PORTFOLIO Digital

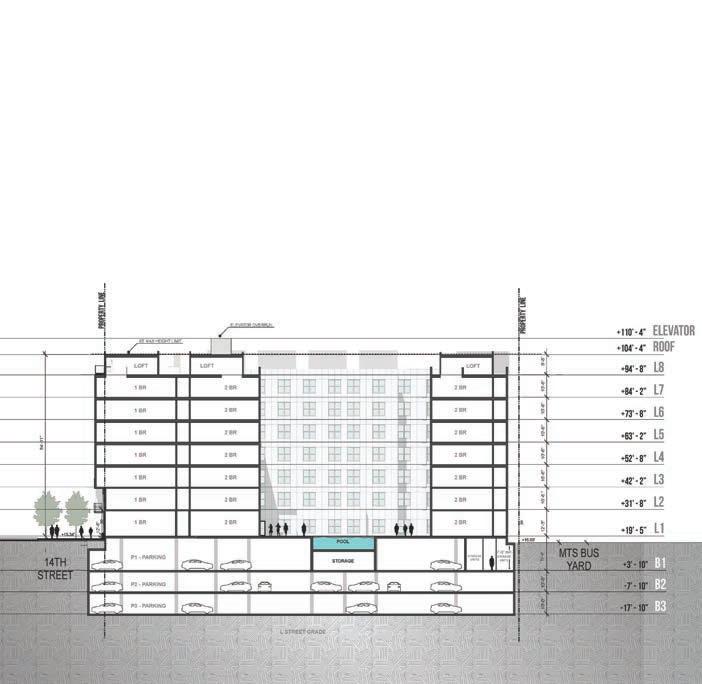

AS THE DESIGNER AND JOB CAPTAIN FOR A LARGE-SCALE CLASS A MIXED-USE DEVELOPMENT, I WAS RESPONSIBLE FOR DRIVING THE PROJECT FROM CONCEPT TO CONSTRUCTION COMPLETION. MY ROLE ENCOMPASSED A BROAD RANGE OF RESPONSIBILITIES, INCLUDING THE CREATION OF CONSTRUCTION DOCUMENTS, DEVELOPMENT OF DESIGN PROPOSALS, AND HANDS-ON INVOLVEMENT IN THE CONSTRUCTION ADMINISTRATION PROCESS.

I LED THE CREATION OF THE BIM MODEL AND DETAILED CONSTRUCTION DOCUMENTS THAT ADHERED TO BOTH DESIGN INTENT AND THE TECHNICAL REQUIREMENTS NEEDED FOR CITY APPROVALS. THIS INCLUDED PRODUCING ALL ENTITLEMENT AND SUBMITTAL PACKAGES FOR CITY DEVELOPMENT PERMITS, ENSURING THAT EACH SUBMISSION MET THE CITY OF SAN DIEGO’S STRINGENT GUIDELINES. MY ABILITY TO NAVIGATE THE COMPLEX-

ITIES OF CITY REGULATIONS AND COORDINATE DIRECTLY WITH MUNICIPAL TEAMS WAS KEY IN OBTAINING TIMELY APPROVALS, REDUCING DELAYS, AND KEEPING THE PROJECT ON SCHEDULE.

BEYOND DOCUMENTATION, I WAS DEEPLY INVOLVED IN THE CONSTRUCTION ADMINISTRATION PHASE. I SERVED AS THE PRIMARY LIAISON BETWEEN THE DESIGN TEAM, ENGINEERS, CONTRACTORS, AND THE CITY OF SAN DIEGO, ENSURING SEAMLESS COMMUNICATION AND COORDINATION. THIS ROLE REQUIRED ME TO SOLVE ANY ISSUES ON-SITE, RESPOND TO RFIS FROM THE CONTRACTOR, AND OVERSEE QUALITY ASSESSMENTS TO ENSURE THE WORK MET DESIGN STANDARDS. I REGULARLY PERFORMED SITE VISITS, MONITORED CONSTRUCTION PROGRESS, AND COLLABORATED WITH THE PROJECT MANAGER TO RESOLVE ANY CHALLENGES THAT AROSE.

