28 minute read

Joint Meeting makes more changes

THE LATE SHOW

MULTIMODAL • THE JOINT MEETING OF RID/ADR/ADN EXPERTS MAKE A SURPRISING NUMBER OF DECISIONS AT ITS SPRING SESSION, MANY OF THEM AFFECTING THE 2023 REGULATORY TEXTS

THE JOINT MEETING of the RID Committee of Experts and the Working Party on the Transport of Dangerous Goods (WP15) of the UN Economic Commission for Europe (ECE) held in spring 2022 session in Bern from 14 to 18 March. The meeting was chaired by Claude Pfauvadel (France) with Silvia García Wolfrum (Spain) acting as vice-chair; it was attended, either in person or virtually, by representatives of 22 states, the European Commission, the EU Agency for Railways (ERA), the Organisation for Cooperation between Railways (OSJD) and 18 nongovernmental organisations.

The role of the Joint Meeting is primarily to discuss items of common interest for the regulatory bodies that cover the transport of dangerous goods by rail (RID), road (ADR) and inland waterway (ADN) with the aim of ensuring harmonisation – insofar as is possible – to facilitate multimodal international transport.

In more normal times, this spring session prior to the new editions of the regulations entering into force in 2023 would focus primarily on finalising the details of amendments already agreed. However, in light of the ongoing Covid-19 pandemic and the difficulties it has presented to regulators, there was rather more work outstanding and some significant new amendments were agreed at the session. These do, however, remain to be formally adopted by the relevant regulatory bodies at their upcoming meetings.

TALK ABOUT TANKS While there have been some changes to the way that the Joint Meeting has been operating during the pandemic – and the UN ECE Secretariat is optimistic that a return to normal working practices in the second half of this year – some things remain the same. As ever, the session began with discussion of topics involving the transport of dangerous goods in tanks, starting with some issues held over pending final decisions, although not all were taken to a conclusion.

The first two items related to the new breed of extra-large tank containers. The first issue to be resolved was actually what is to be taken to be meant by “extra-large”. On the basis of a paper from the European Chemical Industry Council (Cefic) and the International Union of Wagon Keepers (UIP), it was decided to add the following definition in 1.2.1, after the definition of ‘Tank-container’:

In addition:

“Extra-large tank-container” means a tank-container with a capacity of more than 40 000 litres.

That new definition had been amended from the original proposal to remove specific reference to rail transport, highlighted in an informal paper from the UK, which also affected the proposed change in 6.8.2.1.18. In the right-hand column, third paragraph, “, or 4.5 mm if the tank is an extra-large tankcontainer” is added after “3 mm”. That has necessitated a new transitional provision, which appears at 1.6.4.62:

Extra-large tank-containers constructed before 1 July 2023 in accordance with the requirements in force up to 31 December 2022, but which do not meet the requirements of 6.8.2.1.18, third paragraph, concerning the

minimum thickness of the shell applicable as from 1 January 2023 may still be used.

The International Organisation for International Carriage by Rail (OTIF) summarised earlier discussions on the pressure resistance of closures on extra-large tank containers and provided a formal proposal, which was agreeable. That involves an additional two paragraphs after the first sentence in the right-hand column of 6.8.2.2.4:

These openings for extra-large tankcontainers intended for the carriage of substances in the liquid state which are not divided by partitions or surge plates into sections of not more than 7 500 litres capacity shall be provided with closures designed for a test pressure of at least 0.4 MPa (4 bar).

Hinged dome covers shall not be permitted for extra-large tank-containers with a test pressure of more than 0.6 MPa (6 bar).

Again, that has necessitated a new transitional provision, this time at 1.6.4.61, to

GROWING VOLUMES OF LNG AND HYDROGEN IN

TRANSPORT PRESENT NEW HAZARDS allow tank-containers built before 1 July 2023 in accordance with current provisions to continue to be used.

On the subject of transitional measures, OTIF had spotted two that will no longer be relevant after the end of this year and the Joint Meeting agreed that they should be deleted. This applies to 1.6.3.3.3 and 1.6.3.17.

