18 minute read

NEW PRODUCTS

from BPD March 2021

Why Lumber Grading Is Important

This story undoubtedly takes considerable liberties with the tale of Noah and the building of the ark; however, it does illustrate some of the problems which culminated in the necessity for writing grade rules for lumber. If all trees were cylindrical and straight, were free of knots and other defects, showed the same width of ring, and contained little or no sapwood, there would be no occasion for classifying the lumber product into grades. Unfortunately, every tree grows in a diff erent way with characteristics that add to or detract from its usefulness for certain purposes.

From the earliest times, the conversion of round trees into desired shapes and sizes for commercial purposes has included the separation of the product into diff erent classes based upon the number, character, and location of distinctive features such as knots, cross grain, stain, decay, pitch streaks and pockets, checks, and wane. Therefore, the direction and width of growth rings and the size, number and location of knots are important considerations with any grade rule.

How Lumber Grading Started in the US (Hint: It Was British)

Let us now look at some real history of lumber grading from its true beginnings in the U.S. Hints of various tree and lumber grades were noted in spatterings of writings from the early 1600s as sawing the vast New England forest began to unfold. The most famous tree grading was performed by the British king’s appointed surveyors, who “graded” trees to receive the Broad Arrow mark signifying it as the crown’s property.

While most of the lumber was primitively sawn and shaped in the 1600s for home and farming needs, the business of using lumber and squared timbers as a trading material was taking root with the colonists. Cities such as Boston, Portland, Portsmouth, Providence and New Amsterdam continued to grow and expand. Numerous other coastal towns were springing up, all requiring wood material. Separating their sawn products was simplistic at that point, using terms like “marketable” and “worthless.”

Lumber Grading Takes Off

As the buying and selling became more sophisticated in the 1700s, the number of grades expanded and were given a variety of names from highest quality to lowest, such as clear, merchantable, refuse and scoots. The area of the country now known as Maine (part of Massachusetts until 1820) was the fi rst large source of commercial lumber, so it was natural that the initial systematic lumber grading classifi cation in the U.S. would be established here.

These early rules for lumber grading and their measurement were eventually bound in Massachusetts Law in 1783 that required a “surveyor” (lumber grader) in each town to grade and measure all boards for sale as a requirement. No pine boards less than 10 feet could be shipped, and the law included a hefty fi ne for material arriving in a port for sale without a survey. This law became known as the “Boston Survey” since Boston was the major port of the region and a destination for most all ships carrying lumber for sale, the primary method of getting lumber to market. The law became so unpopular due to the surveyors questionable grading with tendencies to “downgrade” material to keep prices low that sawmills renamed it the “Boston Cheat!”

LUMBER GRADING in the 1950s was apparently a group activity.

Lumber Grading Expands Across the US

As the country grew westward and the sawmill industry with it, other major hubs for handling lumber were established. Burlington, Vt., became the focus of local and Canadian sawn lumber, and Tonawanda, N.Y., for lumber coming from the Great Lake states to be put on barges for trans-shipment on the Erie Canal. Each port devised its own set of grade levels, with the Tonawanda rule made up of more than 20 grades and sub-categories.

By the late 1800s it became apparent that region-wide common grades, at a minimum, would be needed to uncomplicate the confusion in the process of selling lumber. Regional lumber grading associations were established as a fi rst eff ort to consolidate the grading systems, based primarily on the area’s wood species.

The fi rst eff orts to standardize lumber began in 1922 and resulted in the American Lumber Standard, fi rst published in 1924.

Lumber Grading Today

Over the next 50 years, further standardization took place on offi cial lumber sizes in addition to the establishment of a National Grading Rule for lumber to be used in construction applications. The standard, now called the American Softwood Lumber Standard, has evolved over the years to keep current with ever-changing needs of consumers, regulators and manufacturers. Separate 1” board rules still exist for species used in non-construction, appearance applications, such as Eastern White Pine, maintained and administered by the Northeastern Lumber Manufacturers Association (NELMA).

Like most industries, lumber manufacturing and grading have come a long way over the last 400 years. Technology permits faster, more effi cient lumber production and advanced optics allow for machine grading in many mills. Those early colonists were blessed to have arrived in areas of vast forests that supplied them with all their habitat needs. The subsequent years of further development and growth of this country can be directly attributed to the continued supply of grade-stamped lumber manufactured from the only renewable and sustainable building material!

