LOCKOUT TAGOUT SOLUTIONS

DEDICATED & BESPOKE ONSHORE/OFFSHORE OIL & GAS

Lockout Tagout is the best industry practice to securely isolate hazardous energy. Within the Oil & Gas industry, the necessity to effectively utilize LOTO procedures & equipment is more important than ever. Every action when manually handling equipment upon an offshore or onshore rig is strictly governed to the highest level of safety and requires high quality equipment and processes to keep operatives and workers safe from injury or worse.

Gibb Safety & Survival have partnered with specialists to ensure an expert supply into the industry. Providing a wide range, yet specific catalogue of Lockout Tagout Equipment. Each LOTO kit & product have been designed and chosen to provide the required solutions for all requirements and needs when actively controlling Oil & Gas energy sources. The process and procedure to implement each task is only as effective as the equipment used to fulfil & vice versa. Highlighting the need for specialists to assist in the process from survey to implementation.

Below shows a 10 step LOTOTO process which can be used to keep everyone safe.

7. ENSURE THAT ANY DISSIPATED ENERGY IS SAFETY RELIEVED AND CAN NOT RE-ACCUMULATE.

9. COMPLETE ALL TASKS, ENSURE VIGILANT OBSERVATION IS CONTINUED.

6. TAGS ARE TO BE APPLIED IN ALL CASES WHERE A LOCK IS PRESENT.

8. TEST THE OPERATING CONTROLS. BE SURE NOBODY CAN GET HURT BEFORE TESTING

10. RESTART EQUIPMENT.

The environmental conditions can often be extremely harsh. Premises and equipment are routinely exposed to highly corrosive, chemical, explosive, and salt air conditions. Longer term shuts, complex isolations, and turnarounds, all mean LOTO (Lockout-Tagout) equipment is under these extreme conditions for longer periods of time.

Gibb Safety have ensured that the highest quality and most durable equipment choices for these harsh environments, including ATEX areas, are available as standard.

Choose our range of LOTO safe Padlocks

• Highly durable in extreme, harsh conditions and resistant to chemicals.

• Zero spark choice to suit ATEX/Explosive environments. ***

• Add our dust cap to prevent debris, increasing durability and key function.

• All locks are available for order with custom key systems. (K2D, KA, MK, GMK).

• Our free Eagle-ID service prevents any cross duplications of key numbers. Every key is recorded internally to guarantee each key systems safety.

• Bespoke colour schemes and engraving available.

Choose our range of Mechanical LOTO Equipment

• Blind Flange - Durable, easy fit, pipeline maintenance device. Equipped with hasp capabilities so multiple locks can be fitted at once.

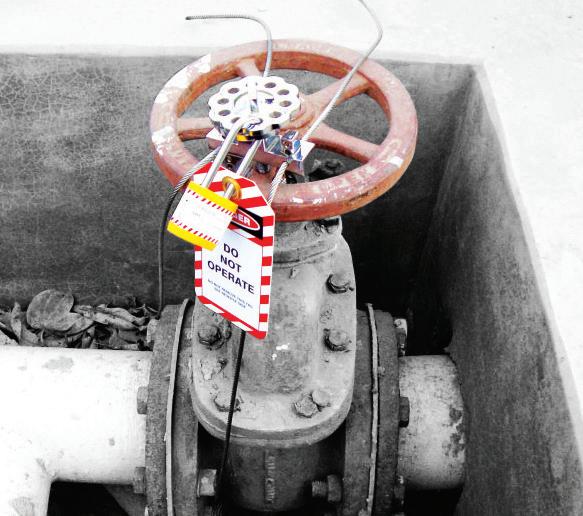

• Rotary Gate Valve Lockout – Chemical resistance, highly durable gate valve cover. Applied in seconds, non conductive with multi lock holes available.

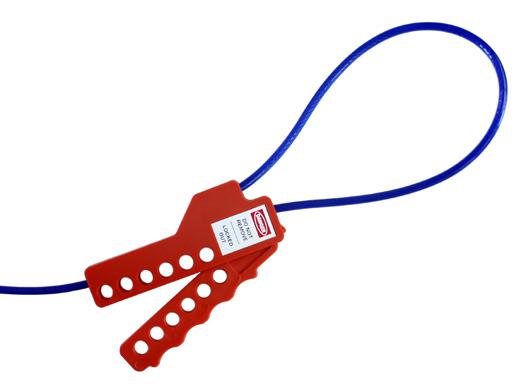

• Cable lockout, Circuit Breaker Devices, Tags & More –Additional Lockout equipment available as standard, to compliment, enhance and provide extra safety choices in any LOTO kit bag.

A universal Electrical Maintenance Lockout Kit has been developed to cover all essential applications and can be used across the relevant Oil & Gas Steams.

