In 2023, Concordia Textiles reaffirmed its commitment to sustainability by spearheading a series of impactful initiatives As part of our ongoing journey towards a greener and more responsible future, these initiatives encompassed a wide spectrum of strategies and actions aimed at reducing our environmental footprint, enhancing workplace well-being, and fostering sustainable growth This document outlines our sustainability actions for the past year of 2023

As a leading textile manufacturer, we embrace the principles of circularity, ethical manufacturing practices, and innovative approaches to minimize our ecological footprint

Headquarters Belgium Waregem Concordia Textiles

“Resilience and power to revolutionise will propel us into a positive future”

- CARL BAEKELANDT

SINCE 1925

OUTERWEAR FABRICS 1975 PRINTING DIVISION 1925 SYNTHETIC WEAVING MILL 1955 DYE DIVISION

2004 CONCORDIA PACIFIC FOUNDATION START BUSINESS UNIT STRUCTURE 2008 FULLY OWNED PRODUCTION IN CHINA FULL FASHION GARMENTS SERVICE 1970

1980 COATING DIVISION 2002 TECHNICAL TEXTILES

2009

SEYNTEX ACQUISITION IN MILITARY 2012 LAB CERTIFICATION ISO 17025

2020

2018 FLAME BOUNDING BANGLADESH 2019

JOINT VENTURE PURFI ® 2015 JOINT VENTURE ADVENTUM 2017 ACQUISITION FUCHSHUBER TECHNO TEX 2013

ESTAMBRIL ACQUISITION 2014 CONCORDIA GARMENTS SERVICES BANGLADESH

ACQUISITION

SOCOMAILLE BEDDING & INDUSTRIAL KNITWEAR 2023

ESTABLISH A WHOLLY-OWNED FABRIC PRODUCTION FACTORY IN HAIAN

Since 1925, Concordia Textiles Group has been at the forefront of the textile industry, with a rich history spanning a hundred years in fabric manufacturing Our broad and profound grasp of textile production is the cornerstone of our business, equipping us with the ability to meet and assist our customers with any inquiries or challenges they may encounter

Concordia Textiles develops and produces textile solutions for selected professional markets. To ensure dedicated research and development together with high quality service, our organisation is divided into 4 Business Units: Workwear, Fashion, Bedding and Innovative Customized Applications. Every business units has its own strategic focus and dedicated team.

PERSONAL PROTECTIVE EQUIPMENT

MILITARY AND POLICE APPLICATIONS

MEDICAL SECTOR AND CLEANROOMS

The group operates through two primary divisions: Concordia Textiles, which specializes in the production of high-standard safety textiles, and Concordia Pacific, which aligns its strategic focus with the dynamic needs of the fashion and performance outdoor sectors.

The synergy between these branches allows for a versatile utilization of our manufacturing capabilities, surpassing traditional market boundaries and ensuring that we can offer a wide range of textile solutions to our diverse clientele.

TEXTILES GROUP

Concordia Textiles develops and manufactures technical protective fabrics used for personal protective equipment (PPE) It ensures the best possible protection for professionals in industrial, civil, medical or military markets

Fuchshuber Techno-Tex is the reference in the German market for technical knits for high end personal protective wear The company is specialized in technical knits and is an established value in Central Europe

Concordia Advanced Fabrics & Apparel offers fabrics for fashion and sportswear, with a vertically integrated structure going as far as including garment service

For premium fashion customers

CPGL offers garment manufacturing Our garment manufacturing services are specialized in outdoor clothing for fashion retail, fashion brands, sports performance and corporate workwear

Estambril International develops high-quality textiles from Nomex® brand fibres , presenting a product range of woven and knitted inherent flame resistant fabrics and knitted garments

Purfi® rejuvenates textile waste into raw materials as a response to the global waste challenge By rejuvenating waste to virginlike quality fibers, it is suited to reuse in a variety of qualitative products and industries

CBL is the only manufacturing specialist in Bangladesh offering waterproof flamebonding and dot laminated textiles, focusing on export-oriented premium footwear linings

CMT is an integral part of the group enabling fabrics manufacturing for fashion, performance and outdoor applications

Concordia Textiles Group is an integrated textiles manufacturer offering sustainable textile technologies and products for a wide range of purposes. We create innovative and sustainable protection.

Sustainable solutions help our customers in the protection of themselves, their own customers as well as their goods. We want to improve quality of life by offering protection and comfort to all parties involved. By protecting people all over the world, we make sure they feel safe and empowered to do what they want without having to worry about their safety.

We are entrepreneurs in heart and soul

We are flexible to changes that create value

We recognize and pursue opportunities

We receive freedom and trust to achieve the best results for all stakeholders involved

We are passionate about what we do Passion drives us forward

It is our engine for creativity and innovation, enabling us to make an impact Through personal development we achieve the knowledge to pursue our passion

We respect people and environment

We respect and appreciate people for who they are and for the work they do Transparent and honest communication build trust

We respect the environment by maximizing our positive impact and minimalizing our negative impact

We believe partnerships are vital for success

A collective mindset increases expertise and resources We work together toward a common goal

We believe in honest and ethical collaboration for achieving long term value

As a pioneer in the textiles industries with a strong customer-oriented approach, our know-how and expertise expand throughout different applications This is reflected in our aim to grow in a sustainable way by adding value for all parties involved

Concordia Textiles Group offers innovative and solutionoriented products in different global and niche markets As a global group we commit to a local and entrepreneurial approach that suits the needs of our partners in varied industries

We believe that innovation, digitalization, sustainability and an inclusive representation of society play an important role in a healthy growth of our company and society at large

Concordia Textiles Group aims to play a central role in the innovative development of the textiles industry We strive to be the one-stop-shop for any textile development

Collaborating with a durable partner such as Concordia Textiles enables customers in achieving their sustainability goals, as such partnerships bring in expertise and innovative solutions that reduce environmental impact and enhance resource efficiency. These partnerships also open avenues for accessing new markets and customer segments, driven by a shared commitment to eco-friendly and ethical practices. Furthermore, working with Concordia Textiles helps in navigating the complexities of global supply chains, ensuring compliance with evolving regulations and consumer expectations in a sustainable manner.

