PO Box 333

Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

OnionWorld.net

ONION WORLD CONTACTS

Editor Denise Keller editor@ColumbiaMediaGroup.com

Publisher / Advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

Director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

EDITORIAL INFORMATION

Onion World is interested in newsworthy material related to onion production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com, or call (509) 697-9436.

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@onionworld.net

SUBSCRIPTIONS

U.S. $24 per year

Canada $40 per year

Foreign $80 per year

Subscribe online at: www.OnionWorld.net/subscribe or call (503) 724-3581.

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to:

Onion World PO Box 333 Roberts, ID 83444

Onion World magazine (ISSN 0892-578X), is published eight times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices. Produced by Columbia Media Group PO Box 333, Roberts, ID, 83444. Copyright 2023. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group.

For information on reprints call (208) 520-6461.

When a flight took us to the Midwest, in the vicinity of Rietveld Equipment, we took the opportunity for another road trip. A new showroom, built to display and demo the company’s post-harvest equipment, was available for touring.

We were able to see brand new machines set in place, not yet wired. But visitors will soon be able to test drive this same equipment as potatoes are washed, sorted and boxed on site.

Run by father and son John and Nick Rietveld, the company sells individual pieces of equipment, but can also design and build complete packing facilities.

New post-harvest machinery on display at Rietveld Equipment will be wired and processing spuds this year, giving customers an up-close look at how the equipment works.

The Rietveld Farm Stand opens mid-July and runs for about three months. Future plans include a greenhouse, which will allow the family to open the stand earlier in the year and possibly expand into flowers.

New post-harvest machinery on display at Rietveld Equipment will be wired and processing spuds this year, giving customers an up-close look at how the equipment works.

The Rietveld Farm Stand opens mid-July and runs for about three months. Future plans include a greenhouse, which will allow the family to open the stand earlier in the year and possibly expand into flowers.

Spare parts are in stock at Rietveld Equipment to keep customers up and running.

Nick Rietveld demonstrates the controls on an Allround destoner.

Spare parts are in stock at Rietveld Equipment to keep customers up and running.

Nick Rietveld demonstrates the controls on an Allround destoner.

The Rietveld family has grown onion sets for five generations on their own or rented property about 60 miles south of Chicago. Due to an ever-decreasing retail market, Canadian competition, increasing input costs and lack of labor, the Rietvelds made the tough decision in 2023 to quit growing onion sets.

They continue to grow sweet corn and sell it at their own farm stand, along with salsa and other locally grown produce. They even sell some imports – namely, Vidalia onions – at the stand. Nick said people drive from up to two hours away to buy their corn and salsa, and they sell as many as 6,000 ears of corn a day.

Eliminating onion cultivation from their farm’s day-to-day routine has opened up more time for John and Nick to spend on Rietveld Equipment. They sell, service and install top-notch machines from European manufacturers including Meconaf, Allround, Upmann, VHM, IPLA, Teneco and Intec.

Follow along with these photos for a tour of this new facility in Bourbonnais, Illinois.

Story

Publisher

Story

Publisher

The National Onion Association (NOA) Summer Convention was held June 14-17 in Grand Rapids, Michigan. Outside, Grand Rapids was cool and pleasant. And the city was convenient and close to three onion-related stops that were on the NOA Ag Tour. Inside, committees met, members dined, auction items sold and speakers talked about the 2023 Farm Bill and the everpresent topic of food safety.

The NOA general session featured a taped appearance from U.S. Sen. Debbie Stabenow of Michigan, chairwoman of the U.S. Senate Committee on Agriculture, Nutrition and Forestry. She shared her thoughts on the impending Farm Bill, which is legislated every five years and comes before Congress again this year. In the 2018 Farm Bill, Congress included permanent, annual funding for specialty crop block grants, research and trade programs. Stabenow has spent her career advocating for specialty crops like onions, she said, and specialties are still frontline for her.

“I’m committed to protecting the progress and permanent investments we’ve made while looking for new and innovative ways to expand risk management opportunities and boost markets at home as well as abroad,” Stabenow said.

But Barry Vculek, owner of Four Star Ag in North Dakota and a member of the NOA Legislative Committee, said money going to agriculture may not be what it seems in the new Farm Bill. He said as much as 80 percent of the total funds could be going to subsidy programs such as the Supplemental Nutrition Assistance Program (SNAP).

