In addition

Upgrade to the full Autodata service at the introductory price of $2* and not only do you receive diagnostics and wiring information but you will also have access to the full training video library of over 350 videos.

In addition

Upgrade to the full Autodata service at the introductory price of $2* and not only do you receive diagnostics and wiring information but you will also have access to the full training video library of over 350 videos.

When was the last time you got away from the workshop and spent some uninterrupted time with your family and friends? How long did you manage to take off? When’s the last time you locked the workshop door at 5pm and went home? Or worked a 40-hour week?

There’ll be a huge range of answers to those questions among Members, of course, but what we know is that many of you are really struggling to take time off and manage some kind of work-life balance. We know because this year’s State of the Nation survey of Members told us exactly that. 42% of Members told us they struggle to take time off for a holiday. The same percentage of Members told us they struggled to maintain a good work-life balance. That made them the top two challenges Members said they faced in running an automotive business — beating out finding good staff (on 39%) and parts shortages (on 31%).

Taking time off and having balance in your life should be non-negotiables for any business owner. Downing tools, shutting up shop, and spending time doing something other than working are vital for your physical and mental health. You need rest. You need time to recharge your batteries. You’re no good to your family if you’ve worked yourself into an early grave.

I’m reminded here of a principle from a famous book called The Richest Man in Babylon. Perhaps you’ve read it? The book is a guide to wealth creation, not work-life balance, but I think the central idea in the book translates well to this situation.

Richest Man says the secret to wealth creation is that, when you get paid, you should pay yourself first. No matter how much comes in, you save 10% of it — before you tackle your bills or head to the pub.

We should start looking at work-life balance the same way: paying ourselves in time off first. Taking a holiday is not a “nice to have”; it’s essential. Pay yourself with time off in the way that you pay your electricity bill or your lease. Plan ahead, book it in, and pay yourself on time.

It is possible. I’m reminded of the article we carried last month with Caroline LanganMinca of His’n’Hers Automotive in Victoria. She and her husband, Craig, prioritise work-life balance, juggling the workshop’s opening hours between each other and around the school drop-off and pick-up. They stopped working Saturdays. They trained their customers to know the workshop shuts at 5pm on the dot. The article is available on CapHub if you missed it.

Work-life balance and prioritising taking time off are themes we’ve picked up again in this month’s Ignition. We’ve got lots of tips and advice to help make running a business easier, from staff retention advice, methods of charging to ways of prioritising your mental health. We hope you’ll find this month’s magazine useful.

The new capability streamlining aftermarket product development.

Why simple hourly charge-out rates might be missing the mark.

But you’ll have to BYO flux capacitor…

The book closes on 6 decades of racing.

Hello vegan leather interiors and carbon neutrality.

Tips on how to keep hold of your best team members.

Why increased efficiency might be the key to growth.

And look after your mental health.

All information, material and content in this edition of Ignition is provided or sourced by Capricorn Society Limited (“Capricorn”) for general information only and is not intended to be advice or comment on any particular matter or subject. Before acting on any information in this edition of Ignition you should consider the relevance of it to your own circumstances and, if necessary, take professional advice. Any opinions expressed in an Ignition article are those of the relevant individual author and do not necessarily reflect the opinions or views of Capricorn. Capricorn makes no representation or warranty as to the accuracy, completeness or reliability of any material (including without limitation, any third party authored article or supplier advertisement in respect of which Capricorn merely acts as conduit) included in this edition of Ignition. To the fullest extent permitted by law, Capricorn, its officers, employees, agents and representatives disclaim any and all liability to you or any other person for any loss or damage whatsoever connected with: i. reliance on any material in Ignition; or ii. any inaccuracy, error or omission in any material in Ignition.

Yours in cooperation, David Fraser Group CEOAccording to our State of the Nation 2022 survey, 62% of Capricorn Members are very/ extremely happy with their career in the automotive industry and 40% view themselves as being very/extremely successful.

Making customers happy was rated as the main positive of working in the industry. Do you feel the same?

Want to learn more about happiness and success in the automotive industry? Use this QR code to visit the State of the Nation web page & DOWNLOAD THE FULL REPORT.

of working in the industry

In a move set to revolutionise how workshops in Australia and New Zealand access technical data and problem-solve repairs, Autodata has just released hundreds of online technical training videos on its platform.

Capricorn Service Data, which is powered by Autodata, is included in your Capricorn membership. It gives you access to 150 of Autodata’s service and maintenance videos.

You can also upgrade to a Diagnostic & Repair subscription for a monthly fee and get automatic and unlimited access, on demand, to the full library of more than 350 technical and training videos as well as additional diagnostic and wiring information.

Launched on 1 October, the videos include high-quality on-demand training modules and diagnostic videos covering everything from electrical, engine, chassis, drivetrain, driver assistance, HVAC, diagnostics and servicing to hybrid and electric vehicles.

Autodata says the video content “seamlessly combines with our officially licenced OEM data across 175 manufacturers to create a winning package of service, maintenance, diagnostic and repair information”.

The release of hundreds of hours of training and diagnostic information will be a boon for workshop efficiency. Eighteen per cent of Capricorn Members who participated in this year’s State of the Nation said that accessing technological information and diagnostics was one of the biggest challenges they faced in their business. We also know from State of the Nation that when Members hit a technical problem they’ve never come across before, threequarters search for information online, more than half spend time working it out on their own, and more than two in five will call a mechanic at another workshop, ahead of using a tech info product like Autodata or Capricorn Service Data.

Most of the videos are no longer than 10 minutes, are delivered by experts, and feature real vehicles and detailed 3D animations. That makes it an easy and affordable opportunity for Capricorn Members to upskill and train employees — which is a powerful option in light of the industry’s ongoing skills shortage and the expected explosion in hybrids and EVs into the marketplace.

Autodata Sales and Product Director Jonathan Sampson said since Autodata was founded in the UK in 1972, its goal has been to support aftermarket workshops with access to up-to-date, expert OEM technical information in a standardised, accessible format.

“We are proud to cover 99 per cent of vehicles on the road in key markets,” he said.

“To be able to provide 24/7 onsite technical support and full expert training in one service to our customers is thanks to our modern, innovative approach to helping dealers get to the root of the problem faster and our understanding that workshop technicians require continual help not only with learning how to deal with new technology but with providing the basics that can often be forgotten if not used.”

