HOW T TO M MAKE A G GARDEN B BED

Creating a garden bed is a wonderful way to cultivate plants and enjoy fresh produce. Let’s dive into the steps for building a raised garden bed:

1. Choose a Location:

Select a sunny spot in your yard or garden where your plants will receive adequate sunlight. Ensure the area is level and free from obstacles like rocks or tree roots.

2. Materials Needed:

Wood: Decide on the type of wood for your raised bed. Cedar, redwood, or pressure-treated lumber are popular choices due to their durability.

3. Hardware: Gather screws, nails, or brackets to assemble the bed. Tools: You’ll need a saw, drill, and measuring tape. Soil: Plan for good-quality soil to fill the bed.

4. Dimensions and Design:

Determine the size of your raised bed. Common dimensions are 4 feet wide by 8 feet long, but adjust based on your space. Cut the wood to create a rectangular frame. Attach the boards together using screws or nails. Optionally, add corner braces for extra stability.

5. Site Preparation:

Clear the area where the bed will be placed. Remove grass, weeds, and debris. Level the ground to ensure stability.

6. Assemble the Bed: Place the frame in the prepared area. If you’re concerned about weeds, consider laying down landscape fabric or cardboard inside the bed before filling it with soil.

7. Fill with Soil: Fill the bed with a mixture of good-quality soil. You can blend garden soil, compost, and other organic matter. Aim for a depth of at least 6 to 12 inches of soil.

8. Planting:

Now that your raised bed is ready, start planting! Choose vegetables, herbs, or flowers that thrive in your climate. Remember, raised beds offer several benefits, including better drainage, improved soil quality, and easier maintenance. Happy gardening!

Page 2 • March 28, 2024 SPRING HOME LAWN & GARDEN GUIDE

How to Install Porch Screens forBreezy OutdoorLiving

What You'll Need Equipment / Tools: Straight edge •Drill •Chop Saw •Rubber Mallet •Utility Knife •Screen Tight Roller Knife

Materials: Screen Tight •Mini Track Screw Clips •Screen Tight Mini Track Channel •Fiberglass Screen •Screen Tight Mini Track Spline

Instructions:

Install screen system measure and mark placement with pencil install screen system drill screw into window ledge install screen system adjustment of screw clip

Install Screws:

Using a straightedge, draw a line through the center of the opening to be screened. Measure and mark the placement for the screw clips, about 8-10 inches apart along the line, starting and ending 2 inches from each corner. Drill a pilot hole at each mark. Insert a screw clip into each hole; do not overtighten. Use a small channel piece (we used the Screen Tight track system) to properly adjust the height of each screw clip so that the channel slides easily over the screw without being too loose. Repeat on all four sides of your window. Install screen system tap channel onto screw clips with rubber mallet

Install Channel Pieces:

Cut channel pieces to fit the top and bottom of the opening using a chop saw. Install the pieces by sliding the end of a channel piece over an end screw, then tap the rest of the channel onto the screw clips with a rubber mallet. After the top and bottom channels are installed, measure, cut, and install the side channels in the same manner. Install screen system trim excess screen with roller knife

Fasten Screen to Tracks:

Cut a piece of fiberglass screen a few inches larger than the opening. Starting at the top of the opening, lay the screen across the top channel track. Using a roller knife, evenly push the spline into the top track channel groove, fastening the screen into the groove as you go. Continue pushing the spline into one side track, then repeat on the opposite side, ensuring that the screen remains straight as you work. Insert the spline into the bottom channel track last. Install screen system complete porch with plants

Trim Porch Screen:

If needed, remove the spline and adjust the screen. Trim excess screen mesh flush along each edge using a utility knife.

