June • July • August Issue 32 Summer 2024 ISSN 2398-2489 Plus all the latest pr oducts & ser vices news fr om the UK drinks industr y’s suppl y chain The

Incorporating

Products & Services Magazine for the UK’s Drinks Production Industry

Brewing & Beverage Industries Business is a quarterly ‘Supply Chain’ magazine targeting the UK drinks production industry. If your company supplies products and services to brewers, distillers, cider makers, etc, then this is the platform for you.

Subscription is free and printed copies are mailed out throughout Great Britain and Northern Ireland If you are one of the very few UK brewers, distillers, or cider manufacturers, not receiving a regular copy, then please contact us today

WHO WE ARE

Magazine Editor

Chris Freer

Digital Editor

Simon Butler

For editorial or advertising enquiries, call the Editor on 0115 8 549 349 or e-mail: chris@brewingbusiness.co.uk

WHO WRITES FOR U S

RUTH EVANS MBE

Ruth is CEO of BFBi, whose membership represents the supply chain for the brewing and beverage industries

JULIAN GROCOCK

Julian Grocock is a former chief executive of SIBA with extensive experience in beer, brewery and pub politics.

ALAN POWELL

Alan Powell is a specialist excise duties consultant, who heads up the British Distillers Alliance

We are delighted to be the home of

Cover illustration - Christian Barden, CEO UK & Europe, Konvoy Kegs, with some of the company’s products at BeerX 2024

by freerbutler limited PO Box 9666 • Nottingham • NG10 9BY United Kingdom

Tel: 0115 8 549 349 brewingbusiness.co.uk

Our print circulation is audited and certified

Brewing & Beverage Industries Business magazine is an independent publication delighted to be a MEDIA PARTNER to All rights reserved No part of this publication may be stored in a retrieval system or transmitted in any form or by any other means, electronic or mechanical, photocopying, recording or otherwise, without the prior permission of freerbutler limited Whilst every effort is made to ensure that the information in this publication is accurate and up-to-date, freerbutler limited does not take any responsibility for errors or omissions Opinions expressed in editorial contributions to this publication are those of their respective authors and not necessarily shared by freerbutler limited © freerbutler limited 2024

Representing the entire value chain supplying the Brewing, Food & Beverage Industry

Members of

freerbutler limited is a Supplier Associate member of

News

Beverage Industr

Association 5

from the Brewing, Food &

y Suppliers

Published

WELCOME TO

The Products & Services Magazine for the UK Drinks Production Industry ISSN 2398-2489 ALWAYS

-

into our

year!

IN PRINT & ONLINE

Now

9th

Ruth Evans MBE

Photo by Gerardo Jaconelli

From very challenging situations, new shoots grow

Just recovering from organising the BFBi National Luncheon, hosting the International Brewing & Cider Awards at Guildhall, City of London.

It is this event and others that remind us all of how fantastic our industry is; how collaborative our industry is; how passionate our industry is.

If we could only bottle the joy, collaboration, passion and, even, optimism that was within the confines of the Crypts yesterday we would be a much more successful, less stressed and more productive industry

Hold onto those feelings and nurture them into optimism – our history (ABTA/BFBi’s) shows us that from very challenging situations, new shoots grow We are a cyclical industry and the cycle will turn

BFBi annual Trade Directory

Now available

The most authoritative directory o UK food & drinks market availab

The directory is free-of-charge to drinks manufacturers and BFBi members

For details of how to obtain a copy please contact admin@bfbi.org.uk

‘Nuff said

Ruth Evans MBE, BFBi C.E.O.

‘Nuff said

Ruth Evans MBE, BFBi C.E.O.

Established in 1907, BFBi’s membership represents the entire value chain supplying the brewing and beverage industry – from seed geneticists through raw materials, brewhouse and process equipment to dispense, point-of-sale and brewers/distillers The Association’s objective is to be the foremost trade association providing opportunities for its Members to develop within the brewing, food & beverage industry.

As well as offering many benefits and services to suppliers of raw materials, process and packaging machinery, dispense and point of sale products, BFBi is a Trade Challenge Partner for various overseas exhibitions and owner and organiser of the oldest international brewing and cider Awards in the world.

SEE PAGE 66 FOR MORE INFO ON HOW TO JOIN BFBi

6

Word from the BFBi

The View Through My Glass Bottom

Julian Grocock

I need to talk about Kevin...

I have mentioned Kevin before, when writing about the regular gatherings of drinking pals in our village local. Known to us all as Kev, he was very much at the heart of our pub community. And yes, sadly the word is now 'was' because, totally out of the blue, he suffered a heart attack on Friday the 9th of February, and tragically passed away suddenly in hospital the following morning. He was 67.

Vee, Kev's partner of 44 years, messaged me very late on the Friday night to apologise for their no-show, explaining that Kev wasn't well, but hoping they'd be able to join us for Saturday's live music So her phone call at about 1 30pm the next day came as a total shock, and I called into the pub straight away to pass on the terrible news

Saturday evening went ahead The covers band I play in performed for two friends' joint birthday party Kev had been a really enthusiastic fan of our music, and Vee insisted he'd want the show to go on

It was our first step into a new reality ~

Writing this hasn't been easy But I wanted to do it. And, more importantly, Vee wanted me to do it She wants everyone to understand and appreciate the pub's positive and therapeutic role in helping her start the difficult journey to build a new normality for her everyday life. Vee came back in as soon as she found the courage, and of course at first it felt totally wrong without her life companion But with determination and perseverance –and the entirely natural and unforced support of the rest of us – she hopes she is progressing at an appropriate rate to where she wants to be. It should also be noted that the supportive pub vibe goes beyond our close circle of friends, to our hosts Leon and Gemma and their staff, and the broader regular clientele right across the age range – from just legal to even more geriatric than I am

~

Together, we're rediscovering humour too. Every Monday night, some of the gang play a few games of dominoes Then, to round off the evening, we all gather round the playing board and throw in a quid apiece for a simple gambling challenge called In The Box – which involves putting the dominoes away by matching with the one next to the box, and trying to win the pot by being the first with no dominoes in hand when none are left on the table

Quite a few of us had noticed Kev had been enjoying more than his fair share of success at this But I have to confess that I was the one who risked drawing attention to the irony that he'd now really taken In The Box too far It wasn't really a risk, though, because all the time spent in the pub with Kev and Vee and our friends meant I knew it would be received in the light-hearted spirit intended – in much the same way everyone knew Kev himself would have responded

~ Please know that I'm well aware of other headline news and developments in our industry, at a national level, which could have much more significant and farreaching effects than the loss of one punter (and which I shall most probably address next time).

Critically important among these is the planned revival strategy for and proposed accompanying investment in the British on trade, via its Star Pubs & Bars chain, by the powerful and influential Heineken multinational corporation

It's a way forward that potentially seriously reinforces the underlying ideology of this article. And if you appreciate the value of what I have written, you will also appreciate the essential value of our pub culture and community

Just as Kev did and Vee does ~

Finally, let's not forget that the driving force behind all this is Kev himself. I was deeply honoured to be asked to pen a few words for his funeral:

'Kev was a pub friend – a drinking buddy, great company, and a true character He was always eager to participate in any and every topic of conversation, from the really serious to the totally frivolous Together we put the world to rights and enjoyed many a laugh at how ridiculous it could be

To say Kev was "larger than life" doesn't make him immortal, but it does mean he will live on in all our hearts and minds.'

And that's all because we met and spent time together in a pub

Julian Grocock

Julian Grocock is a former pub landlord, managing director of Tynemill/Castle Rock, and chief executive of SIBA

Extensive experience in beer and pub politics, brewery and pubco operations, and on the front line in the pub trade...‘from cellar to ceiling’.

8

Showcasing the British spirit

Alan Powell Spirits duty stamps and WOWGR to get the heave ho!

