4 minute read

News bulletin – industrial packaging

NEWS BULLETIN

INDUSTRIAL PACKAGING

MORE FROM MAUSER

Mauser Packaging Solutions is making significant investments in state-of-the-art equipment to more than double production capacity of quart and gallon-sized F-style metal cans at its Memphis, Tennessee facility. The line was only opened last August but this new project will optimise raw material usage, reduce waste, reduce energy consumption, provide enhanced safety features, and offer significantly higher productivity levels, the company says.

The F-style cans are designed for packaging solvents, such as paint thinner, charcoal lighter fluid, chemicals and other products. Cans contain a minimum of 25 per cent recycled content and are 100 per cent recyclable after use, Mauser says.

Mauser has also introduced a new aluminium easy-peel valve seal for its intermediate bulk containers (IBCs). Such seals alert users to potential product tampering or contamination but often require a knife to remove and can leave behind residue that mixes with the product being dispensed. Mauser’s new aluminium IBC valve seal can be peeled off by hand and the design eliminates the risk of glue or metal residue contaminating products. The new seal is being rolled out globally this year and is available for use with 2- and 3-inch butterfly valves. www.mauserpackaging.com

BIGGER TRUCKS FOR IBCS

Schütz has begun using ‘Ecoliner’ trucks (below) to deliver IBCs from its plant in Selters to BASF in Ludwigshafen, Germany. The trucks, supplied by its logistics partner Haaf, can carry 112 empty IBCs, halving the number of trips needed to deliver new IBCs and reducing both costs and CO2 emissions.

“IBCs are a commonly used form of packaging. The square shape allows IBCs to be stacked and transported in a way that saves space,” notes Angela Giubilaro, global category manager, IBCs and HDPE drums at BASF. “Even with these advantages, logistics costs play a major role, which is why we have been working with suppliers and forwarders on the long truck project since 2017. When fully loaded, thanks to the larger volume, only half as many trips are required as with conventional trucks, which is very resource-saving.” www.schuetz.net

GREIF FOCUSES ON INDUSTRY

Greif has entered into a definitive agreement to sell its Consumer Packaging Group (CPG) business to Graphic Packaging Holding for $85m cash. The proceeds will be used to pay down debt.

“We are pleased with the conclusion of the CPG strategic review process,” says Pete Watson, Greif’s president and CEO. “The sale of CPG allows us to de-lever our balance sheet and optimise capital allocation plans. By divesting these assets, we can refocus our business on our core industrial franchise and our stated strategic growth priorities in IBC production and reconditioning and containerboard integration.”

Greif is also installing a blowmoulding machine at its Merced facility in California, which will increase production of plastics drums for the local market; it is due online in the second quarter of this year. The machine will allow Greif to focus on servicing the growing market for both open-head and tight-head plastic drums in various sizes.

“We will continue to invest and grow with our customers to support their increasing needs while shortening lead times,” says Kevin Kling, plastic & IBC development director for Greif. www.greif.com

VASKERIET ACQUIRED BY MJ

MJ Plastics, which invests in companies active in plastics recycling and the circular economy, has acquired the Danish company Emballage Vaskeriet, a reconditioner of IBCs, drums and jerrycans for the chemical industry.

“Our strategy is to invest and develop the company,” says Martin Schack Staffeldt, director of MJ Plastics. “We want to offer our customers new sustainable and innovative best-in-class recycling services, focusing on circular economy. We want to help our customers and meet the new EU packaging directive on extended producer responsibility which goes into force in 2025, and make a difference.”

In the short term, this will involve investing in machinery and equipment to offer new services in plastics recycling, documentation on CO2 emissions control, safety and

quality, according to Jacob Kunøe, director of MJ Plastics. emballage-vaskeriet.dk

MORE INFO FROM ISDI

The Industrial Steel Drum Institute (ISDI) has released a new video, Tips for Buying New Steel Drums, that will answer a lot of frequently asked questions. “There are many attributes of a steel drum that can be adjusted based on your needs,” says Susan Nauman, executive director of ISDI. “What we’ve found is that many people don’t know the options available to them or know what will work best for them and their product. In our new video, we detail everything from regulations and ratings to drum and hoop styles all in an effort to help make the decision-making process as simple as possible.” whysteeldrums.org