IN ADDITION TO MANAGING THE TECHNICAL ASPECTS, I ALSO HAD A STRONG ROLE IN CLIENT INTERACTION, WORKING ALONGSIDE OUR LEAD PROJECT DESIGNER TO REFINE THE FAÇADE DESIGN AND OTHER CRITICAL ARCHITECTURAL ELEMENTS. MY COMPREHENSIVE INVOLVEMENT IN THE PROJECT ALLOWED ME TO INFLUENCE BOTH THE DESIGN PROCESS AND THE PRACTICAL IMPLEMENTATION, ENSURING THE FINAL PRODUCT WAS ALIGNED WITH THE CLIENT’S VISION AND THE PROJECT’S GOALS.

THIS EXPERIENCE DIRECTLY INCREASED MY ABILITY TO SYNTHESIZE DESIGN INTENT WITH PRACTICAL CONSTRUCTION REQUIREMENTS WILL CONTRIBUTE TO CREATING SCALABLE, DATA-DRIVEN WORKFLOWS THAT OPTIMIZE PROJECT DELIVERY. MY BACKGROUND IN COORDINATING BETWEEN MULTIDISCIPLINARY

BRIDGE

TEAMS, HANDLING CITY APPROVALS, AND ENSURING CONSTRUCTION QUALITY GIVES ME A SOLID FOUNDATION TO DRIVE PROCESS INNOVATION AND COLLABORATE EFFECTIVELY WITH CLIENTS, ENGINEERS, AND CONTRACTORS.

AS A CRITICAL CONTRIBUTOR TO THIS COMPETITION-WINNING 39-STORY MIXED-USE HIGH-RISE, MY ROLE WAS INTEGRAL TO THE PROJECT’S SUCCESS IN NAVIGATING THE COMPLEX ENTITLEMENT PHASE AND SECURING PERMITS FROM THE CITY OF SAN DIEGO. THIS HIGH-RISE FEATURED A DYNAMIC PROGRAM COMPRISING FIVE LEVELS OF BELOW-GRADE PARKING, A VIBRANT GROUND LEVEL WITH COMMERCIAL, RESIDENTIAL, HOTEL, AND AMENITY SPACES, AND TWO DISTINCT TOWERS: A TALLER TOWER WITH 34 LEVELS OF RESIDENTIAL AND HOTEL SPACE ABOVE THREE LEVELS OF ABOVE-GRADE PARKING, AND A LOWER TOWER WITH 10 FLOORS OF OFFICE SPACE.

THIS PROJECT, MY FIRST PROFESSIONAL UNDERTAKING, PRESENTED A RICH LEARNING EXPERIENCE AND THE OPPORTUNITY TO APPLY MY PROBLEM-SOLVING ABILITIES IN A FASTPACED ENVIRONMENT. I WORKED DIRECTLY WITH THE PROJECT ARCHITECT AND PROJECT MANAGER TO TRANSLATE THE INTRICATE DESIGN INTO A FEASIBLE AND COMPLIANT STRUCTURE FOR SUBMISSION TO THE CITY. MY ROLE FOCUSED ON ADDRESSING THE UNIQUE CHALLENGES PRESENTED BY THE GROUND LEVEL’S MIXED-USE COMPLEXITY, WHICH REQUIRED CAREFUL COORDINATION AND TECHNICAL REFINEMENT TO SAT-

ISFY BOTH DESIGN VISION AND MUNICIPAL REGULATIONS.

WORKING HANDS-ON, I COLLABORATED WITH THE ENTIRE PROJECT TEAM TO DEVELOP THE TOWER’S ARCHITECTURAL PLANS AND ENTITLEMENT PACKAGE, ENSURING THAT EVERY ASPECT ALIGNED WITH CITY STANDARDS WHILE MAINTAINING THE PROJECT’S BOLD DESIGN INTENT. MY INVOLVEMENT IN CREATING SUBMITTAL PACKAGES, FACILITATING CITY CORRESPONDENCE, AND TROUBLESHOOTING DESIGN OBSTACLES WAS CRUCIAL TO KEEPING THE PROJECT ON TRACK. BY EFFECTIVELY MANAGING COMMUNICATION BETWEEN VARIOUS STAKEHOLDERS—INCLUDING ENGINEERS, CONTRACTORS, AND CITY OFFI -

CIALS—I HELPED GUIDE THE PROJECT THROUGH THE PERMITTING PROCESS AND ENSURED IT MET THE TECHNICAL AND REGULATORY REQUIREMENTS NEEDED FOR APPROVAL.