The UK returned with a proposal following up on earlier, unfinished discussions about the need, if any, to include minimum thicknesses for partitions or surge plates in tanks. Time constraints had made it impossible to return to this at the September 2021 session. The matter received a similar fate now, with the Joint Meeting decided this should be held over to appear in the 2025 edition of ADR.

A rather more urgent matter was presented by the Netherlands, which again referred back to earlier discussions. This related to the need to be able to stop the uncontrolled outflow of gases due to unintended events during the handling of tanks by means of an instant/ automatic stop valve. The issue had arisen after safety advisers involved in the LNG transport chain had found that new tank designs are no longer being provided with automatic closing valves, possibly due to a misinterpretation of the existing provisions. Its paper stressed that, in the event of the rupture of pipework or hoses, or in a fire, it is essential that the flow of gas can be stopped immediately. The Netherlands noted that the carriage of refrigerated flammable gases is nothing new but that changes in the energy mix mean that more LNG is now being carried and, in the future, it is likely that liquefied hydrogen will become a more common cargo. While Chapter 6.8 is already currently under review, it was felt that this issue was so important it should be addressed independently.

The Joint Meeting agreed and adopted a new special provision in 6.8.4(b):

TE26 All filling and discharge connections, including those in the vapour phase, of tanks intended for the carriage of flammable refrigerated liquefied gases shall be equipped with an instant closing automatic stop-valve (see 6.8.3.2.3) as close as possible to the tank.

‘TE26’ is added in column (13) of the Dangerous Goods List against UN Nos 1038 (ethylene, refrigerated liquid), 1961 (ethane, refrigerated liquid), 1966 (hydrogen,

refrigerated liquid), 1972 (methane, refrigerated liquid – aka LNG), 3138 (ethylene, acetylene and propylene mixture, refrigerated liquid) and 3312 (gas, refrigerated liquid, flammable, nos).

This change has also necessitated two transitional measures: 1.6.3.59 Tank-wagons/Fixed tanks (tankvehicles) and demountable tanks constructed before 1 July 2023 in accordance with the requirements in force up to 31 December 2022, but which do not, however, meet the requirements of special provision TE 26 of 6.8.4 (b) applicable as from 1 January 2023 may continue to be used. 1.6.4.63 Tank-containers constructed before 1 July 2023 in accordance with the requirements in force up to 31 December 2022, but which do not, however, meet the requirements of special provision TE26 of 6.8.4 (b) applicable as from 1 January 2023 may continue to be used.

At this stage, no provisions have been agreed to require the retrofitting of stopvalves but this will be considered based on the outcome of the development of 6.8.3.2.3.

The UK continued to press its case for the inclusion in the new 1.8.6.2.1 of reference to the standard EN ISO/IEC 17065:2012 Conformity assessment – Requirements for bodies certifying products, processes and services. This would apply to the accreditation of inspection bodies for the purpose of authorisation and surveillance of in-house inspection services. The Joint Meeting confirmed that WP15 and the RID Committee of Experts’ standing working group had addressed the issue but also noted the comments that the issue being addressed is outside the scope of that standard. Rather, EN ISO/IEC 17021-1:2105 and a document from the European co-operation for Accreditation (EA) were more relevant. The Joint Meeting agreed to circulate a copy of this document to experts and to resume discussion at the next session.

The UK also commented that the notes to the new 6.8.1.5.1(a) and 6.8.1.5.4(a) adopted at the previous session of the Joint Meeting could be misinterpreted; it had brought the problem to an inter-sessional meeting of the informal working group on the inspection and certification of tanks (the ‘London Group’) and offered an amendment. However, that meeting felt that the UK’s suggestion might be consistent with the application of the amendments in RID but not necessarily so in the case of ADR. It asked the Joint Meeting to consider the issue, but that body felt that the general note to 6.8.1.5 in both RID and ADR is sufficient and prevails to both new notes.

FROM THE TANK EXPERTS Other matters pertaining to the use of tanks in the transport of dangerous goods were remitted to the Working Group on Tanks, which met for two days during the Joint Meeting session in a hybrid format.