This is a follow-up to my article in the winter edition of this magazine (WOWGR and duty stamps review – crawling to finishing line)

I have been lobbying and campaigning for repeal of the law concerning spirits duty stamps and registration of third party owners of goods in warehouse (WOWGR) for several years There was never any justification for these measures, which were initially conceived in error by HMCE that there was widespread spirits duty fraud involving the warehousing sector

That fraud was in fact HMCE’s honey trap sting known eponymously as the London City Bond fraud to “let loads run” between 1994-98 and led to nearly £500 million irrecoverable excise duty losses That entrapment operation, run covertly by HMCE’s elite Investigation Service, was stopped dead by highestlevel edict to prevent further spirits duty losses WOWGR and duty stamps were in fact a cynical deception by HMCE to deflect blame from themselves and to smear legitimate industry that the fraud was endemic to the warehousing sector, causing havoc for many innocent traders up to this day. It is HMCE’s “Post Office” scandal and has infuriated me at the injustice

Anyway, at Spring Budget 2024, the government announced its intention to abolish the Duty Stamp Scheme with plans to publish draft legislation to achieve this later in the year HMRC made a presentation to industry representatives shortly afterwards with what draft legislation to end the scheme might look like:

1 A fixed end date - a final date on which the Scheme will no longer apply

2 No prohibition on stamping is required because traders regard it as a burden and will cease on their own volition

3 No restriction on stamped product Stamped and unstamped containers should both be acceptable for sale and supply immediately after the Scheme's end

4 No requirement to remove stamps from stamped bottles

5 The rules will continue to apply until the end date That will apply to books and record keeping

HMRC prepared a questionnaire for industry to be returned mid-May The feedback from the British Distillers Alliance (BDA) members has been to get rid of the duty stamps law with minimum fuss

Moving on – at the Joint Excise Consulting Group (JECG) meeting held on 18 April, HMRC reiterated that repeal of WOWGR remained their “preferred option” (for utterly compelling legal reasons), the recommendation having been made to senior (director level) HMRC officials in April for sign-off to repeal the law to be sent to minister May/June for minister ’s decision This ought to be a formality I should record, however, that HMRC said at the JECG that there had been few responses to a consultation on repeal of WOWGR (27 in total) - most had been from warehousekeepers who wish to retain it as part of their due diligence

I don't know how many responses came from trade bodies and how many from individuals, but the BDA response was wholly to repeal WOWGR, providing the legal reasons why the scheme never had legitimacy HMRC did not reference this but if individuals from the BDA had responded, it would have been rather more than 27 in favour of repeal HMRC said they would respond/explain to industry what "due diligence (residually) would be required post WOWGR In any event, HMRC said (to paraphrase) that WOWGR was not to be wholly relied on as to the on-going probity of a registered person and is not to be seen as a "comfort blanket" I agree and to repeat what I said in my earlier article, I think the concern about WOWGR (which applies only to beer and spirits for alcohol) misses the point - there is no difference whether owners of beer and

The British Distillers Alliance (BDA) is a non-profit making body which provides a professional service for independent and craft businesses in the spirits production industry and supply chain. The BDA represents distillers, rectifiers and compounders and those in related sectors. New members always welcome.

spirits are subject to WOWGR registration or not

Such owners may be WOWGR registered but that does not mean the standard due diligence condition is modified The Due Diligence condition is a risk-based “probability” process to identify risk of alcohol duty fraud in the specific supply chain and mitigate any risk identified, the process commencing with “discovering how the fraud occurs”, as the courts have told us In terms of whisky cask sales, say, there is not even a supply chain per se, so one has to assess if there is even a risk to mitigate Sensible and reasonable commercial due diligence augmented by excise duty fraud awareness would be a responsible approach to assess such fraud risk and whether there is any risk to be mitigated

This is regardless of WOWGR registration of the owners of the goods For comparison, wine is not even subject to the due diligence condition per se in the warehousing system (but is for AWRS)

Utterly irrational and needs the boot!

Alan Powell

Alan Powell is a specialist excise duties consultant, formerly a Policy official within HMCE’s HQ teams He is excise duties advisor to the Chartered Institute of Taxation, honorary advisor to the UK Warehousing Association and founded the British Distillers Alliance as a conduit for consultation with, and representation to, Government bodies and to assist and advise on technical matters The BDA represents distillers, rectifiers and compounders and those in related sectors. New members welcome!

For further information:

www.britishdistillersalliance.com

10

SHOWC ASE Containers

l Bottles & cans plus labelling and decoration, and on-shelf packaging l IT systems for container tracking

l Bulk packaging & associated labelling for transportation of beer and other beverages

Bid farewell to oxygen contamination with Arlington

Arlington's revolutionary 1000L containers, coupled with Sterile Airless inner liners, have swiftly emerged as a ‘gold standard’ for maintaining hygiene and preserving beer quality during transportation from brewery to bottling / canning.

Offering a cost-effective solution, these transport tanks ensure zero contamination and eradicate the risk of Dissolved Oxygen exposure,

safeguarding the integrity of your precious brew throughout its journey

But Arlington doesn't just stop there In an ongoing quest to enhance beer quality, we've introduced innovative solutions to further minimise oxygen exposure during the filling process Our cutting-edge "Air Bleed Valve" empowers brewers to expel all air from their filling hoses, ensuring a seamless flow of beer right up to the valve on the liner By eliminating any residual air in pipes or fittings, this breakthrough significantly reduces the risk of oxygen ingress during filling, yielding exceptional outcomes for brewers and canners alike

For those venturing to send their beer on extended journeys or planning for prolonged storage periods, Arlington presents an additional layer of protection with our High Oxygen Barrier and UV Barrier Liners (Metalized Foil Liners) These premium liners feature the highest oxygen barrier film available in the market today, guaranteeing unparalleled preservation of your brew's freshness and flavour integrity

What's more, Arlington containers and liners are readily available in stock, with same-day dispatch and no minimum order quantities required Whether

New 1-piece shive is now available from UB Plastics

UB Plastics announces the successful launch of our new 1-piece Shive

Manufactured from a tough food grade Linear Low Density Polyethylene, and being a 1-piece moulding as opposed to 2 pieces, the cost of manufacturing the Shive is greatly reduced, meaning we can pass these savings on to our customers

We have 2 different sizes in the range, designed to seal any stainless steel casks

We are also manufacturing our range of

keg caps from 100% recycled Black Polypropylene, this not only offers a cost saving for our customers but also highlights our commitment to our green agenda

Coloured keg caps manufactured from virgin Polypropylene material are also available.

Up to 5-colour branding using in mould labelling technology is of course still available on our complete range of keg caps

For further information:

you're transporting 500L or 20,000L+, our efficient logistics ensure prompt delivery, minimizing downtime and maximising efficiency for your operations

When it comes to moving your brew, don't settle for compromises Choose Arlington, the industry's trusted partner, dedicated to preserving the purity and quality of your beer every step of the way

12

stevebrown@ubplastics.co.uk

www.arlingtonpackaging.com For further information:

We asked companies supplying the following products and services to let us know something about themselves....

l New, or pre-owned and re-furbished casks and kegs – for purchase or lease – plus cask repair/branding services, and container closures

UB Plastics Ltd, situated in Burton on Trent, are the primary UK manufacturers of a range of Shives and Keystones to suit all UK cask variants Our Shives and Keystones come in a range of colours

We also manufacture a complete range of Keg caps for the following keg spear specifications S type, A type and G type in Tamper Evident and Dust cover designs.

Our caps are manufactured from either virgin or black recycled Polypropylene offering 5 colour branding using the latest IML technology.

Our Brown keystone resealing plugs are a cheaper more environmentally friendly alternative to Cork and offer an excellent seal to used casks on their journey back to the brewery.

Please contact Steve Brown for further information on 07885 866777 or email sales@ubplastics.co.uk / stevebrown@ubplastics.co.uk

13

SHOWC ASE Containers

Let’s start to talk kegonomics…

Says Christian Barden, CEO UK & Europe, Konvoy Kegs

Kegonomics (noun) is an applied science concerned with the study of keg and cask efficiency in their working environment. As you might have already guessed, it isn’t a “thing” (yet) but it should be.

Kegonomics should be the ratio of the useful work performed by a keg or cask compared to the cost of purchase, the carbon footprint of production and the total input supply chain activities

The most efficient keg fleets have lowest loss rates, highest rotations and travel the lowest amount of road miles between fills and deliver the lowest economic and environmental cost per pint Given the global statistics on loss rates, replacement rates and rotation rates there is a huge industry opportunity to push towards net zero in the broadest sense of the term

Keg fleet management metrics must begin to move from aggregation to disaggregation by starting to break down minute keg fleet management activities and costs into individual component parts Keg fleet management attitudes must also begin to change from accepting what the industry has always done, and that

tracking technologies are unreliable and add unnecessary costs and activities to the supply chain, when the costs of what the industry does today are already unsustainable whilst new technologies are already proving to revolutionise multiple industry supply chains by creating sustainability through traceability

Enabling the appropriate infrastructures and processes for the reusable to be reused, the shareable to be shared, the traceable to be traced and the circular in perpetual circulation, lies at the core of the opportunity that Internet of Things (IoT) asset tracking can bring in addition to immediate benefits such as improved visibility and real-time monitoring of assets, enhanced operational efficiency through better asset utilisation, reduced loss or theft of assets, streamlined supply chain management and enhanced customer service through accurate tracking of deliveries or shipments

There are ~200m kegs and casks globally with ~5%-10% lost each year at a cost of ~USD$800m-1 6bn and ~300k–600k tons of carbon to replace them, and that’s before the cost of any carbon credit offsets The Corporate Sustainability Reporting Directive

Schäfer announces new sales team

Schäfer Container Systems, an established supplier to the UK brewing market for many years, has announced changes to its sales team which will now be led by Edward Ros as Container Business Sales Director and Oliver Evering as Global Key accounts Manager. Both Edward, a qualified brewer, and Oliver bring with them experience of the European brewing industry.