THIS EXPERIENCE HONED MY SKILLS IN LARGE-SCALE PROJECT COORDINATION, COMPLEX PROBLEM-SOLVING, AND INTERDISCIPLINARY COLLABORATION, SKILLS. THE SUCCESSFUL NAVIGATION OF THIS COMPLEX DESIGN AND ENTITLEMENT PROCESS HAS EQUIPPED ME WITH THE ABILITY TO TACKLE MULTIFACETED ARCHITECTURAL CHALLENGES, MAKING ME WELL-PREPARED TO LEAD INNOVATIVE DESIGN AND PROJECT DELIVERY INITIATIVES.

THIS PROJECT INTRODUCED ME TO ADVANCED METHODS OF MANAGING COMPUTATIONAL MODELS, ESPECIALLY FOR COMPLEX FABRICATIONS. THE CROWN OF THORNS WOOD WALL WAS AN INTRICATE FEATURE COMPOSED OF NUMEROUS DIFFERENTLY SIZED WOODEN PIECES. TO ENSURE THE PROJECT’S FEASIBILITY FOR THE FABRICATOR, I DEVELOPED A COMPUTATIONAL MODEL THAT ORGANIZED AND STREAMLINED THE PRODUCTION OF EACH UNIQUE PART. THE MODEL WAS DESIGNED TO CATEGORIZE AND TAG EACH COMPONENT BASED ON SIZE, MATERIAL, AND ASSEMBLY SEQUENCE, MAKING THE FABRICATION AND ASSEMBLY PROCESSES MORE EFFICIENT AND REDUCING THE RISK OF ERRORS. BY AUTOMATING THE WORKFLOW FOR HUNDREDS OF PARTS, WE WERE ABLE TO ACHIEVE A LEVEL OF PRECISION THAT ALIGNED WITH THE CLIENT’S VISION.

THIS PROJECT WAS SIGNIFICANT DUE TO ITS IMPORTANCE TO BOTH THE PRINCIPAL OF THE FIRM AND THE CLIENT, REQUIRING A THOUGHTFUL BALANCE OF DESIGN COMPLEXITY AND PRACTICAL EXECUTION. MY ROLE INVOLVED CLOSE COLLABORATION WITH FABRICATORS, ENSURING THAT THE DIGITAL MODEL TRANSLATED SEAMLESSLY INTO A PHYSICAL PRODUCT. THIS EXPERIENCE ENHANCED MY EXPERTISE IN COM -

PUTATIONAL DESIGN, PARTICULARLY IN OPTIMIZING FABRICATION PROCESSES, AND DEMONSTRATED MY ABILITY TO SOLVE COMPLEX CHALLENGES WHILE WORKING AT THE INTERSECTION OF DESIGN AND PRODUCTION.

AFTER CONTRIBUTING TO THE 7TH & MARKET HIGH-RISE AND SEVERAL OTHER PROJECTS, I ESTABLISHED A REPUTATION WITHIN THE DESIGN TEAM FOR MY KEEN EYE FOR DESIGN AND MY ABILITY TO LEVERAGE DATA IN THE ARCHITECTURAL PROCESS. THIS LED TO THE OPPORTUNITY TO LEAD THE DESIGN OF A 5 OVER 2 PODIUM PROJECT, WORKING DIRECTLY WITH THE DESIGN PRINCIPAL TO CREATE A DATA-INFORMED APPROACH TO OPTIMIZE THE PROJECT’S LAYOUT AND FUNCTIONALITY.

