design + fabrication portfolio 2016 - 2024

CONTENTS

Professional

Island Exterior Fabricators

East Coast Van Builds

Paul Lukez Architecture

SHIFTboston

Student

Studio Projects

Fabrication Projects

Installations

design + fabrication portfolio 2016 - 2024

Professional

Island Exterior Fabricators

East Coast Van Builds

Paul Lukez Architecture

SHIFTboston

Student

Studio Projects

Fabrication Projects

Installations

Computational Fabrication Lead, Facade Designer, Fabrication Manager

400 Summer Street

Fabrication Manager (PMU, VMU, Early Project Phases), System Design, Facade Design

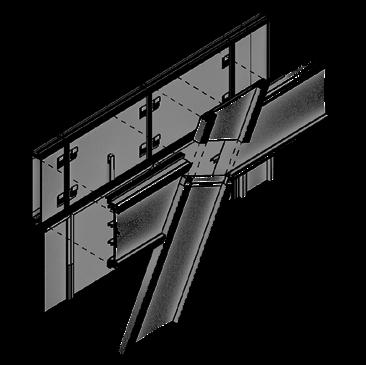

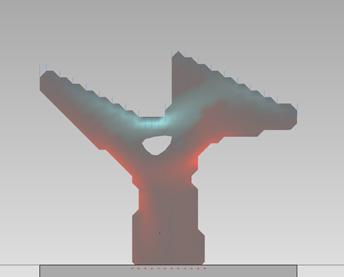

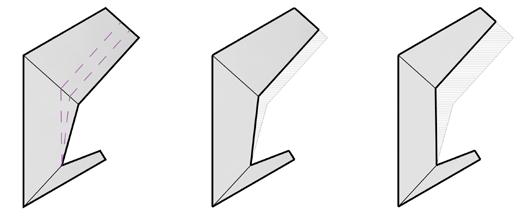

Frame Hem Cut Design

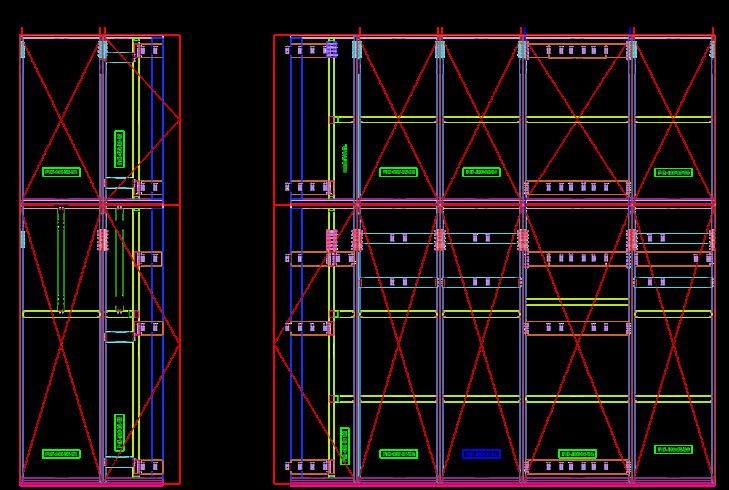

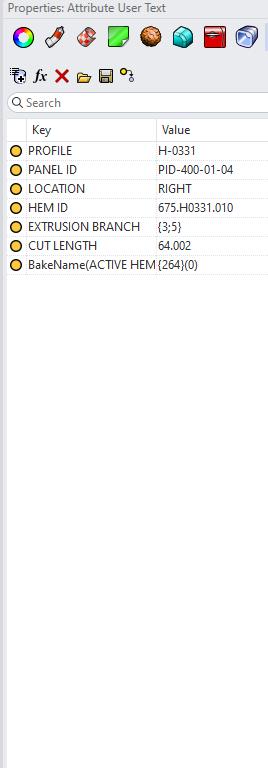

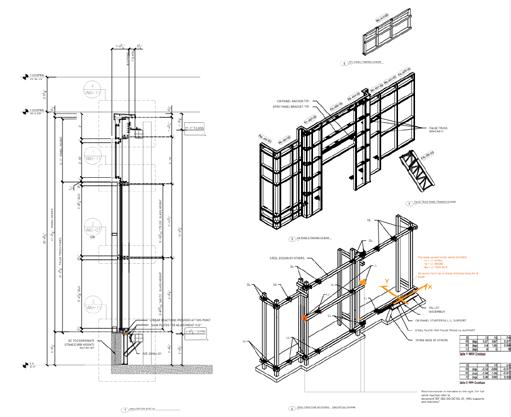

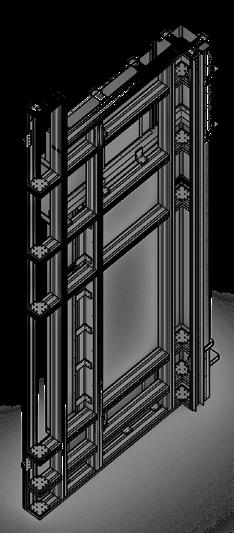

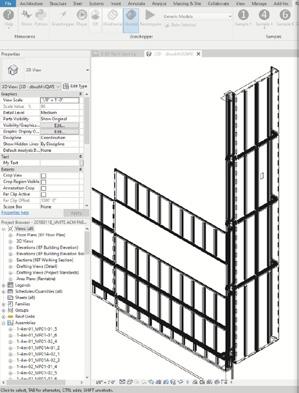

My role as Fabrication Manager for 400 Summer Street included the design of facade systems, developing project fabrication standards and procedures, producing 3D study models, working on shop drawings, and overseeing the development of fabrication 3D models and drawings for VMU (Visual Mock-Up), PMU (Performance Mock-Up) and early project development. This also involved coordinating with various project stakeholders to facilitate smooth transitions from design to production, such as collaborating with practice leadership and shop management to develop project standards and procedures for the transmittal of fabrication shop drawing releases through BIM 360.

