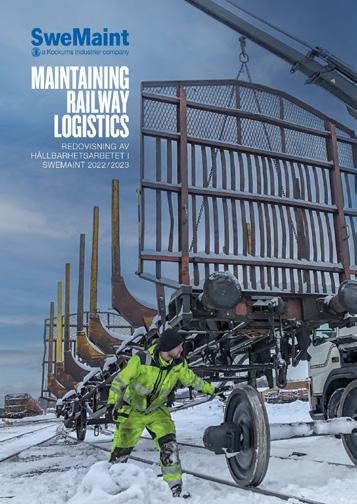

MAINTAINING RAILWAY LOGISTICS

REVIEW OF SUSTAINABILITY WORK AT SWEMAINT 2022 /2023

“ WITHOUT US SWEDEN WOULD COME TO A STANDSTILL”

Since Railport Scandinavia was founded in 1966, the share of rail container transport has increased from 20 to 60 percent. The port's calculations show that the switch from road to rail container transport results in an annual reduction of over 60,000 tonnes of CO2 in port-related emissions.

SweMaint is a proud partner, providing mobile units in the port area. The Port of Gothenburg is currently running a project looking into its capacity for stationed workshops: SweMaint hopes to be entrusted to operate these workshops.

2023

We are all colleagues

for our business

We take responsibility

come to a standstill

Without us, freight would

and the environment

SweMaint 2022/2023

BUSINESS MODEL

How does the business work? The business model clarifies what we do, how the various different parts of the company contribute to the business, and how we create value for our customers or in other words what does the company offer in terms of value.

The REVENUE component SweMaint

1860 1905

Responsibly Acting, Managing and Growing 1859 1994

1859FransHenrikKockumbegins manufacturingrailcarsinMalmö.30November1860 KungligaJernvegsstyrelsen(theRoyalRailwayBoard)signsitsfirstevercontractwithaSwedish workshopforthemanufactureoffreightcars.Theprestigiousorderfor60gravelcars,worthSEK70,200goestoKockums Mekaniska Verkstad.

1998 2001

1905StatensJärnvägarsMaskinoch Teknikdivision(SwedishStateRailway’s MachineryandTechnologyDivision),whichwouldeventuallygivebirthtothe SweMaintweknowtoday,iscreated. 1994Ournameischangedforgoodto SweMaintandwearenowentirelyowned bySwedCarrier. 1998TheactivitiesofthefreightcarworkshopsinMalmö,Helsingborg,Norrköp-ing,Hallsberg,KilandBorlängearetransferredtoSweMaintAB. 2001FromthecorporatisationofSJ,three staterailwayoperatorsemerge:SJAB,thepassengertrainoperator;GreenCar-goAB,whichoperatesfreighttrains;andABSwedcarrier,aholdingcompanywhich, amongstotherthings,handlestrainmaintenance.

2007

2007Asafurtherindustrialstep, KockumsIndustrieracquires state-owned SweMaint.

• ECM certification train car maintenance

• Quality certification

ISO 9001:2015

• Welding certification

EN15085

• Environmental certification

ISO 14001:2015

• VPI certification for rail cars

• VPI certification for wheels

• EVIC

2009

12

locations from north to south

PRIORITISED

2021 2009

Thetagline“Maintaining yourrailwaylogistics”isdevisedto alignwithKockumsIndustriersslogan “Railwaylogisticssince1859”.

2023

2021Rebrandingisonthecardsandthe mergerofthesetwoenrichedcompanies iscomplete. 2023ParentcompanyKockumsIndustrier acquiresMidwaggoninÅnge.Withthat SweMainaddsthe maintenanceofelectriclocomotivestoitsserviceoffering.

30

40 unique wheel supply locations mobile units always connected – all work orders are carried out online using tablets.

24 7

A natural part of our business is an ongoing interaction with our prioritised stakeholders.

These are primarily our:

• Employees;

• Owners;

• Customers;

• Suppliers; and

• “Society” (public authorities, interest groups, etc).

In 2022/2023 SweMaint continued conducting reviews inspired by the Global Reporting Initiative. This year’s report and subsequent reports will continue in the same vein and with the same ambition. n

We have been systematically expanding our range of services since way back in 1905 by focusing on and listening to customer benefits. This gives us a unique platform for making rail freight an even more obvious and more competitive alternative. n

THE

FUTURE ON

TRACK: “ THE FREIGHT TRAIN PULLS AWAY ”

Business’s need for effective transport and society’s demand for climate-smart logistics gives SweMaint the opportunity to grow and contribute to a positive future for both people and companies.

A change is taking place in the transport sector; the transition to a climate-smart society is proceeding at breakneck speed and the need for energyefficient and high-capacity logistics by those companies dependent on transport is greater than ever.

This means that the key role of freight traffic in an efficient transport system becomes clearly evident.

As a consequence, the demand for the maintenance of rail freight is constantly increasing, which is very good for the environment and provides opportunities for SweMaint to increase its operations. As a nationwide maintenance partner, SweMaint is involved as a subcontractor in all major transport solutions, which is very interesting and stimulating work.

Another partner in the logistics chain, and undertaking a major contribution to the environment, is

the world-leading Port of Gothenburg, Scandinavia’s largest freight hub. Last year, the Port of Gothenburg was awarded the international environmental prize Energy Globe Award for the development of Railport Scandinavia, the port’s rail network. Railport Scandinavia connects the Port of Gothenburg to 30 inland terminals located across Sweden and Norway via 80 departures every week.

Since the start of Railport Scandinavia over 20 years ago, the share of rail freight transport increased from 20 to 60 percent. According to the port’s own calculations, port-related emissions of carbon dioxide have reduced by over 60,000 tonnes per year since the transition from road to rail transport. SweMaint is a proud partner with mobile units stationed there. The Port of Gothenburg is now investigating and planning for the establishment of stationary workshops in the port area, which SweMaint hopes to be able to operate.

The construction of the Fehmarn Belt tunnel is underway and within a few years (2029) the tunnel connecting Germany and Denmark should be ready. This will increase the number of high-speed trains, long-distance trains and freight trains across the Öresund Bridge, simultaneously reducing bottlenecks in the transport system. The Swedish Transport Administration must therefore ensure that the increase in traffic and increasingly longer trainsets can be accommodated.

In order to meet the increased needs within our sector, we are continually increasing efficiency and improvements. In short, increased focus and investment in IT, digitisation and production technology. Everything that will provide our employees with more effective tools and support.

During the previous business year, we focused on redefining the company’s strategy and goals and extended the timeline for them. This is to make SweMaint’s fundamental purpose and goals clear, so that we become an attractive and safe employer that works sustainably and long-term on every level.

The recruitment of new employees is ongoing,

both to replace staff that retire but also to expand our capacity.

The next sustainable investment that SweMaint will make in the coming year will be to invest in the hardware that is used in wheel workshops to ensure that wheelsets can be changed in accordance with VPI regulations (IS3). Swedish wheel discs are shrunk on while the European norm is to press the wheel discs on. The goal is to be able to produce and deliver 1,250 wheelsets per year. In addition to this, the wheel workshop will also be able to handle wheelsets with brake discs as we see an obvious increasing trend for freight cars with these kinds of wheels.

Investing in machinery will enable production to be kept at home, thus reducing the countless number of annual truck journeys transporting wheels and wheelsets forwards and backwards between Sweden and Central Europe so replacements and corrective maintenance.

