FEBRUARY 28 & MARCH 1

FEBRUARY 28 & MARCH 1

1:30 p.m.

Southern Cotton Ginners Association and Foundation Annual Meetings, Venetian Room.

Presiding: Jeff Lindsey, Southern Cotton Ginners Association President Welcome and National Update: Larry Black, National Cotton Ginners Association President Trade Impacts on US Commodities: BRICS, Outlook and Marketing Management, Ryan Loy, PhD, University of Arkansas

Weather Prediction Technology for Agriculture and Weather Outlook for 2025. John Baranick, Ag Meteorologist, DTN Integrating Gin Technology for the Farmer and Ginner. Jonathan McBride, Bogue Chitto Gin, Macon, Miss., and Rich Lindsey, Jr., Cherokee Gin and Cotton Company, Centre, Ala.

Ag Achievement Award

Lewis Rone, Rone Farms, Portageville, Mo.

Christopher Daubert, Vice-Chancellor & Dean of the College of Agriculture, Food & Natural Resources, University of Missouri

Cotton Gin Service Award

Mitch Billigsly, B & B Lint Cleaners Service - In memorium and Henry Giompoletti, Giompoletti Gin Repair

6:30 p.m. Honors Reception, Peabody Forest Ballroom, — Sponsored by Memphis Tourism. All Association members welcome (Tickets for reception and banquet must be purchased in advance.)

7:15 p.m.

7:30 a.m.

Honors Banquet, Peabody Continental Ballroom. Sponsored by Bayer, Martin Specialty Products and Signode. All Association members welcome. (Tickets are required.)

I Honoring Ginner of the Year, Allen Espey, Epsey Gin Co., McLemoresville, Tenn.

I SCGA Memorial Scholarship Honoree, John Edmonston, Edmonston Gin Co., Hornersville, Mo.

I The A.L. Vandergriff Cotton Pioneer Award: U.S. Senator John Boozman, (Arkansas)

Shuttle bus service from Peabody, to the Renasant Convention Center begins.

255 North Main Street

8:30 a.m. AG Outlook Meeting, Cannon Center Stage

lPresiding: Jeff Lindsey, Southern Cotton Ginners Association President lCotton Issues: Patrick Johnson, Jr., Chairman National Cotton Council

lOutlook for U.S. and World Cotton; Joe Nicosia, Trading Operations Officer, and head of the Cotton Platform for Louis Dreyfus Company, Executive Vice President of Louis Dreyfus Company LLC., Cordova, Tenn.

9:00 a.m.

11:00 a.m.

MID-SOUTH FARM & GIN SHOW OPENS

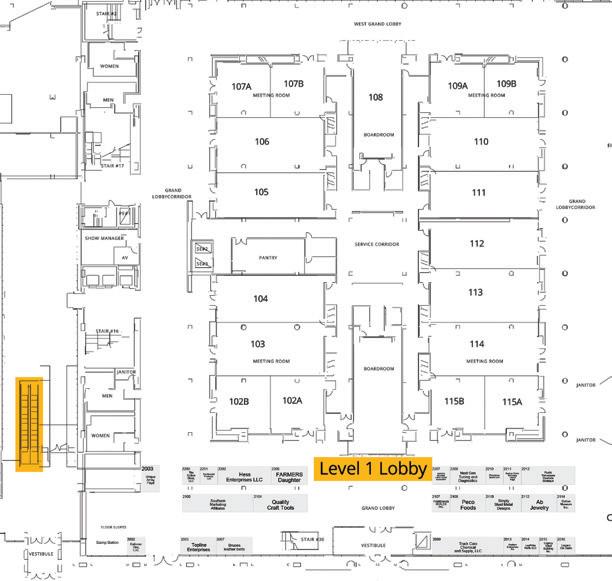

Mid-South Agricultural Trade Conference, Room 115 Level 1 Lobby

The 2025 Mid-South Agricultural Trade Conference seeks to inform farmers, agribusinesses, and agricultural leaders in Tennessee and the Midsouth about the role and significance of international trade on local agricultural production, global markets and economies, as well as increased awareness of agricultural exporting tools and resources. Experts on trade as well as State and National commodity leaders will provide context on today’s changing trade landscape.

