CERAMIC

ART

TRENDS,

TOOLS,

AND

®

TIMES

Clay

TECHNIQUES

Volume 20 • Issue 98 SUMMER / FALL 2014

Remembering Don Reitz 1929-2014 Building Peter King’s Gulf Breeze Arch OSHA Proposes New Silica Guidelines Preparing for a Kiln Inspection Linda Arbuckle’s “Fresh” Majolica Mosaic Mania: Four Detailed Projects Dealing with Procrastination

$8.95 U.S./$10.95 CAN

What Makes a Real Artist? PLUS: This Year’s New Tools • Dave: The Slave Potter White-on-white Glaze Effects • CERF Safety Tips

“Some days I’m standing up, some days I’m sitting down when I throw. So being able to adjust the height of the legs in nuanced ways is a real advantage... I also love the large aluminum builtin splash pan. It gives me something very stable to lean my body into as I’m throwing. It gives me extra stability and a little extra strength.”

Steven Hill

powerful tough innovative

ergonomic smooth value Visit skutt.com/video/hill CLAYTIMES·COM n AUTUMN/WINTER 2013

to see video of Steven discussing the ergonomics of throwing.

2

calls for entry at

The THE RefRacToRy REFRACTORY SupeR SUPER SToRe! STORE!

Lots of Inventory. Lowest Prices.

larkin REFRACTORY SOLUTIONS Unparalleled Service & Refractory Design Assistance for over 30 years by the folks who truly care about your business. Firebrick – straights, arches, wedges & tiles Insulating Firebrick – straights, arches & wedges Ceramic fiber blankets, boards, papers & textiles Castables in several insulating & dense compositions Mortars, patches & inexpensive coatings

Nitride Nitride&&Fines FinesBonded BondedKiln KilnShelves Shelves Custom Manabigama Kiln Refractory Packages P.O. Box 716, Lithonia, GA 30058 Phone: 678.336.7090 Fax: 678.336.7094 Email: LRS@LarkinRefractory.com

www.LarkinRefractory.com

Larkin Refactory.1_4.5-6_08.indd 1

Untitled-1 1

Kiln Furniture

GALORE! ALL SIZES AVAILABLE!

4/2/08 11:16:05 AM

Olympic FL12E 11/3/08 3:51:54 PM Inside dimensions 24” x 24” x 36”, 12 cu. ft., fires to 2350°F – Cone 10, 12 key controller with cone fire & ramp hold programming, 240-208 volt, single phase. $5710

For less than $6,000, you could be firing a 12 cubic foot, cone 10 gas or electric kiln.

More value for your dollar, more bang for your buck!

Olympic DD9 with Vent Hood* – Inside dimensions 30” x 25” x 25”, inside volume 15 cu. ft., setting area 23” x 23” x 30”, 9.2 cu. ft., fires to 2350°F – Cone 10, propane or natural gas $5870 * Pictured with optional stainless steel vent hood

Contact an Olympic Kilns Distributor to purchase an Olympic Gas or Electric Kiln

www.greatkilns.com

Phone 800.241.4400 or 770.967.4009 Fax 770.967.1196

Earline Green’s clay spirit quilts on display in the Dunbar Lancaster-Kiest Branch Library in Dallas, Texas.

A Texas potter makes 1,300 pound quilts with her Paragon Dragon As a child, Earline Green made hand-stitched quilts with her grandmother Mama Freddie. Earline spent more time quilting with the older ladies than she did playing with children her own age. Her early experiences with the lively quilters taught her a life-long love of artwork.

CLAYTIMES·COM n SUMMER/ FALL 2014

Earline’s other grandmother, Mama Ginger, taught her advanced quilting patterns. Later this influenced the design of Earline’s stoneware quilt tile mosaics displayed in the entrance of the Paul Laurence Dunbar Lancaster-Kiest Library in Dallas, Texas. For that project, Earline fired 284 white stoneware tiles—all in her faithful Paragon Dragon.

4

“The Dragon's design and controls are perfect for firing large flat pieces,” said Earline. “The digital programming controls provide a consistent firing environment that eliminated cracks and warpage in this project. “During tile production, I fired my Dragon two or three times a week for four to six weeks at a time. I expected and received excellent results with each firing.” Contact us today for more information on the exciting Dragon kiln. Ask about the easy-open switch box hinged at the bottom. Call us for the name of your local Paragon distributor.

Earline Green with her Paragon Dragon front-loading kiln. This kiln is becoming a favorite with potters. It is easy to load, heavily insulated, and designed to reach cone 10 with power to spare.

Join the Clayart pottery forum here: lists.clayartworld.com

Constantly looking for better ways to make kilns

2011 South Town East Blvd. Mesquite, Texas 75149-1122 800-876-4328 / 972-288-7557 www.paragonweb.com info@paragonweb.com

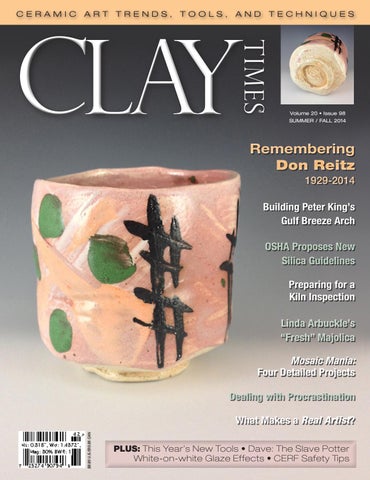

Cover photo: Tea Bowl by Don Reitz. 5" tall. Wheel-thrown and altered stoneware decorated with slips and underglazes, salt-fired to cone 10 in reduction.

®

contents

TIMES

Clay

SUMMER / FALL 2014 Volume 20 • Issue 98

features ➤ 14 Building Peter King’s Gulf Breeze Arch Regarded by many as the master of contemporary architectural ceramics, Peter King shares his secrets to success in part one of this illustrated series on large-scale slab building. ➤ 24 [COVER STORY] Remembering Don Reitz

Face 2 close-up of the Gulf Breeze Arch.

Rick Berman pays homage to the legendary Don Reitz, the energetic soul whose positive attitude and love of clay influenced generations of potters to keep at it ... ➤ 28 Mosaic Mania Paula Smith provides a detailed account of her inspiration and techniques for mosaic projects including a simple trivet, a bath tub enclosure, and two large outdoor sculptures.

Detail of Mosaic Sea Turtle by Paula Smith.

exhibit ➤ ➤ 36 Fresh: Linda Arbuckle Get a taste of delicious majolica from Schaller Gallery’s recent online show.

Pasta Bowl by Linda Arbuckle. Majolica-decorated earthenware. 2" x 8½" x 8½".

5

SUMMER / FALL 2014 • Volume 20 • Issue 98

®

contents

TIMES

Clay

Cone 6 stoneware bowls with narrative illustrations by Rich Peterson. See more at The Gallery, p. 35.

departments

columns

9 EDITOR’S DESK

18 AS FAR AS I KNOW

“Seize the Moment...”

“Artistic Considerations for Striking Effects” by Pete Pinnell

11 WHAT’S HOT Clay world news, events, and calls for entries

21 BENEATH THE SURFACE

20 GREAT GLAZES

“Dealing with Procrastination” by Lana Wilson

Recipes for “White on White” clay body & glazes

26 SLURRY BUCKET

27 STUDIO HEALTH AND SAFETY

CERF’s Tips to Prevent Studio Disasters

“OSHA Proposes New Silica Guidelines” by Monona Rossol

34 THE GALLERY A selection of unique works by CT readers

36 TOOL TIMES

42 CLASSIFIED MARKETPLACE Goods and services offered especially for clay artists

47 POTTERY CLASSES Where you can learn claywork in your community

50 ADVERTISER INDEX Find your favorite ceramics suppliers in this issue (please tell them you found them in Clay Times!)

6

“This Year’s New Tools” by Vince Pitelka The Craft Emergency Relief Fund (CERF) is now offering a handy guide to help artists protect themselves and their livelihoods from disaster. Available in the form of an interactive diala-wheel, this device is loaded with tips devoted to topics regarding artist insurance, workspace, documents, portfolio, and the art inventory itself. Turn to The Slurry Bucket on page 26 for a sampling of these helpful disaster prevention and preparedness guidelines from CERF, and find out where to get your own wheel for just $16 ...

43 BOOKS & VIDEOS A look at three books on “Dave: The Slave Potter” review by Steve Branfman

45 KILNS & FIRING “Preparing for a Kiln Inspection” by Marc Ward

49 AROUND THE FIREBOX “What Makes a Real Artist?” by Kelly Savino

7

! New

MKM HandRollers Clay

CLAYTIMES·COM n SUMMER/FALL 2014

MakE iNCrEdiBlE dEsigNs Fast & Easy!

8

• No EdgE Marks! ng Shoppi e n i l n O ailable! Now Av

• 32 dEsigNs!

• BEvEllEd Cuts!

