10 minute read

INNOVATIONS TO SECURE THE FUTURE OF CANADA’S OIL SANDS INDUSTRY IN A NET ZERO EMISSION WORLD

INDUSTRY BRIEF

Innovations to Secure the Future of Canada’s Oil Sands Industry in a Net Zero emission World

Advertisement

BY DR. JOHN ZHOU, VP CLEAN RESOURCES, ALBERTA INNOVATES

INTRODUCTION

Governments and businesses around the world have been making pledges to reduce greenhouse gas (GHG) emissions to net zero. Net zero emissions (NZE) for a country, business or other entity means it will either emit no GHG emissions or completely offset its emissions.

Society will continue to demand crude oil and natural gas while the energy transition takes place and in an NZE world. The future of the hydrocarbon industry in an NZE world may be secured if NZE can be achieved across the life cycle of production through to consumption of the oil and gas.

The combined environmental, social, and governance (ESG) performance of the oil sands industry has improved over recent decades to become one of the best in the world (Dziuba et al., 2021.). GHG emission intensity in oil sands production decreased by 20% between 2009 and 2018 (IHS Markit, 2018) and the emissions intensity from some large oil sands assets is comparable to the average U.S. barrel of oil (Sleep et al., 2020). However, the growth of the oil sands industry production has been outpacing the rate of decrease in GHG emissions intensity, so absolute GHG emissions in oil sands production have been increasing. Total GHG emissions from oil sands extraction were 83 million tonnes in 2019, representing 11 per cent of Canada’s overall GHG emissions (Environment and Climate Change Canada, 2021).

This paper highlights a range of key innovations required for the oil sands industry to achieve NZE from production to end use. Emphasis is placed on direct GHG emissions (Scope 1) created during the production of bitumen and fuel production. Indirect GHG emissions (Scope 2) in bitumen and fuel production operations (typically utilities provided to the operations), and emissions from product consumption (Scope 3) will also be discussed.

Follow-up papers are to be developed for presentation of detailed information on selected areas identified in this high-level summary.

Decarbonizing Bitumen and Fuel Production Processes

In the coming decades of energy transition, while there are still large demands for oil, bitumen can be positioned as the preferred barrel by targeting bitumen as “the NZE crude oil” or the crude oil with the lowest GHG production intensity. Bitumen-to-fuel refinery processes will also require decarbonization.

Recently, six oil sands operators, representing 95% of Canada’s total bitumen production, committed to the goal of achieving net-zero emissions from the companies’ oil sands operations by 2050 (https:// www.oilsandspathways.ca/). Their Oil Sands Pathways to Net Zero initiative will position Canada as the supplier of choice for responsibly produced oil needed to meet the world’s energy demand.

