5 minute read

Something from nothing?

processes bringing hope ‘Magical' manufacturing

Sometimes, all we need is the air that we breathe — and a bit of hi-tech genius. BV editor HAL WILLIAMS reports.

Advertisement

SOMETHING from nothing: it’s an age-old siren song — dreams of perpetual motion or three magic wishes from the genie in the teapot.

But, spoilsport science tells us, zero sum transactions can’t be had (for perpetual motion, anyway; no official word on genies). Laws of Thermodynamics pull rank and tell us that no machine can work indefinitely without some sort of energy input.

So how about the next-best thing: fuel — or food — from thin air?

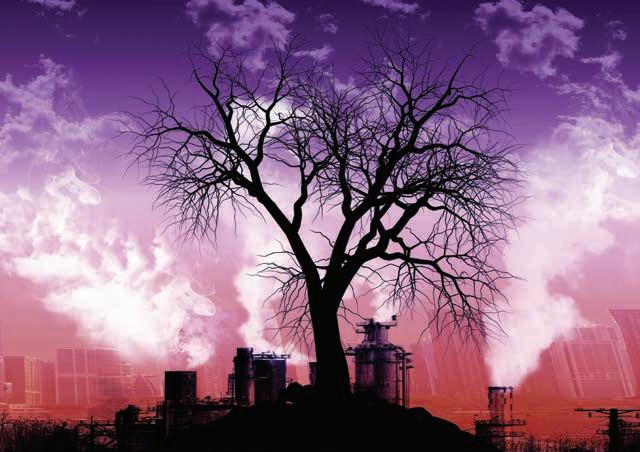

With concern about climate change, fuel reserves and clearfelled rainforests approaching

Renewable

methanol

from invisible

realms

(justifiable) international neurosis, if alternatives exist to the crudeness of crude and the brutality of beef, the world is surely ready for them.

And — it seems — exist they do. But so far, their creation has been without fanfare, and promising developments seem to be small-scale. Enter — modestly, as the result of chance encounters and a bit of idle internet browsing rather than publicity from the companies concerned — Carbon Recycling International (CRI), of Rejkyavic, and San Francisco’s Air Protein.

CRI is a self-proclaimed world leader in the production of renewable methanol from the invisible realms of carbon dioxide, hydrogen and electricity. Air Protein recently announced the creation of “meat” — or at least a protein product — from the air that we breathe, without the usual land, water or weather

Carbon Recycling International was founded in Iceland on the idea of recycling carbon dioxide

requirements. CRI says it has produced “a synthetic liquid fuel at industrial scale from CO2 capture”.

It designs, engineers and implements methanol production plants based on its Emissions-toLiquids (ETL) technology, with no impact the food chain or land use.

The ETL platform “enables integration of more electricity in various modes of transport that are ‘hard to electrify’, including long-range travel, heavy goods transport, marine transport and aviation”. As carbon-neutral fuel, renewable methanol could potentially eliminate air pollutants such as nitrous oxides and sulphur compounds, as well as particulate matter.

The resulting methanol can be used for fuel applications, greener chemicals and products. Working with partners, CRI is developing “transformative” projects, increasing resource efficiency and creating value from waste gases.

Air Protein, meanwhile, claims that its food production method “will revolutionise how we approach food production in the future”. The process uses elements found in the air, combined with water and mineral nutrients. It uses renewable energy and a probiotic production process to convert the elements into a nutrient-rich product with the same amino acid profile as meat. As an added bonus — to a something-from-nothing deal — the protein is packed with B-vitamins, which are often deficient in a vegan diet.

ENABLING TECHNOLOGY In a world where averting, or at least moderating, climate change is vital, and carbon emissions count, the ETL and Air Protein technologies promise large-scale recycling of CO2 as a raw material for liquid fuels, food and chemicals.

“ETL is a key enabling technology for the transition to a circular economy… avoiding the use of fossil fuels,” CRI says on its website. The company has a Powerto-Gas and Power-to-Liquid processing plant capable of recycling thousands of tons of carbon dioxide and regurgitating it as renewable fuel via a hydrogenation process. “We offer technical solutions to industrial clients and investors, including technology licenses and services to engineer, build and operate renewable methanol plants.”

Air Protein says it uses carbontransformation technology which was inspired by NASA’s closedloop carbon cycle concepts for long space missions. The protein found in air-based meat is produced using natural processes, and is free of pesticides, herbicides, hormones or antibiotics.

The new protein source can be used to make meatless burgers, protein-enriched pastas, cereals and beverages. The United Nation Food and Agricultural Organisation (FAO) predicts that to meet the nutritional needs of a population expected to reach 10 billion by 2050, farmers will need

Cruelty-free: an elegant solution to nutritional and evironmental challenges from Air Protein

to increase food production by 70 percent — with only a five percent increase in land use.

Air-based meat “offers an elegant solution to that equation”. The probiotic production process takes just days, the company says, independent of weather conditions or seasons, and works in a similar fashion to yogurtmaking or beer brewing.

“We believe air-based meat is the next evolution of sustainablyproduced food,” says Air Protein CEO Lisa Dyson.

So, is the future of food and fuel happening around us, at no environmental cost? How do these miracles of genesis take place? Can the mopping-up of greenhouse gas really become a production process that yields clean energy? BV hopes to bring you the answers to those questions and more detail on similar developments in 2020. For the moment, let’s just enjoy the glimmer of hope that innovation brings.

FOOD FROM THIN AIR: CAN IT REALLY BE TRUE? THIS US FIRM SAYS YES

AIR PROTEIN, a San Franciso-based company, is pulling off a new trick: food from thin air.

Air Protein recently announced the creation of “meat” — or at least a protein product — from the air that we breathe, without the usual land, water or weather requirements.

The United Nations Food and Agricultural Organisation (FAO) has been facing up to the challenge of meeting the world's nutritional needs. It the global population will to reach 10 billion by 2050.

Coming to terms with numbers like that will entail lateral thinking in terms of agriculture. Farmers will need to boost food production by 70 percent, and achieve that with just five percent increases in suitable land use.

Air Protein's probiotic production process uses carbon-transformation technology to pull off the sort of miracle the world will need. In just days, a brewing process similar to that used in brewing creates nourishment.

The company's claim that “air-based meat is the next evolution of the sustainably-produced food movement” seems reasonable, given the early advances — and the potential.

And while it's a search for a natural solution to a problem, the food product called for scientific intervention. NASA's closed-loop carbon cycle concepts for long space missions played a part here. The good news is that the protein is free of pesticides, herbicides, hormones or antibiotics.

The new protein source can be used in various forms, and the technology is beginning to attract serious attention.