In today’s rapidly evolving world, the concept of partnership extends far beyond mere business transactions. As a durable partner, we are committed to the ethos of creating shared value that resonates through every layer of our operations. By forging synergistic collaborations with our customers, employees, peers, and the academic research centers, we are on a mission not just for success, but for significance.

We’re broadening our product range with sustainable offerings across our four business units, and venturing into new markets where the potential of textiles as a solution is yet to be fully discovered.

Being a vertically integrated company, we possess a strategic advantage in transforming our value chain. This integration allows us direct control over each stage of production, from raw material sourcing to final product delivery.

By reevaluating our processes and supply chain, we can create ecosystems that are advantageous for everyone involved. This commitment extends to our suppliers, partners, employees, and the communities we serve.

As a vertically integrated manufacturer, we control every aspect of our production process From the initial stages of material sourcing to the final delivery of our products, we maintain a comprehensive and hands-on approach This vertical integration empowers us to ensure quality, efficiency, and sustainability at every step, resulting in a stronger and more reliable supply chain

This vertical integration also positions us as a one-stopshop for our customers With the ability to oversee the entire production cycle in-house, we offer cover our customers’ needs providing a single point of contact for a diverse range of textile solutions

VIRGIN & RECYCLED FIBERS

DISTRIBUTION

ACCREDITED LAB

MANUFACTURING GARMENT

PRINTING

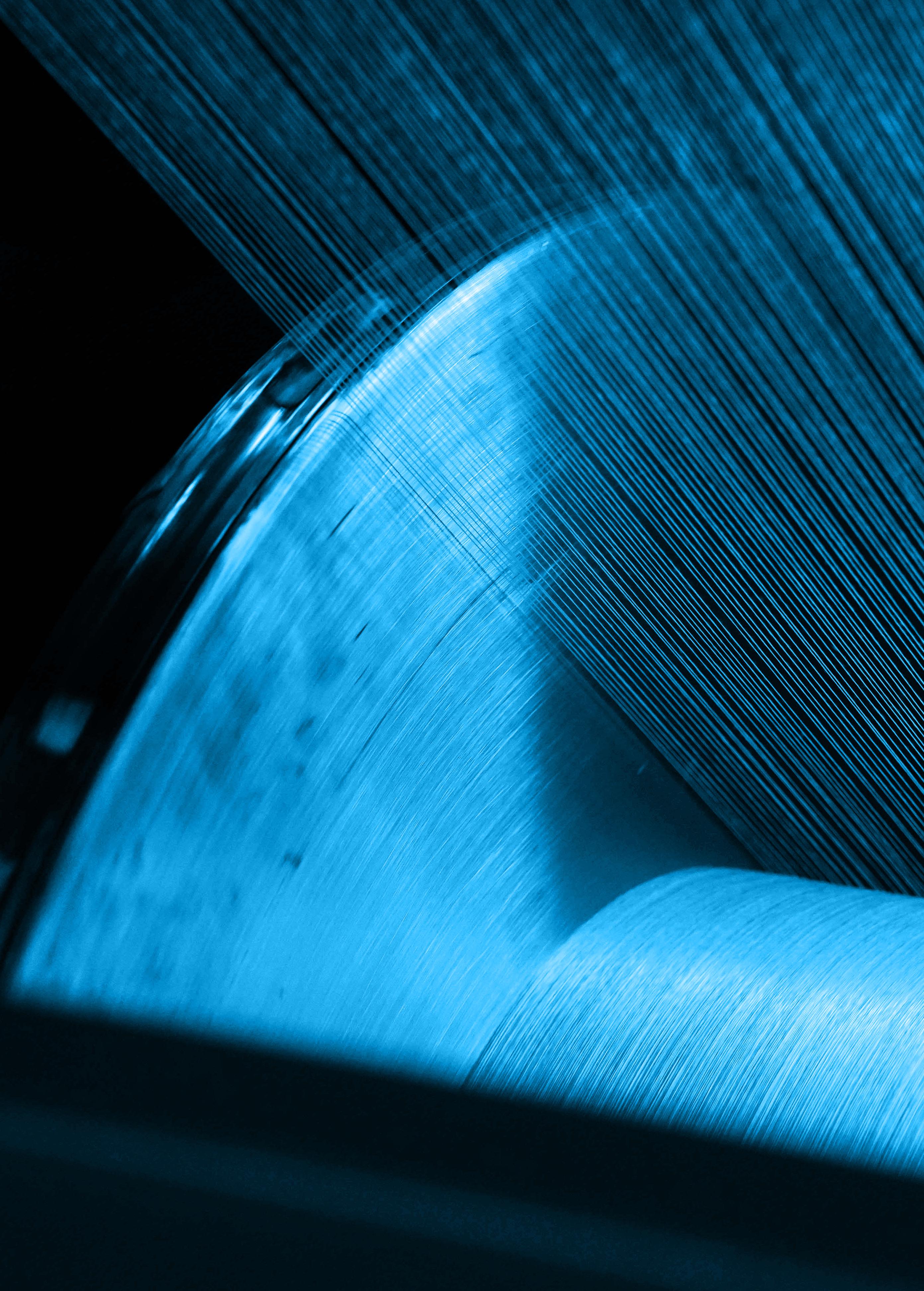

SPINNING

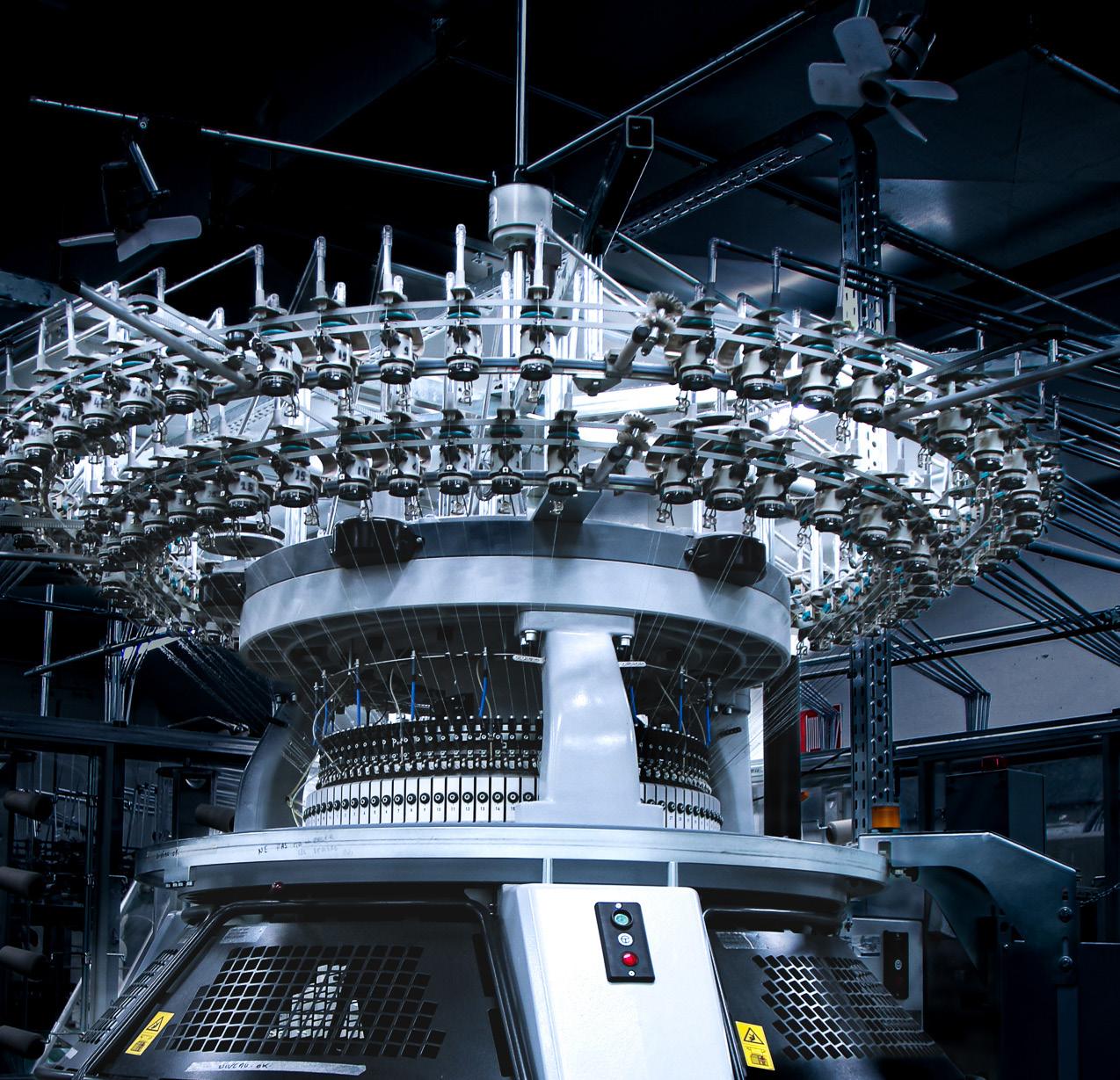

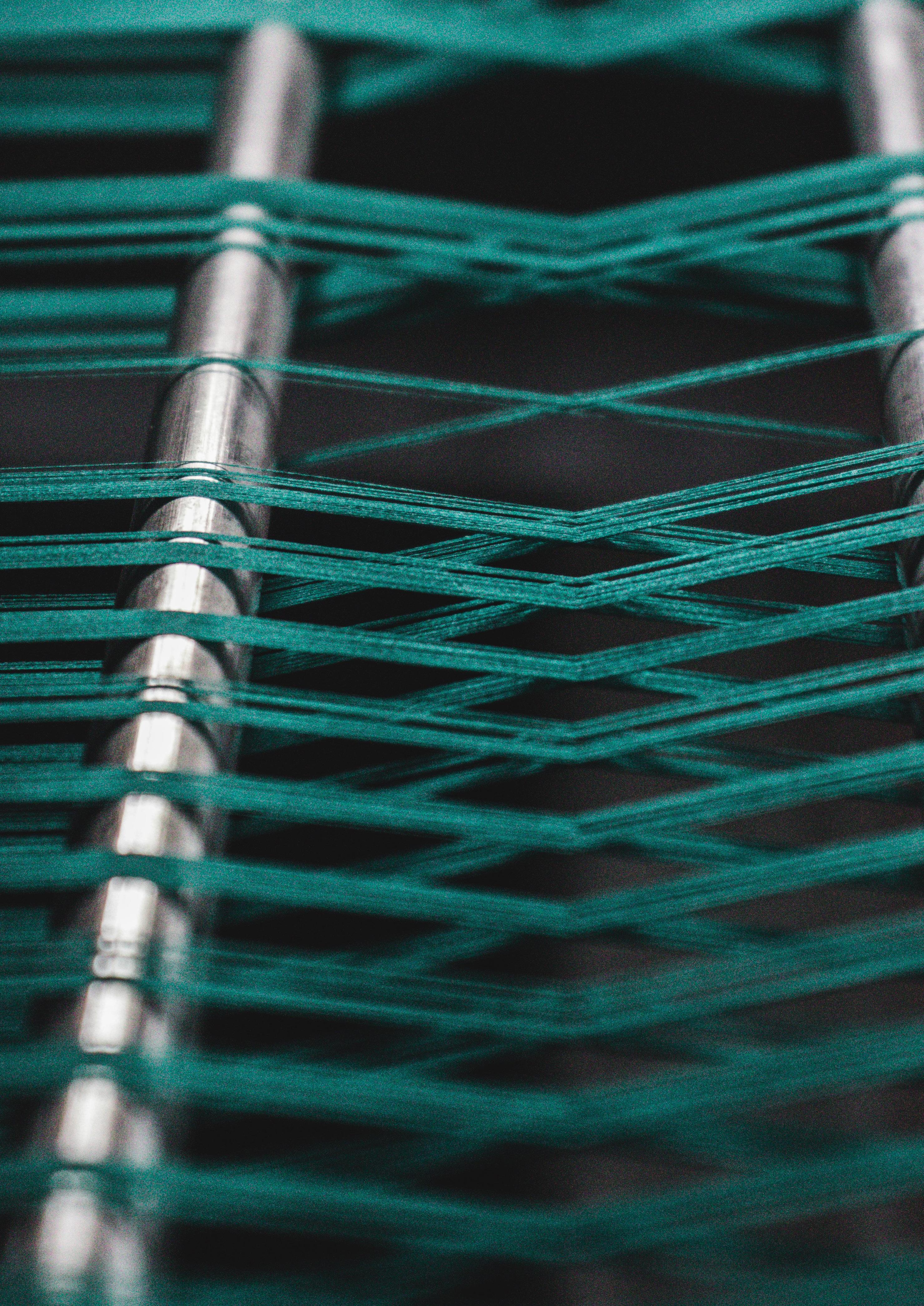

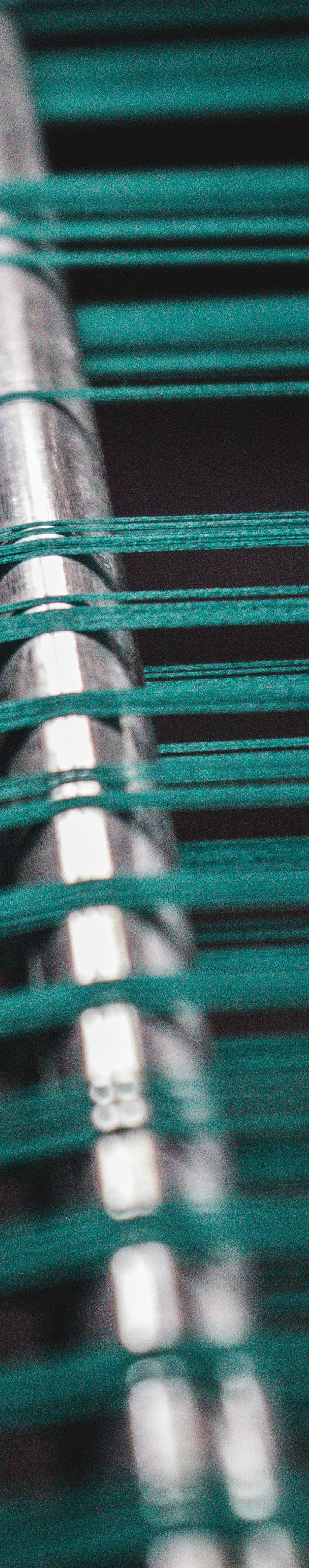

WEAVING & KNITTING

DYEING & FINISHING

Thanks to our in-house ISO/IEC 17025 accredited lab, the majority of tests can be conducted in-house controlling our production at different stages, which drastically accelerates the timeto-market of our new developments

Our Research & Development (R&D) department is the cornerstone of our textile innovation With a focus on meeting diverse needs, our team engineers tailored solutions, driving our production process to ensure top-quality technical textiles

We take responsibility for reducing our environmental footprint and promoting eco-friendly practices Our sustainable manufacturing processes focus on optimizing energy efficiency, minimizing water consumption, and reducing waste generation

Water is a precious resource. Our manufacturing processes prioritize water conservation through efficient technologies and recycling practices.

Through energy-efficient processes, renewable energy sourcing, and carbon offset initiatives, we are actively working towards a greener future.

We implement waste management strategies that prioritize waste reduction, segregation, and recycling throughout our operations.

All water used in our production goes through a purification process, after which it is reused in our productionprocess. This ensures a closed-loop water system that’s measurable and sustainable.

11,1 l/m2 fabric

217.140 m3 of purified water treated by communal purification plant

100% of our water is purified

20.000 m2 solar panels

Production of 1.000 MWh/year

Consumption 16.667 MWh/year

705 ton waste and disposal volume

45% recycled waste

55% waste disposed with energy recuperation

Our Business Unit Workwear offers specialized fabric solutions designed for distinct industries and applications Our expertise extends to textiles suitable for jobwear, military and police, medical and cleanroom environments, fire services gear, and industrial safety clothing

STRATEGIC POSITIONING IN A SPECIALIZED MARKET

In the highly specialized market of Heat & Flame Textiles, we maintain a comprehensive approach with various levels of protection and performance, positioning ourselves as a European expert covering every segment. Our extensive range of textiles allows us to serve professionals across the entire spectrum of heat and flame protection. Our commitment to offering solutions for every level of need underscores our expertise in this niche market, making us a trusted partner for those seeking top-tier protection in challenging environments.

