29 minute read

PUBLISHER’S PAGE

from Bodyworx 7#3

CLAIM YOUR STAKE

Hold onto your dreams—this could one day be you

BY DARRYL SIMMONS

What makes a technician tick in 2020?

According to SkillsTrader founder and CEO Fadi Smaidi, high-paying wages are no longer the ticket to securing top talent. Instead, industry professionals, such as yourself, are seeking careers that will propel them toward their future career goals. And it’s up to you to get that message out to owners and managers.

During the Canadian Collision Industry Forum (CCIF) virtual event in October, Smaidi said the industry needs to get a whole lot better at recruiting top talent. With the average age of Canadian technicians closing in on 49-yearsold, the collision repair workforce will see a total revamp in the years to come.

To understand the audience pool of today, collision repair facilities need to refocus their recruitment efforts to narrow in on aspects of the job that will drive candidates closer to their respective goals. It’s time for you to speak up and show your enthusiasm by asking questions, by taking courses and by job shadowing your mentors. If your goal is to manage or own your own shop, let your manager know.

While wages still play a role, I’m sure you are seeking opportunities to propel yourself closer to your respective career goals. The industry, as a whole, needs to not only raise the level of appreciation for those behind-thescenes in the bodyshop, but also be abundantly clear about all the exciting paths a career in collision repair can lead you.

This issue’s cover star is a great example of the recruitment opportunities out there; prior to working in a dealership, Southpointe

Toyota’s Tim Hopwood had never considered a career in collision repair. But once he picked up the spray gun and mastered his technique, he couldn’t be stopped. Now, he’s a mentor for other painters and is on a path to great success.

If pay grades really lack the same weight they once had, everyone need to start promoting a ‘this could be YOU!’ mindset in the collision repair industry. After all, some of the industry’s top players began working in bodyshops just like you.

The readers of Bodyworx Professional— painters, technicians and the whole lot of behind-the-scenes workers—are what make this industry tick. Never forget how important your role is and shout it from the rooftops.

PUBLISHER

Darryl Simmons

publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

STAFF WRITERS

Julia Lloyd | julia@mediamatters.ca Kenzie Letman | kenzie@mediamatters.ca Max Reid | max@mediamatters.ca Maddy Kylie | maddy@mediamatters.ca Sophie Price | sophie@mediamatters.ca

ART DIRECTOR

Yvonne Corvers | yvonne@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

DIRECTOR OF BUSINESS SOLUTIONS

Ellen Smith 416.312.7446 | ellen@mediamatters.ca

INDUSTRY RELATIONS ASSISTANT

Wanja Mann (647) 998-5677

wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

CONTRIBUTORS

Aidan Labbossiere, Ben Hart, Stefano Liessi,

SUBSCRIPTION One-year $25 / Student Discount is 10% Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in Bodyworx Professional ™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher.

PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2

“We acknowledge the financial support of the Government of Canada.”

Bodyworx Professional is published by Media Matters Inc., publishers of:

ppgrefinish.com

WHEN THE SPRAY SUIT FITS

Tim Hopwood fell into the industry—and found his perfect match

BY MAX REID

Tim Hopwood, a painter at Southpointe Toyota in Calgary, Alberta, fell into the collision repair industry at 20 years old. He hasn’t looked back since. Kids all over the world grow up dreaming about the cars they see in movies and on TV. James Bond’s Aston Martin DB5, Steve McQueen’s Mustang Fastback, Mad Max’s Interceptor; the cars that inspired so many to pick up a wrench or a spray gun and dream of one day getting the chance to work on their dream job.

But then for some, their twenties hit—and so does reality. They’ve got bills to pay. That’s how Tim Hopwood discovered his passion and found his way into the collision repair industry.

“I was 20 when they hired me, so I had no idea what I wanted to do with my life, of course. I just happened to be in the right place at the right time. I saw the work and it seemed like each avenue available to me was more and more interesting.”

For Tim, it wasn’t a childlike wonderment for the cars on screen, but rather a measured appreciation for the craft of refinishing vehicles—the inexpressible satisfaction that comes from working with your hands and seeing the results speak for themselves.

