ONION WORLD NOA Drops Into Desert February 2023 Voice of the Industry • OnionWorld.net H-2A in 2023 • Nitrogen Use in Muck-Grown Onions • Crop Protection Essentials Bejo ......................................6 Chemport CSI......................17 Chinook Equipment ............23 Clearwater Supply ..............11 Gearmore .............................9 Germains ............................16 Gowan Seed .......................23 L&M ....................................14 Nate Vandenberg ................19 NOA ....................................19 Nunhems ............................12 Redwood Empire ................19 Rietveld ................................3 Seed Dynamics ...................24 Seedway .............................11 Solex ...................................15 Terramera ...........................23 Verbruggen ...........................7 Advertiser Index

PO Box 333

Roberts, Idaho 83444

Telephone: (208) 520-6461 Circulation: (503) 724-3581

OnionWorld.net

ONION WORLD CONTACTS

Editor Denise Keller editor@ColumbiaMediaGroup.com

Publisher / Advertising Manager Dave Alexander dave@ColumbiaMediaGroup.com

Director of Operations Brian Feist brian@ColumbiaMediaGroup.com

EDITORIAL INFORMATION

Onion World is interested in newsworthy material related to onion production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com, or call (509) 697-9436.

ADVERTISING SALES

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@onionworld.net

SUBSCRIPTIONS

U.S. $24 per year Canada $40 per year Foreign $80 per year

Subscribe online at: www.OnionWorld.net/subscribe or call (503) 724-3581.

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to: Onion World PO Box 333 Roberts, ID 83444

Onion World magazine (ISSN 0892-578X), is published eight times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices.

Produced by Columbia Media Group PO Box 333, Roberts, ID, 83444. Copyright 2023. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group.

For information on reprints call (208) 520-6461.

2 Onion World • February 2023 FEBRUARY

2023

ONION WORLD Volume 39, Number 2 NOA 2022 Annual Convention field day attendees tour Sunbelt Transplants. Read the full story on page 4. Sunbelt Transplants in Buckeye, Ariz. hosted an optional field day during the National Onion Association Annual Convention held in nearby Scottsdale. Read about the industry issues discussed at the meeting on page 4. ON THE COVER DEPARTMENTS 13 ...Onion Disease Quiz 17 ... In the News 19 ...Calendar 22 ... Peels of Laughter 22 ... Advertiser Index TABLE OF CONTENTS 4 NOA Drops Into Desert NOA 2022 Annual Convention 10 H-2A in 2023 14 Nitrogen Use in Muck-Grown Onions Cornell Studies Indicate Opportunity to Reduce Rates 18 Creating Sweet Moments with Vidalia Onions Vidalia Onion Committee 20 Crop Protection Essentials Buyers' Guide

www. rietveldequipment .com 815|936|9800 john@rietveldequipment.com

NOA Drops Into Desert

The National Onion Association (NOA) landed a notable speaker for its annual convention, held Dec. 7-10 in Scottsdale, Arizona. The keynote address at the “West’s Most Western Town” was delivered by Dr. Samir Assar, director of the Division of Produce Safety for the Food and Drug Administration (FDA).

Assar has a staff of about 30 people at the FDA. That staff is roughly divided into thirds: one group is responsible for manufactured and fresh-cut processed produce, another third sets policy for raw agricultural commodities, and the rest focus on training and education. Their primary mission is to set science-based safety standards for agriculture, but Assar said he and his agency are big believers in technical assistance, education and training, spending millions of dollars every year in that pursuit.

“We need to educate before and while we regulate,” he said.

Part of the FDA’s education process is the Produce Safety Network (PSN). The PSN provides growers and packers with experts to answer questions about

food safety and has located PSN staff in specific growing regions.

Educating and talking about food safety includes conversations about Salmonella outbreaks, though Assar said he is never comfortable broaching the subject. Assar said the 2020 California Salmonella Newport and the 2021 Chihuahua, Mexico, Salmonella Oranienburg outbreaks, both attributed to onions by the FDA, were a “watershed moment.” The 2021 incident logged 1,040 illnesses and 260 hospitalizations in 39 states, the District of Colombia and Puerto Rico.

The 2020 case was determined by the FDA to be from contaminated irrigation sources, possibly from animal intrusion or sheep grazing. But there is often a long delay getting investigators into the suspected contaminated operation, and not all growers are convinced onions were the root cause of the outbreak.

“Very rarely do we find the smoking gun. We have a limited ability to say ‘this is how it happened,’” Assar said. “We are often out there many months after the outbreak has occurred. What we see

when we are out there isn’t necessarily reflective of what may have happened or the conditions that were apparent at the time of the contamination.”

Assar gave kudos and thanks to the NOA and onion industry at large for its response to the outbreaks. Though a new commodity-specific onion food safety best practices document was already started, the outbreaks accelerated the timeline to finish.

Referring to the “Commodity-Specific Food Safety Guidelines for the Dry Bulb Onion Supply Chain,” Assar said, “You’re an example of how industry can come together, address an adverse outbreak situation and put out best practices that are aimed at addressing and preventing that situation from ever happening again.”

Written by NOA, industry members and the International Fresh Produce Association, the new onion guidelines were released in July 2022. The FDA is using the document as an example for other commodities of how to produce good food safety guidelines.

Story and photos by Dave Alexander, Publisher

Diners enjoy the banquet at the NOA convention in Scottsdale, Ariz.

NOA 2022 ANNUAL CONVENTION

Samir

“done a really good job addressing food safety.”

Kimi Maag (left) with Jamieson Produce Inc. and Barry Vculek with Four Star Ag both won awards

From left, Nick Rietveld with Rietveld Equipment, Jose Cardona and Alma Palayo with Rio Farms and Theresa Rietveld with Rietveld Equipment visit during the social hour before the NOA banquet.

Tom Uriu (left), an Oregon onion grower for 70 years, accepts the NOA Lifetime Achievement Award from NOA executive vice president Greg Yielding. Bob Sakata from Colorado was also honored posthumously.

Assar, director of the Division of Produce Safety for the Food and Drug Administration, speaks to attendees at the NOA convention in Scottsdale, Ariz. Assar said the NOA has

René Hardwick, National Onion Association director of public and industry relations, adresses attendees at the annual convention.