2:00 p.m. Mid-South NAMA Student Competition, Room 102A Level 1 Lobby

2:30 p.m.

Integrating Gin Technology for the Farmer & Ginner, Room 109 Level 1

Hear discussions, challenges and success stories for ginners, farmers, ag equipment dealers and others

3:00 p.m. MSU Alumni Reception, Room 103 Level 1

5:00 p.m. MID-SOUTH FARM & GIN SHOW CLOSES

7:30 a.m. Shuttle bus service from Peabody to the Renasant Convention Center begins.

255 North Main Street

8:30 a.m. AG Outlook Meeting, Cannon Center Stage, Sponsored by Bayer

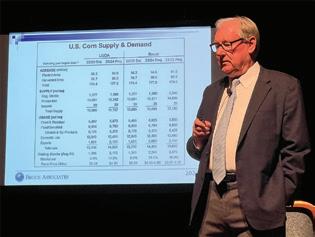

lPresiding: Jeff Lindsey, Southern Cotton Ginners Association President lGrain Market Outlook/Marketing Strategies/Projections for 2025: Richard Brock, Richard Brock Associates, Milwaukee, Wis., will provide a grain market outlook and his unique insight into grain marketing and the challenges farmers will face in the year ahead.

Special $500 Cash Attendance Prize. The prize will be awarded at the end of the seminar. Must be present to win.

11:00 a.m. SCGA Safety Award Luncheon, Room 114 Level 1

9:00 a.m. MID-SOUTH FARM & GIN SHOW IS OPEN

12:30 p.m. Rice Marketing Educational Seminar, Room 101 Level 1 Featuring Milo Hamilton, Firstgrain, Inc., and John Anderson, Rice consultant for Firstgrain, Inc. Rice rules of thumb may not work so well in 2025. Is the price of rice shaking your world? Is the cost of growing it shaking your world? This workshop looks at the rice price as trapped between uncertain input costs and other factors you may never have thought about before. Milo and John are here to help you sort through your new crop rice price outlook.

1:00 p.m. 4-H Mid-South Food Pantry Competition, Room 105-108 Level 1 4-H members will compete in a food challenge at the Mid-South Farm and Gin Show to demonstrate their knowledge and skills as it relates to preparing a healthy meal with items commonly found in a local food pantry. The contest will emphasize limiting food waste, food efficiency, and healthiness of a meal. Attend the award ceremony to see the winning recipes and the top three 4-H Chopped teams!

4:30 p.m. MID-SOUTH FARM & GIN SHOW CLOSES

9:00 p.m. The Jamboree (Adults only, please) Everyone Welcome! Cash Bar. Brought to you by Jamboree Sponsors: Agriculture Guaranty, AZA Import & Export Co., Bank First, Barnhardt Natural Fibers Group, Chem-Cotton, Egon Keller, Inc., Indianola Electric Co, Langston Companies, Inc, Lubbock Electric Co., LLC, Lummus Ag Solutions, McCleskey Saw & Machine, MTS Kimbell, Olam Agri, Planters Cotton Oil Mill, Samuel Packaging, Signode, Square Weber, LLC, Tannehill Industries, Vandergriff American

For more information: www.farmandginshow.com

Special Note: Exhibits, exhibitor information, and seminars from the 2025 Mid-South Farm & Gin Show will be available for registered attendees on-demand at the Mid-South Farm & Gin Show Virtual Show Site