As for the UK market, Mike Hickmanformer Sales Director - is now an agent, so continuing his twenty-five-year involvement with the company

According to Mike, “It is a far more volatile brewing Industry now than the one I entered over forty years ago, and with a myriad of challenges facing both brewers and suppliers, we are seeing

the same picture globally particularly for the on-trade

“To help face this challenge Schäfer is improving its reaction time and competitiveness for lower volume orders. As the original keg suppliers to such companies as Camden, Brewdog, Beavertown and Meantime, we hope to see the newer entrants to the market emulate their growth in the future

“With production capacity of 1 2 million containers per year, manufacturing three different styles of keg including the light weight Ecokeg, noiseless PLUS keg and traditional all stainless steel keg, Schafer makes an excellent partner for all your container needs ” Mike can be contacted on 07538 069886

As a footnote, Mike also remains the UK consultant for Lambrechts and comments, ‘’We are currently seeing a

(CSRD) will also impact 50k PLC’s & SME’s in the UK over time Scope 3 emissions make up 70% of carbon footprint of hospitality, 85% of brewing, and packaging contribution within that ranging from ~15-40%,

~85% of consumers consider sustainability when making a purchase and are prepared to pay more for ethically sourced, sustainably made products A typical 30 litre keg used for 30 years, never lost, used 3 times per year will have 2 4 times less carbon per 500ml serve, at just 5 6 grams of CO2e, than a keg that’s has to be replaced once over the same 30 years and used 2 5 times per year which is why we need to be embracing the real kegonomics of keg and cask fleet management for a better world of beer

great deal of interest in our equipment ’

“This has in part been triggered by multiple-use keg rental schemes which are now on offer, so requiring the brewer to invest in his own equipment for keg sterility, rather than the rented kegs arriving ready to fill

“With the increasing cost of transport, we could well see this trend continuing ”

Pictured are Mike (right) and Lambrechts sales engineer Steven Clymans, at the recent BeerX show

14

www.konvoykegs.com For further information:

mike.hickman56@outlook.com

For further information:

SHOWC ASE Containers

Trappist brewery launches new beer in Beatson Clark bottle

The UK’s only Trappist brewery has released a second beer, which is now on sale in a bottle designed and manufactured by Beatson Clark

Mount Saint Bernard Trappist Brewery in Coalville, Leicestershire has brewed a tasty blond beer to join its internationally renowned Tynt Meadow dark ale – both of which are sold in the 330ml amber beer bottle from Beatson Clark’s standard range

Trappist beers are traditionally sold in bottles because they undergo secondary fermentation in the bottle, a process that is ideal in glass It means the beer matures in flavour for the first three years, and because of the inert nature of glass it can have a much longer shelf life than that if the bottle isn’t opened, something that isn’t possible in other packaging materials such as cans

“Because of this process, if the bottles are kept in the right conditions – out of UV light, at a consistent room temperature – and the crown and bottle is kept sealed so that no oxygen can get in, the beer will last indefinitely,” explained Peter Grady, Brewery Manager at Mount Saint Bernard Abbey. “The flavour profile of a Tynt Meadow changes drastically over the course of

the first three years and, in our opinion, less so after that This is why we put three years on the bottle, but it will last much longer than that as it’s packaged in glass ”

Because the bottle is made from amber glass it offers extra protection from the harmful effects of UV light “The bottle design is exactly the same – it has already become quite iconic and recognisable,” said Peter “The only differences in the packaging are minor adjustments to the label and the goldcoloured crowns on top ” Mount Saint Bernard Trappist Brewery now regularly brews over 1,000 hectolitres of its famous ale every year, which is distributed throughout British and international markets It is the only Trappist brewery in the UK and one of just nine worldwide

“It’s rare for a Trappist brewery to launch a new addition to its core range,” Peter explained “Our very premise is predicated upon the solemn production of the ales synonymous with our order, with Trappist beers having earned their reputation from their centuries-long tradition of Cistercian ale-making, using closely guarded recipes in a timehonoured process Tynt Meadow Blond has been created to pay homage to this tradition, representing both a classical interpretation, yet uniquely Trappist take

One-stop container shop for a reason

THIELMANN kegs are industry gold standard containers for beer transport, preservation, and storage

Built from premium stainless steel, our kegs range in size from 5L to 100L and are available in a wide range of formats and sizes Our industry-leading manufacturing processes produce kegs of the highest quality materials (AISI 304 / AISI 316 austenitic stainless steel), delivering unrivaled hygiene standards and protecting your beer from UV light, pollution particles, and corrosion. THIELMANN kegs leave the organoleptic properties of your beverage unaltered, regardless of its handling and climatic conditions THIELMANN is truly your one-stop container shop for a reason; not only can we offer you kegs

of the highest quality, but we also provide a myriad of solutions for storing and emptying large quantities of beer and cleaning and servicing solutions

Meet our multipurpose Aseptic IBCs for fermentation, carbonation, yeast propagation, and more, made from the highest quality non- wearing stainless steel For beer line cleaning solutions, our Cleaning Can pressure vessel delivers optimum results, available in a variety of sizes and formats

THIELMANN boasts a wealth of experience in engineering, design, and manufacture of container solutions

Over time, the needs of our clients have changed dramatically, and now, their priority is sustainability

A stainless steel keg’s carbon footprint falls below that of single-use plastic

on this ever-popular mid-strength ale ”

While Tynt Meadow, with its amber hue and distinctive depth of flavour, is a classic strong, dark ale, its blond cousin is closely related in composition if not in style

“Tynt Meadow Blond uses the exact same ingredients as our famous Tynt Meadow, but it brings a zesty, sharper twist on the original classic,” said Peter “It carefully balances vanilla, mandarin and lemon with gentle hints of orange and sherbet

“After the solemn observance of Lent, Easter was the perfect time for us to introduce Tynt Meadow Blond, as we know it will pair perfectly with the lighter, brighter days of spring and summer ”

kegs after just twelve rotations, yielding 20%

lower carbon emissions in the 30 years of its useful life* Once the keg reaches the end of its life, stainless steel is 100% recyclable with no limit to the number of times the material can be reused

We are a founding member of the Steel Keg Association, a non-profit organisation that seeks to develop the market by highlighting steel kegs’ environmental and financial benefits

16

www beatsonclark co uk Tel: 01709 828 141 For further information:

thielmann.com For further information:

SHOWC ASE Containers

How to gain brand success in a changing market?

By Susan Ellison & Chloe Robinson, OPM Group

The brewing industry is evolving, health-conscious consumers want to be able to enjoy their favourite tipple, while keeping an eye on alcohol content, ingredients, and their wellbeing.

The rise of non-traditional beers such as low/no alcohol, low carb, low calorie, low purine and allergy friendly, are a great way to add variety and alternatives to your existing, well-loved beer portfolio Diversifying your range tickles the tastebuds of your existing loyal customers, making it suitable for every occasion, and introducing new clientele to your brand

Health drinks are beginning to branch out into the alcoholic market Drinks you wouldn’t traditionally expect to be alcoholic now have an additional kick Recent trends include gutfriendly hard Kombucha and fruit-infused beers. These changes have awakened cross industry brand collaborations, increasing brand awareness, exposure to new audiences and exciting promotional opportunities

How can OPM Group help you?

So, you’ve decided to take the leap and diversify your brand into this emerging market How do you make sure that your brand stays true to itself and stands out on the supermarket & bar shelves? Partner with OPM Group!

We are an independent, family-owned, label and flexible packaging printer, who have been a trusted supplier to the beverage industry for over 30 years We hold grade AA+ BRC grade for packaging materials, so you can rest assured that your bottle, can and keg labels are in safe hands

Our skills, expertise and passionate team help you to take your brand to the next level; with both flexographic and digital printing Our label solutions work seamlessly from bottling line to retail, home and even end of life recycling

Our digital press can get you to market smarter and faster with short runs and low lead times Perfect if you are just testing the waters with your new products Offering flexibility with multiple SKUs, multiple languages, seasonal and variable data/personalisation

Our flexographic offering is great for brands who know exactly what they

want and require a high volume

We can work with you to transform your label, with innovative design ideas such as peel-and-read, tear-off coupons, glow in the dark and scented ink to help you stand out

We can help you to build curiosity around your product with the incorporation of showstopping embellishments such as foiling, embossing, varnishes, and material choice

We know that sustainability is a priority to you, and we can offer recycle ready solutions such as water wash-off adhesive labels, and responsibly sourced alternative substrates’ cane fibre paper, bio-based PE and recycled content liners.

If you would like to make a splash with your beer alternatives

Our team are ready to hear from you!

Rawlings leads way in bespoke glass packaging design

Bespoke-designed glass packaging for your product offers numerous advantages that can significantly enhance your brand's presence and appeal in the market.