Access to and use of Capricorn Service Data is governed by the Capricorn Service Data Terms & Conditions found at www.capricorn.coop/ terms-conditions. Access to the Autodata Diagnostic & Repair subscription is subject to further terms To find out more visit cap.coop/servicedata

With Christmas just around the corner, we have your last minute gifts sorted with e-vouchers available for purchase until 12 December 2022.*

E-vouchers are delivered straight into your inbox, ready for printing for a gift, or you can forward the e-voucher straight to the recipient’s inbox. As e-vouchers can be stored on the receiver’s phone, they won’t be forgotten or lost, making them the perfect gift option.

As a Capricorn Member, you’re probably aware that Capricorn Risk Services offers protection that can help protect your business. But did you know we can also organise your personal insurance and protections?

It’s just one of the many ways that we’re always striving to make life easier.

As a one-stop shop Capricorn Risk Services gives you the convenience of having all your risk protection and insurance options in one place (instead of having to manage multiple policies and memberships with multiple providers). This means less paperwork and hassle because you can consolidate your billing and use your Capricorn Trade Account

to pay for your protection and insurance. It also means that you’ll earn even more Rewards Points to spend as you please! There are a range of personal assets we can help you with, all while you enjoy personalised service from your dedicated Risk Account Manager. You already know and trust us, so why not let us handle your personal protection as well as look after your business? Check out the info below to learn more.

HOME

Includes cover for your home, contents and valuables.

You can choose from comprehensive, third-party fire and theft, and third-party only to cover your car and motorbike.

LANDLORDS*

WATERCRAFT*

Whether you have a jetski or a boat, we can provide access to cover for your watercraft in and out of the water.

Covering you if you become injured, disabled, or ill, or in the event of death.

Australia’s automotive manufacturing sector is the beneficiary of new Advanced Emergency Braking (AEB) testing capabilities to promote and streamline aftermarket product development.

AEB testing capability is now offered by the Auto Innovation Centre (AIC) as part of its suite of cutting-edge vehicle testing services for aftermarket product developers.

The new service will enable companies developing frontal protection systems, such as bull bars, or producing GVM upgrade packages, to test these new products on AEBequipped vehicles to ensure safety, and compliance with vehicle standards.

“We’re proud of our work cooperating with vehicle standard regulators to answer key questions before they are asked so the aftermarket doesn’t face roadblocks. Confirming vehicle modifications integrate with Advanced Driver Assistance Systems (ADAS) is important for aftermarket product developers, and AEB testing capability will further boost their ability to quickly get products to market,” said Lesley Yates, Australian Automotive Aftermarket Association Director of Government Relations & Advocacy.

AEB is one of the first ADAS systems to be legislated in Australia through the Australian Design Rules ADR98. ADR98 specifies the procedures and acceptance criteria for testing the AEB on a vehicle at various speeds and test configurations.

At the heart of AIC’s new AEB capability is a Soft Car Target that is compliant to ISO 19206, meeting the specifications for ADR98. The physical target is combined with sophisticated GPS positioning equipment to provide accuracy to less than 20 mm for collision data.

“Thanks to our new AEB testing equipment we can test modifications on AEB-equipped vehicles in a safe environment to ensure their compliance with ADR98. We’re proud to be leading the way for the aftermarket in supporting ADAS compliance. The AIC’s purpose is to break down development barriers by offering the aftermarket solutions as vehicle technology and regulations continue to change. Adding AEB testing to our ADAS testing capability ensures product manufacturers have the capability to integrate their products safely and in compliance with the law,” said Luke Truskinger, AIC Managing Director.

According to our State of the Nation 2022 report, these are the biggest challenges our Members face when running their auto businesses.

Having a good work-life balance Finding time to take a break or holiday Finding good staff

Shortage of parts Balancing different parts of your role Increase in parts prices

concerns

technology/ staying up to date Access to technical information & diagnostics

Finding time to take a break and maintaining work-life balance again topped the list of challenges to running a business — although things seem to be getting better.

A parts shortage has been impacting the industry globally and that’s reflected in this year’s report. Difficulty getting parts was up three percentage points on 2021, to 31%.

Keen to learn more about how to meet the challenges facing the Australasian auto industry? Use this QR code to visit the State of the Nation web page and DOWNLOAD THE FULL REPORT.

Almost two in five Members said finding good staff was a challenge.

Despite several excellent resources being available, threequarters of Members still google to find technical information.

