6 minute read

Industry tackles plastics pollution

EVERGREEN AMBITIONS

SUSTAINABILITY • INDUSTRY IS GENERATING MOMENTUM IN THE FIGHT TO COMBAT PLASTIC POLLUTION ACROSS ALL SECTORS THROUGH INNOVATION AND COLLABORATION

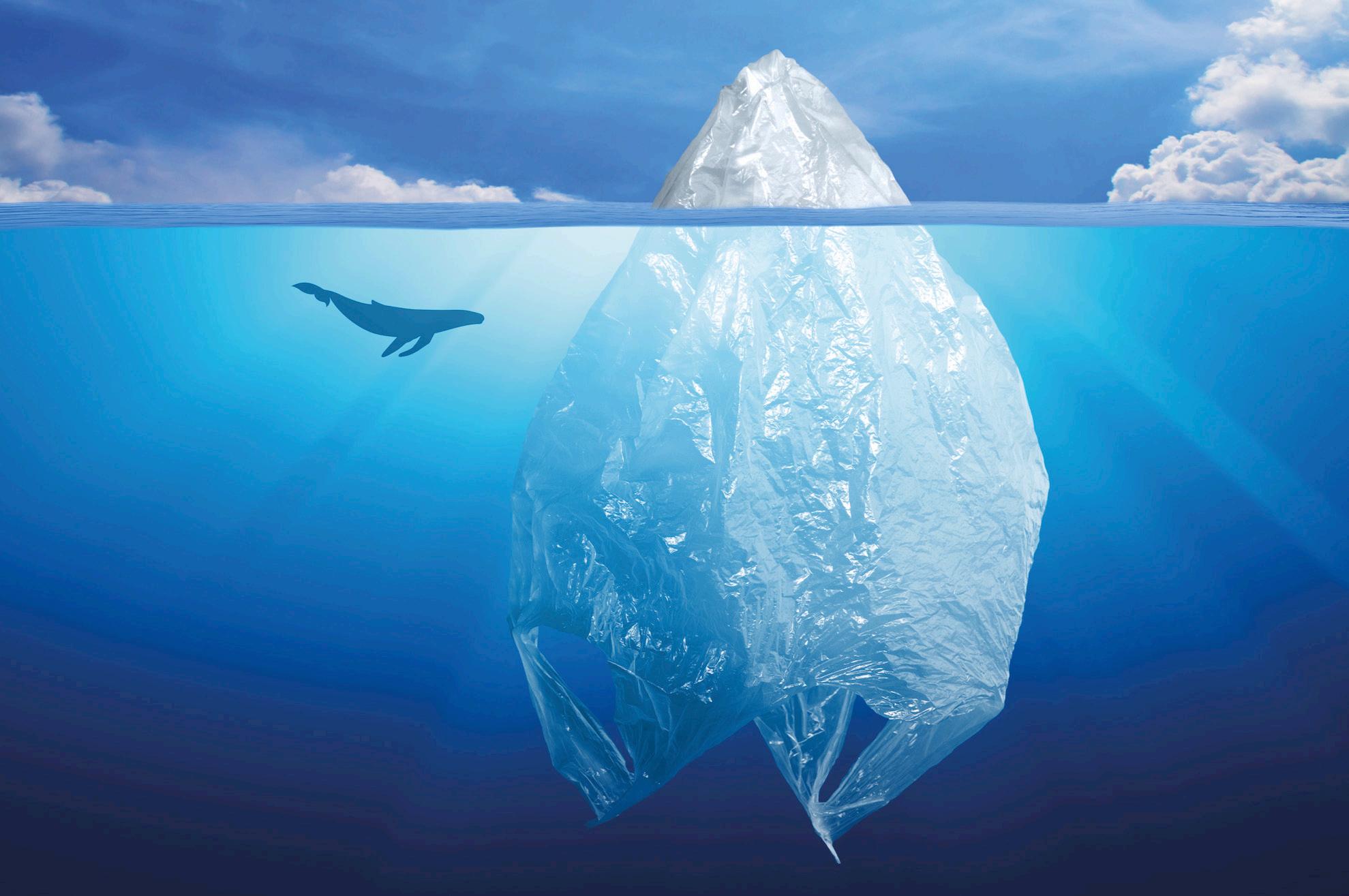

THERE IS ARGUABLY no greater challenge facing the world, and the petrochemical industry in particular, than the need for sustainability and being able to extract the most from materials without generating waste. The world has experienced a rapid growth in demand in middle-class and industrial economies that has led to a sharp increase in plastics consumption, with recycling development unable to keep pace. The result has been a dramatic volume of waste plastics inadvertently ending up in key ecosystems.

Being able to stop product loss at the point of manufacture and ultimately reusing plastics packaging are key parts of achieving sustainability targets, but there are hurdles to overcome, particularly as there are legitimate health risks concerning crosscontamination in the reuse of plastics.

Fortunately, drastic steps are being taken by businesses across the industry, such as committing to large-scale initiatives and working with different authorities. Many businesses that are holding the torch for others by implementing new procedures and assisting in wider clean-up efforts are being rewarded for their innovative efforts.