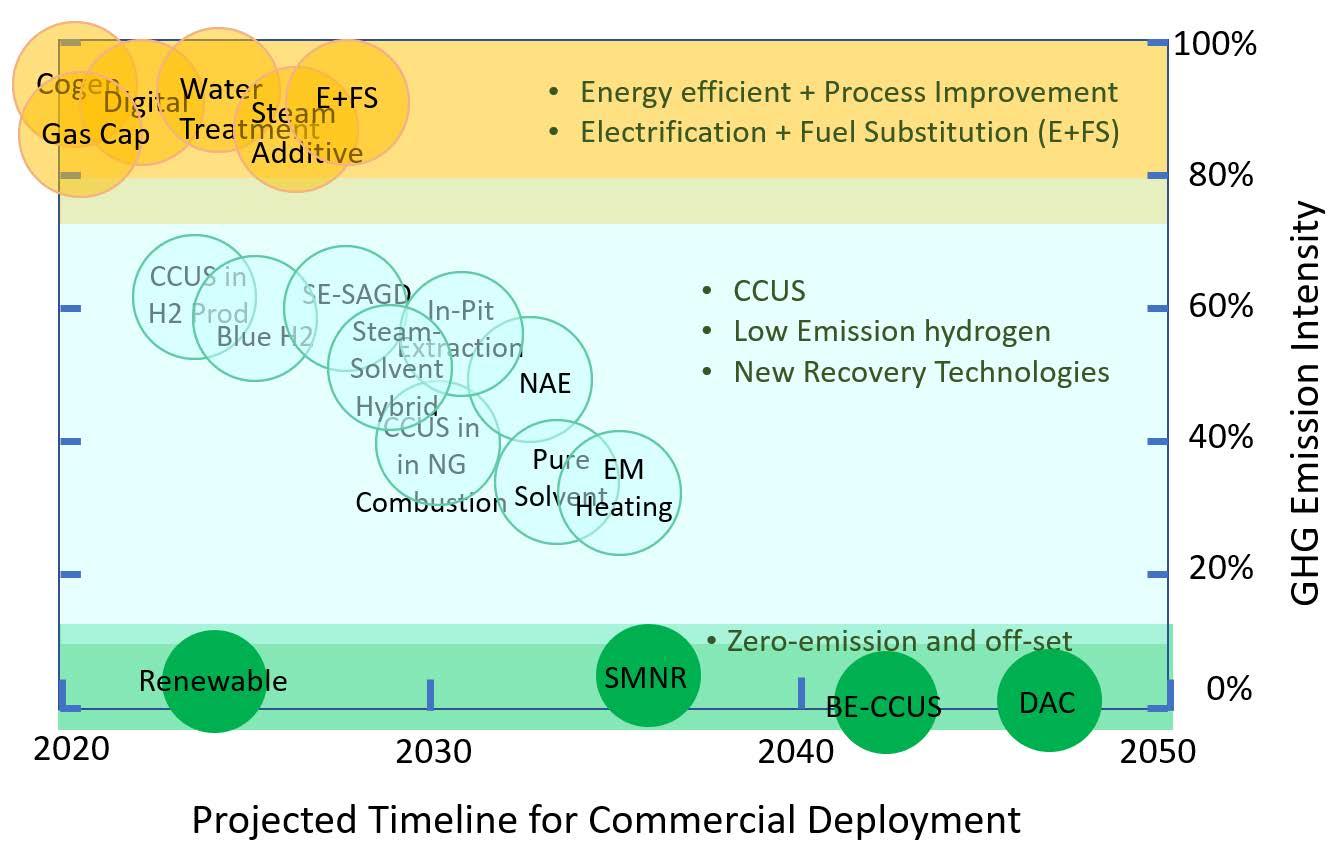

Significant technology developments in last 15 years have enabled meaningful reductions of GHG emissions from oil sands production. Continued future GHG emission reductions in the industry can be achieved through combining multiple innovations in the next two-tothree decades, including:

- Energy efficiency and process improvements, particularly for in situ projects. These include increased use of cogeneration, more energyefficient water treatment and steam generation, digital oilfield tools, steam additives, non-condensable gas cap, etc. In combination, these may lead to up to a 20% reduction in upstream direct GHG emissions.

- Electrification and fuel substitution in drilling, mining equipment and vehicles, etc. In oil sands mining, these have the potential to reduce upstream GHG emissions by more than 10%.

- Carbon capture, utilization, and storage (CCUS). Natural gas combustion is responsible for 50 - 85% of direct GHG emissions in bitumen production. CCUS has the potential to greatly reduce such emissions. CCUS has been commercially demonstrated for flue gases with high CO2 concentrations in emissions from upgrading and refinery facilities; however, CCUS requires more development and demonstration for applications at lower CO2 concentration streams from natural gas combustion (once-through steam generators, co-generation, and natural gas combined cycle).

- Low emission hydrogen including blue hydrogen produced from natural gas coupled with CCUS. Blue hydrogen may reduce GHG emission by 50% in upgrading and refinery processes.

- New recovery technologies. These include non-aqueous extraction (NAE) and in-pit extraction in mining processes, and solvent enhanced SAGD, steam-solvent hybrid, pure solvent, and electromagnetic heating assisted recovery for in situ production.

These technologies have the potential to achieve 20 - 90% direct upstream GHG emission reductions. Most of them will require further development and commercial demonstration. The technologies summarized above will not be able to achieve complete NZE in bitumen and bitumen-derived fuel production. At a high level, these technologies address only direct (Scope 1) GHG emissions in bitumen and fuel production and none can achieve 100% Scope 1 emissions reduction. None of the above technologies addresses indirect (Scope 2) emissions that include imported electricity, indirect natural gas, diesel, gasoline, and diluent, land use, fugitive emissions, etc., that may contribute up to 50% of the total upstream emissions (Sleep et al., 2020).

To achieve NZE in bitumen and fuel production, additional zero-emission and off-set technologies are required. These technologies include renewables, small modular nuclear reactors (SMNRs), bioenergy CCUS (BE-CCUS), and direct air capture (DAC).

