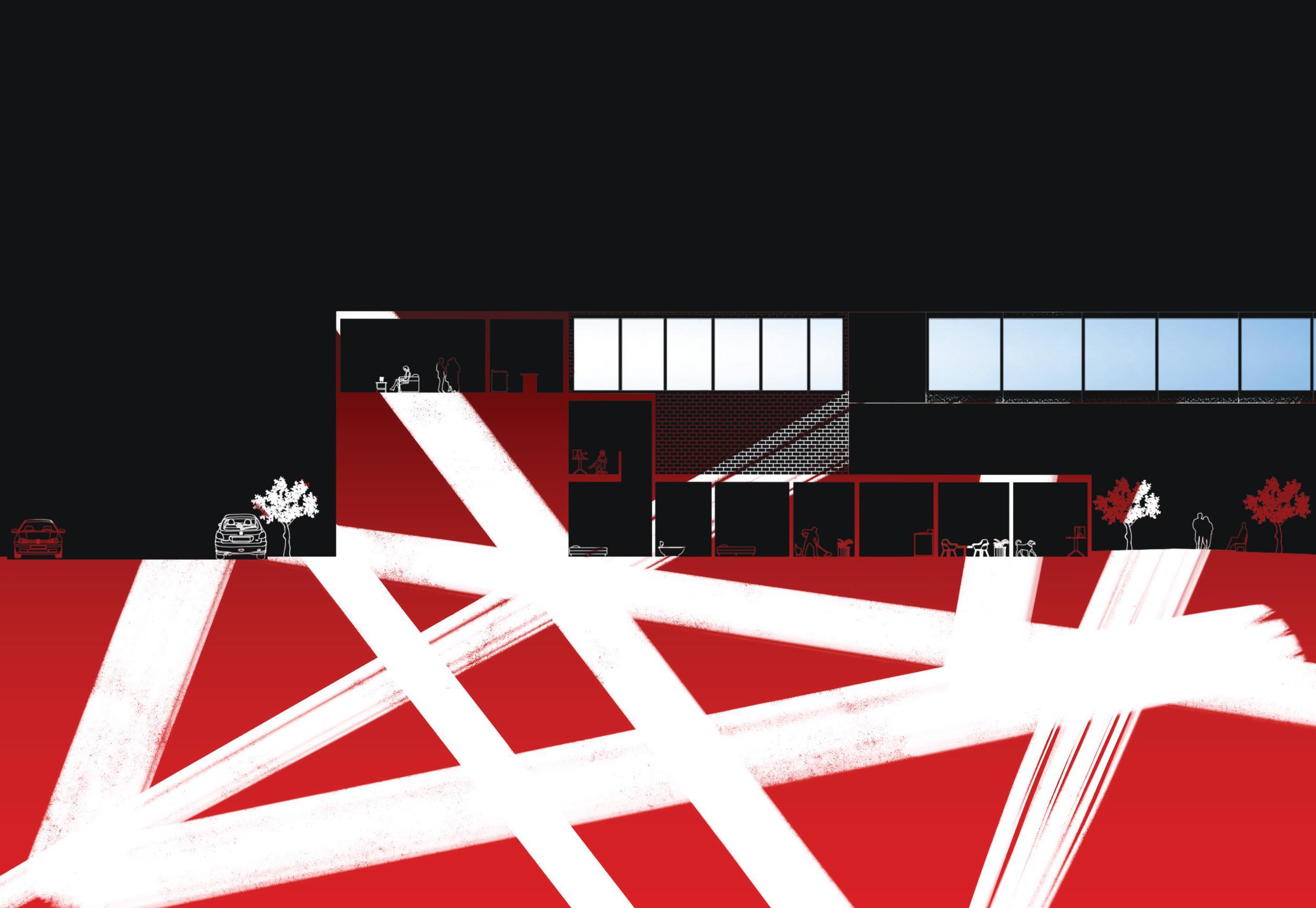

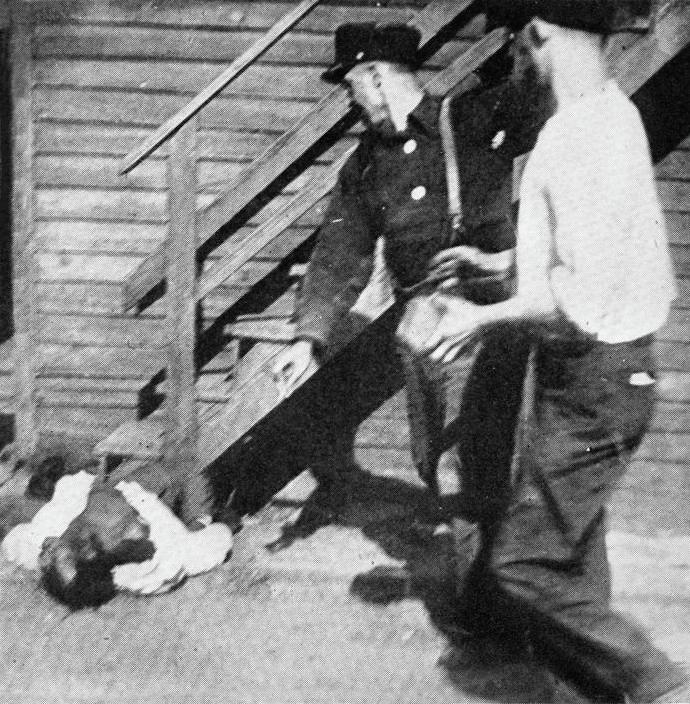

In the year 1919 race riots swept through the United States. This period of racial strife would come to be known as the Red Summer because of the sheer amount of violence committed in the name of racial discrimination.

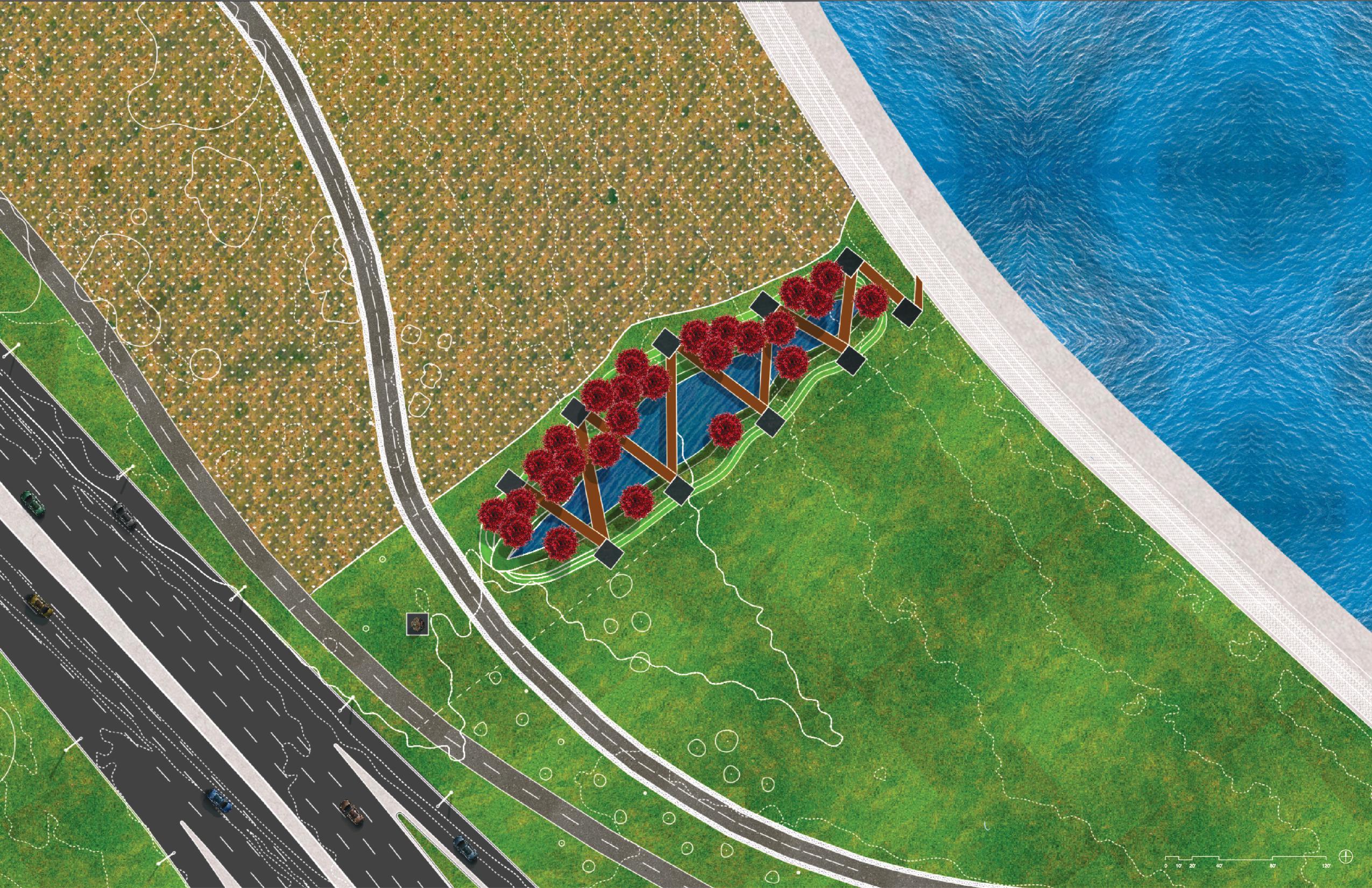

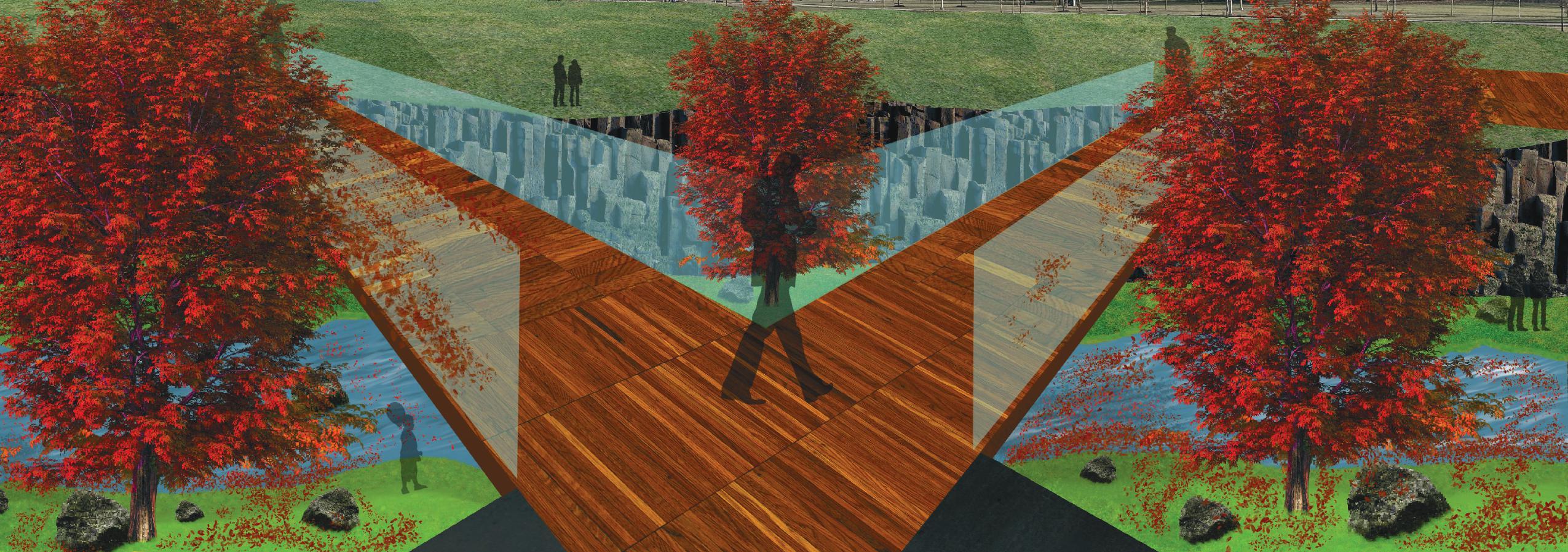

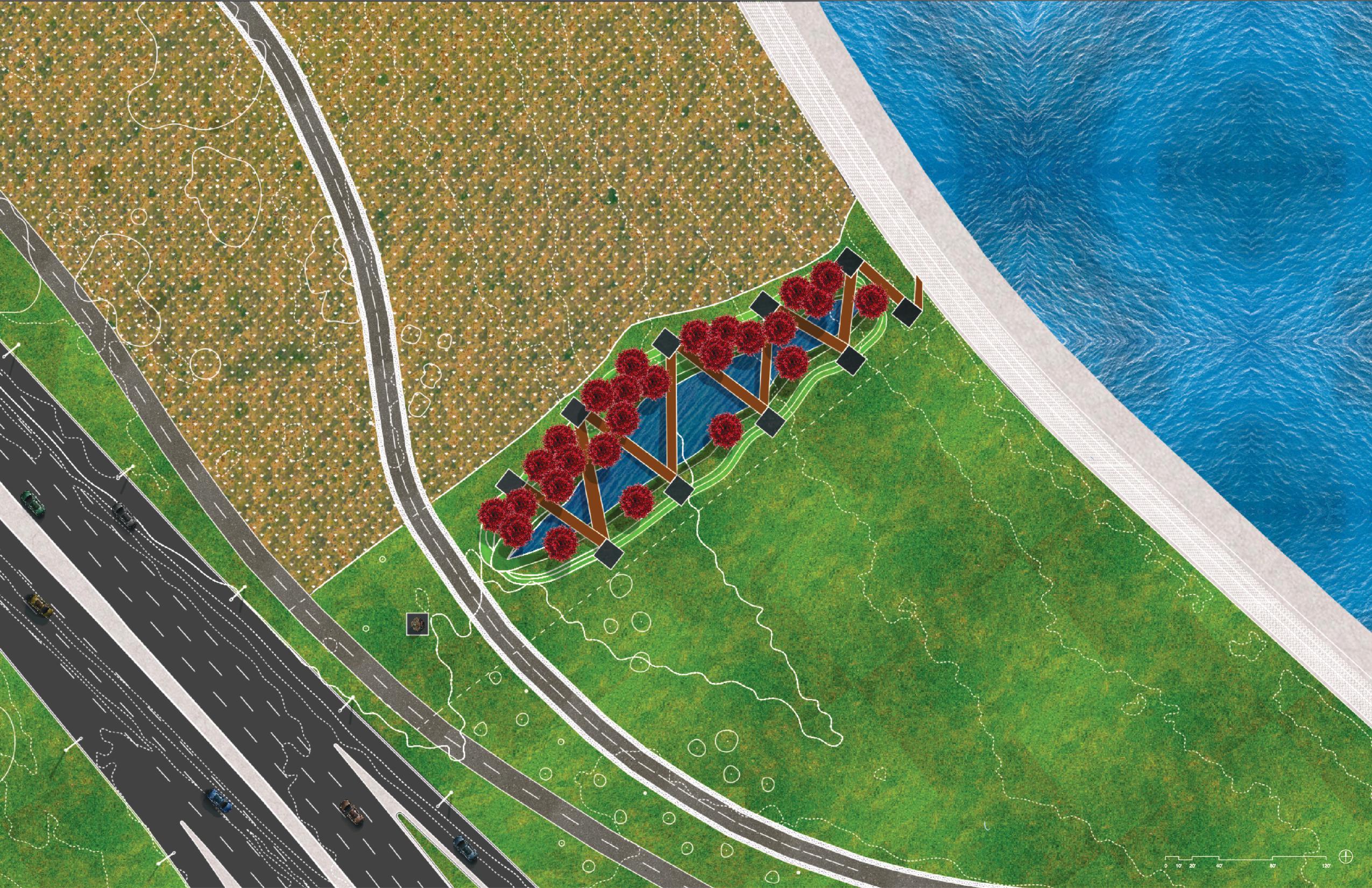

During the Red Summer race riots made it into Chicago when a black male Eugene Williams floated onto the white side of a racially segregated beach. In retaliation white beach goers began throwing stones at Willams when one struck him and he drowned in the lake. This site intervention is in memory of Eugene Williams. The goal is to give people to the opportunity to heal from the scars created from racism.