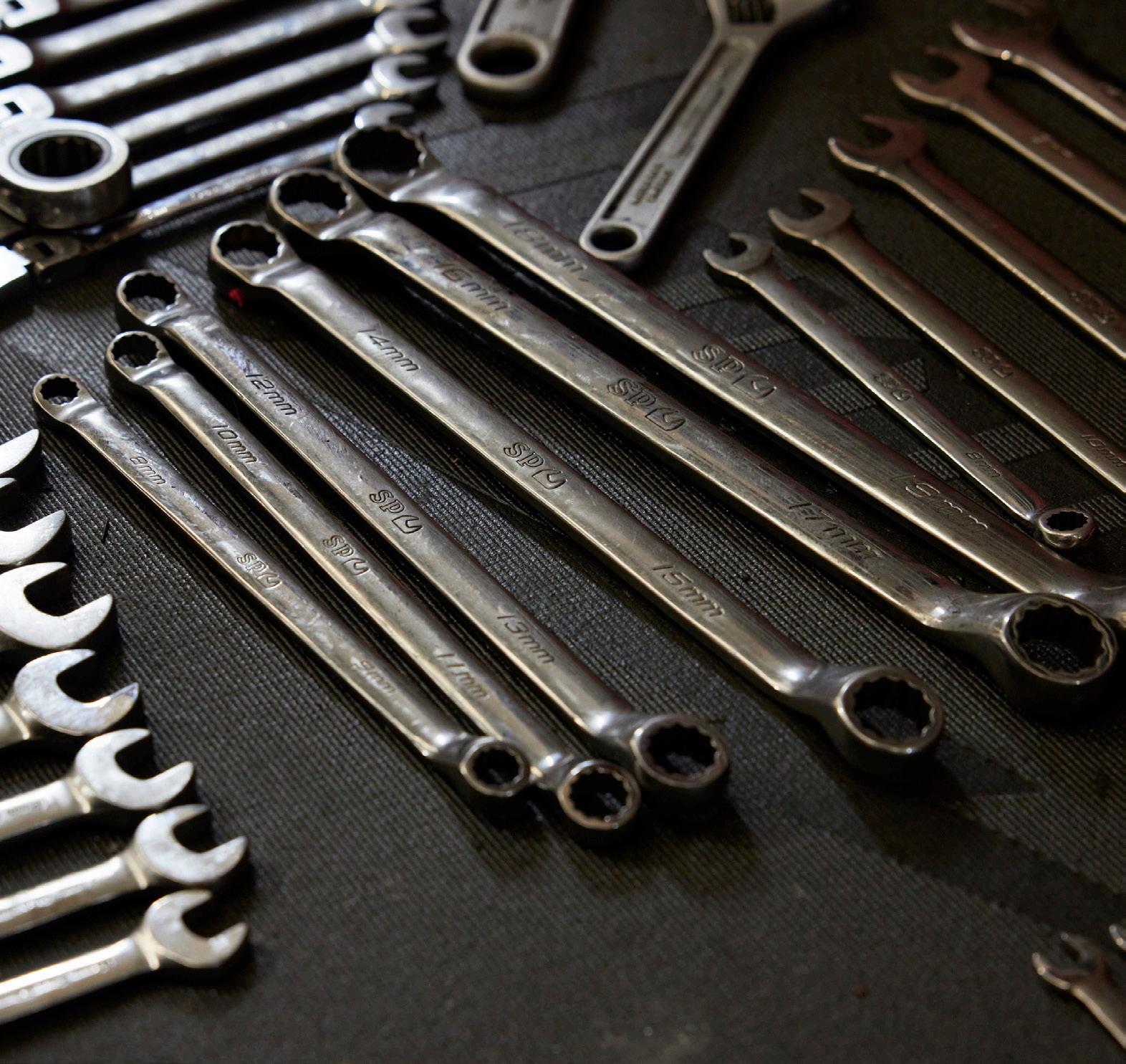

As cars have become increasingly technologically advanced, so have the tools required to diagnose, service and repair them. This means that the success of auto workshops will become increasingly defined by their ability to master and apply all this technological knowledge successfully and efficiently.

In other words, it’s all about working smarter, not harder.

This is going to have a dramatic impact on the way successful workshops estimate and charge for their work. If you’re still only charging for the time you spend working on a vehicle – and not the knowledge, expertise and equipment required to diagnose and service it quickly and correctly – then chances are you’re doing yourself a financial disservice.

Our most recent State of the Nation survey told us that almost half of the workshops surveyed are only charging for diagnostics some of the time, and more than 10% never charge for them. This represents a huge, missed revenue opportunity.

After all, diagnostic equipment is expensive and charging for it helps cover the cost of the equipment, the all-important updates, and the training required to upskill and master the equipment and processes, not to mention the time taken to perform the actual diagnosis.

Here’s an example to demonstrate this point – a late model vehicle comes in with a technical problem not experienced before in your workshop. This is not an unusual scenario for those in the auto aftermarket game.

A competent and professional workshop will have processes in place to effectively manage every job, and while many will have systems in place to track every hour spent on a job, there remains a great deal of confusion about how to charge to resolve a unique technical problem.

More confusion follows when jobs which may have taken a lot of time and diagnostic skills to resolve the first time around become easier and take less time as a result of the workshop’s accumulated experience and knowledge.

Therefore, should subsequent customers pay less for the expertise a workshop has accumulated by being charged only the labour time spent on the job? It seems counterintuitive to invest time and effort in becoming more knowledgeable and efficient, only for this to result in you bringing in less revenue.

Here’s a more predictable job most workshops do regularly – timing belts. The first time, a late model car with twin cam and variable cam timing may take five or six hours, which should be charged out accordingly.

The next one is a little easier and with a newly purchased tool, the timing belt job is done in 4.5 hours. By the time the third similar vehicle arrives for the same repair, the workshop is able to complete the job in just 3.5 hours. What is the charge?

Every job is worth a certain value, in which the labour time should play one part in determining that value. If workshop owners committed to charging a fair and reasonable amount, they should consider basing their charge out rates on what a job is worth, not how long it takes. This same philosophy should be applied to all types of jobs – including more technical jobs involving diagnostics.

Workshops able to employ and train good staff and invest in the latest equipment, tools and information sources will be best equipped to cope with the rapidly changing future vehicle landscape.

The knowledge accumulated by the workshop becomes part of the workshop’s assets. Future similar repair jobs should therefore be charged based on the established value of the job, not the fact that the workshop has applied its knowledge and special tools to do the job in half the time.

In this year’s State of the Nation report, Capricorn CEO of Automotive, Bradley Gannon, said “Members are running a knowledgeand-skills-based business and they need to think of themselves as a knowledge worker. They need to be proud of that and unashamedly charge well for their time, in the same way an accountant, lawyer or engineer does.”

Is it time that you started to adopt this mindset?

Nothing in this article is intended to constitute personal business or financial advice. Members should consider their own circumstances and seek their own personal advice as necessary.

The DeLorean holds a special, and slightly weird, place in motoring history. Its fame, almost entirely, is due to the Back to the Future films which defined so much of what was considered cool in the 1980s.

y the time those films came out, the American motor company DeLorean had already gone broke, having made just 9000 of the soon-to-be-iconic gull-winged DMC-12s. Its bankrupted founder, John DeLorean, would be caught on tape in an FBI sting operation, agreeing to bankroll drug trafficking,

before later being acquitted on the basis of entrapment, in a bizarre trial. In the 80s, everything DeLorean touched made headlines. He died in 2005. Despite a lot of love for the DMC-12, and the brand itself continuing to hold value, the DeLorean never went back into production.

