Project by: Malvern Kandemwa

Words by: Michelle Duncan

Larry Williams is the President and Chief Executive Officer of Henniges Automotive, a leading global supplier of highly engineered sealing and anti-vibration solutions for the automotive industry. With extensive experience in the automotive sector, Larry has successfully guided Henniges Automotive toward innovation, operational excellence, and market expansion, positioning the company as a key player in the automotive supply chain.

After joining Henniges Automotive in 2003 as CFO, Larry Williams was elevated to interim CEO in 2015. By 2019, he officially assumed the role of President and CEO following the company’s acquisition by a Chinese organisation. This marked a significant milestone in Larry’s career and a major advancement for the company.

“It was an opportunity to lead the company under new ownership,” Larry Williams explains. “We had recently been acquired by AVIC Automotive, a Chinese state-owned entity, which had a long-term vision for the company’s growth. I saw this as a chance to implement a strategy

that would not only drive topline growth and business expansion but also strengthen the company’s culture.”

Larry envisions the opportunity unfolding through both local and global growth, driven by a solid financial foundation. He emphasises that global expansion is inherently tied to local production, ensuring that as Henniges grows internationally, it also strengthens its local manufacturing capabilities. This approach not only supports the company’s global ambitions but also fosters sustainable development within the regions where Henniges operates.

“We aim to expand in the Chinese market by leveraging the market strength of our owners and capitalising on the growing automotive sector in China,” Larry Williams shares. “However, it’s equally important to continue building on our strong foundation in North America. Financially, we are backed by long-term strategic owners who fully support our vision, and the company is profitable. Henniges is a very healthy, growing company.”

UNDER

HAS REINFORCED ITS COMMITMENT TO QUALITY AND CUSTOMER SATISFACTION, WHICH HAS BEEN A CORNERSTONE OF ITS SUCCESS.