I DEVELOPED A SET OF COMPUTATIONAL TOOLS TO STREAMLINE THE DESIGN PROCESS, FOCUSING ON OPTIMIZING THE FLOOR PLAN LAYOUT WHILE ENSURING THAT ALL CLIENT REQUIREMENTS WERE MET IN A FAST-PACED DESIGN PHASE. BY MANAGING DATA DIRECTLY FROM THE BIM MODEL, I WAS ABLE TO TRACK DESIGN CHANGES IN REAL-TIME, ENSURING THAT ADJUSTMENTS WERE BOTH RESPONSIVE AND EFFICIENT. THESE TOOLS ALLOWED ME TO MAINTAIN A BALANCE BETWEEN THE CLIENT’S DEMANDS, DESIGN INTENT, AND THE FUNCTIONAL NECESSITIES OF AMENITIES AND SERVICES, ALL WHILE STREAMLINING COMMUNICATION BETWEEN THE DESIGN AND DEVELOPER TEAMS. THIS EXPERIENCE HIGHLIGHTS MY ABILITY TO INTEGRATE DATA-DRIVEN DESIGN INTO COMPLEX PROJECTS, ENSURING THE CREATION OF EFFICIENT, WELL-COORDINATED, AND HIGHLY FUNCTIONAL ARCHITECTURAL ENVIRONMENTS.

