26 minute read

Industry Bits

Hilti North America Region Head and CEO Avi Kahn Promoted to Hilti Group Executive Board; Hilti Canada General Manager, Martina McIsaac, Named as Successor Avi Kahn, Region Head and Chief Executive Officer of Hilti North America, has been promoted to the Hilti Group Executive Board effective Jan. 1, 2020. “It has been a great honor to be part of the Hilti North America team over the last 15 years and I look forward to continuing to support the growth and development of the organization as a Member of the Executive Board for the Hilti Group. I know the team here in North America is in great hands under the future leadership of Martina McIsaac,” said Kahn.

Martina McIsaac, currently general manager of Hilti Canada, will be promoted to Region Head and Chief Executive Officer of Hilti North America effective Jan. 1, 2020. Martina was chosen after a comprehensive internal search for a candidate with a proven track record of success, deep understanding of the business and commitment to company culture. “Over the last five years, I have developed a deep passion for our industry, our team members and our customers. I look forward to continuing to build on the strong foundation created by Avi by working alongside my colleagues on the North America Executive Management team to take Hilti even further,” said McIsaac.

Advertisement

Dan Wade, currently division manager for the Midwest located in the Central Market Organization, will succeed Martina as general manager of Hilti Canada. With this role, Dan will join the Hilti North America Executive Management Team. Dan has been with Hilti since 2007 when he joined the company in the technical services department after first serving as an engineering intern. Over his 12-year career, Dan has held a number of positions of increasing responsibility in engineering, marketing and sales before taking on his current role in 2016 as a division manager. For More Information Contact: Leah Kelso Tel: 918-605-0779 Email: Leah.kelso@hilti.com

GPRS Acquires Master Locators Ground Penetrating Radar Systems, LLC (“GPRS”), has acquired Master Locators utility locating business (“Master Locators”), a leading provider of private utility locating, concrete scanning, vacuum excavation, SUE and video pipe inspection services. Master Locators’ clients include utilities, engineering firms and contractors who rely on its services to identify and map the presence of subsurface structures using ground penetrating radar and other locating techniques. Master Locators represents the fourth acquisition for GPRS.

“This is a terrific opportunity for us,” said Gus Sareyka, President of Master Locators. “The new partnership with GPRS and CIVC gives us additional capital and resources, enabling Master Locators to better serve our customers and support our growth.” Kyle Sareyka, Chief Operating Officer of Master Locators, added, “GPRS is the market leader in the private locating industry and we are excited to partner with Matt Aston and his team to continue to extend GPRS’ leadership position.” Kyle Sareyka will join GPRS as the Regional Director of the company’s Northeast Region. Master Locators’ Vacuum Excavation business will form a new company Level A Underground Solutions that will continue to service its existing customers and work closely with GPRS to provide a full suite of subsurface utility engineering solutions. Master Locators enhances GPRS’ market position in the private utility locating, concrete scanning and video pipe inspection markets by adding scale to GPRS’ existing business in Pennsylvania, New Jersey, Delaware, New York, Maryland and Connecticut. “Master Locators represents a highly complementary acquisition for GPRS that enhances our market position in several rapidly growing regions,” said Matt Aston, President of GPRS. “Master Locators operates with strong core values around humility, integrity and passion. We are excited to collaborate with Master Locators’ management team to better serve our customers’ current and future needs.” For More Information Contact: Jason Schaff Tel: 303-945-5415 Email: jason.schaff@gprsinc.com www.gp-radar.com

K2 Diamond & Sanders, Inc. Announce New Laser Welded 60-Inch Diamond Blades K2 Diamond & Sanders, Inc. are happy to announce another technical advancement of increasing our capacity to laser weld up to 60-inch diameter diamond blades! This new threshold fits the needs of pro cutters encountering bigger situations, where the job requirements determine that diamond blades as large as 60-inches in diameter need to be laser welded, as well as continuing our high standard brazing.