Great for thrown pots & on slabs!

MKMPotteryTools.com Phone: 920.205.2701 Email: MKMTOOLS1@gmail.com

magazine Editor & Publisher: Polly Beach

Regular Columnists: Steve Branfman, Books & Videos David Hendley, Around the Firebox Pete Pinnell, As Far as I Know Vince Pitelka, Tool Times Monona Rossol, Health & Safety Kelly Savino, Around the Firebox Marc Ward, Kilns & Firing Lana Wilson, Beneath the Surface

Don was an amazing potter and enigmatic presence, with great character and boundless enthusiasm. He literally touched thousands of lives throughout his lifetime; clay artists across the globe were all saddened to learn of his passing on March 19 this year. Don was a true friend and supporter of Clay Times from the get-go, thanks to our mutual friend, Rick Berman. Rick not only wrote the piece honoring Don in this issue of CT, but also introduced Don to Clay Times and its readers way back in 1996, soon after the magazine’s inception. Rick’s two-part interview with him drew a great deal of attention to Don, as well as to the fledgling magazine. Don was so thrilled with the coverage he’d received in Clay Times that he gave me the tea bowl that appears on this issue’s cover. I’ve cherished it ever since. I am honored with the privilege of sharing it with you now, along with a story that comes to mind in my own memories of Don.

Proofreader: Jon Singer Contributing Writers: Rick Berman • Peter King • Paula Smith

to our booth, we used the backdrop again the next year. But afterward, when it came time to pack up the booth, I surrendered the poster to Don. He wanted to hang it up in his home studio. It was so sweet to see how happy that poster made him— his sheer exuberance made me feel like I’d done something really special. Those two issues featuring Rick’s Don Reitz interview have long since been out of print. But thanks to the digital age, we can share the full two-part interview again online, in Don’s memory. Check it out at: www.claytimes.com/DonReitz. Back to the subject of time: in the world of magazine publishing, it’s crucial for a magazine to be as “fresh” as possible for its readers. It’s also unfortunate for the publisher and potential readers that bookstores often pull magazines off their shelves too soon, before issues are outdated or the next issue is yet available. As such, this and all future quarterly issues of CT will cover two seasons as opposed to one: Summer/Fall, Fall/Winter, Winter/Spring, and Spring/Summer. After all, no one wants to “judge a book by its cover,” right? [

— Polly Beach, Editor

✦ Printed on 100% FSC-certified and 75% post-consumer recycled paper ✦ Published by: CLAY TIMES, LLC P.O. Box 17139 • Amelia Island, FL 32035

Toll-free subscription line: 800.356.2529 Clay Times® (ISSN 1087-7614) is published quarterly, four issues per year. Periodicals Postage Paid at Burlington, VT. Annual subscriptions are available for $33 in the U.S.; $40 in Canada; $60 elsewhere (must be payable in US$). Digital subscriptions are just $20 worldwide. To subscribe, call toll-free 1-800.356.2529, or visit www.claytimes.com. Freelance editorial and photographic submissions are welcome: Please contact Clay Times or visit our Website for writer’s and photographer’s guidelines. POSTMASTER: Address service requested. Send address changes to: Clay Times, PO Box 17139, Fernandina Beach, FL 32035. Copyright ©2014 Clay Times, LLC. All rights reserved. The material contained herein is derived from various sources and does not necessarily reflect the views of the publisher. All technical material is offered as general information only and should not be acted upon without expert supervision. No part of this publication may be reproduced or transmitted by any means without the written permission of the publisher.

Questions? Comments? Please e-mail us! Editorial: claytimes@gmail.com Advertising: clayaccounts@gmail.com Circulation: ctcirculation@gmail.com Website: www.claytimes.com

CLAYTIMES·COM n SUMMER/FALL 2014

During the year that followed Rick’s CT interviews with him, we had enlarged the image of Don on the magazine cover (re-printed above) into a life-sized poster, for our NCECA conference booth backdrop. Don stopped by the booth and fell in love with the poster, making me promise to give it to him one day. That image of Don—with cigar hanging from his mouth, while surrounded by massive, freshlythrown pots—drew so many visitors

Clay

®

e’ve all heard that familiar saying, reminding us to make the most of what we have now because we just can’t know what tomorrow may bring. While reading our cover story in memory of Don Reitz, I was reminded of the importance of time, and how much we have (or don’t have).

Spouting Off I Editor’s Desk

W

TIMES

“Seize the Moment...”

CERAMIC ART TRENDS, TOOLS & TECHNIQUES

9

Spectrum Glazes Introduces three new lead-free metallic finishes for Cone 5; Gold, Gold Rain, and Mirror. In addition to our popular Pewter and Oil Spot, we think you’ll be impressed by the newest metallic additions to our Stoneware Glaze line when you give them a try.

1112 Gold

1114 Gold Rain

1116 Mirror

1188 Pewter

1198 Oil Spot

SPECTRUM GLAZES INC. CONCORD, ONT. PH: (800) 970-1970 FAX: (416) 747-8320 www.spectrumglazes.com info@spectrumglazes.com

NEW

Think Big. 12x16x½” 10x12x½”

CLAYTIMES·COM n SUMMER/FALL 2014 CLAYTIMES·COM n SUMMER/ FALL 2014

8x8x½”

10 10

Our heavy duty studio boards are the perfect way to move, stack and store artwork. Safely transport works in progress. • Strong • Lightweight • Will not warp • Absorbent • No flexing • Pre-drilled for hanging

All sizes available for under $5.00 Discount pricing and accessories at continentalclay.com

L&L Kiln’s patented hard ceramic

1101 STINSON BOULEVARD NE, MINNEAPOLIS, MN 55413 1-800-432-CLAY CONTINENTALCLAY.COM

Toll Free: 888.684.3232 Swedesboro, NJ 08085

element holders protect your kiln.

• ceramic art world news • events • • calls for entries • Conferences

Calls for Entries

‰ Earth and Fire: The 3rd Southeast Asian Ceramics Symposium takes place Oct. 10-12 at the Workhouse Arts Center in Lorton, Virginia. The event will feature lectures and demos by 12 clay artists representing nine southeast Asian countries, concurrent with an exhibition of works by 35 southeast Asian clay artists. Full program details may be found online at www. workhousearts.org

‰ Student entries are being accepted through Sept. 24 for the 2015 NCECA National Student Juried Exhibition, to take place Mar. 21-Apr. 9, 2015 in Providence, Rhode Island. Entry fee: $15 NCECA members; $30 for non-members. For full details and online application link, log onto www.nceca.net

‰ Ceramic entries by NCECA member non-students are being accepted through Sept. 30 for 2015 NCECA Emerging Artists, to be recognized during the organization’s annual conference in March, 2015. To learn more, email kate@nceca.net, or click on the entry link at www.nceca.net

Hot Stuff I News & Events

What’s Hot

continued on next page

‰ The 30th Alabama Clay Conference takes place Feb. 2728, 2015 in Birmingham, AL. Featured guest presenters will include Nick Joerling, Patti Warashina, and Peter Rose. Sponsored by the Alabama Craft Council, the 2015 event will be held in conjunction with the 2nd Bunting Ceramics Symposium at the Birmingham Museum of Art. To learn more, log onto www.alclayconference. org, or e-mail Paula Reynolds at: preynolds6510@charter.net

“So how does a small child make such a giant mess with such a tiny amount of clay?”

CLAYTIMES·COM n SUMMER/FALL 2014

‰ Lively Experiments, the 49th Annual Conference of the National Council on Education for the Ceramic Arts (NCECA) will take place in Providence, Rhode Island, March 25-28, 2015. Log onto www. nceca.net for full event details.

11

Hot Stuff I News & Events

What’s Hot (continued from previous page) ‰ Entries of ceramic cups of all kinds are being accepted through Sept. 30 for Personal Voice, the Fifth Cup of Comfort International Biennial, to take place Nov. 7-Dec. 26, 2014 at the Swope Art Museum/ Halcyon Art Gallery in Terre Haute, Indiana. Entry fee: $30 for up to three entries. For more, e-mail: raychenhalcyon@ gmail.com; click on the forms link at www.halcyonartgallery. com; or call 812.645.3535.

CLAYTIMES·COM n SUMMER/FALL 2014

‰ Entries by fine craft artists of Hawaii are being accepted through Sept. 30 for the Hawaii Craftsmen Annual Statewide Juried Exhibition, to take place Oct. 10-Nov. 1. Entry fee: $25 for members; $75 for non-members. For details, e-mail info@hawaii craftsmen.org; log onto www. hawaiicraftsmen.org; or call 808.532-8741.