Distinct brand identity and unique visual appeal not only reinforces your brand’s recognition, but also catches the eye of the consumer

Working together, Rawlings helps its clients develop their visual ideas and capture them in a comprehensive design brief Providing the client with an initial concept and technical specifications for discussion Rawlings offers a constructive review process and may suggest improvements for technical reasons to avoid potential problems during production, filling, labelling, or capping that could later increase costs. Making the most economical use of glass while ensuring a robust product that's fit for purpose, sustainability and

quality are key factors of the development, design and production process

Concept & Design Development

With the client’s input, Rawlings develops the chosen concept and finalises the technical drawings, typically using CAD modelling and 3D printing for fast prototyping At this stage the technical specification is validated prior to sample production

Once the design is approved by the client and everyone is happy, Rawlings organises sample moulds and manufactures a few hundred sample containers

These sample containers are used to:

• Check material quality, embossing and other intrinsic design features

• Test performance on filling lines and other equipment

• Trial proposed decorative techniques, labels and closures

• Packaging trials

The final stage is bulk production The production slot is booked, final moulds are delivered, and full-scale manufacture commences A final quality check is made before the finished containers are carefully packed and delivered to the client.

Have a bespoke design project in mind? Contact Rawlings to start the conversation

www

18

rawlingsbristol.co.uk

hello@rawlingsbristol.co.uk For further information:

sales@opmgroup.co.uk www.opmgroup.co.uk

For further information:

SHOWC ASE Containers

Beer Box Shop - bringing down costs for packaging essentials

DPL / Beer Box Shop is celebrating 10 years of producing and supplying packaging to the brewing industry.

Simon Hulse (Director) said, “It’s amazing to have been working in the most creative and collaborative industry for the last 10 years, and it feels like were only just getting started!” Moving to a new purpose-built warehouse allowed Beer Box Shop to extend its in-stock product range and the services the company provides to the brewing industry

“We’re always looking to develop our proposition; over the last 12 months we’ve added even more shipping and gift boxes to our in-stock range, we’re now providing free storage options for our customer ’s bulk packaging orders, we’ve launched a consolidated production project that allows us to supply full colour bespoke gift boxes with low minimum order quantities at low

prices, and we’ve launched a home fulfilment service to deliver our customers’ own online drinks orders ”

The new warehouse also means that Beer Box Shop is able to produce and store shipping and trade boxes in even higher volumes Larger volumes mean lower raw material costs and increased production efficiencies Simon commented, “Our core business has been built on efficiently producing big volumes of boxes so we can competitively supply all sizes of breweries, but our additional warehousing space is allowing us to take this to a whole new level and to pass on the savings to our customers ”

The consolidation of its raw material supply also means that Beer Box Shop can offer lower costs for the production of bespoke printed shipping and trade boxes too

Whether a customer needs 100 or 10,000 boxes, Beer Box Shop will

Small cap, big impact: How crown caps can elevate your beer brand

Josh Webster, Head of Marketing at Croxsons, the family-owned company that supplies glass packaging, explores branding opportunities for the beer industry.

In the world of packaging, every detail counts. From each choice you put your perfectly crafted recipe to the eyecatching bottle design, breweries strive to create a unique experience for their consumers Often overlooked however is a prime piece of brand real estate: the crown cap Branding is everything

It’s what I’ve been hearing in the industry and understanding the power of a well-designed crown cap can bring a greater shelf presence It's the final touchpoint, the silent ambassador that speaks volumes about your brand identity long after the last sip

Beyond its functional purpose of sealing the bottle, the crown cap offers a unique opportunity to enhance your brand in several ways

Firstly, consider the impact on shelf appeal In a crowded marketplace, a creative crown cap design can be the eye-catching element that differentiates your beer from the competition Think vibrant colours, playful graphics, or even custom embossing to make your product stand out Remember, in a split-second decision at the point of sale, visual impact is key

The crown cap is more than just a pretty addition; it's a canvas for your brand story Use it to showcase your brewery's name, logo, or even a playful mascot Limited-edition designs for seasonal brews or special collaborations can create a sense of collectability and excitement, further engaging your customers

Furthermore, consistent use of a welldesigned crown cap reinforces brand recognition Every time a customer opens your beer, they're reminded of the experience your brand offers This subconscious reinforcement strengthens brand loyalty and encourages repeat purchases

provide high quality packaging at low prices with the same great level of service - including next working day deliveries for in-stock items.

Heather Hulse (Director) said, “Where we can work closely with our brewery partners to plan their shipping and trade box requirements, we can provide them with further loyalty discounts and free of charge storage for their bulk packaging orders ”

Engaging designs can spark conversation and create a sense of community among your customers Limited edition designs can turn into collectors’ items and live long in the memory.

By investing in creative crown cap designs, you're not just sealing your beer; you're sealing the deal with your customers It's a small detail with a big impact, a powerful tool to elevate your brand and connect with your audience at every opportunity So, open up and let your crown caps tell your brand story – your customers are waiting to listen (and drink!)

20

www.beerboxshop.co.uk Tel:

For further information: www.croxsons.com hello@croxsons.com For further information:

01538 528181

SHOWC ASE Containers

Casks, credit, and cash

Casks, credit, and cash - three important items if you brew beer. Now more that ever brewers need to be careful how they invest in their business

NDL Keg Europe Ltd, a leading supplier of kegs, casks and brewing equipment to the brewing trade, has been working closely with Moorgate Finance to assist brewers who are looking to invest in their fleet of containers and brewing equipment

It’s important to grow your business at a sustainable rate, but like many industries the brewing business is full of peaks and troughs Sudden demand of your product puts strain on your fleet of kegs and casks and very few breweries have the funds to just go and purchase more when the need arrives

With this in mind, NDL has found a suitable partner in Moorgate Finance to offer brewers some great alternatives, to enable them to increase their fleet of kegs and spread the costs Renting is

one method used by many breweries, but isn’t always the right answer, especially when looking long term

We recently spoke with a small brewery that was spending £960 per month on rentals By purchasing the casks over a 5 year period they were able to bring this monthly cost down to just £197 39 a month Far more affordable, and allowed them to allocate the funds elsewhere in the business Also knowing that after the 5 years they will own the assets, which are branded in their own livery, and no longer have that particular cost at all

NDL Keg Europe Ltd has one of the widest range of kegs and casks offered to the brewery trade, and we speak with breweries of all sizes Moorgate Finance is actively helping us to make sure we give them the financial support they need in order to make their businesses grow.

A taste for more sustainable labels

With increasing competition for the consumer pound, it’s essential for brewers of all sizes to consider not only the quality of their products, but also their environmental impact.

In a world where sustainability is no longer a trend but increasingly becoming a necessity, every aspect of operations, including the labels, must be scrutinised, which is why more brewing and bottling companies are choosing WoodFilm® as their label substrate, enabling them to make a positive environmental statement without compromising on print quality or label performance

Developed by the paper mills of Scandinavia, WoodFilm® offers a number of benefits that resonate with brewers and environmentally conscious consumers alike

The first and potentially most significant of these is that the material is both renewable and sustainable, as the wood based ‘oils’ used to form the basis of either the white or clear Polyolefin WoodFilm® product, are extracted from a by-product of the wood pulp to paper

manufacturing process, meaning the label substrate is not only created using non-fossil-fuel based materials, making it easier to recycle through normal household waste streams, but it also utilises what would otherwise be a waste product

The whole manufacturing process, from the extraction of the wood-based oils, to the finished substrate leaving the suppliers warehouse, is independently ISCC (International Sustainability and Carbon Certification) certified, further boosting WoodFilm®’s environmental credentials; whilst the environmentally conscious production process also enables brewers to significantly reduce their carbon footprint, as it reduces total Greenhouse Gas Emissions by up to 60%* compared to fossil-fuel based plastic alternatives; depending on whether the white or clear option is chosen

Of course, environmental benefits aren’t the only consideration when it comes to producing labels, so brewers will also be pleased to hear that WoodFilm® boasts exceptional print quality and performance capabilities, with its durability and resistance to moisture

making it ideal for the demanding conditions of the brewing industry, and a perfect alternative to their traditional fossil-fuel based counterparts

With this fantastic combination of sustainability, performance and consumer appeal, WoodFilm® is connecting brewers with their eco-conscious consumers on a deeper level whilst simultaneously improving their environmental credentials, making it the perfect label choice for brewers across the country

* Cradle-to-Gate on 1,000m2, based on ‘Life Cycle Assessment’ study in accordance with ISO 14040/44 and PAS2050 standards

22

Tom Roberts, Managing Director Moorgate Finance (left) & Justin Raines, Operations Manager NDL Keg Europe Ltd

www.mercianlabels.com For further information: ndlkegeurope.com moorgatefinance.com For further information:

How to attract customers with 'WOW' factor printed packaging SHOWC ASE Containers

In a vast ocean of popular products, your brand’s success hinges on the exhilarating challenge of finding a way to make a bold statement and stand out amongst competitors

Many brands are turning to ‘WOW’ factor printed packaging to catch a customer ’s eye Packaging with the ‘WOW’ factor has designs that are visually striking and eye-catching, incorporating vibrant colours, unique shapes and captivating graphics It’s packaging that is creative, protective and kind to the planet, while also providing a memorable and engaging unboxing experience for consumers, which will be irresistible to share on social media so your brand can be seen by millions worldwide

Functionality will always be an important part of the design and structure of packaging, but ‘WOW’ factor printed packaging is there to take the impact of packaging to the next level Below, we have cast our expert eyes over some of the main benefits of choosing ‘WOW’ factor printed packaging for your business

What gives packaging the ‘WOW’ factor?