Turning technical advancement into another benefit for all pro cutting contractors in North America is what K2 Diamond and Sanders Inc are all about! For More Information: Contact: Bill Chapple – Sanders, Inc. Tel: 610-273-3733 Email: bchapple@sanderssaws.com Contact: Cliff Hansen - K2 Diamond Tel: 800 539-6116 Email: cliff.hansen@k2diamond.com

Aquajet System’s Three Aqua Power Packs are Available for Efficient Hydrodemolition Operation Aquajet Systems AB, a global leader in manufacturing hydrodemolition machines, offers three power packs for powering Aqua Cutters, their range of hydrodemolition robots: the standard Aqua Power Pack, the Ecosilence and the Aqua Skid. The power pack is a combination diesel engine and high-pressure pump, necessary for hydrodemolition.

“We understand that not all projects are the same, which is why we have developed a series of power packs to best meet your operation’s requirements,” said Roger Simonsson, Aquajet Systems managing director. “The Aqua Packs are designed to accommodate a wide range of projects, whether they require a standard pack, a compact footprint or a quieter alternative.”

Power packs are cost effective and easy to transport and set up. The standard Aqua Power Pack contains more than just motors and pumps to power the Aqua Cutter; the container also serves as storage for machine accessories and tools. A built-in workbench with a vise provides contractors a space for jobsite maintenance and a place to store spare parts. Operating at as high as 43,500 psi, Aquajet’s standard Aqua Power Packs are available in multiple versions: Aqua Power Pack 270, 400 and 700.

Similar to the Aqua Power Pack, the Ecosilence provides everything contractors need in a quieter package. Both the standard and Ecosilence measure 23 feet by 8 feet by 8.5 feet (7 meters by 2.4 meters by 2.6 meters). The container’s sound-absorbing design features insulated walls and double doors, as well as seals on all doors and hatches. The Ecosilence offers noise levels less than half that of competitive high-pressure units on the market. With an average of 57.5 dB, the unit is ideal for use in urban areas that have high noise restrictions. In addition, users will see an improved fuel consumption of as much as 10% compared to alternative high-pressure units. The Ecosilence can be equipped with a roll-off frame for simplified on/off truck loading and transport. Maintaining the same dimensions of the standard power pack, the Ecosilence is available in two sizes: The Power Pack 400 and 700 and operates at as high as 18,700 psi.

Aquajet’s compact Aqua Skid power pack measures 8.5 feet by 5.9 feet by 5.5 feet (2.6 meters by 1.8 meters by 1.7 meters) and provides the same performance and basic functions as the containerized packs, just in a smaller footprint. The compact high-pressure unit is designed for installation on a truck, trailer or local container, which is ideal for contractors or operations with space restrictions, such as plants or factories. Operating at 43,500 psi, this power pack offers contractors a fast and easy way to upgrade an outdated high-pressure unit, plus, the Aqua Skid can be used in areas where metal enclosing — such as the exterior of the standard power pack or Ecosilence — is not necessary or possible. For More Information Contact: Aaron Boerner Tel: 701-373-0062 Email: aaron@ironcladmktg.com www.ironcladmktg.com

STIHL Inc. Building Dedication Reinforces Commitment to Manufacturing in America STIHL Inc., headquarters for U.S. operations of the worldwide STIHL Group, celebrated a new administration building and campus improvements during a ribbon-cutting ceremony on October 10th. The $30+ million project is part of the company’s continual investment in infrastructure in support of growing U.S. operations. The new 80,000-squarefoot building brings the Sales & Marketing, Finance & Controlling, Legal and Customer & Technical Service teams under one roof.

“This new building will improve administrative and operational efficiency allowing us to better serve our network of more than 9,000 authorized STIHL dealers and their customers,” said Bjoern Fischer, president of STIHL Inc. “As we mark 45 years of growth and expansion in Virginia Beach, we look ahead to a continued positive economic environment for successful modern manufacturing in the City of Virginia Beach.”