Important Note: This article was made possible through research conducted by Richard A. Hale, a Professor of Forestry at the University of Maine. During his career, Mr. Hale was one of the most respected and revered forestry scholars of his time, who spent his last years making sure his extensive research was housed properly. NELMA was the recipient of a portion of his publication collection in addition to his extensive notes on lumber grading.

The White Pine Monographs

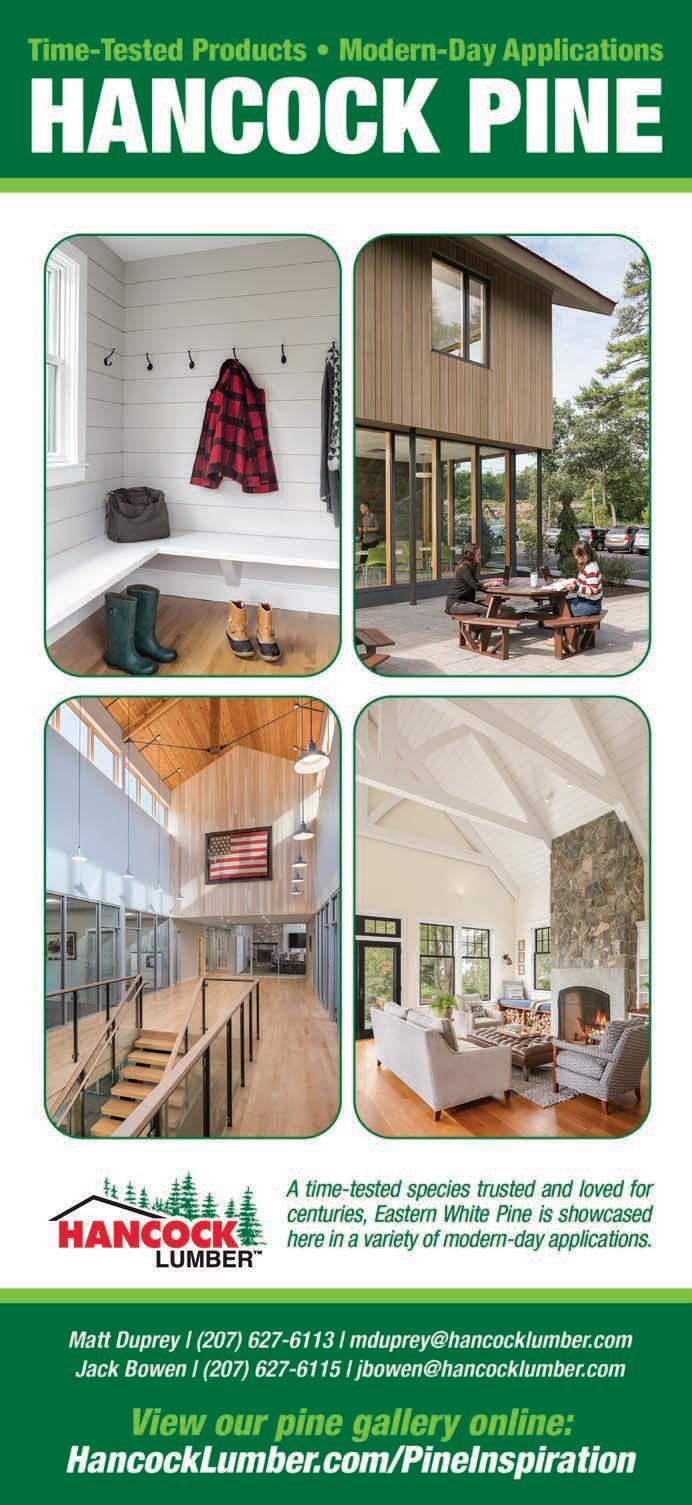

400 years of choosing eastern white pine

Eastern white pine has long been the building material of choice for New Englanders: it’s locally grown, strong, durable, beautiful, and renewable. And would you believe it has a history older than the United States of America? Read on!

Back in the 1600s, when America was being colonized, eastern white pine was a hugely relevant part of construction in the new world. Homes, churches, businesses—wood was used everywhere, including for heat. Without photos and video, how do we know this? Because of The White Pine Monographs.

How It Started

First formed in 1915, the White Pine Bureau was tasked with coordinating an advertising campaign on behalf of the white pine manufacturing industry. Supported by an assessment on total lumber production, the Bureau represented two separate white pine organizations: the Northern Pine Manufacturers Association of Minnesota, Wisconsin & Michigan and the Associated White Pine Manufacturers of Idaho.