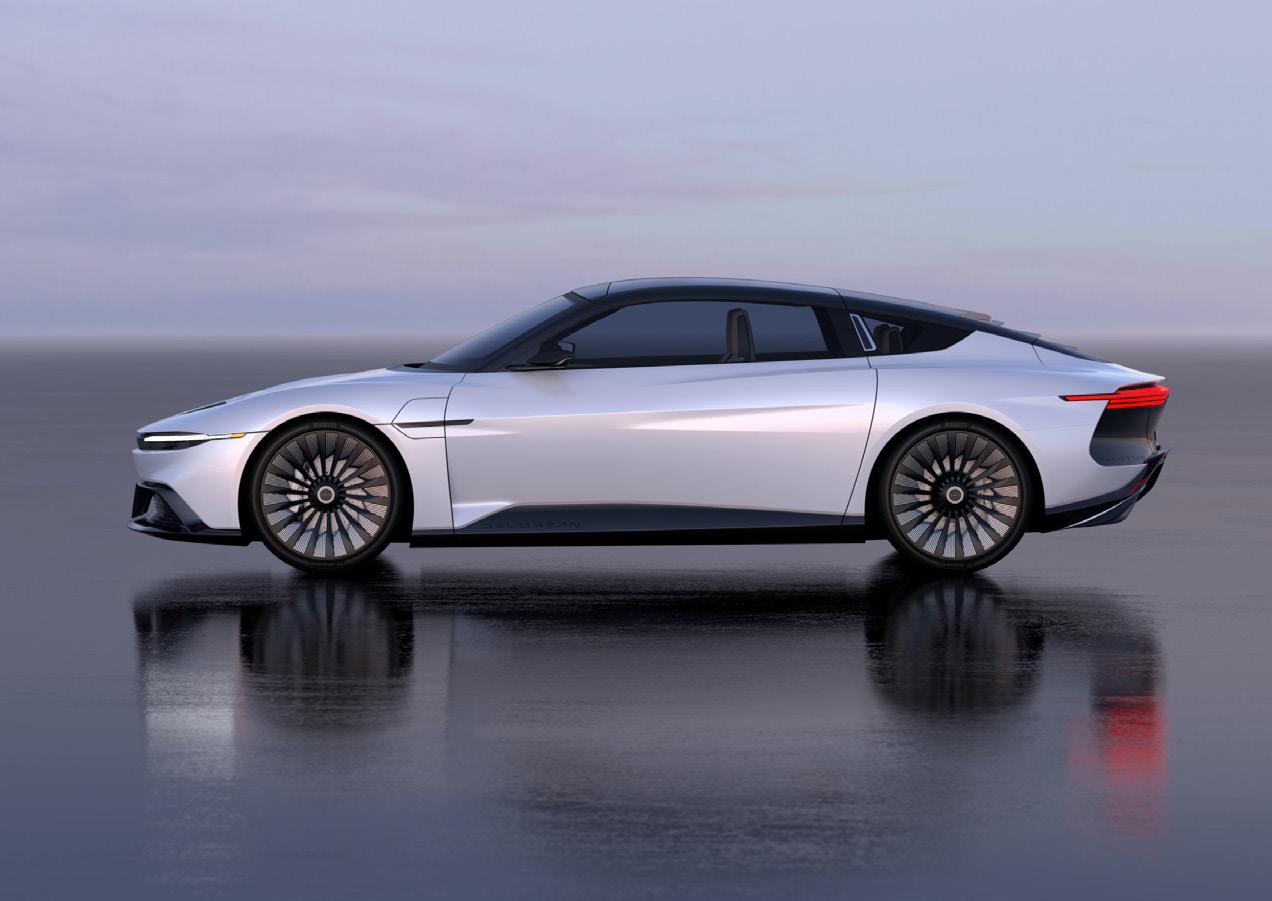

Four decades later DeLorean is back from the dead. The car, that is, not John. And, like Frankenstein, the DeLorean has been brought back to life with electricity. Earlier this year, DeLorean introduced the Alpha5 — the EV DeLorean of the future Doc Brown never asked for and Marty McFly never saw coming (to be fair, he was too distracted by the hoverboards). We know what you’re thinking. Is this really happening? Yes, it is. The new DeLorean Motor Company, DeLorean Motors Reimagined, unveiled the Alpha5 earlier this year, initially as a concept. But it’s a concept no more, with the EV going into production for release in 2024. And it’s all there: the gull-wing doors, the classic rear louvres, the three-layered tail-lights.

Joost de Vries, CEO of DeLorean Motors Reimagined, says the Alpha5 is the DeLorean DeLorean would be producing today if DeLorean had never gone away.

“Our goal was to bridge the gap between the past and the future, so we produced extensions of the DMC-12 that would have been icons in their time, to create the next generation of vehicles, starting with the Alpha5,” he said.

The fully electric Alpha5 does 96.5 kmph in 2.99 seconds (that’s 60 mph in case you’re doing the maths in your head. If you want to leap back in time a la Marty McFly, you need to hit 88 mph, which is 141.6 kmph) and has a projected top speed of 250 kmph (155 mph).

De Vries says the all-wheel-drive vehicle offers an exceptional driving experience with multi-mode adaptive suspension, dynamic handling and an estimated 482 km range with a 100 kWh battery.

“The vehicle’s interior design and high-performance technology are human-centered and create an environment that engages the driver and the passion for the drive, including enhancing the driver’s connection with loved ones,” the company’s promo promises. What does that look like in practice? Um, well, it comes with a watch-like device someone can wear and through that device the seats will heat to their body’s exact temperature and a pulse in the seat can sync with their heartbeat and they can give you a virtual hug (the seats will wrap around you a bit) and even blow you a kiss (involving a creepy puff of air emanating from the headrest). Who comes up with this stuff, who approves it, and who wants it, we have no idea. It’s no substitute for a flux capacitor, that’s for sure.

Imagine the customer coming in through the workshop door demanding you fix the virtual kissing function on their DeLorean. Is it April first?

That’s not even the weirdest part of the new DeLorean. Want to buy one? You can’t just phone up and place an order. There’s a whole deal where you have to join a club first, then there’s a process you have to go through involving blockchain and non-fungible tokens (NFTs) and the creation of something called “a digital twin” that allows you to customise your vehicle. Whatever that means, people are buying it. The DeLorean Alpha5 is oversubscribed (they’re only making 88 in the initial run (yes, 88, just like the mph speed that sends you back in time in the movies).

Still want one? We understand the real deal will set you back at least US$150,000, before you even look at importing it. However, there is a more affordable alternative. Hot Wheels is selling 1:64 scale die cast models of both the DMC-12 and the Alpha5. The models won’t let you travel back in time, but they won’t try to kiss you either.

New Zealand has an incredibly rich motorsport history; it has nurtured some of the world’s most successful racing drivers for decades. One of the reasons for this is the number of challenging motor racing circuits that can be found across the length and breadth of the land of the long white cloud.

One of the most exciting of these, Pukekohe Park Raceway, will close as a motor racing venue in April 2023, ending a more than six decade run as one of New Zealand’s most significant, successful and exciting motorsport venues. First opened in 1963 and named after the city where it is located, the name “Pukekohe” is an abbreviated Te Reo phrase, translating to “Hill of the Kohekohe,” which is a tree that is native to the region. Pukekohe is located approximately 40 kilometres south of Auckland and has been a popular horseracing, motor racing, cycling and community events venue.