During the ribbon-cutting, members of the Stihl family and STIHL executive board from ANDREAS STIHL AG & Co. KG, as well as local dignitaries including the mayor of Virginia Beach, members of City Council and representatives from Hampton Roads learned more about the new facility and campus improvements including:

A state-of-the-art training center for authorized STIHL Dealers featuring an auditorium, training lab and outdoor demonstration area for hands-on product testing and training

A chain saw “Helix” art installation, crafted out of more than 30 STIHL chain saws dating back to 1936, representing how chain saw innovation is part of the STIHL DNA

Brand experience: STIHL concept store showcasing an ideal STIHL retail space

An enhanced entryway at the main gate for improved traffic flow and security For More Information Contact: Marcella Nicotra Tel: 757-340-7425 Email: marcella.nicotra@themeridiangroup.com www.themeridiangroup.com

Brokk Offers Three Darda Concrete Crushers for Reinforced Concrete Applications Brokk®, the world’s leading manufacturer of remote-controlled demolition machines, has launched three new concrete crusher models — the CC440, CC480 and CC580. The attachments, manufactured by Brokk’s German sister company, Darda®, offer contractors a highperformance tool for Brokk’s Next Generation SmartPower™ series, increasing operator safety and productivity on a variety of tough demolition jobs including top-down and interior demolition.

The CC series sets new standards in terms of ruggedness and performance. The three new crushers are equipped with a newly designed pressure booster, which allows them to operate independently of the carrier’s working pressure, resulting in increased speed and crushing forces. When used in high pressure mode, the new models offer faster operation and jaw closing compared to their predecessors. The crushers excel in challenging applications, such as elevator shafts, piers, concrete walls and ceilings where reinforced concrete is present. In addition, the CC series offers virtually silent operation, making them ideal for jobsites with strict noise restrictions, such as interior demolition projects in occupied spaces like hospitals and office buildings, where traditional methods, such as hydraulic hammers, would be too noisy.

The new models are available with Darda’s standard features, including wear-resistant, replaceable steel alloy crusher tips and cutter blades, as well as a full 360-degree rotation. Additional teeth are available for greater efficiency and crushing, enabling higher breaking forces for hard, thin walls and separation of concrete and rebar.

Despite their compact size, Darda crushers can easily keep up with the performance of larger, heavier models. When paired with a Brokk machine, the new concrete crushers are controlled with a belt-mounted remote-control box, allowing operators to work from a safe distance without concern for vibration, silica dust-related health issues or falling debris.

The CC440, CC480 and CC580 crushers are just a few of the more than 80 attachments that operators can quickly mount on Brokk demolition robots for greater versatility on a jobsite. Brokk supplies a wide range of remotecontrolled machinery and attachments around the world to maximize productivity, improve efficiency and increase safety. For More Information Contact: Mike Martin Tel: 800-621-7856 Email: mike@brokkinc.com

Vacuworx Hires Area Business Manager for Southern Latin America Vacuworx has announced an addition to its international sales team as the company continues to explore and develop new opportunities for the faster, safer and smarter handling of pipeline and construction materials worldwide.

Christian Sellan has been hired as Area Business Manager for Southern Latin America. Building on past successes, Sellan will continue his support and development of Vacuworx customers in Chile, Peru, Bolivia, Paraguay and Argentina. At the same time, he is working to identify new business opportunities and growth potential in target markets as the Tulsa-based manufacturer expands its network of qualified distributors.

“The strong partnerships we’ve developed in Europe and other parts of the world have helped create a springboard and a lot of interest in Vacuworx,” Smith said. “We are focused on areas in which we can we bring the most value to the customer. From oil and gas pipelines to mining, water resources, civil construction and other industries, the potential is really high and rising alongside demands for improved safety standards.” For More Information Contact: Paula Bell Tel: 918-259-3050 Email: paulab@vacuworx.com www.vacuworx.com Sellan