Kimi Maag (left) with Jamieson Produce Inc. and Barry Vculek with Four Star Ag both won awards

From left, Nick Rietveld with Rietveld Equipment, Jose Cardona and Alma Palayo with Rio Farms and Theresa Rietveld with Rietveld Equipment visit during the social hour before the NOA banquet.

Tom Uriu (left), an Oregon onion grower for 70 years, accepts the NOA Lifetime Achievement Award from NOA executive vice president Greg Yielding. Bob Sakata from Colorado was also honored posthumously.

Assar, director of the Division of Produce Safety for the Food and Drug Administration, speaks to attendees at the NOA convention in Scottsdale, Ariz. Assar said the NOA has

René Hardwick, National Onion Association director of public and industry relations, adresses attendees at the annual convention.

Exploring nature never stops

TANIA

New short day yellow granex introduction: Strong upright tops with great plant habit. High yielding deeper granex shape, strong root system, and firm bulbs. Pink root and bolting resistance.

Earliness: Early main Sowing period: 09-15 - 09-25

Taste: Sweet Pyruvates: 3.6 Lacrymatory Factor: 2.8

Shape: Granex

IR: Foc; Pt

RED SENSATION

Early maturing grano red. Strong healthy tops. Pink root resistance. Excellent bulb firmness and color. Uniform round bulbs. Good internal color. Widely adapted across short day growing regions. High percentage single centers.

Earliness: Early Sowing period: 09-25 - 10-05

Taste: Very sweet Shape: Grano

IR: Foc; Pt

ALISON

Late season short day yellow granex with upright tops. Deeper high yielding granex shape. Bolting resistance and very uniform. Strong outer skin layers. Produces well sized bulbs that result in good yields. Great option to fill later season slot in Vidalia.

Earliness: Late Sowing period: 09-25 - 10-05

Taste: Very sweet Pyruvates: 3.5 Lacrymatory Factor: 2.4 Shape: Granex IR: Foc; Pt

PIRATE

Main Season short day yellow granex. Attractive lighter colored skin. Uniform and extra firm bulbs with high yielding deeper granex shape. High percentage of jumbos. Great post harvest appearance. A widely adapted variety across many short day regions.

Earliness: Main Sowing period: 09-18 - 09-28

Taste: Sweet Pyruvates: 3.4 Lacrymatory Factor: 2.6 Shape: Granex IR: Foc; Pt

6 Onion World • February 2023 NOA 2022 ANNUAL CONVENTION

Jared Gutierrez with Columbia Basin Onion reminds NOA convention attendees that the NOA is non-profit and the best bang for the buck of any group. Gutierrez won a recruitment award at the banquet.

bejoseeds.com

Cody Nickoloff with Helena Agri-Enterprises celebrates a good night at the NOA banquet, winning a recruitment award for the first time and announcing his engagement to Brooke Ulrich.

Bejo Seeds Inc. (main office) 1972 Silver Spur Pl. Oceano, CA | T: 805- 473-2199 | E: info@bejoseeds.com BEJO ONIONS - LAYERS OF EXCELLENCE

Crop Reports

The last day of any NOA convention is reserved for crop reports. The reports are delivered by growers over breakfast in an informal setting. The 2022 growing season was a mixed bag of results, presented here in the growers’ own words.

Michigan

“We had an above average crop that went into storage good, and movement has been good. We’re pretty happy right now.”

-Bruce Klamer, V&W Farms Inc.

North Dakota

“We had a small crop, late planting and didn’t get all of our acres in. The bins were not full, but shipping is going great, so we’ll be out of onions this year.”

-Barry Vculek, Four Star Ag

Wisconsin

“We had a really nice crop and really good, brisk movement.”

-Doug Bulgrin, Gumz Farms

Colorado

“We had an up and down season. We were late to get planted. We had a little bit of hail over the summer that wiped out some of our stuff. We had a fairly average crop and should be wrapped up by mid-March.”

-Colby Cantwell, Faberberg Produce

Idaho-Eastern Oregon

“It’s been a rough year with lots of heat and wind damage. From harvest on, you can drive by and there are boxes stacked everywhere empty outside.”

-Tyler Wagstaff, Central Produce Distributing

Oregon

“In my area, it was a cool spring. The crop actually finished up pretty good. It looks good, storage is good. There are a few more mediums than normal.”

-Delbert Gehrke, AgriNorthwest

Oregon

“We’re pretty close to the same.”

-Jared Gutierrez, Columbia Basin Onion

Oregon

“After planting, we got 10 inches of rain, so everything was behind. Crops turned out to be average with a medium summer. Shipping is good and quality is good.”

-Tony Bennett, Northwest Onion Co.

Washington

“Quality is excellent. We’re going to be pretty close to what we should be.”

-Bart Connors, Skone and Connors Produce

Editor’s note: To contact an FDA produce safety expert familiar with your region, visit www.fda.gov/media/105420/ download. Onion safety guidelines can be found at www.freshproduce.com/ resources/food-safety/commodityspecific-resources.

We take perfect care of your onions.

Discover the ultimate onion stacking & palletizing solutions.

Do you need the ability to accumulate boxes with multiple SKUs? Scan the QR to watch our flagship machine VPM-VHV stack pallets at blistering speeds or visit verbruggen-palletizing.com

OnionWorld.net 7

Sunbelt Transplants

Buckeye, Arizona, is home to Sunbelt Transplants. Located about 45 minutes (two hours in traffic) from Scottsdale, the NOA organized a lunch and a tour of the farm, owned by Gary Mayfield.

Known as the “Valley of the Sun,” the Phoenix-Scottsdale area is in Maricopa County, where there are nearly 4.5 million people, around 2,500 farms and some very interesting politics.

NOA 2022 ANNUAL CONVENTION

Gary Mayfield with Sunbelt Transplants hosts NOA attendees at his farm in Buckeye, Ariz., to tour his onion seedling operation and to eat lunch.

Sunbelt Transplants delivers onion starts in small bundles with pencil-sized diameter shoots.

Stecklings (sugar beet seed transplants) are harvested at Sunbelt Transplants.

René Emch with Enza Zaden, NOA president Delbert Gehrke and NOA executive vice president Greg Yielding have lunch at the home of Sunbelt Transplants owner Gary Mayfield.

8 Onion World • February 2023

Cotton is an important rotation crop for Gary Mayfield, owner of Sunbelt Transplants.