02

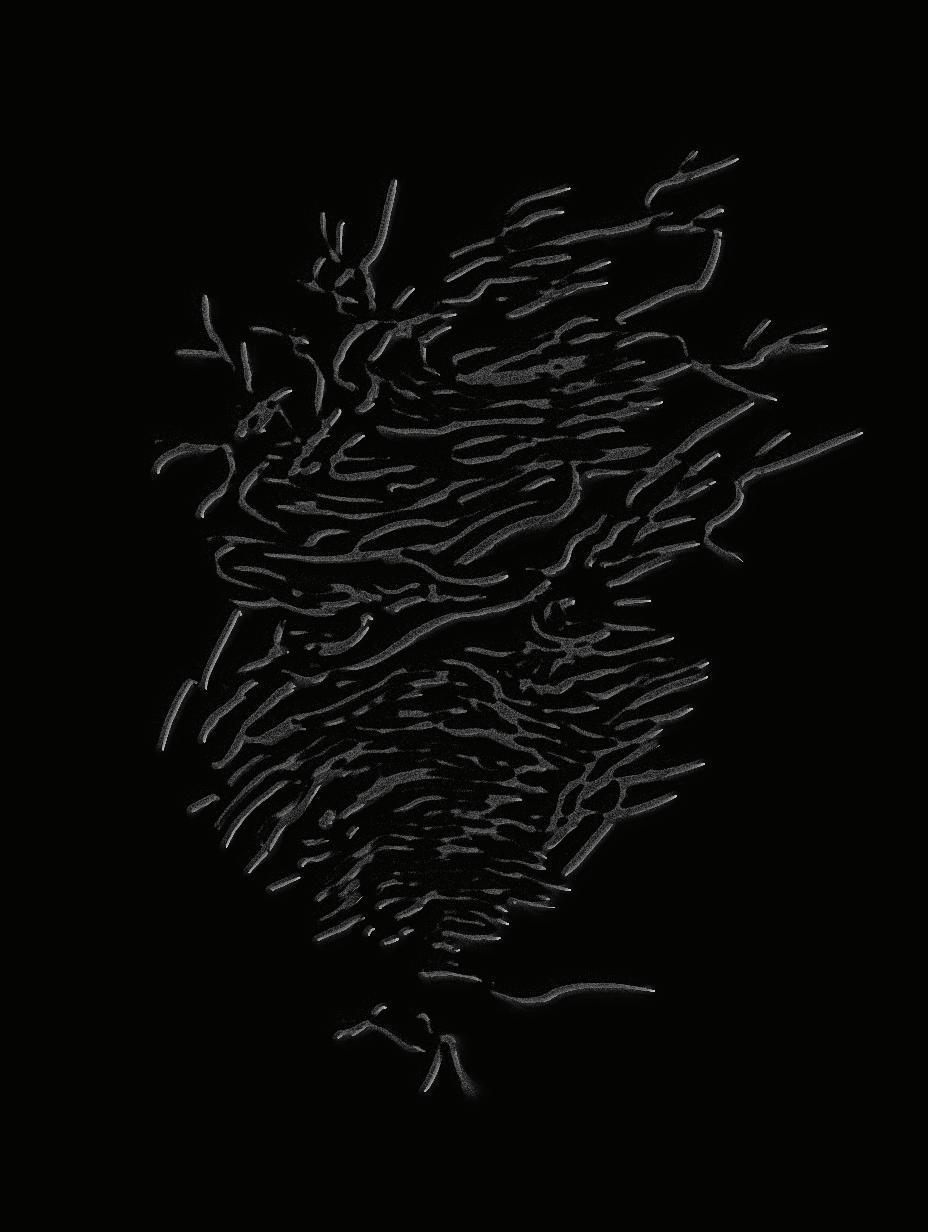

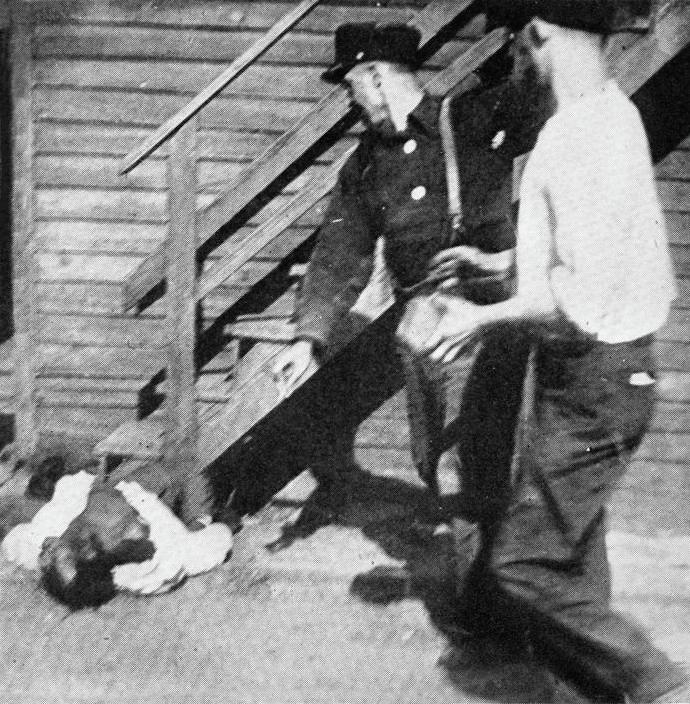

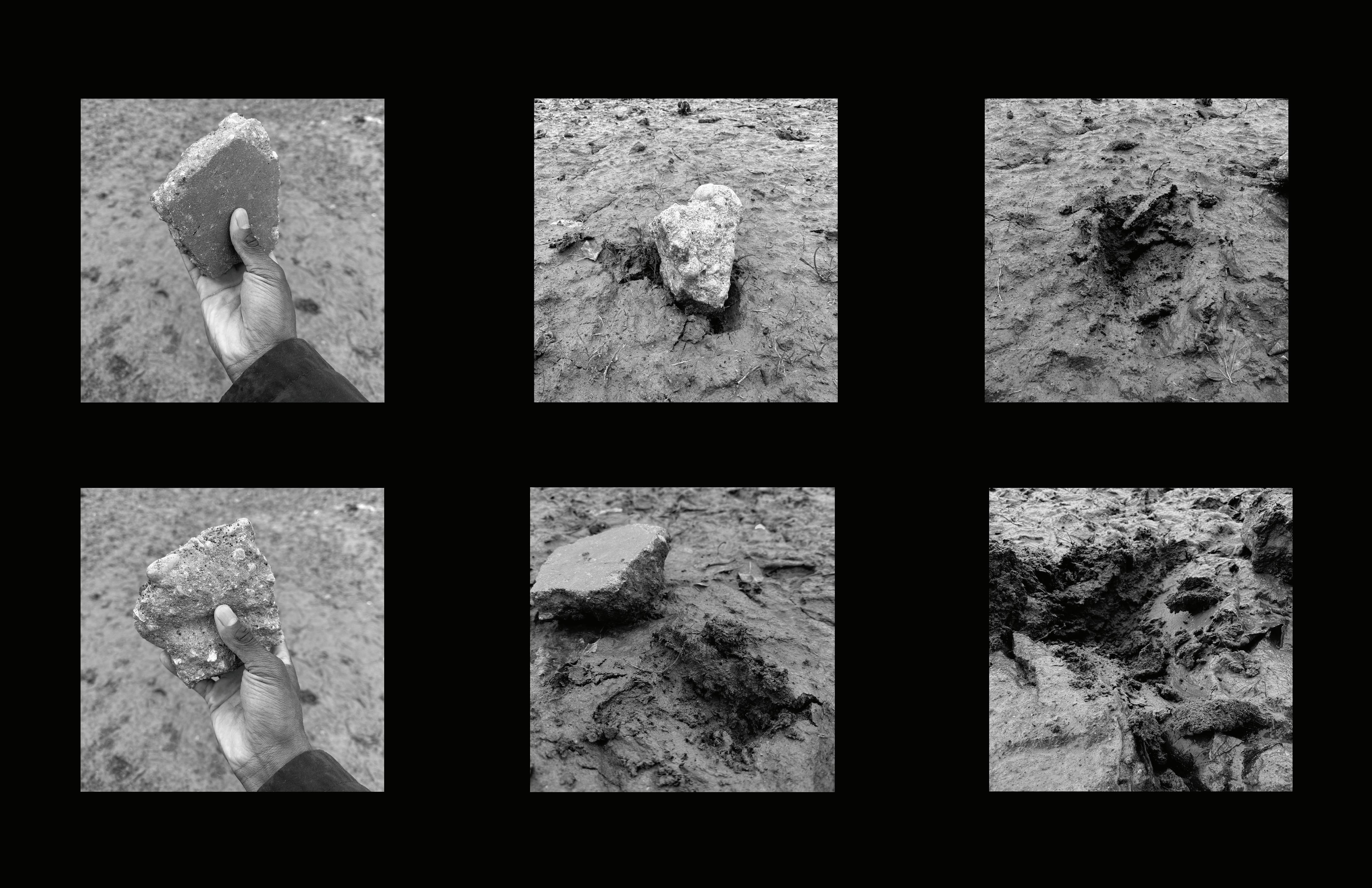

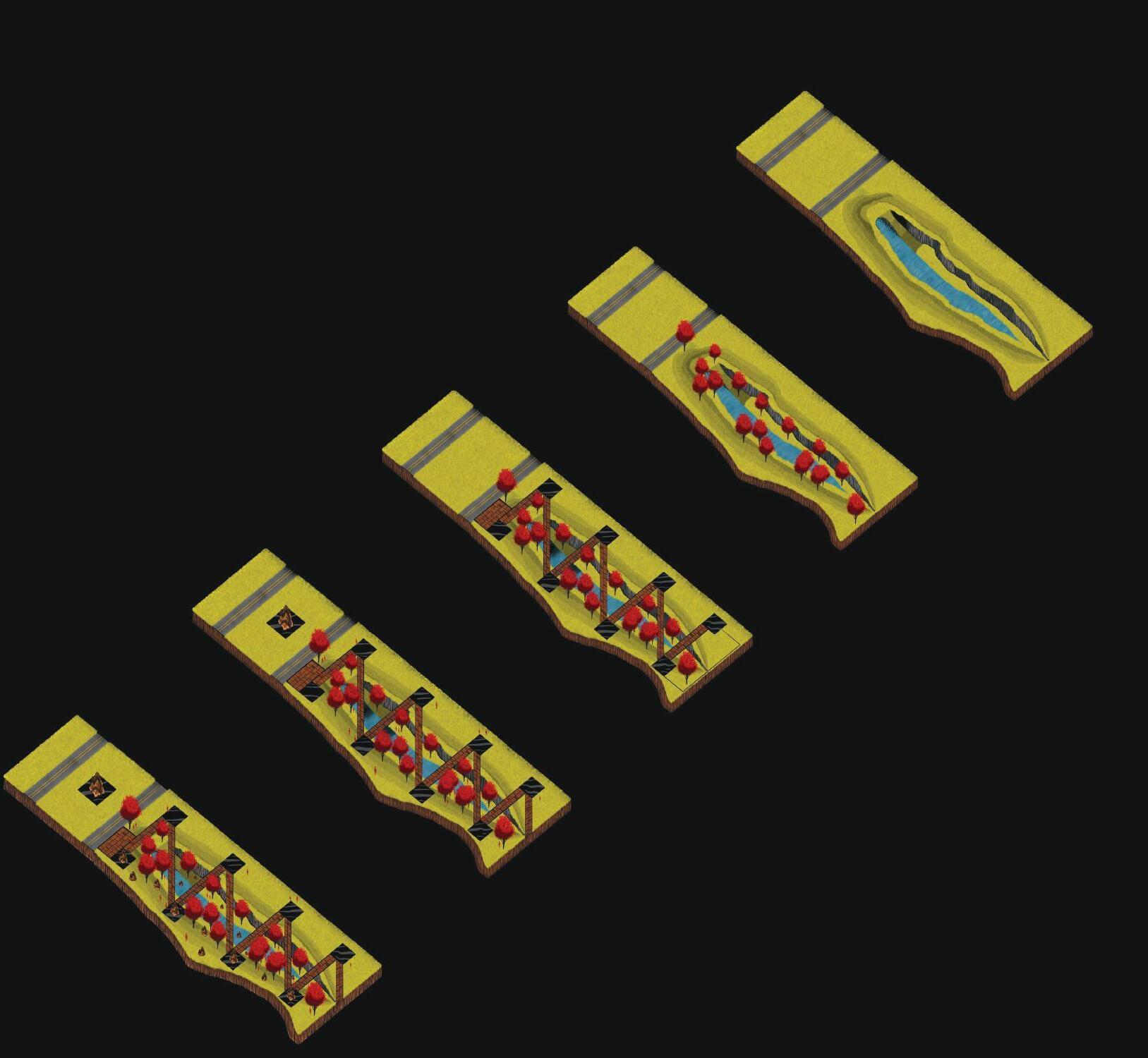

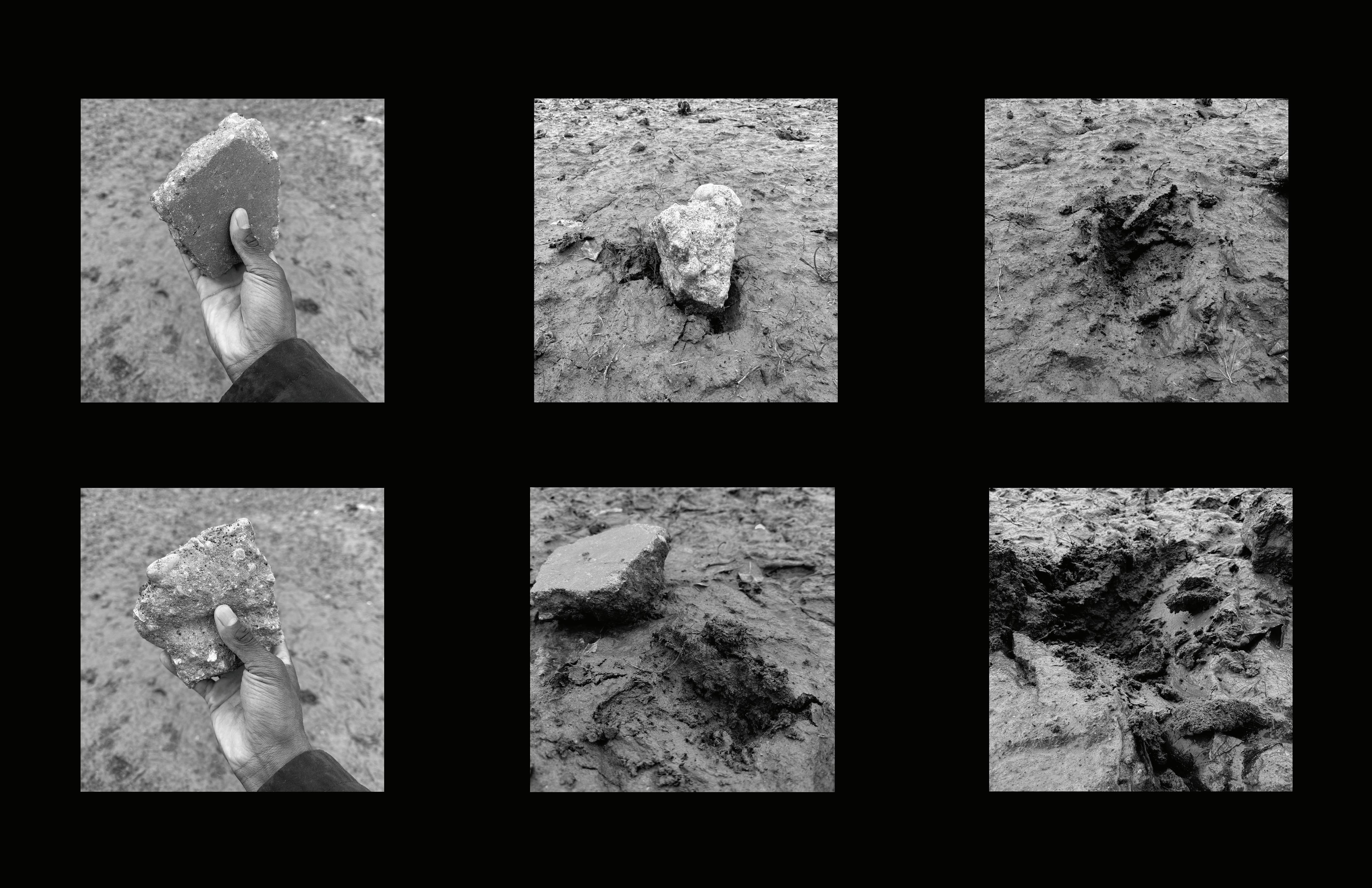

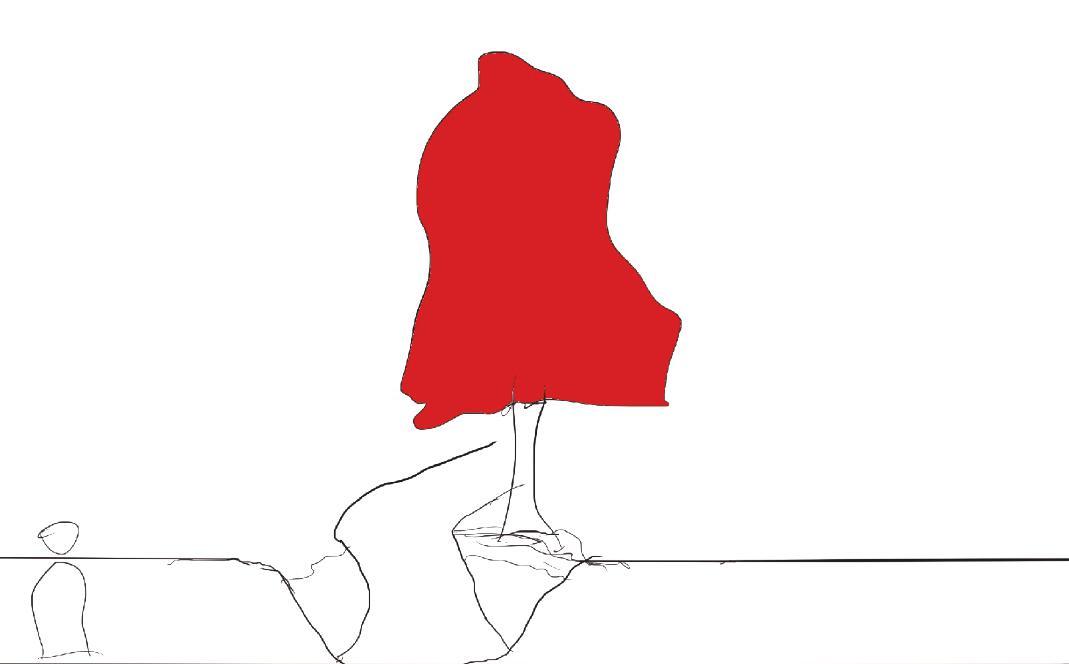

Image of African American Male, being stoned by white rioter during the 1919 Chicago Race Riots informs process of casting stones into the earth in order to visualize my design.

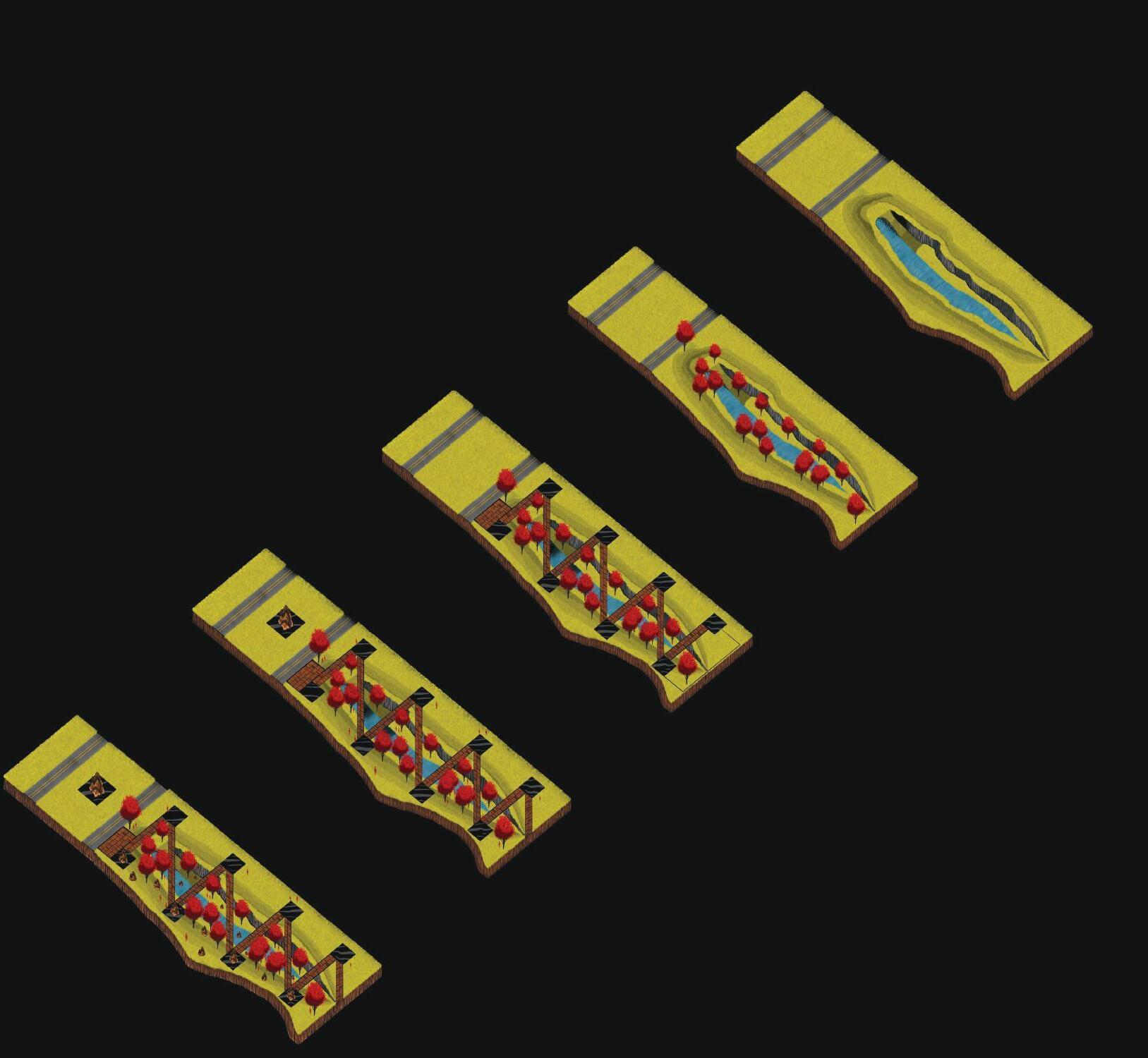

As the site develops new elements appear that act as reminders of the violence of the Chicago riots and symbolize the process of healing from ruin.