SPRING HOME LAWN & GARDEN GUIDE March 28, 2024 • Page 3

Page 4 • March 28, 2024 SPRING HOME LAWN & GARDEN GUIDE

SPRING HOME LAWN & GARDEN GUIDE March 28, 2024 • Page 5 OVER 100 VANITIES IN STOCK SOLID WOOD, MANY STYLES & SIZES TOY BOXES STEPPING STOOLS CORNER CABINETS 6 PANEL INTERIOR DOORS (IF WE DON’T HAVE IT, WE CAN ORDER IT) “The prices are worth the drive! CABINETDOORGUYS@GMAIL.COM • SEE US ON FACEBOOK All Base Cabinets Solid Wood 30” Wall Cabinets 42” Wall Cabinets 271 State Route 54 East • Fordsville, KY 42343 Locally Owned & Operated (270)276-3545 For photos & more info: www.facebook.com/CabinetDoorGuys WASHER &DRYER CABINETS 30” WIDE X 30” TALL 48” WIDE X 30” TALL 16” DEEP ADJUSTABLE SHELVES TRIM MOLDING BASE, CROWN, & CASING 8’ OR 16’ LENGTHS NOW YOU CAN SHOPIFY CABINET HARDWARE & HAVE IT SHIPPEDSTRAIGHT TO YOU NEW STORE HOURS: Monday - Friday 8am-5pm Saturday 8am-12pm OVER 10,000 FINISHED CABINET DOORS IN STOCK $5.00 each WE NOW CUSTOM MAKE CABINET DOORS! ANY SIZE, SOLID WOOD & UNFINISHED NOW IN STOCK NIGHT STANDS, SOFA TABLES & FOYER TABLES NOW CARRYING MOBILE HOME DOORS LAMINATE FLOORING 5 COLORS (PAD INCLUDED) Adult & Childs Rockers GARAGE CABINETS Base & Wall Cabinets 21” & 24” •Solid Wood •Pre-Finished •Soft Close Hinges •No Drawers NOW IN STOCK! CHEST OF DRAWERS Unfinished solid wood kitchen chairs & counter top height bar stools HALL TREE AVAILABLE IN ANY SIZE BUTCHER BLOCK TOPS Unfinished Kitchen Cabinets All sizes available! Check out our great selection! 2 STYLES TO CHOOSE FROM

3.

HOW T TO P PAINT K KITCHEN CABINETS P PERFECTLY I IN 1 10 S STEPS

GATHER YOUR TOOLS When it's time to get your project started, you'll need to gather some basic tools. Here's what you'll need: Painter's tape for keeping paint off your walls and other surfaces Drop cloth to protect floors Cleaning supplies to work with a clean surface and rejuvenate hardware Screwdriver or drill for removing cabinet doors and hardware Caulk for filling any imperfections on your cabinets Sandpaper for sanding down existing finishes or paint Foam roller or paintbrush for applying paint and primer Paint tray for an even paint application Primer to make paint last Paint for a finish you'll love Gloss or finish to seal in your hard work 2. CREATE YOUR BUDGET On average, it costs between $900 and $1,200 to repaint a standard kitchen. This can vary depending on hired labor, paint quality, and cabinet design. The cost of painting kitchen cupboards is often lower than paying for brand-new cabinetry. However, dedicated time and attention to the project is a must. Painting kitchen cabinets that look professional requires meticulous preparation and care throughout the entire process. TIP: Include appropriate tools in your budget like painter's tape, drop cloths or rosin paper, liquid deglosser, silicon carbide sandpaper, a paint scraper, putty knife, gloves, sanding sponges, primer, siliconized acrylic latex caulk, and paintbrushes.

1.

CHOOSE YOUR PAINT The quality and durability of the paint you choose will affect the lifespan of newly painted cabinets. Find the best paint for kitchen cabinets by selecting a manufacturer that formulates a product specifically for use on cabinets. Oil-based paint is more traditional but takes more time to dry. Latex paint takes less time to dry and gives a smooth finish. TIP: Slow-drying paint like oil-based paint, although more time-consuming, dries with fewer visible brushstrokes and offers a more professional finish.

