3 minute read

Going Off the Rails (and Rollers) with Vekta

Ed Serrano, Managing Director VektaUSA V ekta is probably best known for our Razer linear saw, and the next product most associated with our company is the Vekta PackFeeder, a lumber infeed system that takes up less space and costs less than anything else on the market. But... Did you know that Vekta has a variety of products designed to improve the post manufacturing stages of your production?

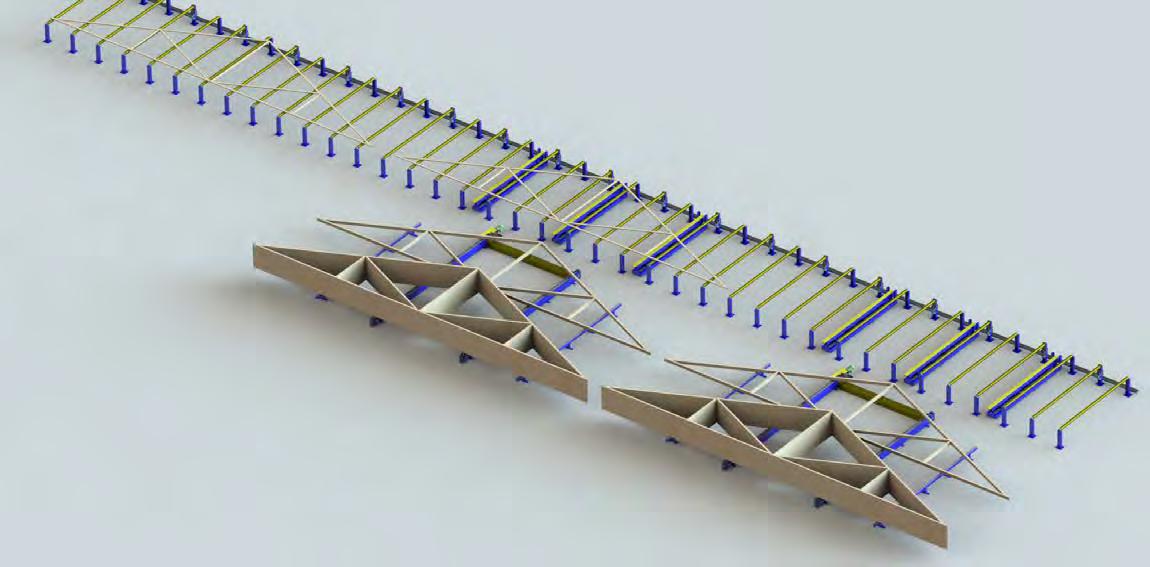

Introducing the Vekta Truss Transfer system

Can your team move 5500 lbs of 50 ft trusses within a few seconds? What about even bigger, heavier

trusses? With the Vekta Truss Transfer system, you can easily eliminate a potential bottleneck in your yard and move a stack of trusses out of the way with the touch of a button!

In a high volume, efficient facility, the last thing you want is for a stack of trusses to hold up production – even for just a moment. Vekta’s Truss Transfer is a surprisingly simple product that takes the time pressure off your forklift drivers. And, it’s built like a tank! (We know how forklift drivers can be…)

Vekta’s Truss Transfers are a heavy-duty chain conveyance system designed to move full stacks of trusses. When a stack of trusses is complete, the Truss Transfers move the stack out of the way immediately. While a new stack is underway, the last stack can be strapped and fork-lifted away as time allows. This eliminates a bottleneck at the stacking station or a rush to get a stack moved.

The Truss Transfers are controlled with a remote control. When combined with a StakPro Truss stacking system, or the Smart Roller Conveyor system, the Truss Transfer is controlled by the same remote control as the rest of the system.

Move full stacks of trusses so they can be strapped while a new stack is started

Extremely heavy-duty transfer chain

Simple concept that makes life easier in your yard

Built to withstand even the worst forklift drivers

Center way clear to allow a forklift to drive between the transfer chains

Easily integrates with roller conveyors and stacking systems

Taking the ‘dumb’ out of the roller system

The Vekta Smart Roller Conveyor is a roller conveyor designed to handle your finished trusses. Rather than simply being a dumb, ‘always on’ roller conveyor and relying on someone to catch the trusses for stacking, the Smart Roller Conveyor actually tracks the size and position of the trusses along the line. The trusses can be automatically moved and stopped “The Vekta Smart Roller Conveyor is in their position for stacking. If the line is equipped with Stakpro booms, the trusses can even be automatically or semi-automatically stacked with a charm and has more capacity than we can feed it. It’s our only line and all that we use now.” or without operator intervention. Once stacked, the Vekta Truss Transfer system can be used to move complete stacks out the way for strapping while the next stack is started. Graham Footer, Footers Structural Timber, South Australia

The benefits of automating your roller line are: Increase your plant efficiency – trusses are automatically moved to the center of the required bay, and there is no need to manually start or stop the rollers.

The system is programmed to automatically know which bay the truss needs to go to, eliminating human error.

One operator can handle stacking at multiple bays.

The next truss can be parked and ready to go instantly, increasing efficiency and production.

Auto stacking off a framing line is just as important – and this will help keep your team focused on making the frames in the first place. Consider a Vekta Stakpro Frame system to easily reduce an already labor intensive process.