Stone carving into the earth forms the basis of this design.

The scar that heals. over time.

Stone carving into the earth forms the basis of this design.

The scar that heals. over time.

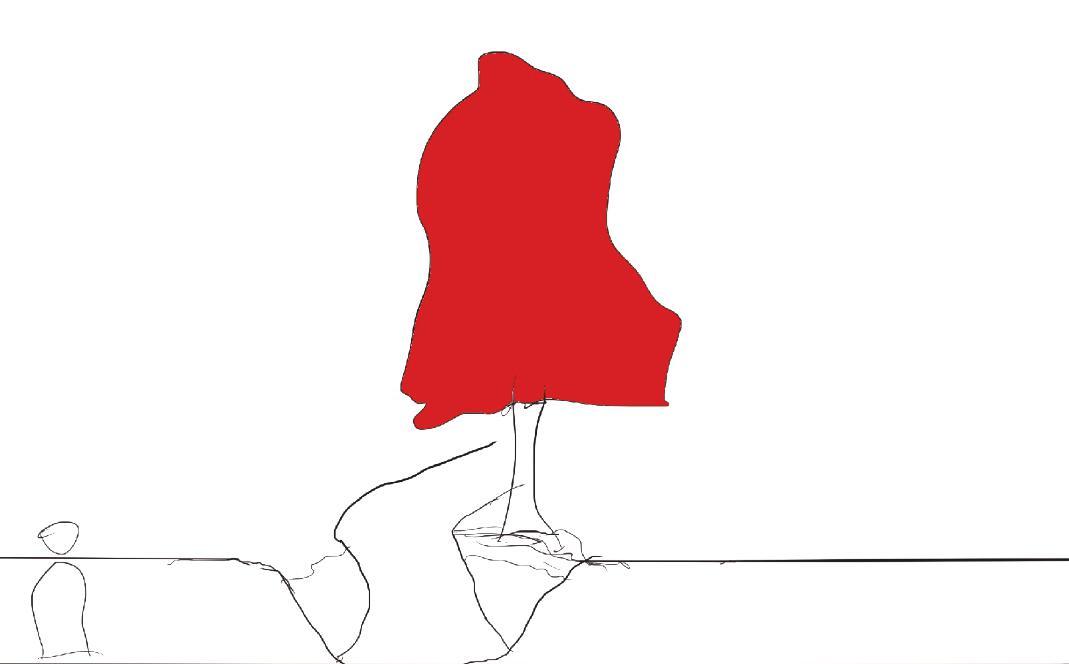

Summer Red Maple Acer Rubrum

The Summer Red Maple is a wonderful shade tree, with an ever changing display of purple-red leaves all season. In spring it is completely covered in glossy, deepred new leaves, and in summer the new leaves on every branch are burgundy red, while the older leaves become a rich dark green. This tree selection is symbolic of the red summer of 1919. The deep red color is representative of the blood shed during this fateful summer.

03

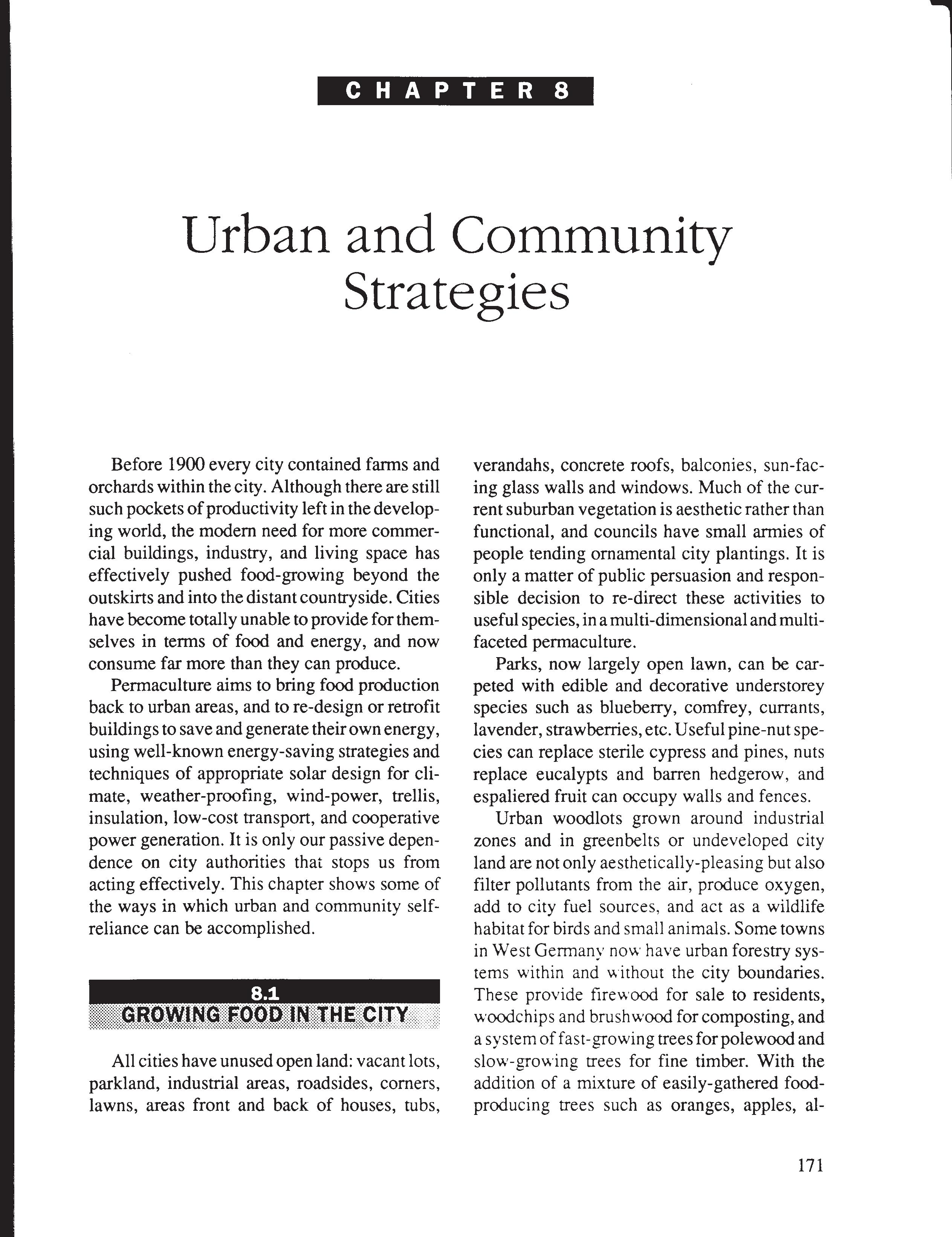

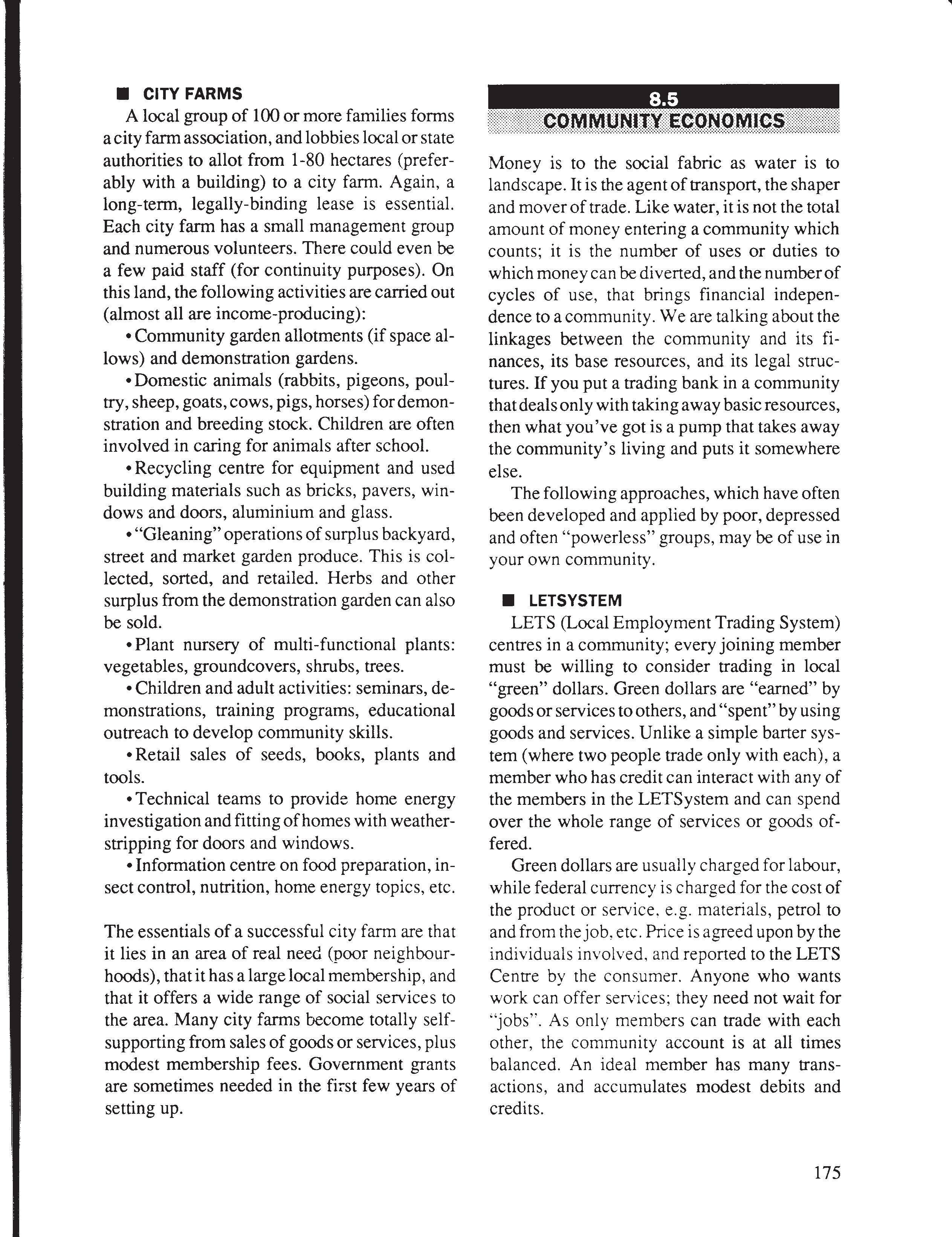

A Place for community

Building on the mission of the El Paseo Community Garden in Pilsen Chicago, this site interventions centered on the 0.4 acre lot recently acquired by NeighborSpace for expansion of the garden.

Community informed design project.

Community informed design project.

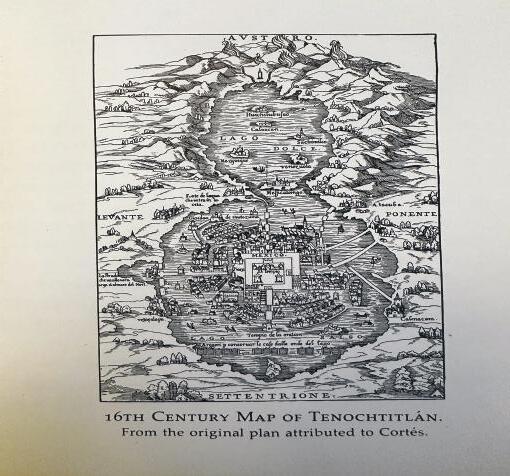

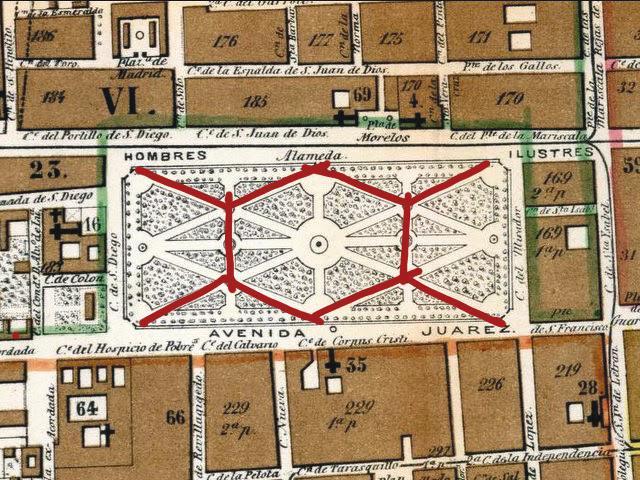

This site being in Pilsen, Chicago a predominantly Latino neighborhood. I wanted to draw on latino design for references.

