16 minute read

What does top production look like for the average Canadian bodyshop—and how do you determine your limits?

TEMPTING TOP TALENT

What the young collision repairers truly seek

With spring comes the season of hope. However, it also presents a host of new graduates—students that are the ready for hiring in Canada’s collision repair sector.

Looking to hire young talent in today’s climate? Collision Repair sat down with new autobody students working in the field to learn what they were looking for when they kicked off their job search, and what you need to offer to bring them to your door!

NOTE YOUR NICHE

When it comes to hiring, attracting the right people is quite similar to traditional marketing strategies your business may apply to consumers. For instance, if your shop is skilled in BMW repairs and holds certifications for the brand, you should be pushing your top-notch abilities in your promotional schemes.

Similarly, you need to highlight your strengths when seeking a student or young autobody professional for a role. If your business prides itself on staying up to date with the latest welding trends and courses, advertise as such. If an incoming apprentice or technician is seeking a workplace with top-notch tools to expand their skills, or opportunities available for them to pursue and, ultimately, up their trade game.

LET THERE BE LIGHT FOSTER THE PEOPLE

In today’s climate, aspiring technicians and apprentices are seeking a “work-life balance,” says Fadi Smaidi, founder and CEO of SkillsTrader. A clear way to signify your commitment to this ideology is to foster a healthy shop culture—you may even witness other benefits along the way.

There are many elements that come with fostering a healthy shop culture, but the first step is transparency and honesty. Let them in on your financials and be clear with them on how business is running.

If you make you staff feel part of a team, they’ll be that much more inclined to take their efforts—and your business—further.

Tidiness is the first thing a potential employee will notice when they step into repair bay. Are your tools scattered about the room like confetti? Does the feeling of stepping into your bodyshop resemble that of wandering into a cave?

Lighting was the first aspect Albertan autobody student Edison Syme noted in his job search. He said it was immediately clear to him that a shop took pride and care in its work if its repair floor was clean, organized and well-lit.

DON’T PUT BABY IN A CORNER

Shop apprentices are all-too-often shoved into a corner or told to sweep up messes without ever being offered the opportunity for further training or growth. Shops—if you have an apprentice, use them!

Student apprentices are in your shop to do exactly what their position implies—be a student. While they’ve grasped a basic understanding of automotive repair, it’s your job as their mentor to strengthen those ropes and present them with new opportunities they may not find elsewhere.

ATTAINING PRODUCTION PERFECTION

Production is about relationships and quality

In the pre-covid era, many of us would book vacation time in the southern hemisphere to get a taste of the “good life”; however, in 1994 Tanesh Persaud decided to leave Guyana, and try to attain a “better life” in Canada. Possessing hands on experience in the automotive realm, servicing heavy equipment for many years, he wasn’t able to land a role in the automotive field at first. Given he had an education in electronics, he was able to secure a role servicing photocopy machines, after the company he worked for folded, he started his own delivery company. In April of 2015, Andrew Singh finally convinced Tanesh to join Assured, as a Parts Co-ordinator at our Scarborough West facility. After a few short months, he was asked to help out the team at our Ajax location, where he still is today.

Gus Stavropoulos saw the potential in Tanesh, and convinced him to take interest in the Production Manager role, so his grooming began. With no experience in this role, he relied on coaching from his peers and Gus. Being a participant in an internal estimating course Assured ran at the time, gave him perspective on what his task was, and how it impacts the team. Timing of this couldn’t be more perfect, as the facility was getting busier, he was moving away from this dual responsibility of Parts Co-ordinator and Production Manager, and after about a year and a half - Tanesh just felt “ready” for the full transition.

Today, Tanesh is also tasked with trying to keep up with evolving technology, how it is applied to the vehicles, more importantly – how it impacts our repair plan and cycle time. “Touch Time is another key metric we need to be aware of, and there is a fine balance between this and quality of work – with experience you’ll know how to achieve this balance”. Assured Ajax has shown they can achieve this as they have won corporate awards for both Sales and Customer Service Excellence.