- Renewable energy can be used for oil sands operation. At least one project is already underway to use solar energy at a refinery (Shell Canada, 2021).

- Oil sands and pipeline companies are studying the feasibility of SMNRs in oil sands operations. SMNR technology is getting mature and would meet the needs for heat and power in oil sands operations. SMNRs also can help reduce Scope 2 emissions for oil sands operations.

- Oil sands companies have been producing biofuels and are adding more capacity. Bioenergy production fitted with CCUS can result in overall negative emissions. BE-CCUS can be either on-site, or off-site to generate off-set credits for oil sands operations.

- DAC can generate negative emissions and therefore offsets for oil sands emissions. However, DAC operation is energy intensive. The data provided by a leading developer (Keith et al., 2018) indicate that a one megatonne per year emissions reduction will require 366 GWh electricity plus 5,250,000 GJ natural gas. If the electricity is provided by solar, a 278 MW photovoltaic solar facility will be required to provide the electricity.

Projected timelines for commercial deployment of various emission reduction technologies are illustrated above. Most energy efficient and process improvement technologies (located in the top, yellow area of the diagram) are commercial, but need to be more widely deployed to impact emissions.

Technologies identified in the blue mid-zone can contribute to emissions reduction in the oil sands industry as they are commercialized, but not all technologies will be successful or be deployed on the projected timeline.

Considering the magnitude of emissions reduction required, CCUS and SMNR (in the bottom green zone of the diagram) are particularly important high-impact pathways for oil sands to reach NZE.

Product Diversification Towards Net Zero

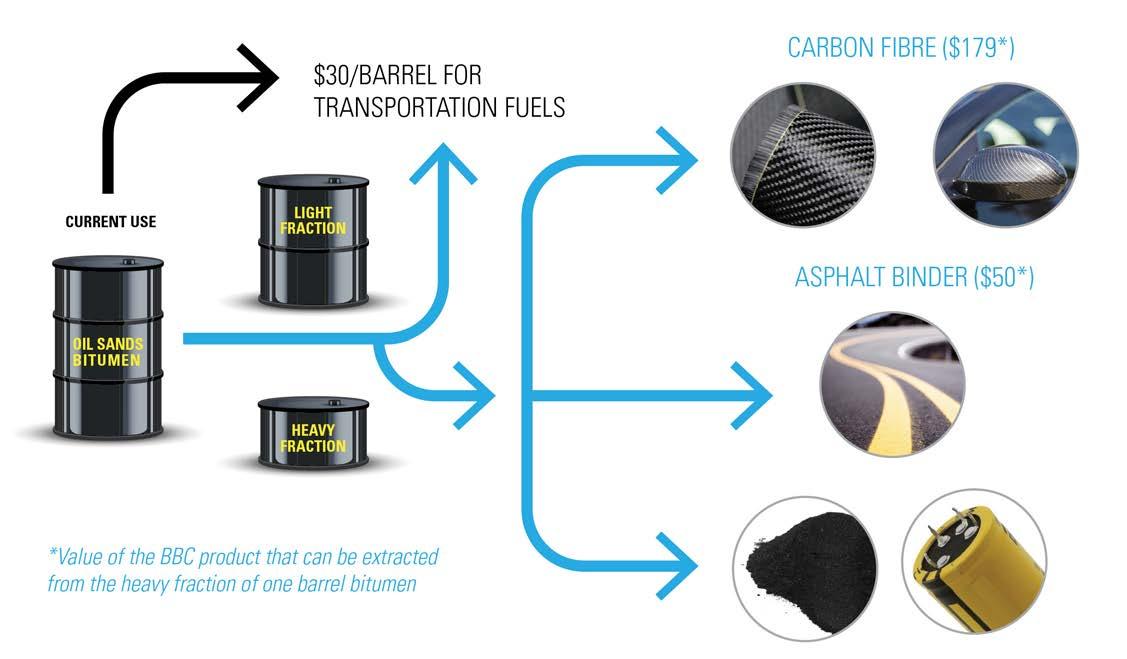

The discussion so far applies entirely to Scope 1 and 2 emissions. The long-term viability of the oil sands industry will require Scope 3 emissions reduction and can be improved if bitumen is used to make non-combustion products. Bitumen beyond combustion (BBC) provides the industry an opportunity to diversify and grow during energy transition and even in an NZE world (Alberta Innovates, 2021).