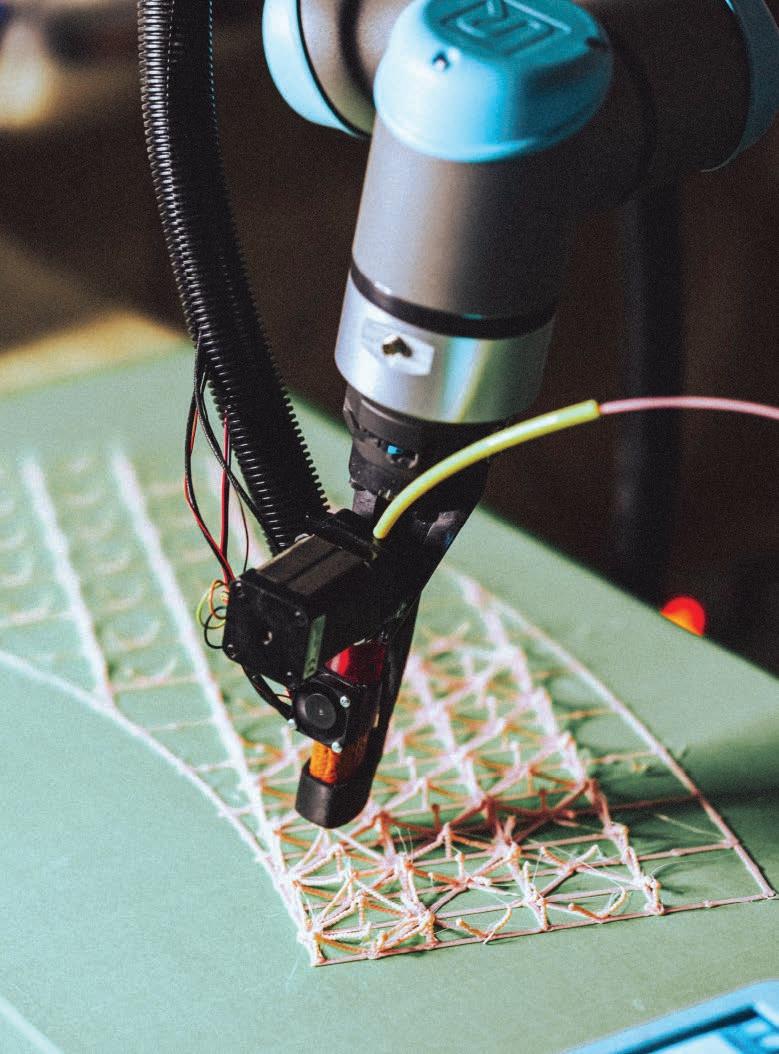

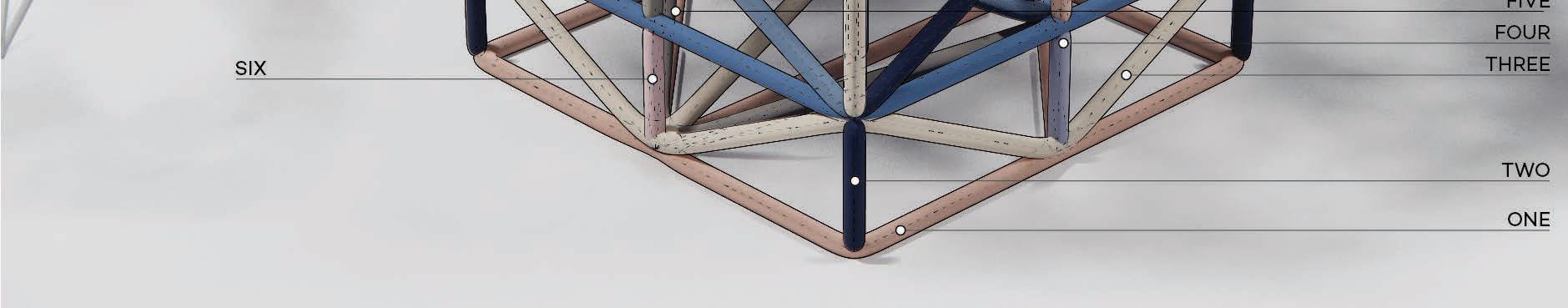

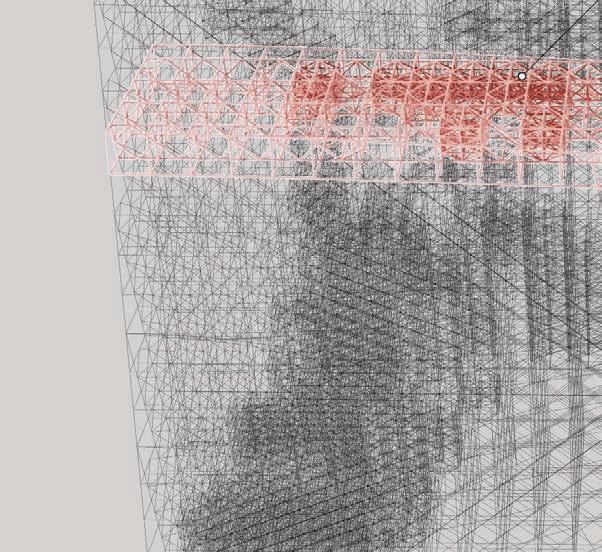

AS THE CAPSTONE OF MY MASTER’S PROGRAM, THIS PROJECT FOCUSED ON THE PRECISE INTEGRATION OF DIGITAL MODELING, DATA-DRIVEN DESIGN, AND ROBOTIC FABRICATION TOOLS. THE OBJECTIVE WAS TO CREATE HIGHLY ACCURATE, DIGITALLY CONTROLLED SYSTEMS THAT WORKED SEAMLESSLY WITH THE KR60 ROBOTS IN OUR LAB. MY ROLE INVOLVED DESIGNING A COMPUTATIONALLY CONTROLLED SAW CAPABLE OF PRODUCING EXACT CUTS FOR WOOD MEMBERS, ENSURING PRECISION AT EVERY STAGE OF THE FABRICATION PROCESS. THIS INITIAL PHASE LAID THE GROUNDWORK FOR THE METICULOUS CONTROL NECESSARY FOR THE PROJECT’S SUCCESS.

THE SECOND PHASE OF THE PROJECT INVOLVED SOLVING A MORE COMPLEX CHALLENGE: COMPUTATIONALLY SORTING THE WOOD MEMBERS TO PREVENT COLLISION ERRORS AND ENSURING A CORRECT SEQUENCING DURING ASSEMBLY. I DEVELOPED AN ALGORITHM THAT PRIORITIZED ORIENTATION AND Z-HEIGHT, ASSIGNING SPECIFIC WEIGHTS TO EACH MEMBER BASED ON ITS POSITION AND ROLE IN THE STRUCTURE. USING A RECURSIVE MODEL, I ENSURED THAT ALL WOOD COMPONENTS WOULD BE SELECTED AND ASSEMBLED IN AN OPTIMAL SEQUENCE. THIS PROCESS MINIMIZED ERRORS IN THE PHYSICAL BUILD WHILE MAXIMIZING EFFICIENCY, SHOWCASING MY ABILITY TO COMBINE DATA, AUTOMATION, AND COMPUTATIONAL TOOLS FOR LARGESCALE DIGITAL FABRICATION. THIS PROJECT EXEMPLIFIES MY TALENT FOR DESIGNING ALGORITHMS AND DIGITAL WORKFLOWS THAT DRIVE AUTOMATION AND PRECISION IN FABRICATION