PRECISION VACUUM PLANTERS The Planter Used By Vegetable Growers In The Western United States and Canada For Over 25 Years Our proven accurate seed placement is why growers have continued to purchase our planters over these many years. Special inner and outer singulators removes doubles to insure placement of individual seeds. All moving pivot points have either hardened bushings or bearings installed to prevent damage to the frames. UHMW poly wear rings are installed between the seed disc and planter housing to prevent the stainless steel seed disc from damaging the planter housings. These are only a few points that separate us from the competition. All planters are assembled and tested at our plant in Chino, California, to insure accuracy. 6 Modules - 24 Lines Model # AI-640-SNT Shown 13477 Benson Ave. Chino, CA 91710 Ph: 909/548-4848 www.gearmore.com e-mail: sales@gearmore.com

By Jennifer Uranga, Partner, Gem Ag Professionals

he H-2A temporary agricultural workers program may not be perfect, but it’s hard to argue that it’s not popular. The number of growers employing the program continues to grow despite its increasing costs and an ongoing push for a better system.

On Dec. 22, 2022, the U.S. Department of Labor released the Adverse Effect Wage Rate (AEWR) for 2023, which took effect on Jan. 2 (Fig. 1). The AEWR is the hourly rate for H-2A workers or those

in corresponding work, defined as work done by those who are not H-2A workers but are doing the same or “like” work that is listed on an approved job order, or any agricultural work performed by H-2A workers during the period of the job order.

The average 2023 AEWR is $16.13, up from $15.56 in 2022. The top five H-2A employment states and their AEWR (nonrange occupations) increases for 2023 are:

• Florida: $14.33, up 15 percent

• California: $18.65, up 7 percent

• Georgia: $13.67, up 14 percent

• Washington: $17.97, up 3 percent

• North Carolina: $14.91, up 5 percent

The Department of Labor also recently released fiscal year 2022 certification numbers. The H-2A program saw a 17 percent increase over fiscal year 2021 in certifications.

FY 2023 Adverse Effect Wage Rates

10 Onion World • February 2023 H-2A in 2023

State <$14.00 $15.00 < State > $16.00 $17.00 < State > $18.00 $14.00 < State > $15.00 $16.00 < State > $17.00 $18.00 < State Puerto Rico $14.26 West Virginia $16.95 Rhode Island Alaska $16.55 Delaware $17.17 Indiana $17.97 Oregon $17.34 Wisconsin $17.33 Nebraska $17.54 Missouri $16.55 Pennsylvania $16.95 New Hampshire $17.17 Illinois $17.54 Iowa $17.34 Minnesota $15.62 New Mexico $13.67 Alabama $16.95 Vermont $16.55 New Jersey $15.68 Wyoming $17.25 Hawaii $17.33 South Dakota $16.95 Connecticut $14.87 Oklahoma $15.68 Montana $16.95 Maine $17.33 North Dakota $16.95 Massachusetts $16.55 Maryland $17.33 Kansas $17.97 Washington $16.34 Utah $16.34 Colorado $17.17 Ohio $15.62 Arizona $16.34 Nevada $13.67South Carolina $14.87 Texas $15.68 Idaho $13.67 Mississippi $14.26 Tennessee $14.33 Florida $18.65 California $13.67 Arkansas $16.95 New York $13.67 Louisiana $14.91 Virginia $13.67 Georgia $14.91North Carolina $17.34 Michigan $14.26 Kentucky

FY 2023 Adverse Effect Wage Rates

T

Figure 1. Adverse Effect Wage Rate (AEWR) for 2023

Congressional Efforts

The program continues to grow exponentially while there is still no consensus in Congress to help farmers find long-term relief from labor shortages.

The recent Farm Workforce Modernization Act did not pass the Senate, and advocates for ag labor and immigration reform had been trying to find some common ground and compromise.

Another ag labor reform bill proposed by Sen. Michael Bennett had hoped to find bi-partisan support and did not make it in the omnibus spending bill. The Affordable and Secure Food Act would have helped year-round producers like dairy and meat processors bring in foreign workers on the H-2A program and provide a pathway to citizenship to those agricultural workers already in the U.S. Both bills have had bi-partisan support but have been unable to move forward. The failure of these bills has producers questioning if they will ever see a solution at a time when the price of inputs continues to climb and the on-farm labor shortage continues to worsen.

Program Considerations

While many have called for reform of the current H-2A program, the program is working for an ever-increasing number of farms. Currently, there is no “cap” on H-2A visa numbers, unlike H-2B and other visa programs. The government agencies involved in the H-2A certification and visa process have improved processing times and listened to feedback from stakeholders to make the application and certification process more userfriendly while keeping up with increasing application numbers.

Because the H-2A program is seasonal in nature, deadlines and timeliness are important. H-2A applications must be submitted to the Department of Labor 60-75 days in advance.

One of the biggest challenges is finding available and affordable housing that meets state and federal housing requirements for farmworkers, especially during the recent housing market boom. H-2A housing must pass inspection by state agencies before job order certification, which is typically 30 days before the start date of the job order or the date the employer needs the worker to begin.

UNITED STATES

Lancaster & San Joaquin Valley (661) 9785342

Desert Southwest (928) 4467737

Colorado & New Mexico (970) 3969728

Idaho, East Oregon, Utah & Nevada (208) 9411421

Skagit Valley, Washington (360) 9417503

Rio Grande Valley & West Texas (956) 6185574

MEXICO

Torreón, Coahuila (461) 1173878

Colima, Col. (461) 1040134

San Luis Potosi (461) 1409452

Chihuahua (461) 1719401

Tamaulipas (461) 1342421

Irapuato, Gto. (461) 5465792

OnionWorld.net 11

Your Acres. Your Livelihood. Our Priority. (800) 952-7333 WWW.SEEDWAY.COM SEEDWAY_Onion World_Oct2021_Layout 1 10/4/2021 2:52 PM Page 1

