By Irwin Rapoport CEG CORRESPONDENT

A severe blaze beneath a section of the I-10 in downtown Los Angeles late last year closed one of the city’s busiest highways for several days, but herculean efforts by two general contractors and California Department of Transportation (Caltrans) engineering and emergency teams allowed the road to reopen weeks in advance of a much longer anticipated delay.

The Griffith Company tested and cleared hazardous materials while Security Paving Company Inc. conducted immediate emergency repairs for the reopening. Security Paving crews are currently on-site completing the repairs to the columns and other infrastructure damaged by the inferno.

The fire occurred in a 40,000-sq.-ft. storage yard for wooden pallets and other goods, with the intense heat impacting the infrastructure supporting an elevated section of the highway.

“Over the next six days, our dedicated team, drawn from across the state, worked tirelessly under challenging conditions,” Security Paving said in a statement. “Our in-house engineering team collaborated with agencies to design a hybrid wood/steel braced shoring system capable of supporting the heavily damaged structure under full traffic load.

The Griffith Company tested and cleared hazardous materials while Security Paving Company Inc. conducted immediate emergency repairs. Currently, Security Paving is onsite completing the remaining repairs to the columns and other infrastructure.

By Lucy Perry CEG CORRESPONDENT

The face of the skilled craft trade industry is getting younger. Literally.

More younger people than ever before are entering the construction industry and driving down the average age of tradesmen and women. As more construction workers retire, the industry’s labor needs are growing exponentially. But Gen Z workers drawn to the specialty trades may fill those venerable shoes.

see GENERATION page 40

As more younger workers enter the construction trades, the average age of craft trades men and women has come down.

A/C & Heat, 592 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng $29,500

2018 John Deere 750K LGP, Stk#: 13236, EROPS, A/C &

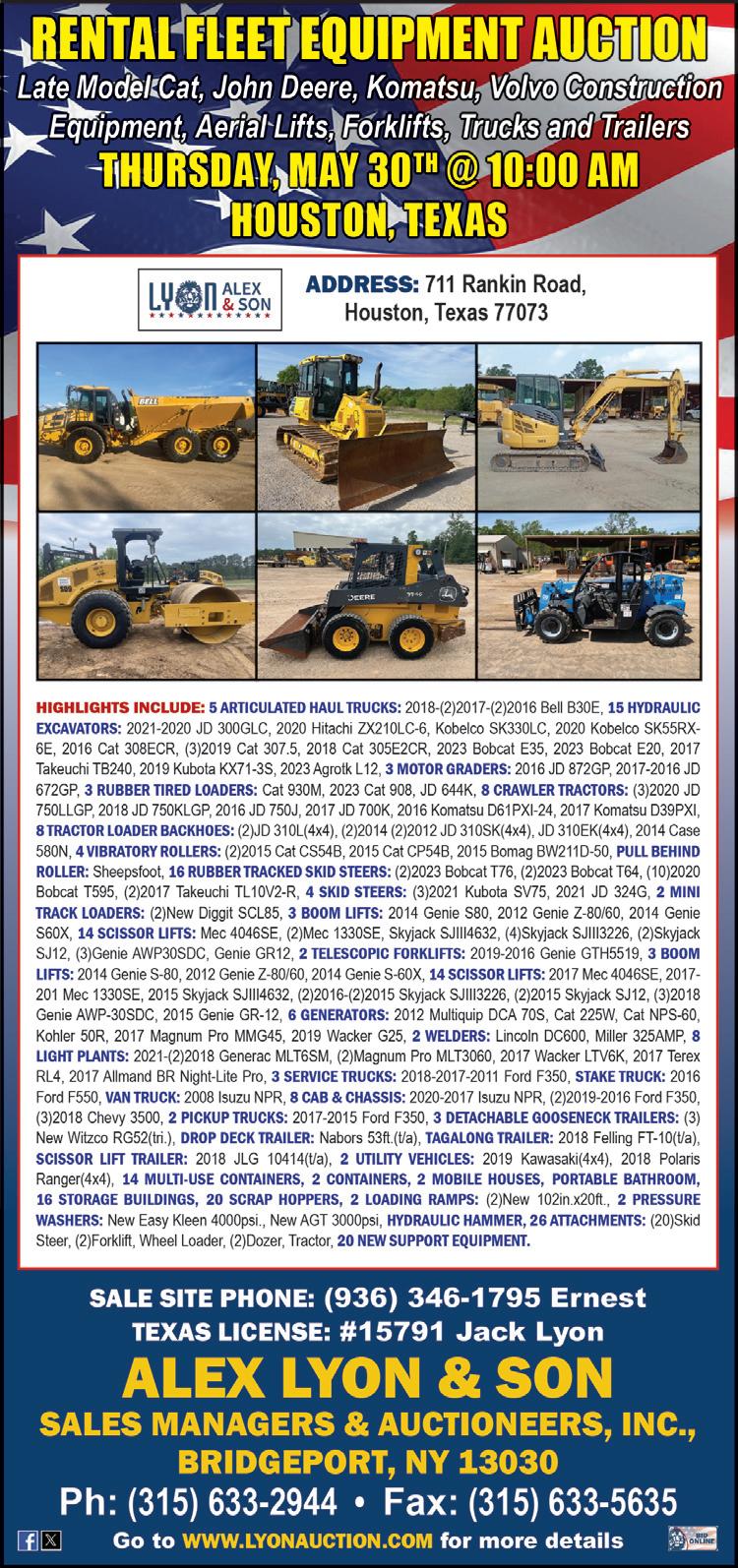

Brightline West broke ground on the high-speed rail system which will connect Las Vegas to Southern California. The 218-mi. system will be constructed in the middle of the I-15.

Common Ground Alliance (CGA), the national association dedicated to protecting underground utility lines and the people who dig near them, hosted its 2024 Annual CGA Conference & Expo at The Broadmoor in Colorado Springs.

Liebherr exhibits at the International Foundation Congress & Equipment Expo in Dallas from May 7-10, 2024, at booth #3200. Attendees will be presented with the exclusive opportunity to explore a diverse range of Liebherr products.

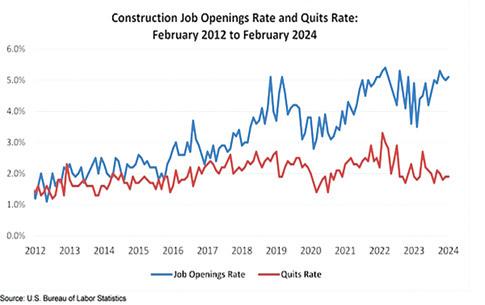

The construction industry had 441,000 job openings on the last day of February, according to anABC analysis of data from the U.S. Bureau of Labor Statistics’ Job Openings and Labor Turnover Survey.

Attendees can develop their skills and take advantage of new trends impacting their industry due to expanded education and certification classes at Equip Exposition this Oct. 15-18 at the Kentucky Exposition Center (KEC).

16 BOBCAT NAMES ITS LEADERSHIP GROUP; HONORS 16 DEALERS

Bobcat Company has announced its 2024 Dealer Leadership Group. The 16 Bobcat dealerships honored this year are its highest-performing dealers in North America according to the company’s Dealer Performance Review.

16 CHARLIE JOHNSON PASSES NSSGA GAVEL TO MARK KRAUSE

At NSSGA’s Gavel Exchange dinner DSC Dredge’s Director of Domestic Dredge Sales, Charlie Johnson, passed the gavel to Mark Krause of McLanahan as the newly appointed chairman.

26 EQUIP EXPO PLANS 30-ACRE OUTDOOR DEMO YARD

The outdoor demo yard at Equip Exposition, the international landscape, outdoor living and equipment exposition, will be abuzz with activity Oct. 16-18, 2024, at the Kentucky Exposition Center.

26 PCL ANNOUNCES LEADERSHIP CHANGES TO SUPPORT GROWTH

PCL Construction Enterprises Inc. announced the appointment of several executives to guide its operations throughout the country. This strategic move comes on the heels of a successful year for the company.

30 TAKEUCHI RECOGNIZES TOP DEALERS AT DEALER SUMMIT IN SAN ANTONIO

Takeuchi recently announced its Dealer of the Year, Dealer Salesperson of the Year and the recipients of its 2023 Dealer 360° awards at the company’s 2024 Dealer Summit in San Antonio.