“What originally attracted me to the job really was the hand skills. It’s true for all trades—if your workmanship is poor, you can tell by the time you’re done. So, I suppose what drives me day-to-day is learning and mastering the skills and being able to tell at the end of the day that the work is done well.”

Tim got his start at Southpointe Toyota in Calgary, back when they were just a dealership with no collision centre, learning the ropes of the industry as a detailer.

“I had been working at the dealership before the collision centre was opened, probably a year-and-a-half, maybe two years before. I started in the detail department as an automotive detailer. Became a detailer, sprayed undercoats and eventually started spraying box liners. Then, I was basically in the right

“We pretty much do everything in-house: full bodyshop, collision repair, detailing, window tinting, windshields. On the sales side, selling cars, servicing them—parts department, typical dealership, all that stuff.” − Trent Dayton, Manager

place at the right time at every moment and was able to get a position as an apprentice. I’ve been on that track ever since,” said Tim.

“Tim was an excellent employee of ours at the dealership,” said Southpointe Collision’s manager, Trent Dayton. “In the detail department, he always took pride in his work and went that extra mile on everything that he touched. When we opened the collision shop here six years ago we bought a building, did all the renovations and we started out with this one small paint booth and Tim was the guy that expressed interest in that, so we put in a box liner booth and started spraying our own internal box liners as well as used car spot repairs on bumpers.”

The incorporation of a collision repair business on top of the pre-existing Toyota dealership would prove to be a game-changer for Trent who was looking to set up a onestop-shop for his customers.

“Southpointe Toyota has been around now for about 10-and-a-half years. We opened the bodyshop, at a separate location down the street—about six years we’ve been running full now. We pretty much do everything in-house: full bodyshop, collision repair, detailing, window tinting, windshields. On the sales side, selling cars, servicing them— parts department, typical dealership, all that stuff.”

Trent continued, “Being attached to a Toyota dealership, it was pretty important for us to become a certified collision repair shop with Toyota. So, we’ve gone and done that. Throughout the years, we’ve also been certified with the likes of Nissan, Kia, Dodge FCA. Toyota’s are about 75 percent of our workload. Being a certified shop with Toyota is very important to us.”

It’s through these many opportunities provided at South Pointe that Tim was truly

Trent Dayton, (left) manager of Southpointe Collision, and Tim Hopwood.

able to thrive, picking up several different skills and lessons all along the way.

“The people around me thought enough of me to train me in whatever needed to be done. When I started as a box liner tech, we needed two technicians. We had one who was experienced—and I was not. So, he recommended and trained me to do that and then when we needed an apprentice, we had journeymen who knew what they were doing, and I did not, but they figured I was good enough to be trained,” said Tim.

A technician with a genuine interest in picking up the skills and operating as part of the team is an enviable asset to a collision centre, and Trent knows that.

“In just four years, at his age, he’s become a journeyman—and we’ve only been open six years. I’m amazed almost daily at his skill level. Other painters have been around for more than ten years, and I could easily say that Tim is already at their level. It’s impressive; I’m amazed,” said Trent.

While COVID-19 lockdowns may have put a small bump in the road for Tim’s education, he still has big plans as he prepares to take his craft to the next level.

“Tim is working towards the platinum-class technician certification. My other painter in the shop and my prepper are both I-CAR platinum at this point. So, that would be Tim’s next stage, but we’re not sure when the next course will be coming up. They usually do them once a year but with this COVID stuff, you never know,” said Trent.

This passion for passing on skills and knowledge throughout the business has carried from Trent to Tim, and in turn, Tim has assumed the role of mentor around Southpointe.

“I’ve been very lucky at our shop, actually, a majority of our staff on the backside is very young and there’s not a lot of younger individuals coming into the industry very often,” said Trent.

“As we’ve grown, we have younger guys now coming in. Tim and I have had a few conversations about some of the newer employees that are coming in and are wanting us to sign onto their apprenticeships and are already getting into their first and second years. He definitely takes them under his wing and recognizes what they are good at; Tim’s always taken a lot of pride in that.”