Pukekohe Park Raceway was constructed to replace Ardmore, which was an aerodrome, to become the new home of the New Zealand Grand Prix from 1963. As the host of this major motorsport event for 29 years, Pukekohe was visited by many of the world’s greatest Formula One racing drivers. Between 1964 and 1975, this event was also the jewel in the crown of the Tasman Series that saw Australia’s fastest open wheeler drivers join New Zealand’s and the

world’s best in a multi-race dual country competition. This provided European drivers with an opportunity to stay sharp competing against strong competition during their winter, attracting the best of the best.

To give you an idea of the calibre of the drivers who raced in the New Zealand Grand Prix and the Tasman Series at Pukekohe Park, race fields included Stirling Moss, Graham Hill, Jim Clark and Jackie Stewart. Winners of the New Zealand Grand Prix at Pukekohe Park include legendary Kiwis Bruce McLaren and Chris Amon, along with Craig Baird and Paul Radisich.

Formula One World Champions John Surtees, Graham Hill, Jackie Stewart and Keke Rosberg also stood on the top step of the New Zealand Grand Prix Pukekohe podium, along with international racers such as Australian Frank Gardner, Italian Teo Fabi and Brazilian Roberto Moreno.

Legendary Kiwi driver Ken Smith was also a New Zealand Grand Prix winner at Pukekohe Park, along with countrymen Steve Millen, Dave McMillan, David Oxton and Andy Booth. Australians Frank Matich, Neil Allen, John McCormack and Warwick Brown also won this most prestigious of TransTasman motor racing accolades.

Along with Pukekohe Park’s outstanding open wheeler racing history, the tight and speedy 2.91-kilometre circuit has also been the host of some of the most spectacular Production Car and Touring Car series races, including Australia’s Supercars Championship.

Pukekohe was also the venue for New Zealand’s premier production car race, the B&H 500 mile race (later a 1000 kilometre race) featuring famed drivers such as Peter Brock, Dick Johnson and the outstanding Kiwi Jim Richards.

Australia’s V8 Supercars returned to the circuit in 2013 following the completion of safety upgrades including the addition of a series of corners before the hairpin turn to lower the high average speeds around the circuit. Supercars remained at the venue, save for pandemic forced cancellations in 2020 and 2021, through to their fifteenth and final Pukekohe showdown which was held in September 2022. The Pukekohe Supercar swansong saw Will Davison and super-fast Kiwi Shane Van Gisbergen share each of the race victories.

New Zealander Greg Murphy takes the prize for the most Pukekohe round wins, with five, followed by Van Gisbergen who shares double round wins with the most successful ever Supercar driver, Australia’s seven-time Champion Jamie Whincup.

I’m sure I speak for anyone who has ever experienced the excitement of Pukekohe Park Raceway in full flight as a fan, driver, official or team member when I say ngā mihi which is the Te Reo Māori phrase for “Thank You”. Pukekohe Park Raceway will be greatly missed.

The iconic silver fern, emblematic of New Zealand’s national identity, was added to the sides of Thomas Randle’s Castrol Racing Mustang along with the message “ngā mihi, Pukekohe” as a tribute to the historic New Zealand racing circuit at the final Supercars Championship round held there in September 2022.

The BP Ultimate Safety Car was used to say Farewell to Pukekohe Park Raceway at the final Supercars Championship round held there in September 2022.

In 1996 the New Zealand Mobil Sprints held a round at Pukekohe Park Raceway and the Auckland region venue also held an annual V8 Supercar round from 2001 to 2007.

The BP Ultimate Safety Car was used to say Farewell to Pukekohe Park Raceway at the final Supercars Championship round held there in September 2022.

In 1996 the New Zealand Mobil Sprints held a round at Pukekohe Park Raceway and the Auckland region venue also held an annual V8 Supercar round from 2001 to 2007.

As the demand for more sustainable solutions reaches fever pitch, two of the world’s leading luxury car brands are taking the initiative to meet this demand while staying true to their respective DNA.

The BMW Group plans to launch its first vehicles featuring completely vegan interiors, made possible primarily through the development of innovative materials with leather-like properties. These materials can be used for steering wheel surfaces, which must fulfil demanding criteria when it comes to feel, premium appearance and wear resistance. Fully vegan interiors will be available for both BMW and MINI models for the first time from 2023, serving the demand for vegan and leather-free interiors that is set to increase in the near future, especially in the US, China and Europe.

The reduction of CO2 emissions over the entire life cycle of a vehicle is the central goal of the BMW Group on the road to climate neutrality, which is to be achieved by 2050 at the latest. Material selection has a key role to play in achieving this goal. Replacing raw materials of animal origin significantly contributes to increasing vehicle production sustainability. The introduction of a new surface material for steering wheels will see the proportion of vehicle components that contain traces of raw materials of animal origin fall below 1% in the respective BMW and MINI vehicles. As a result, these materials will now only be found in areas that are not visible to the customer, for example, in various waxy substances such as gelatine used in protective coatings, lanolin in paints, tallow as an additive in elastomers and beeswax as a flux for paints. The BMW Group has been offering various fabric alternatives to leather for a long time.

Now, for the first time, a suitable substitute for leather is offered for the most important interface between driver and vehicle. The fact that there is now a high-quality vegan surface material with equivalent properties to the real leather previously used in the production of steering wheels represents another major step towards CO2 reduction. The new steering wheel surface material reduces CO2e (carbon dioxide equivalent) emissions along the value chain by around 85% compared to leather. Until now, about 80% of the emissions produced were in the form of methane gas from cattle rearing. The remaining 20% came from processing the cowhide, which is highly energy- and water-intensive.

To achieve the goal of climate neutrality, the BMW Group is relying on the use of green electricity in production and in the supply chain, a consistently increased proportion of secondary materials and natural raw materials, highly efficient electric motors and combustion engines, and a high recycling rate in line with the principles of a circular economy.

It’s all in the detail. The floor mats for various models are made from monomaterial, thus avoiding material mixes that are difficult to recycle. As a result, the BMW Group saves around 23,000 tonnes of CO2 and an additional 1,600 tonnes of waste yearly since the recycled floor mats and waste material are also reused in the production process.

