Cameron Mixner

Architectural Portfolio: Construction Drawings

Table of Contents

Construction Drawings

3 Construction Documentation Roger Williams University Nov. ‘20 - Dec. ‘20 Channel Community Center CD Snippet Roger Williams University Feb. ‘22 - May ‘22

4-24 25 The Spheroid Sanctuary CD Roger Williams University April ‘23 - May ‘23

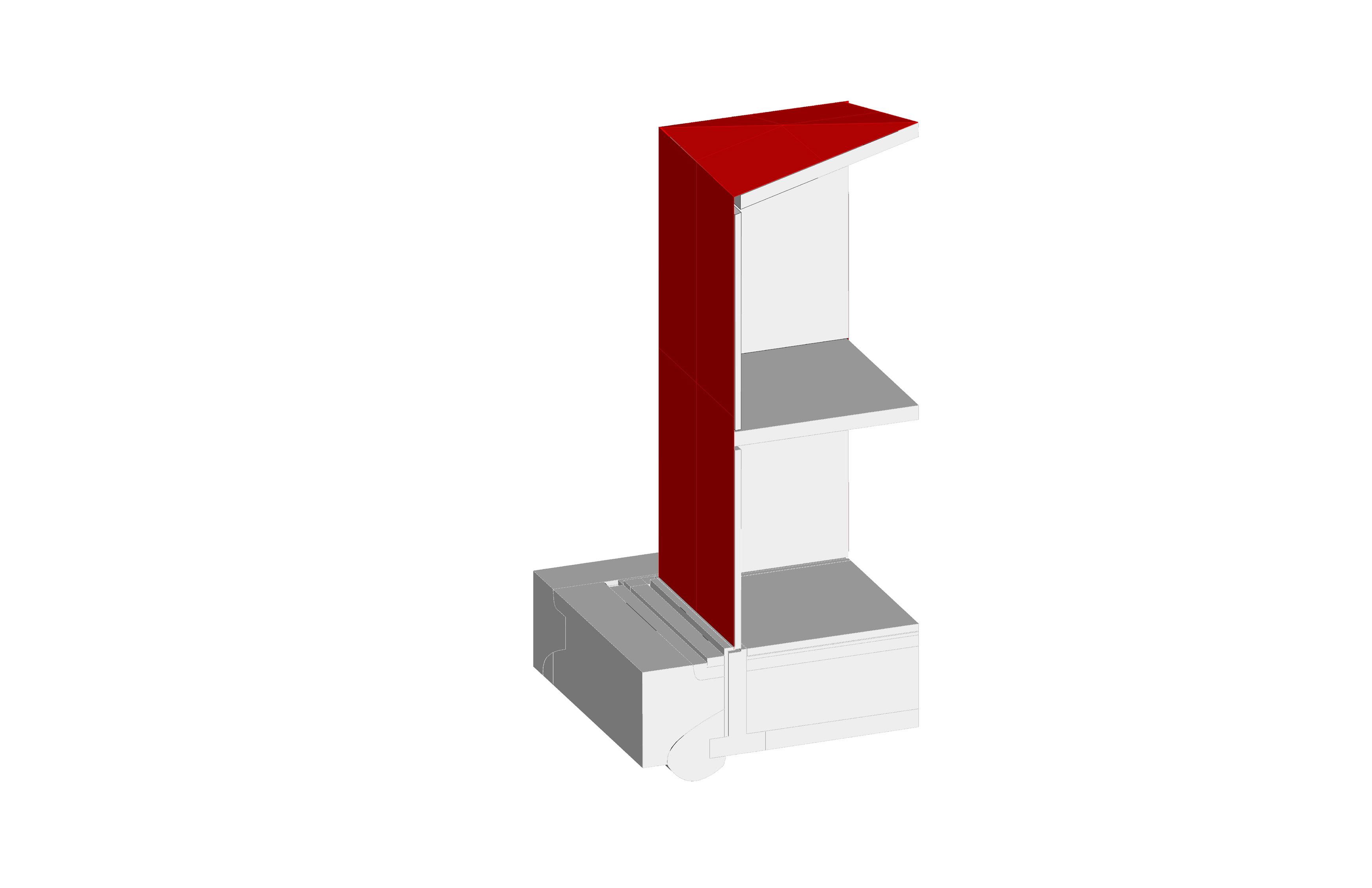

26-55 The Spheroid Sanctuary 3D Assembly Roger Williams University May ‘23

Detail Drawings

These were working drawings created in my Construction Materials class, with proper notes as well as hatching and dimensions. These specific drawings are both from brick construction.