The Working Group agreed with an argument from France that the requirements of 1.8.7.2.2.1 on the information that should be annexed to the type approval certificate would benefit from clarification. The Joint Meeting also agreed and amended the text of 1.8.7.2.2.1(f) to read: The data contained in the documents for the type-examination according to 1.8.7.8.1,

NEW PROVISIONS HAVE BEEN AGREED ON THE

CHECKING OF WELDS IN TANK SHELLS necessary for the identification of the type and variation, as defined by the relevant standards. The documents, or a list identifying the documents, containing the data shall be included or annexed to the certificate;

The Working Group had been asked to consider two papers on non-destructive checks of welds, on which the Joint Meeting had failed to reach consensus. This was meat and drink to the tank experts, who agreed some changes. In the second paragraph of 6.8.2.1.23, the last sentence is deleted and footnotes 6 and 7 are deleted. A new paragraph is added after the paragraph f or λ=1:

The non-destructive checks of the circumferential, longitudinal and radial welds shall be carried out by radiography or by ultrasound. Other welds allowed in the appropriate design and construction standard shall be tested using alternative methods in accordance with the relevant standard(s) referenced in 6.8.2.6.2. The checks shall confirm that the quality of the welding is appropriate to the stresses.

The Netherlands contended that the applicability of 4.3.2.2.3, concerning the maximum filling degree for substances carried at temperatures of 50°C or above, is

limited by its wording, which appears to prohibit an increase in temperature above the filling temperature. Its paper offered a clarification, which met with general support, and was adopted by the Joint Meeting for entry into force in 2025.

The International Union of Railways (UIC) questioned whether the holding time for refrigerated liquid gases should also be applicable to empty uncleaned tanks. The Working Group felt that it would be very difficult to determine a holding time in such cases but the European Industrial Gases Association (EIGA) noted that it is currently working on this question for the guidance document that is referenced in footnote 4 to 4.3.3.5(e). UIC and EIGA will work together and report back.

A number of other matters were brought to the Working Group to sound out opinions, some of which may return in the form of a formal proposal at a later stage. One worth noting was a paper from the International Tank Container Organisation (ITCO), alerting the meeting to work by the European Chemicals Agency (ECHA) that may result in a ban on the use of per- and polyfluoroalkyl substances (PFAS) in articles. There are some 4,700 PFAS substances that could be in scope of such a restriction, including polytetrafluoroethylene (PTFE), which has a wide range of uses, including in seals and gaskets used on transport tanks. The material is used due to its superior properties in providing a tight seal and chemical resistance, performs better than the asbestos seals it replaced and no equivalent alternative exists, ITCO said. The Working Party strongly advised concerned parties to respond to ECHA’s consultation, which is due to close in June or July this year, and also encouraged schemes for the environmentally sound recycling of used materials containing PTFE.

SETTING STANDARDS The Joint Meeting welcomed the regular report from the European Committee for Standardisation (CEN) on its ongoing work to publish new and revised standards relevant to the transport of dangerous goods. Those had been examined by the Working Group on Standards, resulting in a number of changes in Part 6, although some remain to be confirmed pending publication by CEN. If they were not available by the end of May, they would have to be held over to the 2025 editions of RID and ADR.

A new edition of EN 12245:[2022] is due out, applying to fully wrapped composite cylinders and referenced in the table in 6.2.4.1. Assuming this is published in time, applicability of EN 12245:2009 + A1.2011 will end on 31 December 2024.

Similarly, EN 14427:[2022] is due for publication. It is also referenced in the table in 6.2.4.1, referring to the design and construction of transportable refillable composite cylinders for LPG. If it is published in time, applicability of EN 14427:2014 will expire at the end of 2024.

EN ISO 17871:2020 on the specification and type testing of quick-release cylinder valves is already available so it is confirmed as appearing in the 2023 editions of RID and ADR; applicability of EN ISO 17871:2015 + A1.2018 will expire at the end of 2024.

EN ISO 14246:[2022] had not been published at the time of the Joint Meeting but again, assuming it does, it will overtake EN ISO 14246:2014 + A1.2017, which will expire at the end of 2024. This applies to manufacturing tests and examinations of cylinder valves.

There is a new row at the end of the table in 6.2.4.1 for EN ISO 23826:2021 – Gas cylinders – Ball valves – Specification and testing, which will apply mandatorily from 1 January 2025. This is also added to the tables in 6.8.2.6.1 and 6.8.3.6.