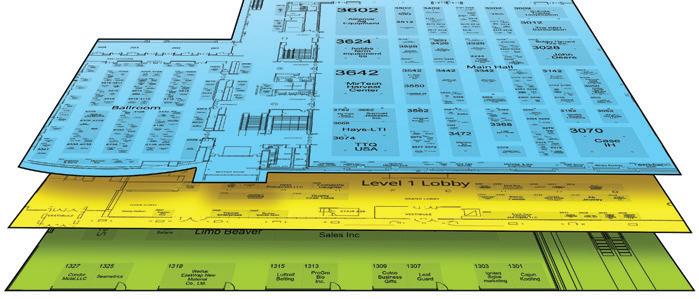

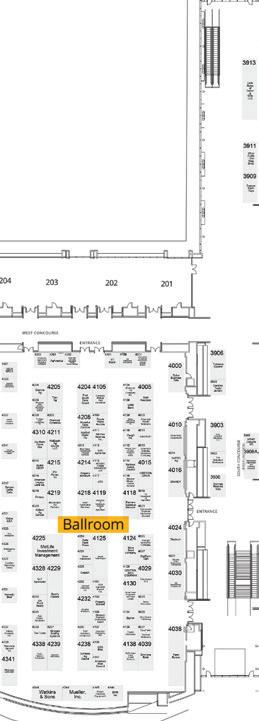

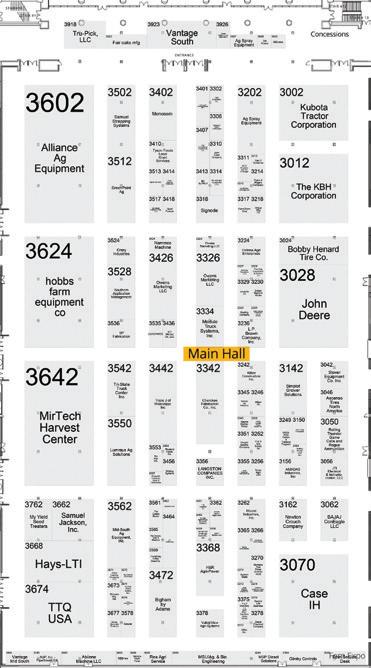

LOWER LEVEL EXHIBITS - CONCESSIONS

LEVEL 1 EXHIBITS - MEETING ROOMS - CONCESSIONS

LEVEL 2 EXHIBITS - CONCESSIONS

Sponsored by Southern Cotton Ginners Association Southern Cotton Ginners Foundation and Delta Farm Press

Adams Welding & Millwright .....................1126

Ag Technology Solutions Group ..................1106

Arkansas Propane Education and Research Council .....................................1024

Cajun Kooling Outdoor Cooling Fans ..........1301

CC Diesel Performance & Tuning LLC ..........1226

Certi-PIK USA .............................................1012

Condor Metal, LLC ......................................1327

Cutco Business Gifts ...................................1309

DT550 FRICTION REDUCER ..........................1127

Duck Tote ...................................................1210

Ecodrum Composter ...................................1206

EzeWrap .....................................................1319

Farm Credit ................................................1203

Fortify Building Solutions ..........................1000

Get Wet Irrigation Engines, Inc. ..................1119

Ignited Digital Marketing ...........................1303

Kuchar Combine Performance, Inc. ............1018

Kwan Safaris ..............................................1322

Leaf Guard..................................................1307

Limb Beaver LLC .........................................1316

Luttrell Belting ...........................................1315

Martin Till ..................................................1107

MidSouth Plastics.......................................1224

NACHURS ...................................................1007

Parman Energy Group ................................1021

PERKINS SALES INC.....................................1308

Planter-Tech Solutions LLC .........................1113

ProGro Bio ..................................................1313

Propel Sliding Door Automation ................1027

Rovensa Next .............................................1003

S&K Packaging ...........................................1125

Schlagel Manufacturing .............................1009

Seametrics .................................................1325

Southern Chics ...........................................1209

STOR-LOC ...................................................1006

T&B Welding & Trailers, LLC ........................1215

TANNEHILL- Mi-T-M HOT WATER WASHERS - AIR COMPRESSORS / VAL 6 HEATERS.........................................1103

Thompson Machinery ................................1013

Ab Jewelry .................................................2112

Alabama Mountain Lakes Tourist Association ..............................................2207

Bruces leather belts ...................................2007

Buckup Drone Recovery/Aerial Edge..... .....2211

Continental-Pipe ........................................2201

Cotton Museum, Inc. ..................................2114

Directpivotparts.com .................................2210

Enforcer One, LLC. ......................................2002

Fairbanks Scales Inc. ..................................2107

Farmer’s Daughter ......................................2205

Hess Shoes .................................................2202

LeafFilter Gutter Protection ........................2014

Legacy Gin Saws ........................................2016

Legacy Steel Building (Quonset / Roundtop) ..............................................2015