400 Summer Street

For the mock-ups, I adapted Grasshopper scripts that I had developed as part of the Boston Children’s Hospital fabrication team to automate the conversion of 2D wireframes into attribute-rich 3D frame models and production drawings, streamlining the design-to-fabrication process and allowing us to quickly evaluate framing conditions throughout the mock-up.

of

400 Summer Street

For the VMU, I worked closely with the shop production team as well as our outsource partners at Maffeis and the Island shop drawing team to work through design and fabrication details and logistics from a number of perspectives.

VMU Fabrication Ticket

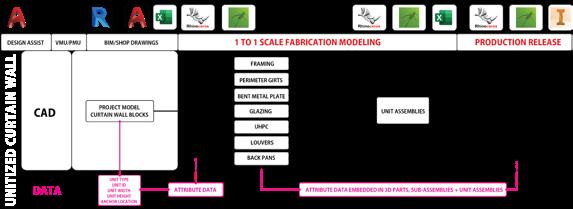

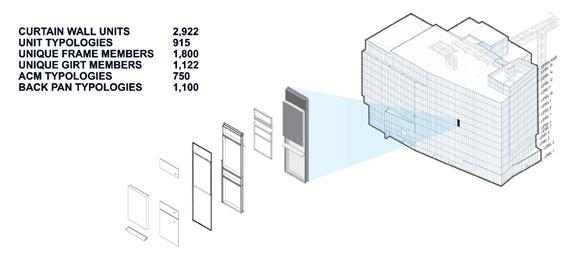

My primary contribution to this project was the development of computational workflows that automated the translation of AutoCAD architectural drawings into detailed, attribute-rich 3D fabrication models and shop drawings. Using Grasshopper, AutoCAD, and Excel, we significantly increased the speed and accuracy of this process. Development happened in concert with production, and provided enough dividends in productivity that many of these workflows were later adapted for use on other projects. I also worked to establish best practices, standards, and documentation for computation-based workflows.

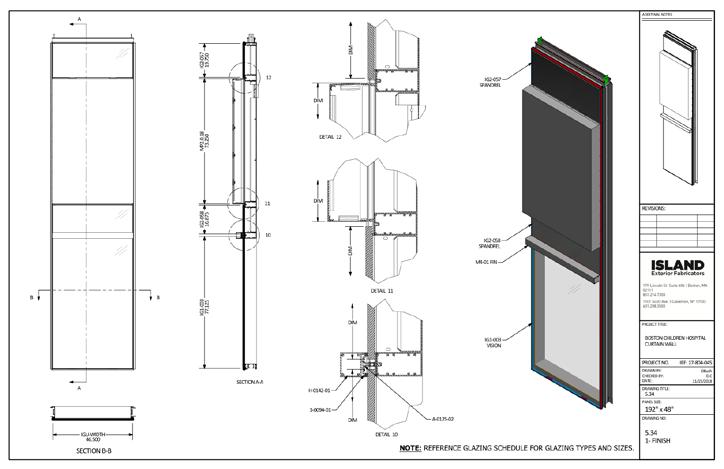

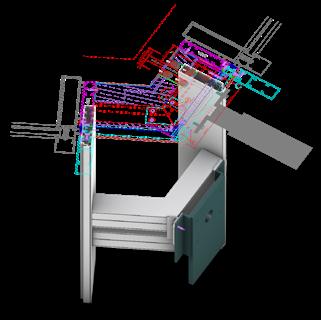

In addition to workflow development and fabrication, earlier in the project I contributed to the shop drawing team, working on facade design at the podium, and the design of removable facade panels that allowed for crane-loading of large equipment such as MRI machines. I also played a role throughout the project in the design and 3D modeling of unique and complex facade conditions.

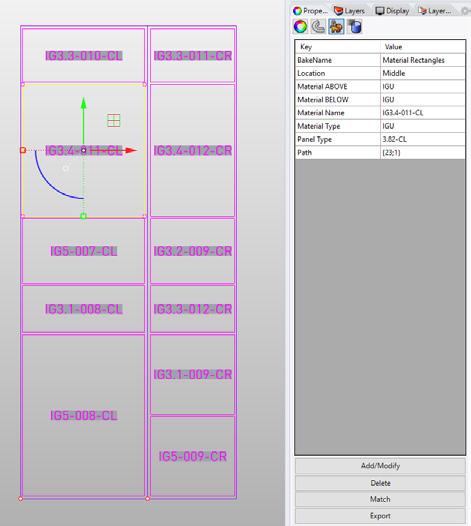

Translation from AutoCAD Elevation Blocks to Attributed Rhino Wireframe

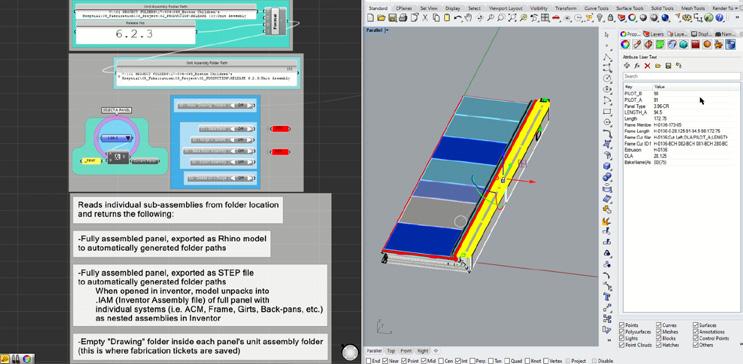

Grasshopper and Excel are used to translate the wireframe into 1-to-1 3D geometry, which is then packaged into nested blocks and exported to STEP file.