You can add the ‘WOW’ factor to your packaging which can hugely impact your business’s branding efforts, helping your products leap off shelves and make a statement with eye-popping custom printing The look created through custom printed packaging boxes is a vibrant reflection of your brand’s personality, and this is often the first physical touch point a consumer will have with your brand Remember, as it takes only between 3 to 5 seconds for a consumer to notice a product on-shelf and decide to purchase (LinkedIn), first impressions really do count

Packaging that tells (or sells) a story Consistency is key, as they say, and that is certainly the case with product packaging and brand messaging It helps reinforce brand recognition among consumers, building trust and loyalty along the way. Each time your customers encounter your products, they're greeted with the same vibrant packaging and messaging that they've come to know and love

Customers often look for products that align with their core values Did you know that a whopping 75% of consumers are willing to switch brands if their values clash? (Consumer Goods Technology) That's right – shoppers want products that resonate with their beliefs, and they're not afraid to seek them out

When packaging tells a compelling story, suddenly, your product isn't just a purchase; it's a vital chapter in consumers’ own narratives and an extension of what they stand for They feel a connection, a unique bond, with the product This boosts brand loyalty and encourages them to buy again But they won’t then just buy from you; they champion your brand, spreading the word like wildfire to anyone who will listen If they are impressed with a product, it’s likely their friends will be too

Packaging that stops you in your tracks

Unleashing bursts of colour and creativity, printed packaging can transform simple products into shelf and screen showstoppers When it comes to eye-catching designs, litho printed packaging is one of the most popular choices for jaw-dropping visuals. Lithographic printing is high-end and high-quality and works perfectly for bespoke luxury packaging It’s an effective way of ensuring your product is showcased in all its glory

The power of printing techniques

There are a whole toolbox of tricks when it comes to printing techniques - such as embossing, debossing, foil stamping, holographic effects and scented inksthat can take your packaging to the next level These cardboard box printing techniques not only improve the visual appeal of the packaging, but also create an experience that dazzles the senses! Embossing and debossing, for example, add a tactile element to the packaging, allowing customers to physically feel intricate patterns

As well as printing techniques, packaging materials and textures add to the overall tactile experience for customers From the smooth elegance of matte finishes to the dazzling sheen of gloss, every texture and material tells a story of its own, adding a delightful

twist to the unboxing adventure

Adding interactive elements

By incorporating interactive elements into printed packaging designs, you can create unique experiences that captivate consumers' attention and leave a lasting impression A significant 88% of businesses are gearing up to implement interactive packaging in the future (Packaging News), which will help them to stand out for doing something different, whilst showcasing their business as one keen to go beyond the box

VIP - very important packaging

Printing personalised and limited-edition design elements on packaging is a great way to grab customers’ attention They create a sense of exclusivity, giving someone the feeling of FOMO if they don’t snap the product up immediately. Limited edition releases - which can be linked to special occasions, brand collaborations or promotions - add an element of scarcity and create a sense of urgency, while boosting the item’s perceived value After all, who could resist the thrill of snagging a one-of-akind treasure before it's gone for good?

By embracing environmentally responsible materials and printing practices, you're not just appealing to a niche market – you're tapping into a whole army of environmentally savvy consumers who are hungry for green products Using eco-friendly printing techniques contributes to reducing the environmental footprint of printed packaging Sustainability isn’t just a trend – it’s now an expectation of consumers, and they are increasingly drawn to brands that showcase a commitment to reducing their impact on the planet

How to find the wow

Get ready to unleash the "WOW" with printed packaging that'll make heads turn and jaws drop! Here at Saxon Packaging (part of the Smurfit Kappa Group), we're all about bringing the fun to your packaging game and helping you stand out from the crowd like never before

24

www saxonpackaging co uk For further information:

25

FO CU S UK Distilling

28 bottles and counting...

Enterprise Tondelli was delighted when it was awarded the contract to supply the heart of line 4 with a new blower/filler/capper and infeed conveyors to provide probably the most flexible medium speed line ever!

Loch Lomond Distillery can trace its roots back over 200 years Today, it crafts three distinctive whisky styles including its flagship Scotch single malt brand, Loch Lomond Whiskies; its single grain whisky, Spearhead made from 100% malted barley and distilled in a copper coffey still; and its latest creation Noble Rebel, a range of blended malt Scotch whiskies that seek to break the norm by combining new ideas with deep-rooted traditions in whisky making Enterprise Tondelli has been working at the bottling plant of Loch Lomond since 2004 and has supplied much of the equipment on site ranging from high speed flask and cylindrical bottle filling to depalletising, shrink wrapping, palletising, conveying and labelling

This new project has a bottle filler that can handle from 500 ml PET bottles up to 1 75 litre glass jugs along with square, cylindrical and rectangular bottles all on the same line Additionally the line can handle 11 different closures that are automatically applied These include 8 different sizes of “T” shaped corks and 3 different sizes of ROPP caps.

Due to the variety of bottles sizes etc to be handled, a bulk bottle reception mattress table was supplied that can

accommodate 2 layers of bottles allowing greater autonomy in the semi-automatic depalletising process Depalletised bottles are single-lined by a pressureless combiner which has the capability for many different programmes depending on the bottle This handles both cylindrical and some of the shaped bottles

As already mentioned, the area is quite compact so special disc type bends were used with quick changeover system to accommodate the very differing bottle sizes using quick adjustment levers No change parts are required thus allowing quicker size changes The conveyors are controlled from the Eurosistemi stainless steel panel which has a touch screen hmi for menu selection

The bottles are fed to a monobloc blower/filler/capper which has a number of interesting features With 28 bottles the traditional change parts would have consisted of at least 11 different components including starwheels, wormscrew etc. However Enterprise supplied an adjustable starwheels system and universal wormscrew that allows most of the bottles to be handled with no bottle handling change parts at all, except the rinser grippers

Fill level on the low vacuum filler is set from the operator panel and each bottle has its own pre-set value for

Return of Craft Distilling Expo

The Craft Distilling Expo is back for 2024, Wednesday 2nd & Thursday 3rd October 2024, with tickets available soon.

The UK's number one conference for distilling; providing education, supplier exhibition and networking will once again open it’s doors at the Truman Brewery, London On Wednesday 2nd and Thursday 3rd October we are bringing together the world’s preeminent Master Distillers, still makers, packagers and marketers, professionals

and connoisseurs in an Exposition and Conference offering talks, workshops and displays.

Exhibitor stands and sponsorship packages are currently on sale The deadline to book is the 15th July However, anyone who books before the 15th June will receive a 10% early bird discount

For the 2024 Craft Distilling Expo the organisers have decided, in an effort to help you make the most of your visit, to have a more concise

repeatability A low level cap hopper and fltted belt elevator feeding the dual purpose capping turret ensures safe working for the operators A pre-set bottle counter allows them to set how many bottles to produce before the filler stops and advises batch complete

The conveyor layout produced in the UK office of Enterprise Tondelli also meant that one operator was centrally located to monitor several aspects of the line reducing wasted movement The machine will fill both brown and white spirits as well as some new ranges of products such as flavoured liquors To ensure good hygiene, CIP cups were also supplied to allowing machine cleaning without medium going to waste or creating a slip hazard on the floor Stop press – another two bottle sizes are now being handled bringing the total to 30 different bottle shapes and sizes! Enterprise Tondelli have been working in the industry since 1977 and supplying equipment in over 40 countries. This wealth of experience ensures Enterprise add something to all their projects ”

schedule of talks

This will largely be made up of 25 minute sessions focusing on particular subjects that are relevant to distillers today. This should allow attendees to get to the heart of pertinent issues whilst also having more time to interact with our vendors, who are an invaluable source of knowledge

26 www enterprisetondelli co uk For further information: distillingexpo.com For further information:

We asked companies supplying the UK Distilling market to let us know something about their products and services.

FO CU S UK Distilling

A more sustainable future for packaging

Croxsons, a family-owned company that supplies glass packaging and closures, is always exploring sustainable initiatives in the operations process.