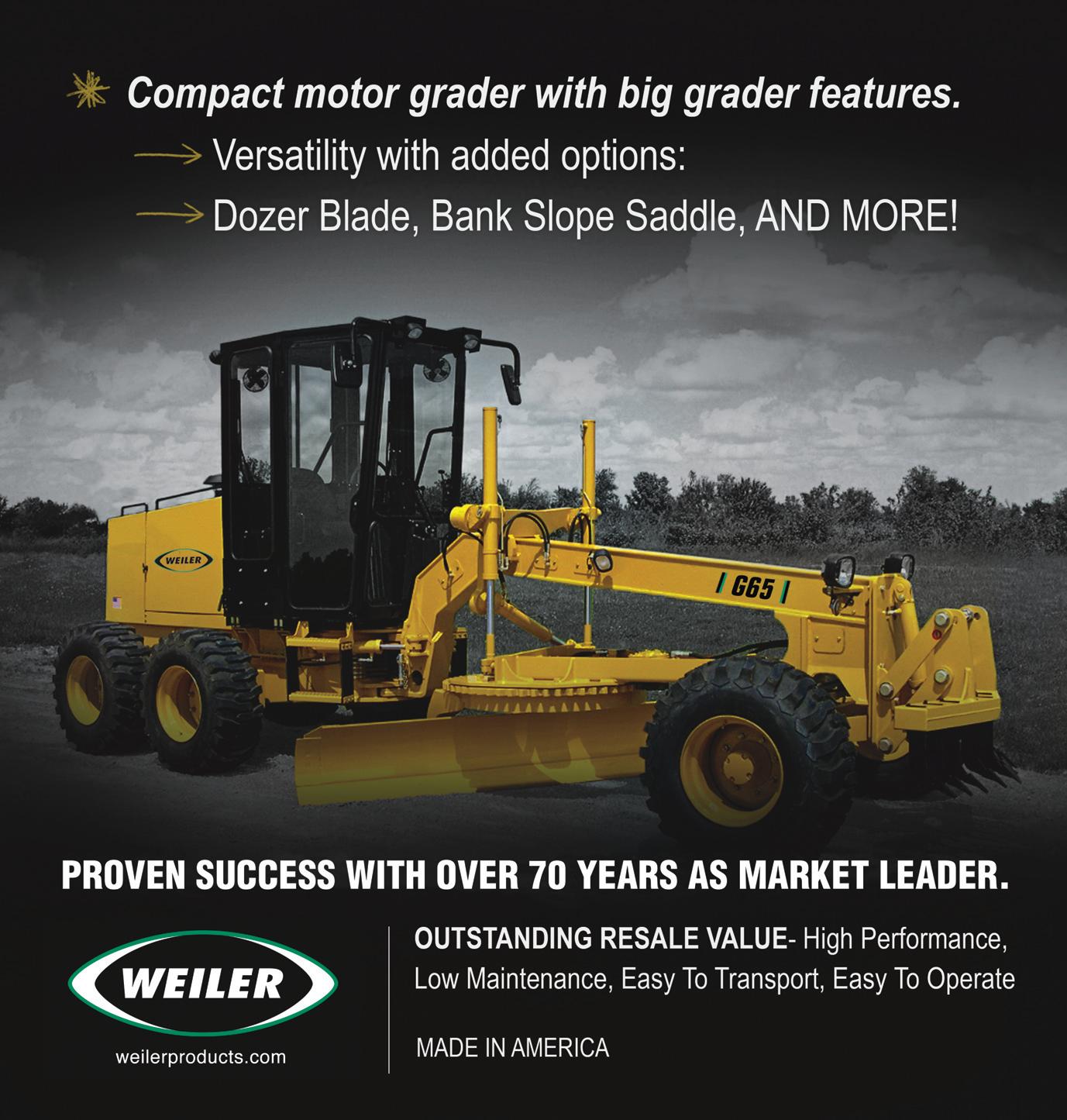

30 WEILER NAMES ENGINEERING MGR., MEMBER OF SENIOR MANAGEMENT

Weiler has appointed Joel Weiler as engineering manager of the Knoxville, Iowa-based manufacturer and elevated him to the senior management team. He joined the company in August of 2019 as safety manager.

38 WACKER NEUSON EXTENDS TRACKUNIT PARTNERSHIP THROUGH 2028

Wacker Neuson Group has strengthened its ties with Trackunit by agreeing to extend its partnership agreement for another five years. The deal is a renewal of a previous agreement.

Sales

the

Brightline West officially broke ground on the high-speed rail system which will connect Las Vegas to Southern California.

The 218-mi. system will be constructed in the middle of the I-15 and is based on Brightline’s vision to connect city pairs that are too short to fly and too far to drive. Hailed as the greenest form of transportation in the world, Brightline West will run zero emission, fully electric trains capable of speeds of 200 miles per hour.

Brightline West is a watershed project for high-speed rail in America and will establish the foundation for the creation of a new industry and supply chain. The project was recently awarded $3 billion in funding from President Biden’s Bipartisan Infrastructure Bill. The rest of the project will be privately funded and has received a total allocation of $3.5 billion in private activity bonds from USDOT.

Construction

Brightline West’s rail system will span 218 mi. and reach speeds of 200 mph. The route, which has full environmental clearance, will run within the median of the I-15

highway with zero grade crossings. The system will have stops in Las Vegas, as well as Victor Valley, Hesperia and Rancho Cucamonga, Calif.

The privately-led infrastructure project is one of the largest in the nation and will be constructed and operated by union labor. It will use 700,000 concrete rail ties, 2.2 million tons of ballast and 63,000 tons of 100 percent American steel rail during construction. Upon completion, it will include 322 mi. of overhead lines to power the trains and will include 3.4 million sq. ft. of retaining walls. The project covers more than 160 structures including viaducts and bridges. Brightline West will be fully Buy America Compliant.

“People have been dreaming of highspeed rail in America for decades — and now, with billions of dollars of support made possible by President Biden’s historic infrastructure law, it’s finally happening,” said Secretary Buttigieg. “Partnering with state leaders and Brightline West, we’re writing a new chapter in our country’s transportation story that includes thousands of union jobs, new connections to better

economic opportunity, less congestion on the roads, and less pollution in the air.”

“This is a historic project and a proud moment where we break ground on America’s first high-speed rail system and lay the foundation for a new industry,” said Wes Edens, Brightline founder. “Today is long overdue, but the blueprint we’ve created with Brightline will allow us to repeat this model in other city pairs around the country.”

Brightline West will connect Southern California and Las Vegas in two hours or almost half the time as driving. The Las Vegas Station will be located near the iconic Las Vegas Strip, on a 110-acre property north of Blue Diamond Road between I-15 and Las Vegas Boulevard. The site provides convenient access to the Harry Reid International Airport, the Las Vegas Convention Center and the Raiders’ Allegiant Stadium. The station is approximately 80,000 sq. ft. plus parking.

The Victor Valley Station in Apple Valley will be located on a 300-acre parcel

southeast of Dale Evans Parkway and the I-15 interchange. The station is intended to offer a future connection to the High Desert Corridor and California High Speed Rail. The Victor Valley Station is approximately 20,000 sq. ft. plus parking.

The Rancho Cucamonga Station will be located on a 5-acre property at the northwest corner of Milliken Avenue and Azusa Court near Ontario International Airport. The station will be co-located with existing multi-modal transportation options including California Metrolink, for seamless connectivity to Downtown Los Angeles and other locations in Los Angeles, Orange, San Bernardino and Riverside Counties. The Rancho Cucamonga Station is approximately 80,000 sq. ft. plus parking.

The Hesperia Station will be located within the I-15 median at the I-15/Joshua Street interchange.

The Vehicle Maintenance Facility (VMF) is a 200,000-sq.-ft. building located on 238 acres in Sloan, Nev., and will be the base for daily maintenance and staging of trains.

Common Ground Alliance (CGA), the national association dedicated to protecting underground utility lines and the people who dig near them, hosted its 2024 Annual CGA Conference & Expo at The Broadmoor in Colorado Springs.

With 1,400 damage prevention leaders in attendance, the CGA Conference & Expo is the largest gathering of its kind in America.

More than 38 times each day on average in Colorado, buried power, water, gas, internet and other utility lines are damaged by digging. That’s over 14,000 times each year that Coloradans’ lives and businesses are interrupted by damage to underground infrastructure. In fact, contractors were fined $500,000 for damaging 766 utility lines just in Colorado Springs alone. April also is National Safe Digging Month across the country.

“This was our largest-ever Conference & Expo, and it’s a testament to the growing importance of preventing damage to underground infrastructure that affects Coloradans 38 times each day,” said CGA President and CEO Sarah Magruder Lyle.

“We thank Colorado Springs and the state of Colorado for the warm welcome to this beautiful state. And we’re grateful for the partnership of our attendees, sponsors and Colorado 811 for helping share that preventing damage to the utilities we all rely on is a shared responsibility we can achieve together.”

Prominent Colorado elected leaders welcomed CGA and the attendees to the state with video messages, including Gov.

Jared Polis, Congressman Doug Lamborn, Congresswoman Lauren Boebert, Congressman Jason Crow, State Senate Minority Leader Paul Lundeen, State House Minority Leader Rose Pugliese and State Senator Chris Hansen.

“Thank you to CGA for the work you do to protect our homes, businesses and communities from underground utility damage,” said Polis. “It’s important to follow best practices when protecting our key services and keeping people safe. Taking steps to mark utilities and contacting 811 before every dig can help us know what’s below and prevent accidental damage to underground utilities.”

“As a former county commissioner, I understand how critical it is that we work together to support the underground infrastructure that helps power our communities,” said Colorado House Minority Leader Rose Pugliese. “The work you all at CGA do to prevent and minimize that damage is critical to helping our communities safely grow and deliver the energy and water that we use every day in Colorado.”