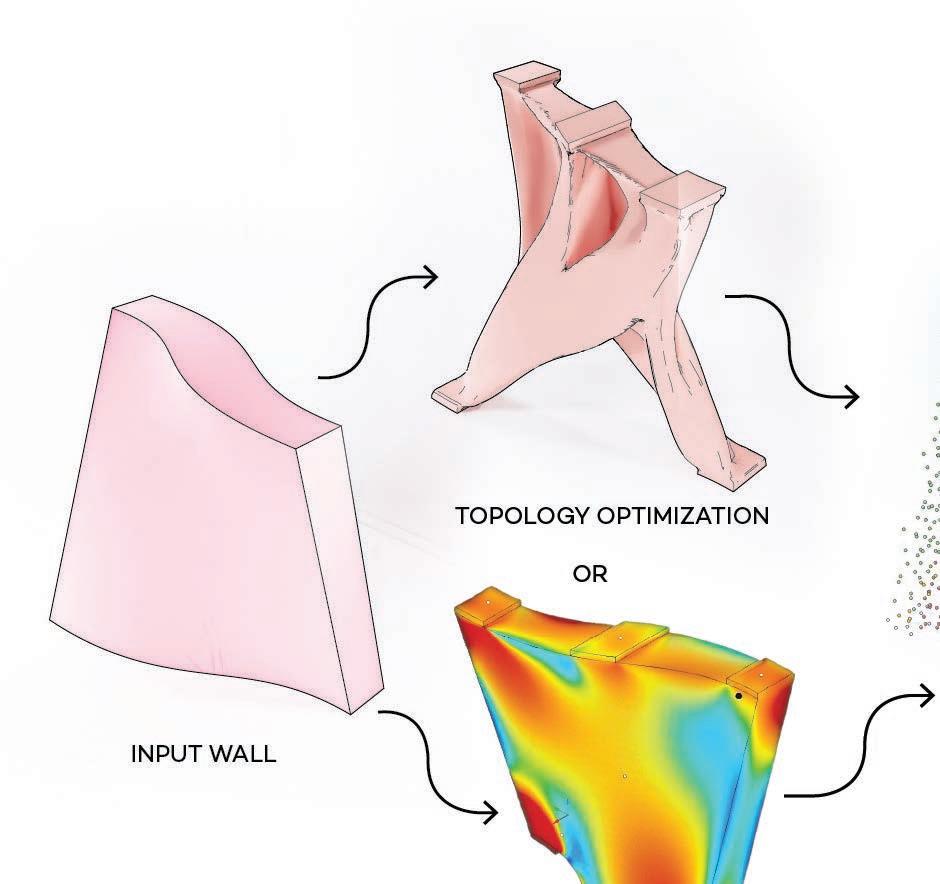

THIS PROJECT EXPLORED THE ADVANCED USE OF ADDITIVE MANUFACTURING TO EXPAND THE DESIGN POSSIBILITIES OF CONCRETE ELEMENTS, SPECIFICALLY FOCUSING ON THE FABRICATION OF FREEFORM FORMWORK USING MULTIPLE THERMOPLASTIC MATERIALS. THE DEGREE OF GEOMETRIC COMPLEXITY A CONCRETE ELEMENT CAN ASSUME IS DIRECTLY LINKED TO THE CAPABILITIES OF THE FORMWORK FABRICATION METHOD. THROUGH THIS RESEARCH, I DEMONSTRATED HOW FUSED DEPOSITION MODELING (FDM) 3D PRINTING OF THERMOPLASTICS OFFERS A TRANSFORMATIVE APPROACH TO FORMWORK CREATION. THE LIGHTWEIGHT PROPERTIES OF

FDM-PRINTED FORMWORK, COMBINED WITH THE ACCESSIBILITY OF THE TECHNOLOGY, MAKE IT AN IDEAL METHOD FOR PRODUCING COMPLEX, NON-STANDARD CONCRETE ELEMENTS. MY RESEARCH INVOLVED CROSS-REFERENCING VARIOUS THERMOPLASTIC MATERIALS—INCLUDING PLA, PVA, PETG, AND A COMBINATION OF PLA-PVA—TO ASSESS THEIR SUITABILITY FOR FORMWORK IN LARGESCALE CONCRETE STRUCTURES.