At Croxsons, we have always had sustainability in our heart With over 150 years in the glass industry, we’re embracing sustainable practices in all aspects of our operations process Our customers demand the highest sustainability standards from us and we are more than happy to rise to that challenge

We have all kinds of initiatives in place to make a positive difference, from working with a furnace powered by low carbon hydrogen, renewable fuels and electricity, to planting over 150,000 trees to help reverse the effects of deforestation

Let’s take a closer look at some key initiatives for us and across the industry

Net zero bottles at scale Plans are already developed and in-process to produce in furnaces powered by 100% renewable electricity, as well as furnaces utilising hydrogen

Having already trialled alternative fuels such as 100% biogas, we have delivered bottles with an estimated 99% reduction in carbon footprint, but with the same benchmarks for quality and performance

Green energy

We are switching to green and renewable energies, a key move in reducing our environmental impact

Across the glass sector, measures to reduce combustion emissions by 2028 include increased use of cullet, oxyfuel combustion and liquid biofuels

At Croxsons, we aim to continue increasing our use of post-consumer recycled (PCR) glass up to 90% This move will mean energy savings over melting virgin raw materials, reduced CO2 emissions and other environmental benefits like the infinite recyclability of glass (unlike plastic alternatives)

150,000 trees planted

To mark our 150th anniversary and take

a huge step in our carbon footprint reduction efforts we funded the planting of 150,000 trees through environmental services company Ecologi Trees are one of the best carbon capture and storage containers

Across the glass packaging industry, we are building sustainability into our processes from the very start to the very end We are not only making better bottles We are making a better tomorrow too

A natural look for West Highland Spirits

West Highland Spirits is a company that aimed to achieve two things Firstly, it wanted to create a range of spirits full of flavour that reflects its Scottish heritage and the beauty of the surroundings in the Highlands Secondly, it wanted a creative brand design that showcases the natural habitats and wildlife of the surrounding environment

West Highland Spirits recognised it needed to take drastic measures to compete in the high-quality Craft Spirits market Although highly confident in the quality of its products, it required a brand design that matched the craftsmanship of its products To stand out in the marketplace, West Highland Spirits also understood that they needed to push the boundaries of creative design

As a result, the company engaged the services of LemonTop Creative, who

have their own LemonTop Gin and were already known to be experts in creating brand designs that stand out on the shelf With the knowledge and confidence, the LemonTop creative team could provide the Spirits company with a brand design and a range of bottle designs that align with its ethos of caring for the Highland environment while standing out among its competitors wherever they were displayed

www.croxsons.com/about

The new West Highland Spirits brand has been designed with creativity and innovation in mind The bottle designs are a perfect blend of modernity and traditional craftsmanship, appealing to those who seek uniqueness These designs reflect the brand's pride in tits Highland roots, the love for the

environment, and the quality of the Highland produce it makes These beautifully illustrated designs are a testament to West Highland Spirits' commitment to standing out from the competition and are on sale via their website https://www westhighlandspirits com

For further information:

28

For further information:

