14 minute read

New CalAPA member Tahoe Asphalt, Inc. proudly serves the greater South Lake Tahoe area

By Brian Hoover, CMS

The California Asphalt Pavement Association is pleased to welcome its newest producer member, Tahoe Asphalt, Inc.

The company, based in South Lake Tahoe, Calif., is owned and operated by Mike Plumer, president, and his son, Patrick Plumer, who serves as vice president. The family-owned business produces Hot Mix Asphalt (HMA) in South Lake Tahoe, as the sole supplier in El Dorado County and the Lake Tahoe Basin.

The asphalt company was founded in 1965 by Martin Brothers, a Tahoe family who also operated a paving company that performed smaller, local projects. The plant was eventually purchased by Dick Solari, former president, CEO and chairman of Granite Construction. Mike Plumer purchased the company from Solari in 1995 and now represents the fourth generation and longest in ownership.

“I am the second generation in my family to make a career in the asphalt business,” says Mike Plumer. “I spent the early years overseeing the materials division for Gallagher and Burke, a well-known contractor in the Bay Area.” Mike Plumer helped to expand the quarry operation at Gallagher and Burke and was instrumental in the installation and implementation of the company’s, hot mix asphalt plant, which utilized the most leading-edge technology available.

“Dick Solari was preparing to retire, and I was offered and accepted an opportunity to purchase Tahoe Asphalt in 1995,” Mike Plumer continues. “I am proud to have two sons who are actively involved and pursuing careers in the asphalt

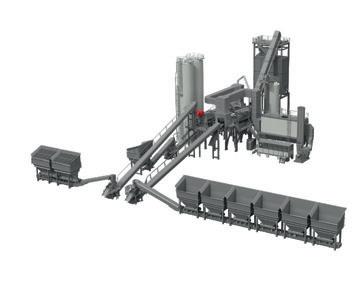

Tahoe Asphalt's Brand New NAPA Diamond Achievement Award-winning drum plant.

business. My younger son, Andrew Plumer, is working for a large Bay Area producer and now, 25 years later, my son, Patrick, is joining the business and preparing to manage and oversee all operations.”

Patrick Plumer represents the third generation in his family to pursue a career in the asphalt construction industry. He was previously working in technology sales in Silicon Valley after graduating from Loyola Marymount University with a business degree.

“I worked summers as a laborer and an opportunity to join my father’s business finally arrived, so I began working at Tahoe Asphalt in April,” Patrick Plumer said. He points to one of the benefits of being a member of CalAPA ® , and that is the opportunity to access technical training classes and other educational opportunities.

“Being fairly new at this, I was looking for some fundamental understanding and just finished my first class that was led by Roger Smith (a CalAPA ® instructor who is a former senior materials engineer with Caltrans and the Asphalt Institute). I cannot say enough good things about the class and Roger Smith,” continues Patrick. “I enjoyed the virtual format and was impressed with CalAPA ® ’s respect for my time. I would get online for a couple of hours, get the information I needed, and move about my day.”

Tahoe Asphalt supplies most of its HMA products to public entities like cities, counties, municipalities and the state. They also provide materials for private industry, where there is a lot of maintenance work going on right now. This includes casinos, ski resorts and commercial parking lot jobs. According to Patrick Plumer, Tahoe Asphalt services a 25-mile radius of South Lake Tahoe, serving customers large and small. “We will go as small as a ton or two of asphalt, but we try and add those orders in with other larger orders,” Patrick Plumer said. “It is just not cost-effective to fire up a plant for less than 50-tons, but we work hard to make it work out for everyone.”

Tahoe Asphalt purchased a new, clean-burning drum plant in 2016, after being awarded a significant contract from Caltrans to provide HMA on the Highway 50 project. The $56 million project included reconstructing a two-mile stretch of U.S. Highway 50 in South Lake Tahoe from “Y” intersection with State Highway 89 to

the Trout Creek Bridge. The job began in 2017 and was completed in fall 2019, with Tahoe Asphalt providing 30,000 tons of 3/4-inch Superpave mix over three years.

“We purchased the plant in 2016 and installed it in 2017, around the same time we were awarded the Highway 50 project from Caltrans,” says Mike Plumer. “We were being put out of the game when Caltrans switched from CT109 certification to MPQP certifications. We had an old Madsen 4,000-pound batch plant, and this Caltrans project afforded us the opportunity to upgrade to a highly efficient, clean-burning drum plant.”

Mike Plumer explains that the opportunity to upgrade to the new plant came about when Granite Construction decided to divest themselves of certain assets. “Granite had three plants in the Sacramento area, and we were given the opportunity to purchase the plant located outside of the Sacramento airport,” Mike Plumer recalled. “It is a NAPA Diamond Achievement Awardwinning plant, and we are grateful to have this opportunity to upgrade our capabilities to better accommodate our local market.”