CenPoint Releases Brand New Mobile App CenPoint is excited to announce the official release of our brand new, rewritten, rethought, reworked, beautified, enhanced, simplified, faster, easier and sleeker mobile app! Taking what we learned by processing over 4.5 million work orders, it is now 44% faster and auto saves as you go. Offline support allows you to keep working even when you don’t have cell signal. Works on Android phones and tablets, iPhones, iPads and desktop computer browsers. The new mobile app is designed and built to bring even more efficiency for your field technicians/ operators. Field techs can be dispatched, fill out and return their paperwork, capture customer’s digital signature, attach photos and complete JSA’s all on their mobile device. Field techs can review and sign automatically generated silica safety plans, customized for each work order. Field techs can also track their timecards, submit vehicle inspections and even complete company safety training/CSDA Toolbox Safety Tips (TST’s) right from their phone or tablet. This new mobile app is specifically designed to save your company time, money, and hours of frustration. For More Information Contact: Jenni Rindlisbacher Tel: 801.478.6822 ext. 303 Email: jhr@cenpoint.com www.cenpoint.com

See this product at the

Booth # C4439

American Society of Concrete Contractors Publishes Safety Pre-Construction Checklist The Safety & Risk Management Council (SRMC), a specialty council of the American Society of Concrete Contractors (ASCC) has published a Pre-Construction Checklist for Safety Policies & Procedures. The purpose of the document is to stimulate discussion of job-specific safety protocol and procedures, with all pertinent parties prior to project start-up. The document covers general information such as contact data for significant persons, safety goals and planning, reporting, discipline and quality of life. It also covers more specific criteria including silica, crane activities, heat, and an evacuation plan.

“Making sure all parties understand and are onboard with safety before mobilization is a key factor in maintaining a safe job place,” says Joe Whiteman, director of safety services, ASCC. “It’s in everyone’s best interest to understand what’s expected prior to starting work.” For More Information Contact: Beverly A. Garnant Tel: 314-962-0210 Email: bgarnant@ascconline.org

Makinex Expands BDM Into New Territory Makinex Business Development Manager, Robert Millikan, expands territory to cover the demand for Making Inefficiencies Extinct into Kansas and Missouri. Millikan, who has successfully expanded the Makinex product range into the South Central USA region, will now be duplicating that success, contributing to the company’s overall growth throughout USA and supporting the current demand within Kansas and Missouri.

“Robert is a stellar BDM with an endless amount of energy and industry knowledge. He’s the first to show up on a job site or live demo, jump in, get his hands dirty and do whatever it takes to help the customers and any other partners involved in what’s going on. We’re looking forward to substantial growth into Kansas and Missouri, and happy to have Robert covering those areas.” Said Mark Choate, National Sales Manager of Makinex. For More Information Contact: Robert Millikan Tel: 818-625-4639. Email: R.Millikan@makinex.com www.makinex.com

Dynamic Infrastructure Implements Deep AI Technology to Prevent Bridges and Tunnels from Collapsing

The New York and Tel Aviv based startup Dynamic Infrastructure is implementing the world’s first deep-learning solution which allows bridge and tunnel owners and operators to obtain visual diagnosis of the assets they manage. The system provides live, cloud-based, 3D views of the bridge or tunnel and automatically alerts when changes are detected in maintenance and operation conditions - before the issues evolve into large-scale failures.

With huge Opex and Capex positive impact, Dynamic Infrastructure is already conducting projects in the U.S., Germany, Switzerland, Greece and Israel with different transportation infrastructure stakeholders. The company’s clients operate a total of 30,000 assets, ranging from Departments of Transportation to Public-Private Partnerships (PPPs) and private companies.

Dynamic Infrastructure quickly creates “medical records” for every bridge, tunnel and elevated highway, based on existing images taken through periodical condition inspections along the years, including images from smartphones, drones and laser scanning. The proprietary technology compares old and archived images to new ones, detecting maintenance and operation issues, defects and anomalies. Like MRI for humans , the 3D “medical records” serve as the basis for the alerts on changes in maintenance conditions. The diagnostics can be easily accessed through a simple browser and can be instantly shared with peers and contractors to speed maintenance workflows and increase return on investment. For More Information Contact: Lior Kleinberg Tel: 972-77-2129988 Email: lior@meirovitch.com