12

‰ Entries of professional quality cups and mugs, each of which will represent a child in foster care, are being accepted through Oct. 1 for the Finding Forever Exhibition. The event will take place Nov. 1-Dec. 31 in Greenfield, MA. Each cup will ultimately be sold for $50, with $20 to benefit the Massachusetts Adoption Resource Exchange, $20 to go to the artist, and $10 to cover event production costs. To learn more, e-mail findingforeverexhibition @gmail.com; log onto www. findingforeverexhibition.org, or call 413.773.1214. ‰ The Studio 550 Community Art Center of Manchester, New Hampshire is accepting entries through Oct. 10

of functional ceramic works made for drinking for its 2nd Annual Cup Show & Sale. The event will take place Nov. 10, 2014 - Jan. 17, 2015. Entry fee is $25 for three entries; $10 per additional entry. To learn more, e-mail info@550arts. com; log onto www.550arts. com / opportunities / or call 603.232.5597. ‰ The Pro Arts Gallery of Oakland, California is accepting entries through Oct. 10 by artists who live in the Greater Bay Area for The Annual 2015. The event will take place Dec. 2, 2014 - Jan. 16, 2015. Entry fee is $25 for three entries; $5 per additional entry. To learn more, e-mail info@proartsgallery. org; log onto www.proarts gallery.org, or call 510.763.4361. ‰ Entries of ceramic drinking vessels by potters who live in Ohio, Pennsylvania, or West Virginia are being accepted through Oct. 13 for Daily Ritual: The Ceramic Cup, to take place Nov. 8-Dec. 27, 2014 in Saxonburg, PA. Fee: $10 for one cup. To learn more, e-mail christylculp@ yahoo.com, log onto www. saxonburgarts.blogspot.com, or call 724.422.0851. ‰ The Association of Clay & Glass Artists of California (ACGA) is accepting entries through Oct. 31, 2014 for its 3rd Clay & Glass Biennial in Brea, California, to take place Jan. 24 - Mar. 6, 2015. Fee is $30 for three entries from clay or glass artists ages 18 and up. To learn more, e-mail acganational @gmail.com; or log onto www. acga.net.

‰ Ceramic art entries made within the past three years are being accepted through Nov. 7 for the Korea Ceramic Foundation’s International Competition to take place Apr. 24-May 31, 2015 at Korea, Gyeonggido. To find out more, e-mail hycho.seyartnet@gmail.com, call +82-(0)31-799-1518, or log onto www.kocef.org

‰ Entries of tea-related ceramic, metal, and wood art ranging from infusers and teapots to cups and sets are

being accepted through Dec. 5 for All Things Tea, to take place Jan. 22-Mar. 6, 2015 in Manchester, NH. Fee: $25 for three entries. For prospectus, log onto www.550arts.com. For more information, email info@550arts.com or call 603.232.5597. ‰ 18 Hands Gallery of Houston, Texas is accepting entries through Dec. 10 for its 8th Annual Texas Teapot Tournament, to take place Jan. 10-31, 2015. Entry fee: $45 for up to two teapot entries composed of at least 60% clay [fee also covers membership in CAMEO, Clay Arts Membership and Education Organization]. For prospectus and complete submission details, log onto www.18handsgallery.com, e-mail info@18handsgallery.com, or call 713.869.3099. ‰ Entries of bonsai containers handmade in the U.S. are being accepted through Mar. 21, 2015 for the 3rd National Juried Bonsai Pot Exhibition, to take place June 12-Aug. 2, 2015 at the National Arboretum in Washington, DC. Fee: $35 for up to 10 entries. For full details, visit www.bonsai-nbf. org, e-mail AskRon@comcast. net, or call 561.832.0480. [

To list your events, clay conferences, calls for entries, exhibitions, or ceramic news items in Clay Times®, please e-mail complete details to: claytimes@gmail.com, or click the submission link at www.clay times.com/contribute.html to fill out an online entry form.

The Fulwood

Measure

TM

The perfect tool for same-size production pottery. Unique hinged pointer measures height and diameter of the pot and moves out of the way when not in use. With the Fulwood Measure, you can get it right every time. Handcrafted in beautiful hardwood and made in the USA.

Kissimmee River Pottery

Stangl Factory 12 Mine Street Flemington, NJ 08822 908.237.0671 riverpots @ earthlink.net www.riverpots.com

QUALITY BrandPOTTER'S New VIDEOS ☛ Items... special deals! & BOOKS

22

fun styles ... sizes s-xxxl

☛ CLEVER POTTER'S T-SHIRTS

new back issue downloads & more at the Clay Times® Online Store

www.claytimes.com/store.html

CLAYTIMES·COM n SUMMER/ FALL 2014

‰ Entries of works made primarily of porcelain are being accepted through Nov. 14 for All About Porcelain, to take place Feb. 6-27, 2015 at The Clay Studio of Missoula, Montana. Fee: $25 for up to two entries. Works must measure less than 20 inches and weigh less than 20 lbs. For further details, e-mail: info@theclay studioofmissoula.org, telephone 406.543.0509, or log onto www. theclaystudioofmissoula.org

Hot Stuff I News & Events

‰ The Workhouse Arts Center of Lorton, Virginia is accepting entries of ceramic drinking vessels from artists worldwide through Nov. 2, 2014 for Drink This! The Workhouse International Cup Show, to take place from Jan. 7 - Feb. 2, 2015. Fee: $25 for one entry, $30 for up to three entries. Entries must have been completed within the past two years. Mixed media works are permitted if clay is the primary component. To learn more, e-mail dalemarhanka@ workhousearts.org; log onto www.workhousearts.org; or call 703.584.2982

13

14

CLAYTIMES·COM n SUMMER/FALL 2014

Building the Gulf Breeze Arch Part one of a step-by-step series on Architectural Ceramics BY PETER KING

Fig. 1

Fig. 2

Pictured, opposite page: Xinia Marin, who assists husband Peter King with construction, beneath the completed arch.

lose out to mosaics made with commercial tile or, more often, welded sheet metal. With these it is far easier, cheaper, and faster to make something of monumental size. Architectural ceramists must give themselves an edge. This can be done with narrative.

For pure symbolism, my favorite such passageway is a “Torii Gate,” the entrance to a Shinto Shrine. While freestanding in the open, it is a clear passage from profane to sacred space.

This land is the site of one of the first U.S. Strategic Reserves. It was created to preserve and cultivate the native live oak trees to build the Country’s first real Navy. Ships like the U.S.S. Constitution were built with wood from such live oaks. Gulf Breeze, Florida is today a huge boating community.

The Torii is what attracted me to the use of the freestanding arch as a vehicle for architectural ceramics as a public art medium. Pursuing and refining this led to our most complex, challenging commission to date, “The Gulf Breeze Arch” in Gulf Breeze, Florida. Public art is extremely competitive. Handmade ceramics usually

I have found that proposals that win many public art competitions have symbolic content that speaks to their context: the surrounding space, its history, and the local community. I find that something of the history of the art work’s location is always a winner. This means the artist is listening to the community. The work is about its residents, and where they live and work. This is why we chose the history of the Gulf Breeze Peninsula from PreColumbian times to the present day as our subject.

For these reasons the starting point for our design is a radial arch representing watercraft, ancient and modern, including the surf boards used in the adjacent Gulf of Mexico (Figs. 1 and 2).

continued on next page

CLAYTIMES·COM n SUMMER/FALL 2014

“Over the past 40 years, I have used and altered a few basic handbuilding techniques and applied them to the construction of high-relief architectural ceramics. All of these use readily available materials, homemade tools, and the tools found in most pottery studios. The many large-scale architectural works we have created, in a myriad of styles, have been made using these same basic techniques. Our latest commission, The Gulf Breeze Arch, used all of these—some in new and different ways.”

W

hile making a living building fireplace façades, fountains, murals, and such, I have always been more attracted to the passage or entryway as a format for artistic expression. Maybe this is the carpenter or wannabe architect in me, but I think it’s more my background in religious studies. Entryways, or portals of any kind, have been important in both utilitarian and spiritual ways since the time of our cave-dwelling ancestors. They can symbolize the security of the home, forbidden space, or political power, but they are also often a clear symbol of spiritual transition. Think of the entrance to a Gothic cathedral or, in fact, the temples of any religion. Entrances to “Holy Space” can be more or less ornamental, but they all carry the same symbolic weight of meaning.

15

Building the Gulf Breeze Arch (cont. from previous page)

Preparing the Studio & Equipment We have evolved a design for home built work tablets that are ideal for studio architectural ceramics. They are 2' x 4' x 33" high. They are made with ¾" plywood tops, have 360°, 750-lb.-capacity locking casters, and thus can hold up to 3000 lbs. We can arrange these in various configurations, making them adaptable for projects of different dimensions and profiles. For most projects we configure them, clamp them together, dust them with grog, and start laying out slabs.

Fig. 3

However, sometimes it is necessary to make custom additions. This was the case for “The Gulf Breeze Arch.” We wanted the radius opening to wrap to the inside in one continuous piece of the clay. Once installed, this completely covers the reinforced concrete substrate, making the sculpture more visually substantive. To achieve this, we configured our tables to maximum advantage for the profile of the arch (Fig. 3). We then built the radius by screwing 2x4s to the same level as those of the table frames, and extended our work surface by screwing ¾" plywood into the top edge of these 2x4s (Fig. 4).