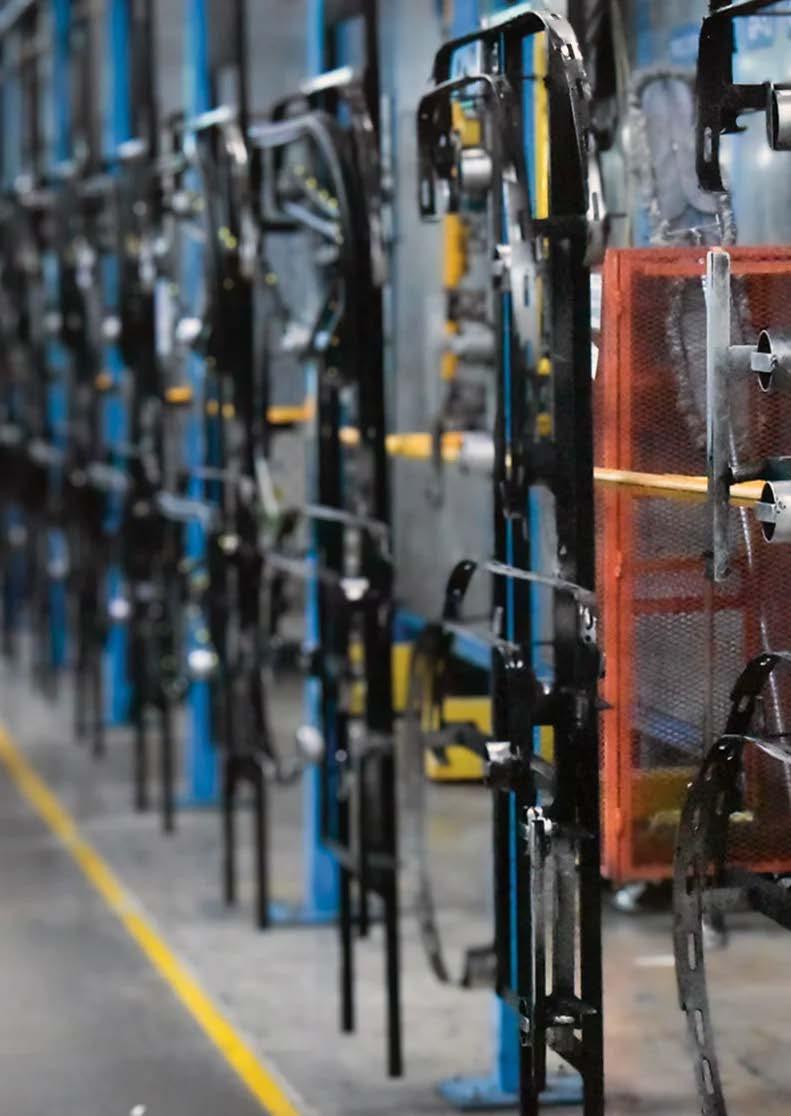

Henniges Automotive specialises in providing highly engineered sealing and anti-vibration solutions for the automotive industry. The company’s products are critical components that contribute to vehicle safety, comfort, and overall performance. These include door seals, window seals, trunk seals, and other rubber-to-metal bonded components that are designed to reduce noise, vibration, and harshness (NVH) in vehicles. Henniges serves a diverse clientele that includes some of the world’s leading automotive manufacturers, providing them with tailored solutions that meet the specific needs of each vehicle model.

Under Williams’ leadership, Henniges has reinforced its commitment to quality and customer satisfaction, which has been a cornerstone of its success. The company operates on a global scale, with manufacturing facilities and technical centres strategically located in North America, Europe, and Asia. This global presence allows Henniges to serve its customers efficiently, ensuring prompt delivery and local support, which are crucial in the highly competitive automotive industry.

Henniges consists of 19 manufacturing sites in eight countries with annual sales in excess of $1 billion and its operations are centred around delivering high-quality products through advanced manufacturing processes. The company opened a new European Headquarters and Technical Centre in the Czech Republic, a 35,800 square-foot facility aimed at enhancing their engineering capabilities and constructed the company’s largest manufacturing facility in China. They employ ultramodern technologies in its production facilities, ensuring that each product meets stringent quality standards. The operations are supported by a strong supply chain network that is carefully managed to keep efficiency and minimise lead times.

One of the key aspects of Henniges’ operations is its focus on continuous improvement. The company employs lean manufacturing principles across its facilities to enhance productivity

and reduce waste. This commitment to operational excellence has enabled Henniges to keep a competitive edge in the industry, even as it faces challenges such as fluctuating raw material costs and the need for rapid adaptation to new automotive technologies.

Larry emphasises that local manufacturing is crucial in today’s global environment. “We focus on producing our products within the country for that specific market,” he explains. “For instance, what we produce in China stays in China, and what we manufacture in North America, whether in the US or Mexico, largely remains within those regions. We’re not seeking out lowcost labour markets to relocate jobs and exploit those advantages. Our priority is to maintain production close to where our products are needed, ensuring quality and efficiency while supporting local economies.”

THE COMPANY EMPLOYS LEAN MANUFACTURING PRINCIPLES ACROSS ITS FACILITIES TO ENHANCE PRODUCTIVITY AND REDUCE WASTE.

The future of clamping profiles has a name. bfc – the innovative cut.

The bfc Group is a leading manufacturer of metallic lanced and stretched clamping profiles, which are used as a stabilizing but flexible carrier for rubber seals. Due to its high development competence and innovative strength, bfc has become an important strategic partner of Henniges Automotive.

With production sites in North and Central America, Europe and Asia, bfc is globally positioned and represented wherever it can support its customers with high flexibility and short time to market. bfc works closely with its customers and develops solutions according to their individual requirements. We see ourselves as a true partner throughout the entire value creation process, from the first inquiry to the completion of product approval. bfc is therefore a valued adviser and agile, creative partner for its customers.

A high vertical integrity of processes offers bfc the possibility to drive superior solutions and to meet the consistently growing market requirements. The development department has many years of specific technical knowledge that is second to none. All machines and tools for production of the lanced clamping profiles are developed and manufactured completely in-house by bfc’s tool shop. This enables flexible intervention in the process at any time and thus optimum support for the customer.

At a time when climate protection is increasingly at the center of economic decisions, bfc has established itself as a pioneer in sustainability and innovation. Since the beginning of 2024, bfc has been reporting the Product Carbon Footprint (PCF) for each of its products, relying on the „Cradle to Gate“ method, which covers the entire production process from raw material extraction to leaving the factory. In this way, it makes a significant contribution to transparency and environmental protection. This approach allows the company to quantify exactly how much CO2 emissions are generated during the production of a product. This gives

customers a clear view of the environmental impact of their purchasing decisions. Another highlight of bfc is the development of innovative products that further reduce CO2 emissions. For example, new materials, new patterns/designs and manufacturing processes have been introduced that require less raw material use.