Attendees included senior level executives from across 16 key industries, including leading utilities, state 811 call centers, oil and gas pipeline, construction, insurance, equipment manufacturing and damage prevention and underground locating technology companies, such as Verizon, Rust-oleum, Colorado 811, Honeywell, Colorado Springs Utilities, Black Hills Energy, Kinder Morgan and others.

Attendees received inspiring lessons from keynote speaker former NASA astronaut and retired U.S. Air Force Colonel Mike Mullane. He spoke about the risks of accepting a lower

standard of performance until that lower standard becomes the norm. Attendees also participated in nearly 70 interactive educational sessions on improving collaboration, safety, accurate underground mapping, machine learning and artificial intelligence and more.

More than 100 exhibitors and nearly 100,000 sq. ft. of exhibit space — the conference’s largest-ever and the equivalent of nearly two football fields — showcased the latest technology for safely digging, locating and installing fiber/broadband, water, gas, power and other utility lines. Examples include GPS-enabled ground-penetrating radar devices, vacuum excavation equipment that allows digging using compressed air or high-pressure water, and cloudenabled handheld subsurface mapping equipment.

CGA also recognized top leaders in the industry through prestigious industry awards. Shawn Lyon, senior vice president of logistics & storage at MPLX, received the President’s Award. Josh Hinrichs, president of UtiliSource and outgoing CGA board chair, received the Hall of Fame Award. This year’s Groundbreaker Award honored the late Craig Rogers, former Nevada Public Utilities Commissioner.

The 2025 CGA Conference & Expo will be held at the Orlando World Center Marriott in Orlando, Fla., April 7 to 11, 2025.

Liebherr exhibits at the International Foundation Congress & Equipment Expo (IFCEE) in Dallas from May 7-10, 2024, at booth #3200.

At this year’s show, attendees are presented with the exclusive opportunity to explore a diverse range of Liebherr products. Machines from the deep foundation and crawler cranes segment include the LB 25 drill rig with BAT 250 rotary drive, the LRH 200 piling and drilling rig with an H6 hydraulic hammer, and the LR 1100.1 crawler crane located within the IFCEE demo area.

Additionally, Liebherr also will exhibit the THS 110 D-K crawler concrete pump from the concrete technology product segment.

IFCEE provides an excellent platform to showcase the synergy of Liebherr’s diverse offerings as they work together to serve the varied needs of the deep foundation and construction industries, the manufacturer said.

“Our participation in IFCEE is a testament to Liebherr’s commitment to providing leading technology and innovation to the deep foundations industry. We are thrilled to have the opportunity to engage in meaningful dialogue and contribute to the advance-

ment of our industry,” said Shane Kuhlmey, divisional director of crawler cranes and foundation equipment, Liebherr USA Co.

As a turnkey supplier in deep foundation engineering, Liebherr offers cutting-edge piling and drilling equipment as well as attachments. Liebherr deep foundation machines are ideally suited for the construction of cast-in-place piles and slurry walls, for the installation of sheet piles or for soil improvement. Additionally, the deep foundations machines pair seamlessly with concrete technology and crawler cranes to provide customers with an integrated fleet of equipment to make each job cost and time effective.

The LB 25 is the successor of the proven rotary drilling rig LB 20-230.

The LB 25 offers a modular design for quick and easy assembly, as well as strong winches for high performance under challenging conditions. The drill rig is equipped with a leader top designed for different drilling axes providing customers the ability to utilize the rig in multiple applications including Kelly drilling, double rotary head drilling and continuous flight auger drilling.

The focus of the LB 25 drilling rig is to provide greater mobility therefore it can be transported fully mounted. This ensures quick transport of the machine between different job sites, saving customers time and money. The rig also is equipped with an innovative control system offering many program and control options for various drilling methods making it easier for the operator to maneuver quick working cycles.

The combined piling and drilling rig LRH 200 offers flexible leader kinematics enabling very high radii and inclinations of up to 18-degrees in all directions. A flexible in-house hammer concept with various weight configurations allowing concrete, steel or timber piles to be optimally installed.

The new LRH 200 offers a large range of applications for operators. When configured as a drilling rig, a high-performance drilling drive provides the necessary torque for the common methods such as continuous flight auger, full displacement and down-the-hole drilling processes.

The compact machine is based on the proven LB 30 basic machine from Liebherr’s range of drilling rigs. The compact rig can be transported in one piece with the leader mounted and is consequently ready for operation on the job site in a short time.

The Liebherr crawler concrete pump is ideal for bored pile foundations to supply concrete to any foundation machine. This work involves deep drilling holes to prepare the ground for construction. When the drill is pulled out, these holes are filled with concrete. In the process, the concrete is conveyed down via a tube in the middle of the drill. The crawler concrete pump travels in parallel with the drilling rig to the various pile locations, with the concrete hose remaining connected to the drilling rig.

The crawler concrete pump and the drilling rig are connected by radio and can thus communicate and exchange information on the construction site.

The robust crawler concrete pump is available in two performance classes, the THS 110 D-K and the THS 140 D-K. Both types are equipped with powerful six-cylinder engines. The reliable pump units run very quietly and have minimal line surge on the foundation machine mast. The hydraulic system is particularly easy to maintain due to the open loop hydraulic circuit.

The design also facilitates the replacement of wearing parts, which greatly simplifies servicing.

The LR 1100.1 is the smallest crawler crane of the successful LR series. This crane is featured at the IFCEE demo site where operators showcase its many features. The crane is powered by an efficient 230 kW diesel engine with a max load capacity of 110 tons.

The LR 1100.1 crawler crane is equipped with a self assembly system with the option to remove/attach the side frames or the boom foot and crawlers can remain attached during transport, making tear-down and subsequent assembly quicker and easier even while weighing less than 100,000 lbs. The crane is equipped with a strong steel structure providing a longer service life and less wear for customers and a modern cab featuring improved airflow, optimized field of vision, and increased noise protection.

The LR 1100.1 also offers gradient travel aid for safe movement on uneven terrain through automatically calculating the center of gravity and ground pressure visualization by calculating the current ground pressure of the machine in real time providing a safer operation.

For more information, visit www.liebherr.com.

(Photo courtesy of Liebherr.)

The construction industry had 441,000 job openings on the last day of February, according to an Associated Builders and Contractors analysis of data from the U.S. Bureau of Labor Statistics’ Job Openings and Labor Turnover Survey.

JOLTS defines a job opening as any unfilled position for which an employer is actively recruiting. Industry job openings increased by 16,000 last month and are up by 32,000 from the same time last year.

“The number of open, unfilled construction positions stood at the second highest level on record at the end of February,” said ABC Chief Economist Anirban Basu. “This occurred despite the fact that contractors hired workers at the fastest rate since March 2023.

“While these dynamics are emblematic of ongoing industrywide labor shortages, contractors also laid workers off at an elevated rate throughout February,” said Basu. “This suggests a schism in which certain construction segments powered by federal funding and incentives continue to generate tremendous demand for labor, while privately financed segments had somewhat slower growth.

“Despite the moderating effect of high borrowing costs on projects reliant on private funding, fewer than 11 percent of contractors expect their staffing levels to decrease over the next six months, according to ABC’s Construction Confidence Index.”

For more information, visit abc.org/economics.