Stabenow said she often hears that labor shortages are a real problem for farmers and “Congress must get serious about labor reform.”

Addressing labor, Vculek said the Adverse Effect Wage Rate has raised wage levels in all states and it’s “seemingly getting out of hand.”

He is required to pay $18 an hour for “laborers to throw 50-pound bags” – whether employing locals or H-2A workers.

Specifically referencing H-2A, Vculek warned, “It seems like the government is trying to make this program more restrictive and more expensive for us on a daily basis.”

The U.S. Senate Committee on Agriculture, Nutrition and Forestry is still seeking feedback and taking ideas and proposals for the 2023 Farm Bill at www. agriculture.senate.gov/farm-bill or by email at farmbill2023@ag.senate.gov.

This new educational coloring book and an activity book are both available as free downloads at www.naturesninja.org/ onion-ninja-odyssey. The books use the characters Ollie and Olivia Onion to teach children about nutrition and explore the health benefits of onions.

Food safety has been a constant focus of NOA meetings for the last couple years, so it was no surprise that Rebecca Anderson with GlobalG.A.P. appeared via Zoom with a presentation that included food safety tips and how to implement them.

Anderson stressed the importance of appropriate, achievable food safety operating practices and advised putting checklists in place to get organized and to ensure workers’ compliance. Employees need to have information resources, and policies should be in place. Policy training meetings are critical, but can get overwhelming and stagnant when they remain the same, year after year. Breaking them into monthly meetings or by topic will help workers stay engaged.

Companies also want to ensure all employees have a voice, from frontline workers, to managers, to owners, Anderson said. Employees should be encouraged to speak up and give input, but also accept accountability.

Anderson reminded attendees that food safety is a year-round concern. Sanitation and cleaning of equipment, grounds maintenance, water supply, hand washing stations, restrooms and waste management should always be considered, but remain on the lookout for new or different methods and technology to improve and make things easier.

The next NOA get-together will be the Annual Convention in San Antonio, Texas, Nov. 29 – Dec. 2, 2023. This meeting and the National Allium Research Conference will be held together, so high attendance is expected. Early hotel reservations are encouraged at www.onions-usa.org/ members/conventions.

TANIA

New short day yellow granex introduction: Strong upright tops with great plant habit. High yielding deeper granex shape, strong root system, and firm bulbs. Pink root and bolting resistance.

Earliness: Early main

Sowing period: 09-15 - 09-25

Taste: Sweet

Pyruvates: 3.6

Lacrymatory Factor: 2.8

Shape: Granex

IR: Foc; Pt

Early maturing grano red. Strong healthy tops. Pink root resistance. Excellent bulb firmness and color. Uniform round bulbs. Good internal color. Widely adapted across short day growing regions. High percentage single centers.

Earliness: Early

Sowing period: 09-25 - 10-05

Taste: Very sweet

Shape: Grano

IR: Foc; Pt

Late season short day yellow granex with upright tops. Deeper high yielding granex shape. Bolting resistance and very uniform. Strong outer skin layers. Produces well sized bulbs that result in good yields. Great option to fill later season slot in Vidalia.

Earliness: Late

Sowing period: 09-25 - 10-05

Taste: Very sweet

Pyruvates: 3.5

Lacrymatory Factor: 2.4

Shape: Granex

IR: Foc; Pt

Main Season short day yellow granex. Attractive lighter colored skin. Uniform and extra firm bulbs with high yielding deeper granex shape. High percentage of jumbos. Great post harvest appearance. A widely adapted variety across many short day regions.

Earliness: Main

Sowing period: 09-18 - 09-28

Taste: Sweet

Pyruvates: 3.4

Lacrymatory Factor: 2.6

Shape: Granex

IR: Foc; Pt

Bejo Seeds Inc. (main office) 1972 Silver Spur Pl. Oceano, CA | T: 805- 473-2199 | E: info@bejoseeds.com

bejoseeds.com

e have shared several reports in Onion World over the past few years on the “Stop the Rot” onion bacterial project. The project has two main areas of focus on bacterial diseases that affect onion production across the U.S.: 1) understanding the diversity and prevalence of bacteria that cause onion diseases, and 2) determining how to manage these bacterial pathogens more effectively.