When opened and saved in Inventor, each part becomes it’s own file, with assemblies nested matching the Rhino Block structure. This allowed us to combine the advantages of a computational approach to modeling, with Inventor’s superior drawing tools.

Fabrication ticket pages

Block L4

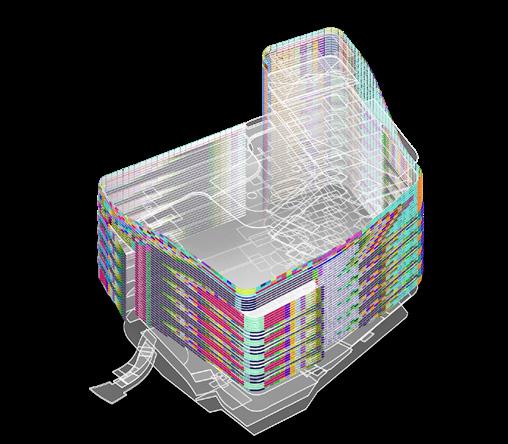

Fabrication Production, Facade Design, Computational Workflow Adaptation with partners at CadMakers

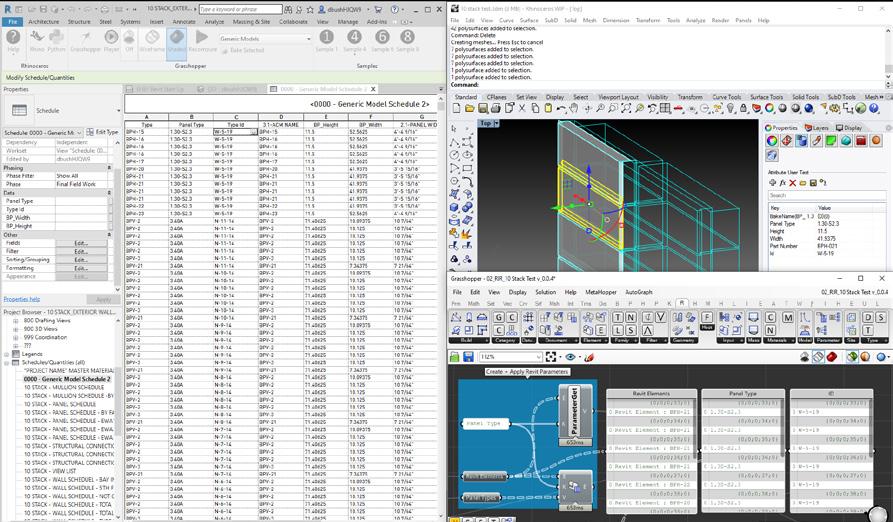

Rhino.Inside Revit Workflow Development

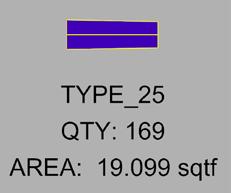

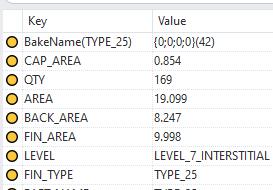

10 Stack Street - Retrieve and create geometry parameters between Revit and Rhino/GH directly. Populate schedules in Revit using flexible GH-based workflows. Goal of eliminating data extracts and geometry exports between design and fabrication teams.

NEU EXP - Extract facade fins from Revit, analyze and visualize approx. number of unique fin types.

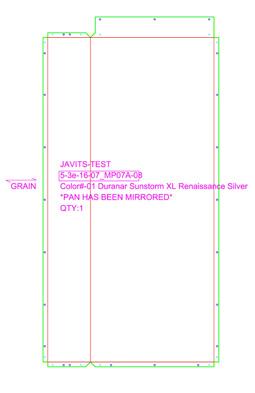

Javits Center - Extract metal panels from Revit, analyze, unfold, create 2D CAM-ready DXF file for plasma cut.