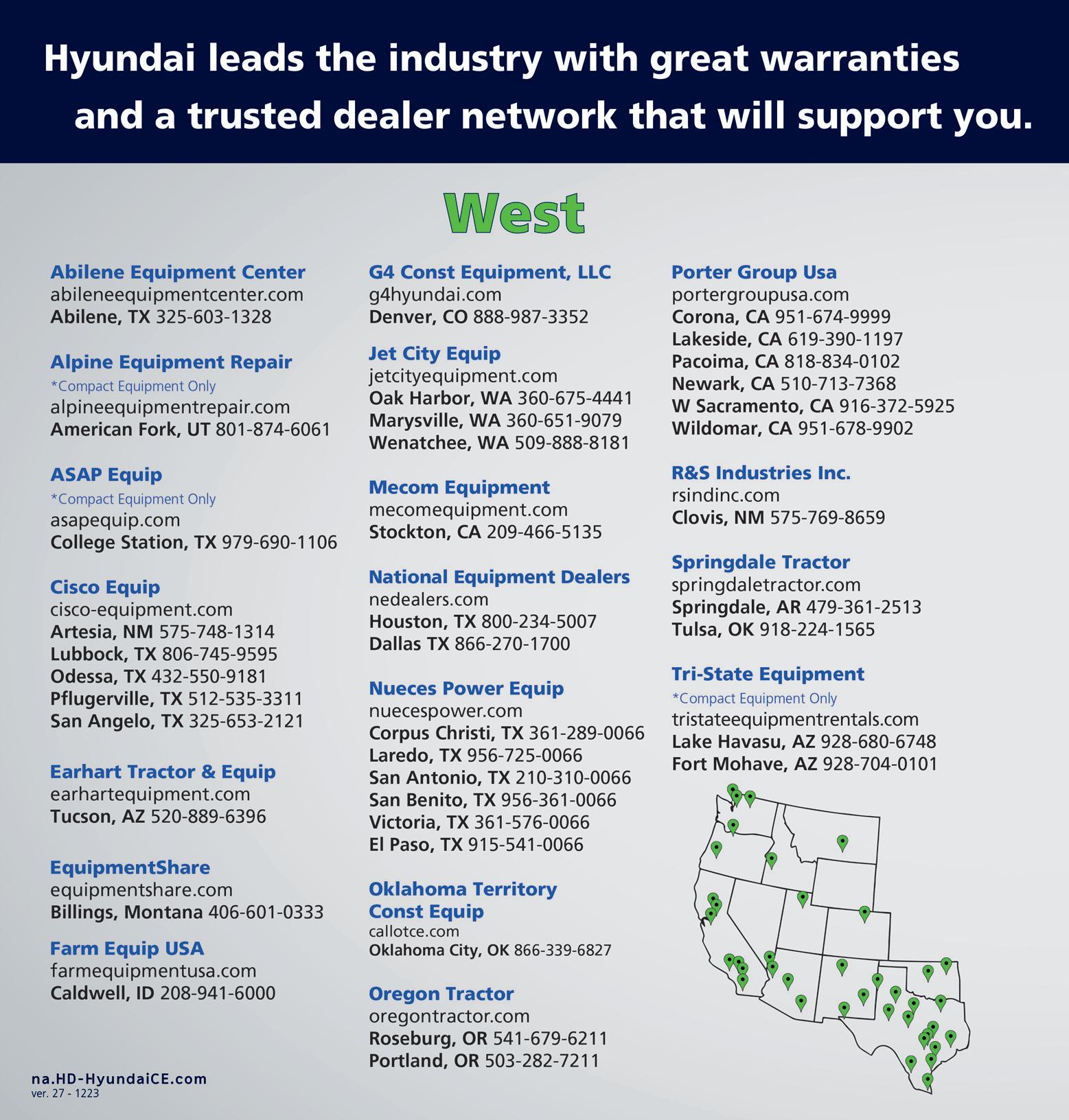

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s easy to own, easy to operate, skid steer and compact track loader.

Standard features include:

• LED front and rear work lights

• Auto leveling bucket

• Ride control

• Review camera

• Two speed travel

• AM/FM bluetooth radio

• Free Hi MATE telematics access for 5 years

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

Landscapers, contractors and outdoor power equipment dealers can develop their skills and take advantage of new trends impacting their industry due to expanded education and certification classes at Equip Exposition this Oct. 15-18 at the Kentucky Exposition Center (KEC).

Exploring new business opportunities is the focus for an entire track at the award-winning show, which drew more than 27,000 participants from all 50 states and 46 countries last year.

“Equip Expo’s mission is to help landscape, contractors and equipment dealers, advance their businesses,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute, which owns Equip Exposition. “Come to Louisville to see the latest and most innovative equipment and leave with a new perspective and greater knowledge that you can immediately apply.”

Or as Roy Thomas of McIntosh Grounds Maintenance said, “We always say Equip is going to sell you a mower. The education will teach you how to make money with that mower.”

Education and workshop sessions offered include such topics as:

• Recruiting and retaining employees,

• Scaling your business,

• Understanding key financial metrics to boost profitability,

• Developing crew leaders into better managers,

• Pesticide management and application,

• Irrigation repair, installation and design,

• Outdoor lighting design and installation,

• Outdoor pool design, installation and maintenance,

• Tree and shrub pruning and plant health,

• Working with private equity to expand — or sell — your business,

• New industry technology,

• and much more.

Spanish language workshops will be back by popular demand and will highlight developing your foreman as a leader among other topics.

Equip Expo’s new Certification Center will provide continuing education units (CEUs) for

• turfgrass cultural practices,

• turfgrass nutrient management,

• weed management in turfgrass,

• interpreting pesticide labels in the turfgrass industry,

• and more.

An exam for Certified Agricultural Irrigation Specialists (CAIS) will be offered, with reduced pricing for Irrigation Association members.

Landscaper-led events are back at Equip and continue to offer landscapers a platform to connect and grow together. Hear honest conversations between leading voices in the industry about marketing, hiring, sales and leadership at ENERGIZE, which takes place Oct. 17, at 2 p.m.

Also, the Morning Show at Expo, held Oct. 17, at 8 a.m., sponsored by Kohler Engines, will combine the largest gathering of in-industry professionals at Equip and guest interviews that help contractors find opportunities in their businesses. Both events are included with your Equip registration.

The Dealer Management track will help outdoor power equipment personnel think through whether it’s smart to open a new location, how to exceed sales goals, keeping departments working together smoothly, and delivering great customer experiences.

“If you’re looking to grow your business, this is the place to be,” sums up Mandy Muschler of Lochness LLC.

Contractor education partners at this year’s show include Landscape Management, the Association of Outdoor Lighting Professionals, the Irrigation Association, and the Pool and Hot Tub Association. Dealer education is provided by the Equipment and Engine Training Council and Bob Clements International. Attendees also have access to sessions produced by Hardscape North America and the Professional Grounds Management Society.

Some class registrations are an additional cost to registration for Equip Exposition, which is also why now is an excellent time to take advantage of spring promotional pricing of $25 for Equip Expo registration. This pricing ends on May 31. Register now before prices go up to $30 on June 1, 2024 during Early Bird registration.

For

The Bobcat Dealer Performance Review is not only used to help dealers compare their performance against their peers, but it also identifies the top performing dealers across Bobcat’s North American network, which is comprised of more than 300 dealer enterprises in the United States and Canada.

Bobcat Company has announced its 2024 Dealer Leadership Group. The 16 Bobcat dealerships honored this year are its highest-performing dealers in North America according to the company’s Dealer Performance Review.

“Every year, our dealer network keeps raising the bar,” said Brady Seavert, vice president of construction sales at Bobcat. “We’re thrilled to recognize these outstanding businesses for their dedication and impressive accomplishments across the board.”

The 2024 Bobcat Dealer Leadership Group includes:

• Bobcat of Brandon — Manitoba, Canada

• Bobcat of Brantford Inc. — Ontario, Canada

• Bobcat of Dallas — Texas

• Bobcat of Fort Wayne — Indiana

• Bobcat of Gwinner — North Dakota

• Bobcat of Lincoln — Nebraska

• Bobcat of New York City — New York

• Bobcat of the Rockies LLC — Colorado

• Bobcat of Vineland — New Jersey

• Bobcat of Westchester/Jim Reed’s Equipment — New York

• Curtis Lane Equipment — North Carolina

• Duron Equipment Inc. — Manitoba, Canada

• Ironhide Equipment Inc. — North Dakota

• Jordan Equipment — Maine

• North Jersey Bobcat — New Jersey

• White Star Machinery — Kansas

The Bobcat Dealer Performance Review is not only used to help dealers compare their performance against their peers, but it also identifies the top performing dealers across Bobcat’s North American network, which is comprised of 300plus dealer enterprises in the United States and Canada.

As members of the Dealer Leadership Group, representatives from these recognized dealerships will function as the “voice” for the dealer network and meet with Bobcat senior leadership throughout the year to provide insights and feedback. To recognize and celebrate the achievements of this select group, Bobcat also will honor members at a dealer incentive trip to Prague, Czech Republic, later this year.

Each year, Bobcat Company continues to grow its North American dealer network. As part of the Bobcat dealer partner program, dealerships are provided with development opportunities, ongoing training and educational and marketing resources to help position their customers, employees and businesses for long-term success.

“Our dealers play a crucial role in advancing the Bobcat brand,” Seavert continued. “Their commitment and teamwork are vital to our continued growth. We’re constantly inspired and thankful for the meaningful difference they bring to our customers every day.”

For more information, visit bobcat.com.

On March 23, 2024, at the NSSGA’s Gavel Exchange dinner held at the prestigious Country Music Hall of Fame and Museum in Nashville, Tenn., DSC Dredge’s Director of Domestic Dredge Sales, Charlie Johnson, passed the gavel to Mark Krause of McLanahan as the newly appointed chairman.

With a year of dedicated service as chair, Johnson gracefully handed over the reins of the NSSGA M&S Division to Mark Krause, who succeeds him as chairman. Krause, a seasoned professional with more than 40 years of experience in the aggregate industry, has spent the last decade contributing to the success of McLanahan.

“Mark couldn’t be a better choice for chair. His passion for the industry is like no other,” said Johnson. “I am honored to have served and will continue to support the committee”.

Expressing his gratitude and readiness for the new role, Krause remarked, “I am honored to be taking on this role and thankful to Charlie and the past M&S Chairs for their leadership.

“I look forward to working with NSSGA staff and M&S members to continue our service to the association and foster benefi-

M&S division past and present chairs 2024.

cial relationships across the industry.”

This transition marks another milestone for DSC Dredge (DSC) with Johnson being the second person from the company to be appointed chair to the NSSGA M&S Division. In 2011, DSC’s now Senior VP and Chief Technology Officer, Bill Wetta, was appointed chair.

“I am proud to see Mark Krause assume the chairmanship role at NSSGA’s M&S Division. His dedication and passion for the industry mirror the values all our past chairs have held. I am confident that under Mark’s

leadership, the division will continue to thrive, furthering our collective goals within the aggregate industry,” said Bill Wetta, senior VP and chief technology officer, DSC Dredge.