DIAMOND VANTAGE ® ZENESIS ™ BLACK CORE BIT A WHOLE OTHER LEVEL OF DRILLING

diamondvantage.com 866.322.4078

MARCH 31–APRIL 4, 2020

OMNI LA COSTA RESORT & SPA • CARLSBAD, CALIFORNIA

Aquajet Systems Introduces Aqua Centralizer for Tunnel and Pipe Applications Aquajet Systems AB, a global leader in Hydrodemolition machine manufacturing, introduces the Aqua Centralizer. Its innovative design and high-quality engineering allow for effective cleaning or removal of concrete, paint, rust and coatings along an entire section of horizontal, vertical or inclined tunnels and pipes. The Aqua Centralizer works in conjunction with Aquajet’s Aqua Cutter Hydrodemolition robots and high-pressure Aqua Power Packs to provide strategic concrete removal in roadbuilding, wastewater and industrial plant applications.

“Whether it’s a brand-new design or a reconfiguration of our current technology to allow for new applications, Aquajet is constantly at the drawing board to help our customers stay ahead of the curve,” said Roger Simonsson, Aquajet Systems AB managing director. “The Aqua Centralizer integrates key components of several of our existing designs to provide operators a new solution for working in pipes and tunnels more effectively than ever before.”

The Aqua Centralizer uses elements of the Aqua Spine as the base for the unit while incorporating technology from the Circular Power Head attachment for concrete removal and cleaning applications. This includes a 360-degree ring and robotic power head with a 25-degree adjustable lance angle and variable stroke oscillation. The power head offers adjustable working angles from 0 to 360 degrees and automatic indexing along the spine rail, minimizing downtime from repositioning and optimizing productivity. Combined with one of Aquajet’s Power Packs, which provide a pressure up to 40,000 psi, this flexibility offers contractors the power and precision to effectively clean steel pipes and remove concrete inside tunnels and pipes. For More Information Contact: Keith Armishaw Tel: 418-928-9638 Email: keith.armishaw@brokkinc.com www.brokk.com

Makinex Construction Products Celebrates Customer Appreciation Month Annually, during the month of September, Makinex Construction Products celebrates and honors all of their customers and partners during Customer Appreciation Month.

Throughout the duration of the month, they handed out over 100 gifts, personally reaching out to over 150 customers and partners, running power promotions and hosting several intimate outings. Also, for the first time ever, they offered an open invitation for all to come and visit the Makinex Headquarters located in Torrance, CA.

“We hope that our customers & partners know how important they are to us,” said Brandy Carmona, Operations Manager. “We would not be where we are today without the support and opportunities that they all provide to us. We truly appreciate and value them, not only during this month, but every single day.”

The relationships and partnerships that Makinex has with everyone whom they encounter is never something taken for granted. For More Information Contact: Brandy Carmona Tel: 855-625-4639 Email: info@makinex.com www.makinex.com

DEWALT Debuts ToughCase+ Accessory Storage Sets

DEWALT debuts ToughCase®+ Accessory Storage Sets that are the latest addition to the brand’s accessory storage, with premium features to help keep drilling and fastening bits organized. The system includes four container sizes; the Small Bulk Storage Container, Small ToughCase®+ Container, Medium ToughCase®+ Container and Large ToughCase®+ Container for unlimited configurations.

The ToughCase®+ Containers feature newly-designed bit storage, with a unique bit bar position that allows for easy removal of bits. Clear lids let users see what’s in the case at a glance. In addition, the Small, Medium and Large ToughCase®+ Containers include a proprietary latch system to connect to each other for optimized storage space. The Small Bulk Storage Container fits into each of the units as well, and helps loose materials stay organized. The user-friendly features included in the ToughCase®+ Accessory Storage Sets help users stay organized and ready-for-action. The sets are available with the most popular lines of bits from DEWALT, including Max Fit® Bits, FlexTorq® Bits, Tough Grip™ Bits and more. For More Information Contact: Sarah Windham Tel: 410.716.3699 Email: sarah.windham@sbdinc.com Website: www.dewalt.com

Vacuworx Names Bruce Williamson Regional Sales Manager Vacuworx is pleased to announce that Bruce Williamson has been hired as Regional Sales Manager, Southeast, serving the territory of Florida, Georgia, Alabama, North Carolina, South Carolina, Kentucky and Tennessee.