THIS PROJECT SHOWCASES MY EXPERTISE IN MANAGING COMPLEX DATA-DRIVEN WORKFLOWS AND AUTOMATING FABRICATION PROCESSES, BY EXPLORING THE USE OF MULTIPLE THERMOPLASTIC MATERIALS AND DIFFERENT 3D PRINTING METHODS, I HAD TO DEVELOP COMPUTATIONAL STRATEGIES THAT OPTIMIZED MATERIAL PERFORMANCE, GEOMETRIC COMPLEXITY, AND PRODUCTION EFFICIENCY. I LED THE PROCESS OF INTEGRATING VARIOUS DATA SETS RELATED TO MATERIAL PROPERTIES, COST, SPEED, AND SURFACE RESOLUTION, AND SYNTHESIZED THESE FINDINGS INTO A SET OF AUTOMATED WORKFLOWS THAT GUIDED THE DESIGN AND FABRICATION OF CUSTOM CONCRETE FORMWORK.

THE PROJECT INVOLVED CREATING BESPOKE COMPUTATIONAL MODELS TO PUSH THE LIMITS OF GEOMETRIC FREEDOM IN CONCRETE DESIGN, WHILE ADDRESSING PRACTICAL CONSTRAINTS LIKE SPEED AND COST. MY ABILITY TO COMBINE COMPUTATIONAL DESIGN TOOLS, AUTOMATION, AND DATA-DRIVEN DECISION-MAKING TO ENHANCE FORMWORK FABRICATION THIS PROCESS LEVERAGED ADVANCED METHODOLOGIES TO OPTIMIZE WORKFLOW AND OUTCOMES, ENSURING I CAN CONFIDENTLY LEAD INITIATIVES THAT REQUIRE INNOVATIVE, SCALABLE SOLUTIONS USING CUTTING-EDGE TECHNOLOGY.

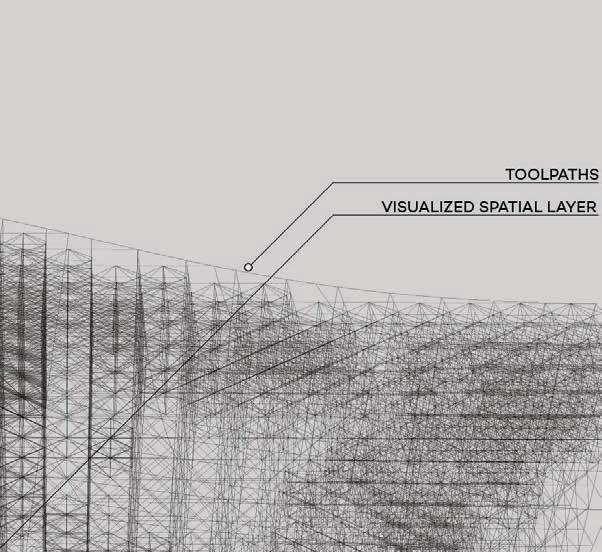

THIS PROJECT, A COLLABORATION BETWEEN UMICH AND ERNE IN SWITZERLAND, WAS INSTRUMENTAL IN ADVANCING MY EXPERTISE IN ROBOTIC FABRICATION AND COMPUTATIONAL DESIGN. WORKING CLOSELY WITH ERNE, WE FOCUSED ON TAKING A DIGITAL MODEL AND OPTIMIZING ITS GEOMETRY FOR ROBOTIC FABRICATION USING A CUSTOM GANTRY AND A 6-AXIS ROBOTIC ARM. MY ROLE INVOLVED LEARNING HOW TO TROUBLESHOOT COMPLEX GEOMETRIC CHALLENGES AND REFINING THE DIGITAL MODEL TO ENSURE IT MET THE PRECISE REQUIREMENTS FOR ROBOTIC CONSTRUCTION, ALIGNING WITH BOTH DESIGN INTENT AND FABRICATION CONSTRAINTS. THIS PROJECT SERVED AS A CRITI -