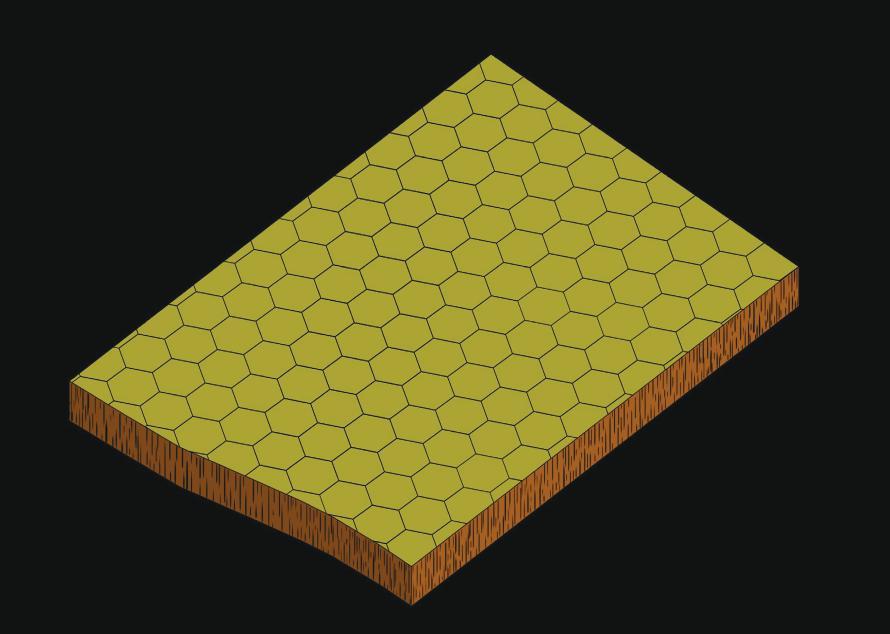

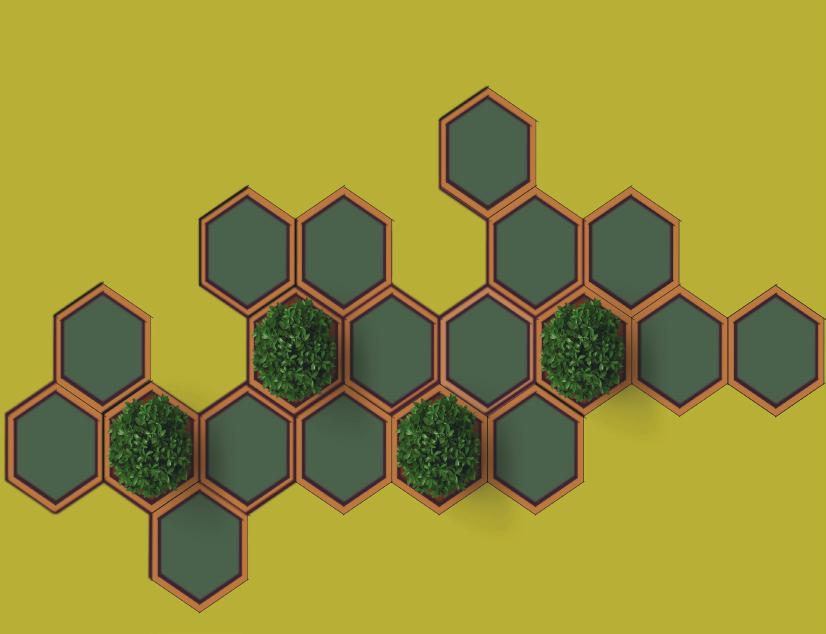

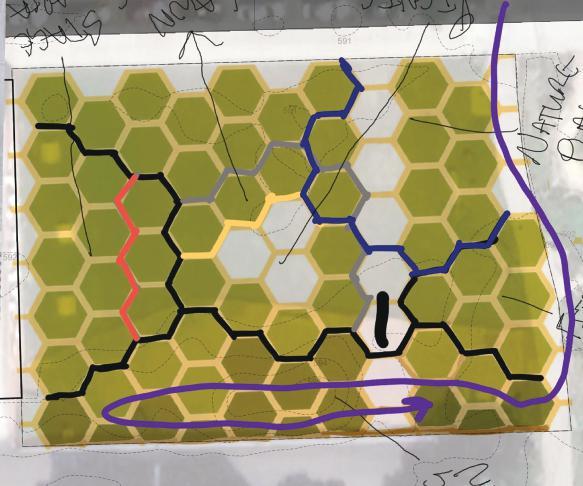

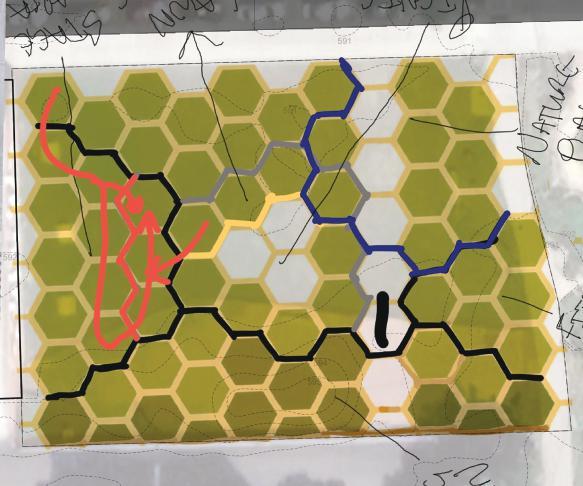

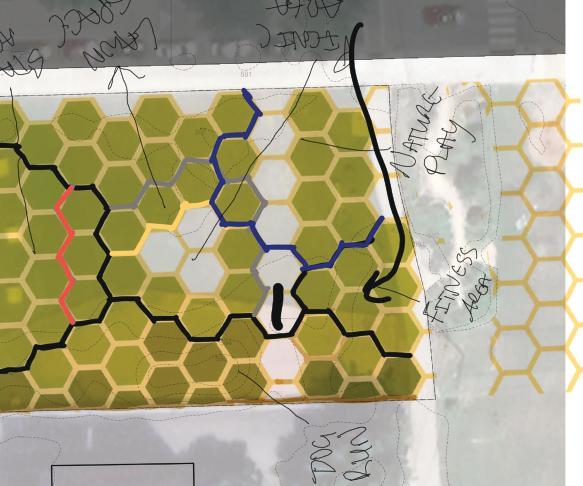

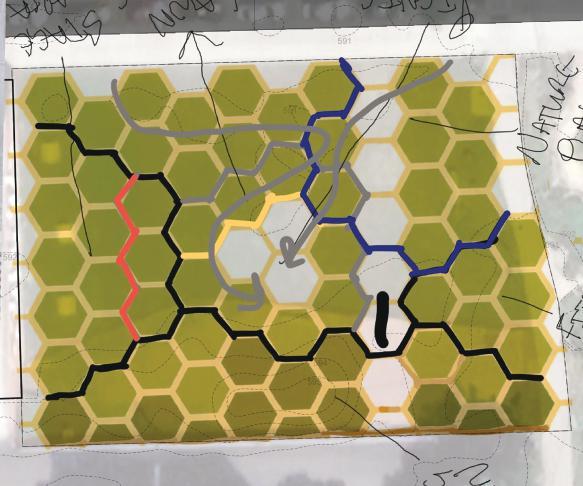

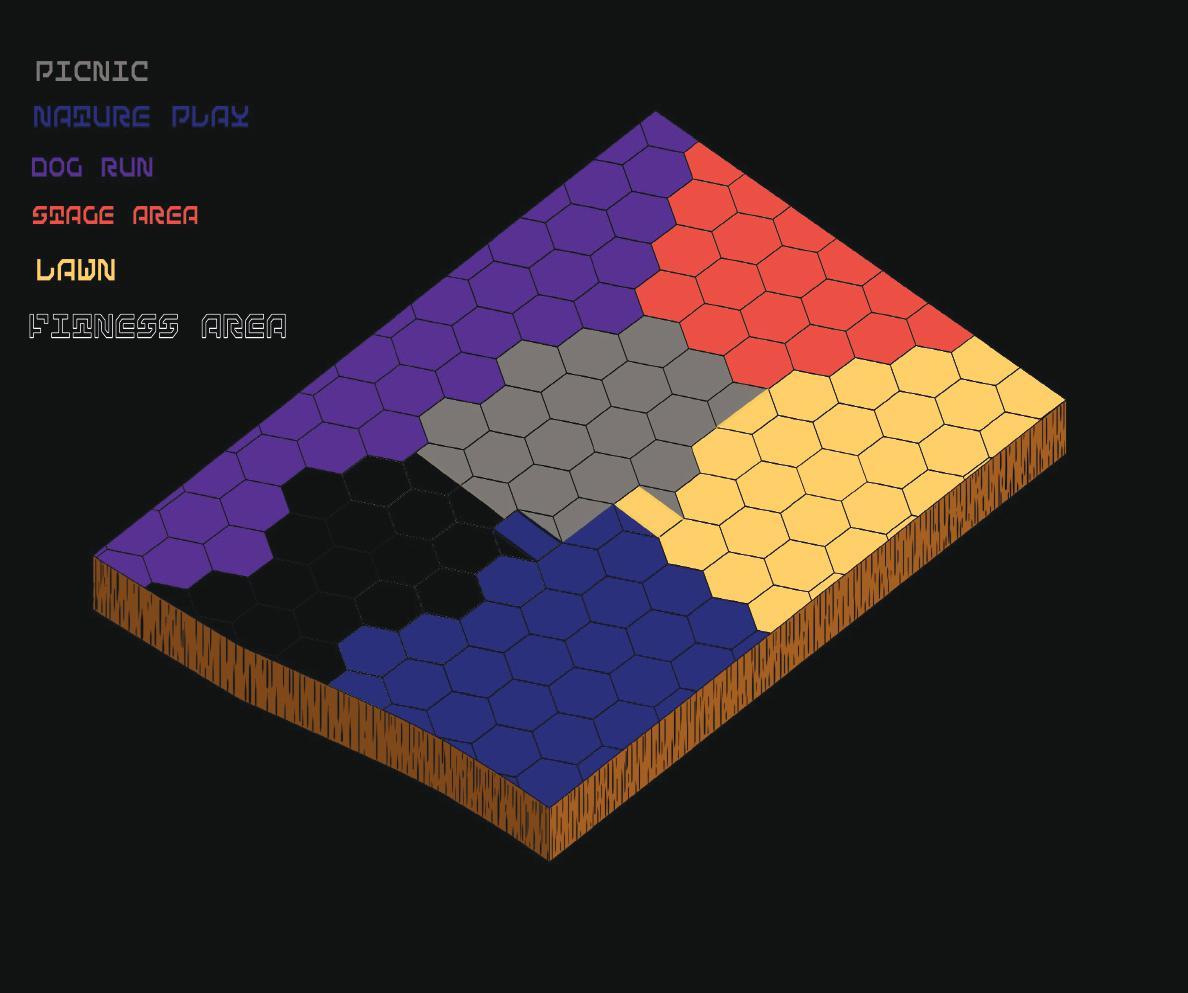

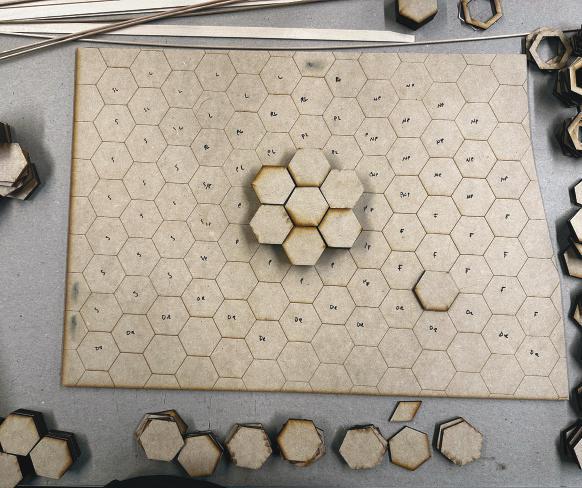

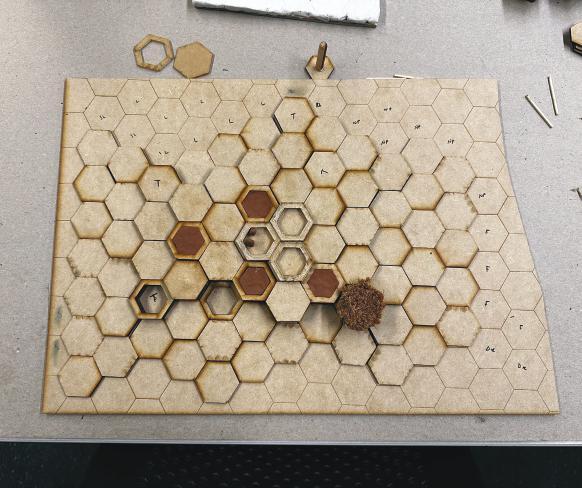

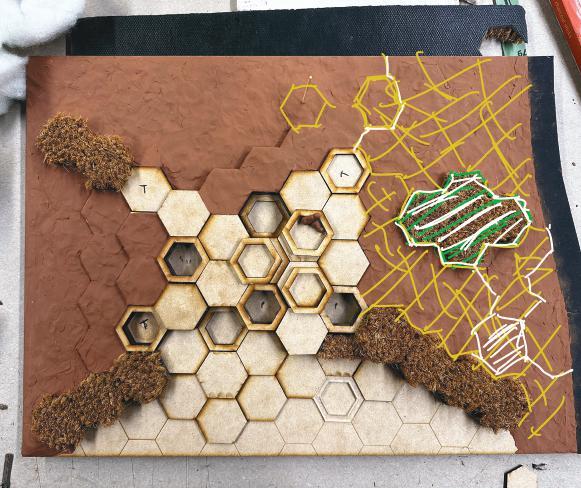

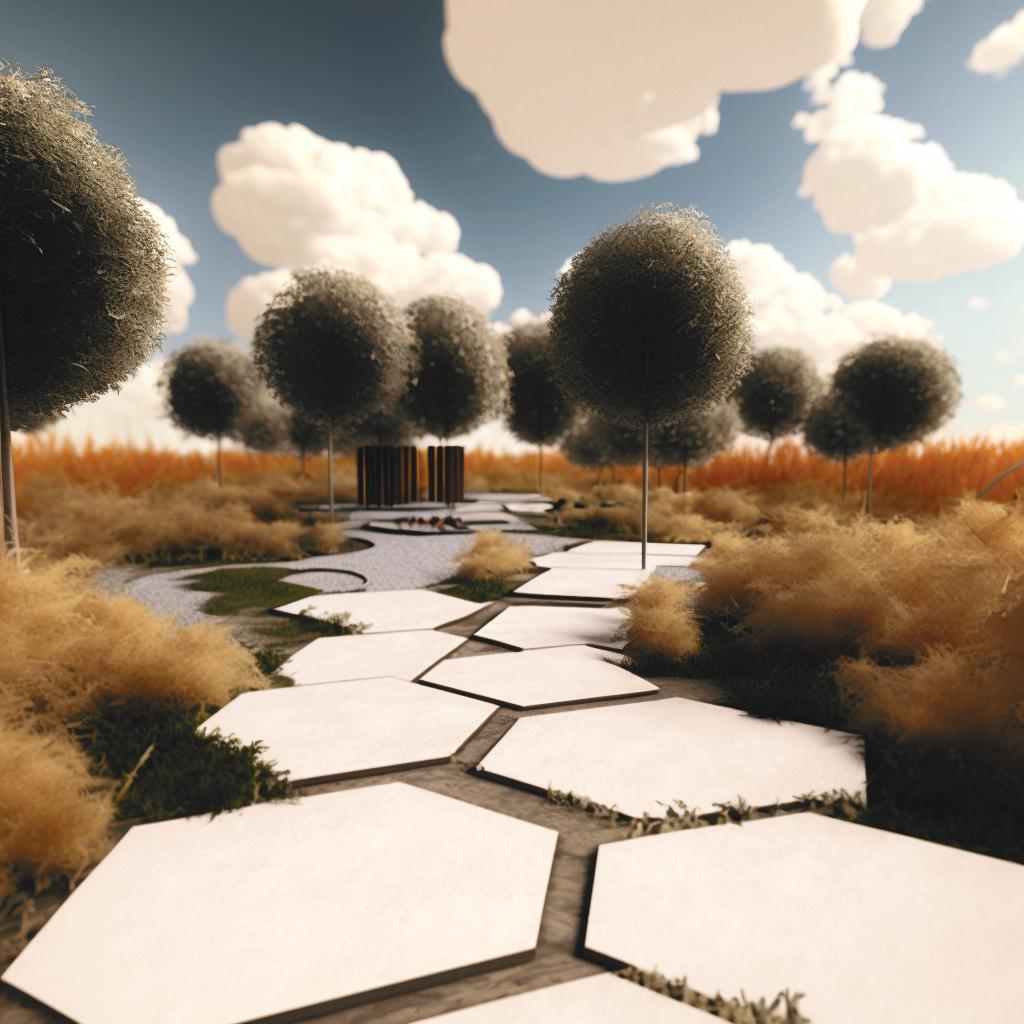

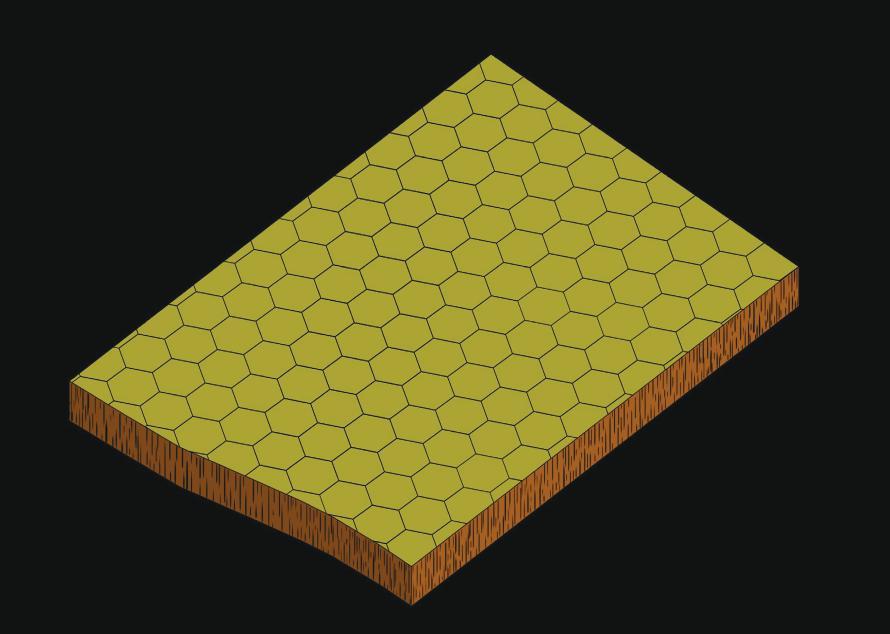

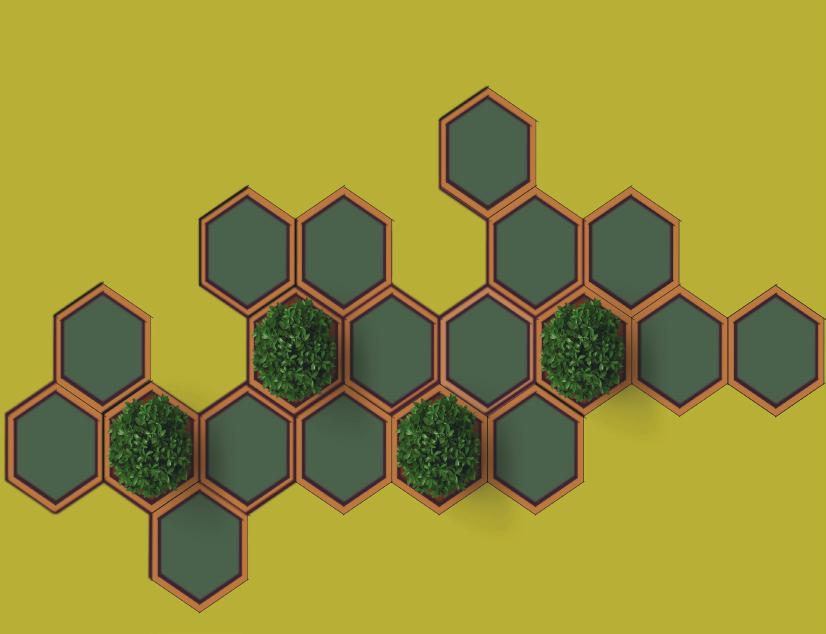

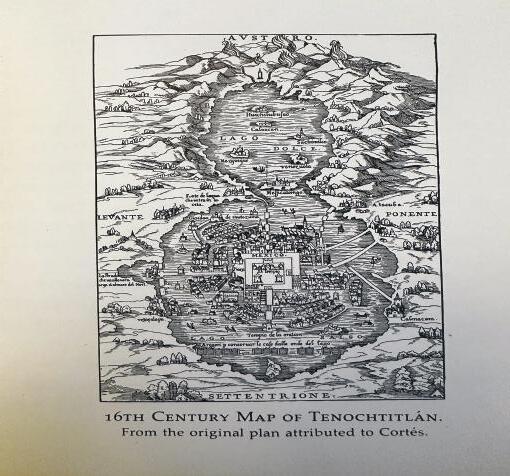

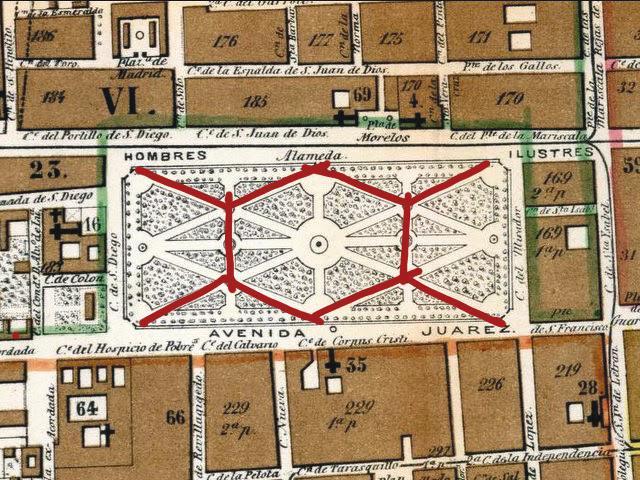

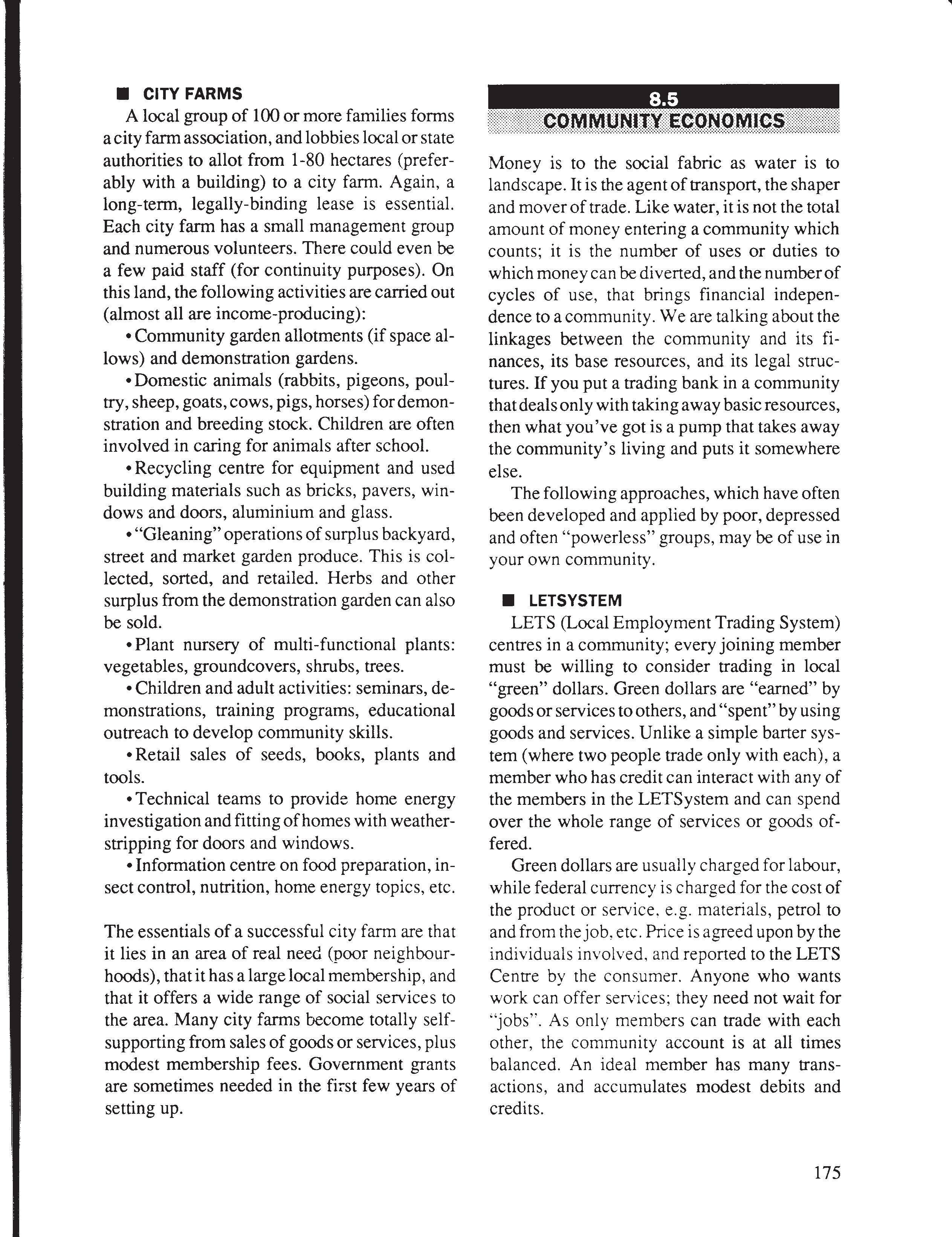

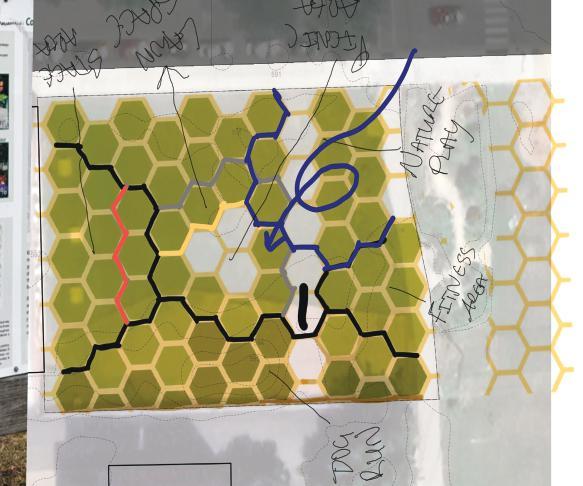

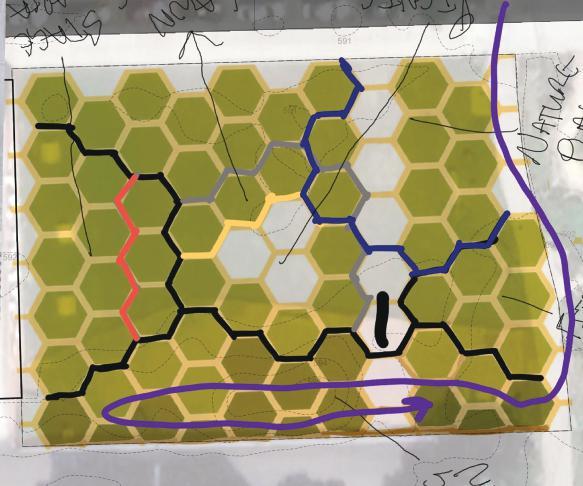

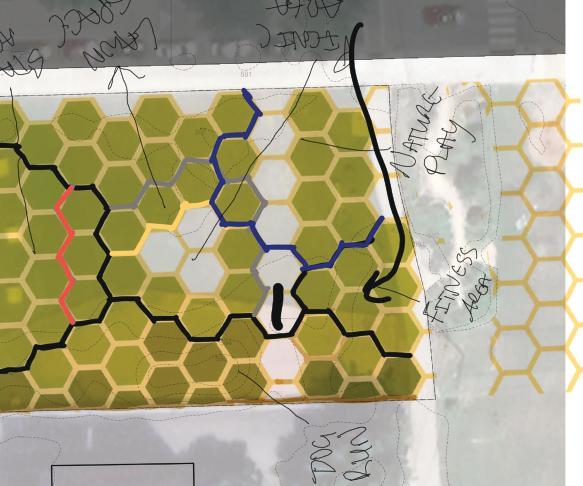

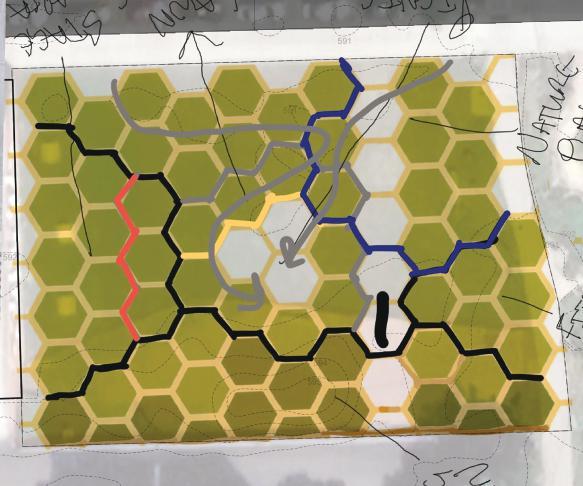

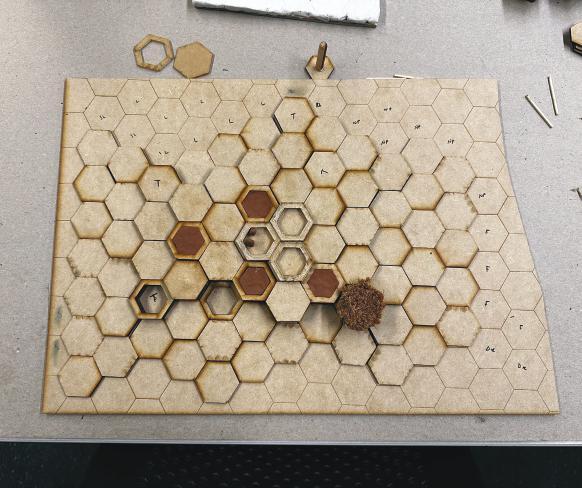

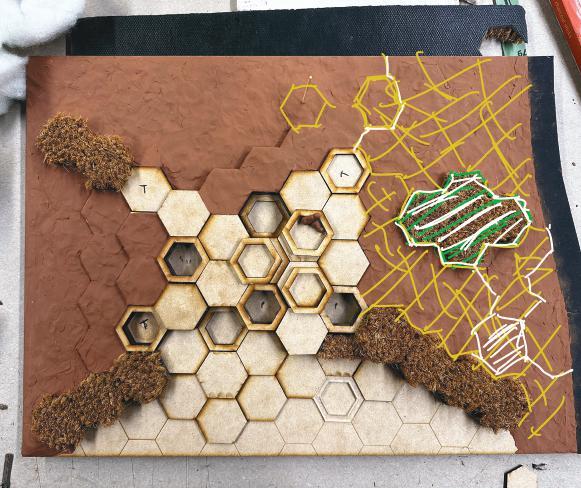

Reoccuring hexagonal patterns throughout the site and among references determined my decision to go with a hexagonal lay out.

EL Paseo Bee Hive outdoor classroom. Program requests by communnity members. Cortes Map of Tenochtitlan. (Now Mexico City) Plan of Alameda Park Mexico City.

EL Paseo Bee Hive outdoor classroom. Program requests by communnity members. Cortes Map of Tenochtitlan. (Now Mexico City) Plan of Alameda Park Mexico City.

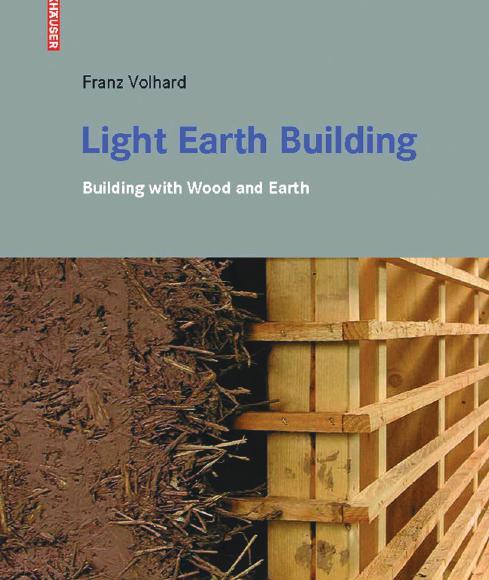

Two books informed my design decisions. It was important to me that because this was a community ran space that my design was able to be built by the community. Using light earth building, structures could be produced by the community to shape the landscape.

34 Light Earth Building straddling in a saddle-like manner, before being smoothed over. In the case of stakes, horizontal timber stakes are wedged into notches in the vertical studs. Once the timber frame, including the floors, has been fitted with stakes, the stakes are either wrapped in place with straw-clay mix, or taken out panel for panel, and then reinserted in alternating layers of straw-clay and stake. The surface is then smoothed over or plastered with a layer of finer straw-clay. Vertical stakes wedged between horizontal Fig. 29 Fibre-clay plaster mortar with chopped straw, prepared as naturally-moist mix Fig. 31 Section through moulded earth brick made of fibre-clay Fig. 30 Straw-clay, made with bale straw Fig. 32 Straw-clay, dry ready-mix formulation

größte Schluffpartikel 60 Mikron 0,06 mm 210-02 CAD kleinste Schluffpartikel Mikron 0,002 mm kleinste Tonpartikel Mikron 0,001 mm Sandkorn 1 mm 210-03 a� �reiig, fl�ssig �� plastisch c� fest 42 Light Earth Building Fig. 43 Consistency of clay particles depending on water content [Hamer 1975 Fig. 42 Grain sizes in comparison (after Piltingsrud) The processing of earth prior to construction serves to distribute the water added to or already within the material as evenly as possible so that the lamellae of the clay molecules are better aligned and form stronger bond. Earth prepared in a wet or fluid state will therefore be of greater strength than earth used in its naturally-moist state. As the mixing water evaporates into the surrounding air, the volume of the earth mass decreases. The more water added and the higher the proportion of clay in the mix, the greater the degree of shrinkage. A clay-rich earth has a larger internal surface area and can absorb more water than lean mass of the same consistency. To reduce the degree of shrinkage to tolerable level to prevent crack formation, earth is blended with aggregates to make the mass leaner for building purposes. The quantity of aggregate required depends on the cohesion of the earth used. Light earth materials have a high proportion of lightweight aggregates or fibres that serve to both lean and stabilise the mixture Grain of sand 1 mm solid Largest silt particle 60 microns 06 mm Smallest silt particle microns 002 mm Smallest clay particle micron 0 001 a) semi-liquid, liquid b) malleable Planning and costs 197 by making a series of test cubes using mould that can be assembled and disassembled as detailed in the [Lehmbau Regeln 2009]. The mould should not be too small: its edge lengths should correspond to the wall thickness or the length of the chopped pieces of straw. Several test cubes are made of the same mixture and compaction used for the building construction. The test cubes are labelled and dried at 60° to 80°C until their dry weight remains constant. The bulk density is determined by the mean value of the test cubes as follows: Bulk density = Dry weight / Volume [kg/dm or [kg/m 740 Design, specification and construction supervision The importance of keeping the construction and architectural design as simple and efficient as possible is often underestimated out of a lack of experience. Clients and