FIN. FIRST FLOOR 100' 0" FIN. SECOND FLOOR 111' 5" T.O. PARAPET 125' 5" B.O. FOOTING 94' 6" T.O. ROOF 124' 3" TYPICAL ROOF ASSEMBLY - SINGLE PLY ROOF MEMBRANE - 1" PROTECTION BOARD - 7'/2" MIN. TAPERED POLY ISO INSUL. - OSB ROOF SHEATHING - 2X12 ROOF RAFTERS @16" OC - VAPOR BARRIER1 CEILING FURRING - " PTD. GR WB TYPICAL WALL ASSEMBLY - 8" SHIP LAP CEDAR SIDING - UNDERLAYMENT - AIR/WATER BARRIER - EXTERIOR OSB SHEATHING - FIBERGLASS BATH INSULATION - 2X6 STUD WALL - VAPOR BARRIER - " PTD. GWB TYPICAL SECOND FLOOR ASSEMBLY - OAK HARDROOF FLOOR FINISH - ROSIN PAPER - OSB SUBFLOOR - 2X10 FLOOR JOISTS - 1X3 CEILING FURRING - PDT. GWD. 2 A4.01 FIN. FIRST FLOOR 100' 0" FIN. SECOND FLOOR 111' 5" T.O. PARAPET 125' 5" T.O. ROOF 124' 3" TYPICAL WALL ASSEMBLY - DRAINAGE BOARD - WATERPROOFING MEMBRANE - 10" REINFORCED CONC. WALL - 2" XPS INSULATION - 8" SHIPLAP CEDAR SIDING -UNDERLAYMENT -AIR/WATER BARRIER -3/4" EXTERIOR OSB SHEATHING -FIBERGLASS BATT INSULATION -2X6" STUD WALL -VAPOR BARRIER -5/8" GYPSUM WALL BOARD TYPICAL BELOW GRADE WALL ASSEMBLY - DRAINAGE BOARD - WATERPROOFING MEMBRANE - 10" REINFORCED CONC. FDN. WALL - 2" XPS INSULATION 3'-87 8 9'-77 8 17'-43" 4'-0" R.O. - PERFORATED FOUNDATION DRAIN WRAPPED IN FILTER FABRIC TYPICAL SLAB ON GRADE ASSEMBLY - 6" CRUSHED STONE - 2" XPS INSULATION - 15" ML. VAPOR RETARDER - 5" CONC. SLAB - 1X4 PT. SLEEPERS - OSB SUB FLOOR - ROSIN PAPER - OAK HARDWOOD FLOOR FINISH - KEY WAY W/ BENTONITE WATERSTOP - CEDAR SHIP LAP SIDING - ZINC COATED COPPER PARAPET CAP - CANT STRIP 1 1/2" = 1'-0" PLAN DETAIL 3 1/2" = 1'-0" WALL SECTION 2 1/2" = 1'-0" ELEVATION PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION - SOLDIER COURSE @ WINDOW HEAD FIN. FIRST FLOOR 100' 0" FIN. SECOND FLOOR 109' 5" T.O. PARAPET 125' 6" B.O. FOOTING 94' 6" T.O. ROOF 124' 3 3/8" TYPICAL ROOF ASSEMBLY - SINGLE PLY ROOF MEMBRANE - 1/2" PROTECTION BOARD - 7-1/2" MIN TAPERED POLY ISO INSUL. - AIR/WATER/VAPOR BARRIER - 3/4" PARTICLE BOARD ROOF SHEATHING - 3-1/2" CORRUGATED STL. ROOF DECK - STL. OPEN WEB JOIST 3 A4.02 FIN. FIRST FLOOR 100' 0" TYPICAL WALL ASSEMBLY - BRICK VENEER - 1" MIN AIR SPACE - HORIZONTAL MASONRY WALL TIES - 2" RIGID INSUL. - AIR/WATER/VAPOR BARRIER - 8" CMU WALL - 7/8" METAL HAT CHANNELS - 5/8" PTD GWB TYPICAL BELOW GRADE WALL ASSEMBLY - 3/8" DRAIN BOARD - 2" RIGID INSULATION - WATERPROOFING MEMBRANE - REINFORCED CONC. FDN. WALL 1 A4.02 TYPICAL SLAB ON GRADE ASSEMBLY - 6" CRUSHED STONE - 2" RIGID INSULATION - VAPOR BARRIER - 5" CONC. SLAB - 1X4 PT. SLEEPERS - 3/4" OSB SUBFLOOR - ROSIN PAPER - TONGUE & GROOVE HARDWOOD FLOOR FIN. SECOND FLOOR 109' 5" T.O. PARAPET 125' 6" T.O. ROOF 124' 3 3/8" M.O. HEAD 106' 0 3/16" M.O. SILL 104' 8 1/2" 6" AGGREGATE COVER 4" DRAIN PIPE KEYWAY W/ BENTONITE WEEP VENT THROUGH FLASHING - WEEP VENT - THROUGH WALL FLASHING - GALU. STEEL LINTEL - THERMALLY BROKEN ALUM. WINDOW W/ IGU TYPICAL FLOOR ASSEMBLY - 2" CONC. TOPPING SLAB - 8" HOLLOW CORE PLANK - 7/8" METAL HAT CHANNEL - 3/8" PTB GWB - PRE-CAST CONC. PARAPET COPING STONE W/ SPLIT TAIL ANCHOR - CONT. TOP OF WALL FLASHING - FIXED IGU WINDOW - MODULAR BRICK RUNNING BOND TYP. - WEEP VENTS 2' O.C. TYP. 11'-113 4 4'-0" M.O. 3'-03 4 19'-01 2 1 1/2" = 1'-0" PLAN DETAIL 3 1/2" = 1'-0" WALL SECTION 2 1/2" = 1'-0" ELEVATION CAMERON MIXNER STUDENT NAME CONSTRUCTION MATERIALS & ASSEMBLIES ARCH 231 AS NOTED EXTERIOR ASSEMBLY FIXED ALL REDLINED NOTES DECEMBER 13, 2020 DATE SCALE DETAIL 4 A4.02 ADDED WINDOW TO SECOND FLOOR PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