Design, CNC Fabrication, Management + Workflow Development

Homesteader

Mercedes Sprinter 170 EXT

Custom Build

Nomad

Ford Transit 148 EXT

Custom Build

Homesteader

Ford Transit 148 EXT

Custom Build

Weekend Warrior

RAM Promaster 159 EXT

Custom Build

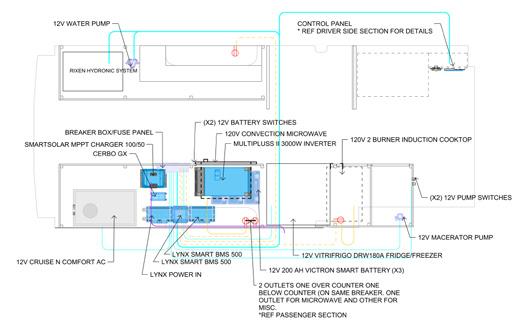

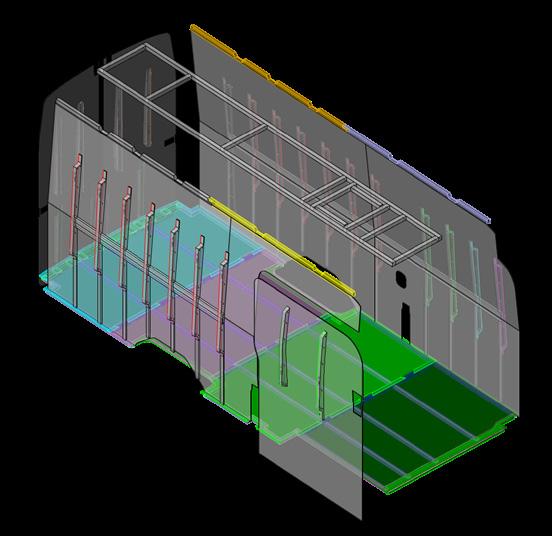

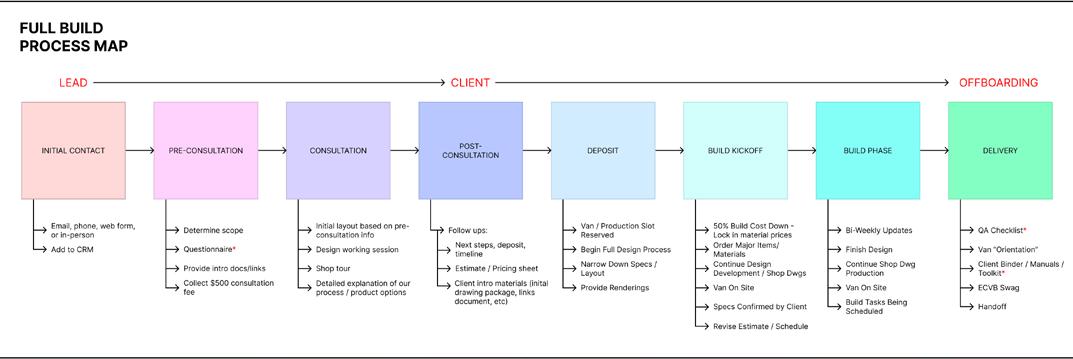

At East Coast Van Builds, I collaborate with clients on schematic design phase, modeling in live design sessions with Rhino to refine concepts in real time. My responsibilities include preparing design packages, producing renderings, tracking the specs of each build, generating takeoffs and estimates, and continuing to refine and increase design fidelity until the project enters the shop drawing phase.

I also produce all CAM modeling and CNC programming, working primarily with wood products, and often plastics, laminates, and phenolic resin-based materials. In this role, I manage CNC operations and train new operators, and work with the shop staff to develop mixed digital and traditional fab/build workflows. This allows us to iterate on design details and tolerances, ensuring our processes take full advantage of our tools as well as our talented shop team.

Additionally, I create custom workflows for project management and tracking, delivering digital shop drawing sets via smart documents. I utilize Grasshopper to automate tasks such as modeling, takeoffs, and the production of fabrication information and drawings.

Electrical Diagrams

Shematic Design

Design Development

Renderings

Architectural Design Intern

Net-Zero Energy Home (CA)

Construction Administration

Kendall Square Parking Garage Conversion

Extg. Conditions Documentation and Schematic Design

Schematic Design Translation of branding guidelines to spacial concepts, space planning, furniture design, shop drawings

Architectural Design Intern

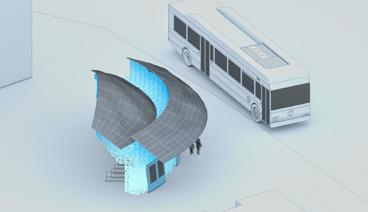

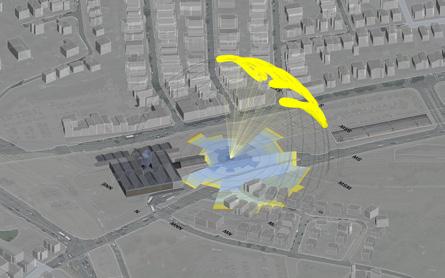

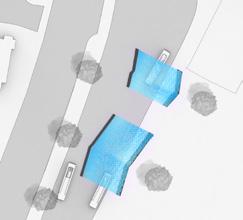

CHANNEL GREEN - Boston Living with Water 2015 Competition Entry

During my time with design group SHIFTboston, we worked on a proposal for Boston’s Living with Water competition.

Sited at the Fort Point Channel, CHANNEL GREEN is a series of floating treatment wetlands designed to bring the channel to life though plant, animal, and human activity, while cleaning the water of toxic buildup resultant from the lack of outward water circulation. Additionally, this design anticipates the effects of climate change by providing a significant defense against potentially damaging storm surges.

Project Team:

Kim Poliquin - lead designer

Anamarija Frankic - marine biologist

Dylan Bush - designer

Congratulations, you have made it to the student work portion of the portfolio.