“My goal is to get out and establish relationships and continue the conversation, presenting the Vacuworx value as we go,” Williamson said. For More Information Contact: Paula Bell Tel: 918-259-3050 Email: paulab@vacuworx.com www.vacuworx.com

Williamson

Hilti Announces Software Collaboration with Procore to Support Digital Workflows

The Hilti Group, a world-leading manufacturer and provider of construction tools, technology and productivity solutions, is collaborating with Procore, a leading provider of construction management software, to help strengthen digital workflows and drive productivity on jobsites. As part of the joint effort, Hilti ON!Track asset management system will become compatible for Procore platform users. The announcement was made during Procore’s Groundbreak 2019, one of the largest construction conferences in the U.S.

In recent years, Hilti has made major efforts to digitize the construction industry with software solutions. Hilti ON!Track is specifically designed to give contractors visibility into who has their assets. Smartphone scanning and active Bluetooth tags help track items moved between warehouses and jobsites. It also enables contractors to proactively manage

@diteqcorporation

DITEQ Channel www.DITEQ.com

repairs and inspections, set reminders for maintenance and verify proper training and certifications before assigning certain assets.

The API will open data exchange between Hilti ON!Track and Procore, starting with basic project info and expanding over time into further seamless workflows. Procore users appreciate the benefits of reduced duplicate data entry of the same information into multiple spreadsheets or workflows. Customers using both Procore and ON!Track suggest for example that an open item from Procore’s Tasks tool to request a piece of equipment could be For More Information Contact: Danielle Wilson Tel: 800-363-4458 Email: Danielle.Wilson@hilti.com www.hilti.ca

ASV to Showcase Eye-Catching Machines at GIE+EXPO 2019

ASV Holdings Inc., an industry-leading manufacturer of all-purpose and all-season compact track loaders and skid steers, will exhibit flashy, special edition versions of two of its popular Posi-Track® loaders at GIE+EXPO 2019. ASV will showcase “The Green Beast,” a green and black version of the RT-120 Forestry, the industry’s largest and most powerful compact track loader, in its booth 10134. A black and red version of the RT-40, one of the industry’s smallest sit-in compact track loaders, dubbed “The Black Widow,” will be on display in the Soucy International Inc. booth 21080. The coloring on the sleek machines showcases key features of ASV’s unique Posi-Track undercarriage.

Show attendees are invited to stop by and take pictures of the machines. The indoor booth will also include the RT-25, a safer and more capable alternative to stand-on and walk-behind loaders. Attendees will also be able to visit the outdoor booth 6031D to try out the new mid-frame, vertical lift VT-70 High Output, as well as the RT-40 and RT-25. For More Information Contact: Regan Meyer Tel: 218-327-5385 Email: regan.meyer@asvi.com www.asvi.com

ACI Announces Winners of Annual Excellence in Concrete Construction Awards The American Concrete Institute (ACI) announced the winners of the 2019 Excellence in Concrete Construction Awards, who were honored at a Gala event during the Institute’s Concrete Convention & Exposition, October 21, 2019, in Cincinnati, OH, USA.

The highest honor was presented to the King Abdulaziz Center for World Culture, located in Dhahran, Eastern Province, Saudi Arabia.