Foreman Repreve FF PBP stands out as a significant advancement in sustainable workwear fabrics, offering a unique solution worldwide since it’s composed entirely of recycled materials.

Its impact, as assessed through a comprehensive life cycle assessment (LCA) conducted with an external partner, is noteworthy. With a reduction of 97% in water usage, 49% in CO2 emissions, 98% in land utilization, and 43% in energy consumption, Foreman Repreve PBP underscore the importance of LCAs in evaluating and mitigating the environmental footprint of textile products.

At the core of Foreman Repreve PBP lies Purfi®’s Soft-Mechanical-Recycling Technology, a innovative approach to textile recycling and rejuvenation. By rejuvenating fibers sourced from postindustrial and post-consumer waste streams, Purfi® not only addresses textile waste but also reduces dependence on virgin materials, contributing to the circular economy. With plans for global expansion, Purfi® remains committed to localized recycling efforts, ensuring its impact is felt both globally and locally.

water reduction 100% recycled textile 33% fiber 2 fiber recycled yarns 67% recycled pet filament 100% fluorfree fabric 43% energy reduction 98% land usage reduction 49% CO2 emissions reduction

Over the past years, we have focused our efforts on the development of our Greenline range of fabrics. These fabrics offer a trustworthy and durable solution for our customers. Developments started with recycled fabrics, moving on to developments in fluorinefree fabrics, followed by waterbased coatings and rejuvenated fabrics with inhouse Purfi®-technology. By choosing our Greenline collection, customers are making their products futureproof, considering upcoming European legislation.

Our recycled and rejuvenated fabrics are available in woven and knit options They are suitable for a variety of applications, including heavy-duty, waterproof-breathable, lightweight, and medical & cleanroom uses By opting for recycled polyester and polyamide yarns, customers not

RECYCLED FABRICS

Our waterbased coating process offers a sustainable alternative to traditional solvent-based methods, reducing volatile organic compound (VOC) emissions and minimizing our carbon footprint VOCs are chemicals that vaporize during production and everyday use, contributing to harmful ground-level ozone By utilizing water instead of solvents, our coatings are solvent-free and

In response to environmental concerns, we’ve developed fabrics that repel water and stains without PFAS-based chemicals PFAS, commonly used for their repellency, pose risks to health and the environment

Our fluorine-free finishes offer a sustainable alternative, prioritizing both performance and eco-

only make an eco-friendly choice but also conserving precious resources and reducing energy consumption Additionally, these fabrics play a role in minimizing textile waste and supporting recycling efforts, contributing to a healthier environment for all

REJUVENATED FABRICS

formaldehyde-free, making them safer for both the environment and human health Unlike conventional coatings, which require afterburners to purify emitted solvents, our waterbased process eliminates this need altogether With durable performance and eco-friendly credentials, our waterbased coatings provide a responsible choice for various textile applications

consciousness While slightly different from traditional options, they provide effective protection for workwear It’s essential to consider specific requirements and intended use when selecting fluorine-free finishes to ensure they meet desired resistance levels while complying with safety standards

Our Fashion Business Unit specializes in creating high-quality fabrics tailored for diverse markets, including outdoor lifestyle, outdoor functional, sports performance, and sport athleisure Leveraging our expertise in fabric development, we cater to the unique needs of each sector, offering innovative solutions for fashion and performance wear Whether it’s crafting fabrics for outdoor adventurers, athletes, or casual wear enthusiasts, we excel in providing premium materials designed to meet the highest standards of quality and performance

Our services encompass the entire process from textile production to garment manufacturing, specializing in fashion outerwear, sports outerwear, and knitwear. We provide comprehensive support by producing garments using our own technical fabrics, covering a range of jackets and outerwear for middle and high-end brands.

Our involvement extends from the initial design phase to the final distribution, ensuring a seamless experience for our clients. With manufacturing facilities located in Belgium (Waregem) for our European operations, and offices in key production hubs such as Suzhou (China) and Dhaka (Bangladesh) for our Asian operations, we have established a robust global presence. Through our extensive network of supply chain partners, we are equipped to meet the diverse needs of our clientele across the globe.

With increasing legislation and consumer awareness driving change, there’s a growing demand for transparency, traceability, and accountability throughout the supply chain As legislation tightens and consumers become more informed, there’s a notable shift towards sustainability-driven practices, placing emphasis on reducing environmental impact and promoting ethical production methods With our vertically integrated production process, we have the unique ability to make a difference at every step of the manufacturing journey From sourcing raw materials to optimizing our production processes, we’re committed to implementing practical initiatives that drive positive change

Our dedication to sustainability extends beyond the production floor to engaging with informed consumers and partners, enabled by the transparency in our practices and thorough life cycle assessments.

1. Enhanced Reputation: Partnering with sustainable suppliers enhances the reputation of both brand & supplier It demonstrates a commitment to ethical and environmental practices, which can positively influence consumer perception and loyalty

2. Risk Mitigation: Working with sustainable suppliers reduces the risk of negative publicity or backlash associated with unethical practices, such as environmental pollution or labor exploitation This helps safeguard the brand’s reputation and minimize potential legal and financial risks

3. Environmental Impact: Collaborating with sustainable suppliers contributes to reducing the overall environmental footprint of the supply chain Sustainable practices such as responsible sourcing, energy efficiency, and waste reduction help minimize environmental degradation and support conservation efforts

4. Long-term Viability: Sustainable suppliers are often more resilient and better positioned to adapt to changing market dynamics, regulatory requirements, and consumer preferences Co-branding with such partners ensures longterm viability and continuity in the supply chain

5. Innovation and Differentiation: Sustainable suppliers are often at the forefront of innovation, developing new technologies, materials, and processes that align with environmental and social objectives Co-branding with these suppliers can provide access to innovative solutions, helping brands differentiate themselves in the market

6. Stakeholder Expectations: Stakeholders, including consumers, investors, and regulatory bodies, increasingly expect companies to prioritize sustainability throughout their operations, including their supply chains Co-branding with sustainable suppliers demonstrates a commitment to meeting these expectations and aligning with broader societal values

37.5

Mixed materials in textiles pose recycling challenges, also due to additions such as elastane. This leads to significant clothing waste. To tackle this, mono-materiality, using a single material in product composition, emerges as a sustainable design principle. It simplifies recycling, essential for the circular economy, by preserving material value and promoting resource regeneration.