In the table in 6.2.4.2, the current entry for EN 1251-3:2000 will now expire at the end of 2024. A new row is added directly after for EN ISO 21029-2:2015, Cryogenic vessels – Transportable vacuum insulate vessels of not more than 1 000 litres volume – Part 2: Operational requirements, which will apply mandatorily from 1 January 2025. This entry also specifies that, clause 14 of the standard notwithstanding, pressure relief valves shall be periodically inspected and tested at intervals not exceeding five years.

There has been an update (A1:2021) to EN ISO 18119:2018, which will be added after the Who do you contact for the latest DG compliant labels?

Free DG Label ID poster with every order

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

THERE ARE THE USUAL NUMBER OF REVISIONS AND

ADDITIONS TO THE STANDARDS APPLICABLE TO GAS

CYLINDERS

existing entry with a changeover from 1 January 2025. This relates to the periodic inspection and testing of seamless steel and seamless aluminium allow gas cylinders and tubes.

EN ISO 22434:[2022] Gas cylinders – Inspection and maintenance of valves, and EN 14912:[2022] LPG equipment and accessories – Inspection and maintenance of LPG cylinder valves at time of periodic inspection of cylinders, were both awaiting publication at the time of the Joint Meeting. Should they appear in time they will both replace the earlier editions (EN ISO 22434:2011 and EN 14912:2005, respectively) as from the end of 2024.

Moving to Chapter 6.8, in the table in 6.8.2.6.1, EN 14025:2018 + AC:2020 is being updated, with a new edition due out this year; once more, should it appear in time it will replace the existing entry, with immediate applicability. This applies to the design and construction of metallic pressure tanks for the transport of dangerous goods.

In the same table, there is a pending update to EN 13094:2015, which will no longer apply after the end of 2024. An additional row is entered in the table for EN 13094:2020 + A1:[2022]. This standard relates to the design and construction of metallic gravity-discharge tanks.

Another revision awaiting publication at the time is EN 12252:[2022] on the equipping of LPG road tankers; the current 2014 edition will no longer be applicable after the end of 2024, should the new edition appear in time.

At the previous Joint Meeting in September 2021, France had expressed problems in applying EN ISO 11118:2015 Gas cylinders – Non-refillable metallic gas cylinders – Specification and test methods, which is referenced in 6.2.4. CEN reported that a task force has been convened to consider the issue and a report will be prepared, probably in time for the autumn 2022 Joint Meeting.

The UK reported that Chris Jubb (CEN) has decided to retire fully and will not longer be able to chair the Working Group on Standards, having been attending the Joint Meeting for 25 years. Andy Webb of the European Cylinder Makers Association (ECMA) was elected as his replacement.

INTERPRETATION OF RID/ADR/ADN The UN ECE has since 2016 published a list of ADR interpretations on its website and also offers interpretations of ADN; in both cases those interpretations are adopted and confirmed by the relevant regulatory bodies. The Netherlands, finding these useful, suggested to the RID Committee of Experts’ standing working group that OTIF should do the same for RID. However, that working group noted that most such interpretations are common between RID and ADR and suggested bringing the matter to the Joint Meeting.

In its informal document, the Netherlands made some relevant points about the availability of such interpretations, saying: “Although we are of the opinion that the provisions in RID/ADR/ADN should be written in such a way that its meaning and goal is clear for everyone and interpretations, in principle, should no longer be needed. Unfortunately, this is not always the case or possible. Therefore, knowledge on previous discussions and the rationale behind the decision for a provision is sometimes necessary in order to implement that provision correctly.”

Furthermore, the paper observed, a lot of the knowledge about the discussions and rationale behind decisions made on the provisions in RID, ADR and ADN rests in the collective minds of the members of the regulatory bodies and, unless this is written down, valuable expertise can be lost when members no longer participate.

The Joint Meeting was not keen on the idea. Firstly, regulatory interpretations are normally developed by the respective committee in charge of RID, ADR and ADN – although it

acknowledged that it would not be desirable if, say, RID and ADR had a different interpretation of the same provision. It also felt that, to avoid stakeholders having to search for guidance in different places, it would be cautious about publishing all its interpretations. The Netherlands representative said the comments would be reviewed and, if necessary, a further document may be presented at a future session.