CLAYTIMES·COM n SUMMER/FALL 2014

Fig. 4

16

Fig. 5

Once built, the added surface was flush with the existing tables (Fig. 5). I then built a large compass using 2x4s, calculated the size and placement of the opening, swung and marked an exact radius on the plywood addition. I repeated this to create a mirror image for the opposite edge. Once these had been cut away with a jig saw, we wrapped the inside of each radius with a double layer of 1 8 / " luan. This fine-grain material will flex more without breaking than other types of plywood. We affixed a ledger to the bottom edge of the luan to support the 1" slab we later wrapped down from the table’s surface. With the tables dusted with grog so the

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

slabs would move and release, we were then ready for the clay (Figs. 6-17). Flipping Slabs

We set the roller at 1", roll out a large slab, leave the canvas attached to the bottom side of the

Fig. 18

Then, using a rounded chop stick, we outline onto this smooth, 1"-thick surface the areas to receive relief construction. At this point, we are ready to begin application of the relief design (Fig. 19). [

Tune in to part two of this series in the next issue of Clay Times to continue with the sequentially illustrated construction process of the Gulf Breeze Arch.

Fig. 19

CLAYTIMES·COM n SUMMER/FALL 2014

I have a 1978 Bailey 30" drive board slab roller. We have made 100-lb. slabs with it since that date without a problem. My entire handbuilding system is based on this machine. If I didn’t have it I would have to invent it!

slab, and use it to carry the slab to our configured work tables. We then flip it onto the grogged surface. By lapping the slabs with a 2" lap, and pounding, sewing, and scraping the seams, we can quickly create a large, smooth “clay canvas” for our design. We call this our base slab (Fig. 18).

17

Perspectives I As Far As I Know

Artistic Considerations for Striking Effects BY PETE PINNELL

D

uring a lecture at the University of Lille in 1854, the scientist Louis Pasteur made his famous statement, “In the fields of observation, chance favors only the prepared mind.” This quote is often shortened to state simply, “Chance favors the prepared mind.” Either way, the meaning of it is as important to artists as it is to scientists: “chance” may present us with opportunities, but only those who are open to those possibilities will be able to take advantage of them.

White on White. Thrown porcelain plate by Amy Smith. 12" x 12" x 2".

I thought about this recently when I saw a show of work by Amy Smith, a Lincoln, Nebraska artist. The pieces that caught my eye were shallow, wall-mounted plates. The plates were coated on the inside with a white, semi-gloss glaze. This glaze has a slightly pebbled surface that diffuses light in a soft, skin-like way. Artfully arranged inside of each plate were round, high-gloss islands of a second glaze. These islands take the form of a thick, translucent lens that floats on top of the background glaze and has a sense of depth that contrasts nicely with the opaque, textured glaze around it. The effect is both quiet and dramatic.

CLAYTIMES·COM n SUMMER/FALL 2014

As someone who occasionally teaches glaze chemistry, it was easy for me to see what had happened on a chemical and physical basis. The background glaze (OU White) melts first, allowing the islands to sink slightly into the surface. This satin-white glaze has a lower silica-to-alumina level, so it devitrifies (crystalizes) slightly in a slow cooling, resulting in the slightly pebbled surface.

18

Detail of the plate’s glaze application before firing.

By contrast, the islands are made from Matt Long’s Accent Glaze. Matt’s glaze has a very high alumina level, so it is very stiff (has a high viscosity) and begins to melt later in the firing. A high silica-to-alumina ratio prevents crystal growth that would alter the surface, and a relatively high level of alkali (sodium and potassium oxides) lowers the glaze’s fired surface tension, resulting in a contrasting, high-gloss surface.

Perspectives I As Far As I Know Close-up view of White on White plate. The reflection of the light reveals the difference in surface textures of the two glazes.

In order to make this work, Amy had to (first) recognize the potential of each glaze; (second) decide how to combine them; (third) push the

qualities of that application far beyond the norm; (fourth) create a vessel worthy of this composition; and (finally), compose all of these elements in an aesthetically effective manner. This is what artists do. They recognize an aesthetic potential and then take that germ of an idea and develop it into something wonderful. Information is an important tool for artists, and it’s a good thing when we strive to learn more. On the other hand, artists don’t work from information alone: art also requires the heart, the hand, intuition, and experience. These are the things that create “the prepared mind” that Pasteur mentions. These are also the things that separate the scholar from the artist.

I’ve often told my students that you can memorize every word in the dictionary and still not be able to write poetry. What Amy does with this work is carefully select just a few visual elements, and combine them in an unusual way that results in the creation of visual poetry. That’s what I call art. [

Turn to “Great Glazes” on [next] page 20 to see recipes for the clay body and both glazes used to make Amy Smith’s plate pictured on these pages. Peter Pinnell is Hixson-Lied Professor

of Art at the University of Nebraska at Lincoln. E-mail him at ppinnell1@unl.edu or contact him via his Facebook page at

www.facebook.com.

CLAYTIMES·COM n SUMMER/FALL 2014

From an artistic perspective, all of the information I provided in the last paragraph is completely irrelevant. What’s important is that Amy recognized the contrasting, yet complementary, qualities of the two glazes. The white glaze is applied in a conventional manner and then the islands are slowly poured onto the surface in small, thick pools (see image). The placement and size of the islands are carefully selected to achieve the best composition: composed in a way that produces a serene but striking effect.

19

looking for hasslefree, one-stop shopping for your pottery making needs?

❀

Great Glazes furnished by Pete Pinnell (supplement to story and photos on p. 18-19)

log onto ❤ claytimes.com for BRAND-NEW OFFERINGS in potters’ books, tools, t-shirts, printed and digital back issue collections, magazine SUBSCRIPTIONS & RENEWALS, and more ... PLUS the VERY BEST DEALS of the season!

CLAYTIMES·COM n SUMMER/FALL 2014

✷

✿ VISIT us online at WWW.CLAYTIMES.COM OR CALL 1-800-356-CLAY

20 20

Amy Smith’s Porcelain (clay body) Grolleg China Clay 50% Ball Clay 5 Flint 13 Custer 20 Pyrophyllite 12 TOTAL 100% add: Macaloid

2%

OU White* Glaze Kona F-4 Feldspar 25% Custer Feldspar 20 Whiting 9 Dolomite 10 Talc 6 EPK 18 Silica 12 TOTAL 100% add: Zircopax Bentonite

8% 2%

* “I tried to find the original author of this glaze and I believe it may have been Val Cushing, who published a similar glaze (with slightly different proportions) called Cushing Stone White Matt.” — Pete Pinnell

Matt Long Accent Glaze Cornwall Stone 90% Whiting 10 TOTAL 100%

PART 1 OF 2

P

rocrastination is a universal topic for clay people and everyone else. We delay doing things that we don’t like, such as doing paperwork or a placing a difficult phone call. Following are remarks by five clay people about their thoughts and experiences with procrastination.

Susan Feagin, Clay Coordinator Penland School, North Carolina “I still put off the paperwork stuff like taxes. I got my taxes done early one year because I knew we were going to build the wood kiln, and I had to get ready. I have to write a manual for Penland on how to be a clay coordinator. It is due January 25 so, of course, I am going to start on January 22. I put off getting my car inspected and then when I go there, it goes so fast. I am a deadline-oriented person, like lots of potters. If I have to ship it on the 15th, I plan backwards and fire at the last possible minute.

I have to prioritize tasks during the summer when I am really busy. Like

I should file stuff instead of having piles and I just never get around to it because it is not crucial. Like old kiln logs — do I have to keep them? Where should they go? So they stay in a pile. Every year for the big August Penland auction, we make 500 cups to give away. We have even started earlier and earlier each year, and I am proud of that because now we have the cups done before summer classes even start.”

Jeff Oestreich Studio Potter, Minnesota “I have always procrastinated. I put off doing my taxes so I always get an extension on taxes.

At the end of a wet cycle of making work, I try to get one more mini series done because I so want to get one more idea in the kiln. I really push the drying process with these last-minute pots, so sometimes things blow up in the oven overnight, or in the bisque. But it is stimulating for me to make that new mini series and push the time on drying. Even today I am procrastinating because I am at the beginning of a cycle of pots. About ten years ago I figured out this was my pattern. I started looking at what my habits are, and what I can do to have more joy in my pottery making. If we know better, we do better. I have thought about some of my other traits and their connection to procrastination. I am a bit obsessive

“I am a deadline-oriented person, like lots of potters. If I have to ship it on the 15th, I plan backwards and fire at the last possible minute.” — Susan Feagin I am always slow to get going on the beginning of the clay making cycle. Later in the cycle of making pots, I get really focused; I don’t procrastinate as much. I am so focused preparing for the big St. Croix Pottery Tour (www. minnesotapotters.com) that when it gets down to that last month, if there are any interruptions I can be easily annoyed [and annoying, too]!

and compulsive (you may have already guessed!). For me, the end result of my obsessiveness is procrastination. I read in the book Please Understand Me, which tests one’s temperament, character, and intelligence (Myers-Briggs Test), that artists go for stimulation. My obsessive-compulsive side creates stimulation for me, and in the end, it can fuel my work. continued on next page

CLAYTIMES·COM n SUMMER/ FALL 2014

The process I like the best is forming things out of clay, working with wet clay. I also like the printing on clay; it is exciting. Glazing is okay, but not great. I procrastinate photographing my work. I have a photographer in Georgia just over the border, but I put off taking work down to be photographed. I just have to buckle down and do it.