Tim is hoping to continue to instill in his co-workers the value of lessons learned and the mistakes made in the process of mastering a craft.

“Being on the other end now as a journeyman, the things that stand out to you are the people that have an interest; they want to learn, they ask the questions and when you give them an answer, they actually listen and learn and then apply it. Learn from the journeymen and show that you have learned.

“I feel, as an apprentice or pre-apprentice, that was my attitude; like, ‘Hey I see that work you’re doing is interesting, but it’s beyond my current skill level. How are you doing it? Why are you doing it?’ so on and so forth,” said Tim.

“Then it’s just taking that information and applying it—it’s just an interest in the work and an open mind.”

HOW AN ACCIDENT LAUNCHED JEREMY JARABEK’S CAREER AT BOYD From Detailer to Mentor, and planning for his next challenge…

For most of us, an accident is not career launcher; however, when Jeremy was in grade 11 and was 21, (a 2nd year Apprentice) he was able to buy his first home, which also had a “shop” in the backyard. As he was involved in an accident with his ’93 Civic, becoming financially stable, he was able the Boyd facility out in Victoria BC wasn’t to complete his “formal” education/ only the place where his vehicle was apprenticeship concurrently. Taking pride repaired, but it’s where he got his start in his work and having great relationships in our industry as a Detailer. Jeremy’s with his mentors he was able to hone his first job was at McDonald’s, saving up to skills, standing out from his classmates. buy car and he couldn’t wait to get his In his third year of being in the Auto Body driver’s license, this job was “ok”, but Programme, Jeremy was asked to enter he wanted a job where he could work on the Provincial Skills Competition – his his car – it’s this passion which has keep skills landed him a second place finish. Jeremy in our realm for over 20 years. People today talk about their “side

When Jeremy completed High School, hustle”, back then Jeremy was just he continued to work at Boyd as he got looking for some extra cash, so he took accepted to an Apprenticeship program a part-time job with a limo company to at Okanogan University College in keep their fleet looking good pristine. Kelowna, B.C. For the next four years her “If you want to learn how to work with worked beside the same Journeymen, bondo and block properly, do body work which ended up being a benefit to on limos” is advice Jeff would give him, as he was not only able to build anyone who wanted to improve their upon his spectrum of skills – but build skills in this area. As life took him from relationships with the mentors he was the west coast to Edmonton, Alberta – he working with, as they were the ones who is currently the Head Body Technician DROP & GOpassed their knowledge down to him. Jeremy had a lot of cars to work on, as there was a race track near the facility where he worked – with this volume of at Boyd’s location on 103rd Avenue. Jeremy preaches the usefulness of All Data, and its importance to the repair process.. “repair is not like it used to work coming his way, by the time he was be, and young kids getting into the trade shouldn’t always listen to the ol’ guys – All Data is key to proper repair”. Jeremy not only looks to technology and modern tools to help him with his job, but he finds that Gavin MacKenzie, (Boyd’s Technical Trainer for Western Canada) is a huge support in the repair process and his own personal development.

Currently Jeremy has an Apprentice working with him, (Ryan) and urges him to take advantage of every learning opportunity he can, such as learning to work with Aluminum and other composite materials – as this is the trajectory our industry is headed in. Also Jeremy stresses that “practice” is key, and don’t be afraid to make a mistake, as you will need to learn how to “undo” your mistakes, and you can only do this with practice. He is sure to share his journey with the students he comes in contact with, and is honest with them, “this career takes commitment, and is hard work – low paying initially, but efficiency will make you money”. Jeremy’s commitment to this industry and his peers has not gone unnoticed, as in 2019 Boyd awarded him a Silver Star award and we anticipate this won’t be the last time we see him at the podium.

INDUSTRY

ELECTRIC ENDOWMENT

Ford of Canada and Unifor have reached a tentative agreement on a three-year national labour contract covering nearly 5,400 unionized employees in Canada. The tentative agreement will see Ford retool the Oakville assembly plant to build five new electric vehicle models, thanks to a $1.95 billion investment from the federal government, Unifor president Jerry Dias announced Tuesday morning. The plant will also assemble batteries, adding 300 new jobs.The first electric model will roll off the line in 2025, and the fifth will come in 2028. A new four-litre engine—to be used in Ford Mustangs and F-150—will also be built at the Windsor, Ontario engine plant, securing and potentially adding jobs at the plant, said Dias.