As part of the first objective, we are taking a close look at the genetics (DNA) of the numerous bacteria we have found in onion crops surveyed around the U.S. over the past three years. You might ask “So what? Why is this important in order to manage onion bacterial diseases?”

Genetics of onion bacteria are important to distinguish the good from the bad. Many species of bacteria can cause diseases of onion. Even more bacteria can make a “happy home” inside a rotting onion once another pathogen starts to break down onion tissue. This can make it extremely difficult to get an accurate diagnosis of which bacterium is the primary culprit for causing an onion to rot and which ones are “along for the ride.”

In three years of onion surveys for the Stop the Rot project, we have isolated more than 5,000 bacterial strains that belong to more than 110 different genera. A majority of these bacterial isolates do not cause onion diseases.

Sometimes, diagnosing the species of the bacterium is not enough. A prime example is the center rot pathogen, Pantoea ananatis. We routinely recover isolates of P. ananatis that are aggressive pathogens of onion, but we also routinely recover isolates of P. ananatis that are harmless (not pathogenic) as they are not able to cause disease symptoms on onion bulbs or plants. Sometimes, pathogenic and non-pathogenic strains of P. ananatis can be isolated from the same onion plant or bulb. This is similar for several other bacterial species with strains that can cause onion diseases and strains that are not pathogens of onion. This kind of situation can lead to mistaken identity and misdiagnosis of the primary pathogen; a strain that is “along for the ride” may get “accused of committing the crime.”

The variation in ability of bacterial strains to cause diseases of onion can be the result of genetic differences among strains of the same species. A bacterial cell reproduces by splitting into two perfect clones; this is often called vertical transfer of genes, analogous to genes inherited by children from their parents.

However, bacteria also can trade snippets of genetic material (DNA) with each other, a process often called horizontal transfer of genes.

Usually, bacteria trade pieces of DNA in this manner between cells of the same or closely related species, but sometimes they can trade pieces of DNA with bacteria of other species. Even though DNA trading is relatively rare, it can have big consequences. For instance, bacterial gene trading is one of the ways that antibiotic resistance genes and genes for copper resistance spread among bacteria, undermining the effectiveness of antibiotics and bactericides. This is similar to the situation where some strains of Escherichia coli bacteria contain genes for toxins that give people food poisoning, whereas most strains of E. coli lack those genes and are harmless or even helpful members of the bacterial community in your digestive tract. Likewise, pathogenic and non-pathogenic bacteria can trade pieces of DNA when they are colonizing an onion together. This could turn the “saprophytes” (harmless bacteria) into pathogens of onion.

One of the overall goals of the Stop the Rot onion bacterial project is to develop diagnostic tools so that accurate diagnosis complements effective, pathogen-specific, targeted disease

management strategies for various regions of onion production around the U.S. Currently, the primary method of diagnosing bacteria pathogenic to onion entails isolating bacteria from symptomatic tissue, and then characterizing the isolates and inoculating healthy plants to see if the isolates cause similar symptoms to what was observed on the original tissue. This can take weeks or even months to perform. DNA-based testing can be robust, rapid and relatively easy to standardize and can reduce the risks of “mistaken identity” with a non-pathogenic strain being diagnosed as the cause of the disease.

Sequencing the genome of a bacterial strain entails reading the individual letters (C, A, G and T) in the sequence of all the DNA in that bacterium. The sequenced genomes of pathogenic strains and non-pathogenic strains of the same species of bacterium then can be compared to identify specific genes found only in the pathogenic strains. For instance, we’ve learned that onion pathogenic strains of P. ananatis carry genes to synthesize the compound pantaphos, which is toxic to onion plants and allows the bacteria to cause onion leaf blight and bulb rot. The next step is to develop a DNA-based diagnostic

tool that can be used to identify whether a bacterial strain contains the cluster of genes that produce pantaphos.

Developing DNA diagnostic tools requires a lot of testing to confirm the tool does not give false positive results (indicating a strain is a pathogen of onion when it is not) or false negative results (indicating a strain is not a pathogen when, in fact, it is). Since the DNA of every species of every genus of bacteria is different, the genes that confer pathogenicity in Pantoea agglomerans may not be the same as those in P. ananatis, Burkholderia species, and the many other bacteria that are pathogens of onion. Since there are numerous bacteria that can cause diseases of onion, developing DNA diagnostic tools for identifying specific bacteria that are pathogens of onion takes a lot of testing and time.

