Jim Klaustermeyer Jr. grows 2,000 acres of carrots for processing in Basin City, Wash. Read about the farm’s harvesting method and management practices on page 4.

PO Box 333

Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

CarrotCountry.com

CArrOt COUNtrY CONtACts

Editor Denise Keller

editor@ColumbiaMediaGroup.com

Publisher / Advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

edItOrIAL INFOrMAtION

Carrot Country is interested in newsworthy material related to carrot production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com, or call (509) 697-9436.

AdvertIsING sALes

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@carrotcountry.net

sUBsCrIPtIONs

U.S. $20 per year

Canada $30 per year

Foreign $45 per year subscribe online at: www.CarrotCountry.com/subscribe or call (503) 724-3581

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to: Carrot Country PO Box 333 Roberts, ID 83444

Carrot Country magazine (ISSN 1071-6653), is published four times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices.

Produced by Columbia Media Group PO Box 333, roberts, Id, 83444

Copyright 2023. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group.

by Denise Keller, Editor

by Denise Keller, Editor

When it comes to growing carrots for the frozen process market, Jim Klaustermeyer Jr. says it’s a lot like baseball.

“The crop is all grown for contract; there’s no open market,” Klaustermeyer says. “I use the analogy of hitting singles and doubles. There are no homeruns. But you are in the game all the time.”

Klaustermeyer has been in the game since 1989, when he returned from college to farm with his dad in Basin City, Washington. Jim Klaustermeyer Sr., who remains involved in the day-to-day operation of the farm, had been a crop science professor at California Polytechnic State University, San Luis Obispo, before moving to the Columbia Basin in the late 1970s to farm with other growers and, ultimately, start Klaustermeyer Farms in 1986.

“I like to say that he came up to Washington to practice what he preached,” Jim Klaustermeyer Jr. says of his dad.

When the younger Klaustermeyer joined his dad in the operation, they were farming 300 to 500 acres. Today, they grow 2,000 acres of carrots for processing, along with a couple hundred acres of pearl onions and 500 to 700 acres of rotation crops including wheat, beans and hay. Klaustermeyer attributes much of the farm’s steady growth in the 1990s to its implementation of a method of crowning carrots in the planting bed.

After harvesting the first several carrot crops with a top lifter, Klaustermeyer Farms transitioned to planting carrots in wider beds and share-lifting the crop. When the processor requested that the farm begin crowning the carrots in the early to mid ‘90s, the Klaustermeyers modified their harvest process. After topping the carrots, the growers began using a homebuilt implement to crown the carrots before share-lifting the crop. The technology had been adopted in

Europe and commercial crowners were being built, Klaustermeyer says. Since then, the practice has become common in processing carrots.

“When we developed the crowning technique, it was a big labor savings for the processors. They were taking the crowns off the carrots manually, and in order to save them some labor and add

value to our product, we developed this crowning technique,” Klaustermeyer recounts. “I remember pretty vividly the first year that we did that, the comment back from the processor was ‘We were able to remove up to 30 people from the line.’ It was a cost savings for them and a value-added step for us.”

Klaustermeyer’s contract calls for 90 percent of the carrots to be crowned. Therefore, depending on how they’re growing in the bed, some will be topped more aggressively than others. Careful management is needed to remove the minimal amount of the carrot and still meet the contract requirements. Even under ideal conditions, crowning reduces yield by about 12 percent.

On the flipside, crowning the carrots in the beds means that top attachment is not nearly as critical, Klaustermeyer says. This allows the grower to fight diseases with chemicals that could weaken top attachment later in the season and allows him to select varieties for attributes other than top attachment, prioritizing durability to withstand the more aggressive harvest process, followed by color and taste. He also seeks out cultivars that stay flush with the soil surface rather than protruding out of the bed, in an attempt to minimize the amount of carrot lost during crowning.

Through the years, Klaustermeyer has seen the number of carrot growers in the region decrease and each grower’s acreage increase as consolidation reshaped the industry.

“We were at the right place at the right time to grow with it, and now we’re able to keep up with a pretty robust harvest demand,” the grower says.

Klaustermeyer Farms grows 1,100 acres of slicer-type carrots, 400 acres of dicers, 200 acres of cut-and-peel carrots, 250 acres of yellow carrots and 50 acres of “natural baby carrots.” The farm takes advantage of the Columbia Basin’s extended growing season. Planting starts mid-March and continues through the first week of June, while harvest extends from the third week of July through Thanksgiving. The long planting window keeps carrots – especially slicers – at the proper maturity, but also adds complexity to managing the crop.