architects should conduct research and where necessary consult an expert or contractor. Building with earth is much quicker, simpler and cost-effective when the design and construction has been carefully thought through. Using product information sheets, working recommendations and by consulting the manufacturer, earth building materials can be incorporated into the typical practice of design and construction. Manufacturers, contractors and publishers provide specifications and typical costs that one can refer to when drawing up a specification, tendering and calculating costs based on bills of quantities. A suitably experienced expert in the field of earth building should be appointed to supervise construction work. 750 Self-building With appropriate instruction and supervision, earth building techniques are easy to learn and not excessively labour intensive. Laypeople, helpers, friends, and entire families can contribute to the building process. Working with earth is a satisfying experience and can make the construction process an unforgettable experience. Earth differs from many other materials in that dries slowly rather than curing. The workability can therefore be prolonged as desired, again and again if necessary. Dry or unused material is easily re-used. The material is kind to one’s hands, and not caustic like lime or cement. Equipment, machinery and soiled building elements can be easily cleaned with water. All these characteristics make earth building materials ideal for self-building. The use of prefabricated building materials obviates the need for laborious mixing and processing, simplifies organisation and makes for a cleaner building site. Instructions are provided with factory-made building materials to ensure proper use. Earth building therefore represents an opportunity for clients to save money by contributing their own labour: a contractor provides the equipment, machinery and materials as well as a degree of instruction. The clients then undertake the manual work themselves to save money. Such models are likely to gain popularity and contractors will begin to adapt their services to meet this demand. 710-01 CAD Planning and costs 187 700 Planning and costs 710 Construction period The timber frame construction should be completed in spring and the roof covered, including gutters and downpipes. For as long as the walls of the construction are open, roof sheathing is advisable to prevent updrafts during storms from dislodging the roofing material. All other work can then take place without being interrupted by bad weather. The side walls, at least those made of straw light earth, do not generally need extra protection during construction as the straw prevents surface erosion, except on the windward side, where protection against driving rain is advisable. When inserting light earth in a wet state, the construction period should begin as early as possible to ensure that the building can properly dry out and is ready to be plastered or rendered by autumn. 30 cm thick external walls of straw light earth take about two months to dry in summer, sometimes longer depending on the weather. Woodchip light earth dries out slightly more quickly. One should begin with the building elements that are least well ventilated (often internal walls) and finish with those more exposed to the sun. The drying period need not hinder further construction work, such as electrical installations and the installation of building services. All wet earth material, including plasters, must be able to dry out as quickly as possible. If these remain wet for extended periods, the organic constituents can rot and cause damage to adjoining timber elements, and mould can form on surfaces (see chapter 827). Ensuring good ventilation helps moisture to be transported out of the building by dry outdoor air as it passes over the surfaces of internal building elements. If this is not sufficient, additional forced drying using fan dryers can be used, especially in the cold season of the year, when the absolute air humidity is very low. The drying process should be monitored on regular basis by keeping drying protocol [Lehmbau Regeln 2009]. Dry bricks and panels can be laid at any time of year, using a hydraulic mortar frost is to be expected. It is often sensible to employ a combination of wet and dry construction methods, for example quick drying external walls as wet construction in spring, and dry bricks and panels for the internal walls, floors and ceilings during the rest of the year. Fig. 301 Construction periods Foundations, timber frame, roof covering Wet construction, compacted *) Brick and panel/slab manufacture Dry construction using bricks and panels/slabs Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec possible all-year-round with artificial forced drying