Mike Plumer says that the large drum plant is capable of producing any mix up to 250 to 300 tons per hour. “Our new plant was running 350 to 400 tons an hour in Sacramento, but due to our elevation here in South Lake Tahoe, that tonnage has been cut by about 15 percent to 20 percent,” Mike Plumer said. “We are permitted to produce up to 3,000 tons

Top: Patrick Plumer, Vice President.

Above: Dale Linkous, General Manager.

Top Left: Robyn Wilson, Office Manager.

Bottom Left: The only MPQP Caltrans certified plant in El Dorado County, Lake Tahoe Basin, and Carson Valley. Above: Tahoe Asphalt's excellent crew that keeps things running smoothly. Left to right: Wyland Guthrie, Martin Hernandez, Brian Hart, Anthony Ortiz, Dereck Biagini, and Dale Linkous.

per day, and another bonus is that we can now recycle up to 25 percent RAP (Reclaimed Asphalt Pavement), and that is just a win-win all the way around.”

“We did several upgrades after installing the plant,” Mike Plumer added, “including new system controls, an additional cold feed bin, so we can now do 3/4-inch, 1/2- inch, 3/8-inch and just about any other mix design or size.” He points out that they also went completely through the baghouse and upgraded all required maintenance components while installing new scales to accommodate any sized truck. “We have three storage silos to store a variety of mix designs. As anyone in this business will tell you, the biggest challenge when going from a batch plant to a drum plant is the change in production and variety of mix designs available.

“We used to provide 2-tons here and 5-tons there,” he continued, “but the orders are much more varied with this new drum plant. It comes down to doing what you can to keep it all within reason, like going with a 3/8 mix design whenever possible. It’s not like it was in the Bay Area, where it was all high-volume and low margin. In South Lake Tahoe, it is just the opposite and you have to adjust accordingly.”

According to the Plumers, asphalt construction in the mountainous area is a seasonal business and in Tahoe, the agencies dictate when paving can begin. “We are not permitted to break ground before May 1 and not after Oct. 15, so that pretty much defines our construction season right there,” Mike Plumer said. “We were on the Highway 50 project for three years, which amounted to around 100 working days each year. We provided approximately 12,000 tons of hot mix asphalt last year alone,” Mike Plumer said. “It was like doing emergency work with four straight weeks of heavy-duty paving, starting right after Labor Day weekend.”

Around this same time, the plant was also providing a virgin Marshall Mix for work out at the Tahoe Airport. “We have been tasked with producing some unique and stringent mix designs. This year has been predominantly municipality work, and the city has a couple of jobs coming up that we are excited about bidding next month,” Mike Plumer said. “This keeps us pretty busy when you combine it with all of the maintenance work and smaller projects. Caltrans also has more contracts coming up, including additional Highway 50 work, and Echo Summit is in pretty bad shape, so that will need to be addressed.”

Tahoe Asphalt also purchased a recycling plant a couple of years back, making them the most significant single producer of recycled materials in the area. “South Tahoe Refuge is strictly a transfer facility, and they divert all of their aggregate and asphalt construction debris to our facility. We recycle this material by using it as RAP, or by combining it with other materials for use as base rock,” Mike Plumer said. “Our recycling operations

alone are saving almost 2,000 truckloads per season in each direction due to the transfer facility diverting this material to our plant. We then use the material locally rather than hauling it out and bringing in virgin material.”

In addition to all of these changes and additions, Tahoe Asphalt will also be receiving their aggregate from a different source. “The aggregate source we have used for the past 25 years is nearly depleted. To protect our investment, we acquired a pit out of Fredericksburg,” Mike Plumer said. “This pit was on lease to Teichert, and we were able to make a deal with them on a long-term contract going forward. This is a permitted site with good reserves and quality rock, so we are looking good for the next 20 years.” Mike Plumer points out that he and his family were fortunate to acquire a niche market in an area with excellent growth potential. “We are doing our best to cover all of the bases here in South Lake Tahoe with an eye toward growth in the Carson City and Gardenville area that is close to our aggregate source,” he said. “Becoming a member of CalAPA ® made sense, not only to keep up on the latest technology, specifications and mix designs but also just the camaraderie of working with other people and companies where our vote and opinion means as much as anyone else’s.”

Mike and Patrick Plumer have a great, tight-knit group of people working with them in both the on and off-seasons. “During the season, we run our own interplant trucks and we staff drivers, plant operation staff and a recycle operation team. Dale Linkous is our General Manager, and he has been with us for more than 17 years. Dale stepped up when our former General Manager retired, and we could not have made the transition to the new drum plant without his expertise,” says Mike Plumer. “I also want to recognize Robyn Wilson, who is the face of our company. She does a great job interacting with all of the customers and truck drivers that pop in and out every day. We have a great team and tremendous potential. I am very excited about the next chapter and incorporating Patrick as an integral part of overseeing our business. Can’t wait to see what the next 25 years bring.”