Customers appreciate the company‘s transparency and commitment, and experts also praise its pioneering role in sustainability. Sales have increased since the introduction of the PCF disclosures, which shows that conscious consumers are willing to prefer sustainable products.

The bfc Group has a longstanding strategic partnership with Henniges Automotive. Together, several significant new product developments have been launched that will decisively increase the competitiveness of bfc and Henniges.

The markets of the future will always confront us with new challenges. bfc sees itself well equipped to meet these challenges with a young, dynamic team that is stronger than ever after the acquisition of Arrowhead in 2023 and the establishment of a new production plant in Spain this year.

bfc is fast, flexible, solution-oriented, innovative and globally positioned. We therefore see ourselves as the ideal partner who knows how to support its customers and make decisive contributions, allowing them to achieve their own goals.

Henniges Automotive has undertaken significant infrastructure upgrades to enhance its manufacturing capabilities and support its growth strategy. These upgrades have included the modernization of existing facilities and the expansion of production capacity to meet the increasing demand for advanced sealing and anti-vibration solutions.

A key component of these infrastructure improvements has been the integration of advanced automation and robotics into the manufacturing process. This has not only increased production efficiency but also improved the consistency and precision of the products. Additionally, Henniges has invested in the development of its R&D facilities to foster innovation and support the creation of new products that meet the evolving needs of the automotive industry.

These infrastructure upgrades have also extended to the company’s IT systems, where Henniges has implemented advanced data analytics and enterprise resource planning (ERP) systems. These systems have enhanced the company’s ability to monitor and manage operations in real-time, leading to better decision-making and a more agile response to market changes.

Larry elaborates on the company’s operational strategy, stating, “We’ve implemented what we call ‘the Henniges Production System,’ which closely resembles the Toyota Production System. It focuses on continuous improvement, lean principles, and making incremental enhancements every day to drive operational efficiency.”

He highlights the role of automation and robotics in this strategy: “We’re exploring ways to incorporate automation and robot-

ics to handle some of the more routine, manual tasks. This approach allows us to elevate the skill level of our workforce, transitioning from basic manual labour to managing and improving robotic systems. It’s not just about reducing headcount; it’s about transforming the skill set required and addressing gaps in our workforce where finding qualified employees is challenging.”

Larry also notes the company’s success in retaining employees:

“Once we find the right people, they tend to stay with us due to our strong company culture and the opportunities for career advancement. We provide our employees with the freedom to shape their careers based on their ambitions and efforts. Being a global company offers numerous opportunities to work in diverse cultures and locations. With 19 factories across eight countries, our employees can gain international experience and further their careers in various global contexts.”

Strategic partnerships have been a cornerstone of Henniges Automotive’s success. Recognizing the importance of collaboration in driving innovation and growth, Williams has prioritised building strong relationships with key players in the automotive industry, including suppliers, customers, and technology partners.

Henniges’ partnerships with automotive OEMs (Original Equipment Manufacturers) are particularly significant. These collaborations have enabled the company to work closely with vehicle manufacturers during the design and development phases, ensuring that Henniges’ products are perfectly tailored to the specific requirements of each vehicle. This close cooperation has not only strengthened customer relationships but has also positioned Henniges as a preferred supplier for many leading automakers.

Larry also emphasised the advantages of long-term partnerships, particularly in relation to capital equipment expenditures. “One of the biggest benefits of having long-term partners is in managing our capital equipment investments. We collaborate closely with our vendors to explore innovative approaches for manufacturing our products as we launch innovative programs. This collaboration helps us find ways to reduce our capital expenditure while simultaneously enhancing operational efficiency,” he explains.

He further elaborates on the process: “By working together with equipment suppliers, we can develop best manufacturing solutions rather than simply purchasing off-the-shelf equipment or dictating to suppliers how they should perform their roles. Our expertise lies in manufacturing, not in designing equipment, so leveraging the suppliers’ knowledge and experience leads to more effective and cost-efficient solutions.”

Larry underscores that successful strategic partnerships require mutual benefit: “For these longterm partnerships to be effective, they must create a win-win scenario for both parties. It’s about finding shared value and achieving the best outcomes for both sides.”