● The massive granite construction speaks to the history of Fall River with the textile mills. It therefore gives a familiar, yet new feel.

● The material choice is local, so it is a smart choice.

CONCEPT 1: MASSIVE CONSTRUCTION

PRINCIPLES

Place, contect, scale: The massive granite construction speaks to the history of Fall River with the textile mills. It therefore gives a familiar, yet new feel. The material choice is local, so it is a smart choice

SPACE / CHARACTER / ATMOSPHERE / IDENTITY:

● Granite has a strong and resilient quality.

● It is part of the identity of Fall River.

Space, character, atmosphere, identity: The massive granite construction speaks to the history of Fall River with the textile mills. It therefore gives a familiar, yet new feel. The material choice is local, so it is a smart choice. Granite has a strong and resilient quality. It is part of the identity of Fall River.

ORGANIZATION / ARTICULATION:

● The ground floor is kept mostly open to the street, so that the various activities occurring can be seen by passersby and invite people to join.

Organiztion, articulation: The ground floor is kept mostly open to the street, so that the various activities occurring can be seen by passersby and invite people to join. The top floors, where more private program is organized, are where the granite is introduced as a more solid versus void facade system.

● The top floors, where more private program is organized is where the granite is introduced as a more solid versus void facade system.

Wall Scheme Details

TECHTONICS / MATERIALITY / DETAIL:

Tectonics, materiality, detail/hapticity: Materiality is determined mostly by looking at solar orientation, public/private relationships, access, and views. This massive type envelope is heavy, but meant to seem like it’s floating above the street level. Material changes in this method would be slightly highlighted where cuts into the granite occur, where a pop of color would be added.

● Materiality is determined mostly by looking at solar orientation, public/private relationships, access, and views.

● This massive type envelope is heavy, but meant to seem like it’s floating above the street level.

● Material changes in this method would be slightly highlighted where cuts into the granite occur, where a pop of color would be added.