The company is growing – particularly when it comes to wheel workshops. To manage personnel and resources to the best extent, we will be restructuring in the autumn of 2023; a production manager will be appointed for the wheel maintenance business as, at the same time, the workshop and wheel pool – previously separate entities in the organisation – will merge.

In summary, SweMaint’s sustainability work is progressing according to plan. We are continuing our approach to reporting, inspired by GRI, the Global Reporting Initiative. The goal is to be able to make a full report according to the GRI index within the next three years.

As the Nordic region’s leading provider of maintenance services for rail freight, we have a particular responsibility towards all our stakeholders – our owners, customers, suppliers, society – and the environment. A responsibility that gives us the task of creating incentives for motivated co-workers who, with sustainability at the forefront, work to ensure that Sweden does not stand still. n

Agenda 2030 factsheet

Agenda 2030 is an action plan for the prosperity of people and the planet which also aims to ensure world peace through increased freedom. It is the most ambitious agenda for sustainable development ever adopted by the nations of the world, and it is an acknowledgement that ending all forms and aspects of poverty, including extreme poverty, is the world’s biggest challenge and an absolute must for achieving sustainable development.

The UN has formulated the 17 goals as follows:

1. End poverty in all its forms everywhere

2. End hunger, achieve food security and improved nutrition and promote sustainable agriculture

3. Ensure healthy lives and promote well-being for everyone at every stage of life

4. Ensure inclusive and equitable quality education and promote lifelong learning opportunities for al

5. Achieve gender equality and empower all women and girls

6. Ensure availability and sustainable and sanitation for all

7. Ensure access to affordable, reliable, sustainable and modern energy for all

8. Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

9. Build resilient infrastructure, promote inclusive and sustainable industrialisation and foster innovation

10. Reduce inequality within and among countries

11. Make cities and human settlements inclusive, safe, resilient and sustainable

12. Ensure sustainable consumption and production patterns

13. Take urgent action to combat climate change and its impacts

14. Conserve and sustainably use the oceans, seas and marine resources for sustainable development

15. Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt the loss of biodiversity

16. Promote peaceful and inclusive societies for sustainable development, provide access to justice for all and build effective, accountable and inclusive institutions at all levels

17. Strengthen the means of implementation and revitalise the global partnership for sustainable development n

BIOSPHERE

Most relevant global goals for SweMaint

Most relevant for SweMaint

We must be engaged in working towards achieving the SDGs by 2030. We have therefore chosen the following five goals which we can best contribute to achieving based on challenges, risks and opportunities:

• 5 Equality

• 8 Decent work and economic growth

• 9 Industry, innovation and infrastructure

• 12 Responsible consumption and production

• 13 Climate action

Deep-dive and explanations – see next page.

Climate challenges are both local and global. As a company, we choose to see and take advantage of the opportunities and profits that arise from transitioning to sustainability.

PLAN FOR: THE PLANET’S NEW BUSINESS

The global goals in Agenda 2030 can only be reached if more people realise that these goals not only pose considerable challenges, but that they actually create significant business opportunities. This agenda for sustainable development, which has been agreed around the world, thus becomes both decisive for the future of the entire world and at the same time a business plan for humanity and the planet.

Companies that find and develop solutions to global challenges thus have good conditions to grow, flourish and attract both expertise and loyal customers.

During the year, we have continued to work on both efficiency and better support and tools for our employees in both IT and production technology. We have also taken a new strategic approach in order to be able to work more long term and incorporate sustainability into everything we do.

Our move to further invest in our capacity to work with re-wheeling in accordance with VPI (IS3) regulations in the wheel workshop is the next step. As more foreign freight trains begin to roll in Sweden, we will be able to start offering re-wheeling from the beginning of 2025.

The first sub-goal is to handle the 1,250 wheelsets forecast per year, saving 160 truck journeys used to transport wheels and wheelsets on round trips around Europe totalling 380,000 km! n

THE ONLY SUSTAINABLE ROUTE TO TAKE:

ON TRACK FOR FOSSIL-FUEL INDEPENDENCE

A sustainable and well-constructed infrastructure for people and goods is a cornerstone of a functioning society – both now and in the future.

Today, however, the Swedish transport system is far too dependent on fossil fuels, with domestic transport accounting for almost a third of the country’s greenhouse gas emissions. Although emissions have declined between 2007 and 2012, according to the Swedish Environmental Protection Agency, this reduction has slowed down and emissions are back at the same high levels as before the pandemic.

In order to reach the climate goal of reducing greenhouse gas emissions from traffic by 70 percent, emissions need to fall by 8 percent every year between now and 2030. But even if we succeed, it is still not enough. We need to reduce

traffic in general, get more people to cut down on traveling by car and plane, but also find alternatives to the long-distance transportation of goods by lorry such as rail transport, as many agree.

In that respect, Sweden is a role model as 25 percent of domestic freight transport over 10 kilometres is carried by rail. But that figure can and should increase even more.

The Port of Gothenburg is a world leader when it comes to connecting container logistics with a climate-smart rail network: 40 transport terminals across Sweden are served daily. The port is also an important partner for SweMaint; we have mobile workshops in the port area and aim to operate all the stationary workshops that the Port of Gothenburg plans to build.

In its role as Europe’s leading northern repair and maintenance company for freight cars, SweMaint has a higher purpose and responsibility: To forcibly demonstrate that rail freight transport can have a competitive business edge when environmental and climate benefits form an integral part of the business. n

Business and industry has a particular responsibility to implement the UN’s Global Goals. As a market leader, SweMaint intends to be one of the companies that takes the lead in working towards global sustainability. Therefore, we undertake to minimise the obstacles that our business may pose in terms of reaching these goals.

How SweMaint is contributing to the selected global goals:

Gender equality

Equality between women and men is an absolute must in terms of achieving sustainable and peaceful growth. Equality is about the fair distribution of power, influence and resources. Research clearly shows that political, economic and social equality between women and men contributes to all aspects of sustainable development.

At SweMaint women are still underrepresented with women only accounting for 8% of the total number of employees, evenly distributed between the workshops and administration. It is a major challenge in a traditionally male-dominated industry; nonetheless, our priority to reach our vision that 15% of all new hires are women. n

Decent work and economic growth

Figures show that more than half of the world’s workforce is currently working under insecure conditions, often with poor wages and limited access to both education and social security. Simultaneously, the global workforce is expected to increase by 800 million people over the next 20 years. It requires major efforts to create new jobs that are also sustainable for people and the environment.

As a company operating nationwide from Malmö to Kiruna, SweMaint has a responsibility to offer safe and proper working conditions for all current and future employees. n

Industry, innovation and infrastructure

A functioning and stable infrastructure is the basis of a modern welfare society. In order to meet the challenges facing humanity and the planet in terms of infrastructure, every industry and infrastructure must become more inclusive and sustainable. At SweMaint, we work towards this every day, but we want –and must – do even more. n

Responsible consumption and production

Historically, the earth’s natural resources have been more than enough to provide us with food, fuel and everything else we need. But after many decades over consuming these resources, we have now exceeded the limit of what the planet can handle. In order to achieve sustainable development, we must change the way we produce and consume goods and resources.

At SweMaint, we try to do our part by minimising our own environmental impact; we also help our customers to minimise their environmental impact. n

Climate action

Climate change is increasingly evident, and in the long run it risks threatening our entire civilization. If we do not succeed in curbing emissions that negatively impact the climate, there is a risk that global warming will exceed two degrees. This will have serious consequences for ecosystems, oceans, human health and safety, food production and the availability of water due to an increased risk of natural disaster such as fires, floods, droughts and extreme weather events.