Over the past year, we’ve dedicated our efforts to developing the ‘We Care’ fabric collection. Our aim is to inspire fashion and performance brands and designers to embrace positive change, personalization, gender fluidity, and functionality in their designs. We’ve worked tirelessly to create fabrics that not only meet industry demands but also promote inclusivity and sustainability. Our hope is that this collection will serve as a catalyst for the fashion industry to prioritize these values in their creations, ultimately benefiting both wearers and the environment.

Our latest fabrics feature recycled, biobased, and rejuvenated yarns, offering high-quality options with reduced environmental impact With bio-based polyester yarns like SORONA® and GRS-certified materials, we provide renewable alternatives for outdoor enthusiasts Our recyclable technical yarns promote circularity, while fabrics made from recycled polyester and polyamide, including REPREVE®, offer both performance and sustainability

Eco-friendly pigmented ECO-dyeing coatings offer a sustainable alternative to traditional dyeing methods

These coatings are derived from iron oxides or sourced from ferrous waste materials, which makes them non-harmful and eco-friendly

The binder used in the coating is for 43% based on sugarcane

ECO-dyeing coatings are less harmful to the environment:

✔ No use of catalysator in the recipe means that the coating paste does not need to be used immediately Surplus of the coating paste can be used for a next production, or if necessary downcycled for other uses

✔ Less water consumption compared to traditional dyeing

ECO sustainable coating LESS WATER CONSUMPTION per 1 000m fabric

✔ No solvents used 83%

Instead of using C8 or C6 chemistry, our product range offers water-repellent products that are 100% fluorocarbon free We have partly bio-based solutions and soon 100% biobased solutions will be available

On request, our performance fabrics can be finished using a recycled membrane These recycled membranes meet strict waterproofing, breathability, protection and comfort requirements

Our expertise in Research & Development, coupled with our vertically integrated production capabilities, positions us at the forefront of textile innovation We specialize in developing a wide range of textile solutions, from transparent mesh screens to durable fabrics for wind turbine blades, catering to diverse industries Our non-clothing fabrics are engineered to serve multiple functions across different markets, reflecting the adaptability of our products Whether for base textiles, finished products, or market-ready offerings, our solutions are tailored to address various challenges in the textile industry

AIR-tiles eliminate harmful substances from indoor environments AIR-tiles are designed to do much more than just enhance the aesthetic appeal of a space By integrating air purification into the ceiling, we have redefined the concept of clean and healthy indoor environments

AIR-tiles improve the air quality in the direct environment of the panels Thanks to Airmax 2 0 technology, harmful substances are eliminated from living spaces Which means it also reduces bad smells upon contact with indoor air

✔ The AIR-tiles consist of 100% polyester and are fully recyclable

✔ In case of fire, AIR-tiles won’t propagate the flame, with very little smoke and no melting drops (classification NBN EN 13501-1: B-s1, d0)

PURIFY

AND REDUCE BAD SMELLS

Conventional windmills have blades entirely made of composite materials This makes them heavy, difficult to repair in case of damage, and impossible to recycle at the end of life Together with ACT Blade, we developed Zephyr™, a textile laminate that is stretched over the lighter rib structure of the newly designed wind turbine blades

Zephyr™ is a laminate made of specially engineered yarns for strength and fire resistance and a customized protective membrane

7% reduction in the LCOE (levelized cost of electricity) 9% more energy generated 10% longer blades 32% lighter blades

Easier and cheaper maintenance and transport

Windmills endure extreme weather conditions, meaning our Zephyr™ must as well During the development process we tested our fabric on 24 parameters such as rain erosion resistance, UV-resistance, tear- and tensile strength, lamination force, resistance to lightning strikes, weather resistance, etc

Zephyr™ contributes to more sustainable, durable, and energyefficient blades:

We co-developed Zephyr™ with ACT Blade, who use their technology to design the world’s most efficient wind turbine blade. Together, we’re on a mission to create the next generation of blades.”

The EIT Awards were held during the INNOVEIT EIT Summit in Brussels. The most promising entrepreneurs and innovators in Europe were honored, as well as ACT Blade’s CEO Sabrina Malpede. She ended up as 2nd for the Woman Leadership Award and took home the Public Award! A great recognition of their journey in developing the next generation of wind turbine blades for a net zero future.