BY LANA WILSON

Perspectives I Beneath the Surface

Dealing with Procrastination

21

Perspectives I Beneath the Surface

Procrastination, cont. For example, here is what happened today: I woke up, made coffee, and got back in bed with my iPad to answer e-mails. An e-mail from Judy Davis mentioned a Website that sells a liquid wax for batik artists. As I am always on the lookout for a better wax resist, I checked out the Website. Later, I checked out an e-mail from Red Lodge Clay Center. I saw some cups with great slip trailing by Ron Philbeck, and I thought of thickening a wax so I could trail it.

by the time I got back from buying the varnish. It was dark out, but I got the board out of my system and was calm enough to work in the studio.) I realize that one of the benefits of being self-employed is that I can be as obsessive as I want; I am allowed to be who I am. This creates stimulation, and that gets funneled into my work. But this behavior can backfire on occasion (and yes, you can print this)!”

From there, I practiced the piano and was having a hard time with the timing. I began to wonder if my timing problem was due to the possibility of my left brain not functioning as well as my right brain. “Time to take a bath,” I thought. I would research it while in the bathtub.

Claire Reishman, Director Shakerag Workshops, Tennessee

Then I thought I’d better go out in the studio and cut a board to lay across the bathtub for my iPad. I got out there and found some boards ... but then thought, ‘it must be a beautiful board’, so I sanded down a nice oak board. From there, I thought I should varnish it, but had no marine

“I am not realistic about how long things will take. Ultimately one must prioritize, and I do, which always leaves some things at the bottom of the list. I have needed to varnish my front door for two months and mend my horse blanket for three weeks. I have had the time to do those things, but have chosen to do other things instead — ride the horse (repeatedly!), fire the kiln, make pots, clean the studio, bake cookies. We all have 24 hours in a day, and I for one tend to do what interests me, and what I feel responsible

“... most procrastination issues happen from not knowing how long something might take to do, so I put it off, thinking I can just get it done easily.” CLAYTIMES·COM n SUMMER/ FALL 2014

— Sandi Pierantozzi

22

varnish. (I’m in the bath typing this and will get out, get dressed, and drive 20 miles to buy some varnish.)

to do. Only at the end do I do what I know I should do, but don’t really enjoy!

After decades of battling this obsessive-compulsive part of me, I now just give in to it and let it run its course. (It was mid-afternoon

Clay procrastination is on a shorter time line, since one can’t let things dry out before handles and alterations are made. Bisqued but

unglazed ware must eventually go somewhere so it finally gets glazed ... but the procrastination still exists, even within a shorter time period. I don’t know how others handle this problem but for me, the things that I procrastinate on gradually bubble up to the top and eventually get done, albeit not in a timely fashion — and last month I even cleaned my sewing room, which has needed to be done for years! All of my procrastination is inadvertent, as it is not procrastination so much as it is a consistent underestimation of the amount of time things take. I will make cups one day and plan to put handles on after trimming the next day, but then the sun comes out and it seems like a wonderful day to be outside trotting through the woods on my horse ... so I tell myself that I can trim and get those handles on in just a few minutes before dinner, which is obviously impossible. Even though I know how long it takes me to put on handles, or trim pots, or glaze, I consistently underestimate the time needed. So I end up having to postpone a firing, or move ahead without the work that I had hoped to have in [the kiln]. I see this pattern over and over, yet I expect a different result each time, even though any idiot would be able to foresee the impossibility of being able to do what I set out to do within the time I’ve allowed! It is a dilemma, but one I’ve grown accustomed to see looming before each show or firing. I take comfort in my mother’s saying that it is better to have too much to do than to have nothing one wants to do!”

“For the most part, I am not too bad at procrastination with studio work, but it is easy to be distracted from things like desk and computer work, which I do at home. If I am home, I would rather be cooking, and so I do … the desk work will get done, I tell myself. For me, most procrastination issues happen from not knowing how long something might take to do, so I put it off thinking I can just get it done easily. Years ago, when I was trying to make the transition from graphics to clay, I could only get to the studio at night. I would plan too much to get done in the available time, so I finally started timing myself to see how long various tasks took me to do. That really helped. I knew I could get handles on 15 cups in two hours, and then if I had time, I could start on something else. If I did procrastinate, at least I knew how long I could put things off!

Making work is not usually a problem. We have a calendar of when we are going to fire. I write down all the deadlines and get them on my calendar and use postit notes on my table. I often forward e-mail reminders of deadlines to myself, until the deadline is met.

time management. Besides that, my parents were good role models. I do procrastinate on getting back to e-mails I’ve put off. I type with two fingers and it takes me forever. E-mail is the worst. With income taxes, we never do it at the last minute. We do them in March. For our open house, we plan with a calendar and we know when we have to get things done. I have a friend who is a big procrastinator and I watch it. I never want to do that because it would make me crazy.

“I will make cups one day and plan to put handles on after trimming the next day, but then the sun comes out and it seems like a wonderful day to be outside trotting through the woods on my horse ...” — Claire Reishman My mother was very organized. She worked in the home as a seamstress and was always on her deadlines. I never saw my mother in a frenzy about things, so I had a good role model for organization. I hate being in a frenzy, so I try not to put myself in that head space. It has taken some time to learn how to do that. I don’t think because you procrastinate you are not organized, I just think that time can evaporate and there is always so much to get done!” Neil Patterson, Potter and Co-owner of Neighborhood Pottery, a gallery and teaching studio in Philadelphia “I’ve never been much of a procrastinator. I had to work to get through college, and that was good because I had to be good at

When I teach, I recognize that my students never do their best work when they are stressed or crunched up against a deadline. There is so much time management involvedin working with clay; I feel that it is an important part of any studio practice.” [ PROCRASTINATION PART 2: [to be continued someday soon!]

The second part of this column, to appear in the next issue of Clay Times, will offer more artist interviews and will highlight Lana’s online research on this topic (a process which, along with interviewing people, has already helped her deal with her own procrastination!) Lana Wilson may be reached at lana@ lanawilson.com. Her Website for workshop info. and images is www.lanawilson.com.

CLAYTIMES·COM n SUMMER/FALL 2014

I can deal with my own procrastination, as long as it only affects me. I find it much harder to be on the other end of someone else’s procrastination, such as getting an e-mail requesting that images, approvals, or other written info is needed by noon tomorrow, or an unreasonable deadline for the given request. This is difficult because I might not have time to deal with the request on the spot, given that I already have other things to get done that day.

I once heard a quote, “The disorganization on your part does not constitute a crisis on my part.” That made me laugh, but it does get to the point of what it is like to be on the other end of procrastination.

Perspectives I Beneath the Surface

Sandi Pierantozzi, Potter and Co-owner [with husband Neil Patterson] of Neighborhood Pottery, a gallery and teaching studio in Philadelphia

23

CLAYTIMES·COM n SUMMER/FALL 2014

24

Directly above: Reitz covered pitcher, 12½" tall; and (above pitcher) its foot detail. Top right and background/detail: Don Reitz platter, 13½" diameter. Pictured works are wood-fired stoneware from the Clay Times permanent collection. Top left: Don Reitz (center) with Tom Coleman (l) and Glen Blakley at the 2011 NCECA conference in Tampa, FL.

Remembering Don Reitz BY RICK BERMAN GLEN BLAKLEY PHOTO

Please allow me to speak from the heart about our beloved friend, Don Reitz, who passed away in early March, 2014.

I

’ve always said that if there were one potter in the world who could represent all of us at the U.N., the White House, or on one of the late night talk shows, it would most definitely be Don Reitz. Of the thousands of people he met in his many travels and workshops around the world, I would bet there is not one person who would disagree with this statement. Don was a one-in-a-million personality who touched everyone’s heart because he gave love and encouragement to everyone he met. He truly was bigger than life. I would like to share one small story about the first time I met Don, in summer of 1970. I had started making pots in the fall of 1968, and was starting my last year of undergraduate school at Georgia State University in Atlanta. I heard somehow that there was a workshop coming up at the University of Georgia in Athens. Even though I knew nothing of such things, I decided to go.

At that time, however, I had never heard of Don Reitz, so I didn’t know what to make. Instead, I observed.

had covered every table and floor space in both the undergraduate and graduate studios.

