10 minute read

The area of the size of the regional hospital as a semi-LDA

from CITY:ONE.1.2020.EN

by CityOne

A CONSORTIUM OF FOUR RESEARCH ORGANIZATIONS IS CURRENTLY WORKING ON A PROJECT ENTITLED „LOCAL SOURCES OF ELECTRICITY AND HEAT IN THE MUNICIPAL ENVIRONMENT WITH THE POSSIBILITY OF ISLAND OPERATION“. DUE TO ITS FOCUS, THE PROJECT FALLS INTO THE SUB-PROGRAM „LONG-TERM TECHNOLOGICAL PERSPECTIVES“, IN THE PERIOD 2018-2025 AND IS FINANCED WITHIN THE PROGRAM SUPPORT PROVIDED BY THE TA CR AGENCY. THE EXTERNAL APPLICATION GUARANTORS OF THE PROJECT ARE THE CENTRAL BOHEMIAN INNOVATION CENTRE AND THE ZLÍN REGION.

The aim of the project is to design a comprehensive solution of the energy source for selected type solutions of LDA (local distribution areas), which consider possible cooperation with higher TYPES of distribution from central energy suppliers and alternatively an autonomous energy cycle. The following standard solutions are developed in the project: The area of the regional hospital, a municipality with a size of 500 ÷ 800 inhabitants, a set of apartment buildings on the outskirts of the district town and a smaller production plant. There is a real model for each of the presented type solutions, which is the source of a wide range of input data: Overview of parameters of sources, distribution equipment and appliances, aggregated or purposefully divided overviews of energy supply in selected tracing time intervals, real expenditure on energy consumed, other circumstances condition and operation of energy systems in standard solutions.

Advertisement

The research work focuses on the variant processing of the energy mix: Central Energy provision, combined production of heat and energy, RES (PV, FTE, geothermal sources, wind energy, heat pumps) and energy storage in individual types of solutions, where not only the resulting energy balance is used to evaluate the design quality, but as well as an economic evaluation of the proposed variants and, fi nally, an assessment of the impact of the solution on the environment.

: Initial realities of the analysed area

The area has been used for medical purposes since 1927. Since the original concept of the strictly pavilion hospital, the character has been gradually changed in several waves (especially in the second half of the 20th century): there was extensive use of the area, when large multi-storey buildings were added, but also to increase the intensifi cation, when the existing buildings were rebuilt, consisting mainly in the increase of the built-up volume. The types of building structures and their thermal insulation parameters then correspond to the standards usual for the period of building activities. During the last 20 years, the insulation of the outer shell and the replacement of windows was carried out for some of the buildings, and for the installation of effi cient air conditioning. Nevertheless, the condition of the area (and only from the energy point of view) can be assessed as morally obsolete and underfunded in the long run.

At present, the entire hospital complex includes more than 30 buildings almost 1 kilometre apart. Bed stations are in 15 buildings, operating rooms in four places. Acute and follow-up care has over 900 beds. The complex employs more than 2,200 people. The procedures are over 45,000 patients a year.

The energy system of the complex is based on the central supply of energy: electricity, heat, and natural gas. Electricity generators powered by diesel engines and a suffi ciently dimensioned natural gas boiler for heat production and hot water preparation are installed in the complex. Approximate values of the annual energy intensity of the complex: Electricity consumption 7÷9 GWh, heat consumption 42,000÷46,000 GJ, natural gas consumption 60,000÷63,000 m3. Aggregated energy costs for the year are lower in the tens of millions of CZK.

: Simulation models

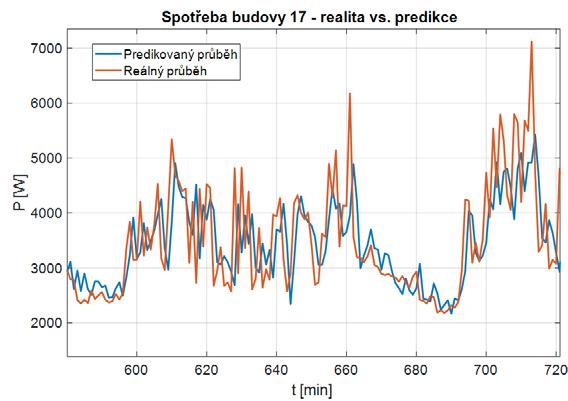

To generalize the functional dependencies of parameters determining the performance and dynamics of energy systems in individual types of solutions, two diff erent approaches are used, a dynamic physical model of heat consumption (addressing the eff ects of outdoor temperature, air exchange with the environment, solar radiation, presence of people and equipment in the building) and Prediction model with neural networks of future electricity consumption (e.g. for setting power system controls, power accumulators, chargers for electric cars, etc.).