“We’re planting so long that we’re managing a different size crop throughout the season. By that, I mean in August, I still have carrots that are very small and I have carrots that are ready to harvest,” the grower explains. “You can’t just say ‘It’s August 15, so I do this.’ Until early fall, the carrots are at so many different levels

The crew at Klaustermeyer Farms tops a row of slicer carrots.of maturity that you have to be on your toes to keep up with the different stages of growth the carrots are in.”

With more than 30 years of experience, Klaustermeyer has learned to manage the various challenges in growing carrots, from pests to pathogens. Carrots are grown on a four-year rotation, and the grower considers the crop produced in the field the previous season, preferring to follow wheat, onions, timothy hay or beans.

With a diverse range of soil types in the Columbia Basin, Klaustermeyer also chooses to plant carrots in sandy or sandy loam soil. This makes for better harvest conditions and fewer dirt clods in the load compared to farming in heavier soil. At the same time, however, sandy fields are more vulnerable to wind erosion. After a year in which a 40-hour windstorm took out 500 acres of carrots, Klaustermeyer adopted a cover crop system, now sowing wheat between rows of carrots. The wheat, emerging more quickly than early-season carrots, provides erosion protection before being killed with a selective herbicide when carrots reach the two- to three-leaf stage.

Looking ahead, Klaustermeyer sees the importance of efficiency on the farm. Although the industry is already fairly automated, higher production costs and new labor laws in Washington state will likely lead to more mechanization. The grower also expects new carrot cultivars to be developed and hopes the new releases might include varieties that grow more evenly across the bed in order to increase crowning uniformity.

For now, Klaustermeyer appreciates the opportunity to farm with his dad and values the contributions of his crew, including employees who have been on the farm for 20 to 25 years.

“I really enjoy working in the dirt and being able to measure my progress daily. I have a great crew that helps me accomplish this every day,” he says.

When growing carrots for the fresh market in the USA, it’s all about taste, seed uniformity and suitability for mechanical sowing and harvesting. By the development of Jacinto and Olancha, these characteristics were at center stage. Find out everything about our carrot varieties on popvriendseeds.com/usa/carrots

OLANCHA IMPERATOR CUT & PEEL

� VERY HIGH FIELD DURABILITY AND UNIFORMITY

� HIGHER PROCESSING PERFORMANCE

� GREAT FLAVOR

� GOOD TOP ATTACHMENT

JACINTO IMPERATOR CELLO

� EXCELLENT FLAVOR

� GREAT DURABILITY AND UNIFORMITY

� GOOD CORE DEFINITION

� STRONG HEALTHY TOPS

TheH-2A temporary agricultural workers program may not be perfect, but it’s hard to argue that it’s not popular. The number of growers employing the program continues to grow despite its increasing costs and an ongoing push for a better system.

On Dec. 22, 2022, the U.S. Department of Labor released the Adverse Effect Wage Rate (AEWR) for 2023, which took effect on Jan. 2 (Fig. 1). The AEWR is the hourly rate for H-2A workers or those in corresponding work, defined as work done by those who are not H-2A workers

A 10 inch cello type that displays excellent tops as well as a smooth exterior. Good root shape and vibrant orange color.

MAVERICK

Early. High quality, uniform roots have excellent interior color and taste. Strong foliar disease tolerance. Widely adapted.

but are doing the same or “like” work that is listed on an approved job order, or any agricultural work performed by H-2A workers during the period of the job order.

The average 2023 AEWR is $16.13, up from $15.56 in 2022. The top five H-2A employment states and their AEWR (nonrange occupations) increases for 2023 are:

• Florida: $14.33, up 15 percent

• California: $18.65, up 7 percent

• Georgia: $13.67, up 14 percent

• Washington: $17.97, up 3 percent

• North Carolina: $14.91, up 5 percent

The Department of Labor also recently released fiscal year 2022 certification numbers. The H-2A program saw a 17 percent increase over fiscal year 2021 in certifications.

The program continues to grow exponentially while there is still no consensus in Congress to help farmers find long-term relief from labor shortages.