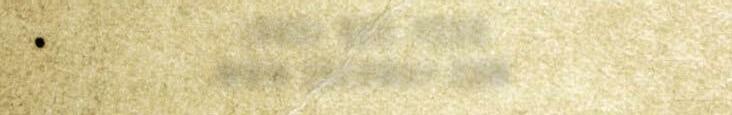

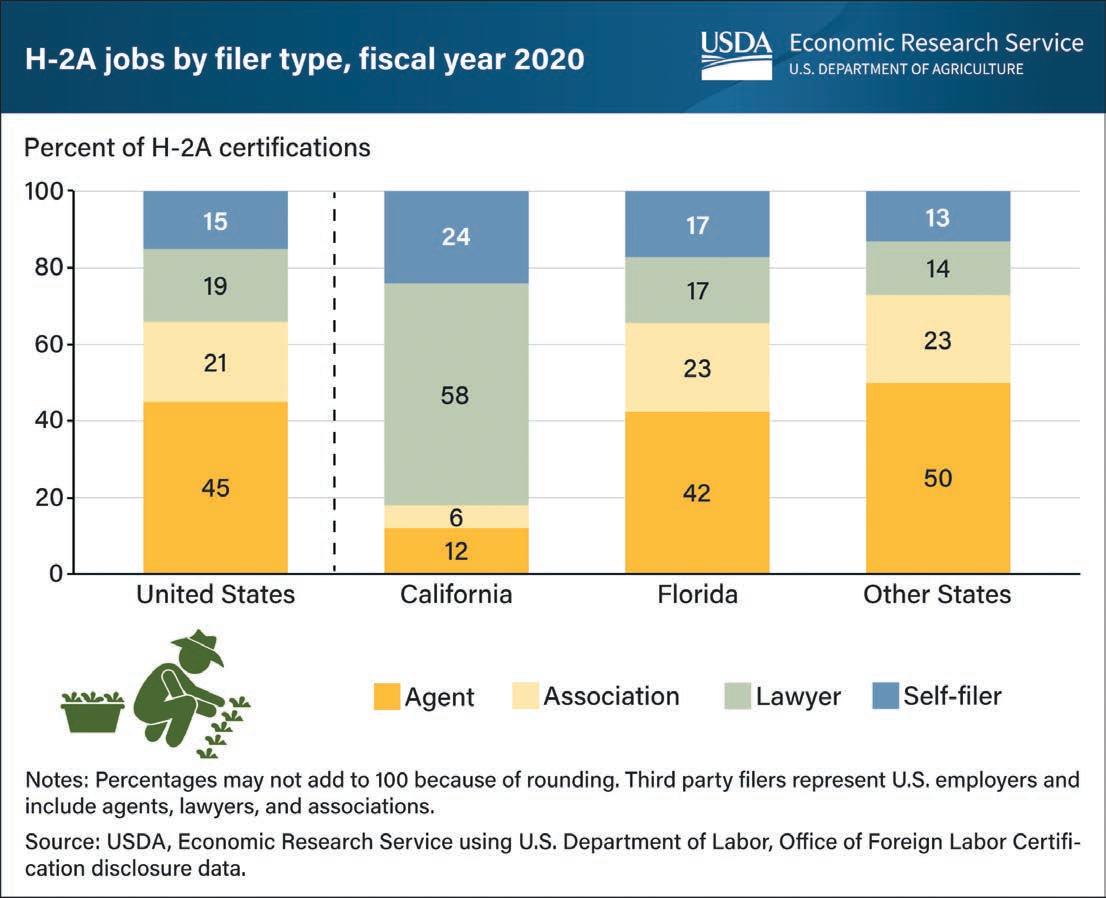

Proper planning is a must to have workers arrive at the farm on time. Most farms or ag businesses that use the program use an agent or attorney to navigate the application process. According to the USDA, 21 percent use

an agriculture association, and only 15 percent of employers file their own applications (Fig. 2). The H-2A program has over 200 rules and regulations, and that number is not getting any smaller. While the program may seem daunting

and complex, having a reliable, seasonal workforce has been an important asset for U.S. farms. Finding a reliable partner and advocate to assist in the application process is a vital part of having a successful H-2A program for your farm.

12 Onion World • February 2023 H2-A IN 2023

Figure 2. Third parties utilized by U.S. farmers to hire temporary foreign workers through the H-2A program

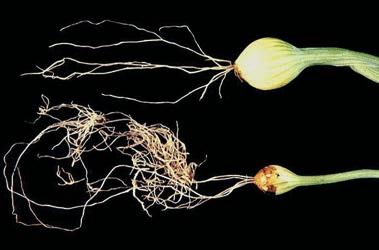

Onion Disease Quiz

This material is provided courtesy of: Bhabesh Dutta, Associate Professor and Vegetable Disease Specialist, University of Georgia Ron Gitaitis, Professor Emeritus, Phytobacteriologist, University of Georgia

Onions can be affected by a variety of pathogens and diseases. Below are three photos of diseases of onion, along with some key information about each. Can you identify what’s affecting the onion in each photo? Answers on page 19

1.The symptoms of this disease usually occur on one or two outer dry leaves of the bulb, especially the lower parts. Small, round, dark spots develop, which may be scattered over the surface of the bulb in diffuse areas. The spots contain cream spore masses and stiff, long, black hairs visible with a hand lens.

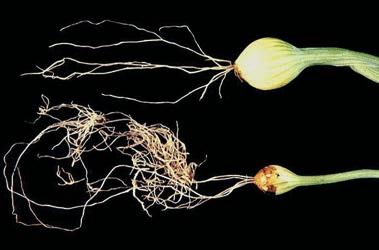

2.Plants with this disease are stunted, turn yellow or when in seedling stage, may die when infected. Roots develop numerous stubby branches, often in clusters, as a result of the pathogen feeding on root tips. Despite feeding on the roots, the pathogen will not be embedded in root tissue.

3.Symptoms include yellowing, stunting and overall appearance of nutrient and water deficiencies. Plant stands may be thin and irregular. When plants are lifted from the soil, swollen galls can be observed on the roots. Galls may be round or spindle-shaped, depending on the species of the soil-borne pathogen.

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

OnionWorld.net 13

Photo courtesy Jonathan D. Eisenback, Virginia Polytechnic Institute and State University, Bugwood.org

Nitrogen Use in Muck-Grown Onions

Cornell

Studies Indicate Opportunity to Reduce Rates

By Christy Hoepting, CCE Cornell Vegetable Program

Recent record high nitrogen prices have begged the question: How much nitrogen do muck-grown onions really need? Luxurious use of fertilizer by muck onion growers to ensure large onions and high yields (e.g., 120-140 lbs/acre of nitrogen) has been a tradition passed down through generations. This practice is hard to change because lowering fertilizer rates risks producing smaller onions. But with the cost of nitrogen fertilizer more than doubling from around $225/ton in 2020 to around $500/ton in 2022, this “cheap crop insurance” was suddenly not so cheap anymore. In addition, excessive use of nitrogen fertilizer contributes to greenhouse gas emissions that curb New York state’s ambitious climate change mitigation goals.