One area which Tanesh has mastered is working with the “evolving customer”. Today, being more demanding, having greater expectations and their knowledge of vehicle repair is better than it ever has been. Tanesh shares that “no longer do customers quickly walk around their cars and say “great job” – they take time to ask questions, inspect the work completed and ask what line items mean on their repair summary. People are finally looking at their cars.”

As a Production Manager, he motivates the team and reminds them that we work together. Success and failure falls on the team, not an individual. It’s everyone’s job to ensure we keep our commitment to all our customers; vehicle owners, insurance partners and our brand. For someone who is thinking of moving into this role, Tanesh feels that strong time management skills and attention to detail are traits one must have in their tool belt, and if you have experience in communications or dealing with people, in a face to face environment, this will also help your development and success in this role.

When asked how Assured has impacted his life, Tanesh shared,“Assured has helped me immensely, given the times we are currently in I feel lucky to be employed and able to provide for my family. Typically when my Market Manager – Jason Raposo or the regions Director, David Raposo comes by and asks if they can do anything for me, I ask that they support my team by addressing their needs. I feel good working for Assured, it’s a long term commitment between each other, with us being part of the Boyd Group, I do feel more secure”.

As for future goals, Tanesh is quite content with his career; however, given the opportunity to train others in this role, would be something he would consider, as he would like to help his peers attain ‘Production Perfection’.

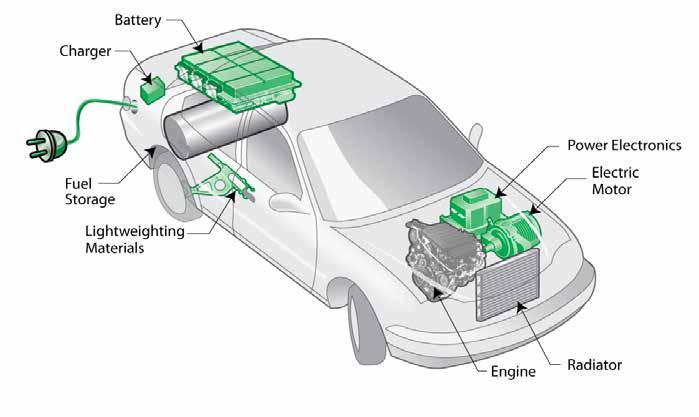

While current national EV sales figures are low, the bevy of recent automaker statements to convert all drivetrains to battery-electric or hybrid models suggests a clear path to EV growth.

ELECTRIC EVALUATIONS

Andrew Shepherd gives insight on I-CAR’s new courses

BY MAX REID

With automakers the world over announcing wide-scale conversions of their fleets to battery-electric vehicles (EVs) and telematics systems becoming nearly commonplace, the collision repair industry is no longer simply on the verge of a technological revolution—we’re in the midst of it.

That is why Collision Repair took the time to conduct a phone interview with Andrew Shepherd, executive director of I-CAR Canada, to discuss this fundamental shift in automotive technology and how Canada’s educators are responding to meet these new demands.

I-CAR has begun offering a new series of courses focused on emerging technologies, like ADAS (Advanced Driver-Assistance Systems) and EVs, in the effort to better prepare Canada’s techs-in-training for what is shaping up to be a new form of automobile altogether.

“These are a new couple of courses in a long series of new courses focused on new technology, in particular on ADAS and EVs, offered as a group. They are not required as any foundation, but they are produced as quickly as I-CAR can get the information from the OEs,” said Shepherd.

“They’re 30 minutes long; very focused. They have a quiz at the end, and they deal with how to treat an electric vehicle as soon as it comes into the shop. Before even touching it, assessing it for external damage, dripping fluids, things like that, because the voltage of the battery is so high that there has to be an understanding of how to deal with this right from the start.”