Research and development in the field of secondary raw materials and sustainable materials are a top priority. Future vehicle generations will offer other attractive alternatives to leather. The BMW Group is working with start-up companies to develop innovative bio-based materials.

Compared to the synthetic leathers previously used, these result in around 45% lower CO2 emissions. Mirum, a 100% bio-based material, has the potential to mimic all the properties of traditional leather, while another new material, Deserttex, is made from pulverised cactus fibres. Replacing raw materials of animal origin with these materials can significantly reduce CO2.

Ambition 2039 is Mercedes-Benz’s goal to have a CO2-neutral fleet of new passenger cars and vans across the entire value chain and life cycle by 2039 – 11 years earlier than EU legislation requires. Special attention is paid to the careful use of resources. The company is working intensively on closing material cycles, significantly increasing the proportion of recycled materials and researching new materials that are in harmony with nature.

Sustainability is the foundation of all Mercedes-Benz research and development activities, with the goal to be the technology leader in environmental engineering by achieving more with less. To this end, the Group is accelerating its innovation speed and bringing new, sustainable technologies into production as quickly as possible. At Mercedes-Benz,

sustainability begins in the early stages of product development because the company takes a holistic approach to both CO2 emissions and resource consumption. When developing the vehicles, the composition of all materials is considered, and possibilities for more sustainable alternatives are examined. The vehicle interior is an important part of the brand experience for customers, and the highest visual and haptic quality is a top priority, along with comfort, functionality and durability. Since the early days of the car, leather has been synonymous with the highquality interior features that many customers desire. However, Mercedes Benz is taking a holistic approach to making this luxury sustainable.

From 2023, Mercedes-Benz will successively offer only sustainably produced and processed leather in all model series. This consideration ranges from livestock breeding to the tanning process. Mercedes-Benz already requires compliance with various animal welfare criteria in its specifications. In addition, an important awarding requirement for suppliers is that the leather supply chain must be free from any form of illegal deforestation and that grazing areas do not contribute to the endangerment or loss of natural forests. The company is conducting intensive research into animal-free alternatives to genuine leather, which should be resource-friendly and offer the highest quality in all parameters.

Through the power of biotechnology, fungal mycelia are growing into innovative leather alternatives in the lab, pointing to the future of sustainable, luxurious interior equipment. Mercedes-Benz offers vehicles in many segments worldwide that have leather-free interior ex-works or are part of an individual customer request. The various trim options include a high-quality leather replica and a microfibre fleece fabric with a suede look and feel. It is used in the vehicle interior as a seat cover, roof lining and pillar trim and contains a high proportion of recycled materials, which will be continuously increased in the future.

In the Group Research division, the company is examining the launch of promising materials that meet MercedesBenz’s high standards of sustainability and quality. This includes a high-performance plastic with a painted surface obtained through innovative chemical recycling. Another promising material that could be used in rear seat cushions is a partially CO2-based foam. In the polyol, the main component of this automotivegrade polyurethane foam, CO2 that would otherwise be released into the atmosphere is chemically bound. The carbon dioxide can make up to 20% of the weight of the polyol.

Mercedes-Benz is also intensively researching the readiness for the production of other innovative materials, such as a silk-like, biotechnologically produced textile that is entirely free of animal products, as well as carpets made of bamboo fibres. These materials are not only particularly sustainable but also an exquisite visual and tactile experience.

It is clear that there is an accelerating demand for more sustainable solutions in all aspects of our busy lives. However, as both BMW and Mercedes-Benz can demonstrate, there is no need to compromise our insatiable appetite for luxury.

Record low unemployment rates across Australia and New Zealand look good on paper but at the coalface they are causing chaos for many industries. The automotive aftermarket industry has not been spared and the Western Australian Motor Trades Association estimates there are close to 40,000 vacancies across Australia for jobs such as mechanics, motor trimmers, panel beaters and spray painters.

Unfortunately, there is no magic wand to fix this, and it’s going to take a lot of collaboration between employees, industry associations, national suppliers and governments to solve the issue.Given the current employee shortages, retaining staff will become imperative because it could take months, or even years, to replace those who leave for whatever reasons. Here are some staff retention policies to adopt in your workshop:

First things first – money. It’s essential for workshops to pay what we call competitive compensation, which requires employers to evaluate pay rates and adjust them regularly. If this has not been done in the last six to 12 months, I suggest you attend to this immediately. To ensure the workshop can cover the rising costs, the workshop’s hourly labour rate may need adjustment. This evaluation and adjustment needs to be done every

six to 12 months. There are also other forms of compensation to consider, such as staff bonuses. Every gesture ticks another box for the employee to stay put.

Perks come in many different shapes and sizes, and they need to be matched to your employees. Perks like fuel cards, use of workshop vehicles, free Friday lunches, coffee machines, flexible work hours, fourday work weeks, and team morning fitness sessions are all simple but tangible things that will boost employee morale.

The physical environment of the workspace sets the tone for workshop morale. It’s not difficult to make sure the office, lunchroom and staff amenities are always clean and tidy – a cleaning roster could help. A fresh coat of paint does wonders. Workshop heating and air conditioning are significant investments but they contribute enormously to workshop comfort and morale during extreme weather conditions.

Good technicians will leave if there are no opportunities for them to progress in their career, or if they are not offered any training. In contrast poor-performing technicians are likely to resist offered training. Regardless of their attitude, training should now be non-negotiable in every business. Survival of the business itself, in today’s age of rampant technology growth, depends totally on training.

Our experience as trainers shows that once the initial resistance is broken, staff will enjoy learning new things, and there will be a spring in their step the day after a training session. Persevere – your business will thank you for it.

Not all training has to be external. Senior technicians can often help with in-house training, and it tends to boost their confidence and makes them feel appreciated.

Appreciating that routine servicing and simple mechanical repairs constitute the majority of a workshop’s daily chores, there will always be a steady flow of different jobs that vary from simple to highly complex. It’s important for job satisfaction that all employees are challenged with different jobs from time to time. Job satisfaction is described as how employees feel engaged and fulfilled in their work and it occurs when employees feel that their job is secure and safe. It’s only human nature for employees to walk away with a sense of satisfaction after completing a different or more complex job.

Finding the time to conduct staff appraisals might be difficult, but the effort will prove to be well worthwhile. At least once every 12 months, sit down privately with each staff member. Ask for their feedback on the workplace, and give them your feedback on their performance. Set goals for them for the year ahead. It is absolutely critical that you follow through with what was discussed and agreed.