Next Gen Tuning and Diagnostics ...............2208

Peco Foods .................................................2108

PICKSMART ................................................2100

Quality Craft Tools ......................................2104

Redfern Enterprises Inc. .............................2013

Rustic Tennessee Cowhide Boutique & Décor...................................................2212

Simply Steel Metal Designs ........................2110

The Cotton Store ........................................2200

Topline Enterprises .....................................2005

Truck Care Chemical & Supply, LLC. ............2009

Unique Art by Floyd ...................................2003

4S&J, INC....................................................3379

Abilene Machine LLC ..................................3684

ADM ...........................................................3310

Advanced Drainage Systems, Inc. ..............3465

Ag Express Electronics ................................3572

Ag Spray Equipment ..................................3202

Ag Spray Equipment ..................................3927

Agrijewelry.com .........................................3462

AgroEcoPower ............................................3513

Alliance Ag Equipment ...............................3602

AMADAS Industries, Inc. ............................3156

Arcot Industrial Manufacturing ..................3355

Ascenco Tires North America ......................3046

BAJAJ

Little Bales of Cotton ..................................3913

Lummus Ag Solutions ................................3550

Martin Specialty Products ..........................3677

McCleskey Saw & Machine .........................3565

Michelli Weighing and Measurement ........3436

Mid-South Ag Equipment, Inc. ...................3562

MirTech Harvest Center ..............................3642

Mississippi Agriculture & Forestry Museum ...................................3908A

Mississippi Department of Ag and Commerce/ Genuine MS ...................3908

Monosem ...................................................3402

Montana Post Driver ..................................3270

Monty’s Plant Food ....................................3585

MSP Diesel Solutions..................................3284

MSU/Ag. & Bio. Engineering ......................3383

MTS Kimbell ...............................................3334

My Yield Seed Treaters ...............................3762

Nammco ....................................................3424

Newton Crouch Co ......................................3162

Nutrien Ag Solutions ..................................3345

Owens Marketing LLC - APV .......................3324

Owens Marketing LLC - Indutar ..................3426

Owens Marketing LLC - Lemken .................3326

P & P Marketing / J & M Mfg / Southern Sales Group ..............................3375

parallelarmexchange.com ..........................3315

PipeBreakUSA ............................................3785

Powerlift Hydraulic Door of Tennessee .......3557

Quail Forever ..............................................3418

Rea Agri Service .........................................3583

Redball .......................................................3517

Riceland Foods, Inc.....................................3454

Rolling Thunder Game Calls .......................3050

S.I. Distributing ..........................................3464

Samuel Jackson, Inc. ..................................3662

Samuel Packaging Systems Group .............3502

SBCotton ....................................................3930

Schaeffer Oil / Melvin Morris ......................3329

Scoular .......................................................3578

Shivvers Mfg., Inc. ......................................3673

SHOUP MFG CO...........................................3218

Signode ......................................................3318

Simplot Grower Solutions ..........................3142

Sm Fab Inc..................................................3553

Southern Application Management ...........3528

Stover Equipment Co. .................................3042

System Scale ..............................................3371

tCotton by TSW Automation, Inc. ...............3302

The KBH Corporation ..................................3012

The Kelly Group ..........................................3234

The Reluctant Beekeeper ...........................3902

Timac Agro USA..........................................3256

T-L Irrigation ..............................................3461

Tripak Superlubricants Inc. .........................3576

Triple J of Mississippi Inc. ...........................3442

Tri-State Truck Center Inc. ...........................3542

Tru-Pick, LLC ...............................................3918

TTQ USA .....................................................3674

Turnrows Apparel .......................................3906

Tyson Foods Local Grain Services................3410

USDA, AMS Cotton & Tobacco Program ......3249

Valent BioSciences .....................................3366

Valley View Agri-Systems ...........................3378

Vandergriff American/Sowega MFG ...........3401

Vantage Mid South ....................................3884

Vantage South ...........................................3923

Vaughn Electric Company...........................3351

Vive Crop Protection ...................................3150

Whiting Systems, Inc..................................3456

Wildfong Enterprises LTD ...........................3327

Wildwood Cotton Technologies ..................3306

Wilger Inc. ..................................................3246

Wind Crafts - The Flag Shop .......................3911

XAG Drones Advance Agriculture

Vantage South .........................................3926

811 Call Before You Dig ..............................4029

ACSA International Cotton Institute ...........4112 AgAmerica .................................................4201