SweMaint has the opportunity to help curb emissions as the work we do helps make rail freight transport the obvious choice. n

Our materiality analysis identifies which issues are most important for us to address in order to meet the needs and expectations of both the outside world and our stakeholders.

SIGNIFICANT INTERESTS:

VITAL INTERACTION WITH SURROUNDING WORLD THE

Stakeholder dialogue

Materiality assessment

Cooperation with our most important stakeholders is a natural part of SweMaint’s business. The various stakeholders can mainly be divided up into Employees, Owners, Customers, Suppliers and “Society”, i.e. public authorities, interest groups, organisations, etc. No company or global actor can solve the challenges of the future alone; instead, everyone needs to help each other when it comes to mutual interests. We are, therefore, in constant dialogue with our suppliers and actively cooperate with our customers.

In the previous financial year, we worked extensively to understand our stakeholders’ expectations of SweMaint’s sustainability work. We then identified a number of priority issues, including customer relations, long-term profitability, technical development, training, work environment and supplier relations.

Based on our materiality analysis, where we identified SweMaint’s most important sustainability issues, we continue to work with a number of prioritised focus areas The materiality analysis includes both an impact analysis and information obtained from discussions with our stakeholders, as described above.

The method we applied comes from the Global Reporting Initiative’s (GRI) guidelines on materiality assessments. In addition to stakeholder expectations and issues which SweMaint clearly has an impact on as part of its business, the assessment also considered risk elements in the form of a SWOT analysis.

After prioritising essential issues, SweMaint’s management has established a number of sustainability issues to be prioritised (in no order of priority):

• Safe, secure and thriving employees

• Skills and personal development

• Sustainable purchasing

• Responsible action, management and development

• Sustainability and risk management

• Service adapted to customer needs for optimal exploittion of railways

• Well-managed customer relationships

• Use of chemicals

• Exploitation of resources

• Environmentally-friendly transport

• Energy use

Outcome

The materiality analysis has led to the decision to prioritise these four areas in our sustainability strategy over the next few years:

• We are all colleagues

• We take responsibility for our business

• Without us, freight would come to a standstill and

• We take responsibility for the climate and the environment.

SweMaint

AREA WE ARE ALL COLLEAGUES 16–29

n Key issues

• Safe, secure and healthy employees

• Skills and personal development

n SDGs

n Ambitions

• All employees identify with the statement that Swemaint is a safe, secure, considerate and inclusive workplace / employer.

• All employees identify with the claim that everyone at SweMaint has equal rights and obligations regardless of gender and background.

• The share of women amongst new recruits should grow continuously.

• No one should be injured at work.

FOCUS AREA WE TAKE RESPONSIBILITY FOR OUR BUSINESS 30–35

n Key issues

• Sustainable purchases (environmentally, socially and economically)

• Responsible action, management and development

• Business ethics

• Sustainability and risk management

n SDGs

n Ambitions

• To systematically manage environmental and climate-related issues, human rights and ethics-related questions in the work undertaken by SweMaint’s suppliers.

THESE FOUR FOCUS AREAS FORM

THE BASIS FOR THE COMPANY’S SUSTAINABILITY

FOCUS AREA WITHOUT US, FREIGHT WOULD COME TO A STANDSTILL

36–41

n Key issues

• Service adapted to customer needs for optimal exploitation of railways

• Well-managed customer relationships

n SDGs

n Ambitions

• Meet the increasing demand for our services.

• Satisfied customers.

• Profitable business.

• Invest to increase our capacity.

• Invest in new technology and digitization.

SUSTAINABILITY WORK

FOCUS AREA WE TAKE RESPONSIBILITY FOR THE CLIMATE AND THE ENVIRONMENT

42–47

n Key issues

• Use of chemicals

• Exploitation of resources (minimising and handling waste)

• Environmentally-friendly transport

• Energy use

n SDGs

n Ambitions

• All employees at SweMaint have a basic understanding of environmental and climate-related issues.

• SweMaint works actively and continuously on reducing emissions from our activities which contribute to climate change.

• SweMaint works actively and continuously on reducing the general environmental impact of our business activities.

SweMaint

n Key issues

• Safe, secure and healthy employees

• Skills and personal development

FOCUS AREA

WE

ARE ALL COLLEAGUES

n SDGs

n Ambitions

• All employees identify with the statement that Swemaint is a safe, secure, considerate and inclusive workplace / employer.

• All employees identify with the claim that everyone at SweMaint has equal rights and obligations regardless of gender and background.

• The proportion of women amongst new recruits should increase continuously.

SweMaint takes a preventative approach to issues of health, safety and the working environment, and combating discrimination and promoting equal rights and opportunities in the workplace.

We care about the sort of long-term well-being in the workplace that a diverse and thriving workforce contributes to.

Our long-term objectives support our ambition to be an attractive, considerate and inclusive employer with access to a pool of competent new recruits. n

In order to be a sustainable workplace, everyone in the organisation needs to take part and have an opportunity to contribute in various ways to a sustainable culture. This, in turn, is a basis for the company's long-term success. We are each other’s work environment; that’s why showing loyalty, respect and concern for each other as a matter of course is part of what makes us a team.

NOT JUST ABOUT THE WEATHER:

FOR A WARMER WORKING CLIMATE

Better employee surveys – and more frequently

In the autumn of 2022, we identified a need for more frequent surveys that we can follow up in real time to quickly gather material for comparison. The aim is to see how employees' well-being and well-being changes over time – hopefully for the better. After exploring the market and meeting with a number of different suppliers, we entered into a contract with Eletive who had the right solution that we were looking for. Above all, a simple platform with a tie-in app makes it easy to log in and answer the questions.

We did our first survey in Eletive in the spring of 2023. In the future, the survey will be carried out every quarter. This will give us an ongoing overview of how everyone is doing, as well as insight into the changes we have made. Eletive’s platform also gives you the opportunity to ask a set of questions yourself if you want to find out something specific.

On a scale of 5 when it comes to engagement, the result of the first survey was 3.8 which is roughly the same as in previous surveys. When it comes to staff’s relationship with management, meaningfulness and participation, as well as goals and

goal-achievement, the approval rate was high. What we primarily need to improve in the workplaces are tools, feedback and communication.

Leadership development

At the beginning of 2023, our newest workshop managers attended the leadership program Leadership development (LD). The program is based on research about what is called “transformational leadership”. LD is the Swedish model developed by the Swedish Defence University based on a broad scientific base. It is also the world-leading model where researchers have most clearly been able to demonstrate a positive impact on profitability and results.

The concept Leadership development includes, among other things, an assessment form, a theoretical model and a method for personal leadership development. As part of the training, participants have gained knowledge about the leadership model, received personal feedback on their leadership style and behaviour as well as come to understand their personal need for development. They have also gained increased self-awareness and created a personal develop-

ment plan with the focus and purpose of developing their leadership.

The LD model is characterised by the fact that a leadership developer acts as a role model, taking up questions about morals and ethics following clear basic principles. The characteristics of someone who has gone through leadership developmentis someone who can inspire and motivate in order to promote participation and creativity, can empathise with others, provide support but also take up difficult issues where necessary when it comes to individuals and the organisation as a whole. Before undergoing training, everyone had to do a 360degree assessment, which forms the basis for the work that takes place during the training days.

Tools to help retain younger employees

Securing the skills that will be needed in the future is a matter of survival and a cornerstone of sustainable business. But the challenge is not only recruitment itself: we need to attract new staff, meet their expectations and ultimately retain those who come and work for us.