Alongside Krause’s appointment as chairman, Tom Suess of Komatsu has been named vice-chair of the M&S Division, further reinforcing the division’s leadership team.

For more information, visit www.dscdredge.com.

(Photos courtesy of DSG Dredge)

By Katherine Petrik CEG EDITORIAL ASSISTANT

Blake Blann likely never thought of himself as a pioneer, but recently, he became the proud owner of the first-ever Powerscreen Premiertrak 900 hybrid portable jaw crusher.

He started an excavating and landscape company in Putnam County in 1999. In 2021, a business opportunity presented itself — Blann purchased Putnam County Aggregate in Greencastle, Ind. The aggregate company was a great way to support his excavating and landscape company.

Putnam County Aggregate supplies a variety of sand, gravel and stone to local contractors, municipalities and businesses. It already has various Powerscreen crushers, screeners and conveyors in place for production.

Business has increased and so has the need to increase material production; this led to the purchase of the Powerscreen Premiertrak 900.

“As the business has grown the capacity has grown by purchasing the Powerscreen Premiertrak 900 hybrid portable jaw crusher and I am very pleased with the results,” said

Blann.

Blann consulted Connor Cobane, sales manager of Powerscreen Crushing and Screening in Indianapolis, Ind., for his advice and expertise. The two not only have had a working relationship since 2017, but also are friends. The partnership benefits both personally and professionally.

“We started working with Blake on a small scale, and as his business has grown, our relationship has grown too,” said Cobane.

Powerscreen Crushing and Screening, headquartered in Louisville, Ky., provides systems for aggregate, coal, sand, gravel and more. It is the official supplier of Powerscreen, Evoquip, MDS, Scania and other brands of screening and crushing equipment.

Cobane listened to Blann as he explained his current needs and came up with the perfect solution. He suggested the new Powerscreen Premiertrak 900 jaw crusher, and Blann would be the first customer to purchase the new machine.

The first Powerscreen Premiertrak 900 portable jaw crusher represents the innovation of crushing and screening equipment, portability, dual power performance and collaboration.

The Powerscreen Premiertrak 900 hybrid portable jaw crusher was transported to Putnam County Aggregates in three truckloads, and in total took less than a day to set up. The trucking and logistics were a bit extensive with such a massive piece of equipment.

Three engineers from Dungannon Co. Tyrone, Northern Ireland, Powerscreen’s corporate headquarters, were on hand to help with set up. This shows the company’s commitment to ensuring the equipment operates at maximum efficiency.

Powerscreen has supported Putnam County with local service support critical for the setup of equipment, training

on how to run the machine and dealer support, offering a wealth of knowledge, service and support that is strategic to ensure excellent service.

The capacity and dual power of diesel and electric, as well as the machine’s versatility will allow for production to double once everything is in place this spring, according to Powerscreen.

There was some speculation about the Powerscreen Premiertrak 900 hybrid portable jaw crusher being the first of its kind, but Blann has been very impressed with how well this machine has worked.

Putnam County Aggregate’s commitment to innovation and Powerscreen’s recognition of its potential as a valuable partner, marks this milestone of both companies showcasing their dedication to delivering solutions in the crushing and screening industry.

“We appreciate Blake’s continued business and look forward to a lifelong friendship and business relationship,” said Cobane.

Blann’s satisfaction with Power Screen’s products and services, along with their local support, highlights the success of their collaboration.

“From buying weed eaters to buying jaw crushers, Powerscreen Crushing and Screening has been the easiest to deal with in 20 years,” said Blann.

“When you deal with a man like Blake Blann and he gives you his word that he is going to do something, you better believe it will get done,” said Alan Coalter, president of Powerscreen Crushing and Screening. “The success of Putnam County Aggregate is down to the hard work and commitment from Blake and his team to grow his business. We are very thankful that Blake puts his trust in Powerscreen Crushing & Screening to be part of his growth.” CEG

The 2024 ISRI Convention and Expo takes place in Las Vegas from April 15 to 18, 2024.

Liebherr displays multiple machines at its booth, including the LH 40 M Industry material handler, L 550 XPower wheel loader and R 922 powerhand crawler excavator. Liebherr experts also are on-site at booth #B8 to answer any questions and provide assistance with equipment.

Liebherr specialized machines are strong, reliable and designed for high performance and maximum efficiency in industrial material handling. This is accomplished through production of its components. The demands of industrial material handling are taken into account during the development stage of these components, and well-prepared Liebherr specialized machines for any application, the manufacture said.

Handling scrap, steel and other metals is one of the toughest operational areas, whether loading or unloading HGVs, loading shredder conveyors or sorting out different kinds of metals; the Liebherr specialized machines are perfect machines for operationally effective scrap material handling.

The LH 40 M Industry is considered a top performer in its class. With the ERC System (energy recovery system), the maximum handling capacity is guaranteed while lowering the overall fuel consumption. This enables a more powerful machine with faster work cycles.

The attachment of the machine is available in a variety of versions and is always optimally matched to your respective application including scrap, waste and recycling.

Performance is extremely important in handling scrap materials. Whether sorting out mixed scrap material, loading and unloading HGVs and ships or loading shredders, shears and press plants, the Liebherr material handling machines are designed for the highest performance in a variety of work applications.

High lift capacities and fast work cycles are essential for efficient handling operations. The optimum interplay between the hydraulics and electronics guarantees powerful, fast movements during handling while working with precision on challenging sorting tasks.

The high-performance XPower wheel loaders are highly productive and can handle a wide range of materials including scrap.

The high-performance Liebherr XPower wheel loaders are highly productive and can handle a wide range of materials including scrap. With strong lift arm variants and application-specific attachments, they are versatile and universally deployable, the manufacturer said.

In addition to the different types of machines, you can choose between industrial and z-bar kinematics within the L 550 to L 566 XPower wheel loaders and the L 580 XPower. This means the right machine is always available for specific operations such as transporting and loading steel and metal scrap or loading the shredder systems. This increases the utilization of the machine and increases productivity by keeping job sites on time and within budget.

The R 922 crawler excavator showcases a completely updated design with characteristics of the new range of Liebherr “generation 8” machines. And in order to provide even greater comfort, better ergonomics and more enhanced performance.

The Powerhand VRS 200 (Vehicle Recovery System) enables you to get the maximum value out of your junk car before they are scrapped. Traditional manual methods of removing and separating high value materials from recycled vehicles are labor intensive and costly. Liebherr equips its R 922 excavators with a preparation kit that virtually makes the Powerhand System a plug and play hook up, the manufacturer said.

The benefits of using a R 922 from Liebherr is that the machine comes preprogrammed from the factory to control the unit and the clamp functions are controlled by the joystick and not foot pedals, making it easier for the operator to control.

Liebherr offers a wide range of crawler excavators with operating weights from 50,930 lbs. to 198,640 lbs. Each is designed with one goal in mind, to meet the demands and specifications of customers in terms of performance, reliability and efficiency, as well as safety and comfort.

For more information, visit www.liebherr.com.

Eric Teague

McCloskey International announced the appointment of Eric Teague as sales director – Americas, Oceania & Pacific. Teague is responsible for sales activities in Canada, the United States, and Central & South America, as well countries in the Oceania & Pacific region including Australia and New Zealand.

Teague joins McCloskey International with 30-years’ experience in the North American heavy construction equipment sector. Throughout his career he had held roles across all facets of the business including sales, rentals, distribution, parts, and service — on both the OEM and distributor sides, providing a depth of knowledge that will serve as a significant asset to McCloskey and its’ business partners.

“On behalf of the entire McCloskey team, I’m delighted to extend a warm welcome to Eric Teague,” said Anthony Bouvie, VP sales and marketing — MPP Global. “Eric is bringing an extensive wealth of knowledge, leadership skills and expertise within the capital goods sector that will enrich our team dynamics. He will help us to become even more customer centric to drive further the collective success of our customers, distributors and ours.”

In his role, Teague will lead the regional sales teams, sales development and dealer growth for McCloskey International.

“My passion is helping grow strong distribution channels and building a brand. It is very exciting to partner up with a company that is considered a pioneer and market leader in the industry,” said Teague. “I look forward to working with the McCloskey International team to further strengthen their distributor network and create a world class experience for our customers.”

Teague will be based out of Atlanta, Ga., and can be reach at 678/416-8244 or eteague@mpp-global.com. The appointment became effective March 25, 2024.

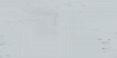

Implementing a magnetic separation process includes several steps, from flowsheet selection to ramp-up and ensuring planned capacity. Alongside financial aspects, miners must also evaluate executional and operational factors when selecting the most feasible solution.

To facilitate the selection, Metso is now introducing modular magnetic separation plant units designed for high recovery and simplified operation.

“As the industry leader in mining process technology and modularity, we are excited to launch the magnetic separation plant units. Besides easy installation and maintenance, the scalable units have been designed to provide unrivaled selectivity, resulting in high recovery of fine and ultrafine particles,” siad Alex Lagerstedt, vice president, plant solutions at Metso.

Compared to a traditional delivery, the modular plant units result in the earliest time-to-volume. Due to maximized prefabrication in a controlled workshop environment and minimized site work, installation is safer, faster and of better quality, the manufacturer said.