The flagship promotional piece developed by the Bureau: The White Pine Series of Architectural Monographs (subtitled “A Bi-Monthly Publication Suggesting the Architectural Use of White Pine and Its Availability Today as a Structural Wood”). The purpose of this publication was to encourage the use of white pine as a building materi-

THE WHITE Pine Monographs first premiered in 1915 as a way to promote the use of eastern white pine throughout the U.S.

al, and a former editor of Architectural Record (1912) was brought on board to oversee the process.

With the first issue of the White Pine Monographs published in 1915, the publications featured early American buildings constructed of white pine inside and out. Each issue would focus on a general architectural style—like Colonial Cottages—or structures in a specific town, or specific architectural elements, like doorways and mantels. Design contests were sometimes integrated into the Monographs, with specific end-use structures like a roadside tavern or a home making up the design criteria. Content within the Monographs highlighted locations within the Eastern, Mid-Atlantic, and even Southern areas of the young country.

High-quality photographs (for the time!) and well-drawn renderings of building and architectural features made the White Pine Monograph series a popular success. At its peak, upwards of 9,800 architects and architectural designers were on the list to receive copies. Public libraries and universities carried the publication as well, reaching an even higher number of engaged readers.

Shout-Out to Lumber Dealers (Then and Now)

Issue Volume I, Number 3, copyright 1915, highlighted “Farm Houses of New Netherlands,” and included a special section entitled “Lumber Dealers, Do You Hear the Band?” In this section white pine was hailed as “the wood that America is mostly built of,” and included the quote “You do not have to argue the merits of white pine to your customer. Everywhere are examples of its many uses which have stood the test of years.”

The article continues with strong pressure on lumber dealers to consider the use of white pine, and only white pine. In a statement oddly forward-thinking for 1915, the writer states: “This advertising campaign (the Monographs themselves) is not only a

help to white pine in competition with other woods, but it is also like a great army of salesmen covering the whole country and persuading people, here, there, and everywhere, to use white pine, who had made up their minds, or were making them up, to build of something which was not only not white pine, but was not wood at all. It is increasing the consumption of lumber and helping the lumber business.”

In 1924, the White Pine Bureau ended its support of the White Pine Monographs and production—and the editor—were picked up by a large manufacturer. The year 1928 saw the title change to The White Pine Monograph Series on Early American Architecture; it then changed again in 1929 to The Monograph Series – Recording the Architecture of the American Colonies and the Early Republic. And the end of 1931, after 98 issues, the Monographs ceased production as a standalone entity and were absorbed by a small architectural trade publication.

How It’s Going

In 2006, the Northeastern Lumber Manufacturers Association (NELMA) resurrected the series as part of a broader marketing and communications program on behalf of their eastern white pine manufacturing members.

The new iteration of The White Pine Series of Architectural Monographs maintains the look and feel of the original publication, while integrating timely trends and architectural examples regarding the use of eastern white pine, a sustainable and versatile wood species.

“The White Pine Bureau was so far ahead of their time when it came to promoting and marketing eastern white pine,” noted Jeff Easterling, president of NELMA. “The brochures were produced and mailed to lumber producers—as they were called at the time— with specifi c pages often encouraging ‘use these to show your customers’ what wood can do. It’s truly amazing what they were able to accomplish, and we’re so honored to carry on that tradition following in their footsteps.”

With the original series lasting 27 years, editions of the White Pine Monograph continue to spark interest today within the architecture and design/build community.

NELMA is honored to house in its reference library all of the original historic Monograph booklets along with the new issues published since 2006. The series can be read or printed online at www.easternwhitepine.org.

Real Wood Look in a TFL

Roseburg has partnered with printing specialist Schattdecor to expand its popular Duramine collection. New technology delivers both a matte and a gloss finish with an optically synchronized visual effect that is always in register.

The six new decolay REAL designs—Alabaster Ash, Fossil Ash, Harbor Gray Ash, Coastal Pine, Desert Sand Hickory, and Pacific Rustic Oak—offer a contemporary selection of fresh wood tones to complement a variety of interior applications and styles.

The new designs are produced at Roseburg’s TFL facilities in Simsboro, La., and Missoula, Mt. With the added flexibility of two-sided or one-sided design options, clients can choose panels that work well for any application, including cabinetry, furniture, closets, casework, and organization systems. n ROSEBURG.COM (800) 245-1115

Versatile Rainscreen

Russin is launching a new brand of custom wood siding products designed for rainscreen installation.

Summit Rainscreen Systems offer options for several wood species with dozens of finish choices and the ability to “customize to infinity.”