A worrying development is that fewer and fewer young people – especially less women – apply to vocational, practically-orientated programmes.

Laws and guidelines

SweMaint follows all legislation that governs our sector, as well as our own agreements. In order to ensure that we are fulfilling our legal and ethical duties, we have put together a number of steering policy documents:

• Work environment and road safety policy

• Sustainability policy

• Crisis policy

• Policy against sexual harassment

• Alcohol and narcotics policy

• Code of conduct

Core values

We work continuously to ensure all our employees feel safe and are proud to be a part of SweMaint. Both internally and in relationships with our customers, suppliers and other external stakeholders, SweMaint’s values form the basis for every employee’s actions and decisions.

We have to help reverse that trend!

A new tool to help achieve that is a degree essay that one of our employees in the finance department has done. The essay focuses on SweMaint as a company and is a study on motivational factors in the workshop industry and provides insights into how to work to retain the younger generation.

Åldersfördelning

We will go through the results of this study and make a plan as to how we continue to work with our personnel policy.

Finders fee and local targets

Linked to recruitment, we have successfully introduced a so-called Finder’s Fee. This means that we pay a bonus to an employee if they tip us about someone, who is currently not employed by us, but who subsequently goes on to be hired.

Staff are now involved in settling goals for their area which are based on the company’s overall goals. In this way, the goals become more relevant to a particular location. Some of the UN’s global goals are also part of our own area of focus here. As an added incentive, each workplace also gets to decide how they should celebrate the achievement of set goals. n

Our values

WHITE COLLAR/BLUE COLLAR DIVIDE among a total of 270 employees.

Kvinna

The

can only grow with employees who are engaged, aware and safe when at work. So, how do we safeguard the working

Nowadays, the concept of attendance rates is most often used, which better reflects the fact that we spend most of our days at the workplace. at swe-

96% (the percentage of employees with no more than 7 days of sick leave in a year). we consciously, therefore, promote preventative healthcare and exercise.

healthcare allowance and its use has also increased. we also arrange activities through sweMaint’s sports club.

Nowadays, the concept of attendance rates is most often used, which better reflects the fact that we spend most of our days at the workplace. At SweMaint, the attendant rate goal is that it should be over 96% (the percentage of employees with no more than 7 days of sick leave in a year). We consciously, therefore, promote preventative healthcare and exercise. Among other things, we have further increased the healthcare allowance and its use has also increased. We also arrange activities through SweMaint’s sports club.

Everyone must feel welcome to work for us. we currently have employees from a number of different national backgrounds, especially on the repair side of the business, who enrich us and help us grow both as individuals and as a business.

We are all colleagues

We are all colleagues

the workshop managers and chief health and safe-

course on work environment regulations. this took place over two intensive full days in conjunction with the divisional business meetings in Gothenburg. the

The workshop managers and chief health and safety officer have been given a much-needed refresher course on work environment regulations. This took place over two intensive full days in conjunction with the divisional business meetings in Gothenburg. The training was adapted to our specific requirements regarding Systematic work on the work environment (SAM) and with major emphasis on the organisational and social work environment.

(saM) and with major emphasis on the organisational and social work environment. health issues and organisational and social work

workplace meetings at all workshops and units. employees have responded positively to the company’s challenge to report every incident. the procedure for

Health issues and organisational and social work environment issues are also highlighted during regular workplace meetings at all workshops and units. Employees have responded positively to the company’s challenge to report every incident. The procedure for making a report is simple as it is done via the intranet. It can also be done anonymously. Computers are available at every workshop. Figures clearly show that more people are filing reports as the number of reported incidents has increased significantly while the number of actual accidents at work, on the other hand, has thankfully remained the same. n

Absences due to illness and occupational injuries when an employee becomes ill, we always investigate how we can help the person get well. absence due to illness is followed up through conversations with employees and if additional support, rehabilitation or other action is needed, we collaborate with the occupational health service (falck) and the swedish social insurance agency (försäkringskassan). the figures for both short-term absences (1–7 days) and long-term absences (more than 7 days in a row) are relatively low, according to falck.

incidents and accidents

the basis of sweMaint’s work to prevent accidents and incidents is the continuous risk assessments that the central safety committee makes, with safety rounds 4 times a year. the safety committee has started measuring air pollution in the workshops when carrying out Hot work the results will be presented in the autumn of 2023. the task of changing the supplier of work clothes is ongoing.

Collaboration and the work environment

all departments have workplace meetings and employee talks. Collaboration agreements mean that as many issues as possible must be dealt with by those who are directly affected by their work. the goal of local cooperation groups meeting 4 times a year has not been achieved during the period. employee appraisal interviews are conducted in all departments once a year.

in addition, sweMaint informs and trains safety officers and supervisors about, among other things, systematic work environment work, delegation, accidents and workrelated injuries as well as rehabilitation. n

available at every workshop. figures clearly show that more people are filing reports as the number of reported incidents has increased significantly while the hand, has thankfully remained the same. n *

Sourcing and growing skills is a key factor in the success of all organisations and businesses.ReCRuitMent stRateGy

fundaMental foR sustainability

During the previous period the personnel department developed a new recruitment strategy with the aim of becoming a more attractive employer in the workshop industry. the strategy includes continuously meeting even higher requirements in terms of values, leadership, personnel policy and clear business goals.

we must ensure that our employees have the necessary skills, and we must shape their continued development based on the overall goals and direction of the business. we will work on issues that are important to our employees so that they will want to remain with us for a long time.

the ability to retain employees is a key issue from many aspects: if we are talk about productivity in the strictest sense, it takes an average of 6 months for a new employee to generate more value than the actual cost of employment.

the goal of this strategy is to ensure that both those employed under the collective agreement and white- collar workers have the “right” skills. w ith those

training at SweMaint

It goes without saying that our goal of proactively helping to shape the future of railway logistics requires colleagues with the highest levels of skill in mechanical engineering. to do this, we have made the most of the proud shipbuilding tradition of cities like Gothenburg and Malmö and the changes in industry that these cities have witnessed in recent decades, which has allowed us to employ highly-skilled sheet metal workers, welders and assembly engineers. but we have also made a significant contribution ourselves with a range of different education courses to guarantee regeneration – in total, the company offers 110 different courses, including 6 in brake technology alone.

employed as part of the collective agreement, we must strive to ensure that they have the right educational background such as the industrial programme, mechanics, or any other relevant programme. but in order to recruit and retain employees, we also need to have good leadership, which requires well-educated managers. here, the investment in leadership training for workshop managers is both an important and appreciated step.

w ith a focus on attracting new colleagues who feel an interest in our workshop operations, we want to reach people of different ages, of different origins and, of course, eventually increase the proportion of women in the organisation. we must have a relevant and convincing “onboarding process” with a view to personal development and with the goal of ensuring that the employee continues to choose sweMaint in the long term, within the scope of the job description. n

some of the training programmes we offer include:

• Traffic safety

• Wheel maintenance

• Reparation

• Welding

hR and Personnel are responsible for drawing up plans for training and further education within sweMaint ab and for ensuring that these efforts are ongoing. the company’s comprehensive education programme, which describes the courses, content and goals, can be accessed via the intranet management system. n

we aRe people fiRst and foReMost

It should be just as likely for women to choose a career in the workshop and technology sector as men. But Swedish industry is one of those with the lowest proportion of women compared to the rest of Europe.