The magnetic separation plant units feature a flexible scope to meet the needs of the end customer or Engineering, Procurement and Construction Management (EPCM). Delivery includes proven technology for the entire magnetic separation circuit with in-house testing for equipment sizing and flowsheet design, and

it also can include automation, installation and commissioning advisory, training, maintenance and service.

Metso’s advanced magnetic separation equipment portfolio consists of SLon Vertically Pulsating High Gradient Magnetic Separators (VPHGMS), Metso High Gradient Magnetic Separators (HGMS), and/or dry and wet Low Intensity Magnetic Separators (LIMS). Additionally, the plant units can be equipped with OKTOP feed tanks, slurry pumps, hoses and valves, and coupled with process control systems and various ancillary products and sampling systems.

“Metso’s high gradient magnetic separator portfolio features a wide range of processing options for many particle sizes and applications, ranging from iron ore concentrates, rare earth ores, battery and industrial minerals to tailings recovery. Combining these magnetic separators into plant units results in flexible and efficient flowsheets,” said Peter Jansson, product manager, magnetic & physical separation at Metso. For the magnetic separation plant units, Metso also can provide an integrated service offering through its global network. The scope ranges from maintenance, modernizations & retrofits, process optimization to spares and wears, training and Life Cycle Services.

The magnetic separation plant units are Metso’s sixth complete plant unit launch for concentrator plants. The previous launches include stirred mill and horizontal mill plant units, flotation, thickening and filtration plant units.

For more information, visit metso.com.

Tech Specs

• 12’x 5’ Trommel Screen

• Stockpiles to 14ft

• Variable Speed Feeder

• Diesel/Hydraulic Drive System

Ship Anywhere in the USA

Units in Stock Today

Best Bang for your Buck

Compact and Productive

Tow with a Dump truck

High Production screener for Topsoil, Mulch, Compost, Recycling and more

Keep the screening revenue where it belongs…in your pocket

The outdoor demo yard at Equip Exposition, the international landscape, outdoor living and equipment exposition, will be abuzz with activity Oct. 16-18, 2024, at the Kentucky Exposition Center as thousands of landscapers, contractors and dealers try out the latest mowers, UTVs, compact tractors, chainsaws, leaf blowers, trenchers, skid steers, backhoes, and the other equipment that helps get jobs done efficiently and profitably.

“Here’s the dirt on the outdoor demo yard: it’s the only place with 30 acres dedicated to giving landscapers, dealers and contractors the opportunity to dig, cut, trim, saw, drive and run equipment through its paces,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns the show.

“Equip is the best place to see and get a hands-on experience with the equipment of the future as the industry changes to keep up with regulations, customer demand and new technology.”

The outdoor demo yard will be open:

• Wednesday, Oct. 16 from 12 p.m. to 5 p.m.

• Thursday, Oct. 17 from 9 a.m. to 5 p.m.

• Friday, Oct. 18 from 9 a.m. to 1 p.m.

Outdoor power equipment is an important investment for a landscaper, so being able to “try before you buy” is savvy.

“Equip helps our attendees make smart business decisions. After all, a landscaper and their staff will spend hours operating that equipment. If they need to carry it, the weight and feel have to be right. If they need to drive it, the maneuverability and features are important. Equip is the only place where you can get your hands on and operate so many different types of equipment all in one place, Kiser said.

As one of the largest annual trade shows in the country, Equip Expo drew a record-breaking 27,000 attendees last year and will again offer 1,000-plus exhibits that cover 1.1 million square feet of exhibit space. The outdoor demo yard makes Equip one of the most unique trade shows.

“This is where the manufacturers announce and show off new outdoor power equipment. From the toughest UTVs, to battery or electric equipment, to the fastest robotic mowers, it’s all at Equip,” said Kiser.

The popular UTV test track is returning, too. Attendees can drive and compare the latest vehicles while navigating curves, hills, rocks and bumps. Attendees age 16 or older with a valid driver’s license will be able to drive alongside a representative of the manufacturer who can answer questions about load capacity, features, price and more.

For more information, visit www.EquipExposition.com.

PCL Construction Enterprises Inc. announced the appointment of several executives to guide its operations throughout the country.

This strategic move comes on the heels of a successful year for the company, marked by record new work totals for PCL’s U.S. Buildings and Civil divisions.

“With the appointment of key executives in target markets across the country, we are setting the stage for an ambitious phase of growth at PCL,” said Deron Brown, PCL president and chief operating officer, U.S. operations. “This team’s expertise will be crucial in propelling our operations to new heights.”

Florida Region

• Rick Goldman — senior vice president, Florida Region. A seasoned veteran of PCL since 1997, Goldman will oversee operations throughout Florida and drive strategic expansion across the state.

• Chris Ritter — district manager, Orlando Buildings. With a track record of spearheading major projects, including

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830

Mojave, CA 661-824-2319

Perris, CA 909-355-3600

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050

Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

work with notable entertainment clients, Ritter now leads the Orlando office to propel growth in Florida.

• Ryan Schmidt — vice president and district manager, Rocky Mountain Region. With a tenure of 26 years at PCL, Schmidt will oversee operations throughout Colorado, focusing on strategic growth throughout the Rocky Mountain Region.

• Jeff Miller — senior construction manager, Denver Buildings. From his start as a PCL intern in 1992, Miller serves as a senior construction manager for projects in the Denver area.

Midwest Region

• Robert Blankmeyer — operations manager, Midwest Region. A long-time PCL employee who started his career as an intern in 1996, Blankmeyer will manage operations in for the both the Minneapolis and North Dakota offices. California Region

• Steve Whitman — operations manager, California Buildings. Over his 20-year tenure at PCL advancing through various roles, Whitman will oversee operations of PCL’s Orange County and San Diego offices.

• Ankur Talwar — district manager, civil infrastructure, West Region. A 30year veteran at PCL whose journey through various roles throughout the United States and Canada showcases his expertise in Civil Infrastructure and adaptability within the industry.

• Brandon Morlet — area manager, civil infrastructure, West Coast Region. With two decades of infrastructure expertise leading major projects and designbuild pursuits, Morlet will be instrumental in leading the West Coast Civil Infrastructure team. For more information, visit PCL.com.

www.powermotivecorp.com

Corporate Office

5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

TX 214-371-7777 Ft. Worth, TX 817-378-0600 Lubbock, TX 806-745-2112 Odessa, TX 432-333-7000 Waco, TX 254-261-1370

www.clairemontequipment.com

2449 Manana Drive Dallas, TX 75220 800-594-BANE (2263) 10505 North Freeway Fort Worth, TX 76177 800-601-BANE (2263)

3402 E. NE Loop 323 Tyler, TX 75708 800-594-2200

Takeuchi recently announced its Dealer of the Year, Dealer Salesperson of the Year and the recipients of its 2023 Dealer 360° awards at the company’s 2024 Dealer Summit in San Antonio.

These awards recognize Takeuchi dealers across the United States and Canada for excellence in sales performance, facilities, training, accounts receivables, marketing/parts and service.

“Our Dealer 360° awards program outlines a unified standard of operation that promotes consistency among Takeuchi dealers,” said Jeff Stewart, president of Takeuchi-US. “We obviously want our dealers to be successful, and it’s our job to support them and provide the tools to make that possible.”

For their outstanding achievements in all program categories, the top five Takeuchi dealers for 2023 will head to Japan for a special visit to Takeuchi’s global headquarters.

• Parman Tractor & Equipment (Tennessee)

• Bennett Equipment & Supply (Georgia and South Carolina)

• Brandeis Machinery (Indiana and Kentucky)

• Luby Equipment (Illinois, Missouri and West Virginia)

• Power Equipment (Tennessee & Arkansas)

Parman Tractor & Equipment of Nashville, Tenn., earned the Takeuchi Dealer of the Year Award for 2023. The dealership focuses on providing top-notch service and machine expertise, making them a trusted partner customers return to again and again for their equipment needs.

“The team at Parman Tractor always goes the extra mile for their customers,” said Shay Klusmeyer, Western division sales manager of Takeuchi-US. “They embody the standards that we’ve set forth for Takeuchi dealers, and they’re always seeking continuous improvement. We’re proud to have Parman Tractor carry the Takeuchi equipment line.”

The following dealers also successfully met or exceeded the Dealer 360° criteria standards by Dec. 31, 2023:

• Alta Equipment Company (Florida)

• Central Illinois AG (Illinois)

• Chadwick BaRoss (Massachusetts, Rhode Island and Connecticut)

• Ditch Witch of South Louisiana (Louisiana)

• Dittamore Implement (Illinois)

• Feenaughty Machinery Company (Oregon)

• Hawkins-Graves (Virginia)

• Hayden Machinery (Missouri)

• Landmark Equipment (Texas)

• MasCo Equipment (Texas)

(L-R) are Clay Eubanks, Takeuchi global director of sales; Eddie Bennett, Bennett Equipment & Supply; Chad Dodson, Power Equipment, Tennessee & Arkansas; Colin Hockenberger, Parman Tractor & Equipment; Toshiya Takeuchi, Takeuchi president; Mike Paradis, Brandeis Machinery; Steve Luby, Luby Equipment; and Jeff Stewart, Takeuchi U.S. president.