Ford was the first of the big three automakers to meet negotiations with Unifor.

PROCOLOUR LOOKING TO FIX ACROSS THE BORDER

Fix Network World announced its plans to launch the ProColor Collision brand in the United States in September, citing “tremendous potential for the continued growth of the automotive aftermarket space in the United States, in particular the collision business.” Fix Network World CEO Steve Leal said the company “looks forward to growing the ProColor Collision brand by directly pursuing aggressive new strategies that leverage our global track record and benefit industry partners and customers in the U.S.” Leal and the company acquired ProColor Collision in 2019 as part of a 172-shop franchise deal with Uni-Select. Fix Network World announced on Tuesday which U.S. states the brand would be first launched in; California, Florida, Georgia, North Carolina and South Carolina.

CLEANING UP

CALLING ON CANADA NIGHT

Following the cancellation of Canada Night at AAPEX, the Aftermarket Auto Parts Alliance has announced that it will host a virtual Canada Night as part of its 2020 virtual Winter Shareholder Meeting, which is currently scheduled for Dec. 9 through Dec. 11. The Canada Night virtual cocktail reception will be open to all shareholder owners and channel partners north of the U.S. border. Further details on the event will be announced when registration opens on Nov. 2. In addition to the virtual networking event, the Aftermarket Auto Parts Alliance’s Winter Shareholder Meeting will include updates for both shareholder owners and channel partners, numerous cocktail receptions and the anticipated announcement Ottawa’s AV industry is flush with cash following a $17 million government investment into their local testing facility. With this joint investment between Invest Ottawa and the federal government through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario), staking $10 million and $7 million respectively, the city will be supporting a number of companies who are leading the way in AV development, as well as the facility itself. The newly named Area X.O., formerly the Ottawa L5 Connected and Autonomous Vehicle Test Facility, will receive a new, fully-equipped 5G mobile command centre with drones capable of deploying a standalone and secure 5G network anywhere. In addition, the facility will also be upgraded with new cybersecurity technology and

of the 2020 channel partner award winners.

In the wake of AAPEX and Canada Night cancelling in-person events for this year’s Industry Week, the Aftermarket Auto Parts Alliance will host a virtual

DETAILING DISRUPTIONS

This year, AIA has included elements of the ‘new normal’ in its bi-annual outlook study, including disruptors like COVID-19, changing consumer preferences and emerging technologies and markets. AIA’s report predicts that kilometres driven in 2020 may slip to approximately 240 billion kilometres, down 30 percent from 2019 levels. This reduction is expected to impact the demand for routine automotive maintenance. While, historically, demand for aftermarket products and services remain relatively resilient in recessionary environments, the aftermarket will need to make some adjustments to accommodate changing consumer preferences in the so-called ‘new normal.’ With new concepts like physical distancing, many industries have turned to list their services online. As a result, automotive consumers are also altering their shopping habits.

PPG has earned itself titles at the 2020 R&D 100 awards for its Clean Surface Technology, which the company says enables stain-resistant, easy-clean interior paint, and the company’s overspray-free application for faster automotive painting. PPG Clean Surface Technology is a combination of stain-resistant, soft-touch coatings originally developed to make premium electronic devices stain proof, as well as an automotive coatings technology that brings toughness and scratch resistance to car coatings. The R&D 100 Awards Committee and R&D World magazine honor the 100 most innovative technologies and services of the past year with the R&D 100 Awards. PPG has earned 29 R&D 100 Awards through the years.

STORM AREA X.O

Canada Night event during its annual Winter Shareholder Meeting. an authentic railway crossing and mobile dummy test targets that enable precise and repeatable test scenarios between autonomous vehicles and vulnerable road users such as pedestrians and cyclists.