•

•

•

•

•

See our 5-step site survey process and solution

A fully comprehensive site survey and gap analysis on all areas of your current lockout isolation and a full report will be provided on these findings.

KEY POINTS FEATURED IN THE REPORT WILL INCLUDE,

STEP BY STEP PROCEDURAL AND PROCESSING OPTIONS.

MACHINERY SPECIFIC ISOLATION SOLUTIONS.

PERMIT SYSTEMS AND CONTRACTOR LOCK MANAGEMENT

SIMPLE AND COMPLEX ISOLATION DISCUSSIONS

ELECTRICAL ISOLATION SAFE SYSTEMS OF WORK.

FULL LOCKOUT, TAGOUT, TRYOUT STEPS AND HOW TO IMPLEMENT THEM EFFECTIVELY

HOW TO MANAGE STORED AND POTENTIAL ENERGY. AUTHORISED PERSONNEL TASK MANAGEMENT

REVIEW OF CURRENT EQUIPMENT ALREADY AT THE PLANT.

KEY METHOD OPTIONS AND BENEFITS.

IDENTIFYING AND CONTROLLING ALL ISOLATION POINTS

HANDOVER PROCEDURES

CONTROLLING ISOLATIONS ON COMPANY SHUTDOWNS, OUTAGES AND TURNAROUNDS

LOTOTO TRAINING AND AWARENESS

DID YOU KNOW?

CONTACT WITH MOVING MACHINERY IS STILL IN THE FATAL 6. IN THE U.S. IT REMAINS THE 5TH MOST COMMON CAUSE OF INCIDENT. THE U.S. AND UK ARE GOVERNED BY STRICT REGULATIONS TO ISOLATE SAFELY.

Following the gap analysis and survey, proposed solutions will be included within the report.

The steps below show the process that should be in place, as standard within the industry utilising LOTOTO. In some instances only small changes may be required within the isolation process.

STEP 1. PREPARATION

STEP 2. NOTIFY

STEP 3. TURNOFF

STEP 4. ISOLATE

STEP 5. LOCKOUT EQUIPMENT APPLICATION

ENERGY HAZARDS AND SOURCES

• ELECTRICITY

• HYDRAULIC PRESSURE

• PNEUMATIC AIR LINES

• KINETIC MOVEMENT

• LIQUIDS AND GASES

• GRAVITY AND FALLS FROM HEIGHT

STEP 6. TAG APPLICATION

STEP 7. CONFIRM – ZERO ENERGY

STEP 8. TRYOUT

STEP 9. COMPLETION

STEP 10. RE-ENERGISE

• SPRING TENSION

• MECHANICAL

• THERMAL

• NUCLEAR

• AND MORE!

TO FINALIZE YOUR ORDER SIMPLY CONFIRM WITH AN OFFICIAL PURCHASE ORDER.

We have all of the stock available to ensure a rapid delivery.

We will be able to print the bespoke boards within the week meaning implementation can be completed in 5-7 days of point of order.

Training dates can be discussed and confirmed but are usually a on a 2-week notice period.

Continued Support.

ISSUES SURROUNDING DUPLICATE KEYS.

The Eagle-ID scheme can be implemented on any of the Lockout Tagout padlocks we supply and will provide an ironclad guarantee that your site is free from key duplications and the safety implications this can present.

Every padlock supplied has its unique key reference recorded on our internal system, and subsequent orders are cross-referenced against this database to ensure no duplications can ever be issued to the user, regardless of site location or company organisational structure.

OUR EXPERIENCED TEAM IS ON HAND TO DELIVER TRAINING ACROSS THE FULL BREADTH OF OUR RANGE.

Our training package is designed to raise awareness of Lockout, Tagout, Tryout, it will ensure that all members understand the dangers of what can happen and how. The training will cover what to look for, how to follow the process’ and procedures effectively and safely, as well as making sure employees are competent in applying the equipment that is being provided for the site’s individual solution.

All training is carried out as a practical and hands on session. It will cover real life scenarios, how accidents could affect you, energy hazards and sources, equipment used in the solution, the 10 steps of LOTOTO & much more.

Everyone will leave with a better understanding and awareness on LOTOTO.

As well as a pocket sized, Total Isolation Guide & LOTOTO Handbook to take away and refer to.

It is recommended that if you decide to replace your Lockout Tagout products or continue with your current setup, that a LOTOTO awareness day is conducted to all affected employees on site.

TOTAL ISOLATION GUIDE & HANDBOOKLOTOTO

TOTAL ISOLATION GUIDE & HANDBOOKLOTOTO

Main Distribution Centre

Brooklyn House, Gapton Hall Road

Great Yarmouth, NR31 0RD

Tel: 01493 602440

Head Office & Distribution Centre

Tern Place, Denmore Road, Bridge of Don, Aberdeen, AB23 8JX

Tel: 01224 620944