CAL STEPPING STONE FOR MY LATER CAPSTONE WORK, PROVIDING DEEP INSIGHTS INTO THE TECHNI -

CAL PROCESS OF DIGITAL-TO-PHYSICAL TRANSLATION IN FABRICATION. BY COLLABORATING WITH BOTH ACADEMIC PEERS AND INDUSTRY PROFESSIONALS, I GAINED EXPERIENCE IN OPTIMIZING DIGITAL MODELS FOR REAL-WORLD FABRICATION, ENSURING ACCURACY, EFFICIENCY, AND SEAMLESS INTEGRATION BETWEEN DIGITAL TOOLS AND ROBOTIC SYSTEMS. THE HANDS-ON EXPERIENCE IN DEVELOPING AND TROUBLESHOOTING SUCH A TECHNICAL WORKFLOW STRENGTHENED MY ABILITY TO DEVELOP STRONGER DATA-DRIVEN DESIGN AND AUTOMATION EFFORTS.

THIS PROJECT REPRESENTS A PIVOTAL EXPLORATION INTO THE APPLICATION OF SPATIAL 3D PRINTING FOR CREATING FUNCTIONALLY GRADED LATTICE STRUCTURES, DRIVEN BY DATA-INFORMED DESIGN. THE RESEARCH AIMED TO OVERCOME THE LIMITATIONS OF TRADITIONAL ADDITIVE MANUFACTURING (AM) METHODS WHEN PRINTING COMPLEX, NON-PLANAR GEOMETRIES BY UTILIZING FUSED DEPOSITION MODELING (FDM) AND A 6-AXIS ROBOTIC ARM. THE CUSTOM FDM SETUP ALLOWED US TO MANIPULATE THERMOPLASTIC MATERIALS, ENABLING THE FABRICATION OF IN -

TRICATE, HIGH-PERFORMANCE STRUCTURES WITH VARYING DENSITIES. THROUGH FINITE ELEMENT ANALYSIS (FEA), STRESS DATA INFORMED THE DESIGN OF INTERNAL LATTICE STRUCTURES, WHICH WERE SUBDIVIDED INTO THREE DENSITY CATEGORIES TO OPTIMIZE MECHANICAL PROPERTIES. THIS COMPUTATIONAL PROCESS INVOLVED GENERATING TOOLPATHS, CATEGORIZING ELEMENTS BY ORIENTATION, AND EMPLOYING A STIPPLING METHOD TO ENHANCE THE RIGIDITY OF CANTILEVERED EXTRUSIONS. METHOD OVERVIEW

THE RESULTS DEMONSTRATED THE FEASIBILITY OF SPATIAL 3D PRINTING FOR LARGE-SCALE CONSTRUCTION-GRADE APPLICATIONS, WITH OVER 200,000 EXTRUSIONS PRODUCED DURING THE CASE STUDY. THE TOOLPATH GENERATION AND STIPPLING TECHNIQUES IMPROVED PRINT ACCURACY AND REDUCED DEFORMATION, WHILE FEA-INFORMED DESIGN ENSURED THAT THE STRUCTURE COULD WITHSTAND SIGNIFICANT LOADS. ALTHOUGH THE PROCESS OF PRINTING HIGH-DENSITY STRUCTURES WAS TIME-CON -

SUMING, THE FINDINGS EXPANDED THE POSSIBILITIES FOR GEOMETRIC COMPLEXITY IN STRUCTURAL DESIGN. THIS RESEARCH ESTABLISHES A ROBUST FOUNDATION FOR FUTURE EXPLORATIONS OF FUNCTIONALLY GRADED, HIGH-PERFORMANCE COMPONENTS IN CONSTRUCTION, DEMONSTRATING HOW DATA-DRIVEN AUTOMATION CAN OPTIMIZE BOTH MATERIAL EFFICIENCY AND STRUCTURAL STABILITY.

SORTING LOGIC FOR CURVE DIRECTION AND ORIENTATION

SORTING LOGIC FOR DIFFERENT CELL SIZES