In the engineering industry, which accounts for about half of all 600,000 employees in the manufacturing industry, the percentage of women in sweden is only about 20%, putting it third from the bottom in europe. only the netherlands and Great britain have a lower percentage.

sustainability is driven by innovation – not gender or ethnicity in line with the un's global goals of gender equality (nr. 5) and economic growth (no. 8), sweMaint is among many other companies that agree with the swedish academy of engineering sciences (iva), which believes that these businesscritical issues are also vital for sweden's ability to be competitive.

Many people feel it is nigh on impossible to change something so entrenched, yet new norms can be created. Joint forces and a sense of conviction help foster change – assuming that both men and women are both onboard. otherwise, nothing will happen.

the fact that the percentage of women applying for positions such as repair technician is in- creasing also hints at a general bucking of the gender trend when it comes to supply and regeneration. the issue has many different aspects, but for sweMaint it

is above all about avoiding future problems with the supply of skills and therefore the issue has the highest priority.

Despite this, women are still underrepresented in the organisation. if or when we reach our goal of 15% women of new hires is difficult to predict. however, the proportion of women has increased from 7% to 8% since the previous report, after we hired two new women as repairers, one in Gothenburg and one in Ånge, and a woman on the staff side in Malmö. n

Women 8%

After previously conducting employee surveys approximately every two years, SweMaint has introduced a new type of survey with both more frequent follow-up and an app that makes it easier for employees to answer the questions.

Mobile aPP PRoviDes

Mobile aPP PRoviDes

staff suRvey in a new foRMat

“In the past, employee surveys took place approximately every two years – that’s not enough. Once the result is reported, it is already out of date, so I felt that this is something we have to look at,” says HR manager Paul Søndergaard.

Said and done. After meetings with several different suppliers just before the turn of the year 2022–23, SweMaint turned to Eletive for help.

“They have a platform that is clear and comprehensible with graphs and colours. Everything also comes in real time, so for example a workshop manager can immediately see how many people have answered. If just 11 out of 20 have answered, the manager can go in and remind the others to answer. They can constantly see in real time how things are going until the survey is closed.”

Possibility of responding more quickly

Quicker follow-up is a prerequisite to dealing with opinions, shortcomings and concrete problems at an early stage that prevents them from growing and becoming more difficult to solve.

“we get a much more up-to-date insight into the

situation, which allows us to be on the front foot. if there is a problem or important issue in a unit or workshop, you can quickly do something. that is the biggest win.”

although there are multiple-choice answers, everyone can add their comments and explain their answer. this was an opportunity that many made use of when it “premiered” in the spring of 2023.

“yes, it was very positive because there were a lot of people who explained their answers and wrote comments even during the first employee survey. in order to take some kind of action, the manager responsible sometimes needs to know more about a problem; at this point the additional built in features of the platform can be used.

“the current manager can never see who has given a certain answer, but if someone has written a comment and points out a serious problem, the manager can go in and write, for example, “thanks for the info. if you would like, you can come forward and talk to me”. “in this way, problems can be prevented and solved early,” says Paul søndergaard.

Anonymity is vital speaking of anonymity, is there any concern that responses from an individual employee can be identified?

“that question has come up, but in order to guarantee anonymity, we have merged those units and workshops that only had a few employees so that there are now enough employees in each ‘response group’. we have also done this at management

How it works:

The survey is created by the eletive and includes 46 questions within 11 different areas of focus:

• Relationship with manager

• Relationship with colleagues

• Meaningfulness and participation

• Goals and goal achievement

• Workload

• Learning and development

• Workplace and tools

• Health

• Feedback and communication

• Autonomy

• Strategy, vision and culture

level,” says Paul søndergaard.

local managers can only see the results from their own workplace and the total results for the whole company, whereas management can see and compare different units.

isn’t there a risk that surveys are conducted too often, that employees get tired if they have to do the survey much more often than before?

“we have also thought about that, but we think that once a quarter works. after all, it won't be more than four times a year. if you as an employee see that it has an effect and leads to improvements, it may also increase your motivation to respond.”

at the time of writing, the new staff survey had only been done so there was, of course, no results to be compared with.

“instead, we compared the results with eletive’s own database of results taken from other companies. next time we can compare with our first result,” says Paul søndergaard.

Valuable input for management

a better employee survey is not only important for

improving every workplace. it also gives management a good picture of the situation at both individual workshops and overall.

“we can look both at the overall level of the organisation and at the individual workshops. for example, it could be that there are many negative responses about the tools at a workshop, what the reason for this is and what can we do about it?

w ith a more modern employee survey and more frequent follow-up, sweMaint expects to be able to improve health and well-being as well as productivity and results.

“yes, i hope so and i believe so. by addressing problems, we show that we take what employees and repairers say and think seriously. if you have problems and solve them, productivity increases. when we feel better and are happier at work, we simply work better.”

Clear and visual platform

the survey covers 46 different questions within 11 different key areas of focus such as goals and goal fulfilment, meaningfulness and participation, workload, health, relationship with managers and colleagues and so on. employees can log into the survey and answer the questions either on a computer or in an app they have download to their smartphone.

“i think that contributes to making it easy. after all, everyone has a smartphone these days that you pretty much always have with you, so it’s easy to download the app and answer the questions.”

Paul søndergaard also thinks that eletive’s platform is easy to understand and visual.

“it gives a very clear picture with diagrams so that you can see the result clearly and visually. you can also produce a “heat map” – a matrix where green means it is good, red is something that needs fixing and an in-between colour shows areas where you need to keep an eye on things. then we can immediately see if and where we have red squares. okay, this is where this problem exists. this is going to be really good, i think!” n

we aRe all colleagues

During 2023, almost all of SweMaint’s workshop managers completed the leadership training course: Developmental Leadership (UL). HR manager Paul Søndergaard already feels that the training has yielded results, apart from the fact that it has been both requested and appreciated.

woRkshoP ManaGeRs’ new tools

leadeRshiptRaining foR a MoRe sustainable coMpany

welcoMe to sustainable leadeRship

“I’ve noticed that a couple of the managers have already used certain tools in the job. those who may have had difficulty conducting slightly tougher conversations have been given templates to follow, which they have then used to have these conversations," says Paul søndergaard.

Developing the leadership of workshop managers is an important piece of the puzzle in the company's work towards sustainability because sustainable leadership affects the entire business from employees who thrive and stay, to better productivity and results. then employees will automatically benefit. there is also value in many managers from the company attending the training because it gets them speaking the same language,” says Paul søndergaard.

“we have focused on our workshop managers because many of them are new and relatively young managers who have good prospects and are motivated. so it's a bit of a generational thing – those between 40 and 50 have a greater appetite and some have asked for leadership training.

employee surveys provided further background

to the training programme in that they pointed towards the need for better leadership. a couple of areas for improvement are feedback and visible goals for the business.

“there, the training can contribute to getting better at setting goals and feedback. as an employee, you not only want to know that you are good, but also what you can improve.”

overall, the participants have been very satisfied with the training, which covers three days in row. a follow-up day is held two months later.

“yes, i feel that several managers have really embraced the tools. someone has said in a meeting that they have used a particular template or model. of course, this is good to hear. i also think that receiving positive feedback from the others has given them courage and confidence, says Paul søndergaard.

Focus on personal leadership

the leadership training, called Leadership Development (lD), is based on a well-established concept that has been developed and researched by >>>

We are all colleagues

We are all colleagues

Facts Paul søndergaard

Age: 59 years old.

Family: w ife susanne, preschool teacher, and three children who have left home.