: Conversion of the area into a semi-LDA

The identifi ed energy revitalization of the regional hospital premises can be divided into two groups: Investments with a signifi cant impact and investments with a less signifi cant impact on cost savings. Another criterion for the evaluation of individual variants of energy optimization is the degree of autonomy of the energy circuit of the area.

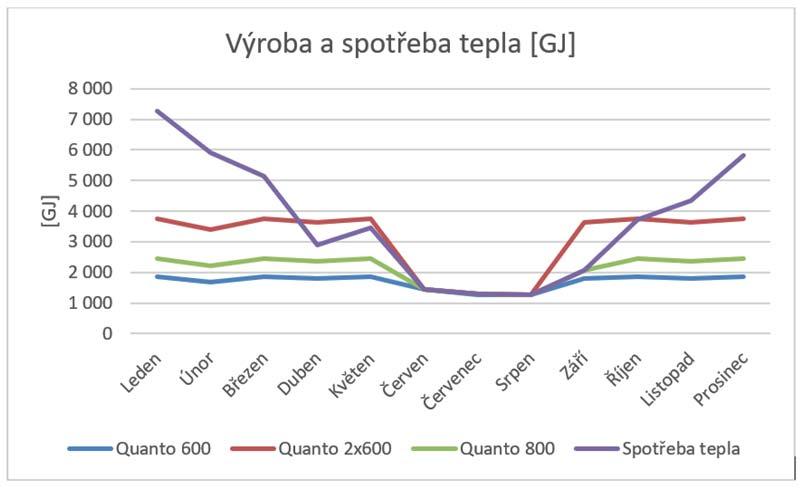

Heat production and consumption (GJ)

Building 17 consuption - reality vs prediction

: In the group of investments with a signifi cant impact, the following variants were identifi ed:

1. Installation of a cogeneration unit (CHP), alternatively in three power categories

From the course of electricity and heat consumption for the last fi ve years, the courses of electricity consumption bands and the courses of average monthly heat consumption were compiled. Subsequently, three power levels (in kWe) of cogeneration units 600, 800 and 2 x 600 (kWe) were identifi ed. The number of operating hours of the CHP in a year was determined by the condition that all the heat produced will be consumed in the LDA. In terms of investment, this option represents the acquisition costs of the CHP and the construction of a heat pipeline in the hospital complex. This variant is based on maintaining partial energy supplies from central sources and partial own production of electricity and heat. Example: For a 600 kWe CHP, own production represents 62% of electricity consumption and 43% of heat consumption.

Compared to the initial state, the gas consumption as fuel for CHP will increase 20 times. From an economic point of view (including CHP support), the calculated return on investment is less than 3.7 years and the IRR internal rate of return is 38% (data valid for KGJ 600 kWe, realities valid to the conditions at the time of balance calculation).

2. Use of an existing gas boiler for heat production and hot water preparation

A boiler with an output of more than 4 MWt is already installed in the hospital complex. With its life cycle, it has used up less than 15% of the planned operating time. In the current energy scheme, the boiler forms a backup unit for central heat supply. In practice, it supplies heat at a time when the central source is undergoing periodic (operative) maintenance, which represents on average 2 weeks in a calendar year, predominantly in the summer. Similarly to variant no. 1, the operating hours of the boiler were determined according to the course of the average monthly heat consumption. In terms of investment, this variant represents the construction of a heat pipe in the hospital complex. This option is based on maintaining a full supply of electricity from a central source. The gas boiler provides 100% of the heat consumption in the LDA. However, the connection to the central heat supply is maintained, as it forms a backup source for heat supply. Compared to the initial state, the gas consumption as fuel for the boiler will increase 25 times. From an economic point of view, the calculated return on investment is less than 0.7 years and the IRR internal rate of return rate is 876! % (realities valid to the conditions at the time of calculating the balance).