Educators across the collision industry are aware of the shifting tides showing a new customer tendency towards battery-electric options, and I-CAR is hoping to meet students right on the frontline of this developing technology, as it is made available, to help propel Canada’s auto industry forward onto the world stage.

“We’ve seen a fair number of the OEs announce a total conversion to electric vehicles over the next ten years, and as always in the collision sector, even the first instance of a new technology can be on a collision shop’s doorstep the day after it’s released,” said Shepherd.

“Either shops have to give up that business and pass on it and say we can’t do it, or they have to get the learning in place to do it.”

According to Shepherd, among the many unknowns surrounding EVs and their devel-

Andrew Shepherd is the director of I-CAR Canada.

oping repair processes, establishing adequate safety protocols across the board should be the top priority for educators bringing new techs into the industry.

I-CAR Canada’s new EV courses are 30 minutes long and deal with how to treat an electric vehicle as soon as it enters the shop.

“There are a lot of things about damage analysis and repair that have to be learned, but the first thing is safety. Because of the high-voltages of the batteries, these shops absolutely need to know how to even approach the vehicle, before they decide to take the job on,” said Shepherd.

He recognizes the apprehension among shop owners to adjust to this shift, but stresses that the choice may soon be made for them, should shops not take the steps to prepare themselves for this new automotive landscape.

“Any shop owner who is interested in staying in business doesn’t like to reject any job for whatever reason. They might reject, for example, a Mercedes where they don’t have the equipment required to fix it because there isn’t a Mercedes in everyone’s driveway. But there is an increasing number of EVs, so a shop might reject the first one or two, but they’re going to get on board very quickly to serve [the demand],” said Shepherd.

Luckily, as a leader for apprentices in the industry, Shepherd has taken note of an increasing enthusiasm for these emerging technologies among students entering the field and is hoping that this will be the beginning of a new public perception of the autobody industry.

“I would say that most of the people who go into, for example, an apprenticeship in collision repair or paint, are car enthusiasts and certainly those people are more digitally familiar, digitally competent than the people training them. I do think that there is a natural bent of new students toward [new technologies].”

Shepherd continued, “I think we have yet to start targeting people in other pursuits to join the collision industry because of the digital revolution. I think apprentices are a bit surprised how up-to-date the collision industry is—clean and digital. But they’re not selling automotive apprenticeships as a computer business yet.”

The results speak for themselves, as technicians with skills geared toward ADAS and EVs are quickly becoming sought-after specialists in the industry.

“You’re seeing the more progressive shops right now hiring people specifically for calibration, or fault analysis, or computer scanning, for example,” said Shepherd.

“All of these trends are pushing shops towards being learning organizations...shops will thrive when they are able to train every day for new technologies.”

On the consumer end of things, the path has yet to be paved, however, as apart from in provinces like Quebec and British Columbia where the incentives for driving an EV are more abundant, the electric option has yet to take hold a mainstream vehicle for drivers in much of the country.

Regarding current national EV sales figures, Shepherd said, “The numbers are low. The numbers are one, two, three percent at this point. But the clear signal of the future is the

OE’s statement that they are going to convert all of their drivetrains to battery-electric or a hybrid. So, the path is very clear; how soon they are going to get here is another question. And unlike a lot of the ADAS technologies, the EV doesn’t require massive changes in space or in equipment. All it requires is training, so it’s a fairly easy process for shops to get ready for those EVs that are going to start to come in.”

The question for Shepherd and I-CAR now is no longer if the industry can get ahead of this technology, but how quickly can it catch up.

“It’s not even an impending shift; it’s the shift we’re in the middle of, towards data-driven vehicles, telemetry, ADAS, battery powered, et cetera. This is a fairly long-term and fundamental shift.”

IN TODAY’S AGE

SkillsOntario takes trades promotion online

BY MAX REID

Last year saw the collision industry endure a period of uncharacteristic helplessness for a trade so foundationally dedicated to ingenuity and independence.