Lives: bjärred outside Malmö.

Education: Police academy stockholm; behavioural science, organisation and leadership at kristianstad university; Project management at Malmö university.

Career in brief: 23 years as a police officer in Malmö in various units. self-employed for 8 years as an organisational consultant; hR manager at sweMaint for the past 6 years.

Leisure interests: sport – mainly strength training, paddle tennis and motorcycling. stock trading.

What private sustainability measures do you take? i’m good at recycling waste. i also fly less and buy less “unnecessary” stuff. n

>>> swedish Defence university. the choice of education was based a lot on Paul søndergaard’s own experiences and network.

“because i have previously been a consultant and i am trained in leadership, i have a pretty good grasp of what is available. i had also heard from several old consulting colleagues that this is a very good leadership program that the swedish Defence university have developed. then we hired a consultant who i know is good, who has completed the training. another advantage was that managers from several other companies participated in the same training, so you get a bit of a different perspective as well,” says Paul søndergaard.

the training is not about teaching factual knowledge; instead, it is entirely focused on the personal aspects of leadership. before the training takes place, the participants undergo a 360degree assessment where the manager, colleagues at the same level and subordinates describe how they experience the manager in different situations. During the training, the participants

welcoMe to sustainable leadeRship

We are all colleagues

work with the input that the 360-degree assessment generated.

“then the participants discuss leadership behaviour and each one gets to make their own development plan with what they need to improve on. this is primarily based on the 360-degree model and the feedback from the others in the group.

Good managers = supplying skills since staffing is part of Paul’s duties as hR manager, he sees leadership training as important for attracting and retaining staff.

“yes, that is one reason why we work on improving leadership. we have an economics student with us part-time who has written an essay on how to retain the younger generation, who tend to move around. we are quite good at recruitment, but employees also need like where they are and feel that they are developing.”

it is a challenge to recruit staff as working in a workshop is a physically “tough job” that simultaneously places high demands on finding informa-

tion on computers and documenting things correctly in writing. therefore, management is extremely important. it is important that employees have a good manager and the support of their manager.

a sustainable leadership that carries on developing will hopefully also result in less absence due to illness and increased productivity, even if these are more long-term changes.

“in our next employee survey, perhaps we can see if something has changed. if short-term absence due to illness is reduced and it has a positive impact on production, then this could be a sign that the leadership has improved. after training workshop managers, it may be important to get give more managers training,” says Paul søndergaard.

“yes, i can imagine that. even though we are a fairly flat organisation, all the other managers may also benefit from the training, not least because everyone in management undergoes same basic training. you can always learn something new about yourself.” n

issues purchases (environmentally, socially and economically) action, management and development ethics and risk management

take

Responsibility foR ouR business

HÅLLBAR

KONSUMTION OCH

mbitions

systematically manage environmental climate-related issues, human rights issues and business questions in sweMaint’s work with suppliers.

SweMaint health, safety more, we work mote equal What we being in the workforce contributes Our long-term to be an attractive, with access

SweMaint takes a preventative approach to health, safety and the working environment; furthermore, we work to combat discrimination and promote equal rights and opportunities in the workplace.

What we care about is the sort of long-term wellbeing in the workplace that a diverse and thriving workforce contributes to.

Our long-term objectives support our ambition to be an attractive, considerate and inclusive employer with access to a pool of competent new recruits. n

WE TAKE RESPONSIBILITY FOR OUR BUSINESS

Everyone in the SweMaint organisation is responsible for how our actions impact the environment – employees, customers, suppliers, stakeholders and society at large. So what do “business ethics” mean for us?

MAINTAINING BUSINESS ETHICS:

ONLY SUSTAIN ABLE BUSINESS APPLIES

Sustainable business is like a motto for us here at SweMaint and is all about conducting business with one eye on the future; it’s about following international guidelines aimed at breaking the dependence on fossil fuels, contributing to positive social growth and minimising our company’s negative impact on the environment.

It’s about showing through our actions every day that we have earned the trust of our employees, our customers, our suppliers and society. Our customer relations are often longlasting and built specifically on trust, trust and – trust.

We are trusted to inspect freight cars, and to identify damage to these cars in an objective and professional manner so that we can restore them to a serviceable condition.

We are our customers’ eyes and ears on the rails and with respect to their fleets of rail cars.

To that end, our Code of Conduct stipulates how everyone in our organisation is expected to behave at work. It highlights our values and the principles that guide us in our relationships with customers, employees and other stakeholders. Everyone who works at SweMaint, regardless of their function or place or work, must adhere to this Code of Conduct.

At SweMaint, we all also have a common ethical responsibility to behave in accordance with basic values of honesty, justice and integrity. This means showing respect for the environment, people, animals and taking account the needs of all stakeholders into account. In all those countries where SweMaint conducts business or partnerships, local laws and regulations must be observed.

Child labour, as defined by the UN and ILO conventions, is of course not permitted under any circumstances. SweMaint also respects and follows competition regulations, environmental legislation, labour laws, agreements and other legal provisions. All employees at SweMaint are prohibited from offering or accepting bribes, gifts, advantages or payments that might impact their ability to make objective business decisions.

We actively avoid situations where loyalty to SweMaint might be in conflict with personal interests. During the last year, we developed our Code of Conduct and introduced a whistleblower service. Both can be accessed via swemaint.com and the whistleblower service is managed by an external party for privacy reasons.

When carrying out work for SweMaint, our suppliers must observe our Suppliers’ Code and ensure that this code is followed by and communicated to both themselves and anyone else further down the supply chain. We have a number of decisions to make every day and our ambition is to observe correct business ethics at every meeting and in every decision.

During the coming year, we will strengthen this approach by giving employees further training on the codes of conduct. These courses are also mandatory for newly employed staff. n

Code of conduct

Our internal Code of Conduct is based on the Ten Principles of the UN Global Compact and the OECD Guidelines for Multinational Enterprises. This Code describes how we at SweMaint conduct our business in an ethically, socially and environmentally conscious manner. The code of conduct is available in its entirety on the intranet. Here we reproduce a shorter summary.

Laws and regulations

All employees must comply with applicable laws, regulations, statutes and standards. SweMaint respects and follows competition regulations, environmental legislation, labour laws, agreements and other legal provisions.

Business ethics

At SweMaint, we conduct ourselves ethically in accordance with our values of honesty, fairness and integrity. We ensure that all information about the business is treated confidentially. We have an effective and trust-building cooperation with customers, suppliers and other stakeholders. We actively avoid situations where loyalty to SweMaint might conflict with personal interests.

The working environment and CSR

We take responsibility for providing a safe workplace and are constantly working to improve health and safety for our employees. All employees at SweMaint have a right of association, without exception.

Human rights

SweMaint supports and respects internationally recognised human rights. We do not tolerate any forms of forced or child labour. We strive for equality and diversity and we understand the value of people's differences. All employees are treated fairly and without prejudice. No one shall be discriminated against with respect to recruitment, pay, professional development, promotions, terminations or any other situations.

Environment

Sustainable business is like a motto for us here at SweMaint and is all about conducting business with one eye on the future; it’s about following international guidelines aimed at breaking the dependence on fossil fuels, contributing to positive social growth and minimising our company’s negative impact on the environment.

We respect national and international environmental laws and regulations, and ensure that we have all permits and licences that are required to conduct our business. At SweMaint, we should always be working to improve our environmental work and we should be aware of and have control over our impact on the environment. We shall apply the precautionary principle when it comes to our environmental risks in order to avoid or limit the foreseeable environmental impact of our activities.