AgHeritage Farm Credit Services ................4138

Agri Drone Solutions ..................................4334

Agri Placements International ...................4100

Agricenter International .............................4239

AgroLiquid .................................................4011

American Legacy Land Co. .........................4316

American National Insurance Company .....4013

Aquarius Farm Controls - Applied Digital Inc. ..............................................4208

Arkansas Rice .............................................4141

Arkansas Soybean Promotion Board ..........4135

ARVA INTELLIGENCE ...................................4323

ATA .............................................................4117

AZA Import & Export Co., LLC. ...................4131

Baker Implement Company .......................4226

Banyon Game Calls ....................................4317

Beck’s .........................................................4229

Benchmark AG Partners .............................4219

BAG COMPANY

Goanna Ag .................................................4304

Hill Manufacturing Company, Inc. ..............4030 Holganix Midsouth.....................................4214

Honestly Beef .............................................4331

Indeco Products, Inc. ..................................4337

Koch Agronomic Services ...........................4218

LiQuiTube Total Tire Protection ...................4303

Louisiana Master Farmer Program .............4113

MetLife Investment Management / Agricultural Finance ................................4225

Metos by Pessl Instruments .......................4321

MidSouth Ag Source LLC ............................4211

Mississippi Land Bank ................................4341

MSU/Ag. & Bio. Engineering-Educational...4028

Mueller, Inc. ...............................................4244

National Cotton Council .............................4114

Nichino.......................................................4111

Nitrogen Sealing Systems ..........................4237

On Point Realty ..........................................4332

One Grower Publishing ..............................4035

Power Cleaning Equipment ........................4145

PPF Gin & Warehouse, LLC..........................4219

Primrose Oil Company, Inc. ........................4104

Prinsco .......................................................4318

ProAg .........................................................4300

Properly Marked.........................................4133

PSI Power, Inc.............................................4215

PumpTrakr ..................................................4325

Purple Wave Auction ..................................4109

QLF Agronomy ...........................................4328

Reeds Farm Drainage .................................4115

Root Cause Podcast and Financial Services 4212

SePRO Ag ...................................................4014

Simmons Bank ...........................................4039

Small Town Properties and Real Estate ......4130

Southern Drone OPS...................................4310

Spraytec Fertilizers .....................................4232

Stalk Knockers ............................................4005

Staplcotn....................................................4024

Stine Seed Company ..................................4124

Sure Crop....................................................4314

TeeJet Technologies ....................................4125

Tennessee Department of Agriculture ........4019

Tennessee Soybean Promotion Council ......4021

Tex-Trude ...................................................4336

Titan Ag .....................................................4205

Triangle Insurance Company ......................4025

Tri-States Grain Conditioning, Inc. ..............4308

UMB Bank ..................................................4106

University of Tennessee - Institute of Agriculture ..........................................4119

USA Rice .....................................................4139

USDA NRCS .................................................4301

USDA/Office of Hearings and Appeals/ National Appeals Division ........................4001

UT Martin Agriculture ................................4101

VISERION GRAIN LLC ...................................4015

Waterhole Apparel Co.................................4339

Waters Agricultural Laboratories, Inc. ........4108

Watkins & Sons Mfg., Inc............................4344

Zerk Zapper Tool .........................................4311

BY TIM PRICE

Mid-South Farm & Gin Show Manager

It seems like we’re in a never-ending cycle of uncertainty. Weather, government, exports, income, farm policy, are a few of the changes we’re facing. There is so much change coming at us – all the time – that we can become overwhelmed.