The recent Farm Workforce Modernization Act did not pass the Senate, and advocates for ag labor and immigration reform had been trying to find some common ground and compromise.

Very well suited for the cut & peel markets because of it’s excellent eating quality, very smooth exterior and root shape.

Another ag labor reform bill proposed by Sen. Michael Bennett had hoped to find bi-partisan support and did not make it in the omnibus spending bill. The Affordable and Secure Food Act would have helped year-round producers like dairy and meat processors bring in foreign workers on the H-2A program and provide a pathway to citizenship to those agricultural workers already in the U.S. Both bills have had bi-partisan support but have been unable to move forward. The failure of these bills has producers questioning if they will ever see a solution at a time when the price of inputs continues to climb and the on-farm labor shortage continues to worsen.

While many have called for reform of the current H-2A program, the program is working for an ever-increasing number of farms. Currently, there is no “cap” on H-2A visa numbers, unlike H-2B and other visa programs. The government agencies involved in the H-2A certification and visa process have improved processing times and listened to feedback from stakeholders to make the application and certification process more userfriendly while keeping up with increasing application numbers.

Because the H-2A program is seasonal in nature, deadlines and timeliness are important. H-2A applications must be submitted to the Department of Labor 6075 days in advance.

One of the biggest challenges is finding available and affordable housing that meets state and federal housing requirements for farmworkers, especially during the recent housing market boom. H-2A housing must pass inspection by state agencies before job order certification, which is typically 30 days before the start date of the job order or the date the employer needs the worker to begin.

Proper planning is a must to have workers arrive at the farm on time. Most farms or ag businesses that use the program use an agent or attorney to navigate the application process. According to the USDA, 21 percent use an agriculture association, and only 15 percent of employers file their own applications (Fig. 2). The H-2A program has over 200 rules and regulations, and that number is not getting any smaller. While the program may seem daunting and complex, having a reliable, seasonal workforce has been an important asset for U.S. farms. Finding a reliable partner and advocate to assist in the application process is a vital part of having a successful H-2A program for your farm.

www.cropvitality.com

KTS, a liquid potassium thiosulfate fertilizer, will provide the potassium boost a carrot crop needs to gain more uniform size and increase yield. Potassium is key to root growth, transport of water and nutrient uptake in the plant. In addition to potassium, KTS will supply sulfur, which is essential for carrot growth and development. A foliar application of Crop Vitality’s KTS is a great way to give carrots a potassium and sulfur boost when they need it most. A field trial performed in Washington in which 1 gallon/acre of KTS was applied twice as a foliar increased yield over the check by 3.2 tons per acre.

www.jhbiotech.com/chelation-and-mineral-nutrition

Biomin is a line of fully chelated plant nutrients resulting from the chelation of mineral nutrients with amino acids. These chelates protect the nutrient from combining with other elements or losing nutrient value for absorption. JH Biotech’s Biomin chelated line is OMRI, CDFA and WSDA organic certified and compatible with humic and fulvic acid products. Without using harsh chemicals, it provides plants with stable nutrients, balancing mineral deficiencies more quickly than conventional inorganic nutrients. It can be used for soil and foliar applications without compromising environmental quality and safety. Biomin may be applied to all crops and turf. It reduces the effects of saline soils, water deficiency and weather conditions while encouraging increased yield, homogeneous ripening, more flavored and high quality fruit, and greater nutrient absorption.

Lorox

www.novasource.com

Selectively manage annual weeds in carrots with Lorox herbicide. When used in a complete integrated pest management program, Lorox provides an important tool to suppress problem weeds that inhibit the growth and yield of a crop. It is a Group 7 herbicide that includes the active ingredient linuron, which helps manage more than 20 broadleaf weeds and grasses. Lorox provides a different mode of action than other common herbicides and can be an important tool to break the cycle of herbicide-resistant weeds. The overuse of popular herbicides such as glyphosate, triazines and others has led to the development of dozens of weed biotypes that are now resistant to these chemistries. To combat this resistance in crops such as carrots, asparagus, celery and pulse crops, growers can trust Lorox agricultural herbicide from NovaSource.

www.omexusa.com

Slyce Ca8% provides organic compounds, feeding soil microbial activity, which increases the soil-available fertility, especially when applied after granular fertilizers (e.g., DAP, MAP, CalSul or KCl), by reacting with those granular nutrients to release their components for faster and more efficient fertilizer use by plants. In addition, Slyce aids in water penetration and increases the permeability of the soil profile, providing better soil moisture movement for developing carrots. Zynergy’s formulation provides the proper balance of zinc, copper and sulphur for use in root-producing crops like carrots. Zinc helps in the formation and activation of hormones that regulate root development and water uptake. Copper is involved in photosynthesis and the binding of cells that support plant structure, as well as forming part of the phenolic compounds used by plants to suppress infection. Sulphur is essential for plant growth, aiding in enzyme and vitamin activities, chlorophyll formation and nitrogen stabilization.