Compliance and monitoring

It’s about showing through our actions every day that we have earned the trust of our employees, our customers, our suppliers and society. Our customer relations are often long-lasting and built specifically on trust, trust and – trust.

We are trusted to inspect freight cars, and to identify damage to these cars in an objective and professional manner so that we can restore them to a serviceable condition.

We have a shared responsibility for how we influence our employees, customers, suppliers, society and other stakeholders which the company comes into contact with. It is our responsibility that we act in accordance with the Code of Conduct, and that we take steps in the event that anything deviates from this Code, in accordance with our Whistleblower Policy. Managers are responsible for ensuring that all employees and other relevant personnel understand the Code of Conduct, and all employees have an obligation to comply with the requirements of the Code of Conduct. n

We are our customers’ eyes and ears on the rails and with respect to their fleets of rail cars. Our Code of Conduct stipulates how everyone in our organisation is expected

for our business

We take responsibility

tRaCeability anD MaPPinG:

lead to sustainability

SweMaint has a well-established base of carefully selected suppliers that ensures both the right product range and a long-term sustainable future.

We work long-term with our suppliers to ensure that they work sustainably. a limited number of large and strategically important suppliers account for the lion's share of the spare parts we purchase. we have an ongoing dialogue with them at all times – relationships like this have proven to be incredibly important, especially during a troubled year like this one with constant challenges.

Delivery forecasting is another important tool in a supplier’s toolbox, and ensures that we have the spare parts in stock that are needed to be able to maintain our commitment to deliver to our customers on time.

the transportation of spare parts to and from the respective workshop is of course done by rail wherever possible. we are certified according to iso 9001 and iso 14001 which sets the standard for how we want to, and how we should, be working. therefore, we expect our subcontractors and suppliers to live up to the same standards or can demonstrate similar working methods.

Supplier follow-up

the purchasing department at sweMaint is, together with the quality department, responsible for developing and following up on our suppliers. we achieve this through supplier assessments, supplier appraisals, and supplier site visits. we al-

so make a simple assessment of all new suppliers before making it possible to make a purchase from them in our business system.

we have previously mapped out which suppliers are strategically important to sweMaint – it is these that will be then subject of our annual supplier evaluation here we look at criteria such as quality, reliable delivery, price, customer service, environmental approaches and sustainability work

a new addition to the valuation process and criteria is the compliance check that we have been applying for some time. in this way, we ensure that every link in the chain works sustainably. at the supplier level, our Supplier Code of Conduct has also been well-established for some years now. the code can be found on swemaint.com and must always be attached when new agreements are signed.

Another challenging purchasing year

Continued delays to deliveries, the increased cost of transport by container ships and soaring raw material prices saw us making extraordinary efforts and finding creative solutions to avoid production coming to a halt because of material shortages.

last year’s decision to not make any purchases from Russia on principle still applies. however, we continue to do business with ukraine. n

Regulations Purchasing

All raw metal materials

that are purchased to repair train cars and are required to be fully traceable must follow particular instructions: The purchase of materials with traceability requirements.

Materials purchased to be used for welding into bogie, chassis, traction device, braking equipment, struts and lashing loops, must be certified and documented alongside the work.

supplier assessment and supplier evaluation is only required from suppliers whose goods and services affect the quality to a high degree of the delivered goods, services, safety or the company's environmental impact.

Supplier assessment

supplier assessments must be performed before a new supplier is approved. for certification to be approved, the standards for iso 9001 and 14001 compliance must be met.

Supplier appraisal

in our appraisal of suppliers, we look at criteria such as quality, reliability of deliveries, price, customer service, business ethics and environmental approach.

Materials and components which significantly affect the safety of products and services delivered may only be purchased from approved suppliers in accordance with the List of approved suppliers.

Chemical products

must be procured in accordance with the procedure for procuring Chemical Products.the head of Purchasing is responsible for all purchasing business. n

for our business

for our business

w e take responsibility

We take responsibility

n Key issues

• Service adapted to customer needs for optimal exploitation of railways

• Well-managed customer relationships

FOCUS AREA WITHOUT US, FREIGHT WOULD COME TO A STANDSTILL

n SDGs

n Ambitions

• Meet the increasing demand for our services.

• Satisfied customers.

• Profitable business.

• Invest to increase our capacity.

• Invest in new technology and digitisation.

We are a nationwide organisation – from Malmö in the south to Kiruna in the north, our growth is driven by demand and in tandem with our clients.

Our customers’ freight cars need to be running all day and all night the whole year round – which is why all our workshops offer an all-round service package. These activities cover three areas: train car maintenance, mobile workshops, and wheels.

Our range of services includes wheel maintenance, a unique wheel procurement programme and comprehensive material procurement which together guarantee quick lead times.

All of this combined is what makes us such an integral part of Sweden’s infrastructure. n

come to a standstill

Without us, freight would

WITHOUT US, FREIGHT WOULD COME TO A STANDSTILL

SweMaint has been working in the rail industry since 1905 and is considered to be a leading supplier of maintenance services to train car owners and other rail freight operators in Northern Europe.

SWEMAINT – PREFERRED PARTNER:

AN ALL-ROUND SERVICE AND MAINTENANCE SOLUTION FOR RAIL FREIGHT

As a leading player in freight car maintenance for rail-borne and climate-smart freight transport, SweMaint is a major contributor to keeping Sweden’s core industries up and running and securing trade with Europe via the rail network and sea. This becomes reality through all our workshops’ complete service and maintenance ofiffering.

The business covers three areas: Workshop maintenance, mobile maintenance and wheel maintenance. The service program also includes the supply of spare parts, which guarantees fast lead times.

Our 40 mobile units provide help with faults both on and along the line, which is essential because time is money. Therefore, minimising downtime and getting customers’ freight cars back into traffic as quickly as possible is crucial.

Both workshops and the mobile units are strategically placed at the major railway hubs from Kiruna in the north to Malmö in the south, all in order to solve the maintenance needs of all the country’s operators and freight car owners with a local presence.

By constantly being at the forefront and deve-

loping the business, we want to make rail-borne, non-fossil freight traffic the best alternative for business and the environment. Our considerable experience in the industry as well as our endless commitment to improving our services is what enables SweMaint to top the Swedish market when it comes to service, quality and value.

Being at the forefront simultaneously places demands upon us – which means that we must constantly be on our toes to maintain our position as a preferred partner. With a clear purpose and ongoing dialogue with our clients and stake-

holders, we constantly adapt our strategy to meet future demands, make changes and refine the value of the work we do compared to our competitors.

In 2023, the workforce amounted to a total of 270 employees, spread over offices and workshops throughout Sweden.

SweMaint is headquartered in Gothenburg. Turnover for the financial year 2022–2023 was SEK 480 million.

SweMaint is privately owned by Malmö-based parent company Kockums Industrier. n

Without

WITHOUT US, FREIGHT WOULD COME TO A STANDSTILL

LEADER SHIRT AND LOCOMOTIVE:

SWEMAINT THE RAILWAY TO THE FUTURE

The Fehmarn Belt tunnel between Denmark and Germany will forever change Northern Europe’s flow of traffic and have a significant impact on Swedish infrastructure and industry.

This stretch of line is probably Sweden’s most important trade link: in 2022, Sweden imported and exported goods to Germany, our main trade partner, to the value of SEK 516 billion. Other countries whose trade routes are affected by the creation of the tunnel make up 42 percent of Sweden’s total export of goods.