It seems like we can’t get away from it. We see it in our emails and texts, hear farm broadcasters talk about it, and we get updates from our membership organizations. We’re entering the fourth year of declining farm income. Input prices are still high, while commodity prices are often lower. We have heard that many lenders are concerned about repayments and a fair number of farmers are concerned they won’t be able to finance their operating needs.

Surveys show that despite the challenges, farmers want to continue to make the world a better place for our children and grandchildren. And we want a vibrant agriculture for those who choose to be a part of it.

So, what do we do? We plant another crop.

I often wish I had a crystal ball or some kind of superhero insight into what future agriculture looks like. Is social media your crystal ball? There is no shortage of revolutionary practices and products, the shiny new equipment, or a Nebraska farmer’s TikTok feed showing others how he does it. It’s all available right on the phone you carry in your pocket.

I remember hearing from my childhood “don’t believe everything you read” or “don’t believe everything you hear.” Abraham Lincoln is famous for saying “don’t believe everything

you read on the internet.” I’m pretty sure that’s a paraphrase of a line in one of Lincoln’s speeches that has just come to light.

But it makes a point. A lot of our mental strain comes from trying to figure out what’s “real” versus “fake news.” A recent article on information overload included this “an abundance of information becomes an abundance of misinformation.”

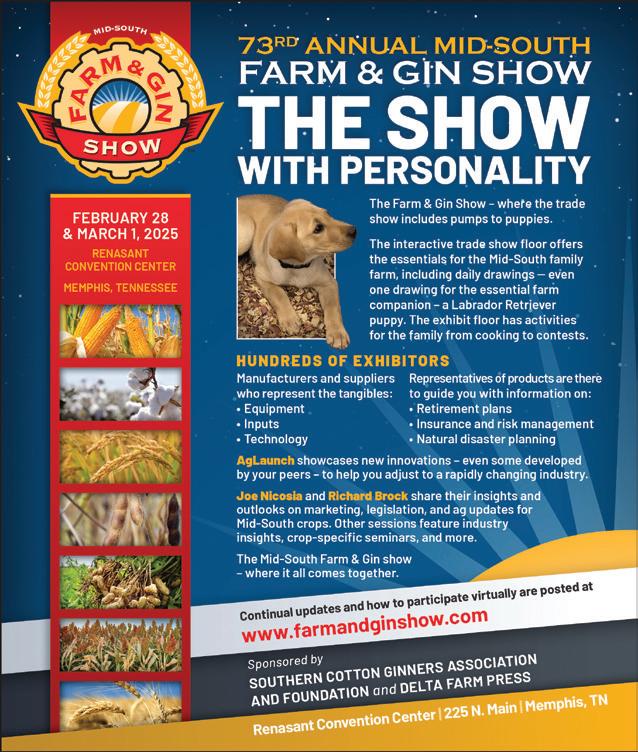

The original Gin Show launched in 1951, as an educational exhibit and marketplace for the ginning industry. It was a place where farmers and ginners could gather accurate, relevant information and talk with peers about the challenges of the day. While many of the challenges have changed, our commitment to providing valid and valuable information remains.

This year is the 73rd year, now called the Mid-South Farm & Gin Show, and we continue to create space for educating farmers on critical issues, providing information on new practices, showcasing new machinery, products and services that can keep farmers updated with cutting-edge ideas, while offering many opportunities for networking.

Ag Outlook seminars feature forecasts for cotton, grains, the economy, and rice. On Friday, Joe Nicosia will talk all things cotton, giving his perspective on domestic and global markets for the year ahead. Saturday features Richard Brock who will cover the outlook for grains and the economy. Ag Outlook seminars begin at 8:30 AM, Cannon Center Stage.

Milo Hamilton and John Anderson will give direction on the rice markets and what to expect in 2025. That seminar will be

Saturday, beginning at 12:30 PM, in Room 101, Level 1 of the Renasant Center.

All have insight on the monumental changes ongoing in government and how that relates to agriculture. You don’t want to miss any of these seminars.

Knowing the issues to effectively communicate with state and federal lawmakers is on the schedule at this year’s Mid-South Farm & Gin Show. The Farm & Gin Show is happy to welcome again the Mid-South Agricultural Trade Conference on Friday, February 28 beginning at 11 AM in room 115 on the Lobby Level of the Renasant Center.