In close cooperation with ACT Blade, our business unit Innovative Customized Applications, developed one of the most resilient advanced textiles to protect wind turbine blades from severe weather conditions Not only does it offer a more practical maintenance, but the fabric also provides a longer lifespan for the blades, making it a sustainable solution for the renewable energies industry

Concordia New Materials Technology (CMT), an integral part of the Concordia Textiles Group under Concordia Pacific, has opened new production facilities, marking a significant expansion in China This strategic move, which includes both CMT and Concordia Advanced Fabrics (CAF), is a response to the evolving industrial landscape, driven by environmental regulations and rising operational costs

CMT has relocated its production to Haian from Suzhou’s SIP hightech zone The new 6000m² facility in Haian, completed in just five months, houses various departments exemplifying sustainable development with solar panels and a Regenerative Thermal Oxidizer (RTO) for efficient energy use

Concurrently, CAF Suzhou has transitioned to a new 1200m² office space, located just 20 minutes from its previous location This move is strategically designed to enhance collaboration and cross-pollination among different teams In this modern office, there are shared spaces including sample rooms for garments and fabrics, a showroom, a fabric test center, and an office area, complete with an inspection area This setup ensures that teams, including garment technicians, work more closely together, leading to increased efficiency and creativity in our work processes

The relocation and expansion were meticulously planned to ensure uninterrupted service to clients This involved pre-manufacturing at CAF, highlighting CMT’s flexibility and commitment to client needs

At the heart of CMT’s expansion is a commitment to sustainability and innovation The Haian facility’s regenerative thermal oxidizer (RTO) showcases this commitment, reducing gas reliance and enhancing energy efficiency

The installation of solar panels and reapplication for ISO14001 and Bluesign certifications ensure quality for customers The Haian facility almost entirely comprises a new production plant, with all machines revised and updated with new technologies

“Our ability to adapt and evolve is the cornerstone of our future success . ”

CARL BAEKELANDT, CEO

The grand opening on December 8th 2023, which saw the presence of government officials and partners, marked a significant milestone in CMT’s journey Special thanks were extended to the entire CAF & CMTteam and new Haian members for their relentless effort As Carl Baekelandt, CEO of Concordia Textiles Group, stated in his speech, “Our ability to adapt and evolve is the cornerstone of our future success ” This ethos is reflected in CMT’s future strategy, led by Shunxing Zhou, General Manager and Valery Ameel, Business Unit Manager Fashion, focusing on exploring new markets, enhancing processes for existing clients, and considering a greater emphasis on workwear and fashion production in China

In Dhaka, Bangladesh, we’re taking measures towards enhancing our production capabilities. By merging two companies, CBL and CPGL, into a single facility, we aim to streamline operations and boost efficiency.responsibility.

We find it important to play our role as a knowledgeable resource in the field of textiles and sustainability By educating and empowering our customers, we ensure that they are wellinformed about the best sustainable practices This goes about washing for garment durability, to in-depth explanations of the impact of fluorine free fabrics

Through our various communication channels, including our website, social media, newsletters, and direct interactions, we provide expert insights and guidance Our goal is to help our customers make environmentally responsible choices, aligning with their values and our commitment to a sustainable future By sharing our expertise, we aim to build a community of conscious businesses and consumers

We have been actively engaged in Life Cycle Assessment (LCA) developments, particularly in the selection of fabrics for workwear. As part of our efforts, we have also conducted in-house LCA training sessions for key project owners.

Over the past year, we have reinforced our internal approach to managing and upholding the Code of Conduct for our suppliers

Recognizing the integral role our supply chain plays in our overall mission and values, we focused on strengthening our internal systems, processes, and team engagement to ensure rigorous adherence to our ethical standards

✔ Team Training and Awareness: We have organized training programs for our internal teams This training ensures that they are fully aware of the Code of Conduct and understand the importance of enforcing it with our suppliers Regular workshops and seminars have been organized to keep our teams up-to-date with the latest standards and practices

We have dedicated considerable effort to developing and reinforcing the Code of Conduct for our employees Recognizing that our workforce is the backbone of our operations and the embodiment of our corporate values, we have focused on creating a robust framework that guides ethical behavior and fosters a positive work environment

✔ Comprehensive Development of the Code: The development of the Code of Conduct involved a process with inputs from various departments to ensure it reflects our diverse workforce and the complexity of our operations We aimed to create a Code that is not only comprehensive but also easily understandable and applicable to everyday work scenarios

✔ Inclusive and Collaborative Approach: In shaping the Code we adopted an inclusive approach, seeking feedback and suggestions from employees at all levels This collaboration ensured that the Code is well-rounded, addressing the concerns and realities of different roles within the organization

✔ Regular Reviews and Updates: The Code of Conduct is not static; it’s a dynamic document that evolves with our organization and the external environment We have established a process for regular reviews and updates to the Code, ensuring it remains relevant and effective

We offer third-party certifications that demonstrate our commitment to producing textiles in an environmentally and socially responsible manner These certifications can be used to assure you and other stakeholders that we are adhering to specific standards and guidelines

This type of certification assesses aspects such as our environmental management, social responsibility, quality management, workplace safety, and ethical business practices

ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and B Corp Certification (overall social and environmental performance)

ISO9001

ISO 9001 is an internationally recognized standard for quality management systems that outlines requirements for organizations to establish, implement, maintain, and continually improve their processes and products to meet customer needs and expectations

Applicable for Concordia Textiles, Concordia Advanced Fabrics & Estambril International.

ISO14001

ISO 14001 is an internationally recognized environmental management system (EMS) standard that provides a framework for organizations to systematically manage and improve their environmental performance It helps businesses identify, prioritize, and address environmental risks and opportunities, promoting sustainability and responsible environmental practices

Applicable for Concordia Textiles, Concordia Advanced Fabrics & Apparel.

The GRS® (Global Recycled Standard) is a certified standard for products created from recycled materials It guarantees that the production process complies with environmental and social criteria, endorsing the use of recycled materials and responsible manufacturing practices across various industries

Applicable for Purfi®.

The focus is on the product itself and can include aspects such as material sourcing, manufacturing processes, environmental impact, and health and safety standards.

This certification evaluates the safety and environmental performance of textile products. It ensures that the products are free of harmful chemicals and meet specific standards for human ecology.