Trials Indicate Opportunity to Reduce Nitrogen Rates

Since 2017, Christy Hoepting with Cornell Cooperative Extension - Cornell Vegetable Program (CVP) and Brian Nault with Cornell Vegetable Entomology and their teams have conducted 11 on-farm nitrogen fertility trials in muck-grown onions, which have overwhelmingly indicated that onions can be grown on good muck soil using 60-90 lbs/acre of applied nitrogen without yield loss.

In 2017 and 2018, in two studies conducted by Nault’s graduate student Ashley Leach in the Elba, New York, muck, there were no significant differences between 60, 75, 105 and

Cornell on-farm trials by Christy Hoepting with Cornell Cooperative Extension - Cornell Vegetable Program suggest that there is opportunity to reduce rates of applied nitrogen from 120-140 lbs/acre to 60-90 lbs/acre without yield losses in good muck soil.

14 Onion World • February 2023

135 lbs/acre of total applied nitrogen (urea), although all of these treatments yielded significantly ~50 percent more than zero applied nitrogen. Note that these trials were conducted in shallower muck with overhead pivot irrigation. These results suggest that 60 lbs/acre of nitrogen is sufficient.

In 2018, there were no significant differences in yield among 37, 100 and 150 lbs/acre of applied nitrogen (urea) at planting in the two CVP onion variety trials where these rates were tested with seven and 12 varieties in Elba and Oswego, New York, respectively. Note that these trials were conducted in deep muck and were not irrigated. These results suggest that 37 lbs/acre of nitrogen is sufficient.

In 2019, there were no significant differences in yield among 10, 30 and 60 lbs/acre in the CVP onion variety trial in Elba, where these rates were tested with nine varieties. It is not known whether a higher rate of nitrogen would have resulted in greater than 448 cwt/acre. In the 2019 Oswego variety trial, 60 lbs/acre of applied nitrogen had significantly higher yield than 10 and 30 lbs/acre, which were not significantly different from each other when tested across 11 varieties. Amazingly, these low rates of nitrogen yielded 986-1,124 cwt/acre, suggesting that maximum yields were achieved. Note that these trials were conducted in deep muck and were not irrigated, and that 2018 was hotter and drier than 2019. These results suggest that 30 lbs/acre of nitrogen is insufficient.

In 2020 and 2021, in the two CVP nitrogen timing trials in Oswego, there were no significant differences in yield between 60, 90 and 120 lbs/acre of applied nitrogen (urea). Note that these trials were conducted in deep muck and were not

irrigated, and that 2020 was drier than 2021. These results suggest that 60 lbs/acre of nitrogen is sufficient.

In 2019, 2020 and 2021, in Nault’s “fertility mile” project, there were no significant differences between zero, half and full rates of NPK (not just nitrogen) in any year of study. For this project, growers were asked to apply zero, half and their standard full rates of NPK in ≥ 30 ft x 150 ft areas for each rate. Rates of nitrogen in the half NPK treatments ranged from 45 to 70 lbs/acre and from 89 to 140 lbs/acre in the full NPK treatments. These large-scale trials varied from being irrigated and non-irrigated, on shallow and deep muck, on rotated and nonrotated ground and among variety. There were no consistent numerical trends among NPK rates within the 21 individual trial sites. Furthermore, growers did not see differences in bulb size or foliar health in their own fields as they walked the “fertility mile” through the different rates of NPK.

There were no significant differences in nitrogen levels in leaf or bulb tissues among rates of applied nitrogen in any of the four variety or two nitrogen timing CVP trials, and no deficiencies in leaf tissue were detected.

Rate of applied nitrogen did not have a significant effect on onion thrips in any of the 11 trials or on bacterial bulb rot in 10 out of 11 trials. In the nitrogen onion thrips trial in 2017, bulb rot in 0 lbs/acre applied nitrogen treatment (1 percent) was significantly lower than it was in 60, 75, 105 and 135 lbs/acre applied nitrogen treatments (5-8.5 percent bulb rot).

Modern muck onion production systems are loaded with nitrogen. Levels of available nitrate-nitrogen (NO3-N) found in

OnionWorld.net 15

e latest development from Stanhay; 50 years of precision planting experience has gone into designing this row unit. e ProAir is a compact, lightweight but durable row unit packed with adjustability and options to suit any type of ground condition or planting pattern. As all previous models the Pro Air can plant one, two or three lines from one metering unit. 1. Adjustable row unit down force 2. Adjustable rear wheel down force 3. Single bolt adjustment to switch between hyline and loline setups 4. In nitely adjustable depth control measurable to a 0.1mm accuracy via mechanical counter 5. Sealed maintenance free exible drive sha 6. Unobstructed access to the metering unit for maintenance and changing seed discs 7. Independently articulating seed press wheels with adjustable downforce 8. Individual scraper blades on each stainless steel press wheel 9. Ability to latch row unit our of work www.solexcorp.com • (707)678-5533

the soil at the time of onion harvest ranged from 29 to 188 lbs/ acre in the five CVP trials where soil samples were collected at harvest. In these trials, the rates of applied N were 10, 30, 37, 60, 90, 120 and 150 lbs/acre. The fact that there was still plenty of NO3-N in the soil at the time high-yielding crops were harvested indicates that muck soil can be relied on to provide a lot of the nitrogen needs of our onion crops. Nitrogen is released when the organic matter in muck soil decomposes (especially in younger muck) and from the decomposing residue of previous crops (such as soybeans), cover crops and barley nurse crops. Today, nurse and fall cover crops recycle nitrogen that was previously permanently lost from the system through oxidation and erosion when nitrogen recommendations were originally made in the late ‘60s and early ‘70s.

More Important Factors Affect Yield

Growing season – The greatest differences in yield occurred among growing seasons. All trials conducted during the moderate conditions of 2019 had higher yields than trials conducted in the hotter and drier years of 2018 and 2020 and the wetter year of 2021.