ENVIRONMENTAL STEWARDSHIP:

Environmental stewardship: Granite is great in terms of thermal mass, meaning that it can store heat from the sun during the day, and slowly release it during the nighttime when it is cooler. This is beneficial, looking at the climate in Fall River. Environmental Stewardship is an important aspect of this design. The main focus will be on solar gain and methods of harnessing and storing solar energy.

● Granite is great in terms of thermal mass, meaning that it can store heat from the sun during the day, and slowly release it during the nighttime when it is cooler. This is beneficial, looking at the climate in Fall River.

● Environmental Stewardship is an important aspect of this design. The main focus will be on solar gain and methods of harnessing and storing solar energy.

Reclaimed Fall River Granite from Abandoned Mills

Open-faced Downpouts

2

MASSIVE CONSTRUCTION RENDERED ELEVATIONS

MASSIVE CONSTRUCTION DETAILS

Glu-lam Column Wall ties 24” O.C. CLT Floor system Window System Granite Lintel Granite Brick CMU block 2” rigid insulation Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Conc. Footing 2” rigid insulation Footing drain Parapet system Roof construction EPDM ¾” Protection Board Four 1” rigid insulation (sloped to drain) CLT roof structure

panel

Ceramic coated aluminum

Ceramic coated aluminum

panel

WATER/MOISTURE BARRIER INSULATION

MASSIVE SCHEME

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

WALL DETAILS LIGHT SCHEME WALL DETAILS Wall ties per glass panel CLT Floor system Window System CLT Lintel 2” rigid insulation Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Conc. Footing 2” rigid insulation Footing drain Parapet system Roof construction EPDM ¾” Protection Board Four 1” rigid insulation (sloped to drain) CLT roof structure Opening Mechanism for panels behind windows Aluminum & Glass Panels

CONCEPT 2: LIGHTWEIGHT CONSTRUCTION

PRINCIPLES

Place, contect, scale: The light metal and glass are both emphasizing the light construction used in this building. From the first floor up, the glass is showing what is through the building, allowing transparency where there are public spaces, and limiting views inside in the private areas. We want to use transparency to not only welcome the community into the space, but also visitors to truly see the great things that occur in this community. The facade aids that by gaining easy access to views outdoors.

Space, character,atmosphere, identity: The facade is repetitive with these longer glass and metal memebers. There were two colors picked for the panels, red for the local brick architecure, as well as blue for the water that founded this city.

Sauerbruch Hutton

Sauerbruch Hutton

Sauerbruch Hutton

Sauerbruch Hutton

Ceramic coated aluminum panel with color Tinted glass Wall ties per glass panel CLT Floor system Window System CLT Lintel 2” rigid insulation Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Conc. Footing 2” rigid insulation Footing drain Parapet system Roof construction EPDM ¾” Protection Board Four 1” rigid insulation (sloped to drain) CLT roof structure Opening Mechanism for panels behind windows Aluminum & Glass Panels # A#

LIGHT SCHEME WALL DETAILS

WATER/MOISTURE BARRIER INSULATION

WALL DETAILS

Tinted glass Wall ties per glass panel CLT Floor system Window System CLT Lintel 2” rigid insulation Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Conc. Footing 2” rigid insulation Footing drain Parapet system Roof construction EPDM ¾” Protection Board Four 1” rigid insulation (sloped to drain) CLT roof structure Opening Mechanism for panels behind windows Aluminum & Glass Panels

Ceramic coated aluminum panel with color

T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" # A# # A# # A# # A# 6 BUILDING ENVELOPE

After several reviews, it was determined that our facade needed more refining. We had determined that both facade schemes, the granite and the colored panels, were still worth incorporating. To resolve the issue that the panels seemed foreign to the rest of the building, it was decided that wherever there are cuts into the main massing, there would be color introduced. So therefore, the colored panels were moved into the courtyard indents.

This correlated well with our massive envelope scheme where the cuts back to the glazing plane show a color as well. This decision strengthens the reasoning behind our main gestures in massing development

# A#

Going back to our envelope system, We are also using a combination of these envelope system cases shown. As one system, we are using local reclaimed granite to harken back to the origins of the city of Fall River being a textile mill town. We want to introduce color to this system where there are cuts back to the glazing plane. This correlates to the second system as well.