TRAINING

SPOT ME A WELDER?

One lucky school could be the recipient of a brand new CTR7 Spot Welder, generously donated by CarO-Liner® as part of the Skills Canada Collision Repair Program, directed by SkillsCanada. Valued at approximately US$24,000, a spot welder of this calibre is expected to be a most welcome upgrade for eligible post-secondary colleges, polytechnic or technical institutes, creating an additional training opportunity for students enrolled in a collision repair technician program, according to Tuesday’s press release. Schools that do not win the prize will still be eligible to purchase one of ten spot welders at a significantly reduced rate, according to the press release. Registration for this giveaway is open until Nov. 30 with the winning school to be contacted on Dec. 14. Training and setup for the unit will be provided by Car-O-Liner® in early 2021.

Car-O-Liner has generously donated a CTR-7 welder to one lucky Canadian school, to be awarded via SkillsCanada.

ATTRACTING TOP TALENT

During the Canadian Collision Industry Forum (CCIF) virtual event, SkillsTrader founder and CEO Fadi Smaidi said today’s generation of collision repairers are often less concerned with pay and more concerned about finding a workplace that drives them closer to their goals. “Understanding the audience pool is very important,” said Smaidi. “A lot of people in the newer generations are less concerned about traditional goals like buying a house, getting married or buying a car. Instead, individuals want to feel they are part of an organization Fadi Smaidi, CEO and founder of SkillsTrader. that gets them where they want to be.” He said a big part of recruitment will involve industry organizations like CCIF hosting events to inform potential recruits about opportunities within the industry. “The industry has a whole lot to do better at attracting new talent to the trade,” said Smaidi. “One part is the industry’s responsibility—organizations like CCIF can help with events like this, highlighting the struggles and successes of our industry.” The Canadian Apprenticeship Forum (CAF-FCA) is releasing an industry-driven National Strategy for Supporting Women in Trades (SWiT), to help increase the participation and retention of women in the field. The strategy has four clear and measurable action items intended to generate awareness, trigger policy change, recognize best practices and create skilled trade workplace environments where women’s representation is recognized and increasing. In 2018, women only represented 4.5 percent of apprentice registrations in construction, manufacturing and transportation, according to Statistics Canada. In the new SWiT strategy, the task force has made a national target to increase female participation in skilled trade careers to

DESIGNING DREAMS

Toyota’s Dream Car Art Contest, which over the past few years, has become so much more than a colourful visual arts talent competition. It has instead become a global platform for the world’s most imaginative kids to bring forward their world-changing ideas. And, not surprisingly, kids and youth from Canada have led the way–their innovations have been recognized at the global level. This year, children aged 15 and under are being asked to put on their thinking caps and design their “dream car.” Pencils, crayons and paintbrushes should be guided by your imagination to create images of dream cars of the future. Children are also being encouraged to explain the innovative ideas they’ve incorporated into their artwork. They’ll need to tell the judges what they’ve drawn and what it does. This year’s contest launched on Oct. 5, 2020, and entries can be submitted until Jan. 8, 2021. Artwork submissions can be created using any type of traditional medium–such as paint, markers and

Youth aged 15 and under can try their hand at automotive design for a chance to win some exciting prizes from Toyota.

SWIT STRONG

crayons. Digital art is not permitted. 15 percent by 2030.

The Canadian Apprenticeship Forum (CAF-FCA) is releasing an industry-driven National Strategy for Supporting Women in Trades (SWiT), to help increase the participation and retention of women in the field.

TECH TRENDS

ULTRASIM UPDATE

BASF has extended the application range of its Ultrasim simulation tool so that it may now calculate component concepts based on elastomers, especially Elastollan, BASF’s thermoplastic polyurethane (TPU). “The simulation tool Ultrasim provides our customers with quick and reliable information about how BASF materials behave in their planned components, during production as well as at a later stage during service life. Customers who apply Ultrasim instead of constructing prototypes or carrying out tests can significantly shorten their development times. This simulation support is now also available for Elastollan,” said Achim Besser, team leader of material modelling in BASF’s performance materials division.