The secretariat asked the Joint Meeting for its opinions on two special provisions: SP 532 (assigned only to UN 2073 ammonia solution, Division 2.2) and SP 543 (assigned only to UN 2672 ammonia solution, Class 8). These do not appear in the UN Model Regulations and do not impose any additional requirements, merely clarifying the classification of similar substances. However, they are not consistent and, the secretariat felt, could lead to misinterpretation. It was keen to hear if the Joint Meeting felt they could safely be done away with or if they warranted some amendment.

The Joint Meeting largely concurred: the assignment of the two special provisions is correct, although they could both benefit from some clarification. It was also noted that these special provisions were developed during the restructuring of the regulations in 2001, when a large number of marginals containing referenced to the assignment of other UN numbers were transferred into special provisions – it is likely that others would need to be reviewed. The Joint Meeting agreed to move forward in a step-by-step approach and asked the secretariat to bring an official document listing the best options for resolving the issue at the next session.

The Council on Safe Transportation of Hazardous Articles (COSTHA) came with two informal documents raising issues about deliveries direct to consumers. It noted that there are exemptions within ADR that limit the provisions that apply in such cases but there are some minimum requirements such as “suitable outer packagings” that might benefit from being clarified. For instance, COSTHA said, when limited quantity materials are packaged and consigned within an overpack, the regulations require that the overpack be marked with the LQ mark and the ‘Overpack’ mark. Parcel delivery and postal services commonly use a bag as a handling device during delivery operations – do such bags constitute overpacks within the meaning of ADR? If so, how to they differ from other handling devices or storage locations within a delivery vehicle? And is there any added safety benefit in requiring the bags to be marked in accordance with 3.4.11?

The Joint Meeting felt that, in the absence of detailed data and more examples of such deliveries, it was not in a position to advise. COSTHA invited delegates to get in touch with any comments and may return with a more detailed document at the next session.

COSTHA’s second paper referred to the rapid increase in online grocery delivery services during the current pandemic. While consumers buying goods such as aerosols, hair dyes, corrosive cleaning products and other items in scope of the regulations are exempted from compliance, does that still obtain when the goods are delivered by a commercial company? COSTHA posed some specific questions: must goods in such operations be packed in “suitable outer packaging”? Is a shopping bag considered an outer packaging or an overpack and, if the former, is it considered “suitable”? Would there be any benefit in making these operations subject to the regulations? COSTHA also offered some text that might clarify the matter.

Some delegates felt those proposed texts were too broad and also might lead to misinterpretation, though there was clearly an acceptance of the need for some action. More time was needed to study the issues, though. COSTHA again invited delegates to send comments and also said it was proposing to put a paper to the UN Sub-committee of Experts on the subject.

PENDING ISSUES The International Association of Dangerous Goods Safety Advisers (IASA) returned to a topic it had raised at the previous session without success, namely its appeal to broaden the scope of special provision 668, which was

Who do you contact for the latest DG compliant labels? Free DG Label ID poster with every order

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com www.labeline.com Who do you contact for DG Regulations?

IATA’s Leading Distributor

Free Worldwide Shipping on the 63rd Edition

ADR available in spiral format

***NEW***

IATA available in spiral format

A Guide to Exemptions from the International Carriage of Dangerous Goods by Road 5

th Edition

ROGER WRAPSON

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

introduced in RID/ADR in 2017 to provide relief from the regulations for substances carried at elevated temperatures for the purpose of road marking. IASA could see no reason why the same relief should not be provided for elevated temperature substances used for road repairs or other construction work.

Most delegates felt that the scope of the document was too broad; following an exchange of views, IASA offered to develop its proposal and return with a revised paper at the September 2022 session.

EIGA fared no better with its proposal to amend the note relating to EN ISO 18119:2018 in 6.2.3.5.1 and 6.2.4.2 of RID/ADR, many delegates being unmoved by the justification offered for allowing cylinders with a wall thickness less than the current minimum to be subjected to periodic inspection. EIGA offered to speak with those who raised concerns and may prepare an updated proposal for the next session.