International trade, a top concern, for farmers will come into play with presentations by Former Underscretary of Agriculture, Ted McKinney, now President of the National Association of State Departments of Agriculture, and respondents will discuss the loss of international market share and needed responses.

Dr. Andrew Muhammad, professor of agricultural and resource economics at the University of Tennessee in Knoxville, along with representatives from other state universities, departments of agriculture, and Farm Bureaus around the Mid-South, will also discuss trade efforts in each state and nationally. The goal is to educate the public on global issues affecting agriculture, to provide a forum for relevant input and Q & A sessions on how to keep US ag competitive and viable in markets around the world.

Each year, I am impressed by the ideas, innovation and solutions-driven farmers and ginners who attend the Farm & Gin Show each year. These attendees show up in years of uncertainty and years of calm. They value the show’s

environment that prompts them to think ahead, ask hard questions, and have farmer-to-farmer and ginner-to-ginner conversations about change, how rapid it seems compared to just a few years ago, and how change can benefit their operations and our industry.

The show tries to have answers for the many questions on attendees’ minds. But, the reality is, we don’t have all the answers. What we do have is a place to have crucial conversations and find meaningful support from others. Sometimes the best information comes from learning how another farmer tackled a similar situation.

Last year, I mentioned the concept of radical resilience as the ability to endure, grow, and thrive through adversity. I am going to repeat Episcopal priest and researcher Alice Updike Scannell’s comments, because I think they are as relevant today as they were last year:

“We usually think of resilience as the ability to recover from an adverse experience and pick up our lives where we left off. It is that too.… But there are times when adversity permanently changes our reality, and we can’t go back to the way things were.…

Resilience then becomes the work of coming through the adversity so that, at least on most days, we see our life as still worth living. With this kind of resilience, we come through the adversity knowing that we’re still ourselves, even though things are very different for us now.”

This offers, in my mind, a realistic picture of agriculture and all we have been through the past several years. We go on, sometimes slogging through adversity and change. We plant another crop. It’s what we know, we do it well, and it provides a measure of stability in an increasingly instable world.

There are still many questions, and seemingly few answers. Right off the top of my head, these questions come to mind: what is the future for farm legislation? How will we address the significant loss of market share to Brazil? How can we continue to transition the farm to the next generation if we don’t have more certainty of markets and prices? How can we remain relevant while meeting the challenges of the day? There is so much change, everything is happening so fast - how do we go on?

Leadership expert John Maxwell said this -“Change is inevitable. Growth is optional.” Change requires us to, well, change, even with so much being beyond our control. If we deny the need to change, we’re stuck. If we try the same things and expect a different outcome, that doesn’t move us forward. Albert Einstein labeled that as insanity.

The one question that connects with nearly every topic we discuss is how do we futureproof the industry, so we won’t become obsolete in the future?

We plant another crop. We return to our roots and rely on the foundations of farming. We plant, and cultivate, harvest, and market. We connect with those we trust, those who have a history of providing accurate information. Extension agents, university scientists, certified crop advisers and certified agronomists, and others who are working with farmers and ginners to address new and different challenges. We attend conferences and trade shows to glean nuggets of information from industry experts and our peers. We attend the Mid-South Farm & Gin Show.

Maintaining connections in an uncertain world is critical. Relationships with family members, neighbors, agribusiness reps, members of ag organizations, civic groups, faith-based organizations, or those who regularly gather for coffee. The organizations themselves are important, but it’s the sense of community that helps us collectively deal with change.

The farmers I have known for years, who talked about their early farming careers, now tell me the main goal for their operation is to survive, and do and be better than previous year. Adopting a growth or continuous improvement mindset helps us see beyond the current crisis to a future where circumstances are better.

Change is inevitable, making changes will continue to be a growing challenge.

Toward the end of the 20th Century, businesses rapidly adopted computer technology. On the farm computers were used to track yields, input costs, grain sales, livestock marketed, and more. The internet paved the way for technology we once saw only in science fiction, on Star Trek, The Twilight Zone, Lost in Space, or The Jetson’s. Today, drones are used to scout crops and spot-spray weeds. Automated systems improve processes, reduce waste, and improve profitability. We don’t have flying cars (yet), but we do have many levels of autonomous machinery.