Rango

www.rangonow.com

Rango is a triple-action fungicide, insecticide and miticide that offers superior protection from major pests and diseases. Field trials have demonstrated efficacy in controlling insects such as onion thrip, western flower thrip, aphids, Lepidoptera species and spider mites, plus diseases such as powdery and downy mildew.

Rango controls target pests on contact or by ingestion. It offers multiple modes of action as an anti-feedant, insect repellent, growth regulator and fungal growth inhibitor.

Rango is EPA registered, OMRI listed and classified as an “NC” FRAC Code – no known resistance, making it an excellent rotation or tank partner in integrated pest management programs for organic and conventional operations.

NAPOLI

Very full-sized Nantes with strong dark green tops and cylindrical, smooth blunt roots. A specialized variety with a sweet taste when sown in fall for winter harvest.

Resistance IR: Ar / Cc / Ps, Pv

YAYA

Similar to Nelson, with more uniform roots and plant vigor. The 5 1/2–6 1/2” roots have mild flavor and crisp, juicy texture with early sugar development. Strong, compact tops for bunching.

Resistance IR: Ar / Cc / Ps, Pv

Chelsey Lenczyk - Organic Lead, Home & Farm Market Manager

T: 267-838-0078

E: c.lenczyk@bejoseeds.com

NAVAL

A Nantes type that produces very shapely, uniform, hairless roots 7-9 inches long. Crisp and sweet, Naval resists cracking with an added bonus of a long shelf life.

Resistance IR: Ad / Ar / Cc

bejoseeds.com

Thecarrot weevil (CW) is an important pest of carrots in Ontario, Canada, especially early in the season. This weevil, Listronotus oregonensis, can cause high levels of crop loss in the high organic matter soils of the Holland Marsh, Ontario, Canada.

The adult CW is active early in the season, even before most carrots are seeded. The adult overwinters in sheltered areas at the edges of fields and walks into the field in early May in Ontario. The weevils begin looking for carrots that are suitable in size to deposit their eggs. Generally, carrot weevils do not feed on carrots, or deposit eggs, until after the first true leaf stage.

The larvae hatch and begin feeding and tunneling through the upper third of the carrot root (Fig. 1). Larval feeding on small carrots, during the fourth to sixth leaf stage, often kills the carrot. Feeding on larger carrots can often go unnoticed until harvest, and this feeding damage renders the carrot unmarketable.

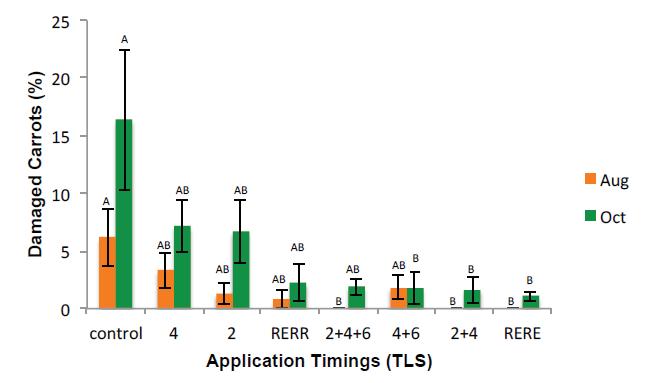

Carrot weevil feeding has caused damage and crop loss in past years in the marsh. In 2016, an average of 7 percent of carrots were lost due to CW (Fig. 2), despite the application of insecticides. Growers were regularly applying Imidan 70-W (a.i. phosmet) for many years, and it is likely that CW was developing resistance, as the product was no longer as effective as it used to be.