BASF has extended the application range of its Ultrasim simulation tool.

DIRECT CONTACT

Mitchell 1’s new MessageCenter texting app that allows shop owners to text message customers directly, is now available in Canada.With MessageCenter auto repair shops can reach out to their customers right away with two-way text messaging directly from inside the Manager SE shop management system. This app eliminates roadblocks such as calls going to voicemail or emails that go to an address that the customer may not check on a daily-basis. The MessageCenter app is an optional add-on to the Manager SE system.Key features include:Text messaging directly from Manager SE work-in-progress, order revision or appointment editor screens; Unique, dedicated texting number (with area code) for each shop; Flexibility to send on-the-fly text messages or create and use custom templates; Conversations with customers (text threads) are saved for later review.

Mitchell’s new MessageCenter texting app that allows shop owners to text message customer directly in Canada.

AUTEL ADAPTER

Autel U.S. has just released a CAN FD Adapter that connects to compatible Vehicle Communication Interfaces (VCIs) to enable its tablets to communicate via the CAN FD communications protocol and diagnose the vehicle. Vehicles currently using this faster CAN FD (CAN Flexible Data-Rate) protocol include many GM and Ford’s 2019 and 2020 vehicles. Autel U.S. says CAN FD is one of the newer communication protocols, noted for being faster, more reliable and more secure. Autel’s latest MaxiSYS tablet releases, the MaxiSYS Ultra, MaxiSYS 919 and MaxiSYS 909 do not need Can FD Adapter to communicate CAN FD-equipped vehicles as these new tablets come with enhanced VCIs that include many of the new protocols including CAN FD. Autel’s CAN FD Adapter can be purchased through any of its authorized distributors or retailers.

PROJECT ARROW HITS ITS TARGET

The Automotive Parts Manufacturers Association (APMA) has announced the winning design for Project Arrow, the national zero-emission concept vehicle competition announced at CES earlier this year. A team from Carleton University’s School of Industrial Design and their concept design, “Traction,” have been selected for the competition. The rollout of Project Arrow’s “Traction” vehicle model will be carried out in four phases. Phase 1 was the competition and selection of the winning design. Phase 2 will take place over this fall and will see the release of the vehicle’s engineering specifications. Phase 3 will involve a virtual concept unveiling at some point in 2021, and Phase 4 will be the release and touring of a concept car design in 2022.

A team from Carleton University’s School of Industrial Design and their design concept ‘Traction’ has been named the winner of the Project Arrow design competition.

TECH TRENDS

BETTER GET WOODWORKING

The Government of Canada is currently trying to find innovative ways to profit off Canadian wood in a variety of different industries, such as automotive. Marco Mendicino, minister of immigration, refugees and citizenship on behalf of Seamus O’Regan, minister of natural resources, announced a $1.2 million investment to GreenNano Technologies. The 1.2 million investment is going towards scaling up production of new lightweight wood-fibre-based composite material to create automotive parts using an innovative process. The project consists of combining wood pulp with polymers to create a special strong and lightweight thermoplastic with more uniform and improved properties compared to other products. If the new product can be successfully applied in the automotive sector, it could have several consumer and commercial applications, including aerospace parts, pharmaceuticals, solar panels and cosmetics. The new material will be tested in production of lightweight cars at Ford Canada’s Power Engineering Research and Development Centre in Windsor, Ontario.

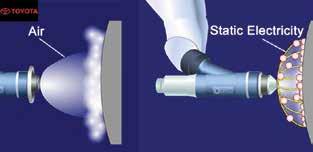

SPRAYING WITH STATIC

Toyota Motor Corporation has developed a new type of paint atomizer that uses static electricity instead of air—the first of its kind in the world. The new airless paint atomizer achieves more than 95 percent coating efficiency compared to conventional air paint atomizer where the efficiency of approx. 60 to 70 percent, according to Toyota’s press release. The move towards an airless paint atomizer in Toyota Group’s painting process was to help reduce their CO2 emissions by about seven percent. As well, the collection device at the bottom of the paint booth, the area where paint gets sprayed, can now be made more compact, and as a result, Toyota can make painting production lines more compact for the future. The tip of the paint atomizer features a rotating cylindrical head that optimized the amount of paint sprayed.