This certification program verifies that a product is made with 100% organic materials. This means that every component of the product, including the fiber, yarn, and fabric, must be certified organic. OCS Organic 100 is intended for products that are made entirely from organic materials and do not contain any non-organic materials.

Applicable for Bedding Products.

This certification focuses on the sustainable production of textiles. It evaluates the entire manufacturing process, from raw materials to finished products, to ensure that the process is environmentally responsible and socially sustainable. This can be requested for Fashion & Performance fabrics.

The GOTS certification ensures that every step of the textile production process, from harvesting the raw materials to the finished product, meets strict environmental and social criteria. This includes prohibiting the use of toxic chemicals, ensuring fair labor practices, and promoting sustainable and eco-friendly manufacturing processes.

Applicable for Bedding Products.

This certification program contains a blend of organic and non-organic materials. To receive OCS Organic Blended certification, a product must meet a minimum organic content threshold, typically ranging from 5% to 95% depending on the product category. This certification program allows for the use of some non-organic materials while still providing consumers with assurance that the organic content of the product meets a recognized standard.

Applicable for Bedding Products.

Compliancy is about adherence to external legal requirements or internal policies It can apply to a company’s operations, its products, or both, depending on the regulations and standards in question

Complying with labor laws, environmental regulations, health and safety standards, and data protection laws like GDPR

The GDPR affects Internet users based in the EU/EEA by granting them specific rights and control over when and how their personal data is processed Data subjects protected by the GDPR have the right to: Access what information is collected about them, who it’s shared with, and how it’s used

REACH compliance is the process of ensuring that a company is following the regulations set forth by the EU to protect human health and the environment from the potential risks of chemicals

As experts in the production process of technical textiles with extensive market knowledge, as well as our joint venture Purfi®’s new technological solutions through soft mechanical recycling and rejuvenation, we can provide valuable input to create solutions to today’s challenges

During its first General Assembly, 18 European companies and organisations have formally joined ReHubs They represent different segments of the circular textile value chain and share a common commitment to invest in textile recycling capacity in Europe Additional partners are expected in the near future as ReHubs is receiving a widespread interest and companies may join at any time

The 18 European companies and organisations represent different segments of the circular textile value chain and share a common commitment to invest in textile recycling capacity in Europe

The new trend platform watf.news aspires to be thé place for inspiration for trends and innovation within the Belgian textile, wood and furniture industry - full of young, creative talents. The platform is part of the efforts of Fedustria in boosting the image of these industries and attracting new, young talents.

Our CEO Carl Baekelandt was interviewed by watf.news, the new trend platform from Fedustria. About the innovativeness of the industry, international allure and endless opportunities for personal and professional growth.

In the latest podcast episode on Ellie Connect, Koen De Ruyck, General Manager of Purfi® Manufacturing, unravels the intricacies of Purfi®’s groundbreaking technology, shedding light on the future of sustainable textile recycling Here’s a sneak peek into the key insights that make this episode a must-listen

At the heart of Purfi®’s technological innovation is the focus on soft mechanical recycling Unlike traditional methods that often compromise fiber integrity, Purfi®’s approach revolves around rejuvenating textile fibers, preserving their length and strength This unique method sets Purfi® apart in the pursuit of a circular textile industry

The urgency to propel sustainable practices is emphasized throughout the episode Koen stresses the opportune moment to act, leveraging existing technology, know-how, and momentum to showcase the opportunities for recycling in the textile and fashion landscape In order to take practical steps towards a sustainable future, Purfi®’s commitment extends beyond immediate gains, prioritizing longterm strategic partnerships over short-term sales

The circular ambition for sustainable practices places Europe at the forefront The episode underscores the significance of clear schedules, eco-design expectations by 2025, unity, and a focus on recycled content in high-quality products Ensuring equivalent importation rules outside Europe is pivotal to

maintain a level playing field and accelerate the industry’s shift towards sustainability

The conversation addresses a common concern: the initial cost differences in adopting recycled materials However, Koen highlights a key insight –as volumes increase, the cost competitiveness of recycled materials improves significantly, making sustainable practices not just environmentally but economically viable

Koen distinguishes between rejuvenation and traditional recycling: while ‘recycling’ often implies downcycling, Purfi®’s emphasis is on upcycling The philosophy of rejuvenation strives to restore fibers to their youthful state, a commitment that consistently frames Purfi®’s work within the realm of circularity

Koen refers to a recent study by McKinsey, which positions Purfi®’s method as ‘soft mechanical recycling ’ This innovative approach involves delicately untwisting various fabrics, transforming them into yarn through reverse spinning The result is a material of comparable quality to virgin materials, making it highly valuable for spinning companies

Ellie.Connect is a digital platform that helps you take sustainability to the next level through finding new connections, knowledge and expertise, as well as countless use cases for your sustainability transformation in and with the textiles & fashion industry.

At the recent Trends Impact Awards ceremony in Brussels Expo, Purfi® was honored with the prestigious Trends Impact Award in the Circular Economy category The event celebrated businesses that make significant sustainable impacts through their pioneering projects Our win marks a significant achievement for our team, underlining our commitment to sustainable business practices

The Trends Impact Awards, a collaboration between Trends, founding partner PwC, and with the support of Antwerp Management School, were instituted to assist businesses in transforming their operations into sustainable business models and to recognize impactdriven entrepreneurs striving for societal change

Purfi®’s recognition in the Circular Economy category serves as a testament to our ongoing efforts to contribute positively to the circular economy, focusing on the processing of post-industrial, pre-consumer, and post-consumer waste, particularly in cotton, aramids, meta-aramids, and denim textiles

As a fabric supplier for G-Star RAW’s outerwear, Concordia Textiles was recognized as the “Innovation & Sustainability Champion for Wovens” at the conference.