In 2016, research trials at the University of Guelph Ontario Crop Research Centre – Bradford (formerly the Muck Crops Research Station) began testing new insecticides for CW control. The insecticide Diamond (in Canada – Rimon 10 EC; a.i. novaluron) was effective and resulted in lower damage (13 percent) compared to the untreated check (35 percent) and Imidan (27 percent). Further trials testing other insecticides found Exirel (a.i. cyantraniliprole) was also effective in controlling CW with lower overall damage (17 percent).

Once effective products were found, the next question was when to apply these products to obtain the best results. Insecticide timing trials took place in 2018 and 2019 to investigate this. Diamond was applied at different leaf stages, and carrots were evaluated at harvest. Diamond applied at the second leaf stage, and again at the fourth leaf stage in high-pressure fields, was the most effective to minimize damage and maximize yield at harvest compared to the untreated check (Fig. 3).

In addition to effective insecticides and well-timed applications, choice of seeding date can avoid CW damage. Late seeding can avoid a high-pressure window. To test this, seeding date trials were conducted without the use of insecticides. Carrots planted earlier in the season, April to the first half of May, had higher CW damage (82 percent) compared to carrots seeded in late May or later (12 to 40 percent). This makes sense as CW are active earlier in the season and require a developing carrot plant to lay their eggs. Carrots seeded later in the season avoid the main egg laying period and, therefore, often end up with less damage.

Scouting and trapping for CW adults is important to know if CW are present in your field, and this starts early in the growing season. Wooden (Boivin) traps (Fig. 4) are set up at the edges of fields before carrots are seeded and are moved into rows after seeding. This trap uses a carrot bait as a lure, and the number of CW found in a field relates to spray thresholds. Generally, if a cumulative 1.5 CW/trap are found, a Diamond or Exirel spray is recommended at the second leaf stage. If the field has over five CW/trap, another spray is recommended at the fourth leaf stage.

Our monitoring of carrot fields, damage and CW egg laying sites has also observed a possible second generation of CW, which we are currently studying to understand more thoroughly.

Successful management of carrot weevil involves scouting, effective insecticides, good spray timing and possibly altering the seeding date. These have decreased the overall CW damage to 0.2 percent, on average.

For more information on carrot weevil management, check out the “How to Control Carrot Weevil” video on the Muck Crops IPM YouTube channel. Details of the trials can be found on the research station website at https://bradford-crops.uoguelph.ca.

Authors’

For more information contact: Merek Dorf | m.dorf@rijkzwaan.com Rijk Zwaan USA & Canada | rijkzwaanusa.com

Redox Bio-Nutrients has incorporated a fleet of ChrysaLabs probes in its soil testing. ChrysaLabs has developed a portable AI-based soil health probe that measures 37 soil nutrients and characteristics in real time. The company describes the probes as each containing their own laboratory. Combining a patented spectroscopy interface and the latest AI possibilities, the optical technology measures the soil properties at 360 degrees, with a large contact surface, at any depth, and without preparation. Soil is analyzed in less than a minute, according to the company, saving producers and agronomists time waiting for traditional lab analysis.

Visit www.chrysalabs.com.

Certis Biologicals has launched its new copper product Kocide 50DF (copper hydroxide) for specialty crops in all states. The high-load copper bio-fungicide is designed to serve as both a preventative and curative product to combat a variety of fungal plant diseases, including Alternaria leaf spot and Cercospora leaf spot in carrots.

The new Kocide 50DF formulation mixes with low dust residue, is easy to pour and disperses into the mix solution quickly, producing even coverage during application, according to the company. The product can be applied through foliar, aerial spray, sprinkler chemigation or ground boom application methods.

Snack foods company Dirt Kitchen Snacks has added Air-Dried Carrot Crisps with Smoky Barbeque Seasoning to its portfolio of products. The snack, which the company bills as a new veggie-based twist on BBQ potato chips, is made from crispy, crunchy air-dried carrots tossed in extra virgin olive oil and a bold, smoky barbeque seasoning. The new product contains 35 calories per serving and is vegan, non-GMO, gluten-free and kosher. The carrot crisps contain no artificial flavors, colors, preservatives or added sugar.

Dirt Kitchen Snacks, a business launched in 2020, also sells a carrot and apricot pressed bar. The carrot snacks are available online at www. dirtkitchensnacks.com.

ASA-LIFT is a leading international company developing, producing and distributing vegetable harvesters. For more than 80 years, ASA-LIFT machines have been sold all over the world, and more than 20 years of experience, on the US market.