Please proceed with caution

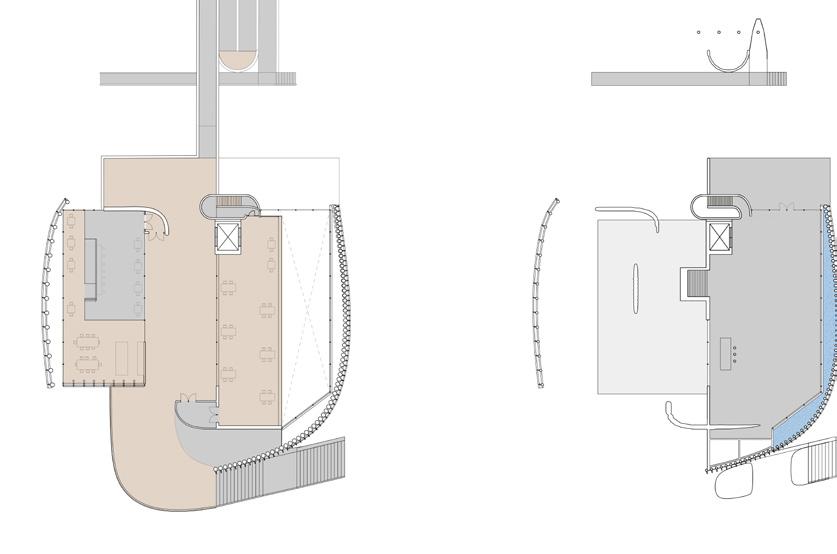

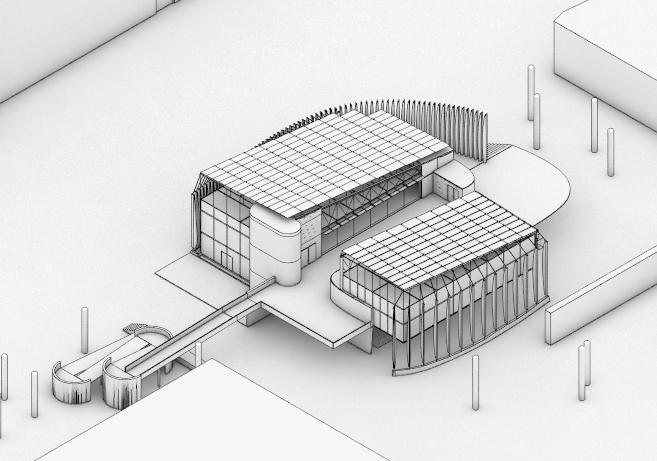

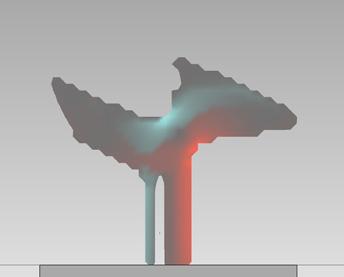

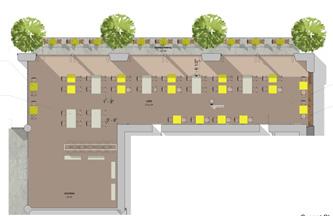

Kresge Oval social workshop designed through a process of research into flexible formworks - Fall 2016 Studio

The goal of this project was to create a space that encourages students to break out of their disciplinary culture by creating an engaging, but casual, platform for learning new skills that inspire different kinds of thought/work processes. To break out of the discipline-specific “cliques” that tend to form, the project was located on the student life area of campus, adjacent to, but separated from the academic side of campus. The programmed spaces are open and flexible, but the circulation leading to those spaces is winding and often vertical to slow the user as they enter the social atmosphere of this “library of tools.”

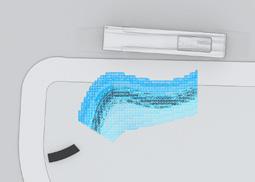

The material strategy used in this project inspired research and experimentation re: funicular forms and flexible formwork with poured materials. Captivating light qualities were revealed in an attempt to recreate scaled-down versions of investigations into fabric-formed variable section beams done by research institutes (primarily Mark West at University of Manitoba). The primary final use of this method of casting is a façade made up of a series of columns whose profiles undulate in response to solar geometry. Reusable flexible formwork allows for this constant variation with little material cost.

There is a connection to historic qualities of site via common embrace of technology and innovation. Simplicity of form allows the project to take on the role of a ‘vessel for experimentation’ both in the process of design/fab/ construction and in its final use. The fabric-formed elements of this design are a diagram of forces through time acting as an aggregation in response to solar geometry.

Professor: Denise Dea

Digital Tools Workshop

Fabrication Shop / Prototyping Space

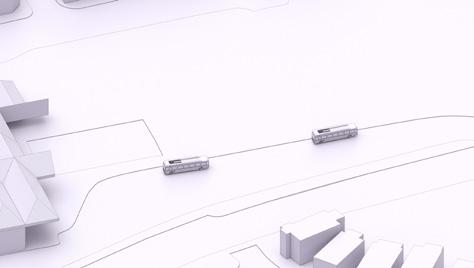

This thesis questions how one can integrate new design and manufacturing technologies not only into the discipline of architecture, but into culture and the social narrative— how new design tools and the often unfamiliar forms and structures that hose tools make possible begin to impact the average person’s experience of the built environment, and how that experience can communicate the value of computation in design.

In parallel with this is the question of how research in digital fabrication can investigate not only the technical and spatial, but also the social. How can the new and unfamiliar be disseminated beyond novelty experiments in a meaningful way? How can these tools be used to create spaces and places of lasting value which begin to study the “human factors” involved in computational design realities?