Don was constantly talking and moving his giant hands as he threw. Soon I witnessed the making of some of the biggest and most beautiful pitchers ever made!

Just keep passing it on. May God bless his precious soul. [

He made covered jars, large plates, sculptural forms to put together later, and handles, handles, handles, on almost every pot. By the end of the first day of the workshop, his pots

Needless to say, my life and awareness were changed forever. I still think about that day 45 years ago and get a huge burst of energy, and a tick in my neck. Just think ... Don Reitz gave this same experience and this sense of freedom to thousands of potters around the world. How could we ever repay him?

Editor’s note: For more on Don Reitz and his work, log onto www.claytimes.com/ DonReitz, where you will find Rick Berman’s complete two-part interview with him (originally published in the Jan/Feb and Mar/Apr 1996 issues of Clay Times). Rick’s e-mail is: rickbermanceramics@gmail.com

CLAYTIMES·COM n SUMMER/FALL 2014

About 30 or 40 potters from many neighboring states were all there waiting for Don, who had been delayed at the airport for an hour or two. Meanwhile, Cynthia Bringle suggested that we all make a miniature Don Reitz piece to surprise him when he arrived.

After a while, Don finally showed up and started wedging very large pieces of clay. (I don’t think he ever wedged less than 25 lbs. of clay at a time.) He eventually sat at the wheel, and went to work. He threw a couple of cups off the hump, and decorated them loosely with his slips straight away. You know the drill: honey, white, blue, green, brown, black. Then a comb tool mark or two, and needle tool lines, then a bowl, more brush strokes, more marks, coil additions, more clay.

25

Slurry Bucket Tips

“My Flex Slider is here and my students are loving it. Thanks for taking the time to get it right.” Charlotte Greenblatt Canyon Pottery Malibu

Editor’s note: With all the crazy weather our world is now experiencing from climate change, it’s a good idea to consider the following disaster preparedness advice for artists, compiled by the Craft Emergency Relief Fund (CERF): CERF Tips for Disaster Preparedness • Document the contents of your studio (photo, video, or paper inventory) and store in a safe off-site location (SOL) 50-100 miles away from your studio • Install smoke detectors, fire alarms, and fire extinguishers, and check them regularly to be sure they are in working order • Keep hazardous materials in appropriate containers, stored in approved fireproof cabinets away from ignition sources • Properly dispose of oily rags and other hazardous waste

CLAYTIMES·COM n SUMMER/ FALL 2014

• Secure all points of entry and install a burglar alarm system

26

The Flex Slider III™ For off-centered, asymmetrical, and plain old wonkey pots.

More of CERF’s tips for “covering your As” (Arts, Assets, Archives) are now available in the form of The Studio Protector Wall Guide. This easy-to-use disaster readiness and response toolkit has been designed by artists for artists, to help save your art, your workspace, and your career. The interactive, easy-to-follow kit features two wheel charts and five pull-out, pocket-sized booklets loaded with tips on how to prevent and prepare for an emergency in your studio; what to do immediately after a disaster; and where to get help. To learn more, log onto the Website at: www.studioprotector.org. [

In response to the continuing high rates of silicosis and silica-induced lung cancer in U.S. workers, the Occupational Safety and Health Administration (OSHA) has proposed a new silica regulation. The public hearings on this proposal were held from March 18 to April 4, 2014 after which written comments and data were accepted for 45 days. Some time in the near future, OSHA is expected to either publish a final rule or reopen the discussion.

Studio I Health & Safety

BY MONONA ROSSOL

The proposal1, all 230 pages of it, includes discussions of the major studies that OSHA has relied on for its opinion. There are reams of studies referenced. Three of these are of special interest because they are of silica exposures in Chinese tin miners and pottery workers. Pottery Workers Studied

T

he primary study of the potters and miners was published in the American Journal of Epidemiology. It measured cumulative silica exposures in a group of more than 30,000 workers over a 44-year period. This study, as well as all the other studies in the proposal, showed clearly that airborne silica dust is associated with significant increase in the risk of developing lung cancer and silicosis.

Clay dust, then, can cause silicosis, but at lower rates because the silica particles in clay don’t have sharp, freshly broken surfaces. There are only a few sources of freshly fractured silica particles in art potteries (such as when chipping or grinding kiln wash from shelves, during abrasive blasting, or when cutting refractory brick during kiln building). Back in 2005, in two issues of Clay Times, I wrote about several potters and teachers with silicosis including Warren MacKenzie, a well-known ceramics professor.2

The New Proposed Limit The proposed rule sets the new OSHA Permissible Exposure Limit (PEL) at 0.05 milligram per cubic meter (mg/m3). However, OSHA says clearly that this standard will not protect workers fully. They note that a better standard is that of the American Conference of Industrial Hygienists® (ACGIH®). This limit is half that of the proposed OSHA limit (TLV® = 0.025 mg/m3). OSHA explains that they must set an unprotective limit because they are required by law to set standards that are both technologically and economically feasible. While the lower limit would be technically feasible, it would require respirator use for many industries, and this is not economically feasible for many continued on next page

CLAYTIMES·COM n SUMMER/FALL 2014

The rates of lung cancer were about the same in both the miners and the pottery workers studied. However, the risk of developing silicosis was somewhat less in the Chinese pottery workers, when compared with the miners. The reason appears

to be that higher numbers of cases of silicosis will occur in industries in which the airborne silica particles are freshly cut or fractured, such as in mine work or sand blasting.

27

Studio I Health & Safety

Proposed Silica Rule Changes industries. As a result, the law requires workers to sacrifice their health and life spans to keep their industries healthy.

In order to alert employers to the fact that other standards are more protective than the PELs, OSHA has provided two new Web-based resources:

New OSHA Strategy on Air Quality

1) a step-by-step toolkit with information, methods, and guidance on chemical substitution in the workplace, and

OSHA and its director, David Michaels, are very aware that most of their standards are not fully protective. In fact, most of the Agency’s PELs are also out-ofdate: they have been unchanged

2) an annotated occupational exposure limits table featuring OSHA’s existing regulations (called

“I remind schools that non-employees, such as students or volunteers, do not come under OSHA standards. Instead, we have a responsibility to protect them completely. They did not agree to accept the risk of contracting either lung cancer or silicosis. Legally, we owe them even more information and protection than the OSHA regulations require for workers.”

CLAYTIMES·COM n SUMMER/ FALL 2014

since 1971, when they first adopted about 400 of the ACGIH’s air quality standards into law. Today, there are over 640 ACGIH TLV®s, which means there are also more than 200 toxic substances for which OSHA has no standards at all.

28

OSHA tried to update 400 PELs in 1989, but a court challenge by a coalition of industries vacated them in 1992. The court required OSHA to develop complete economic and environmental impact statements for each substance. Since writing these two documents for 400 substances would take decades, OSHA is unable to proceed.

the Z-Tables) alongside other occupational exposure standards including the California state standards, the National Institute for Occupational Safety and Health (NIOSH) Recommended Exposure Limits, and the current ACGIH TLV®s. As an Industrial Hygienist and member of the ACGIH, I’m especially pleased to see this annotated table. Until now, the ACGIH TLV®s were only available in a booklet that cost $49.95 plus shipping. Now this data plus the data from California and NIOSH can be seen for free at: www.osha.gov/dsg/annotatedpels/index.html

Recommendations OSHA’s David Michaels advises using the most protective limits for workers when this is possible. I agree ... and if, on occasion, that requires instituting an OSHA Respiratory Protection Program for the workers, so be it. In addition, I remind schools that non-employees, such as students or volunteers, do not come under OSHA standards. Instead, we have a responsibility to protect them completely. They did not agree to accept the risk of contracting either lung cancer or silicosis. Legally, we owe them even more information and protection than the OSHA regulations require for workers. Students who are children, in particular, must have essentially no exposure to substances that cause long-term illnesses. They should be given an array of interesting and educational projects that do not create dust. Proper clean-up and good hygiene should be part of their training. These hygiene practices should keep workers and students well and healthy for a lifetime of working with clay. [ Footnotes: 1. Two Federal Register documents: 78 FR 65242-654244, October 31, 2013 and 78 FR 56274-56504, September 12, 2013. 2. Clay Times, July/Aug 2005 and Nov/Dec 2005. Monona Rossol is an industrial hygienist/chemist with an M.F.A. in ceramics/glass. E-mail her at: ACTSNYC@cs.com

Mosaic Mania BY PAULA SMITH

Mosaic is a visual art form that uses small pieces of ceramic tiles, glass, stones, and/or found objects. This ancient decorative art dates back to the second half of the 3rd millennium B.C., with glazed tiles appearing as early as 1500 B.C. The early Greek mosaic imagery depicted mythological figures, while early Roman mosaics featured beautifully patterned geometric centers with strong borders. There are many historical examples of mosaic throughout the Middle East and Europe, too. Ravenna, Italy is known for its beautiful Byzantine mosaics inside the churches, mausoleums, and historical buildings. In the late 19th century and early 20th century, Barcelona architect Antoni Gaudí created a modern twist with mosaics or trencadis, a form of mosaic, in which he used broken ceramic tiles and dishes to cover park benches, fantastic creatures (i.e., Park Güell), exterior walls, and chimney stacks. Inspired by Gaudí, 20th-century French artist Niki de Saint Phalle created “The Tarot Garden” in Tuscany, Italy. This monumental sculpture park takes its inspiration from tarot card imagery: featured are scaled sculptures are covered in broken tile mosaic. depicting The Wheel of Fortune, The Magician, and The High Priestess, to name a few. Project I: Trivet, 12" x 12" x ½" Materials: Store-bought floor tile, broken found plates, premixed acrylic tile adhesive, cream sanded grout, small bucket to mix grout in, respirator, rubber gloves, and silicone feet.