When the world’s longest submerged tunnel between Denmark and Germany is inaugurated in 2029, people and goods will be able to get to and from Europe significantly faster. It is therefore not possible to emphasise enough the logistical importance the tunnel link will have for Swedish companies trading with continental Europe.

In order to utilise the increased capacity in Sweden – potentially doubling by rail and with ever longer trainsets – political incentives and national investments in railway infrastructure will, however, be needed to keep a pace.

Involvement in the transportation chain is widening

In its role as the Nordic region’s leading player in repair and maintenance services for freight cars, SweMaint also has a more important purpose: To strengthen the basis that gives rail freight its competitive edge. In a practical sense, the role means that SweMaint, as a nationwide maintenance company, is also included as a subcontractor in all major transport arrangements.

Parent company Kockums Industrier’s acquisition of Midwaggon AB and their electric locomotive maintenance in Ånge is another strategic investment in line with a changing environment and transport market and the refining of our service offering for the greatest possible customer, societal and climate benefit. n

2029 Fehmarn Belt – the tunnel

Malmö–Hamburg: 2 hours 50 minutes

The Fehmarn Belt fixed link, more colloquially known as the Fehmarn Belt Tunnel, is an ongoing building project under the Fehmarn Belt. It is being built as a socalled submersible tunnel and will have a motorway and a railway. It will basically have the same route as the Rødby–Puttgarden ferry line.

Stretching 17.6 km, the connection will be the world’s longest combined road and rail tunnel. It is expected to be completed in mid-2029.

The link will total 19 km in length, of which 17.6 will be a submerged tunnel. It will not be Europe’s longest road tunnel as the Lærdal tunnel is longer, nor Europe’s longest bridge if it had been a bridge as the Crimean bridge was completed in 2018.

The construction costs for the building of the link were estimated in 2010 to be 5.1 billion euros. In addition, Denmark was expected to pay roughly DKK 6.7 billion or EUR 900 million in 2007 prices for land-based facilities. The German costs currently stand at 840 million euros in 2003 prices.

Denmark, which has more interest in the link, will carry the cost of the tunnel. At the time of writing, it is the country’s largest construction site, employing approximately 2,000 people. In return, the Danish state can decide and keep the fees after the company’s

paid.

The company running the tunnel will be Danish. The payment kiosks will be placed on the Danish side and provide jobs for Denmark. The costs for building the tunnel are estimated to be paid in 2050. (Wikipedia)

come to a standstill

Without us, freight would

SweMaint

n Key issues

• Use of chemicals

• Exploitation of resources (minimising and handling waste)

• Environmentally-friendly transport

FOCUS AREA

WE TAKE RESPONSIBILITY FOR THE CLIMATE AND THE ENVIRONMENT

n SDGs

n Ambitions

• All employees at SweMaint have a basic understanding of environmental and climate-related issues.

• SweMaint works actively and continuously on cutting down emissions from our activities which contribute to climate change.

• SweMaint works actively and continuously on reducing the environmental impact of the business.

At SweMaint, our environmental work is governed by the ISO 14001 environmental management system, with constant improvements being our driving force. We continuously dissect our business based on the significant impact that our activities and our company have on the environment. Freight, business trips, electricity and district heating, and the use of chemicals are the environmental aspects we are prioritising in our efforts to reduce our company’s impact on the climate and the environment. n

and the environment

We take responsibility for the climate

WE TAKE RESPONSIBILITY FOR THE CLIMATE AND THE ENVIRONMENT

CHANGED WAY OF WORKING

FOR CONTINUED IMPROVEMENTS

The environmental investigation, which takes place throughout the organisation every three years, aims to provide an upto-date description of the company’s environmental impact on the one hand, and the measures it is taking to counter any negative impact.

In this way, and within the regulatory framework and current environmental legislation, the basis for our future efforts is laid out on the way to a sustainable society.

Based on the results, we then assess where SweMaint has the greatest and most significant environmental impact and thus where we can make the biggest difference. These then become the starting point for our environmental policy and the company's goals for the next three years.

district heating materials/transport

Consumption of district heating

Handling of materials/transport

PLANNED ACTIVITIES

Environmental investigation at every location Investigations are carried out at all our premises every three years – with the last investigation taking place two years ago.

The work is led by the Environmental manager, who plans and ensures that those improvements that are implemented are documented. This takes place through recurring meetings where set goals are discussed, along with discussions about how they can trickle down throughout the organisation so local improvements can be made.

This process is everyone’s responsibility and therefore the concern of every workshop. In conjunction with monthly Production meetings and quarterly Management Group meetings, the results are continuously followed up.

Examples of implemented improvements general for all locations are:

• Continued work to review lighting in our premises • Investigated process for handling material transport • New procedures for handling open gates on site • Sealed gates

• Improved chemical handling

Consumption of electricity

Consumption of electricity

Consumption of district heating

Chemistry max count

Consumption of district

Chemistry max count

Handling of materials/transport Paper

Chemical transports

Environmental policy SweMaint AB

Operational activities must:

• Be conducted with minimal damage

• Be undertaken within the framework of applicable laws, regulations

• Undergo continuous improvements to increase efficiency and reduce environmental impact

Environmental goals

• Reduce the amount of transport in connection with the purchase of chemicals

• Maintain the maximum number of approved chemical products

• Reduce electricity consumption

• Reduce paper consumption

• Reduce district heating consumption

Main environmental aspects are

• freight transport

• electricity consumption

• district heating

• paper consumption

• chemicals

Other

• Follow-up is available in diagram form n

Handling of materials/transport Paper

Chemical transports

and the environment

We take responsibility for the climate

Reporting according to the GRI standard involves describing how sustainability issues affect the business and how well adapted the company is as a whole to sustainable society.

ON TRACK YES – AND

WHERE ARE WE GOING?

Science has advanced rapidly in the last four to five years, and in particular, when it comes to making it clear what thresholds we must remain within if we are to avoid incalculable environmental effects. It has led to a new and more robust scientific foundation to support a framework for business and for countries, for social and economic development within the planet’s safe boundaries. Together with the UN’s Sustainable Development Goals, the world now has an even greater ability to better manage global risks fairly.

What trends do we see regarding sustainability in society in general in the next 5–10 years, and what trends do we see for the transport sector for the same period? Will we understand and manage risks and changes in customer requirements, the regulatory environment etc? Will SweMaint be able to attract and retain skilled employees?

By collecting data on key indicators and highlighting key impacts with the help of stakeholders, we can define risks and opportunities

along the entire value chain. We can thereby act faster, smarter and create more value. Because sustainability is not only necessary – it is profitable!

At SweMaint, our environmental work is governed by ISO 14001, with constant improvements being our driving force. We continuously dissect our business based on the significant environmental impact that our company and our activities have. Freight, business trips, electricity and district heating, and the use of chemicals are the environmental aspects we are prioritising in our efforts to reduce our company’s impact on the climate and the environment.

In the immediate future, and so as to better contribute to UN Goal 12, Responsible consumption and production, and Goal 13, Climate action, we will be taking further steps to become even more resource-efficient in our environmental and climate change work. This of course includes the collaboration and dialogue we continuously have with customers, suppliers and other stakeholders. n

and the environment

We take responsibility for the climate

NO SURPRISES:

ALWAYS A STEP AHEAD WITH RISK ANALYSIS AND MANAGEMENT

Risk is a natural part of any business

With a good knowledge of risks, we can develop strategies and measures to minimize negative consequences at the same time as improving our business opportunities.