The central concept of BBC is that the heavy fraction in bitumen will be diverted from fuels production and instead be used to make materials and products of high value and with growing demand around the world. Key BBC products include carbon fibre, asphalt binder, and high-value carbon materials such as activated carbon, graphene, carbon nanotubes, metal carbides and synthetic graphene.

In BBC, the heavy fraction in bitumen becomes an asset instead of a value discount, and carbon from the bitumen remains sequestered within the products and is not released to the atmosphere through combustion. Although at the early stage of development, significant progress has been made in BBC. Commercial demonstrations are taking place for asphalt binder and activated carbon production from bitumen. A dozen technology pathways are being pursued to produce carbon fibre using asphaltene.

BBC products can make transportation more energy efficient, infrastructure less energy-intensive and long-lasting, and renewable electricity generation and energy storage more economic. Instead of contributing to the emissions problem, bitumen can contribute to energy efficiency solutions.

The value creation potential in BBC is significant – BBC could create a multibillion-dollar industry in Canada. In the near- and mid-term, BBC represents a diversification and value-add opportunity for the industry. By its role in addressing Scope 3 emissions, BBC may provide a pathway for long-term sustainability of the oil sands industry in NZE scenarios.

The comprehensive November 2021 Alberta Innovates report, entitled “BITUMEN BEYOND COMBUSTION I How Oil Sands Can Help the World Reach Net-Zero Emissions and Create Economic Opportunities for Alberta and Canada” can be accessed here.

Summary

Although there will be continued demand for oil and gas in the coming decades, the world is transiting its economy toward net zero emissions. The long-term sustainability of oil sands depends on industry’s ability to be a global leader in producing clean hydrocarbons from source to end use.

Innovation has been a key enabler of oil sands development to date and created the oil sands as a major economic driver for Canada today. Future innovation can help the industry to achieve net zero emissions in bitumen production and fuel production, and innovation in BBC specifically can help secure a prosperous future for the oil sands industry in a net zero emission world.

References

Alberta Innovates (2021). Bitumen Beyond Combustion: How Oil Sands Can Help the World Reach Net-Zero Emissions and Create Economic Opportunities for Alberta and Canada. https://albertainnovates.ca/wpcontent/uploads/2021/11/AI-BBC-WHITE-PAPER__WEB.pdf

Dziuba, J. et al (2021). Survivor Canada: The Unparalleled Position of Canadian Oil in a Transition Challenge. BMO Equity ResearchCapital Markets. https://research-ca.bmocapitalmarkets.com/ documents/6252713E-D2A4-482B-A9A2-B99FE0A4F4AF.PDF

Environment and Climate Change Canada (2021). National Inventory Report 1990–2019: Greenhouse Gas Sources and Sinks in Canada. Government of Canada. https://publications.gc.ca/collections/ collection_2021/eccc/En81-4-2019-1-eng.pdf I

HS Markit (2018). Greenhouse gas intensity of oil sands production today and in the future.

Keith D.W., Holmes, G., St. Angelo, D., Heidel, K. (2018). A Process for Capturing CO2 from the Atmosphere. Joule, Vol 2., 1573-1594. https://doi. org/10.1016/j.joule.2018.05.006 S

leep S., Dadashi Z., Chen Y., Brandt A.R., MacLean, H.L., Bergerson, J.A. (2020). Improving robustness of LCA results through stakeholder engagement: A case study of emerging oil sands technologies. Journal of Cleaner Production, Vol. 281.

Shell Canada (2021). https://www.shell.ca/en_ca/about-us/projects-andsites/scotford/shell-and-silicon-ranch-to-build-solar-project-in-canada. html.

Zhihong (John) Zhou Ph.D., P.Geol.

John is the vice president, Clean Resources at Alberta Innovates and is responsible for developing strategic programs and making investments in agrifood, cleantech, energy, environment, and bioindustry materials. Previously, John served as Executive Director, Chief Technical Officer, and Acting CEO at Alberta Innovates – Energy and Environment Solutions. He is a board director for the Petroleum Technology Alliance Canada and a guest board director for the Alberta Chamber of Resources. John developed the vision for Bitumen Beyond Combustion (BBC) in 2016 and is leading the effort to create a multibillion-dollar advanced materials industry in Alberta using bitumen.