Also known as Ithra, the Arabic word for “enrichment,” the King Abdulaziz Center for World Culture is an 85,000 m2 (914,930 ft2) building surrounded by a 220,000 m2 (2,368,000 ft2) Knowledge Park that creates a space to inspire the imagination. Features of the structure include post-tensioned slabs spanning 15.9 m (52 ft), sloped concrete walls and ramps, and twisted and inclined reinforced concrete columns with decorative concrete finish. The building is 90 m (295 ft) tall and is supported on a 3 m (10 ft) thick raft foundation. Stability is provided through a reinforced concrete core acting as a propped cantilever. The columns supporting the elevated slabs are inclined and result in horizontal thrust forces at the head and base of each column lift. The post-tensioned slabs act as structural diaphragms to carry these forces back to the core. Construction was completed in the fall of 2017. For More Information Contact: Julie Webb Tel: 248-848-3148 Email: julie.webb@concrete.org www.concrete.org

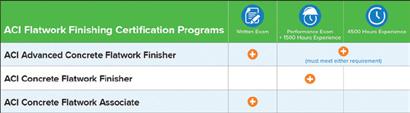

ACI Updates Flatwork Finishing Certification Program Names and Requirements The American Concrete Institute (ACI) has updated the names and requirements for its Flatwork Finishing Certification program. ACI Concrete Flatwork Technician has been renamed as ACI Concrete Flatwork Associate; ACI Concrete Flatwork Tradesman has been renamed as ACI Concrete Flatwork Finisher; and ACI Concrete Flatwork Finisher and Technician has been renamed as ACI Advanced Concrete Flatwork Finisher.

To earn a new ACI Concrete Flatwork Associate certification, individuals need to pass a written exam. To earn a new ACI Concrete Flatwork Finisher certification, individuals need to pass a performance exam and have 1,500 hours of documented work experience. To earn a new ACI Advanced Concrete Flatwork Finisher certification, individuals need to both pass a written exam and either have 4,500 hours of work experience or have 1,500 hours of work experience and pass a performance exam. Additionally, the ACI Concrete Flatwork Finisher and ACI Advanced Concrete Flatwork Finisher programs will have an optional re-certification method through submittal and verification of approved continuing education and work experience.

“These changes are designed to better reflect the knowledge, skills, and responsibilities of certified personnel; provide more flexible and convenient recertification options; and encourage personal growth within the concrete flatwork finishing sector,” said John W. Nehasil, ACI Managing Director, Certification. ACI will begin immediately issuing credentials with the new program names to those individuals earning certification. Individuals who have already been certified with the retiring program names will not receive new credentials now but will upon upgrade or re-certification. For More Information Contact: Julie Webb Tel: 248-848-3148 www.concrete.org

Epiroc USA to Open New Regional Service Center for Northeast

Epiroc, a leading productivity partner for the mining and infrastructure industries, will open a new, modern Regional Service Center to support customers in the Northeast region of the U.S. The center — located in Harrisburg, Pennsylvania — will be up and running by October 15, 2019.

MITO QTH ChainsawKey Features Patented 1 Step Keyless Tensioning Robust Aluminum Casted Body Lightest 12 GPM Chainsawon market Tiger Grip Wall Guide During Cut Flush Cut Universal Bars and Chains up to 30” MITO QTH ChainsawTechnical Features Motor 12 GPM / 45 lpm Weight(with 15” bar & chain) 23 lbs. / 10 kg Cutting Depth Up to 30 in. /76 cm The new Regional Service Center is part of Epiroc’s commitment to being an ever-stronger partner for customers. The center will feature a state-of-theart service shop for Epiroc mining and construction equipment, and it will serve as a home base for field service technicians. Staff at the center will also be available to support customers and provide additional local resources. In addition to the new service center, Epiroc is further investing in the Chambersburg Local Distribution Center in Pennsylvania. The location currently houses Epiroc rock drilling tools and is now expected to stock a robust inventory of spare parts by the end of 2019. The additional in-stock parts will enhance support for customers in the region by allowing them faster access and reduced equipment downtime. For More Information Contact: Mila Armer, MBS, Marketing Communications Manager Tel: 844-437-4762 Email: mila.armer@epiroc.com www.epiroc.us

FIND US IN THE SOUTH HALL AT BOOTH #S11020

Visit RGC @ WOC 2020 • Booth #S12039

RGC

THE POWER OF A DEEPER CUT

RS17 RingSaw Cuts 12.75” in one pass

C120 HydraCutter Up to 30” cutting depth Uses standard bar and chains

351212 HydraPak Power two tools up to 12GPM simultaneously