CLEAN YOUR CABINETS Remove everything from the cabinets and store the contents. Before beginning any prep work, clean your cabinets with mild, grease-cutting soap on a soft cleaning pad. Make sure your cabinets are completely dry before sanding and priming. This helps paint to stick and extends the lifespan of the project. You can also remove hinges and hardware during this step to clean and polish them as necessary. TIP: Remove all doors from the cabinets and keep track of hardware with labels if you plan to reuse them.

PREPARE YOUR KITCHEN Next, it's time to get your kitchen ready to paint. Open up your doors and windows so the room has proper ventilation so paint fumes can dissipate. Then remove any furniture that could get in your way. Once your area is cleared, set down drop cloths to protect your floors, countertops, and any furniture you couldn't move out of the way. The last step to get your kitchen ready is to tape off your cabinets as necessary so your repainted cabinets have a perfect finish. 6. SAND AND PRIME YOUR CABINETS Use a liquid deglosser if the existing cabinets have a high-gloss finish. If not, simply sand with 100 grit sandpaper, vacuuming frequently to remove sawdust. You might start to notice some cracks or holes in the cabinet. If you do, fill them with wood putty, let it dry completely, and sand it smooth again. For the smoothest surface, sand by hand and use an orbital sander. The orbital sander saves you time on larger cabinet surfaces, then you can go in to sand the details by hand. Begin the paint job with a primer. If you have tight-grained wood on your cabinets, like cherry or maple, then a slow-drying oil-based primer works well. For open-grained wood, like elm or oak, use a brushing putty in several coats, using a new brush for every coat and sanding in between. Brushing putty is like a cross between wood filler and primer. It creates a smooth surface on highly textured wood types.

PAINT YOUR CABINETS Prop your cabinets up before painting for an easier application on edges and corners. Consider laying the doors on painter's pyramids for increased movability around the bottom. You can also rest the cabinets on disposable cups in a pinch. Paint the cabinet boxes first, then move on to the doors. Paint with even strokes, finishing back into the wet paint and feathering the edges. For the smoothest finish, paint in the direction of the wood grain. When you're done, use a small foam detail brush along the edges of the cabinet to smooth out any paint that might have gathered there. TIP: Paint the back of the doors before the front to avoid paint smudges in the most visible area.

DRYAND APPLYSECOND COAT Watching paint dry is admittedly not the most exciting part of this process, but it's necessary for professional-looking cabinets. The paint needs to fully cure before another layer is added for maximum durability. Once you've let your cabinets dry, apply a second coat of paint. TIP:Lightly sand your cabinets between coats of paint, especially if you're working in a dusty area. 9. ADD FINISH OR GLOSS Once you're done painting, you have some options to refinish your cabinets and add different effects: Gloss adds a layer of shine. Glaze creates dimension and settles into creases for an antique effect. Lacquer smooth surfaces completely for a glass-like shine. Varnish protects cabinets without altering the finished look. It's not always necessary to add a finish to your cabinets, but it will make your hard work last longer. Asemi-gloss polyurethane varnish is your best bet for a finish that will protect your hard work without changing the painted effect of your cabinets. 10. ADD YOUR HARDWARE AND REASSEMBLE Line up your hinges, handles and knobs with the top of the door rail. Loosely attach the metal cabinet pulls on each end before securing them completely. If you refinished your hardware, make sure you've allowed plenty of dry time before attempting to reinstall. Page 6 • March 28, 2024 SPRING HOME LAWN & GARDEN GUIDE Don’t Be Fooled Into Paying More For Less The Best Price...GUARANTEED! $650 $570 www.replacementwindowsowensboro.com

4.

5.

7.

8.

How t to I Install a an I Interior D Door

Dramatically change the style of your home or replace an interior door that is damaged. You can choose between a prehung or slab door based on your skill level, budget and the condition of your existing door frame. Slab doors, also known as blank doors, include just the door and not any part of the frame. They can be more budget friendly, but installing a prehung door is a much easier project, especially for a DIYers.