The Stop the Rot project has focused initially on developing diagnostic tools for strains of Pantoea that are pathogens of onion because this is one of the most common bacteria found in diseased onion crops and bulbs across the U.S. and many

non-pathogenic strains of Pantoea also are found on onions. This research also has helped us identify strains of bacteria that carry genes for copper tolerance, i.e., genes that enable the bacteria to grow in the presence of copper. We are now testing whether the presence of bacteria with copper tolerance genes in onion crops might explain why applications of copper sprays in field trials across the U.S. typically have shown very poor control of bacterial diseases. We look forward to sharing these results in the near future.

Authors’ note: This work is supported by the Specialty Crops Research Initiative Award 2019-51181-30013 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions or recommendations expressed in this publication are those of the authors and do not necessarily reflect the view of the U.S. Department of Agriculture.

strains collected from onion bulb crops across the U.S. over two seasons of surveys, that are stored in the National Onion Bacterial Strain collection at the University of Georgia. The red section of each bar represents the number of strains of each bacterial genus from each state that caused symptoms when inoculated onto red onion scales, and the blue section of each bar represents the number of strains that did not cause symptoms (non-pathogenic).

Figure

Weeds are commonly found in most crop fields. Weed diversity in different fields is governed by many factors, including the level or intensity of tillage, soil fertility, crop rotation practiced, and whether organic or conventional farming. Successful management of weeds depends on our ability to correctly identify them, particularly at the seedling stage in order to avoid seed production.

The photos below show a type of weed that can invade onion fields.Can you identify the weed? B A

This material is provided courtesy of Joel Felix, Associate Professor, Weed Ecology & Management, Oregon State University Malheur Experiment Station.

This material is provided courtesy of Joel Felix, Associate Professor, Weed Ecology & Management, Oregon State University Malheur Experiment Station.

Agri-Stor Companies carries quality disinfectants for onions, utilizing hydrogen peroxide and peracetic acid to protect storages and produce from bacteria and fungi. The company also carries a full line of organic products. Agri-Stor has the application expertise to handle a wide variety of crop protection solutions.

In addition to crop protection, Agri-Stor Companies helps growers take control of their onion storage with the Agri-Star Panel. The panel can handle everything from curing mode and burners to temperature, airflow and carbon dioxide levels. The intuitive app allows for off-site storage monitoring and controls management to save travel time.

Not all PAA thermal fogging is the same.

More than 10 years ago, GroupAg developed a highly effective thermal fogging application method using Jet-Ag. Since that first application, GroupAg has continuously refined its application equipment specifically designed for applying PAA chemistries in storages. GroupAg has performed and submitted to extensive laboratory testing, as well as real-world bacteria and fungus testing before and after the application in storages, and has shown great results for sanitizing crops in storage.

Restrain is the manufacturer of a unique generator that converts ethanol to ethylene gas. Based in the Netherlands, Restrain has been in Europe for over 20 years. In 2022, Restrain was approved for use in the U.S. and Canada.

Ethylene is a gaseous plant hormone involved with many physiological processes including growth regulation. It restricts the elongation of sprouts after dormancy break and is the basis of the sprout inhibitor Restrain. Ethylene gas is used to prevent sprout elongation in onions and shallots in storage. Ethylene gas is a sustainable product and the only post-harvest sprout control for onions in storage. This treatment can be used in conjunction with MH-30 or on its own.

Suberizer offers turnkey storage systems that are engineered for maximum efficiency. As a proven industry leader in raw product storage, Suberizer’s commitment to innovation has impacted the way raw products are stored. Suberizer Curve and Envelope storage systems use AirEverywhere floors that ensure optimum airflow through the pile. This system minimizes loss, maintains quality and maximizes return.