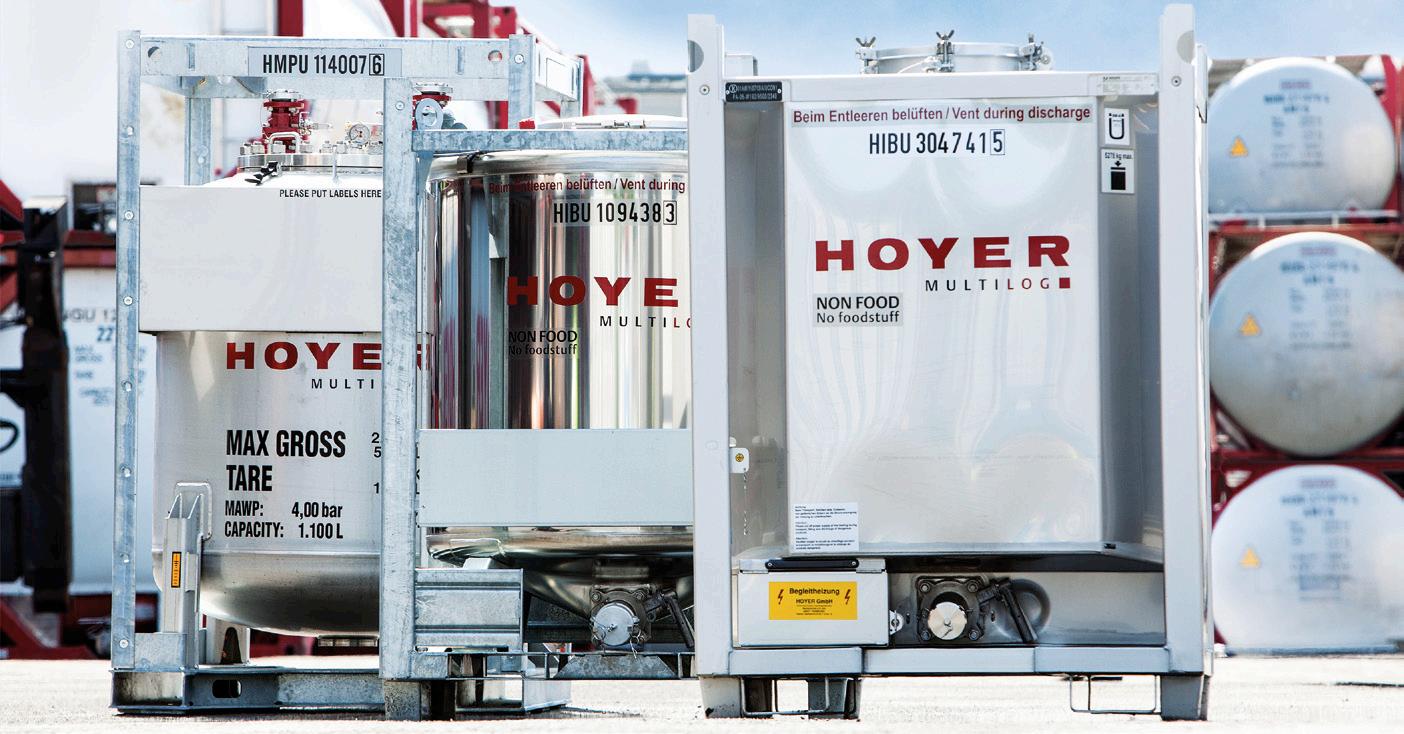

HOYER BIG IN IBCS

Hoyer’s IBC fleet has grown to 50,000 units, more than double the size of five years ago. Hoyer says it is experiencing strong demand for heated IBCs for the food industry, cylindrical containers for the paints and coatings sector, and mini pressure tanks for the transport of special chemicals. Hoyer’s stainless steel IBCs are available in sizes ranging from 500 to 1,110 litres and are mainly deployed in China, Europe and the US.

“The requirements of IBCs in terms of their features are growing. We meet these not only with the right equipment, but also with comprehensive services which ensure the quality and safety of the product as well as efficient planning and delivery,” say Stephanie Muhs, director of IBC Logistics at the Hoyer Group. www.hoyer-group.com