www.lemontopcreative.com hello@lemontopcreative.com

FO CU S UK Distilling

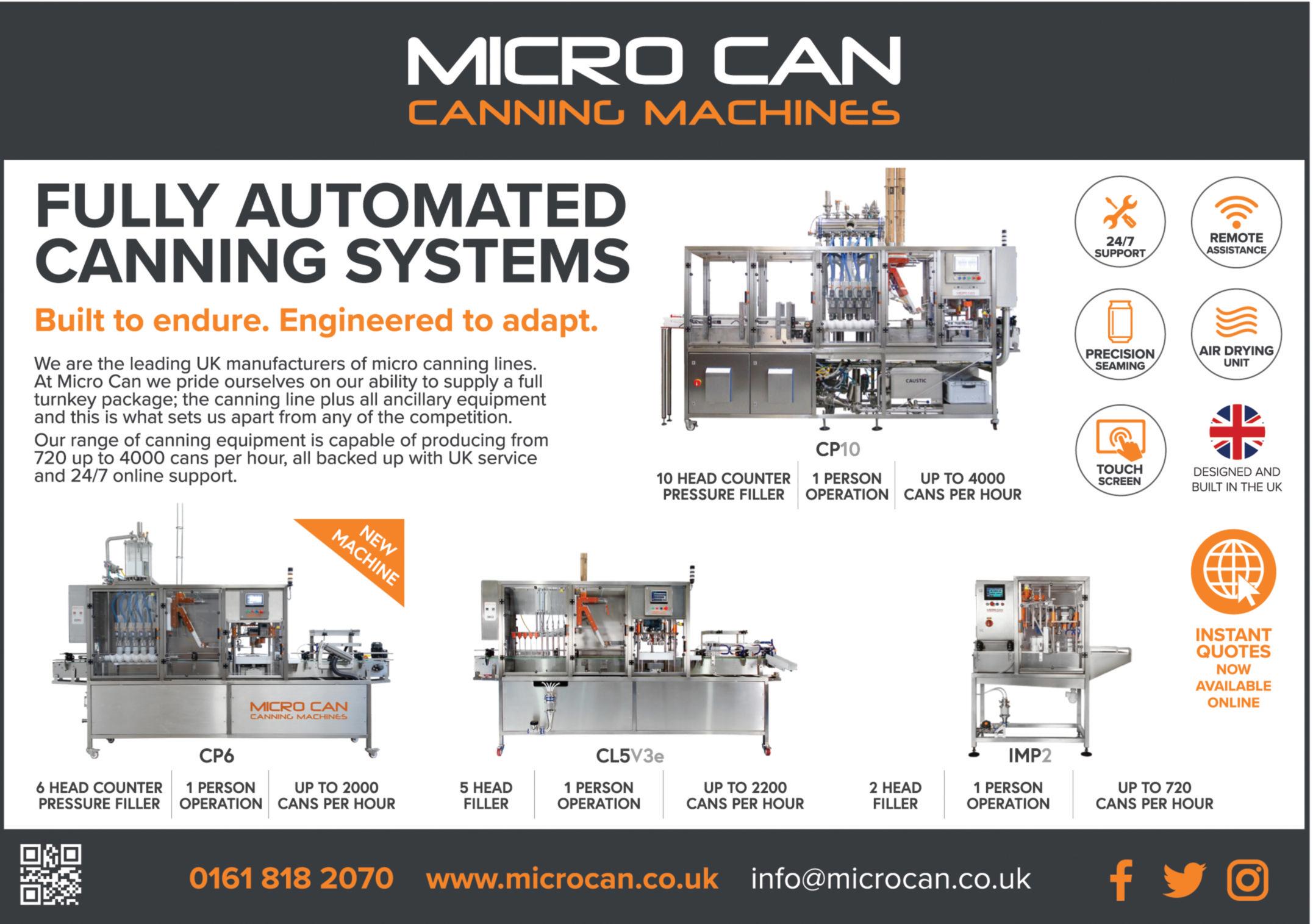

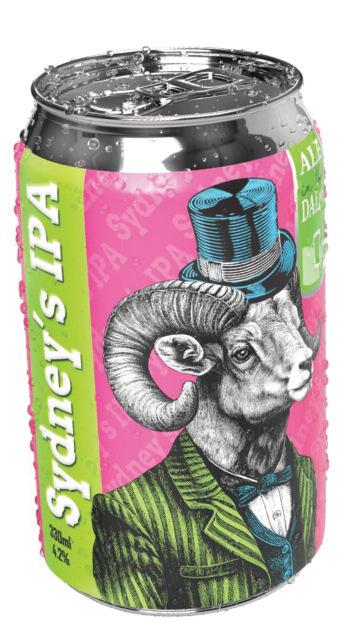

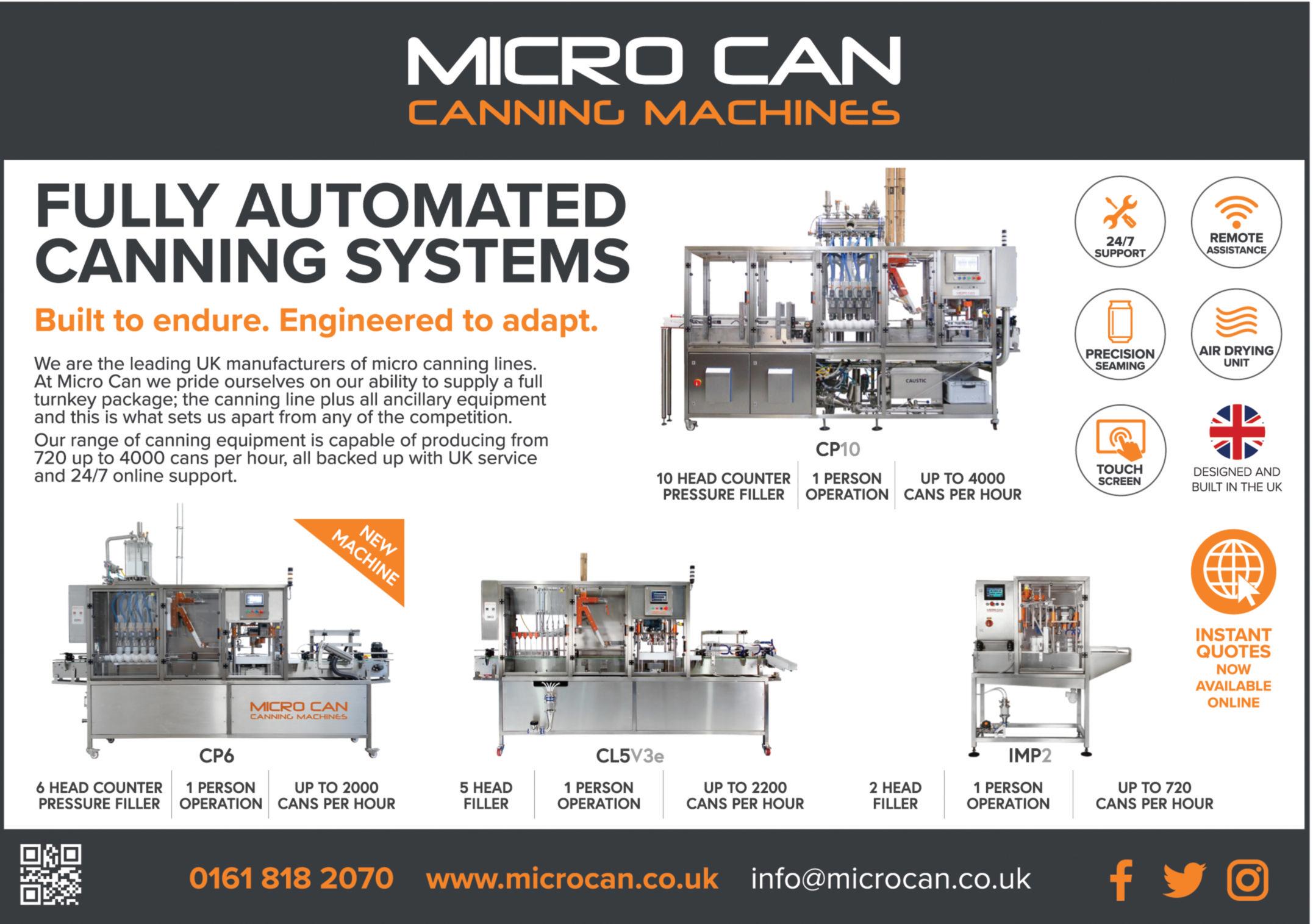

Cardiff Distillery installation for Microcan

UK manufacturing company

Microcan has recently completed an installation at Cardiff Distillery in Wales

Microcan has a range of machines from 700 cph to 4,000 cph or 8,000 cph with the twin CP10 option Now we have the partnership with STM we can offer up to 30,000 cph with full rotary options

We have the ability to provide a full turnkey project from design to installation and support the customer onwards with our vast experience of packaging many different products for the last nine years

With the consistent expansion of our premises, people, equipment and supply partners, we are now in a position to take on much bigger projects After partnering with Mainland Canning from the Netherlands and STM in Poland, we can offer much larger canning systems

Since Microcan was formed and delivered it’s first machine back in 2017 we have been on an incredible rollercoaster ride of ‘design, test, deliver, repeat’ Everything started around 2010 when we began to build brewhouse controls under the banner of Retro Control Retro Control was formed by Warren Stanley in 2009 with the idea of

having a small controls business working from home

Having been given the opportunity to build some cask washer control panels we quickly moved into full brewhouse controls and have built and installed more than 150 systems across the UK

When looking for another avenue to generate cashflow, Warren set up a mobile canning business called CAN IT Mobile

Canning and purchased a Canadian canning line Warren started mobile canning in 2015 working seven days a week trying to build the business, travelling countrywide on a very steep learning curve It was during this period that he realized the canning boom was just starting and there was a buzz around canning machines, and the lack of choice. No one in the UK was supplying a craft machine and Warren believed there was an opportunity to develop a good quality value-for-money machine

The concept of Microcan was created and the hard work really started Any spare time between control panels and canning was spent prototyping canning machines Two years later and after a lot

of blood sweat and tears, Microcan had developed tested and delivered it’s first CL5v1 canning line Fast forward seven years and here we are, over 350 machines delivered across 19 countries

Recent equipment installations include Real Drinks and Seven Bro7hers

Microcan has seen excellent growth with a small but amazing team of very talented and committed people We have also established a great distributor network in various regions around Europe

Here at The Bag In Box Shop UK, we have developed a range of High ABV Bag In Box solutions with our Co-Packers SCS to offer 3L, 5L & 10L High ABV Bag In Box solutions.

Using genuine VITOP bags and taps our system allows you to refill bottles in bars meaning you can cut down on glass usage, breakages and reduce you’re carbon footprint

Our 5L Digital Printed High ABV packs can be printed and delivered from as little as £0.40p per litre and at the same time a standard wine bottle produces 875kg of CO2 compared to 107kg CO2 for a 5L Bag In Box solution

Over the last 12 months BIB UK and SCS have seen a large increase in projects and orders for small and medium High ABV customers looking to move into Bag In Box, this solution allows customers to supply bars and

pubs a reduced number of glass bottles which can then be refilled on site from the Bag In Box system, removing glass bottles from the supply change and allowing High ABV suppliers to ship less often to customers reducing transport costs In partnership with SCS, an independent co-packer with a bonded warehouse we are now able to offer the complete service from packaging to finished product

From lab solutions to liquid development, SCS offers a turn-key solution for virtually all beverage categories We have one of the most versatile packing and processing operations in the country, so whether you are looking to put your spirits into bag-in-box, RTDs into kegs or soft drinks into bottles, our expert technical team will find the right solution for you

With contract filling MOQs of 1,000lts, precise carbonation up to 6 0g/lt, processing options including both flash

pasteurisation and Velcorin, and a site wastage of 4%, your product is in safe hands

Get in touch to see what we can do for your new or established brand

If you are interested in exploring refill packs contact The Bag In Box technical team, or for more information on contract packing at SCS please contact Tom Ebdon, on the email addresses below

30

hello@baginboxshop.co.uk. tom@somersetcidersolutions.co.uk For further information: www microcan co uk info@microcan.co.uk For further information:

Looking for a refill pack solution?

31

FO CU S UK Distilling

Distilling explained in a nutshell

Nick Brading of Murphy & Son walks you through the process...

The process of distilling is one whereby a liquid mixture is separated into its singular components by means of heating, usually boiling, then condensing the vapours returning them to a singular, purified, liquid state by collecting them at a cooler temperature

It is known from the archaeological record that distilling was practised by the Ancient Greeks and the Ancient Chinese in the production of perfumes, alcohol and the desalination of water Most commercial distillation produces alcohol, namely ethanol, that can be matured, blended and packaged for consumption. There are hundreds of variants of the final drink, defined geographically by the materials and methods available and the particular taste of the target market The most famous distilled product in the world is arguably whisky which can be described through the three M’s; Materials, Method and Maturation Materials

The base materials for whisky production are barley malt, water and yeast Barley is a cereal crop that prefers lighter soil, dryer rainfall and cooler growing conditions as found in

the UK, particularly east of the Pennines Barley varieties are bred specifically for malting Water used for “cutting” the neat spirit after distillation is often naturally collected from a spring rather than mains, adding individual character to the final liquor Yeast is a naturally occurring microbe well known for its ability to convert sugars into alcohol Different strains of yeast are used to make different styles of spirit, e g gin, rum, vodka and whisky Fermentis Distilling Yeast ArchivesMurphy and Son

Method

After harvest, barley is malted, a process of steeping, germination and kilning to deliver a dried grain to the distiller for the next stage Malting changes the starchy endosperm in each grain into fermentable sugar The distiller crushes the grain to a coarse grist, mashes with hot water then elutes the cooled sugary worts to a washback Yeast is introduced and allowed to ferment the sugars to alcohol The whole contents of the washback are distilled using heat which drives the volatile alcohol out of solution as a vapour These vapours are condensed then collected and held in various vessels for subsequent blending

The Craft Distilling Business Limited

We design, manufacture, and install custom distillation equipment for distilleries and breweries venturing into craft spirits. Whether you're starting or scaling up, we develop systems that fit your space and budget, with options starting at £11k

We also offer a comprehensive range of support services Services offered include:

Operational Training

Comprehensive and ongoing support is provided to clients to ensure they are comfortable operating their equipment and producing their chosen spirits.

Recipe Development

Matt Servini, a recognised expert in the industry, assists clients in developing their own spirit recipes,

many of which are award-winning and can be exclusive to them

Licensing Support

The company assists clients in navigating the complexities of obtaining necessary licenses from HMRC and local authorities, ensuring legal compliance and readiness for production.