3. Combination of cogeneration unit installation and use of an existing gas boiler

This variant is a combination of the previous two variants with the fact that complete disconnection from the central heat supply is achieved. The necessary condition of securing a backup heat source can be solved in two ways: By installing a backup gas boiler (approximately half the output of the main gas boiler), or by using waste heat from backup diesel generators, which would start only in emergency mode in accordance with their original purpose. In terms of investment, this option represents the acquisition costs of the CHP and either the acquisition costs of the backup boiler or an investment in

the heat exchange system for the use of waste heat from diesel-electric units. Economically, both types of energy advance are similar: Higher investment costs in the backup boiler are off set by the cost of conducting waste heat from diesel generators and subsequently higher fuel consumption compared to gas boiler consumption for the same volume of heat generated. This variant is based on maintaining a partial supply of electricity from central sources and complete disconnection from the central heat supply. Example: For a CHP unit with an output of 600 kWe and a boiler with an output of 4 MWt, own production represents 62% of electricity consumption and 100% of heat consumption. Compared to the initial state, the gas consumption as fuel for CHP and gas boiler will increase 35 times. From an economic point of view (including CHP support) the calculated return on investment is less than 2.3 years and the internal rate of return IRR is 58% (data valid for KGJ 600 kWe, gas boiler 4 MWt, realities valid to the conditions at the time of balance calculation).

1. Completion of the plan for thermal insulation of energy-important buildings.

For the purposes of the study, one model building in the investigated area was selected: The total annual heat consumption for heating and TeV preparation in the given building is greater than 4,200 GJ. The proposed system of thermal insulation of the outer shell of the building and installation of windows with low heat loss can reduce heat consumption by 60% (note: the existing selected building is very energy effi cient). From an economic point of view, the calculated annual savings in heat costs in the building are more than CZK 650,000, the calculated return on investment is less than 16 years and the internal rate of return IRR is 5% (data valid for the selected model type of insulation and selected windows, construction cost applicable to the conditions at the time of the balance sheet calculation).

2. Installation of photovoltaic panels on the roofs of buildings.

In the analysed case, in addition to the orientation of the building, the size and structure of the roofs for installation, it was necessary to consider the fact that some buildings in the area are listed, and therefore unavailable for the installation of FTV panels. For the purposes of the study, ten objects most suitable for the intended purpose were selected. The primary determination of the obtained energy is the conversion of electrical energy into heat in the cells of the cartridges located in the water storage tanks in the building transfer stations and the preparation of hot water, or its preheating or reheating. An alternative use of the generated electricity is to supply air conditioning units close to the FTV panels (especially on warm summer days, this connection will be very frequent). In the considered case, the total installed capacity of FTV panels is 980 kWp. Heat production is 4,000 GJ and covers 13% of all heat consumption of selected buildings.

3. Controlled temperature regime in selected zones.

The following parameters were measured in selected buildings within the project:

· Immediate performance on individual transfer stations · temperatures in the zones of selected objects · air temperatures around buildings · solar radiation outputs in the area

The measured values of internal temperatures in the zones in the period October-December 2019 ranged from 22 ° C to 26 ° C. It is an identifi ed reserve for reducing internal temperatures without the reduction having a signifi cant impact on the comfort of staff and patients. Using a dynamic physical model of heat consumption and parallel measurement of system parameters to achieve controlled indoor temperatures in the range of 22÷23 °C, savings in heat consumption in the analysed building of 4% were simulated. One of the fi ndings was that the greatest savings are achieved in periods with higher outdoor temperatures, especially on sunny days, when the contribution of sunlight to the temperature in the measured zones is evident. Typically, this is the transition period of the calendar year, i.e., the beginning and end of the heating season.

: Conclusion

The team concluded that it makes real sense to deal with selected investments in the energy system of the analysed area. Some simplifi cations were adopted in the solution, e.g., the eff ects on prices from central energy suppliers caused by the reduction of annual energy consumption were not assessed, etc. Although the costs of described energies account for only 2% of total operating costs of medical facilities, savings in nominal values already represent signifi cant amounts for the company‘s operations.

#Jiří Ehrlich, Petr Prokop and Pavel Sláma Department of Fluid Mechanics and Thermodynamics, Faculty of Mechanical Engineering CTU