Thesis Advisor: Carol Burns,

Independent Advisor: Zach Seibold

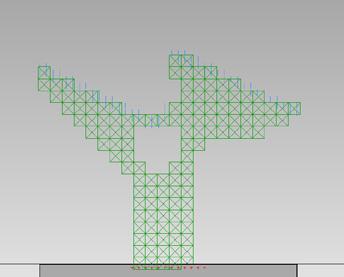

Define site constraints

Space for bikes

Space for people

Compression lines not reaching foundation

Excessive tension in the base

Evaluate initial form: generate force lines

Define occupied areas

Morph top edge to ideal solar angle

Optimize geometry to resolve stresses

Generate form based on optimized section

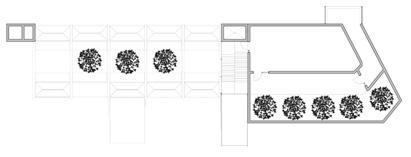

Neighborhoods: Roslindale, Jamaica Plain

Forest Hills Station Washington Street

Site Features:

Schools

Multi-modal transit

Major parks

50

16, 21, 30, 31, 32, 33, 34(E), 35, 36, 37, 38, 39, 40, 42, 50, 51

Sun + Wind

Area of Occupancy

Voxelize Populate with tetrahedral lattice Morph lattice to boundary + equalize strut lengths

This adaptive reuse project is located in an old automobile factory and showroom currently used as an educational facility by Boston University. Housing a collection of over 200 abstract expressionist paintings and pieces of modernist furniture, the galleries at this museum are nested around a series of botanical rest spaces, balancing the intensity of the art with the simplicity of nature.

Project Team:

Kelen Aroujo - Architecture

Jill Arsenault - Interior Design

Dylan Bush - Architecture

Corinne Young - Interior Design

Professor: James P. Allen

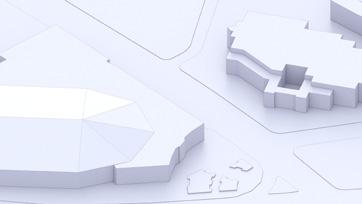

This 35-unit housing development is situated in a growing area of Berlin located between a major urban area and several important parks and green spaces. Neukolln is home to one of Berlin’s largest immigrant populations as well as a growing population of students and young professionals.

This project offers two distinct living styles, one for each “wing” of the building, separated by a core of small offices. Coliving apartments face toward the active street corner while studio apartments are located further down the block. The motif of subdividing geometries offers a modern sensibility to Berlin’s vernacular language.