Toyota has developed a new paint atomizer that uses static electricity.

COLLISION FRANCHISE EXCELLENCE Learn more about the CARSTAR family at CARSTAR.ca

BELIEVE IT OR NOT

HIGH-SPEED SNOOZE

When autopilot for Tesla was first introduced people were excited about what it could mean for the future of cars. However, some people thought the future was now and on July 17 the RCMP received a call regarding a 2019 Tesla Model S speeding south on Highway 2, with the driver’s seat reclined all the way back. Police reported that both front seats were reclined, and both the driver and passenger seemed to be sound asleep. Tesla Model S sedans have autopilot functions such as, auto steer and “traffic-aware” cruise control and according to the police, the car had these functions activated. RCMP Sgt. Darrin Turnbull said the car was doing more than 140km/h when the speed limit on that stretch of highway is 110 km/h. Turnbull said that the RCMP believed the Tesla was operating on autopilot.

In early September, Alberta RCMP spotted Tesla travelling at more than 140km/h with both occupants fast asleep.

UNDER THE SEA

Back in 2019, a carrier cargo ship called MV Golden Ray capsized while carrying 4,200 Hyundai vehicles, and due to a string of setbacks, those vehicles are still trapped today. While there were no casualties, the ship, which is 106 ft wide and has a capacity of 20,995 deadweight tons, is a hard project to dismantle. Preparations were made to go to the site of the ship and start to carefully scrape it for parts. This however, was put on pause due to COVID-19. The group that oversaw dismantling the ship had 10 responders test positive for COVID-19, which then required the other 50 responders to quarantine. The other problem the group ran into was as hurricane season approached, further setbacks quickly arose, and the project was put on hold most likely until October. In terms of the dismantling process, the team will use a VB-10,000 twin-hull heavy-lift vessel, which will then use two 69-metre tall gantry cranes to cut the ship into eight large sections that will then be lifted onto a barge and transported to a recycling facility in Louisiana.

MEET TUSCON

A Hyundai dealer in Brazil has become famous all over the world after they adopted a stray dog and brought him into the dealership as a canine car consultant. The manager of Prime Hyundai, Emerson Mariano, found the dog and started feeding him, giving him water and providing him shelter. The dog stuck around, and the staff became fond of him. The manager then adopted him permanently. The dog has been named Tucson after Hyundai’s small crossover. Tucson is about a year old and since being adopted has been taken to the vet for all his necessary shots. He now owns many accessories as part of the Prime Hyundai family, such as tires, a tuxedo and his own employee badge. He likes to spend his days at the dealership in his very own doghouse.

Tuscon, the first-ever canine car consultant and Employee-of-the-Month.

In early September, Alberta RCMP spotted Tesla travelling at more than 140km/h with both occupants fast asleep.

BELIEVE IT OR NOT

ALONG FOR THE RIDE

The Dog Sack invention started to appear in 1935, making its debut in the June 1935 issue of popular mechanics. The idea behind the invention was to keep the car clean while allowing the dog some fresh air. The original article says: “When you take your dog along for a ride but prefer to not have them inside the car, they can ride safely and comfortably in this sack, which is carried on the running board. The bottom of the sack is clamped to the running board and the top is fastened to the lower part of an open window with hooks, covered with rubber tubing to prevent marking the car.” Thankfully, this invention was never added to any car models.

GAS-GRABBING GETAWAY

A driver being pursued by Los Angeles police stopped to get gas amid the chase, even grabbing the cash discount in the process. While police reportedly struggled to keep up, the suspect pulled into a gas station, stepped out of his car, run inside to pay the cashier and pump gas before speeding off. With a full tank, the driver continued his getaway by traveling through cities on the outskirts of Los Angeles, later merging onto a nearby freeway. He disappeared into a parking garage not long after, and whether the driver was ultimately caught is unclear.

Automate your HD estimate

To learn more, call 1-844-AUDATEX or email sales.canada@audatex.ca