Health & Safety Training & Documentation

We provide a standard operating procedure for every piece of equipment and develop risk assessments in line with the requirements of your setup

Consultancy

Flexible consultancy services are available either on a project basis or as individual purchases, with pricing structured per project or by day rate.

Maturation

The alcohol or raw whisky at this stage is collected in wooden barrels, typically oak and held for at least three years, often more It evaporates slightly in this time, developing oxidation flavours but also picking up flavour and colour from the wood which is influenced by what the oak barrel has previously stored, e g sherry The alcohol is still very strong, in excess of 65% so when it is required for bottling, it is cut to around 40% with spring water which delivers another layer of complexity to flavour

Nick Brading is part of Murphy & Son’s technical support team, previously working as a Master Brewer for Shipstones, Ruddles and Carlsberg International and is a specialist in spirits, so knows a thing of two about the challenges brewers and distillers face from mash to glass

Nick focuses most of his efforts supporting customer predominately in the North of England, Scotland and Ireland However he is always available to help with queries sent to techsupport@murphyandson co uk .

www.murphyandson.co.uk

32

For further information:

They are tailored to meet diverse client needs in spirit production

www.thecraftdistillingbusiness.com Matt@craftdistillingbusiness.com For further information:

33

FO CU S UK Distilling

BRITANX in action at UK rum distillery, Drop Works

BRITANX, the processing brand from UK stainless steel manufacturer Fabdec ltd, has supplied 14 vessels and plate heat exchangers to Drop Works, Europe’s largest rum distillery, located within Sherwood Forest in Nottinghamshire.

Founded by industry expert, Lewis Hayes, the brand was inspired by cultural movements such as Britpop, and is positioned as a new genre of British rum (coined as Brit-rum)

The aim behind DropWorks, and the inspiration for its name, is the introduction of limited edition releases of rum, named ‘Drops’, using a fermentation and distillation process to create different styles of rum The idea is that, alongside its core range of products, everyone can find a rum they love

range bespoke copper equipment is used in the distillation process

Lewis Hayes, founder and owner of DropWorks said rum has so much more to offer the world than what it does at the moment

“Having our own distillery allows DropWorks full control of the process from start to finish,” he says “Meaning we aren’t burdened by limitations existing elsewhere The Rum Distillery houses a colossal collection of copper clad equipment, including the first double retort still in England which has a 1,500 litre capacity

Clear Drop Rum is produced selecting only the highest quality cuts from a long slow distillation process, the first product Drop contains rich flavours of fresh blueberries, vanilla ice cream and banana created from DropWorks own cultivated yeast strain, Trinity Yeast, which, says DropWorks, is the world’s first three strain symbiotic yeast

The DropWorks Distillery creates Clear Drop Rum using three custommade, bespoke stills including a Double Retort still which is the first of its kind in England, alongside the two different raw materials - Molasses and Organic Cane Juice Honey - which are fermented, distilled and blended on site Additionally, Clear Drop Rum is smooth due to the excessive copper interaction and elongated reflux afforded by a deflagmator at the top of an eight plate column

Since 2020, DropWorks has received £1 8m in private funding which has been invested into the distillery, flavour development and top of the

“This kind of still is rare in the Caribbean, let alone the Sherwood Forest! Double Retort stills have a magical ability to turbo charge the aromatics of a distillation, which means we can dial the flavour all the way up ”

The DropWorks Distillery, spans 17,000 sq ft production facility, and a further 8,000 sq ft barrel store and three mile underground tunnel for storing the casks, allowing for a long consistent maturation and three different barrel ageing environments The brand new facility can now produce up to two million bottles of rum a year and up to ten barrels of rum a day

The production facility includes 14 vessels and plate heat exchangers from BRITANX, the processing brand from UK stainless steel manufacturer, Fabdec ltd From mixing tanks, to storage and cooling tanks, with capacities ranging from 3,000 litres to 7,000 litres, BRITANX offered bespoke designs to suit the Distillery giving complete flexibility

BRITANX from Fabdec offers high quality hygienic stainless steel vessels to the Food, Beverage and Processing industries With over 60 years’ experience, all manufacturing is from our state-of-the-art 65,000sq ft facility in Shropshire Specialising in

the design and manufacture of bespoke solutions, our in-house design team can tailor to customer requirements by accommodating any onsite layout or restrictions. All vessels are expertly produced using the very latest technologies in welding, polishing and testing. This includes our very own and the UK’s only laser welded dimple plate machine This enables us to produce and test our own heating and cooling jackets in house All claddings are fully welded and 85mm of injected polyurethane insulation comes as standard

All pressure vessels are designed to PD5500 and both the vessel and jackets come with all pressure test certification To complement the vessels, we manufacture a number of ancillary items, such as Plate Heat Exchangers, in line carbonation, hop dosing and more

Adds Lewis Hayes, “At The DropWorks Distillery we have invested heavily in producing bespoke products which allows us to make Rum that is as light as Vodka, fruit driven as Cognac, funky as tequila, as smoky as Mezcal, as oaky as Whisky or as spiced as Gin. All without the need for additional flavourings. The team have decades of experience in distilling spirits and are committed to continuously bringing new and innovative rum products to the market through new processes and ways of flavouring products ”

For further information:

34

fabdec com/en/

SHOWC ASE Branding

We asked companies supplying the following products and services to let us know something about themselves.... l Logo and image design, corporate branding on clothing, promotional literature, and other marketing material, including company websites

A magical makeover of Welsh brewer Tomos Watkin

The new owners of Welsh brewing icon Tomos Watkin have unveiled a new brand identity after enlisting the services of the brewing industry’s design specialists, LemonTop Creative.

Inspired by the magical tales of dragons and wizards that echo through the wild Welsh valleys, the brand makeover produced by LemonTop Creative has given Tomos Watkin a fresh, new look to start the next chapter in its life

Founded in 1996, the Tomos Watkin brand has been rejuvenated after brewers Joelle and Sarah Drummond, who also set up Drop Bear Beer Co in 2019, bought the brewery in August 2023

The enchanting Welsh valleys and their mystical stories of dragons and sorcerers served as a source of inspiration for the fresh brand identity that LemonTop’s talented team created for the brewery The new owners of the brewery wanted to captivate the modern-day beer drinkers while also commemorating its legacy, so they allowed the brewing industry’s design specialists to let their creative spirits wander as they created a magical makeover of the brand The relaunch not only celebrates the brand's heritage, but also creates a path forward to an exciting future for Tomos Watkin as a

leading light in Welsh brewing

Tomos Watkin’s latest range of beers includes traditional favourites Cwrw Haf, Blodwen and Magic Lagyr, with two new additions, Dragon’s Keep IPA and Miner ’s Pride, intended to entice new customers Stouts and IPAs have both grown in popularity over the last couple of years and the new owners were delighted to have these styles as additions to the core range, updating the range of beers they offer and increasing the potential for growth

Director of sales and marketing for Tomos Watkin, Joelle Drummond, worked closely with LemonTop’s creative team on the new brand identity

Having grown up in Swansea Joelle was already familiar with Tomos Watkin Brewery and wanted to further develop the essence of the brand’s history She worked with LemonTop on the branding and promotion of Drop Bear Brewing, so she knew the agency would be able to help her start a new chapter with Tomos Watkin

The LemonTop team used their illustrative skills and let their imaginations run free as they created a brand with an imaginative and magical vibe, featuring wizards, farmers, miners, and cockle pickers, all tied together by the famous Welsh red dragon Using the dragon as a unifying character created a link for the full range of label designs,

pump clips and packaging The brand also incorporated ‘easter egg’ elements swapping from one to the other, creating a continuous and captivating theme

Tomos Watkin Brewery was excited to unveil the new brand identity that beautifully encapsulates the essence of Wales The refreshed visual identity features stunning imagery that perfectly represents the unique spirit of each beer and the emotions it evokes

The LemonTop team have put great emphasis on showcasing this imagery prominently through a series of beautifully designed beer bottles, pump clips and packaging that are all mesmerising and captivating Each bottle tells a unique story that not only captures the essence of the beer but also celebrates the brewery’s rich Welsh heritage

St Austell Brewery has unveiled a new look for its flagship IPA, Proper Job, which hit supermarkets across the UK from March 2024

St Austell Brewery worked with longterm partners Thirst to revitalise the leading 5 5%abv brand Refined through heartfelt handcraft, Proper Job’s name is amplified with pride whilst its crisp green has been vibrantly refreshed

This modern visual identity brings to life this distinctive story across premium pump clips, bespoke glassware and brand world, reinvigorating the brand’s superior quality for drinkers old and new The inspiration behind the rebrand was

to fuse heritage and heartfelt craft with relevance for today’s market It features a striking new typeface and Proper Job’s iconic green is more prominent to maximise stand out. The new lookwhich was delivered by design agency, Thirst - is being supported with the brand’s biggest ever marketing investment – a multi-channel campaign which will launch in the spring