Staff should be encouraged to share their ideas and suggestions – some will be good, some not so good. More importantly, the worst thing you can do is fail to acknowledge their input or fail to act on their suggestions. This is a sure way to make an employee feel undervalued and another good reason for holding regular meetings, so that staff feedback can be acknowledged and discussed and any appropriate action taken.

If you follow any sporting code, you will find that all the great coaches take a genuine interest in their players and really care for them away from the field. The same principles need to apply in the workplace. Managers or owners who genuinely care about their employees will enjoy high levels of staff retention. Busy or not, take the time to sit down and engage with staff during breaks. Ask about their activities outside of work, and take a genuine interest in their lives. At the very least, think about holding a phone-free lunch every Friday with the whole staff – and you shout lunch.

Shine a light on notable achievements. A birthday, an employee reaching a five-year work anniversary – seize the opportunity and mark the milestone together as a team. Staff shortages are not new to the automotive industry, and judging by today’s figures, staff retention will be one of the greatest challenges ahead. Don’t compound the problem by unnecessarily losing good staff. Investing time in staff management is now more important than ever.

Do you have a plan in place to grow your business? According to this year’s State of the Nation survey, chances are you do, with 73% of respondents responding in the affirmative when asked that question.

When asked how they intended to achieve this growth, 64% said they aimed to improve business efficiency, while 42% expressed the ambition to employ more staff and 40% wanted to increase the capacity of their workshops.

Given the current challenges surrounding finding and retaining qualified staff, achieving growth by employing more staff and/or increasing workshop capacity might not be as easy as many business owners assume.

As such, a more effective strategy might be to concentrate on improving efficiency, and this means focusing more on the cars that you have in your workshop rather than trying to get more through it.

Vehicles are becoming much more complex, timeconsuming and expensive to service and repair. It follows that the role of the automotive technician has become more important than ever. They shouldn’t see themselves simply as service mechanics who do the standard grease and oil change, plus any repairs that the customer wants to do.

Compounding the issue is the fact that car owners have long since stopped fussing with their own cars. This means there is now even more of an obligation on workshop personnel to protect their customers and try to stave off costly repairs.

In fact, customers often need to be educated about the importance of ongoing maintenance.

The longer service intervals now suggested by car makers and their dealerships might be OK in an ideal world, but real-world driving environments and patterns are far from perfect. This makes regular maintenance on a whole raft of vehicle components as vital now as it ever was.

So, when someone drops off their car for an oil service, a good workshop must now look to the vehicle’s future. Technicians must ask themselves, “what maintenance does this vehicle need to ensure it doesn’t break down and have problems in the foreseeable future?”.

This is called preventative maintenance.

Most independent workshops assume they do this well, but TaT research has clearly shown that vehicles are leaving workshops every day without necessary maintenance being completed. This is happening because the workshop might be too busy, or they assume the customer can’t afford it, or even worse, they adopt a “she’ll be right” attitude.

the

However, there is a clear difference between ethically upselling preventative maintenance services and ripping people off by duping them into paying for things they don’t need. The key is to communicate with your customers effectively, build trust and use your knowledge and experience to proactively offer services that will save them money (and hassle) in the future.

To quantify the revenue potential of these routine maintenance items, TaT Biz offers an Average Service Price Calculator template that will calculate how many of these additional items you could be selling on average each week and the associated revenue this will generate. The template can be downloaded at https://cap.coop/3VJnP01

Using this tool has the potential to illustrate that a significant amount of revenue is walking out of your workshops every week. In doing so, it can demonstrate the immense growth potential that exists in focusing on the cars that are already in your workshop, as opposed to worrying about increasing your workshop capacity and servicing more cars.

It’s highly likely that there is enough revenue potential in the cars that are already booked each day to reach the most ambitious workshop growth targets.

Nothing in this article is intended to constitute personal business or financial advice. Members should consider their own circumstances and seek their own personal advice as necessary.

•

•

•

•

•

Stop for a moment and think about everything you have on your plate right now. Chances are that beyond the vehicles on the hoists and the jobs on the board, you’ve got a hundred other tasks to tick off your to-do list — bills to pay, shelves to stock, orders to place, customers to appease, employees to support, and much more besides.

Running a business is demanding and it can be stressful. It can all too easily take over other areas of your life. In this year’s State of the Nation, 42% of Capricorn Members told us having a good work-life balance was one of the biggest issues they faced in running an automotive business. The same percentage told us they struggled to find time to take a break or go on holiday. Does that sound familiar? Are you among those workshop owners struggling to get away from their business to relax, refresh and recharge the batteries?

If you are, you’re not alone — and it could be having a detrimental impact on your mental health. According to a University of Melbourne study (across a wide variety of industries, not just auto), one-quarter of all smallbusiness owners report a high level of psychological distress. That number leaps to 36% for sole operators. If you’re among those struggling to take time away from your business, hopefully this article will help you find ways to reconfigure the way you’re operating so you can take the break you deserve.

Firstly, let’s look at some signs you might be stressed or overloaded with work — because not all indicators are as obvious as losing your weekend to paperwork or not taking a holiday. According to Australian mental health charity Beyond Blue, it’s common for small-business owners under stress to exhibit the following behaviours: Impatience, irritability, being quick to anger

Easily distracted from the task at hand

Consistently looking tired Being less punctual than usual Missing easily attainable deadlines Taking longer than usual to complete tasks

Experiencing conflict with staff or customers

Having difficulty managing multiple tasks

Becoming distant during interactions

Not being engaged in meetings Being negative and not solutionoriented

Speaking about themselves in a derogatory way.

Want to learn more about other challenges facing auto business owners? Check out our State of the Nation 2022 report here.

From this list it’s easy to see that working for longer hours won’t be enough to fix the problems on your plate. If you’re stressed, if it’s affecting your mental health, then you’re also likely to be far less efficient and productive. You risk entering a spiral of stress and ill health, when what you may need is a circuit breaker — getting away from the causes of your stress.

Beyond Blue has a checklist of personal behaviour changes to help small-business owners. They suggest: Keeping your work hours in check Eating well, staying physically fit Prioritising a good night’s sleep Switching off technology after-hours

Staying in touch with family and friends

Developing interests outside of work

Taking time out to relax Monitoring stressors and warning signs of poor mental health and wellbeing.