The system is designed for a hidden-clip installation, which creates a 3/4” rainscreen for air and moisture flow behind the siding, ensuring the best moisture management within the wall assembly. n RUSSIN.COM (800) 724-0010

Woodsier PVC

Versatex Building Products has added two new shades to its maintenance-free Canvas Series PVC for porch ceilings, soffits and accent walls.

Turner Oak is a contemporary “greige” shade that’s lighter than Walnut. Kitami simulates the elegant carbonized surface of shou sugi ban, an age-old Japanese preservation technique.

The T&G system marries durable PVC with a variety of realistic, permanent, wood-tone laminates. n VERSATEX.COM (724) 857-1111

Mass Timber Membrane

Wetguard 200 SA, SIGA’s semi-impermeable, non-slippery membrane that protects timbers during construction, is now available in North America.

With its rainproof, abrasion-resistant, transparent and non-slip qualities, it is the first solution to equip building professionals operating in mass timber construction with this kind of a sealing opportunity.

The high-performance modified acrylic-based adhesive is comprised of a flexible non-woven PO backed with a polypropylene release film. Its water-repellent carrier is lined with an anti-slip coating to keep workers safe while walking across wet surfaces. The self-adhered membrane can be factory applied or installed on site. n SIGA.SWISS (720) 220-5339

Quick Concrete

Sakrete’s new Pro-Mix Accelerated Concrete Mix is ideal for repairs and construction of concrete over 2” thick.

It is the ultimate pre-blended concrete solution for indoor and outdoor applications where rapid return to service is crucial. With excellent workability, it provides a first-class finish for driveways, sidewalks, formwork, warehouse floors, footings, post setting and more.

Full-depth repairs and DOT applications can achieve a drivable surface with a compressive strength greater than 3,000 psi in just one hour, with a final strength of over 7,000 psi. n SAKRETE.COM (866) 725-7383

Tape to Tighten

Fixing a loose screw has never been easier or faster than with DAP’s new Tank Bond Thread Stopper Tape.

It absorbs shock and vibration while holding screws tightly in place. It works on all fastener types and sizes and is ready immediately—no dry time needed. Simply wrap the tape around the threads of any loose screw. n DAP.COM (800) 543-3840

Slim Pickings

Combilift’s Aisle Master-OP stand-on electric powered material handler combines the advantages of a narrow aisle articulated forklift and an order picker for versatile operation in warehousing applications.

Its low floor height of 11” enables convenient, single-step access from both sides of the truck, which speeds up order picking compared to the operator having to get on and off from a seated position. The AME-OP truck has all the key advantages of the conventional Aisle Master—indoor/outdoor, for loading/offloading, and for stock replenishment at other times during shifts when order picking is complete.

It comes in a number of variants, with lift capacities up to 3,300-6,000 lbs., lift heights up to 39 ft., and can operate in aisles as narrow as 72”. n COMBILIFT.COM (877) 266-2456

Self-Adhered Housewrap

Benjamin Obdyke introduced HydroGap SA, the industry’s first self-adhered drainable weather-resistive barrier.

Along with spacers that create a drainage plane, the housewrap features a 100% continuous acrylic adhesive for sealing around fasteners, breathability and increased tear resistance. The adhesive ensures the WRB adheres to the sheathing while allowing for it to be repositioned upon initial application.

As an acrylic, the adhesive is UV resistant, with an exposure rating of 120 days, and can be installed in temperatures as low as 25 degrees F without a primer. It also increases the housewrap’s tear-resistance and, by providing full contact with the sheathing, diminishes the chance for ballooning and blow-off. A reinforcing scrim helps it hold tight during application to avoid wrinkles. It comes in 80-footlong rolls. n BENJAMINOBDYKE.COM (215) 672-7200

Concentrated Fence Stain

U-C Coatings, LLC is introducing an new long-lasting fence stain product.

Eco Chemical 221 Fence Stain will be sold as a concentrate in four premixed colors, offering customers the equivalent of 15 gallons of working stain in a five-gallon pail. Rather than selling customers water, it provides the concentrated ingredients of a high-quality waterborne alkyd stain that can be more conveniently transported. It is then mixed with two parts water at the jobsite before application. n UCCOATINGS.COM (716) 833-9366

Deck Dealer Finder

A Dealer Locator has been added to Simpson Strong-Tie’s online Deck Planner Software and Pergola Planner Software to help builders eff ectively manage project logistics and costs.

The tools’ Dealer Locator function generates a Dealer Location page listing the nearest dealers within a fi ve-mile radius of the user’s zip code, and is included as part of the normal report output, which already includes a list of all materials needed to build the deck and pergola projects.