Variety – The greatest differences in yield occurred among varieties, which was significant in all four CVP trials. The differences in yield between the lowest and highest yielding varieties were 26 percent, 41 percent, 24 percent and 40

percent in Elba 2018, Oswego 2018, Elba 2019 and Oswego 2019, respectively. Comparatively, the difference between lowest and highest yield in the only trial where significant differences in yield among nitrogen rates occurred (Oswego 2019) was only 12 percent. Generally, yield increased as days to maturity increased. In general, the hybrid varieties that are grown today are much more vigorous, with stronger root systems that mine nitrogen more efficiently than those that were commonly grown when nitrogen fertilizer recommendations were originally made.

Growers Successfully Reduce Nitrogen

In 2022, in response to the cost of nitrogen fertilizer more than doubling, and numerous Cornell on-farm trials demonstrating that muck-grown onions could be produced using only 60-90 lbs/acre, four New York muck onion farms reduced their rate of N fertilizer from 100-140 lbs/acre to 60-90 lbs/acre, while another farm reduced its rate from 140 lbs/acre to 120 lbs/acre in addition to reducing the broadacre rate by 50 percent by banding NPK. In total, these five farms reduced their rate of N fertilizer by 27 percent on 4,125 acres, which is equivalent to 144,795 pounds in reduced N fertilizer. This reduction saved $36,200 in N fertilizer expenses and lessened on- and off-farm greenhouse gas (GHG) emissions by 723 tons CO2eq., which is approximately equivalent to the amount of carbon sequestered in 776 acres of forests in one year, the amount emitted by consuming 64,443 gallons of diesel or the amount of energy to heat 83 homes for one year.

Funding for the trials was provided by the New York Onion Research and Development Program, Seminis Vegetable Seeds, USDA SCRI Stop the Rot bacterial bulb rot project (2019511811-30013) and USDA SCRI Onion Thrips project (201851181-28435).

16 Onion World • February 2023

NITROGEN USE

Muck onion growers in Elba, New York, walk an on-farm “fertility mile” trial through zero, half and full rates of applied NPK, and they can’t tell which one is which.

Treasure Valley onion growers gathered in Ontario, Oregon, in mid-December to receive training on Gearmore’s Precision Vacuum Planters. The company hosted the training to update customers on new features of the planter and planter parts, as well as overall operation and maintenance. The training covered the initial setup of the planter, including positioning, setting engine and vacuum speed, desired planting depth and seed plate installation. Homer Holmes, vice president of Gearmore and lead product manager for the planters, instructed the class, along with Brad Bonny, territory manager for the Pacific Northwest, and Matt Souza, sales representative. Organizers say there was a great turnout at the event, with many growers from the surrounding areas attending the one-day training.

Gearmore Precision Vacuum Planters are designed for extremely accurate onion seed placement. The planters are assembled in Chino, California, and come set up for each customer’s planting specifications.

OnionWorld.net 17

INTHE NEWS INCREASES OVERALL ONION YIELD PROVIDES LONGER STORAGE QUALITY • REDUCES INTERNAL DEFECTS AND WEIGHT LOSS Western States Call Walt Grigg at 509-952-7558 Kent Wasden 208-390-7878 www.nutri-cal.com The NUTRI-CAL Difference Unlocking The Key To Calcium CHEMPORT, INC. 800-247-2480 The NUTRI-CAL Difference Gearmore Hosts Planter Training

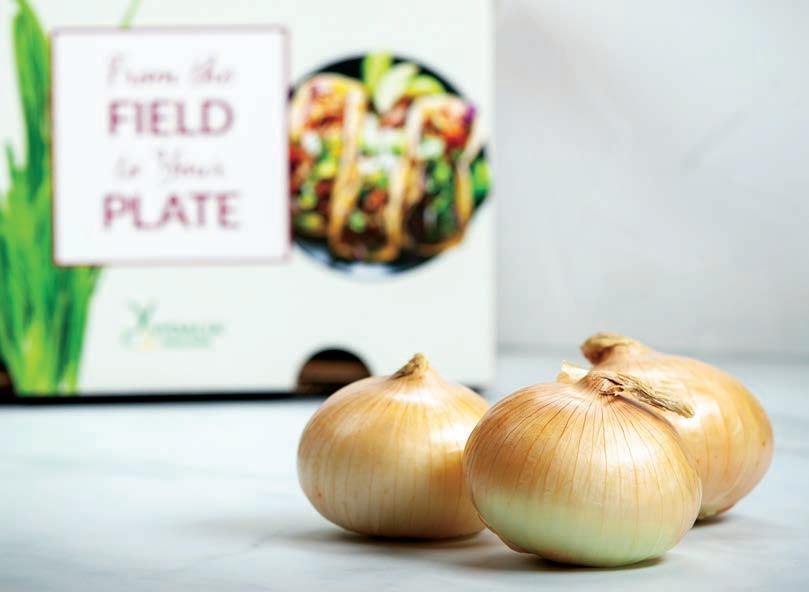

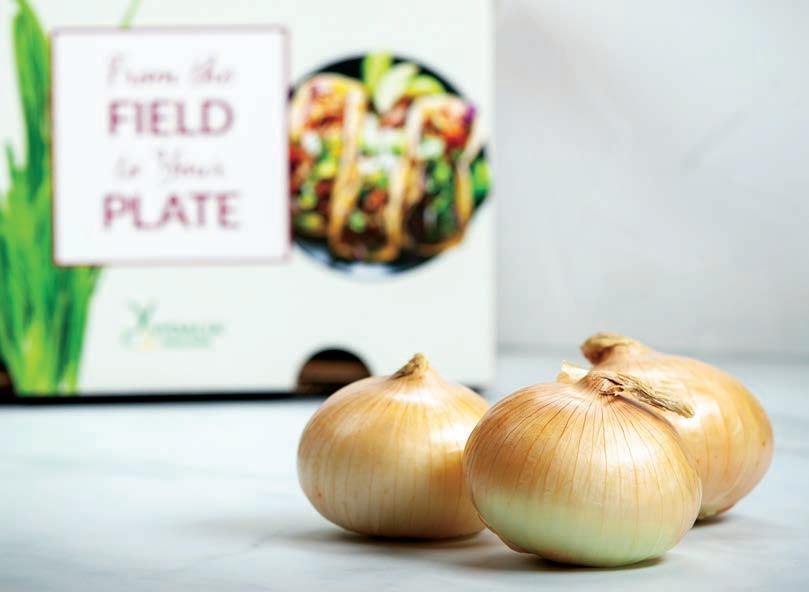

Creating Sweet Moments with Vidalia Onions

By Megan Brodsky, Vidalia Onion Committee Public Relations Representative

By Megan Brodsky, Vidalia Onion Committee Public Relations Representative

tricks for preparing Vidalias and recipe ideas.