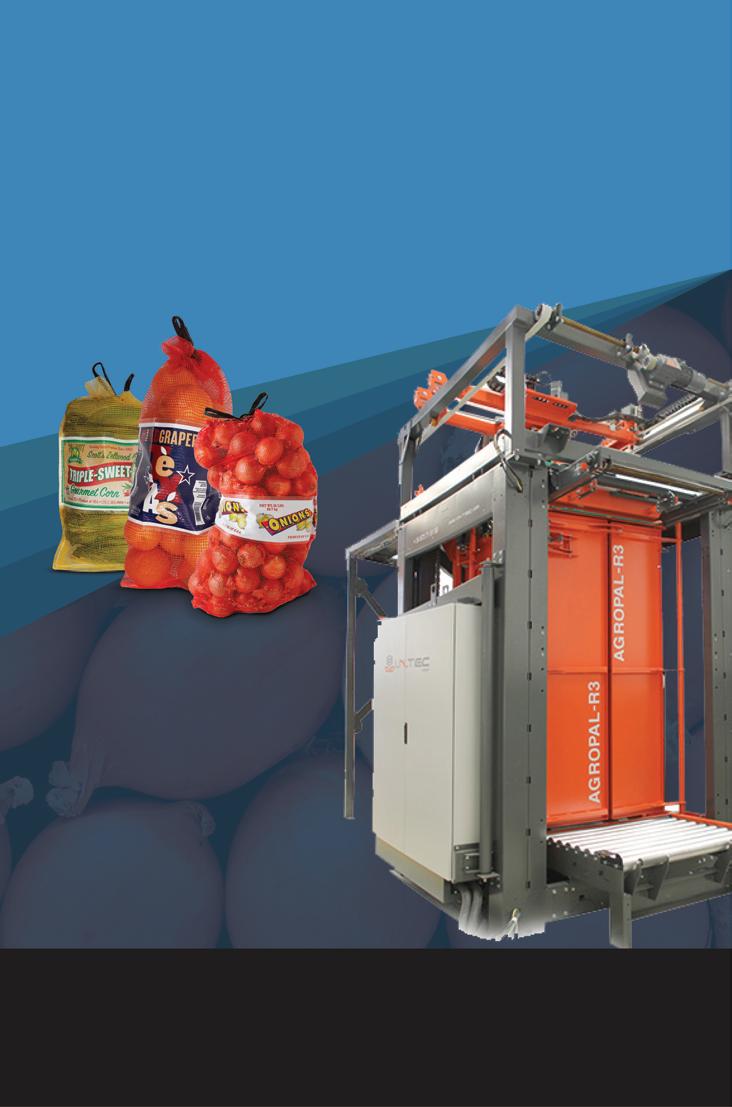

Symach has a long history of palletizing onions and innovating to provide customized modular designs guaranteeing a high stacking rate with maximum flexibility. From 50-pound bulk and baled bags to complex Octabins, Symach has solutions to handle all customers’ palletizing needs.

Symach also offers options to stabilize the pallet at the end of the line, including wrapping and double stacking, palletizing within the margins of the pallet to ensure ease of loading during the shipping process.

For nearly 50 years, Teton West of Idaho has proven itself time and time again as a reliable Eastern Idaho steel buildings contractor. By making large strides to implement modern building technology and processes into the way the company works, Teton West guarantees continued value to its customers. As the original dealer for Varco Pruden buildings and Meridian Manufacturing, Teton West and its trade partners promise that the company’s old-fashioned values coupled with an unmatched product will make customers’ construction experience a pleasurable experience.

Titan Steel's buildings are designed to provide maximum efficiency and convenience for produce preservation. Engineered with the latest industry standard technology, the company offers a perfect solution for producers. With third-party climate controlled systems, paired with ventilated floors or pipe, Titan Steel buildings ensure that onions stay fresh and in optimal condition prior to reaching consumers.

By Josh Smart

By Josh Smart

the global fertilizer shortage has relatively subsided, the market is now challenged with instability and uncertainty. Consequently, onion growers should not

Whileinitially limited Russia’s ability to export products.

Now the supply chain is flowing more smoothly, but supply is still unpredictable. In addition, fertilizer producers’ decarbonization efforts are also impacting production levels.

Urea capacity is forecasted to increase 2 percent in 2023 and phosphoric acid

season, the more likely suppliers will run out. Here are four key strategies to help mitigate risk for your onion crops in this volatile market, as well as how to best maintain your crop yields.

be misled by recently falling fertilizer prices, as that is only part of the story.

The original shortage was created by the Russian war on Ukraine. As the world’s largest producer of fertilizer, sanctions

production by 7 percent, while potash production is expected to decline by 14 percent.