1.How to Remove a Door

If you are replacing an interior door with a prehung door, first you must remove the existing door and its frame. Remove the hinge pins using a screwdriver and hammer. Then remove the door from the door frame. Remove the hinge plates and strike plate from the door frame. Loosen the trim with a stiff putty knife. Use a pry bar and block of wood to remove the trim without damaging the wall. Take your time so as not to cause any damage. If the trim is in good shape, you can reuse it with a prehung door that has a one-piece jamb. A two-piece jamb door comes with trim attached.The head and inside jambs are usually nailed together, so it’s easier to remove them from the opening at the same time. Pry the side jambs away from the studs and then pry down the head jamb. If you would like to paint, repair or alter the wall in any way, now is the perfect time to do so. Any changes to the wall or door frame should be made before installing a prehung door. Once again, take care not to damage the wall during this step in the process.

2. Position the Prehung Door

Once you have removed the old door and prepared the doorway, you can start on the first step in how to install an interior door. Slide the prehung door into the rough opening. Put the door in the opening and slide it until the jamb is flush with the wall. Double check to be sure the door opens in the desired location and direction. Tip: Prehung doors are often heavy and hard to maneuver alone. Ahelper makes it easier to lift and hang the door.

3. Add Shims

Use a level to check that the door is straight. Add shims to adjust the level and ensure the jamb is plumb. The door frame should be slightly smaller than the opening it fits to allow for adjustments. Slip shims under the side jamb until the head jamb is level. Shim between the side jambs and the studs to fill in the spaces between them. On the hinge side, start with the bottom and top of the jamb. Shim between the hinges and studs, positioning the shims so that about half the shim is above the hinge, which will help you later when nailing. On the latch side, shim at roughly the same places and at latch level. Check the level of the door again.

4. Nail Door Frame to Studs

Drive two #8 finishing nails through the frame, through the shims and into the studs. Drive two nails through each shim about an inch from each edge of the jamb, with one about a 1/2-inch above the other. Before driving the nails home, open and close the door and make any necessary adjustments. When you’re satisfied with the way it performs, drive and set the nails.

5. Install Door Trim

Nail the trim to the jamb and studs.Drive #6 finishing nails through the trim and into the studs behind the wall, spacing the nails about 16 inches apart. Trim any exposed shims by scoring them with a knife and then breaking along the line. Cut and install the trim on the second side of the door in the same manner as the first side.

6.Attach Hardware and Accessories

Once the door is hung, attach the backplates and door knobs. Make sure not to screw the knobs on too tightly. Add the lockset and strike plate. Tip: Prehung doors typically come with attached hinges and pre-cut places for the door knob and strike plate. The door knob, lockset and strike plate are sold separately.

SPRING HOME LAWN & GARDEN GUIDE March 28, 2024 • Page 7

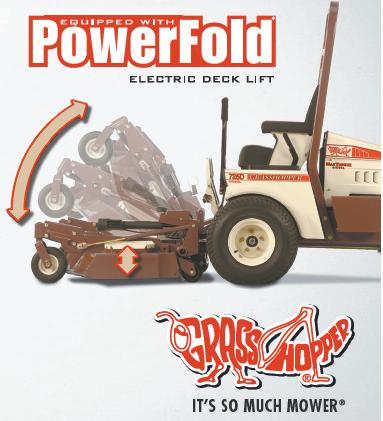

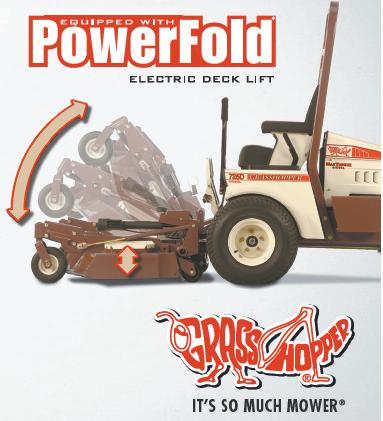

GRASSHOPPERMOWER.COM Page 8 • March 28, 2024 SPRING HOME LAWN & GARDEN GUIDE