Sweden proposed the insertion of new provisions to clarify the conditions for the carriage by road and rail of electric energy systems containing lithium ion batteries. The Joint Meeting noted some general comments and concerns, though France presented an informal document detailing a recent study on how to define an exemption threshold for batteries based on their energy content. This seemed to point a way forward and the Joint Meeting agreed to set up an informal working group on different exemptions related to the carriage of batteries.

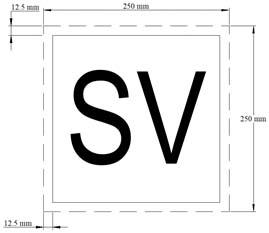

Perhaps the most far-reaching decision made by the Joint Meeting was the adoption of a new marking for tanks carrying flammable liquefied gases that are fitted with safety valves. The amendment results from discussions by the BLEVE working group to prevent boiling liquid expanding vapour explosion (BLEVE) events occurring in the event of a fire during the transport of flammable gases and liquids. There is now a mandatory requirement for tanks transporting flammable liquefied gases to be fitted with safety valves and, to aid the emergency services, it has been deemed desirable to add provisions for such tanks to be clearly marked. That will now appear in a new section: 6.8.3.2.9.6 Safety valve mark 6.8.3.2.9.6.1 Tanks fitted with safety valves in accordance with 6.8.3.2.9.1 to 6.8.3.2.9.5 shall display the mark as set out in 6.8.3.2.9.6.3 to 6.8.3.2.9.6.6. 6.8.3.2.9.6.2 Tanks not fitted with safety valves in accordance with 6.8.3.2.9.1 to 6.8.3.2.9.5 shall not display the mark as set out in 6.8.3.2.9.6.3 to 6.8.3.2.9.6.6. 6.8.3.2.9.6.3 The mark shall consist of a white square with minimum dimensions of 250 mm × 250 mm. The line inside the edge shall be black, parallel and approximately 12.5 mm from the outside of that line to the outside edge of the mark. The letters “SV” shall be black, a minimum of 120 mm high and have a minimum stroke thickness of 12 mm.

Paragraph 6.8.3.2.9.6.4, covering the marking of tanks with a capacity of less than 3,000 litres, differs between RID and ADR; RID thus far applies only to tank containers, while ADR covers both demountable tanks and tank containers.

Subsequent paragraphs give the standard provisions regarding weather-resistance and ability to withstand 15 minutes’ engulfment in fire. The mark will have to be displayed on both sides and both ends of tank containers, though for those of less than 3,000 litres capacity it will only need to be on two sides or ends. The same applies to demountable tanks under ADR. Also in ADR, fixed tanks (tank

Who do you contact for Who do you contact for the latest DG compliant vehicles) will be required to display the mark DG Regulations? labels? on both sides and at the rear. RID has not confirmed the position for tank wagons: a requirement for the mark to be displayed on both sides is currently left in square brackets pending a decision by the RID Committee of IATA’s Leading Distributor Experts’ standing working group. Free Worldwide Shipping on the 63rd Edition The new provisions have necessitated the agreement of transitional provision in 1.6.3.60 ADR available in and, for tank containers, 1.6.4.64 to allow spiral format existing tanks to go without the mark until their next intermediate or periodic inspection after 31 December 2023 (this version for RID ***NEW*** remains to be confirmed). NEW PROPOSALS IATA available in Germany proposed an amendment to special spiral format provision 376, which deals with damaged and defective lithium batteries. SP 376 had been brought into RID/ADR/ADN directly from the UN Model Regulations but it lacks any clarity over the assignment of transport categories, which is needed to apply the provisions of 1.1.3.6 in RID and ADR. While there was some support for the principle of the proposal, many felt that further consideration was needed on the possible side-effects of any change. There was also some preference for a new special provision rather than an amendment. Germany volunteered to work on an updated proposal for consideration at the next session. It was also agreed that the UN Sub-committee of Experts should be advised of any amendments once agreement has been reached. Norway and Sweden brought up an issue that they had already taken to WP15, where it was suggested that, as it applies to RID as well, it should be discussed by the Joint Meeting. This involves 1.10.4 and 1.1.3.6. The first sentence in section 1.10.4 exempts dangerous goods carried in accordance with 1.1.3.6 from the provisions in Chapter 1.10. However, when 1.1.3.6 is applied section 1.10.4 is not applicable. This makes the sentence redundant. Further, the second sentence of 1.10.4 deals with carriage in bulk and tanks in volumes not exceeding those in

You need Labeline.com

Labeline is the leading worldwide “One Stop Dangerous Goods Service” for Air, Sea, Road, and Rail

We serve Freight Forwarders, Shippers, Airlines, DCA’s, Port Authorities, Petrochemical industry and the Pharmaceutical industry.