Project II: Bath Tub Surround, 120" x 29" x ¼" Materials: Concrete backer wall board, Liquid Nails®, screws, thin set mortar, purchased and found broken tiles, black sanded grout, grout sealant, paint brush, sponges, buckets, drill with a mixer attachment, rubber gloves, and a respirator. My next project was our front bathroom tub surround. At that time I didn’t have a lot of money, so I was on a tight budget. I went out to all the local tile companies and collected old tile sample boards and discarded tiles. Then I proceeded to break them into smaller pieces. I wanted a very colorful palette, so I did need to special order some of the colored tiles, (i.e., plum). continued on next page

CLAYTIMES·COM n SUMMER/FALL 2014

A

great way to learn a technique is to make something small like a tile trivet. I went to junk and secondhand stores to collect chipped or broken old plates. I then went to a home improvement store and purchased a few 12" x 12" x ½" floor tile. I broke the found ceramic objects into small pieces, designed, and adhered my mosaic onto the surface of the floor tiles. I let it dry for 24 hours; then I grouted them and put silicone squares on the bottom so that they will not scratch the table surface.

29

Mosaic Projects, cont.

CLAYTIMES·COM n SUMMER/FALL 2014

When you are making your own ceramic shards, rule no. 1 is to wear safety goggles. Rule no. 2 is to break tiles without hurting anything. I did this by finding a good, flat surface strong enough to support the tiles when they are broken with a hammer. I used an old pillow case to cover the tiles so shards of broken ceramics wouldn’t go flying through the air (heavy-duty plastic sheeting or bags can also be used for this purpose). After the hammering process was complete, I sorted all the tiles by color, storing them in separate boxes.

30

a matter of finding pieces that fit together to form the desired pattern. Since I usually work slowly on my projects, I “butter” the individual pieces with tile adhesive, instead of troweling a large area of tile adhesive onto the wall. For this project, I used a premixed acrylic tile adhesive, available from most home improvement stores. After adhering all of the mosaic pieces, I allowed the project to dry for the recommended minimum of 24 hours before use.

Grouting 101

To prep the bathtub surround, I used Liquid Nails® and screws to secure Wonder Board®, a concrete wall board, onto the existing wall. Then I placed a stool in the tub and started adhering the tile pieces to create an abstract floral design similar to that of the existing fabric covering the lower part of the bathroom walls. I chose a black sanded grout that recesses visually, allowing the colorful tiles to come forward.

Whenever working on mosaic projects, I use “sanded grout.” This fills in the spaces left between the tile pieces and creates a smoother surface. Sanded grout can fill in gaps that are 1/8" to ½" wide. With this flat wall project, I used the traditional “float” trowel, (a tiler’s handled trowel with a flat, stiff, foam-covered rectangle) to force the grout into the crevices.

Designing mosaic work with broken pieces of tile is like doing a jigsaw puzzle — it is a time-consuming process requiring patience. I begin by defining the edges or borders of the design. After that, it is simply

To grout, cover the entire surface according to the package directions. Then use a large, flat, damp sponge to wipe away the excess grout and clean the tiles. (This seems like it takes forever!) Because black grout

contains a large amount of stain and the edges of the broken tiles can be sharp, be sure to wear heavy-duty rubber gloves to protect your hands. You will need to clean the sponge often. Do not use your tub or your sink to clean your sponge or your tools. Use a large bucket, and empty it in a proper location. To finish the bathtub project, I used a grout sealant applied with a paint brush. (Yes, I am crazy for details!)

Project III: Mosaic Hand Sculpture 9' x 5' x 25" Materials: Hardware cloth, pressuretreated plywood, 2x4s, screws, fiberglass, handmade ceramic tile forms, mirror pieces, glass forms, thin set mortar, black sanded grout, buckets, sponges, rubber gloves, vapor respirator, and electric drill with mixing attachment. My next mosaic inspiration came to me by way of a large hand armature that I acquired. It was constructed with plywood, 2x4s, and screws. I covered it with hardware cloth and decided to weatherproof it by covering it with fiberglass — a nasty cloth-like material that I cut up into smaller pieces. I then mixed up a two-part resin (incredibly toxic) and applied it to the fiberglass cloth. Throughout the process, I wore protective clothing, a fume vapor respirator, and chemical-resistant rubber gloves. I also did this work outside because of the scale of the piece, the toxic fumes, and the general mess that it created. This project was different from the tub surround, since I decided to make (not break) all of the ceramic mosaic forms. I made glazed stoneware leaves, flowers, round disks, hearts, and various other shapes to cover the entire hand sculpture.

Project IV: The Stylized Mosaic Sea Turtle 12' x 10' x 18" Materials: Weather-treated plywood, 2x4s, a sheet of Styrofoam insulation, Liquid Nails® in caulk tubes, caulk gun, diamond metal mesh, metal snips, screws, washers, fiberglass surface bonding cement, ceramic tiles, pebbles, copper anchors, thin set mortar admix, thin set mortar, brown sanded grout, buckets, sponges, rubber gloves, and drill with a stirring attachment. My latest project is “The Stylized Mosaic Sea Turtle.” The idea was first conceived while delivering my “Mosaic Hand” sculpture to an outdoor juried Public Art Exhibition on Hilton Head Island, South Carolina. Inspiration came from a baby sea turtle housed in a small glass aquarium in the Honey Horn Plantation Visitors Center. For some reason, this little turtle and I connected. South Carolina has a very successful conservation program to help repopulate the endangered sea turtles. Sea turtle nests are carefully watched by volunteers. Injured sea turtles from all over the east coast are rehibilitated at the South Carolina Aquarium in Charleston.

Ever since my encounter with the sea turtle at Hilton Head, I have wanted to create a huge mosaic turtle.

I started making stoneware glazed tiles in the shapes of fish, leaves, dots, flowers, organic shapes, dolphins, and starfish. At first, while I was building the substructure, I thought I would cover the form with a Mandela, which is a complex circle seen in Buddhist and Hindu art forms. Mandela designs create a “sacred place” with shapes forming a radial balance of a circle within a square.

The faces provide a “Where’s Waldo” interactive element to the piece: again, to inspire greater interaction. I decided to build the turtle differently than the mosaic hand sculpture. I did not like using fiberglass, due to its toxicity. This time, I began with treated plywood and 2x4 armature. To begin, I used a rubber toy sea turtle to figure out my proportions. My scale ratio was 1 inch of the toy sea turtle equals 1 foot of my sea turtle sculpture. I made patterns on large sheets of paper, drawing the shapes of the body, the front and back legs, the head, and the tail.

After looking at the shape of the turtle’s back, however, I reconsidered this design, as it did not really fit the shell. Instead, I changed my design to feature various faces from different time periods.

I filled in the negative spaces with layers of sheet foam insulation that I glued together with Liquid Nails®. This allowed me to sculpt the different parts of the turtle with a saw and serrated knife.

This idea also fit with my belief that we are all connected on earth in our desire to protect these creatures. I thought it would be interesting to enlist some of my friends and my students to make flat, ceramic self-portraits or historically based portraits to later apply to the surface.

I then formed sheets of diamond metal mesh around the parts. I used metal snips and screws with washers to form and attach the mesh to the plywood base. I then covered the entire form with fiberglass bonding cement (see step-by-step images, p. 32-33).

continued on next page

CLAYTIMES·COM n SUMMER/ FALL 2014

Throughout history and across the world, many cultures have associated the turtle as a symbol of longevity, protection, stability, and good luck. Others have used the turtle to represent the “great mother creation” myths. Today, the sea turtle has become a symbol for environmentalism. There is evidence that sea turtles have been around since the days of the dinosaurs.

This sculpture was planned to be a bench—an interactive sculpture that invites viewers, especially children, to touch and sit on it [but that’s artist/ author Paula Smith pictured above].

31

Mosaic Projects, cont.