This other system is made up of angled rectangular panels that express cuts into the main massing. The materiality is ceramic-coated aluminum panels and tinted glass, both of which are in gradient shades of red and blue. Some of the panels are also operable and can be used for extra air flow through the building.

Here is a look at a detailed wall section showing the granite facade profile, ventilation, and water management, incorporated as a whole system.

Venting incorporated in glazing

Venting incorporated in glazing

Reclaimed Fall River Granite from Abandoned Mills

Reclaimed Fall River Granite from Abandoned Mills

Reclaimed Fall River Granite from Abandoned Mills

Open-faced Downpouts

2

Open-faced Downpouts

FINAL VERSION

2

2

REFERENCES/ TECH RESEARCH

2

2 2 1

1

3

Roof construction

Planting Material

Drainage fabric & irrigation space

EPDM

¾” Protection Board

Four 1” rigid insulation (sloped to drain)

CLT roof structure

Parapet system

CMU block

2” rigid insulation

Granite Block facade

Window System

Glu-lam Beam

Glu-lam Column

Wall ties 24” O.C.

CLT Floor system

Glazing system

Ground floor construction

½” Porcelain tile

4” Conc. slab

2” rigid insulation

6” gravel

Conc. Footing

2” rigid insulation

Footing drain

Parapet system

CMU block

2” rigid insulation

Granite Block facade

Window System

Ceramic-coated aluminum sheet

Wall ties 24” O.C.

CLT Floor system

Glazing system

Ground floor construction

½” Porcelain tile

4” Conc. slab

2” rigid insulation

6” gravel

Ceramic-coated aluminum sheet

Conc. Footing

2” rigid insulation

# A# # A#

A3-01 05/06/2022 3/4" = 1'-0" WALL COMPOSITE Channel Community Center CAMERON MIXNER & OLIVIA MORA DATE SCALE ARCH 513 INTEGRATED PROJECT DESIGN STUDIO SPRING 2022 Prof. Jim Moses PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION

WATER/MOISTURE BARRIER INSULATION

# A#

Parapet system

CMU block

2” rigid insulation

Granite Block facade

Window System

Ceramic-coated aluminum sheet

Wall ties 24” O.C.

CLT Floor system

Glazing system

Ground floor construction

½” Porcelain tile

4” Conc. slab

2” rigid insulation

6” gravel

Ceramic-coated aluminum sheet

Conc. Footing

2” rigid insulation

# A#

PRODUCED BY AN AUTODESK STUDENT VERSION

PRODUCED BY AN AUTODESK STUDENT VERSION

17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR A2.01 4/01/2022 1/8" 1'-0" BUILDING ELEVATIONS Channel Community Center CAMERON MIXNER & OLIVIA MORA DATE SCALE ARCH 513 INTEGRATED PROJECT DESIGN STUDIO SPRING 2022 Prof. Jim Moses A# # A# # A# A# # A# # A#

17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR 17'-6" T.O. ROOF 45'-6" FIN. SECOND FLOOR 29'-6" FIN. SECOND FLOOR # A# # A# # A# # A# # A# # A#

# A# # A# Roof construction Planting Material Drainage fabric & irrigation space EPDM ¾” Protection Board Four 1” rigid insulation (sloped to drain) CLT roof structure Parapet system CMU block 2” rigid insulation Granite Block facade Window System Glu-lam Beam Glu-lam Column Wall ties 24” O.C. CLT Floor system Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Conc. Footing 2” rigid insulation Footing drain Parapet system CMU block 2” rigid insulation Granite Block facade Window System Ceramic-coated aluminum sheet Wall ties 24” O.C. CLT Floor system Glazing system Ground floor construction ½” Porcelain tile 4” Conc. slab 2” rigid insulation 6” gravel Ceramic-coated aluminum sheet Conc. Footing 2” rigid insulation A3-01 05/06/2022 3/4" = 1'-0" WALL COMPOSITE Channel Community Center CAMERON MIXNER & OLIVIA MORA DATE SCALE ARCH 513 INTEGRATED PROJECT DESIGN STUDIO SPRING 2022 Prof. Jim Moses PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION

1'-4" 11" 1 2 8" 8" 2" 2" 1 2 " 16 2 " 1 2 " 18 2 " 12 2 " 1'-5" 1 2 " 71 2 " 17 2 " 1 2 " 3'-11" 6" 1 2 2" 1 2 111 2 " 1" 61 2 " 4" 5" A4-01 5/06/2022 3" = 1'-0" DETAIL FOR 1:1 MODEL Channel Community Center CAMERON MIXNER & OLIVIA MORA DATE SCALE ARCH 513 INTEGRATED PROJECT DESIGN STUDIO SPRING 2022 Prof. Jim Moses PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION PRODUCED BY AN AUTODESK STUDENT VERSION

STATEMENTOFDESIGNINTENT

Thedesignintentintendedfortheprojectwillinclude combinationofmasstimberaswellasconcrete, specificallyacombinationofpouredcastinplace concrete,aswellas3Dprintedconcretepanelsforthe exterior.ThebulkofthestructurewillbeCLTincludingthe secondfloorslabsandroofing.Theywillsitontopofa concretepadtoaddrigidityaswellasoverallsupporton thissite,whichisnearthewater.Thecomponentscoming intoconstructthisneedtobeportableandabletotravel byferry,so3Dprinting,castinplace,andCLTshouldall havesmallenoughcomponentstobringonaboat.The climateoftheislandissimilartoours,butontheextreme sidesinceisthelastislandinthestripofislesoffof Martha'sVineyard.Thismeansthatfloodingwillneedto bethoughtofandshouldinfluencethedesign.

REWORKEDWINDOWSINPLAN ADDEDSTRUCTURETOPLAN EDITEDSTRUCTURETOSECTION REWORKEDBASEOFSECTION REMOVEDPARAPET EDITEDNOTES

-CIRCULARGLASSELEMENTS TOALLOWLIGHTINTHESECOND FLOOR FIN.FIRSTFLOOR 100'0" FIN.SECONDFLOOR 115'0" T.O.PARAPET 132'6" B.O.FOOTING 95'6" T.O.ROOF 130'0" TYPICALROOFASSEMBLY -3/4"PROTECTIONBOARD -EPDMWATERVAPORBARRIER -FOUR1"RIGIDINSULATIONBOARDS -CLTROOFSTRUCTURE 3DPRINTEDCONC.PANELSYSTEM -6"METALFINTOHOLDCONCRETE -CASTINPLACECONCRETEFOR SEATINGEGG TYPICALWALLASSEMBLY -3DPRINTEDCONCRETEPANELSYSTEM -WALLTIES36"O.C. -2"RIGIDINSULATION -AIRMOISTUREBARRIER -1"AIRGAP -2-5/8"CLTSTRUCTURALCOLUMN -7/8"GYPSUMBOARD TYPICALBELOWGRADEWALLASSEMBLY -FOOTINGDRAIN -2"RIGIDINSULATION -WATERVAPORBARRIER -CONC.FOOTING 3 A4.01 FIN.FIRSTFLOOR 100'0" FIN.SECONDFLOOR 115'0" T.O.PARAPET 132'6" T.O.ROOF 130'0" TYPICALBELOWGRADEWALLASSEMBLY -EXISTINGGRAVEL -CONCRETESTEP TYPICALSLABONGRADEASSEMBLY -1/2"WOODFLOORING -4"CONC.SLAB -2"RIGIDINSULATION -6"GRAVEL TYPICALFLOORASSEMBLY -1"CONCRETEPAD -12"CLTFLOORING 1 A4.01 -6"METALFINTOHOLDCONCRETE -CASTINPLACECONCRETEFOR LIVINGUNIT 1 1/2"=1'-0" PLANDETAIL 3 1/2"=1'-0" WALLSECTION 2 1/2"=1'-0" ELEVATION CAMERONMIXNER CUTTYHUNKISLAND MASSACHUSETTS GOSNOLD STUDENTNAME CONSTRUCTIONMATERIALS& ASSEMBLIESII ARCH535 MAY22,2023 DATE SCALE DRAFTSUBMISSION REVISIONS 1/2"=1'-0" EXTERIORENVELOPEDESIGN A4.01 SITEADDRESS SPHEROID SANCTUARY

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

Ceramic coated aluminum panel with color

Sauerbruch Hutton

Sauerbruch Hutton

Sauerbruch Hutton

Sauerbruch Hutton