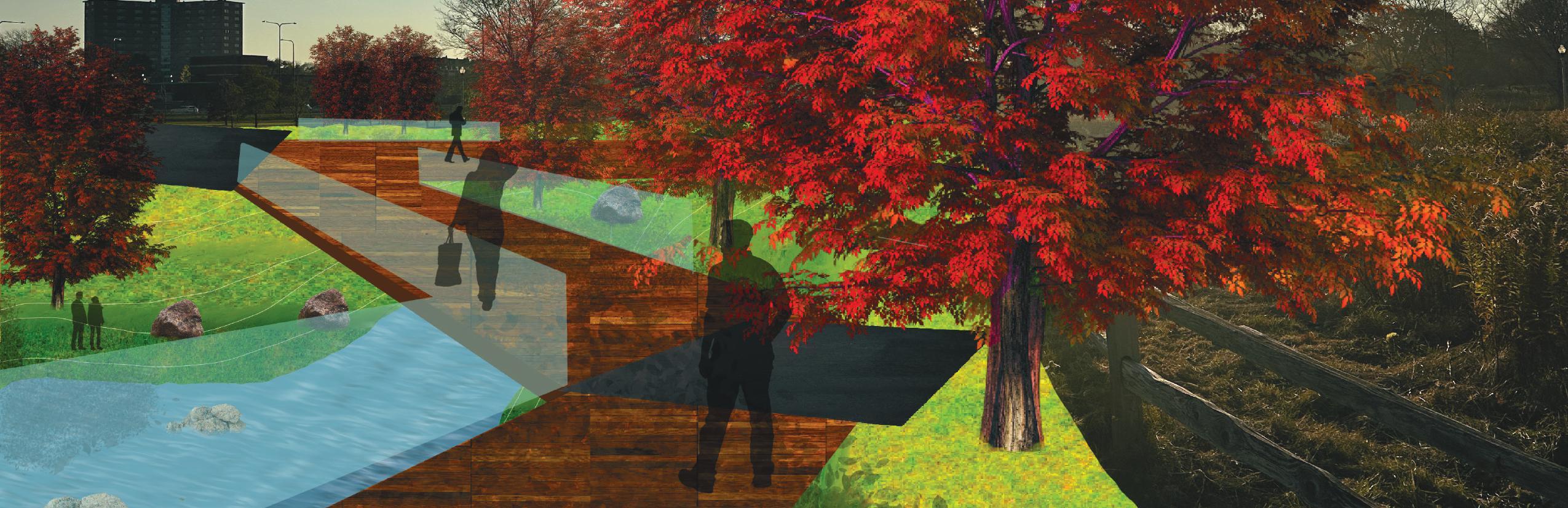

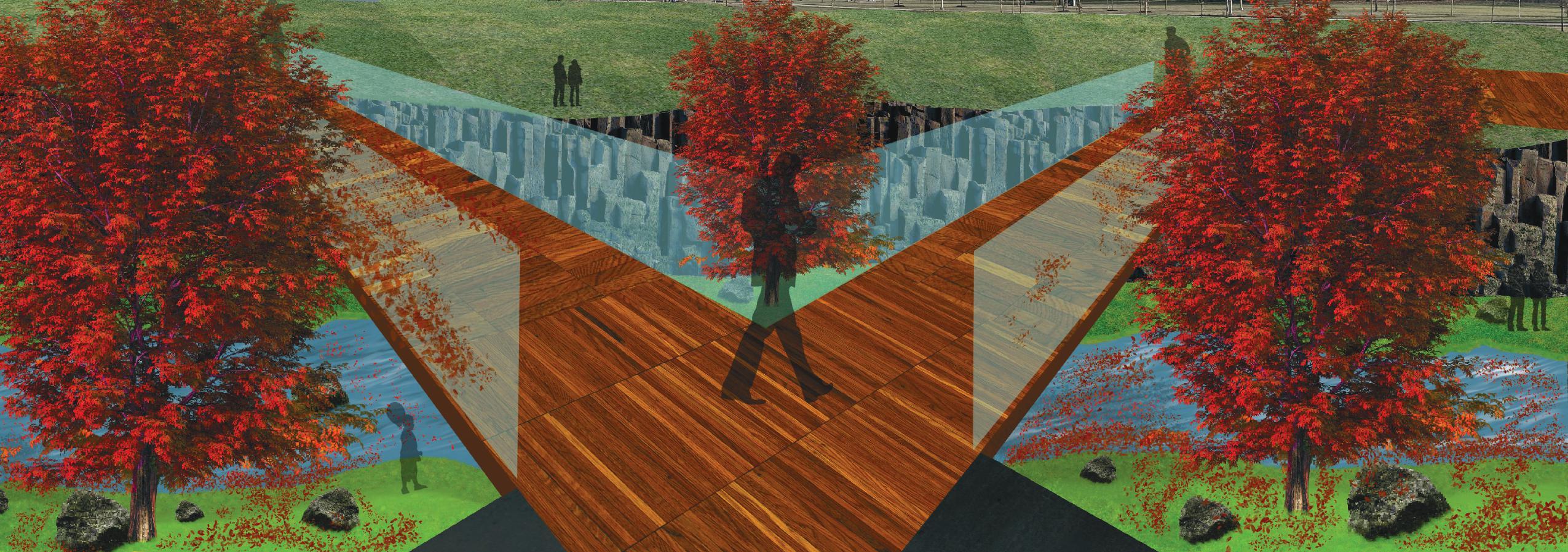

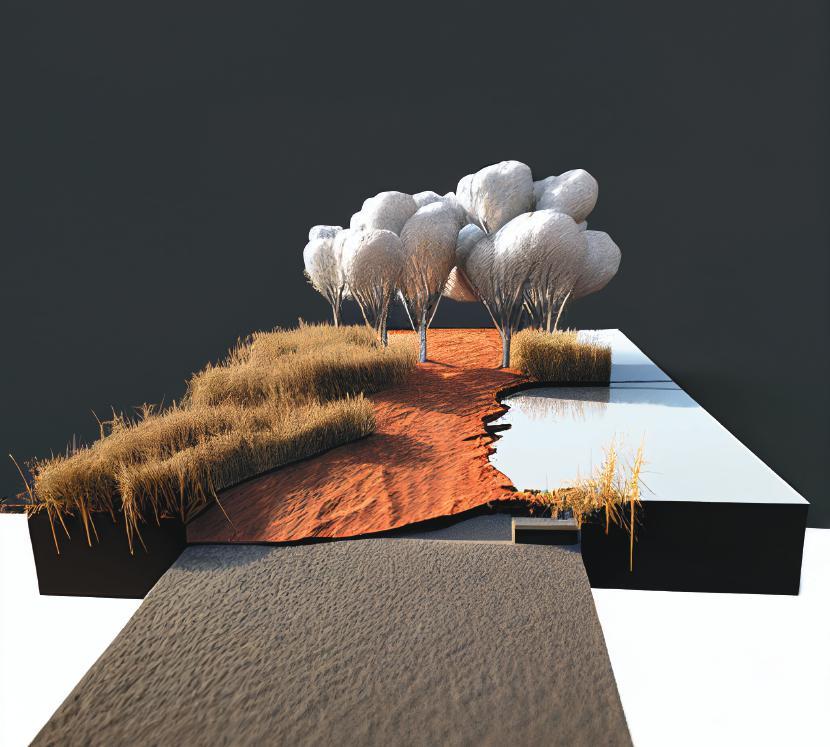

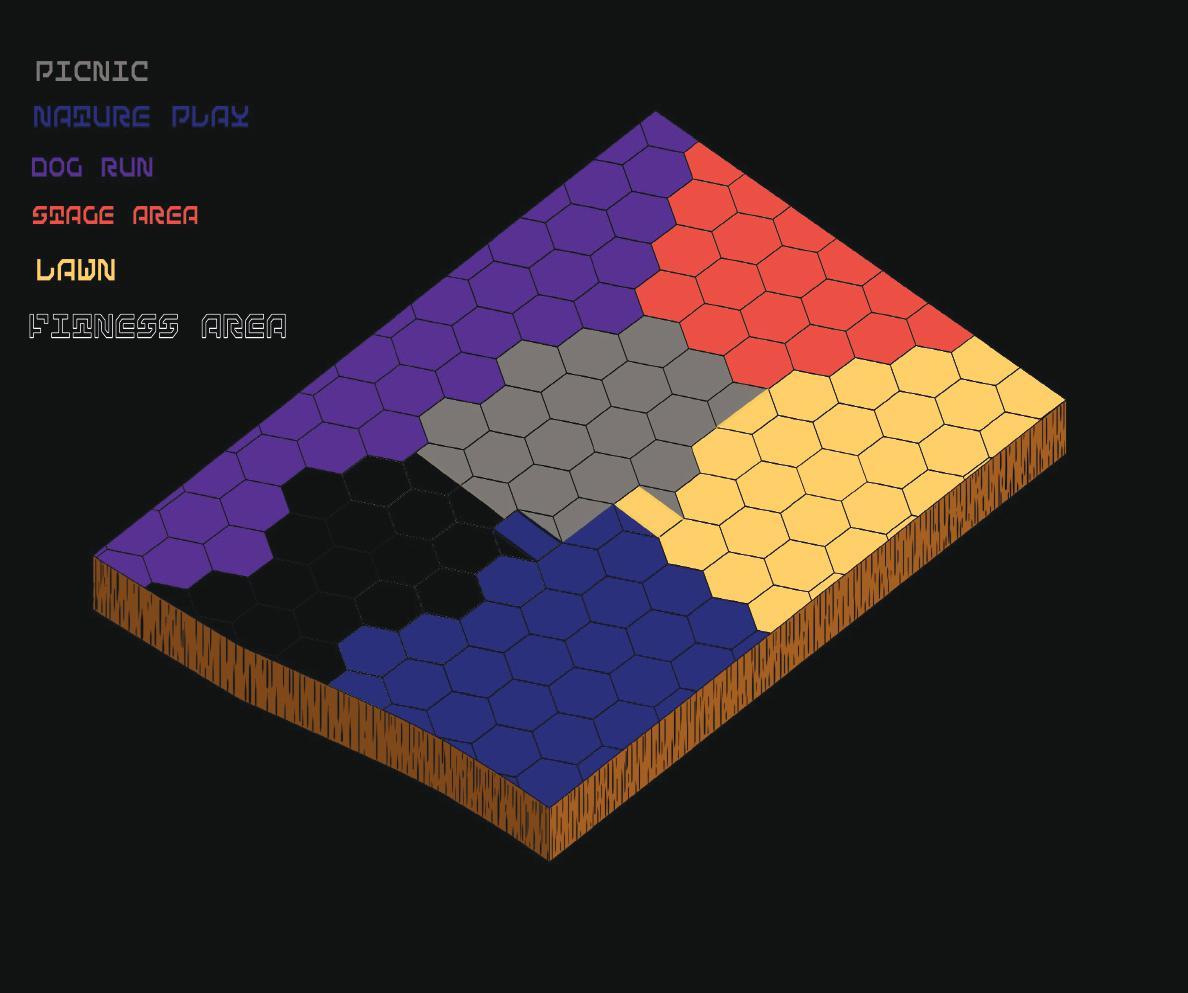

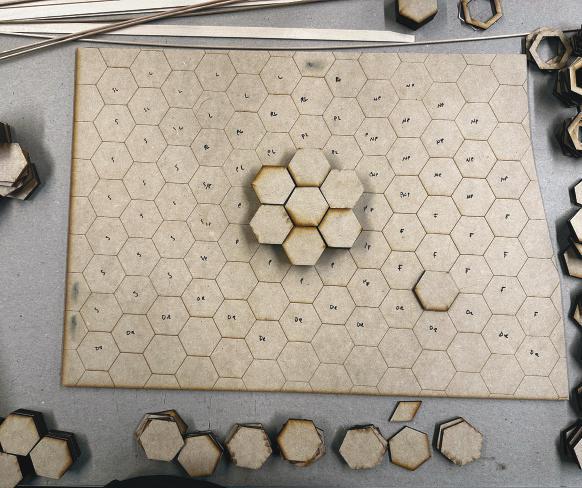

Physical Model Render.

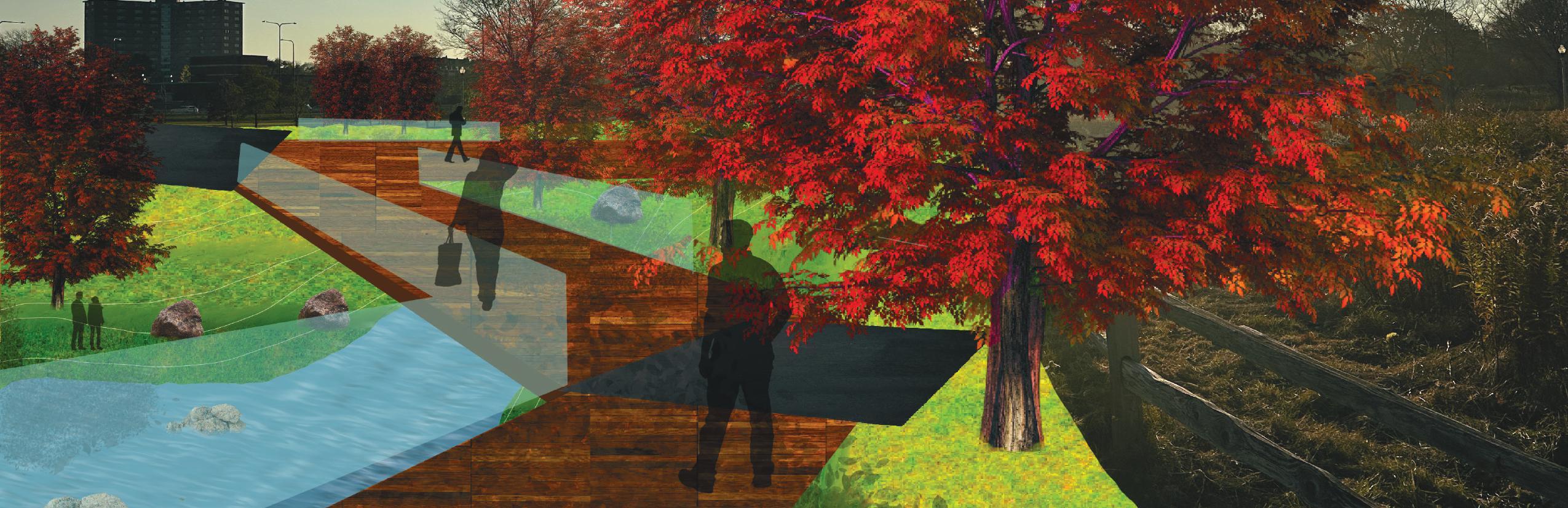

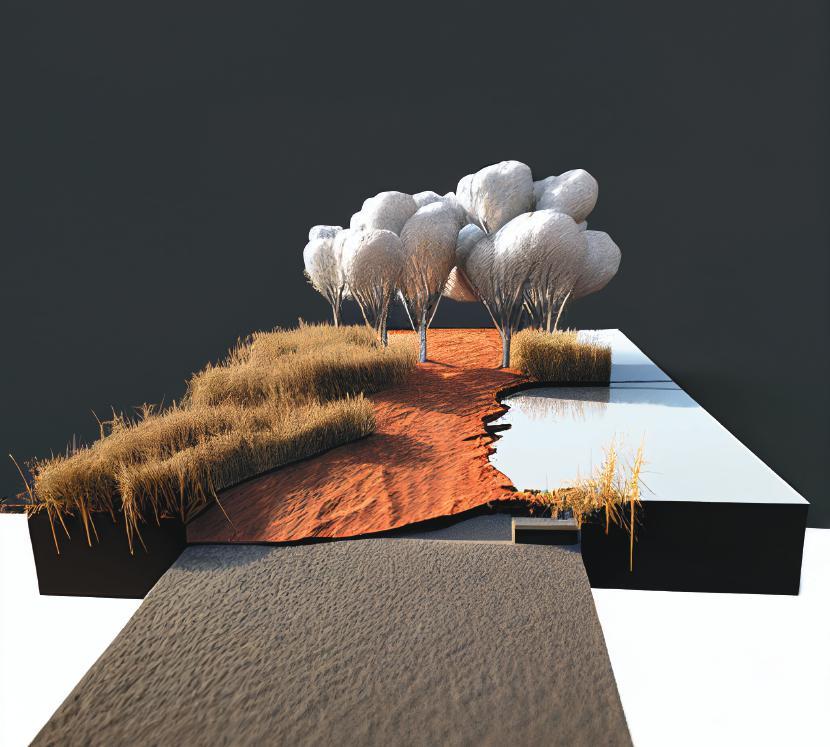

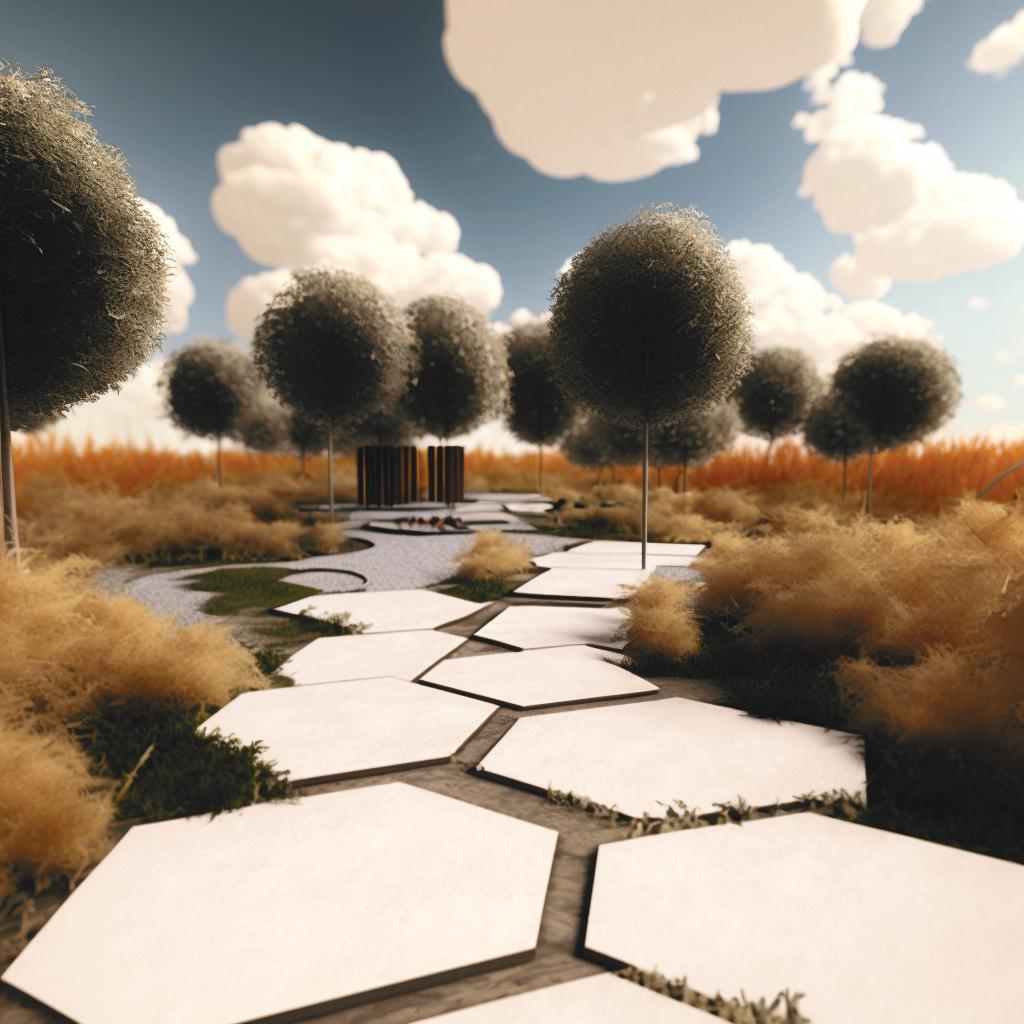

Perspective Render Variation.

Physical Model Render.

Perspective Render Variation.