Professor: Rolf Backmann

Co-Living Apartments Studio Apartments

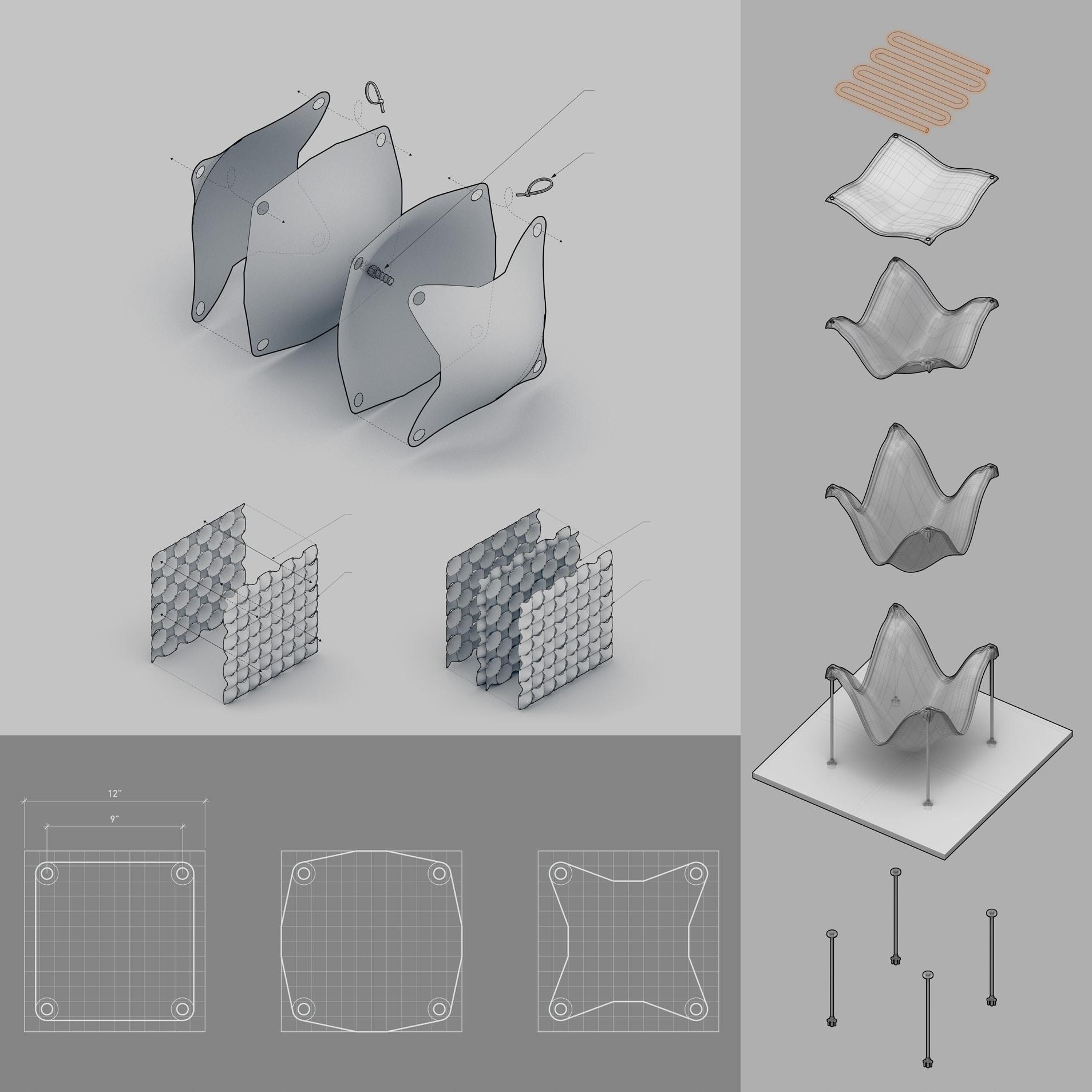

Design/Fab/Build

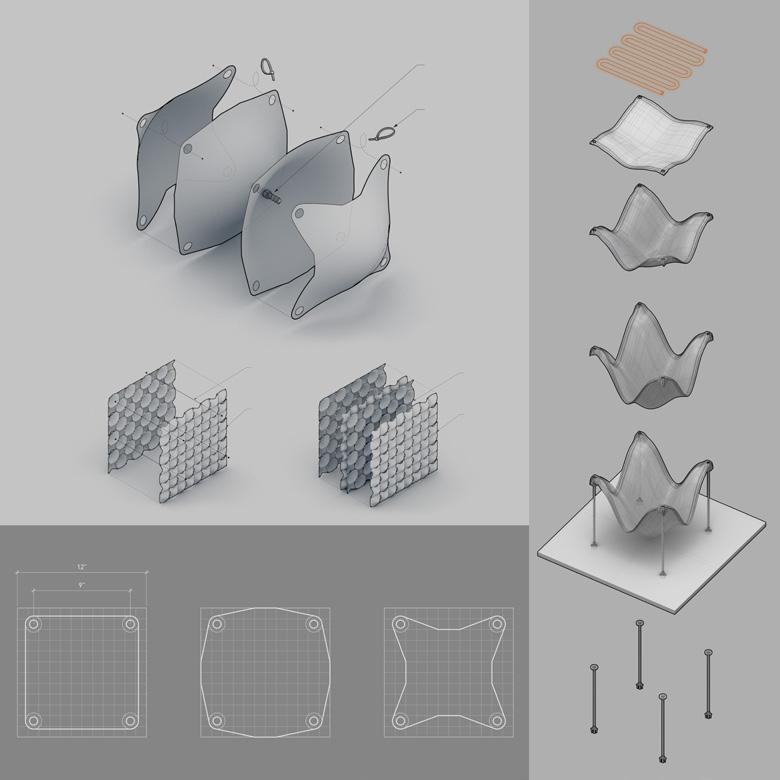

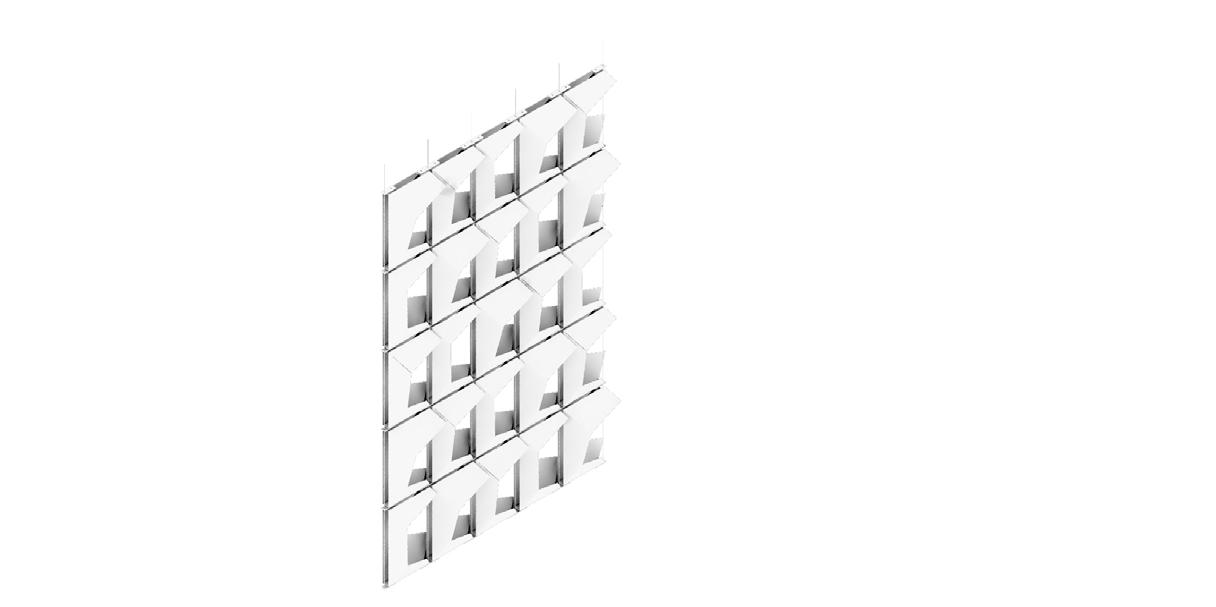

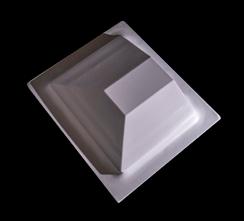

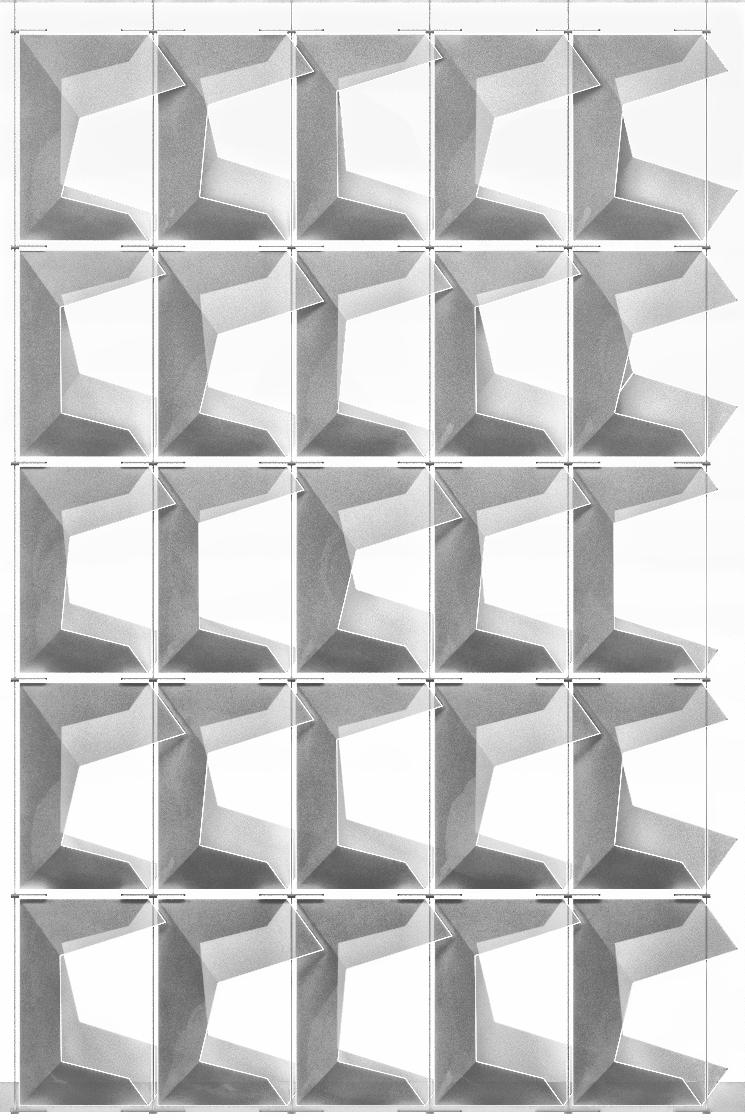

This panelized shading device was developed as part of a prototyping course. The requirements for this project were to develop a system that would achieve variable output using a vacuum-thermoformer and 3-axis CNC router. Our solution was to mill a base-mold from MDF, which would serve as the positive form for the thermoformer; once the white sheet of ABS plastic is formed to the mold, it placed back onto the CNC router where one of three possible openings are milled out of the formed plastic. These units are paired, and then aggregated according to a pattern that creates a polyrhythm of cell shapes, shadows, and openings. The interior volume of each cell pairings causes the exterior layer to cast a shadow on the interior layer, creating a dual visual reading where there is direct sunlight.

Project Team:

Dylan Bush

Stefan Burnett

Sam Fernandes

Caleb Hawkins

Professor: Chris Sledziona

This installation was designed for Wentworth Architecture review’s volume 8 launch event. Addressing the theme of “COLOR,” the fabric canopy is projected onto with colors that are abstracted in real time from guests turning the pages of the journals placed at tables throughout the event space. My role in this project was primarily digital-to-physical integration, programming/troubleshooting, and assisting overall concept design and development.

Project Team: Christian Roidt & Wentworth Architecture review

Wentworth Architecture review Volume 6 with Morgan McMahon - Spring 2016

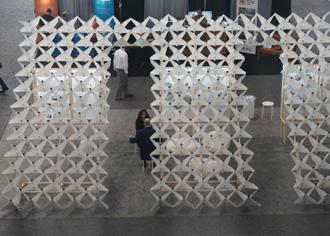