Taken together, the longer farmers wait to purchase fertilizer for the upcoming

Crop rotation is a well-proven strategy for preserving healthy soil; it’s important to rotate your onion crops to other land parcels. Different varieties pull varying levels of moisture from the ground and have different root sizes, which impacts the soil over time. Further, varying produce types will affect the pH of the soil differently; healthy soil shouldn’t be too acidic or too alkaline. By rotating varieties, these factors even out, thereby improving soil health, reducing fungus attraction and increasing production.

Just like managing a 401(k), it’s important to take an informed, longterm approach to contract pricing. Onion contracts should be carefully evaluated and then re-evaluated as time goes on. Farmers should keep their options open, for example, looking into options such as specialty crops.

Skilled crop management can reduce backfill soil costs. By considering variables such as high temperatures and drought, farmers can apply crop rotation strategies to keep soil nutrients high and fertilizer costs low.

Unstable fertilizer costs aren’t the only issue challenging onion growers. Timing when to spray for weeds with chemical herbicide treatments is a continuous discussion if flaming isn’t being used. Destroying the seedbed of the weed before the onion seed has germinated is ideal. In addition, managing insecticide and disease control plans, as well as

“All things considered, if farmers wait too long to buy fertilizer for the upcoming season, they run the risk of supplies running out.”

implementing those plans, on a regular basis also keeps growers increasingly busy.

Fluctuating prices and supply chain issues are not anticipated to resolve any time soon. Consequently, running a successful onion growing business requires planning, growing strategies and actively evaluating different financial and land cultivation strategies and options.

About the author: Josh Smart is the North American practice leader and chief sales officer for agribusiness, food and cannabis with HUB International and is responsible for leading the strategic initiatives around growing and supporting the agribusiness segment.

Nov. 15-16

Pacific Northwest Vegetable Association Conference and Trade Show

Three Rivers Convention Center

Kennewick, Wash.

Sheri Nolan, (509) 585-5460 or www.pnva.org

Nov. 29 - Dec. 2

NOA Annual Convention National Allium Research Conference

San Antonio Marriott Riverwalk

San Antonio, Texas

www.onions-usa.org www.alliumnet.com/narc

Dec. 5-7

Great Lakes Fruit, Vegetable and Farm Market EXPO DeVos Place Grand Rapids, Mich. www.glexpo.com

Editor’s note: To have your event listed, please email Denise Keller at editor@ columbiamediagroup.com. Please send your information 90 days in advance.

AgWest Farm Credit has released its quarterly Market Snapshot report covering the state of major agricultural commodities in its northern region of Idaho, Montana, Oregon, Washington and Alaska.

AgWest’s profitability outlook for onions suggests slightly profitable returns. Wet conditions slowed early onion development in the Northwest, but summer heat is expected to help onions bulk up. According to the report, strong demand and prices for onions were offset by increased production costs.

The S7210 tearless sweet onion variety Sunions, from BASF’s vegetable seed brand Nunhems, is now available for all U.S. growers to purchase for the 2024 growing season. Growers will have the option of marketing the variety under the Sunions name or under their own brand.

S7210 was launched in 2017 with limited seed quantity and no market presence. Now the company says it has built up its seed inventory and created retail market pull, allowing sales to all interested long-day onion growers.

With the S7210 variety, domestic growers can produce a sweet, long-day onion that’s both tearless and available during winter marketing months. A consumer marketing survey found that the S7210 produced less burning sensation, tearing, nose running, throat irritation and overall irritation than other sweet onions.

For more information, contact Nunhems at (800) 733-9505 or visit www.nunhems.com.

Gumz Farms is wrapping up a large expansion and remodel to its Endeavor, Wisconsin, packaging facility to better serve its customers and meet growing demand. To accommodate an average increase of 10 percent in annual sales, the expansion will increase existing capacity by approximately 40 percent. Gumz plans to complete the expansion this fall.

Owners Richard and Roderick Gumz are the fourth generation of Gumz farmers and are joined by a fifth generation, which has returned to the farm to continue building the family’s operation. Gumz Farms specializes in growing and packing onions and potatoes. Growing 40 percent of Wisconsin's yellow onions and over 1,200 acres of potatoes, Gumz Farms is the largest producer of onions and red and yellow potatoes in Wisconsin.