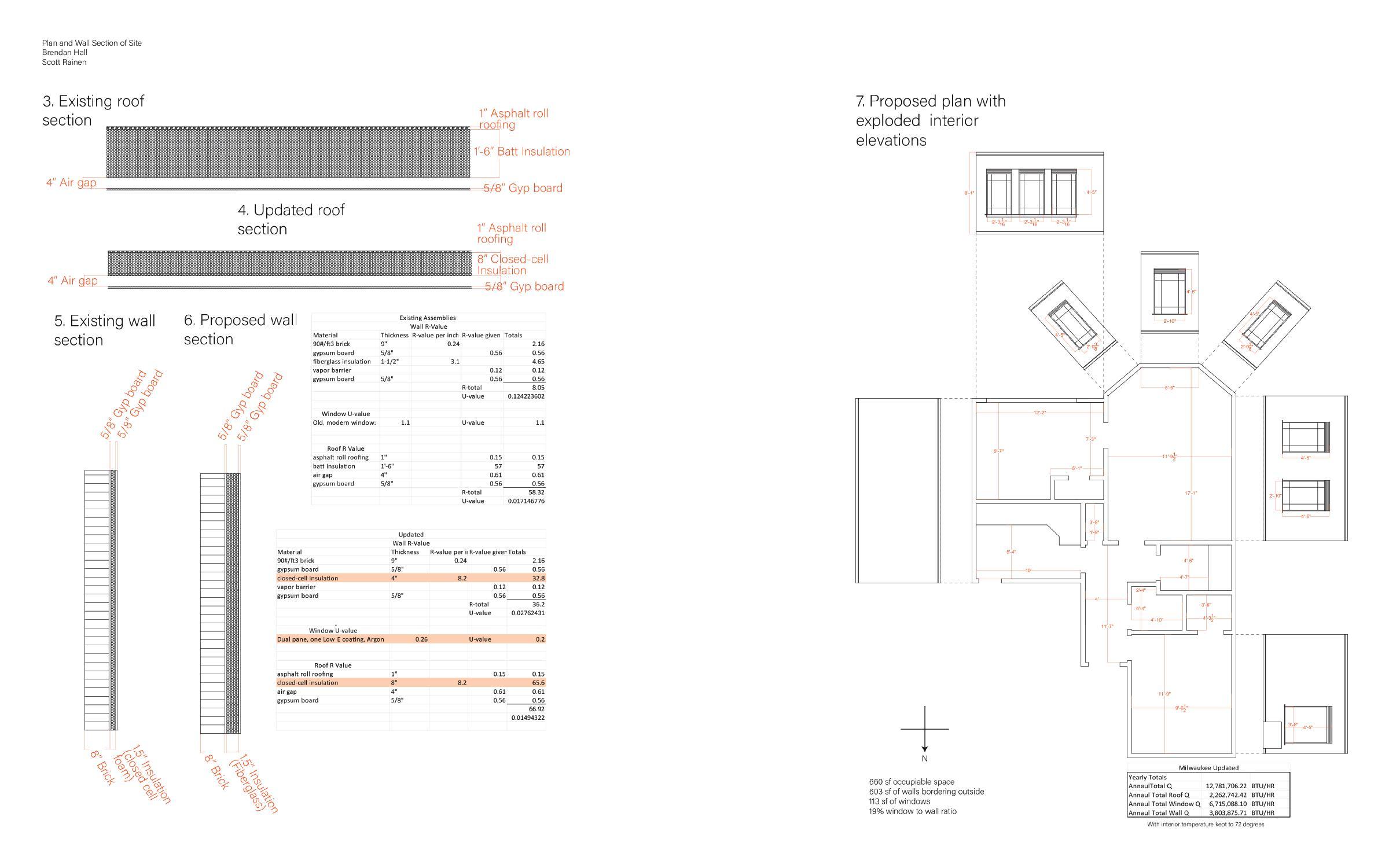

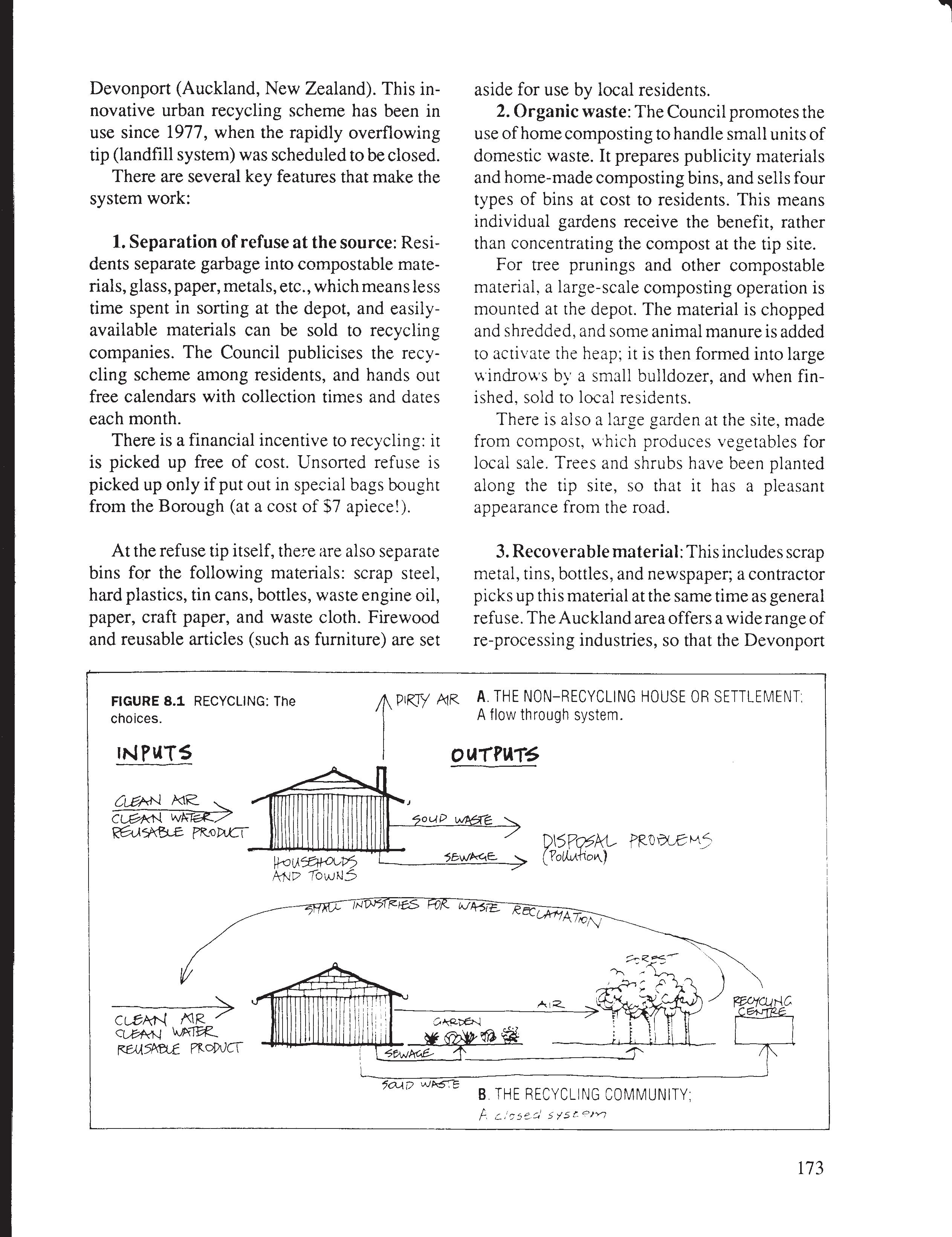

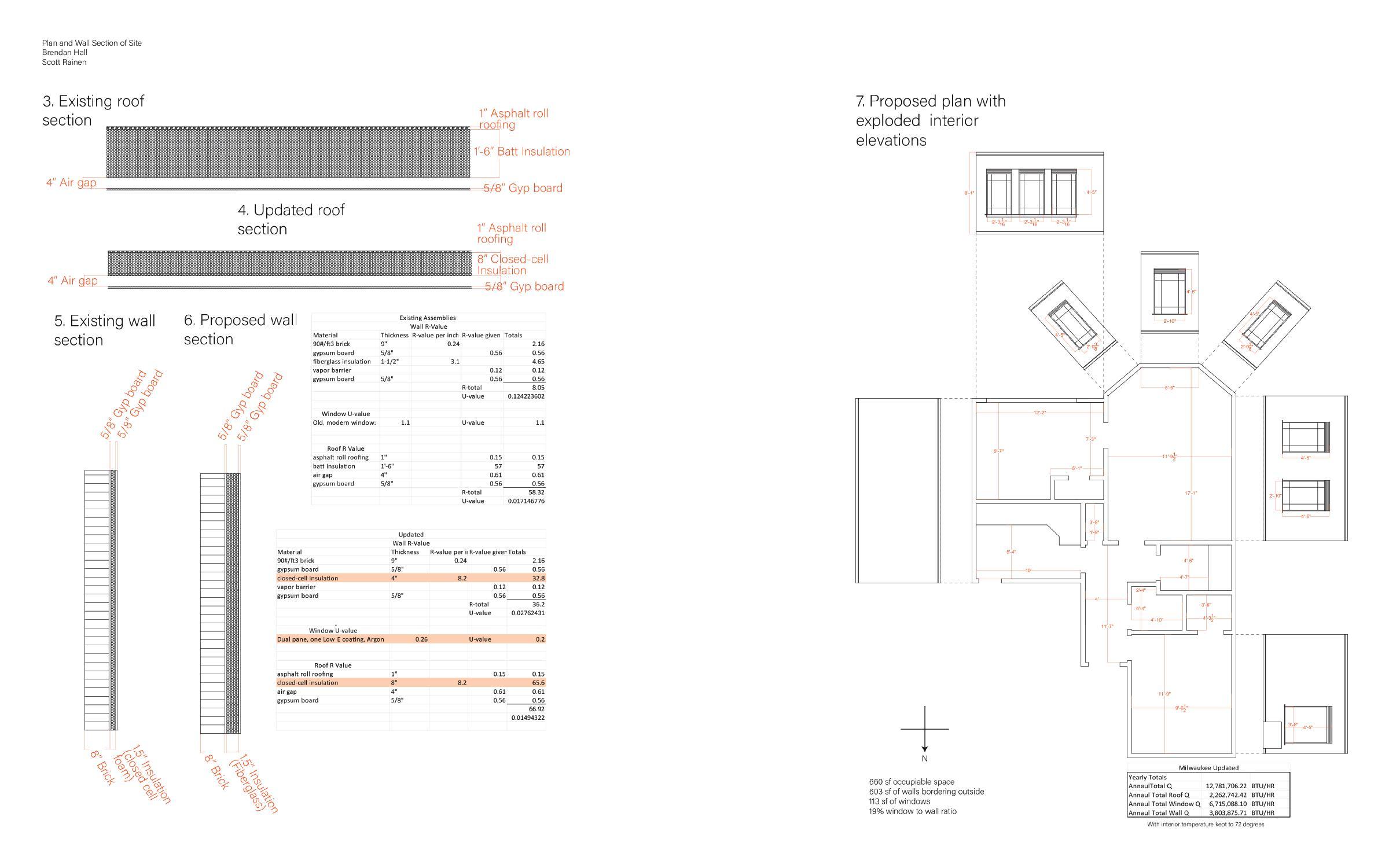

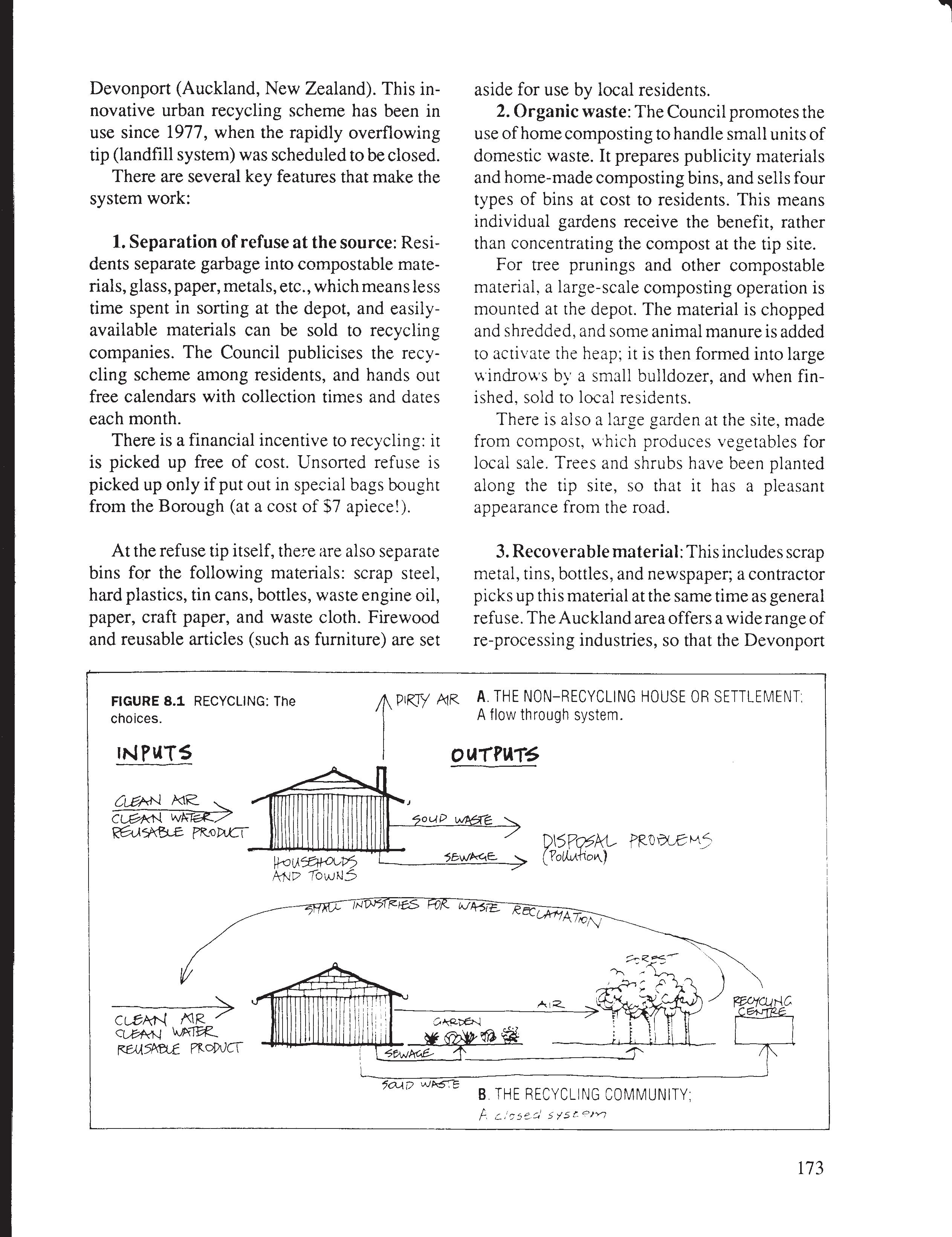

04 a place for systems

In my Environment and Building Systems course, I learned to understand and analyze the efficiency of a building and how various materials affect heat loss. Through a series of calculations my partner and I were able to determine the efficiency of a Chicago aprtment building in Chicago’s varying climate.

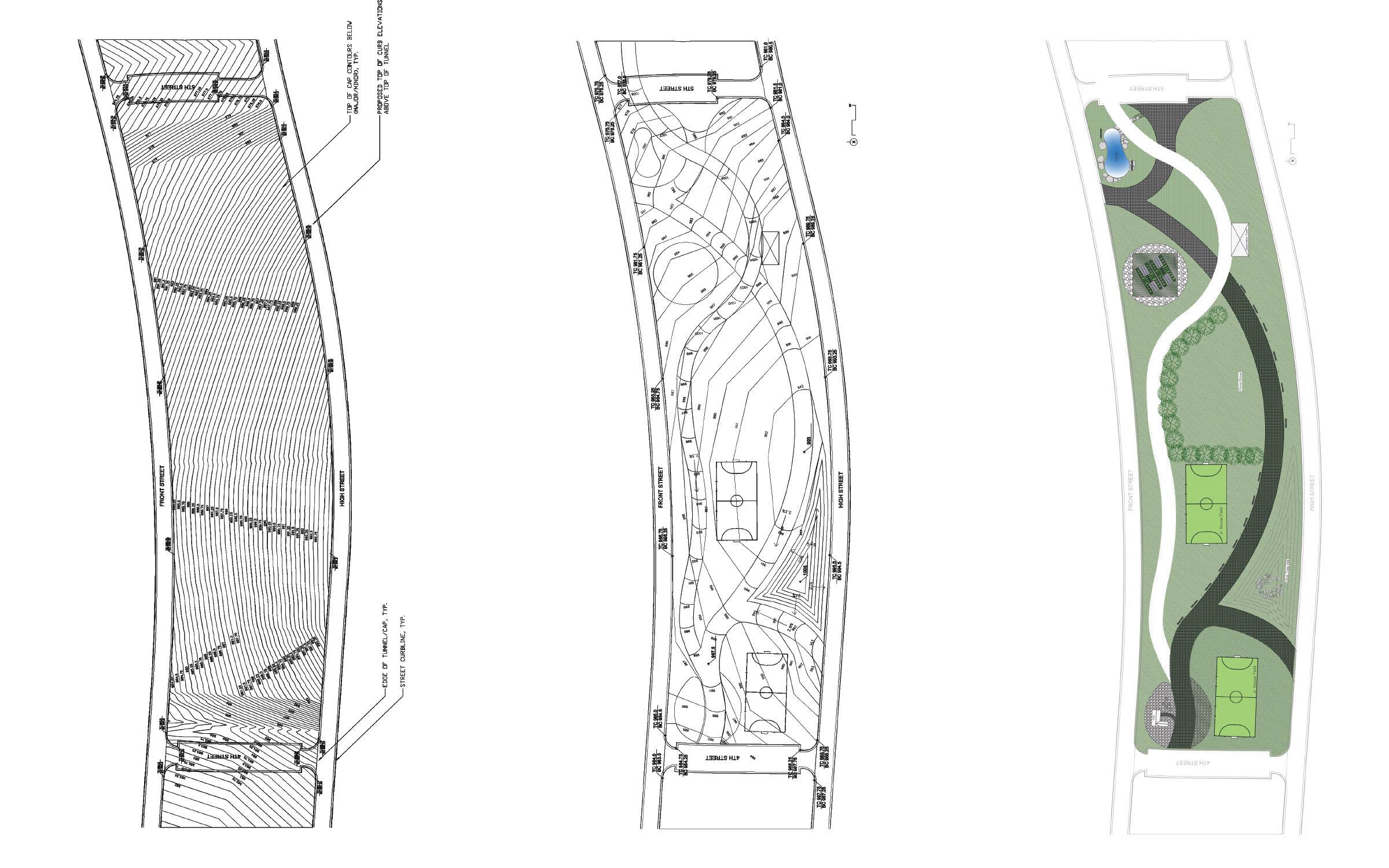

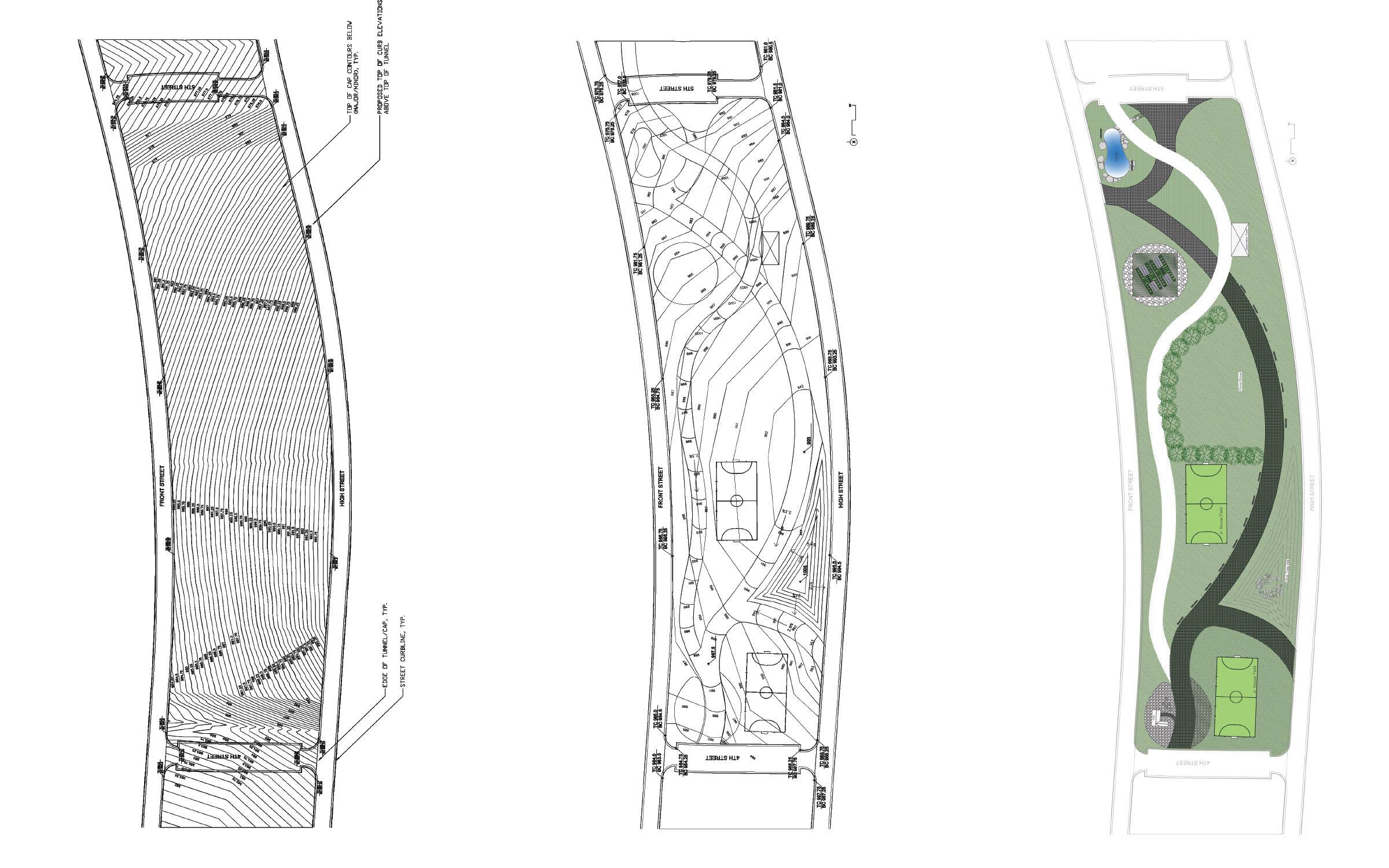

In my Ecology and Materials course, I learned to understand and design grading for a self designed project. I also learned how to determine slopes, interpolate and measure contours.