Originally developed as part of an independent research project, this modular system of recycled plotter tubes and carriage bolts was commissioned by the Wentworth Architecture review to be adapted for the Volume 6 launch party installation at the BSA Space. We developed a joint system that was used to create a pavilion from which the pages of the journal were suspended, creating an occupiable structure with pockets of space wherein partygoers could interact with one another, as well as the contents of the journal.

Project Team: Morgan McMahon & Wentworth Architecture review

When Boston was chosen as the host city for the 2016 AIAS FORUM conference, the WIT chapter of the organization reached out to the Wentworth Architecture review with a unique opportunity for collaboration. Knowing that we were preparing for the launch of our seventh volume, they proposed a joint effort for the design/ fabrication of a system that could be used both for the FORUM stage set and an installation for the Volume 7 launch party. Given the relationship between the themes of our events, Revolution (FORUM) and Impact (WAr), this was a natural partnership. Our main criteria was to design a module reflecting these themes that could aggregate to form either a backdrop or become more spatial to alter an environment.

Project Team: AIAS & Wentworth Architecture review design panel

After KiKi ARCHi won WHAT’S IN’s 2016 competition for an installation design to be displayed at ABX, the Tokyo-based design firm teamed up with Stantec to reach out to a group of local students to fabricate and build the winning design. In November, a member of KiKi ARCHi’s team came to Boston and ran a workshop instructing us on how to fabricate and assemble the installation. Over several weekends, the installation was built by a team of students from Wentworth, MassArt, and the BAC, as well as Stantec employees. It was displayed at the Boston Convention Center as part of ABX 2016.