“Vidalia onions have become America’s favorite sweet onion over the years and something many look forward to enjoying during the spring and summer months,” says Cliff Riner, chairman of the Vidalia Onion Committee. “We know food is often at the heart of special memories made with friends and family and want Vidalias to be part of those fond moments. We’re excited for what’s to come in 2023 and look forward to seeing how consumers use Vidalias in new and delicious ways.”

Known for their distinct flavor, sweet Vidalia onions have become a favorite for professional chefs and home cooks alike. Hand-planted, harvested and cured each season, Vidalia onions are available during a select window from April through August. The Vidalia Onion Committee focuses on marketing and promotions of Vidalia onions and is looking to new and exciting ways to grow awareness and consumption of Vidalia onions in 2023.

Offering an unmatched culinary experience because of their sweetness and versatility, the Vidalia Onion Committee is leaning into the flavor profile these sweet onions offer for its 2023 campaign “Sweet Moments with Vidalia Onions.” Cooking and sharing a meal with loved ones often creates lasting memories. With Vidalia onions, these moments are made even sweeter as home cooks discover new recipes

including fun twists on old favorites and unexpected new creations featuring the sweet, delicate taste of Vidalias.

To reach multiple audiences across the country, the Vidalia Onion Committee plans to execute a variety of tactics. With the growing popularity of meal kits, the committee is looking at the potential to partner with a meal kit company to showcase the distinct flavor of Vidalia onions and how to prepare them in order for consumers to create those fond memories with their families. The committee has seen much success with previous influencer programs, so it plans to support both the meal kit launch and overall season through select influencer partnerships. With many consumers looking to social media channels for eating inspiration, expect to see more social content coming from the Vidalia Onion Committee, as well, including tips and

Since their discovery in the 1930s, Georgia has been proud to call Vidalia onions the state’s own famous seasonal treat. Available in all 50 states and most of Canada, Vidalia onions are solely grown in 20 south Georgia counties with a particular combination of weather, water and soil. Federal Marketing Order No. 955 was established in 1989 to protect the Vidalia onion’s brand name and quality. The Vidalia Onion Committee administers this order for production research, marketing development and promotions of Vidalia onions.

To learn more about Vidalia onions, visit www.vidaliaonion.org.

18 Onion World • February 2023 VIDALIA ONION COMMITTEE

The Vidalia Onion Committee is highlighting the flavor profile of Vidalia onions in its 2023 campaign “Sweet Moments with Vidalia Onions.”

E-News

news to your

ONION WORLD

Industry

inbox: onionworld.net/e-news-sign-up

Feb. 6–7

Empire State Producers Expo

The Oncenter Syracuse, N.Y. www.nysvga.org

Feb. 7

Idaho-Malheur County Onion Growers Association Annual Meeting

Four Rivers Cultural Center Ontario, Ore.

Sarah Freeman, (208) 888-0988, sarah@amgidaho.com

Feb. 7

Utah Onion Association Winter Meeting

Bridgerland Technical College

Brigham City, Utah

Dan Drost, (435) 770-4484, dan.drost@usu.edu

June 14-17

National Onion Association Summer Convention

Amway Grand Plaza Hotel

Grand Rapids, Mich. www.onions-usa.org

Editor’s note: To have your event listed, please email Denise Keller at editor@ columbiamediagroup.com. Please send your information 90 days in advance.

OnionWorld.net 19

CALENDAR Skills: While its nutrients help ward off disease and build immunity, the onion provides amazing flavor to any meal, is healing, and sustainable Ninja Skills Let's use these skills to increase consumption through the Nature's Ninja Marketing Program. Call (970) 353-5895 to learn more. 1. Smudge 2. Stubby Root Nematode 3. Root Knot Nematode ONION DISEASE QUIZ ANSWERS (FROM PAGE 13) FOR SALE Shuknecht Self-Propelled Onion Harvester Set up to harvest two 68” wide beds Asking $85,000 Nate 989-550-8511

CROP PROTECTION ESSENTIALS Buyers’ Guide

BASF • agriculture.basf.us

Merivon Xemium Fungicide

Merivon Xemium brand fungicide from BASF is a powerful tool used for protecting against diseases such as powdery mildew, purple blotch, leaf blight, Stemphylium leaf blight and stalk rot in onions.

Merivon fungicide is powered by Xemium fungicide, which is an active ingredient that continuously distributes its chemistry throughout the leaf.

Benefits of Merivon Xemium brand fungicide include long-lasting, broad-spectrum disease protection; advanced plant health benefits such as stress tolerance and disease control; consistent performance; and market-leading yields.

Fosphite Fungicide

Fosphite is an EPA-approved, reduced-risk fungicide for year-round protection and control. A fantastic input to any integrated crop management program, Fosphite is a systematic fungicide with two modes of action. Working as a plant protectant and as a growth promoter, Fosphite prevents severe disease while supporting onion growth and yield. Fosphite protects onion production by slowing the growth of pathogens and inhibiting sporulation to prevent fungal infections. Effectively fighting off diseases while remaining gentle on crops, Fosphite has a zero-day pre-harvest interval and a four-hour re-entry interval.

Torac Insecticide

Torac insecticide controls thrips in onions and other bulb vegetables (Crop Group 3-07). The active ingredient in Torac, tolfenpyrad, works by blocking cellular respiration and is effective on immature and adult stages of thrips. Because Torac causes rapid cessation of feeding in the pest, it also aids in reducing the transmission of Iris yellow spot virus (IYSV).

Torac belongs to the METI (Mitochondrial Electron Transport Inhibitor) class of compounds and is an IRAC Group 21A insecticide. Torac is an excellent rotational option to manage resistance in spray programs for onions. For effective resistance management, Torac should be used in rotation with insecticides of different modes of action.