These two projects show the results of my instruction.

0 2 00 0 4 00 0 6 00 0 8 00 0 1 00 00 1 20 00 1 40 00 1 60 00 M ilwaukee 0 2 00 0 4 00 0 6 00 0 8 00 0 1 00 00 1 20 00 1 40 00 1 60 00 M i waukee Updated Daily BTU/HR Daily BTU/HR jan feb mar apr may june july aug sep oct nov dec jan feb mar apr may june july aug sep oct nov dec Hea t En ergy 40,507 20 kBTU/HR w/ 10% Sa �ey Fa cto r 55,697 40 kBTU/HR EUI 84 39 kBTU/HR Pre Ren o va � o n EUI Hea t En ergy 12,390.59 kBTU/HR w/ 10% Sa �ey Fa cto r 17,037 07 kBTU/HR EUI 25 81 kBTU/HR A �er Ren o va � o n EUI

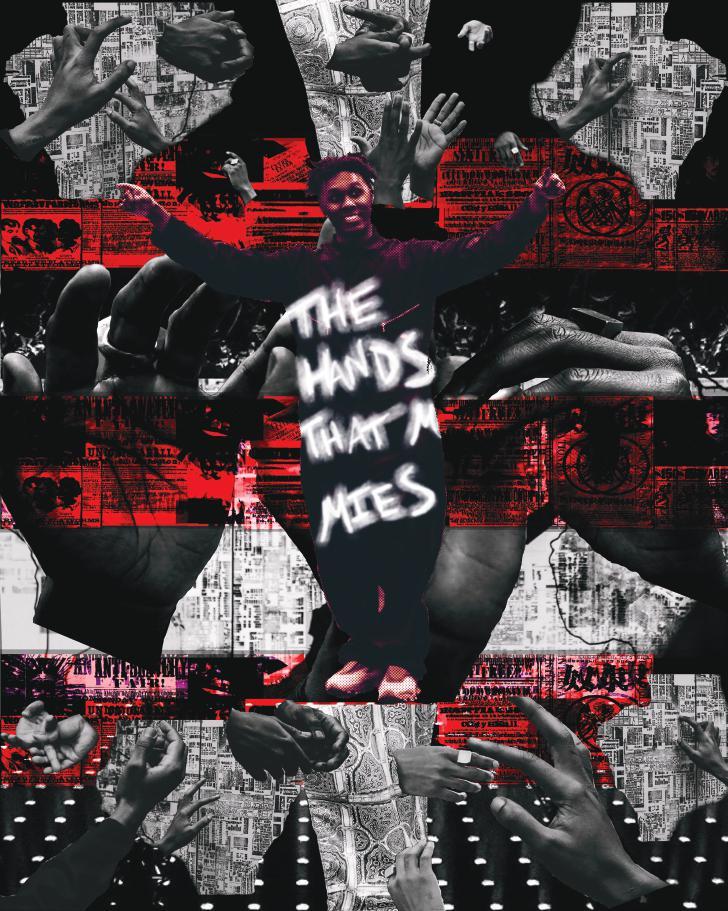

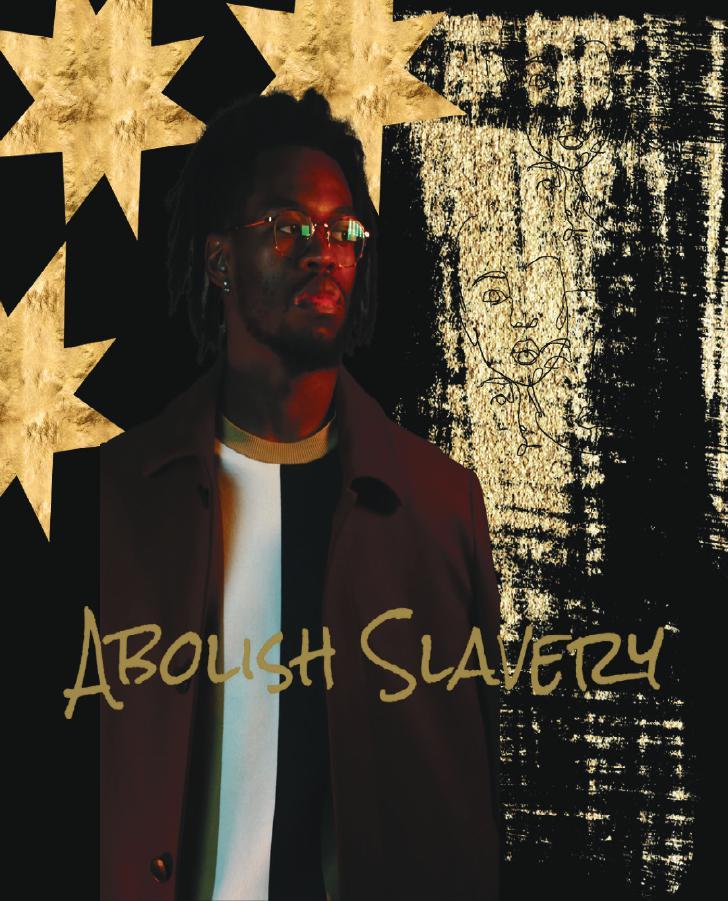

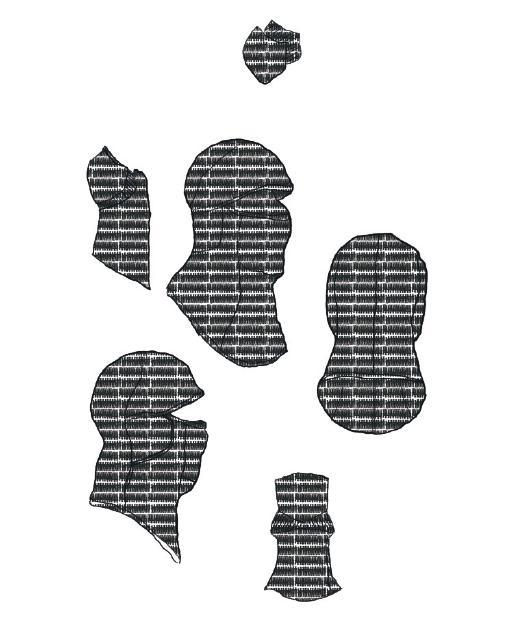

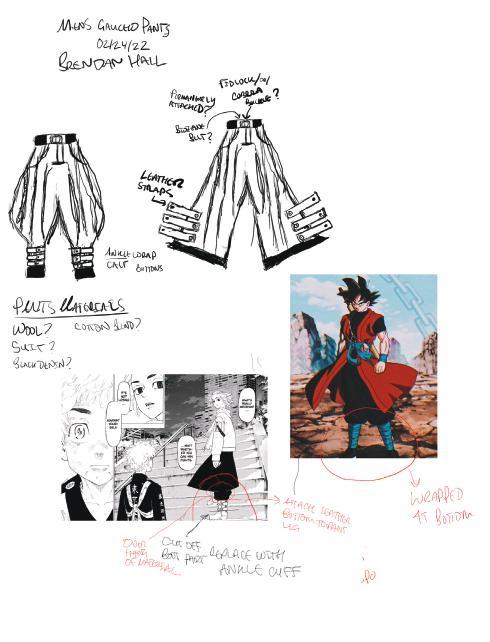

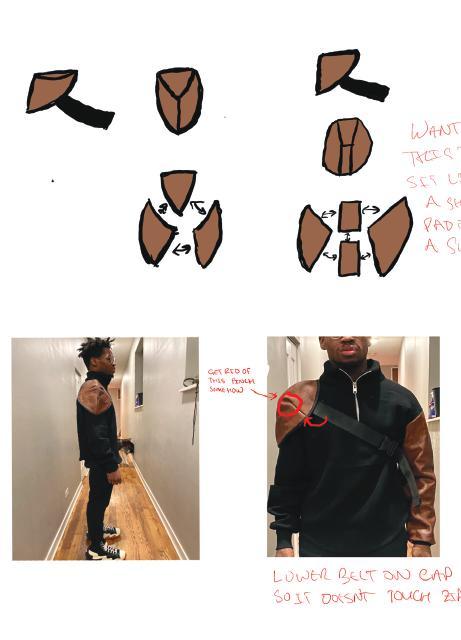

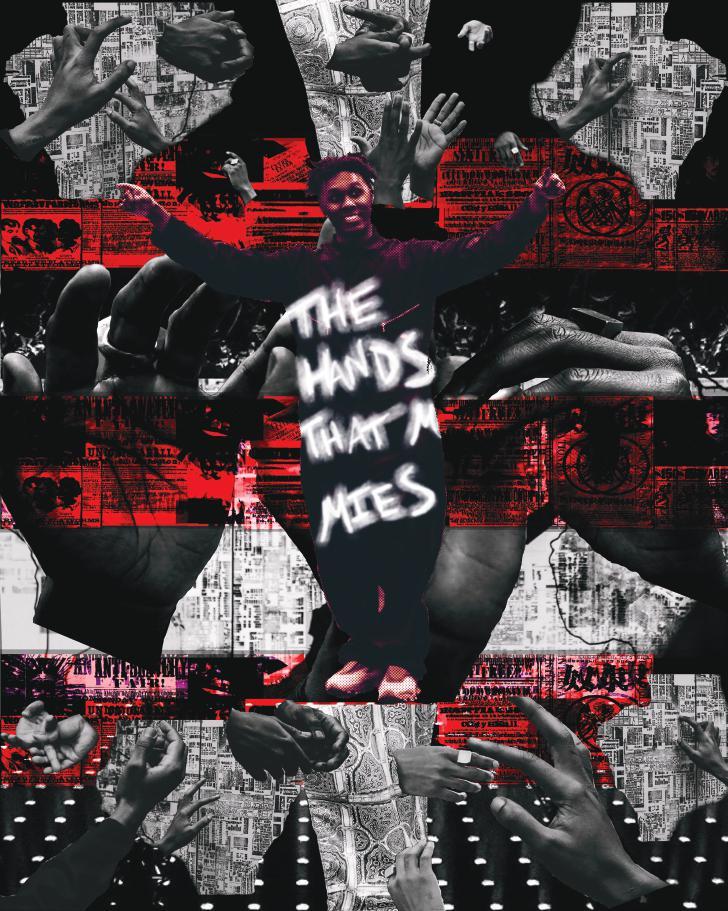

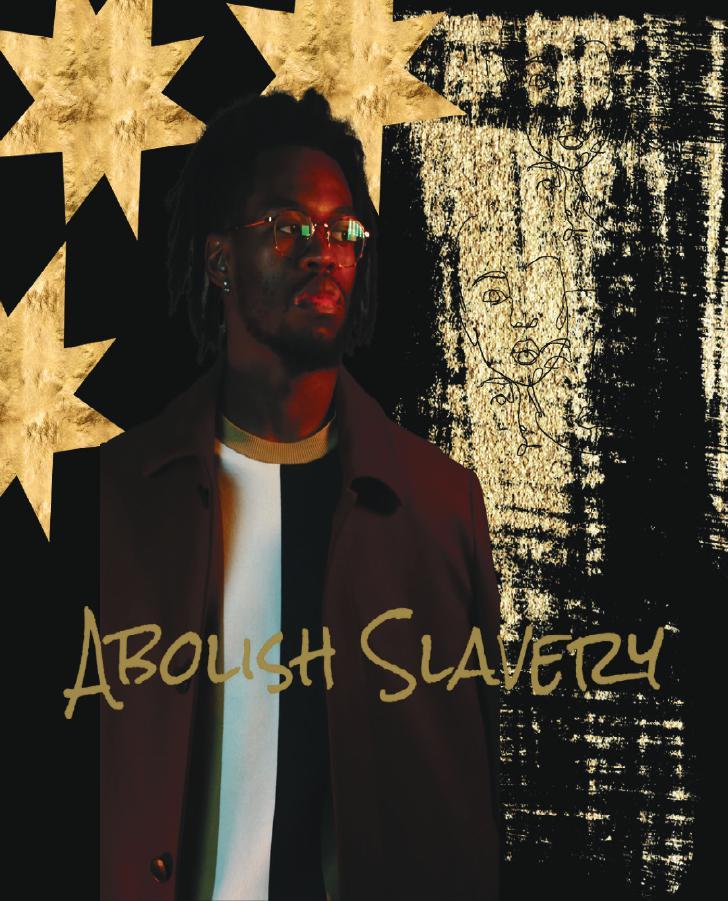

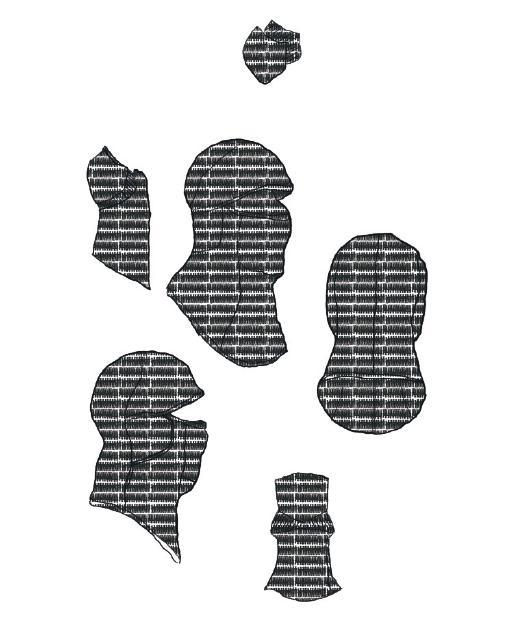

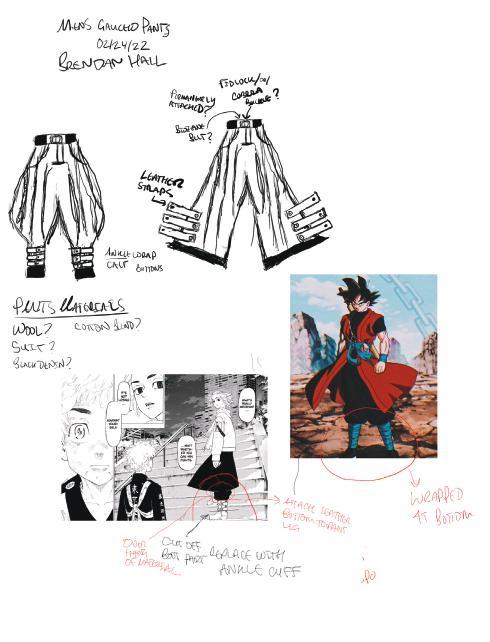

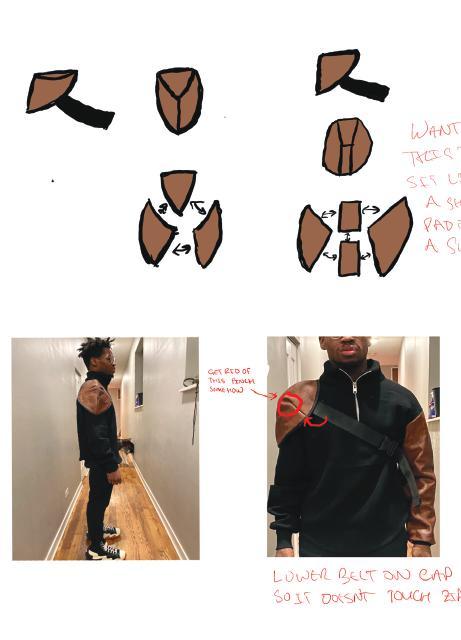

A Place for Personality

A small compilation of personal design projects. My own brand of propaganda through various mediums. Digital paintings, photography, graphic design and garment construction.

05

THank you.

-B.T.H.

Stone carving into the earth forms the basis of this design.

The scar that heals. over time.

Stone carving into the earth forms the basis of this design.

The scar that heals. over time.

Community informed design project.

Community informed design project.

EL Paseo Bee Hive outdoor classroom. Program requests by communnity members. Cortes Map of Tenochtitlan. (Now Mexico City) Plan of Alameda Park Mexico City.

EL Paseo Bee Hive outdoor classroom. Program requests by communnity members. Cortes Map of Tenochtitlan. (Now Mexico City) Plan of Alameda Park Mexico City.

Physical Model Render.

Perspective Render Variation.

Physical Model Render.

Perspective Render Variation.