• McClung-Logan Equipment Company (Virginia)

• Power Motive Corporation (Colorado)

• Road Builders Machinery & Supply (Nebraska and Missouri)

• TEC Equipment Rental (South Carolina)

“We’re incredibly pleased with the performance of our growing dealer network over this past year,” Stewart said. “Their dedication and commitment to excellence have helped Takeuchi continue to increase its market share in North America. We thank them for an outstanding 2023, and we look forward to an even better year in 2024.”

For an unprecedented sixth time, Takeuchi-US recognized Bill Smith of Cobb County Tractor in Marietta, Ga., as its topperforming dealer salesperson in North America. Smith took home top honors after ranking number one in retail sales for North America.

“Bill continues to challenge himself to be our top dealer salesperson, year after year,” said John Vranches, Eastern division sales manager of Takeuchi-US. “His customers say he has an uncanny way of knowing exactly what equipment they need to tackle their projects. He’s always able to identify the best possible solution, and that kind of experience isn’t easy to find. We congratulate Bill on yet another successful year, and we challenge him to outdo himself yet again in 2024.”

For more information, visit takeuchi-us.com.

(All photos courtesy of Takeuchi)

(L-R) are Eric Wenzel, Takeuchi Southeast business manager; John Vranches, Takeuchi East Division sales manager; Bill Smith, Cobb County Tractor; Jeff Stewart, Takeuchi U.S. president; and Henry Lawson, Takeuchi director of sales N.A.

Weiler has appointed Joel Weiler as engineering manager of the Knoxville, Iowa-based manufacturer and elevated him to the senior management team.

Weiler joined the company in August of 2019 as safety manager. Weiler’s efforts reduced the company’s safety incident rate by over 50 percent. He also was tasked with managing the company’s response to the COVID-19 pandemic.

In November of 2020 Weiler assumed the role of HR operations manager and held that position through the end of 2022, a challenging stretch of time for the manufacturing job market. While maintaining oversight of human resources, he was responsible for the integration of a wire harness assembly facility in January 2022 and subsequent in-sourcing of 85 percent of the wire harnesses used on Weiler equipment.

Upon the December 2022 completion of the company’s latest 125,000 sq. ft. building addition, he transitioned into the role of production manager and led the in-sourcing of nearly 100 percent of Weiler’s flat steel cutting.

Starting March 4, 2024, Weiler assumed the role of engineering manager and is responsible for managing the engineering, service and technical publication departments, in addition to human resources and the company’s wire harness assembly department. As a member of senior management team, he will be involved in strategic planning and setting organizational priorities to maintain the company’s longstanding focus on engineered innovation, meeting customer expectations, and being an employer of choice in the area. He also holds seats on the boards of directors for Weiler, Weiler Forestry, and the Weiler Foundation for charitable giving.

Weiler is the son of Pat Weiler, owner and founder of Weiler, and is one of three members of the second generation of the Weiler family to return to Central Iowa to join the business.

“Joel has done a terrific job in his various roles with the company,” said Pat Weiler. “His passion for the customer will now be turned toward managing development of the Weiler product line. I look forward to seeing his impact on Weiler.”

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000

Lufkin • 936-639-5551

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

Named for their automatic variable-speed technology, Montabert variable-speed breakers are built for use in the harshest conditions, as they sense changes in material hardness and adjust the breaker’s impact energy and striking rate. The result is increased productivity, based on the application, and reduced blank firing.

Montabert’s variable-speed technology also reduces unnecessary harmful energy from transferring to the carrier and breaker, helping to prevent wear on parts and components. These breakers ideally work in tandem with Tramac boom systems to productively break oversize rocks prior to primary crushing.

Premium Heavy Breakers: Montabert premium heavy breakers are designed for all types of carriers, from 18 to 120 tons, and are ideal for a variety of applications, including quarrying, mining, excavation and demolition. In addition to its automatic variable-speed technology, the premium heavy breaker features include:

• Energy chamber: Acts as a hydraulic shock absorber and reduces pressure variations in the hydraulic circuits to provide consistent energy to the breaker — reducing pressure spikes and keeping the charge constant, with no periodic maintenance required.

• Progressive start system: Prevents slipping by creating a small recess in the material before full power is applied.

• Blank-fire protection system: Reduces damage on all wear parts by providing a cushion of oil that reduces the energy.

• Automatic lubrication system: Assures the breaker is constantly lubricated to improve life span on wear parts and components.

• Automatic pressure regulator: Ensures hydraulic breaker operation pressure, regardless of changes in outdoor temperature, delivering maximum performance across a large range of carriers.

• Redesigned cradle/housing: Specific to the V32 breaker, built for carriers from 18 to 30 tons.

Montabert’s 2-Speed Line of heavy hydraulic breakers is designed for use on large excavators from 20 to 80 tons in a variety of applications, from demolition to quarrying to excavating. The 2-Speed Line has many of the best features found in the premium line, but with a simpler design:

• Design simplifies maintenance, lowering costs as it also increases productivity.

• Includes two-speed automatic regulation, with unique detection system for the first stroke. This system offers high energy per blow on hard ground, or high frequency on softer ground.

• Increases carrier versatility with acceptable back pressure of up to 435 psi.

Tramac offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360 degrees of swing arc and 1,500 to 13,000 ft lb of hammer impact.

Tramac offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360 degrees of swing arc and 1,500 to 13,000 ft. lb. of hammer impact. Boom weights range from 5,850 to 55,000 lb. and accommodate hammer weights from 1,098 to 9,920 lbs.

Standard across its entire boom line, rugged cylinders of high-strength steel and welded construction are built from chrome-plated, high-tensile steel rods. Heavy-duty, oversize pins are fitted with replaceable aluminum bronze bushings. Self-aligning spherical bushings on the cylinder rod and barrel end ensure long equipment life.

An extremely strong, low-profile base of shaped plate steel attaches easily to any platform foundation. Tramac also offers a number of boom, HPU, hammer, and control options, as well as custom design services.

For more information, visit montabert.com or montabertusa.com. (Photos

of Montabert)

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087 MCALESTER, OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

Ignite Attachments, a manufacturer of compact equipment attachments, has introducted The Fit Finder tool, a digital tool that allows customers to find the attachments and implements that match compact equipment machine specifications for existing machines with the click of a button.

Ignite Attachments was the first OEM attachment manufacturer to develop this type of reliable online tool, ensuring customer confidence and satisfaction even in a new digital landscape. With more than 10,000 data points from across all major compact equipment brands, the Fit Finder remains the most robust and user-friendly tool of its kind in the attachment and implement industry,

according to the manufacturer.

“Online shopping is a staple of the modern economy,” said Trisha Pearson, business director of Ignite Attachments. “However, making large purchases online, like attachments, can still be nerve-wracking for many. When we set out to disrupt a stagnant industry, we knew we’d need to

develop a tool that takes the guesswork out of attachment ordering and allows customers to shop with confidence. The Fit Finder provides the convenience of online shopping, available when and where it works best for customers, with a precise fit for peace of mind.”

For more information, visit www.igniteattachments.com.

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

Global OEM Wacker Neuson Group has strengthened its ties with Trackunit by agreeing to extend its partnership agreement for another five years.

The deal is effectively a renewal of a previous five-year agreement but deepens the relationship between the manufacturer of compact and light equipment products for construction and agriculture and global technology platform player Trackunit.

“We’re excited to be strengthening our relationship with Trackunit by another five years. Trackunit is a key partner for us when it comes to delivering a customer benefit oriented platform for technology and data management,” said Wacker Neuson Group CSO Alexander Greschner. “With five years already in the bank, we’ve developed a strong bond. Trackunit delivers a future-oriented and flexible solution that we can easily integrate into our digital platforms.”

As part of the extension, Wacker Neuson Group, with its North

American headquarters in Menomonee Falls, Wis., and is part of the Works With Trackunit program, will be able to use Trackunit’s Kin for the first time. Kin, which was launched on the market in 2021, connects nonpowered equipment and attachments to the ecosystem and approximately 15,000 new items will become part of Trackunit’s Bluetooth network in the first year as part of the deal.

In addition, Wacker Neuson also will be able to onboard more than 50,000 Battery One units to the network.

“This delivers a Bluetoothenabled solution that will greatly expand our connectivity and help us to increase efficiency through better insight into idling and other downtime factors,” said Alexander Greschner. “We are already selling a lot of battery-powered equipment, and this will help us keep track on those smaller pieces of equipment and power units. This will have a direct impact on the health and lifecycle of our

machines and batteries, directly benefitting the customer,” he said.

“It will also play a part in helping us deliver on our long-term sustainability and emissions reporting goals.”

It is a significant development for Trackunit too which has steadily consolidated its position at the heart of the connectivity ecosystem over the last five years.

“We’re really excited about strengthening our partnership with the Wacker Neuson Group as we believe collaboration is key to building the network and enabling the development of the ecosystem,” said Trackunit CEO Soeren Brogaard.

“The more transparent the industry is and the more we can share data, the more we can effect change on downtime. This in time will enable the industry to restore its former reputation as a force for progress as we find better, cleaner ways of doing business.”