A GREATER GOAL One of the leading programmes that businesses are signing up to is Operation Clean Sweep (OCS). The goal of OCS is to help every plastic resin handling operation to develop and implement the highest quality good housekeeping protocols and exemplary pellet, flake and powder containment practices. Ultimately, this will lead to achieving zero pellet, flake and powder loss, which will protect the environment and save participating companies valuable resources.

Spilled pellets, flakes and powder can unfortunately make their way into local waterways and enter estuaries and the ocean. This is not just an eyesore but a serious health hazard. If these products are accidentally mistaken for food by birds or marine animals it can frequently cause harm to them and can remain in the food chain for many years, even contaminating food for people.

The approach set out by OCS involves all companies along the plastics supply chain and obliges them to take preventive measures, as it is only through the cooperation of all partners that these ambitious and essential targets will be met.

OCS has been operating for several years and Bertschi was one of the first logistics service providers to sign the OCS commitment in 2016. Since then, Bertschi has been continuously developing and expanding its efforts surrounding critical points such as terminals, warehouses and transhipment points. In recognition of its exemplary performance as part of the OCS initiative, Bertschi and its subsidiary Nordic

Bulkers recently received the OCS Award from plastics manufacturer Biesterfeld.

There are other large initiatives that are working diligently to right the wrongs of plastics pollution, including the not-for-profit Alliance to End Plastic Waste (AEPW), which is being strongly supported by the international chemical industry. “History has shown us that collective action and partnerships between industry, governments and non-governmental organisations (NGOs) can deliver innovative solutions to a global challenge like this,” says Bob Patel, CEO of LyondellBasell, a member of AEPW. “The issue of plastic waste is seen and felt all over the world. It must be addressed and we believe the time for action is now.”

This view is echoed by David Taylor, chairman of the board, president and CEO of P&G: “Everyone agrees that plastic waste does not belong in our oceans or anywhere in the environment. This is a complex and serious global challenge that calls for swift action and strong leadership. This new alliance is the most comprehensive effort to date to end plastic waste in the environment. I urge all companies, big and small and from all regions and sectors, to join us.”

WINNING IDEAS Other bodies are also leading the charge for environmental protection and cleaning up work areas. One notable example of this can be found at the Port of Antwerp where a clean-up campaign at the Galgeschoor Nature Reserve takes place every year with the aim of removing huge quantities of historic plastics pollution that has ended up in the waters and accumulated over the years. This year, more than 400 volunteers collected no less than eight tonnes of waste – an impressive feat.

However, millions of small plastic particles remain that cannot be removed by hand. These minute pieces of plastic can be some of the most damaging and are the result of historical pollution from industrial plastic pellets that have been lost from companies or ships, nestling in the vegetation layer over the years.

In an attempt to tackle this problem at the source, the Port of Antwerp and the entire plastics sector came together under the Operation Clean Sweep charter two years ago. The aim was to reach “zero pellet loss”, with participating companies pledging to reduce the loss of pellets to the absolute minimum.

Despite this, more was needed to remove the tiniest pieces of plastic that polluted the area. In response, the Port of Antwerp created the Plastic Challenge, in which participants are challenged to come up with ways to remove these plastics that are feasible in technical, budgetary, logistical and environmental terms. The Plastic Challenge is a great concept to bring businesses together and participate in something that will not only assist the environment, but also benefit the wider industry and all those who use the Port of Antwerp’s facilities.

A total of 55 proposals have been submitted, both from companies and from private individuals in Belgium and abroad, and the winner will be announced 19 December. “We are very satisfied with the high-quality entries that testify to the enthusiasm and commitment for this competition,” says Erwin Verstraelen, chief digital and innovation officer at the Port of Antwerp. “Many feel they are being asked to approach the problem of plastic pellets in the port with a fresh perspective and to come up with possible solutions. What we are creating here is socially relevant and very important for lasting support: innovation with a purpose.”

Based on feasibility, three of the entries have been short-listed, all of which are based on the principle of vacuuming and removing the pellets by suction. The nominated entries come from Arcadis, Deme Group and Envisan (Jan De Nul Group). A jury will decide which is the most creative, promising and feasible proposal. The winner will receive a prize of €10,000 and the Port of Antwerp will assist the winner in implementing the concept.

There is of course no doubt that the use of plastics has been monumental in improving life around the globe. The development of plastics has led to incredible evolutions in living standards, hygiene and nutrition, but the detrimental effects plastics and microplastics are having on the environment are undeniable. Thanks to initiatives such as OCS and AEPW and the efforts of businesses such as the Port of Antwerp and Bertschi, big strides are being taken in reducing plastic pollution and developing industry methods that will limit any potential damage in the future. bertschi.com www.portofantwerp.com/en/galgeschoorplastic-challenge endplasticwaste.org

RECENT PUBLICITY OVER THE IMPACT OF PLASTICS

POLLUTION IN THE WORLD’S OCEANS HAS CONCENTRATED

THE MINDS OF THE PUBLIC AND THE PETROCHEMICAL