Stokes Seeds has formed a partnership with PlantTape to serve as the recommended seed supplier to PlantTape customers across the eastern half of the U.S. and Canada. With this new arrangement, Stokes Seeds and PlantTape will collaborate to supply growers utilizing PlantTape technology with seed for the planting system.

PlantTape is an automated transplanting system in which seeds are sown into the PlantTape material, which is cut into strips and placed into trays. Seeds germinate in a greenhouse and are then transplanted into a grower’s field, with the PlantTape transplanter cutting the strips between plants and placing each seedling into the soil.

Seed will be warehoused at the PlantTape facility in Livingston, Tennessee, to facilitate timely order processing and movement of seeded plant tape to greenhouses.

Vive Crop Protection Inc. continues to grow its U.S. sales team with the addition of three new regional sales managers: Nichole Drake, Pacific Northwest regional sales manager; Jay Holmdal, Eastern regional sales manager; and Dennis Philpot, Great Lakes regional sales manager.

Drake previously worked as the Crop Vitality specialist at TKI. Now at Vive, she will be responsible for covering Oregon, Washington, Montana and northern Idaho.

Holmdal comes to Vive from Corteva Agriscience, where he worked as the Northeast regional sales manager for Alforex Seeds. Prior to that, he worked in various positions in the crop protection and row crop seed business at Dow AgroSciences. Holmdal will be handling business from Maine to North Carolina.

Philpot previously worked as a specialty products territory manager at The Andersons. In his new role at Vive, he will be working in Michigan, Ohio and northern Indiana.

Innvictis has launched a new line of fungicides that includes Innliven Elite. The dual mode of action fungicide contains pyraclostrobin with difenoconazole. Its combination of preventative and curative activity is made to control a wide range of crop diseases. In onions, it can be used to control Botrytis leaf blight, Cercospora leaf spot, leaf blotch, powdery mildew, purple blotch and leaf blight, Stemphylium leaf blight, Cladosporium leaf blotch, rust and downy mildew. The fungicide, which provides disease control through translaminar and systemic uptake, also improves stress tolerance and promotes plant growth, according to the company. Visit www.innvictis.com.

The new SpotOn Soil Moisture Meter from Innoquest is designed to facilitate effective irrigation management by providing users with continuous soil moisture measurements as well as EC (salinity) and soil surface temperature readings.

The unit includes two sets of rubber-mounted probe rods (2.4 and 1.5 inches) that resist bending in dry or rocky soil. The meter maintains accuracy without calibration as long as the rods are not bent or worn. Its ultra-high frequency (100 MHz) measuring circuit ensures accurate moisture measurements in a variety of soil types and salinity levels. The SpotOn Soil Moisture Meter, which sells for $995, is manufactured in the U.S. and comes with a one-year warranty. Visit www.innoquestinc.com.

Coming in the next issue of ONION

WORLD

8 issues per year

To get your company listed in the Buyers' Guide, call 208-520-6461 or email dave@onionworld.net

ONION WEEDS QUIZ ANSWERS

Photos A and B are of common lambsquarters (Chenopodium album) seedling and mature plant, respectively. Common lambsquarters emerges very early in spring, normally when <150 growing degree days have accumulated. Early emergence necessitates some level of control (chemical or mechanical) before crop planting. Common lambsquarters seed could retain viability for more than 40 years in the soil.

Your

UNITED STATES

Lancaster & San Joaquin Valley

(661) 9785342

Desert Southwest

(928) 4467737

Colorado & New Mexico

(970) 3969728

Idaho, East Oregon, Utah & Nevada

(208) 9411421

Skagit Valley, Washington (360) 9417503

Rio Grande Valley & West Texas

(956) 6185574

MEXICO

Torreón, Coahuila

(461) 1173878

Colima, Col.

(461) 1040134

San Luis Potosi

(461) 1409452

Chihuahua

(461) 1719401

Tamaulipas

(461) 1342421

Irapuato, Gto.

(800) 952-7333 WWW.SEEDWAY.COM

TELONE™ II is the world's best defense against destructive plant parasitic nematodes. Applying TELONE™ before planting creates a zone of protection, allowing developing root systems to thrive—leading to healthier plants, higher yields, and improved quality. A custom blend of TELONE™ (to combat nematodes) and chloropicrin (to target soil borne diseases) is an effective one-two punch for all of your onion pre-plant needs.

Remember, there's no coming back from a poor start!

Contact