About Trackunit

Global IoT services provider Trackunit connects construction through one platform to create a living, evolving ecosystem that delivers data and insights to the off-highway sector. With 2 million assets and counting connected, it uses technology to eliminate downtime, improve safety and help customers improve the bottom line in a sustainable, costeffective way.

GENERATION from page 1

Vocational training and apprenticeship programs in the skilled craft trades are filling up with younger people launching their careers in construction. The high cost of a four-year degree has something to do with it. But for many Gen Z workers, the job resiliency offered by the industry is appealing.

As a result, enrollment in vocational programs rose 16 percent in 2023, reported the National Student Clearinghouse. And the median age of workers in many specialty trades, including carpentry and HVAC maintenance, fell from the mid-40s to the high 30s.

That makes Robb Sommerfeld smile. Cofounder of the National Center for Craftsmanship, he likes that more students are attracted to this career field.

“We’re finally seeing a more than subtle change within our society,” said Sommerfeld, whose organization provides vocational training at high schools.

For many years, young people have been “nudged” away from construction careers for various reasons, starting with parental guidance. Seeking to understand the stigmas, Sam Pillar had the company Jobber survey Gen Z workers about their impression of a career in construction.

He said many people think less of blue collar work. “This misguided stigma is ridiculous and puts the future of our homes and our economy at risk,” he said.

After surveying 1,000 people aged 18 to 20 for its Blue-Collar Report, Jobber found that parents play a large role in perpetuating this stigma. These parents “are heavily influencing their children to attend a traditional four-year college,” Pillar said.

The good news is that there are signs that what high-school graduates envision for their careers differs from the ideals of their parents.

In fact, 75 percent of Jobber survey respondents said they are interested in exploring vocational schools that offer paid, on-the-job training.

There’s a lack of understanding among young people about the earning potential of certain trades. The survey majority didn’t know that tree maintenance, landscaping, residential cleaning and plumbing businesses can earn over $1 million per year.

Interestingly, nearly two-thirds of respondents want to start a business at some point, and 11 percent already have.

“Whether they realize it, home service businesses provide the entrepreneurial opportunities that Gen Z is looking for,” said Pillar.

He also found that Gen Z is aware of AI’s

The job resiliency offered by a construction career, along with strong earning potential, is drawing Gen Z-ers to fill the specialty contractor workforce.

potential to automate a range of jobs. Job security was identified as the most important factor for selecting a career.

“It seems that concerns about taking on and managing student debt are impacting their career decisions,” said Pillar. “When looking at AI, 56 percent of respondents believe that ‘blue-collar’ jobs have more job security than ‘white-collar’ desk jobs.”

For years the construction industry has tried any number of plays to tackle a critical labor void. The tide may be turning. Fouryear colleges were the attraction in the early 2000s when the recession forced Millennials to wait out the job market and take on the burden of student debt.

But with the current hot jobs market, many younger workers are calculating the odds in favor of stronger career fields.

Construction is at the top of the list. In fact, a New American survey found that 54 percent of Gen Z-ers believe a high-school diploma is sufficient to gain a well-paying stable job, reported Axios.

And 46 percent of parents said they’d prefer their kids to pursue alternatives to fouryear college, found a Gallup study.

Construction trade careers are seen as more resilient to the rise of AI than white collar alternatives, said Axios.

Nick Largura of Superior Construction told the news service that the pool of 18- to 25-year-old workers is growing.

“That is the pivotal moment when people are really trying to figure out what they want to do,” he said. “And if you can show them a promising future in that time, you can really make a difference.”

Largura makes two points: Construction, like many other trades, is an industry that isn’t going anywhere despite fears that AI will wipe out jobs across sectors.

Also, “you get to see a physical product at the end of the day as a result of your work” in the construction field.

Sommerfeld of the National Center for

Craftsmanship believes with so many people retiring, it’s hard to say if the Gen Z trend will continue growing.

“It’s still a matter of educating our country that, ‘Hey, these jobs are out there,’” he said.

Largura would agree: “I by no means think the work is done, but the momentum is there.”

Samantha DeAlmeida of the ABC of New Jersey also is a firm believer that Gen Z is playing a big part in the future of the construction industry.

In an article for roi-nj.com, she said the picture for filling the 441,000 job openings tracked by the BLS this spring is a bright one.

“The construction industry is one of the biggest, fastest-growing industries in the country,” said DeAlmeida. “And it’s continuing to see an unprecedented demand for skilled employees.”

A recent article in the Wall Street Journal reported that the number of carpenters grew over the past decade, and their median age fell from 42.2 to 40.9.

Likewise for electricians. The ranks of that specialty trade grew by 229,000 workers, while the median age fell by 2.9 years.

The data also shows other skilled trade careers, including plumbing and HVAC occupations, are also trending younger, said DeAlmeida.

“Here in New Jersey, enrollment in vocational-technical schools has grown by about 23 percent over the past two decades,” she said.

And nationally, the ranks of students studying construction trades also rose 23 percent, according to the Wall Street Journal.

She believes skilled trade jobs are a better fit for those who enjoy working with their hands, are entrepreneurial and don’t want the four-year wait to start.

Even better, the demand for trade work continues to grow at unprecedented levels.

“Right now, there is a strong demand for high-paying jobs in infrastructure projects, the construction industry and real estate,” said DeAlmeida.

To capitalize on that demand, the ABC of New Jersey launched its Apprenticeship Training Program three years ago.

“We saw the critical need to educate more skilled trade workers that was not being met in New Jersey,” said DeAlmeida.

ABC-NJ’s apprenticeship program provides paid, on-the-job training and classroom-based theoretical education in 15 skilled craft trades, she said.

Working with local schools and businesses, the association provides pre-apprenticeship construction readiness training, or CORE.

The NJ ABC also can help prospective apprentices get hired with one of more than 1,300 member companies.

And upon successful completion, craft workers are eligible to be recognized at the journey level in their trade and receive a certificate of completion.

“Trade work provides high salaries, fulfilling careers and the opportunity to run one’s own business,” said DeAlmeida. “We need to have more conversations with our high-school students to show them the different ways to enter this promising field of trade work.”

The ABC of New Jersey isn’t the only organization trying to attract the Gen-Z worker to the construction industry. On a national level, NCCER also is at work.

The National Center for Construction Education and Research was named a 2023 DeWalt trades grant recipient for career and technical education (CTE) efforts.

Recognized for its High School Builder Program, NCCER was presented with a DeWalt Grow the Trades grant.

The grant program aims to help close the skilled labor gap by supporting nonprofit organizations that are skilling, reskilling and upskilling tradespeople.

According to DeWalt the program awards funding and tool donations annually as part of a larger $30 million commitment over five years.

NCCER was one of 70 organizations projected to skill and reskill more than 55,000 people in 2024.

“CTE programs provide a pathway for students to learn skills that will make them immediately employable,” said Melissa Perkins, NCCER director of philanthropy and partnerships.

NCCER’s High School Builder Program brings CTE education to new communities where there are exponential growth opportunities, she said.

With generous partners like DeWalt, “we will help close the skilled labor gap and change lives…through high-paying and indemand careers.”

The High School Builder Program is growing the national talent pipeline and making a local impact, according to the tool manufacturer.

With an estimated 20 students per school and annual growth, this initiative is expected to add 10,000 students into the talent pipeline in its first year alone.

“DeWalt is immensely proud to support NCCER,” said Frank Mannarino, president, Power Tools Group, Stanley Black & Decker. “Funding educational programs and non-profits like NCCER connects more people to training, resources and opportunities that will lead to successful careers in the trades.” CEG

“Working around the clock, upper-level management and field crews joined forces to clear debris, set up falsework and ensure the project's safety,” the contractor added. “Despite the congested and hazardous environment, we completed the task without incident. [This] allowed us to shrink the initial 5-week repair estimate to an astonishing six days, meeting our goal of reopening the critical freeway.”

Eric Menjivar of Caltrans District 7 (Los Angeles and Ventura counties) highlighted the current situation and progress of the repair initiatives.

The construction site is a flurry of activity as individual columns (nearly 20 ft. tall) are being repaired, with many surrounded by wood framing that has been erected to provide platforms for workers to access them at various levels. The large construction site provides ample space to store materials and move equipment to various locations.

The repair of columns with moderate damage (57 columns) has been completed and repair of severely damaged columns (eight columns) is in progress. Once the column repairs are done, work on the superstructure can commence.

The damaged structures have been repaired with higher strength concrete than the original concrete structure —50 to 100 psi higher than original concrete. Existing columns and pillars are not being replaced.

“Caltrans performed the tests with concrete and steel samples from the various damaged locations right after the fire damage,” said Menjivar. “The test result confirmed that the damaged columns need to be repaired but do not require replacement. The damaged portion of concrete and rebar from columns was removed and replaced with new material, and columns were externally strengthened by steel column casings.”

Equipment being used includes Skyjack SJ45 T telescopic booms, Doosan portable power air compressors to help with welding pipes and other elements, various types of trucks and loaders. and other key pieces to help with the work. Pick-up trucks have proven themselves on this job, moving construction workers and their equipment to and fro within the work site.