Featuring 3D software, design guides, and an in-app user tutorial, Deck Planner and Pergola Planner are free, web-based design solutions to help contractors, lumberyards and homeowners quickly and easily design dream backyards. n STRONGTIE.COM (800) 999-5099

A Couple of Cut-Ups

Stanley has added two new utility knives to its portfolio of innovative cutting solutions—a versatile Utility Knife with 10-Blade Storage and a ControlGrip retractable Utility Knife.

The tools are ideal for heavy-duty cutting a variety of building materials, from drywall and shingles to fl ooring and packaging. They provide razor-sharp performance, jobsite durability, comfortable use, and easy blade change. n STANLEYTOOLS.COM (800) 262-2161

Horizontal Rod Rail

RDI by Barrette Outdoor Living has added Latitudes Horizontal Rod Rail to its MetalWorks Excalibur product line.

Featuring horizontal 1/2” round steel rods, the preassembled panels are off ered in a matte black fi nish in both 36” and 42” fi nished rail heights. Panels come in 6’ and 8’ level rail lengths and 6’ for stairs, with welded center supports and secure-fi t bushings in the uprights to add strength and safety.

All MetalWorks Excalibur steel panels are factory-welded and preassembled, making installation as easy as measure, cut, install. Their bracketed posts make level installation simple while providing code-compliant bottom spacing. And, the pre-welded base plates also save valuable install time on the job. n RDIRAIL.COM (800) 488-7245

Aff ordable Elegance

MoistureShield has combined its Sold Core manufacturing process with CoolDeck and TruTexture Surface technologies into Meridian, a mid-priced capped composite decking.

TruTexture produces a true woodgrain fi nish and reduced pattern repetition for a more natural look, while CoolDeck reduces heat absorption by up to 35% compared to traditional capped composites.

Offered in three colors (Citadel, Shoreside and Mariner), the line is now available in the Northeast and will roll out to other regions through the year. n MOISTURESHIELD.COM (866) 729-2378

SOCIAL TABLE participants included (top row, l-r) Brian Hawrysh, Chuck Casey, Jim Ivanoff, Brent Comber. (Row 2) Dave Farley, Johnny Matak, Greg Henderson, Randi Walker. (Row 3) Jennifer Raworth, Dai Ona, Ray Greene, JC Lee. (Row 4) Nora Gonzalez, Monica Alvarez.

BC Wood’s virtual Global Buyers Mission spans the globe

Close to 700 attendees, from 21 countries, across fi ve continents met virtually with some of the industry’s top Canadian manufacturers and speakers at the week-long 2021 BC Wood Global Buyers Mission.

The 17th annual event, traditionally held in-person in Whistler, B.C., made the decision to pivot for the fi rst time to virtual late last year—giving the organization just 90 days to translate its always-engrossing format into an engaging online experience for industry members around the world.

Unique elements for the event ranged from dynamically translating the entire platform into eight diff erent languages, to tracking AIA educational credits from presentations, to over 200 individual Zoom exhibitor meeting rooms for hundreds of pre-scheduled and on-demand meetings— many with interpreters included. To host the Global Buyers Mission, BC Wood partnered with 526 Media Group’s interactive virtual platform because, according to GBM program manager Randi Walker, “They understood our industry, had direct access to our targeted U.S. audience, and had already successfully delivered virtual trade events for other like-minded industry associations.”

“We were honored to have been chosen by our friends at BC Wood to help them host their marquee event. Having served this industry for almost 100 years puts an extra pressure on our team to never let a client down and to always over-deliver,” said 526 Media Group president Patrick Adams. “Our industry is made up of tough individuals who always fi nd a way forward in challenging market conditions. This event was too important to a global industry audience for us to deliver anything but perfection.”

Analytics showed that over 85% of the typical attendance registered for the virtual event, with an average daily booth attendance of over three dozen qualifi ed buyers per exhibitor. In addition to being able to take buyers on video plant tours and present in-booth, live accredited seminars, exhibitors also received critical lead generation reports to follow up on after the event.

While this virtual event was made as a necessary substitute due to COVID, the feedback has been so positive that BC Wood is planning a virtual component to its in-person 2022 event. Walker said, “Based on survey feedback from our international audience, it is clear that we will move forward with some level of virtual delivery incorporated into our next live event. Many buyers indicated that having it virtual meant more of their critical staff could attend and meet with suppliers directly, something companies, particularly from Asian and European markets, simply couldn’t aff ord to do for a live event.”