That all sounds straightforward enough, but if you’re working all the hours God gives because you can’t find staff and there’s a skills shortage, or you have a massive tax bill to pay, or the kids’ school fees are due, intending to have a good night’s sleep and actually getting one can be two completely different things — and the problem is still going to be there in the morning.

We asked Jeff Smit, Technical Editor at The Automotive Technician, for some practical tips and advice to help workshop owners achieve a work-life balance. The secret, he said, was structuring your business correctly, including having the right people and processes in place.

In his own business that meant hiring a manager, which freed up his own time so he could either work on the business or on other things.

“You have to make sure whoever is employed as the manager knows what to do and what’s expected, and has the tools and the infrastructure in place to be able to achieve it,” Mr Smit said. “Then get out of the way and let them do it — which is the hardest part of all.”

Have a hierarchy or structure in place, with a clear chain of responsibility when you’re not in the workshop

Have policies and procedures in place and make sure everyone understands them

Train your team, so that they have the skills and experience to do the job while you’re not around Delegate jobs and authority, so everyone knows who is responsible for what tasks when you’re not there.

But what if you’re a sole operator? According to the Workshop Whisperer, Rachael Evans, the same basic principle applies — you have to plan for better work-life balance.

“Stop, take a step back, and consider where you fit on a scale between struggling and high performance,” Ms Evans said. “Somewhere in the middle there is what we call ‘a lifestyle business’ and you can’t become a high-performance business and have it run successfully — with you being like a CEO rather than an owneroperator — if you haven’t paused in the middle at ‘lifestyle’ to assess what you want your work-life balance to look like.

“Do you want to have a four-day work week? Do you want to be able to come in and out as you please? Do you want to have a manager? It’s all that kind of stuff. “But you don’t get there unless you actually plan for it.”

Planning for work-life balance could be as simple as making a decision to work differently. Craig Minca and Caroline Langan-Minca, owners of His’n’Hers Automotive Solutions in Kilsyth, Victoria, decided not to open the workshop on Saturdays and to shut the doors at 5pm on the dot.

Caroline told Ignition last month: “If customers say to us, ‘oh, you shut at 5pm?’ do you know what we say? ‘Yeah, we’ve got kids at home and we’d rather be with them.’ They’re like, ‘oh, okay’. “I reckon once a month we have customers ask if we do Saturdays and we say, ‘no, we have kids; we’d rather be at their sports’. As soon as you mention you’ve got kids and that’s more important, people are like ‘oh, yes, we agree; that is more important’.” They also juggle open and closing between them, so no-one is doing 10-hour days.

Another Victorian Capricorn Member, Glenn Matthew, co-owner of Autoclinic in Heidelberg Heights, decided many years ago to only work a nine-day fortnight. “I have every second Friday off and it just boosts my energy up,” he said. “I find a lot of guys don’t get their holidays and they become flat and start being rude to their customers because they’re burnt out.”

Sometimes, though, taking a Friday afternoon off won’t in itself remove the stressor that’s causing the problem. For example, if the tax office is chasing you for a big bill or your bank is hammering on the door for a mortgage repayment. The advice from Heads Up, Beyond Blue’s workplace mental health arm, is to talk to the institutions or creditors involved to see if a better solution can be worked out.

Assistance with some other common stressors workshop owners might be experiencing include getting dispute resolution support, talking to a financial counsellor, getting free legal advice, or even seeing what Government support you might be entitled to. If the stress is affecting your mental health, if you feel like you might not be coping, then talk to someone. Beyond Blue, Lifeline, Men’s Line, Australia’s National Debt Helpline and SANE all have phone lines you can call.

Remember what life is meant to be all about

It’s all too easy to feel like your business is running you, rather than you running your business. If it’s starting to feel like that, or if it’s already like that, don’t let the situation get worse. Prioritise your health, including your mental health.

Prioritise finding solutions to your stressors — like delegating tasks and responsibilities or restructuring the way things operate. Plan for long-term change.

Prioritise finding time to do the things that make you happy — like spending time with the kids or playing golf — and the things that help you recharge your batteries — like sleeping, going fishing, or taking a holiday.

Remember, you work to live, not live to work.

If you’ve been affected by any of the issues discussed in this article, you can reach out to Beyond Blue in Australia on 1300 22 4636 or through beyondblue.org.au (webchat available).

In New Zealand, free call or text 1737 any time for support from a trained Mental Health Foundation counsellor.

Jefferson Paint Supplies is a specialist distributor of automotive, industrial, aviation coatings and collision repair products. Partnering with Axalta as a distributor for Standox, Cromax, Syrox, Nason, Imron Fleet and aviation paints. Also, distributors for other leading collision repair brands including 3M, SATA, Mirka, Rupes, Devilbiss, Iwata, Sia Abrasives, and more.

Over the years they have developed strong relationships with the most well-known brands in the industry to provide quality automotive paint and panel products to their customers, with an extensive product range including automotive, fleet and aviation coatings, consumables, abrasives, adhesives, polish and compounds, fillers, tools and equipment.

As a leading automotive paint supplier, their engaged team of paint specialists are actively partnering with repair workshops to support their paint requirements whilst providing competitive prices, great service, and support.

jeffersonautogroup.com.au/parts-paint

Alsco have been providing hygienic and sanitised professional textile rental services since 1963. Known for their commitment to cleanliness and hygiene, excellence in service, and friendly approach, their services include a commercial linen service, an extensive uniform range, corporate clothing, chef uniforms and rubber floor matting.

For over 50 years their dedication has been providing a service that is reliable, cost-effective and carefully tailored to your business. If you’re interested in saving your time and money, think of Alsco, they can take the hassle out of linen, workwear, commercial floor mats, industrial cleaners, first aid kits and training as well as washroom hygiene services and scenting in your business to help you focus on what you do best.

alsco.com.au

Chadstone Toyota is more than just a dealership – their parts department takes great pride in supplying Toyota Genuine Parts to the automotive industry. Their professional and knowledgeable parts team have over 43 years of combined experience between them, which means that you’re always able to help you find what you’re looking for – whether it’s related to panel, mechanical, electrical, lubricants or fluids.

They also offer competitive pricing and will price match when possible. Whether you need parts for a HiLux, HiAce, Corolla or anything in between, all of their Toyota Genuine Parts are made to the same high-quality standards and are designed specifically for your model. The security of a well-known dealer network also provides peace of mind when ordering.

chadstonetoyota.com.au

26 YEARS PREFERRED SUPPLIER

26 YEARS PREFERRED SUPPLIER