1

I built the bottom of the turtle’s body first. I laminated pink Styrofoam sheets using Liquid Nails® with a caulk gun. I covered this surface with the diamond mesh (available in 8' x 2' sheets). It is important to use work gloves when working with the metal mesh. I had to cut it with metal snips and form it around the Styrofoam and wooden armature. I used screws with washers to fasten it to the wood.

3

Instead of finishing the bottom area with ceramic tile mosaic, I used acrylic tile adhesive to adhere small pebbles to reference the look of sand. Afterward, I flipped the work over and finished forming the top of the back.

Fig. 3

Fig. 1

2

I used a bonding surface concrete that has fiberglass fibers. When mixing this bonding cement it’s also important to wear rubber gloves, as well as a dust mask, in a wellventilated or outdoor environment.

Fig. 2

To create a water barrier, I used 1" blue Styrofoam sheet insulation on the bottoms of the head, legs, and tail. To deter theft, I screwed copper flanges onto the plywood sheets so that the sculpture could be securely anchored into the ground.

4

Next, I laid out the ceramic pieces to figure out the finished design (see Fig. 4, opposite page). I had all of my ceramic tiles separated into boxes for easier inventory and access. To make bonding cement clean-up easier, I put the armature pieces on thick plastic sheeting before affixing the mosaic pieces with thin set, which I mixed up outside while wearing rubber gloves and respirator.

CLAYTIMES·COM n SUMMER/ FALL 2014

5

32

To mix the bonding cement, I used an electric drill with a mixer attachment, following the instructions on the package: First I mixed it up, then let it rest for five minutes, and then re-mixed it. I simply used my hands (protected by heavy rubber gloves) to spread the bonding cement onto the armature that was covered with metal mesh. I made sure to push the cement into the negative space of the mesh.

Instead of mixing the thin set with water, I used thin set admix concentrate for higher bonding strength. I followed the directions on the label, except that I mixed the thin set to the consistency of cookie dough. This material is time sensitive; because I was hand buttering each piece, I only mixed up an amount I could use within an hour.

Fig. 5

Building the Sea Turtle: One Step at a Time

Fig. 4 Ceramic pieces are laid out to begin work on the final elements of design (described in step 4, opposite page).

6

I applied the thin set to the back of each tile with a knife, then placed each tile onto the turtle. I was careful not to allow the thin set to ooze around the tile too much; otherwise, it would not leave enough room for application of the grout.

Fig. 6

7

As far as the grout is concerned, I followed the directions on the package. I would suggest grouting the whole form in one application, which for the back of the turtle was a hard job. I applied it with my hands (again protected by heavy-duty rubber gloves) and worked in a circular motion, making sure to push the grout all the way into the crevasses.

Making a large sculpture like this is like giving birth to a child. It takes a whole lot of labor, and then you have this amazing thing out in the world. [ Note: Mosaic Sea Turtle is still in need of a permanent home. To learn more, e-mail Paula Smith: paula.smith@cpcc.edu

Fig. 7

CLAYTIMES¡COM n SUMMER/ FALL 2014

I cleaned the grout off of the tiles as soon as it was set [not like the previous wet sponge method], as the tiles will have a dry film all over the surface. This made grout cleanup so much easier. It is called dry wiping. Sometimes I had to kind of dig the grout off of the tile edges. I soon realized the importance of cleaning every single tile so the brilliant colors and surfaces weren’t covered by a permanent film of grout.

33

Readers Share I Art Works CLAYTIMES·COM n SUMMER/ FALL 2014

ERIC WALSH PHOTO

34

The Gallery

Succulence is a Beautiful Thing. 6" x 6". Wheel-thrown porcelain with glaze and underglaze, fired to cone 6 in oxidation. Wendy Shirran, Craft Council of Newfoundland and Labrador, 59 Duckworth Street, St. John's, NL A1C 1E6, Canada. E-mail: wendyshirran@gmail.com; Website: http://wendyshirranceramicart.wordpress.com/

Submit images of your claywork to The Gallery! Send your high-quality color print, slide, or 1050-x-1500-pixel (minimum) digital image to: The Gallery, Clay Times, P.O. Box 17139, Amelia Island, FL 32035. Be sure to include your name, address, telephone number, Website and/or e-mail address, type of clay and glaze, firing method, and dimensions of the work. (Please enclose a self-addressed, stamped envelope for photo or slide return.)

Readers Share I Art Works

The Gallery

Wine Flight with Tray. 14" x 13" x 5". Handbuilt grolleg porcelain with celadon glaze, fired to cone 10 in reduction. Marion Angelica, 4925 Logan Ave. S, Minneapolis, MN 55419. E-mail: mangelica@usfamily.net; Website: www.marionangelica.com

CLAYTIMES FALL 2014 2014 CLAYTIMES SUMMER/FALL ¡COM ¡COMnn SUMMER/

Untitled. Thrown and altered stoneware decorated with narrative illustrations and fired to cone 6 in oxidation. Richard Peterson, Akron, Ohio. Website: https://www.facebook.com/RichThePotter; E-mail: richthepotter@yahoo.com

35

CLAYTIMES·COM n SUMMER/ FALL 2014

A unique new tool for potters this year is the “Do-All” (pictured above and below) from Michael Sherrill’s Mudtools® line. Made of carbon steel, this double-ended trim tool draws its inspiration from the Japanese ‘kanna’.

36

BY VINCE PITELKA

I

first became seriously involved in ceramics during the 1970s, a time when the range of commercially-available clay tools was pretty limited. We all used the same basic types of cut-off wires, needle tools, sponges, soft blue ribs, stiff black ribs, kidney-shaped metal ribs, triangular wooden ribs, loop trimmers, and modeling tools. That was about it, but the limitations eventually inspired many of us to make our own specialized tools. I suppose that nearly all of our most innovative tool-makers of today were in the same boat. The end result is a wonderful plethora of clay studio tools — so many that the selection process can be daunting. My role is now to keep an eye on the makers and the market, in order to supply solid information on what I find to be the most interesting and innovative items. Here’s a summary of tools that have surfaced during the past year.

What a drag ... NOT! Bison Tools’ new J-shaped trim tools let sgraffito curls of clay pass through without the hassle of dragging.

The particular nature of the shapes and curves on the “spade” and “curl” ends of this new design have been well thought out, as seems to be the general case with all Mudtools products. I find that the Do-All works especially well for trimming classic footed items like bowls, plates, and teabowls, just as claimed in their marketing info claims (and visible in the photos pictured on the opposite page). While on the subject of trimming tools, for years I have been hoping

that Dolan or Bison Studios would produce tiny loops suitable for sgraffito and very fine carving, and this year Bison has come through. The image above shows several of the new shapes. Phil Poburka says that the “J”-shapes seem to work especially well for sgraffito, allowing the curls of clay to pass through with less dragging. Keep in mind that all Bison tools are tipped with super-hard-but-brittle tungsten carbide, and must be handled carefully to avoid breakage from dropping. It is a good idea to continued on next page

CLAYTIMES·COM n SUMMER/ FALL 2014

The range of items offered by Mudtools has grown considerably over the years. Their sponges and serrated ribs are favorites in my own work. The only new product from Mudtools this year is the “DoAll,” a multi-purpose double-ended carbon steel trimming tool that draws inspiration from the Japanese “kanna.” I’ve tested it, and really like the way it works. I still love the carbon steel Dolan trim tools, as well as the tungsten carbide Bison tools, but this new Do-All has some wonderful qualities and advantages for specific applications.

Shop Talk I Tool Times

New Tools for 2014

37

Shop Talk I Tool Times

Tools (continued from previous page) tie the handle with an appropriate-length safety cord attached overhead, to prevent them from ever hitting the floor.

Clay Tools & Reference Materials

New Book Figure Sculpting by Philippe & Charisse Faraut

$54.95 + Shipping

PCF Studios.com

PO Box 722 Honeoye, NY 14471 585-229-2976

www.pcfstudios.com

Pottery Supply House (pshcanada. com) has built up an extensive offering of tools, and this year they have begun carrying the “Catalyst” line of silicone rubber and nylon texturing tools (pictured at right) from Princeton Artist Brush Company. These painters’ tools are ideally suited for ceramic decoration. The silicone rubber brushes and profile ribs are unique in studio clay offerings, and work great for applying and sculpting thick slip/ slurry on the surface of a piece. The nylon profile or contour ribs are stiffer, making them ideal for applying profile or texture to plastic clay. MKM still offers wooden throwing sticks and ribs, and are aggressively expanding their line of pattern/texture rollers, stamps,

CLAYTIMES·COM n SUMMER/FALL 2014

MarcsPotteryTools-2inchBlockAd-OL.pdf

38

2

2/4/14

6:57 PM

and paddles. New this year are the “Big HandRoller” pictured above, the “FingerRollers,” and “Woodblock Series Large Stamps,” each in many pattern options. Last year I experimented with the original HandRoller series and liked them very much. For the smoothest field of pattern, especially with quantity work, I think the Big HandRoller is preferable. [All you Goths in the clay world will be happy to hear