The pandemic kept shops apart from their customers, and by extension, the communities in which they operate.

Many felt, understandably, as though they were losing their reach as a shop in the wider collision repair landscape.

However, in certain ways, the pandemic gave us the skills to rethink the ways we engage with the industry.

Zoom calls and YouTube tutorials are now a part of daily life and educators in the training sector of the collision repair industry are capitalizing on the extended geographical reach that an online-based learning model provides.

That is why Collision Repair spoke with the CEO of SkillsOntario, Ian Howcroft, to discuss the ways in which the pandemic, while putting a large part of in-person training on hold, allowed for the provincial trades organization to pivot toward other methods of delivering their content.

“I have to say, the pandemic has been the most impactful and memorable event, for a variety of reasons,” said Howcroft over Zoom. “It caused us to have to look at all we did and how we did it, because we are an organization that went into schools; provided in-person experiential events, conferences, competitions, contests. As of last spring, we had to pivot completely 180-degrees to offer everything remotely, virtually and digitally.” Howcroft and SkillsOntario spent much of the spring last year, when the COVID-19 pandemic was in full swing and many businesses were under lockdown, developing alternate programming to deliver students a fulfilling training experience while making use of remote technologies. “We had been talking about what we need to do to better take advantage of remote technology. ‘Can we have more people work from home?’ Most of our staff were already around the province going out to the schools, so it accelerated our work in this area,” said Howcroft. “I think one of the key examples, which we’ve learned from, is our summer camp program. We used to hold about 24, 25 summer camps in the province, at a college or a facility, and we’d have the kids come out and have a one-week opportunity. Obviously, we couldn’t do that last summer, but we still wanted to provide skills-based and technology-based

Ian Howcroft, CEO of SkillsOntario. Dent Clinic’s new Calgary location is proud to offer free WiFi to its customers, Jeff Blanchard, general manager told Collision Repair.

activities for kids. So, we put together different 35 activity events that we delivered remotely.”

The organization has already seen this transition pay off, says Howcroft, who noted how much greater of a reach online learning provides.

“Normally, we get about 400 kids at our camp program. Last year, we engaged about 800 kids in a variety of activities.”

As to be expected, there were challenges, however. Namely, an apprehension among some in the industry to engage with online learning opportunities and virtual tradeshows.

“We fared fairly well. When we had our big showcase events with our competitions, we would get tens of thousands of people, true. But we can’t do that in the same way remotely. We are using a very sophisticated platform, called vFairs to deliver our programming in May.”

Howcroft says that while the industry seems excited to get back out and networking, not every business is in the situation to be able to facilitate the transition to online events.

“We all recognize that it’s not going to be the same. All of our partners that I’ve talked to have continued to express their support for SkillsOntario. Some have had to lessen the amount because of their own financial issues.

Some had to say, ‘Can we defer until we go back to in-person events?’”

Where SkillsOntario is truly directing its big-picture focus is not solely on the dollars and cents, however, but on the hearts and minds of not only prospective technicians entering the industry, and almost as importantly, on changing the perception of work in collision repair and getting parents on board with helping to make it a viable career choice for their children.

“We want to get the parents on board as well, because they often say ‘Go to university,’ or ‘Don’t look at that opportunity’, because they don’t have a full and comprehensive understanding of what the realities are. They are also dealing with perception. We’re trying to dispel the negative myths and present information in an accurate way,” said Howcroft.

In all, the past year has posed significant challenges to nearly every aspect of our industry, but it has also demonstrated the co-operation and perseverance of collision repairers, educators and students alike to continue along on their paths and create new solutions at every turn.

“It’s been a learning process for us, but I have to again applaud and recognize the team at Skills Ontario for their support,” said Howcroft.

We’re trying to dispel the negative myths and present information in an accurate way,” – Ian Howcroft, CEO of SkillsOntario