Tahoe Asphalt, Inc. is the only Material Plant Quality Program (MPQP) Caltrans-certified plant operating in the Tahoe Basin and also serves Carson Valley, Nev. For more information on Tahoe Asphalt, please visit www.tahoeasphalt.com or call their South Lake Tahoe office and plant at (530) 541-0133. CA

Brian Hoover is co-owner of Construction Marketing Services, LLC, and editor of CalContractor Magazine.

SOUTHERN CALIFORNIA’S PREMIER EQUIPMENT DEALER NEW HOLLAND L228 SKID STEER

• $0 down payment • No payments for up to 120 days • 110% max advance • Titanium & Platinum credit customers only • Eligible Units: – 200 Series Skid Steer Loaders – 200 Series Compact Track Loader FONTANA / 909-822-2200 – Compact Excavators 14635 Valley Blvd., Fontana, CA 92335

SANTA FE SPRINGS / 562-777-0775

10918 Shoemaker Ave., Santa Fe Springs, CA 90670

WORK SMARTER – NOT HARDER

Serving California For 50 Years!

800.316.0327

SALES • RENTALS • PARTS • SERVICE MINI EXCAVATORS / SKID STEERS BACKHOES / SKIP LOADERS

Visit us at Booth S5254

MEET THE AMMANN FAMILY OF PRODUCTS

Ammann America Inc.

1125 SW101 st Road, Davie, FL 33324 Phone (954) 493-0010, Fax (954) 493-0020, info.aaa@ammann.com

For additional product information and services please visit: www.ammann.com GMP-2626-00-EN | © Ammann Group

SERVING: LOS ANGELES, ORANGE, VENTURA AND SAN BERNARDINO COUNTIES.

NEW

ACP CONTIHRT

(800) 300-4240

FIVE STRATEGICALLY POSITIONED PLANT LOCATIONS

Sun Valley Plants

11462 Penrose St. Sun Valley, Ca 91352

Irwindale Plant 2600 Avenida Barbosa Irwindale, Ca 91706

South Gate Plant South Gate Recycling

5625 Southern Ave. South Gate, Ca 90280

Inglewood Plant

441 Railroad Place Inglewood, Ca 90301

Victorville Plant Victorville Recycling

15650 Air Expressway Victorville, Ca 92394

www.BlueDiamondAsphalt.com

Scott Taylor P: (714) 587-2595 Ex 101

C: (562) 762-5142 scott.taylor@tayloresinc.com

Susana Mitchell

www.tayloresinc.com

STANDING STRONG

Jeff Reed, owner of George Reed Inc., stands with his wife Margaret in front of a large, 3-D printed statue March 10 at the CON-AGG convention in Las Vegas. Behind them to the left is Amy Miller, national director of the Asphalt Pavement Alliance (left) and Natasha Ozybko, regional sales manager for Road Science, a division of ArrMaz). Miller and Ozybko are two of the principal organizers of the national “Women of Asphalt” organization. The CON-AGG trade show was ultimately curtailed due to the emerging outbreak of the COVID-19 virus.

Ammann America, Inc. ..........................35

Clairemont Equipment...........................34

Ergon Asphalt Emulsions ......................25

Diversified Asphalt Products ................21

Herrmann Equipment, Inc. ....................17

Matich Corporation................................29 Nixon-Egli Equipment Co. ..... Back Cover

Pavement Recycling Systems ...............20

Sitech......................................................13

Sully-Miller Contracting Co...................35

Taylor Environmental Services .............36

TransTech Systems, Inc.........................33

Volvo Construction Equipment & Svcs...3

NEW MEMBERS OF CalAPA

GLA (GLOBAL LEADERSHIP ALLIANCE)

770 L Street Sacramento, CA 95814 www.gla.world (916) 374-0455

B&M BUILDERS, INC.

11330 Sunrise Park Drive, Ste. C Rancho Cordova, CA 95742 www.bm-builders.com (916) 638-8626

TAHOE ASPHALT, INC.

P.O. Box 8378 South Lake Tahoe, CA 96158 www.tahoeasphalt.com (530) 541-0133

Sam Hassoun

President sam@gla.world

Seth Maxey

Asphalt Division Director jb@bm-builders.com

Mike Plumer

President mplumer@astound.net

Burner FuelFor Asphalt Plants LIQUEFIED NATURAL GAS

Paving the way to cleaner skies with America’s Natural Gas

California’s Largest General Line Construction and Municipal Equipment Dealer. So. California: 2044 S. Vineyard Ave., Ontario, CA 91761 • (909) 930-1822 No. California: 800 E. Grant Line Rd., Tracy, CA 95304 • (209) 830-8600 www.nixonegli.com