Labeline is one of the world’s leading regulatory services and product provider; we hold comprehensive stocks with a fast worldwide delivery service.

We are one of the very few authorised Multi-mode providers worldwide and described by industry as a pro-active organisation, our name is recommended by many leading authorities and a world class service providers.

When it’s time to order your DG products and services, Labeline will be your “One Stop Service”

Compliant with IATA, ICAO, ADR, IMDG, RID, DoT

Free DG Label ID poster with every order

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

A Guide to Exemptions from the International Carriage of Dangerous Goods by Road 5

th Edition

ROGER WRAPSON

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com Dangerous Goods Labels Regulations Documentation Packaging Software Training GHS Chem Regs

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

1.1.3.6, which seems inconsistent.

The paper received several comments with differing views. Norway and Sweden agreed to take those into account in the development of a revised proposal for consideration at the September 2022 session.

Sweden came with a proposal based on information received from the waste industry, concerning problems relating to the handling and transport of waste paint products. Historically, most paint products have been classified under UN 1263 due to their flammable ingredients but, as industry has moved away from solvent-based paints to water-based formulations, a large proportion of paints are now transported under UN 3082. Special provision 650 was added to RID/ADR in 2005 specifically to clarify the transport of wastes of UN 1263 and Sweden believed it would be sensible to extend its provisions to cover those of UN 3082.

The Joint Meeting welcomed Sweden’s initiative and agreed the changes, following some amendment. That involves some additional wording in SP 650 to include reference to wastes involving paint under UN 3082 along with the insertion of ‘650’ against UN 3082 in the Dangerous Goods List. These amendments will enter into force with the 2025 edition of the regulations, though a multilateral agreement is planned to allow their use before then.

The Netherlands had spotted a need for a transitional provision following the inclusion in the 2021 texts of RID and ADR of new requirements for the marking of the inner receptacles of composite intermediate bulk containers (IBCs) as there are many such units in use manufactured prior to the change that comply with the regulations in all other ways. The Joint Meeting agreed and added the proposed measure at 1.6.1.52:

Inner receptacles of composite IBCs manufactured before 1 July 2021 in accordance with the requirements of 6.5.2.2.4 in force up to 31 December 2020 and which are not in accordance with the requirements of 6.5.2.2.4 regarding the marks on the inner receptacles that are not readily accessible for inspection due to the design of the outer casing applicable as from 1 January 2021 may continue be used until the end of their period of use determined in 4.1.1.15.

OTHER BUSINESS The Joint Meeting received an update on progress by the informal working group on the transport of hazardous waste, which hopes to bring its mandate to a close at its next meeting.

The informal working group on e-learning held two lunchtime meetings during the session and will continue its work intersessionally. More information will be provided to the Joint Meeting at its next session.

ERA provided an update on the development of the Risk Management Platform aimed at facilitating the implementation of the risk management framework for the transport of dangerous goods that will be referenced in Chapter 1.9 of the 2023 editions of RID, ADR and ADN. The platform will be made publicly available through the European Commission.

The UK raised a question about the transport of electric vehicles on car transporters, after a transport company had asked whether such consignments needed marking. The UK felt they did not but sought other opinions. In the event, the Joint Meeting agreed with the UK and no action was taken.

The next session of the Joint Meeting is scheduled to take place in Geneva from 12 to 16 September 2022. It was also noted that the next meeting of the Ad Hoc Working Group on the Harmonisation of RID/ADR/ADN with the UN Recommendations on the transport of Dangerous Goods is due to take place in Geneva from 26 to 28 April 2023.