20 Onion World • February 2023

JH Biotech Inc. • www.jhbiotech.com/plant-products/fosphite

Nichino America, Inc. • www.nichino.net

ORO-RZ

ORO-RZ adjuvant improves the efficacy of soil-applied pesticides and nutrients. When tank mixed with pre-emergent herbicides, it improves soil hydraulic conductivity, even in hydroscopic soils, to move the herbicide solution into soil pore spaces to lay down a uniform barrier of herbicide protection. ORO-RZ, when applied with nutrients such as Nanocal, distributes the application uniformly throughout the soil profile, boosting efficient uptake by the root system.

Ethylene Sprout Control & Seed Treatment

Restrain is the manufacturer of a unique generator that converts ethanol into ethylene gas for the control of sprouts in onions and potatoes. Used in over 40 countries, the technology has been proven effective to control sprouts in long-term storages. The process is safe for storage managers, leaves no residue and is an effective sprout control for onions, potatoes, shallots and garlic.

Rango

Rango is a triple-action fungicide, insecticide and miticide that offers superior protection from major pests and diseases. Field trials have demonstrated efficacy in controlling insects such as onion thrip, western flower thrip, aphids, Lepidoptera species and spider mites, plus diseases such as powdery and downy mildew.

Rango controls target pests on contact or by ingestion. It offers multiple modes of action as an anti-feedant, insect repellent, growth regulator and fungal growth inhibitor.

Rango is EPA registered, OMRI listed and classified as an “NC” FRAC Code – no known resistance, making it an excellent rotation or tank partner in integrated pest management programs for organic and conventional operations.

Averland FC Insecticide

Crop Protection. Averland FC protects onion quality and yield from thrip damage and a broad range of other insect pests in a convenient, easy-to-use foliar application with an excellent safety profile and proven return on investment. Created with precision chemistry, Averland FC can be seamlessly tank mixed with over 200 foliar feeds, micronutrients, liquid fertilizers and other crop inputs for a hassle-free and more efficient foliar spray operation.

Get superior thrip control with Averland FC insecticide from

OnionWorld.net 21

Oro Agri • www.oroagriusa.com

Terramera • www.rangonow.com Restrain • www.restrain.io

Vive Crop Protection • www.vivecrop.com/products ONION WORLD FREE ISSUE! OnionWorld.net/subscribe Use code FREE at checkout to get 9 issues for the price of 8

Vive

22 Onion World • February 2023 Bejo ......................................6 Chemport CSI......................17 Chinook Equipment ............23 Clearwater Supply ..............11 Gearmore .............................9 Germains ............................16 Gowan Seed .......................23 L&M ....................................14 Nate Vandenberg ................19 NOA ....................................19 Nunhems ............................12 Redwood Empire ................19 Rietveld ................................3 Seed Dynamics ...................24 Seedway .............................11 Solex ...................................15 Terramera ...........................23 Verbruggen ...........................7 Advertiser Index “Ah, the life of a vegetable farmer. When my husband proposed, he gave me an onion ring.” by Copyright 2020 Peels of Laughter GROWTH ESSENTIALS Buyers’ Guide Coming in the next issue of Never miss an issue Subscibe at OnionWorld.net/Subscribe

OnionWorld.net 23 ® This model now has the ability to do bags as well as cartons with the new touch screen controls. It also comes with pneumatic bag clamps as standard equipment.

NEW! For more information visit chinookequipment.com or call 800-219-2245 or 208-331-1126 P.O. Box 190 • Chualar, CA 93925 25445 Chualar River Road • Chualar, CA 93925 831-679-1900 www.gowanseed.com Pacific North West Brian Haddon, Area Manager (971) 282-2884 San Joaquin Valley Russ Brown, Area Manager (559) 799-0799 Imperial Valley & Yuma AZ Scott Richards, Area Manager (928) 580-2484 New Mexico Greg Patti, Sales Rep. (575) 202-2250 Texas Clegg Smith, Area Manager (956) 340-0022 Florida, Georgia & the Carolinas Derek Levy, Sales Rep (912) 433-4752

Edp Electro-bagger model EB 2218 DF

SeedlingNeedOnions a Hero

When onion seed and seedcorn maggots threaten young crops, our heroes come prepared. FarMore FI-500 and Sepresto seed treatments provide early season disease and insect protection for young onion crops. Seed Dynamics applies the protectant to the seeds themselves, through a safe and controlled delivery. It works at the most critical time — during germination and seedling emergence — so your seeds can thrive, while fending o threats of early damage. Get a hero from Seed Dynamics , the Seed Preparation Professionals. Call us at 86 6.321.9747 or choose a dealer listed above.

Visit our New Website at SeedDynamics.com!

Gowan S eed Company C hualar, California 831.596.1900 S eedway Elizabethtown, Pennsylvania Dean Cotton 717.367.1075 C lifton S eeds Moravia, New York Mark Upton 315.604.1098 S eminova Q uebec, Canada Cesar C hlela 877.337.8423

Kimi Maag (left) with Jamieson Produce Inc. and Barry Vculek with Four Star Ag both won awards

From left, Nick Rietveld with Rietveld Equipment, Jose Cardona and Alma Palayo with Rio Farms and Theresa Rietveld with Rietveld Equipment visit during the social hour before the NOA banquet.

Tom Uriu (left), an Oregon onion grower for 70 years, accepts the NOA Lifetime Achievement Award from NOA executive vice president Greg Yielding. Bob Sakata from Colorado was also honored posthumously.

Assar, director of the Division of Produce Safety for the Food and Drug Administration, speaks to attendees at the NOA convention in Scottsdale, Ariz. Assar said the NOA has

René Hardwick, National Onion Association director of public and industry relations, adresses attendees at the annual convention.

Kimi Maag (left) with Jamieson Produce Inc. and Barry Vculek with Four Star Ag both won awards

From left, Nick Rietveld with Rietveld Equipment, Jose Cardona and Alma Palayo with Rio Farms and Theresa Rietveld with Rietveld Equipment visit during the social hour before the NOA banquet.

Tom Uriu (left), an Oregon onion grower for 70 years, accepts the NOA Lifetime Achievement Award from NOA executive vice president Greg Yielding. Bob Sakata from Colorado was also honored posthumously.

Assar, director of the Division of Produce Safety for the Food and Drug Administration, speaks to attendees at the NOA convention in Scottsdale, Ariz. Assar said the NOA has

René Hardwick, National Onion Association director of public and industry relations, adresses attendees at the annual convention.

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org

Photo courtesy Howard F. Schwartz, Colorado State University, Bugwood.org