I think we’re on the cusp of significant artificial intelligence (AI) contributions to agriculture. We may see robots assist with research and data collection or take calls and manage emails. And while you may not use AI, you can bet those you do business with do. Many say AI will become one of the most important revolutions in agriculture.

We will have to see about that. What we know now is we can’t avoid change, we can’t control it, and it’s difficult to welcome, but we can learn to accept it as part of the journey.

A recent email resonated with me, especially in this time of uncertainty and change. It stated when we’re at the end of our own resourcefulness, when we are full of questions and out of answers, we seek certainty.

And so, we plant another crop. Our discipline to consistently put seeds in the ground, pray for favorable growing conditions, harvest and deliver crops to market, is an important part of the stability we have. We know when we plant another crop, we’re taking more steps forward, even if it is down an uncertain path.

The Mid-South Farm & Gin Show has been a constant in helping farmers, ginners, agribusiness, and others navigate instability. It’s the place where you can interact with those you do business with, and where you can find new products, services, technology, and equipment. The Farm & Gin Show is where you learn that one piece of market intelligence you couldn’t get anywhere else. It’s the place where you share a meal with long-time friends and new acquaintances. And don’t forget, the show is also the place of fun and family -- you have a chance to win a Labrador puppy or cold hard cash with thousands in cash prizes awarded daily.

The Mid-South Farm & Gin Show is where it all comes together, and it won’t be the same without you. Bring the family and join us February 28 and March 1 for the 73rd Annual Mid-South Farm & Gin Show at the Renasant Convention Center, Memphis. We can’t wait to see you at this year’s show!

WHILE SOME OF the more than 300 companies at the 2025 Mid-South Farm & Gin Show are returning exhibitors - some going back to the first show 73 years ago - a host of new exhibitors will be at the show for the first time.

Tim Price, show manager, voiced appreciation for the support of those companies that have exhibited at the show year after year. “We sincerely appreciate their support and commitment to The South’s Premier Farm Show,” he says. “At the same time, we are very excited to welcome our many new exhibitors and the range of products and services they offer.

“The pace of change in today’s agriculture is rapid and a driving force in many of the products and services being offered by these new exhibitors. Farmers attending the show will have the opportunity to get a firsthand look at these new developments.”

There are more than 80 companies at the 2025 show that were not at the 2024 show. New exhibitors for the 2025 show include:

Ab Jewelry, Sheridan, AR; AgHeritage Farm Credit Services, Little Rock, AR; Agri Drone Solutions, Athens, AL ; AgroLiquid, St. Johns, MI; American Legacy Land Co., Monticello, AR; Arkansas Propane Education and Research Council, Jefferson City, MO; Ascenso Tires North America, Stow, OH; ATA, Jackson, TN; AZA Import & Export Co., Lubbock, TX; Banyon Game Calls, Millington, TN; Better Cotton Initiative, Genève, Switzerland; Bigham by Adams, Carlisle, AR; BigIron, St. Edward, NE; Bobby Henard Tire Co., Brinkley, AR; Bowen Equipment Co. LLC, Newport, AR; Brooks Custom Application, Houston, MS; Bruces leather belts, Smithville, MS; Buckup Drone Recovery / Aerial Edge, Huntingdon, TN; BW Fusion, Fort Wayne, IN; Caroline Taylor Jewelry, Brooksville, MS; CC Diesel Performance & Tuning LLC, Horace, ND; CENTRAL BAG COMPANY, Leavenworth, KS; CNC Performance Engineering, LLC., Huntersville, NC; Concept Industries Ltd., Winkler, MB; Condor Metal, LLC, Atoka, TN; Croptell, Hernando, MS; Directpivotparts.com, Saint Edward, NE; Ducks

Unlimited, Memphis, TN; EasyFarm - Vertical Solutions, Minot, ND; Enforcer One, LLC., Peachtree City, GA; EZ-Drops, Kirkland, IL; Fastline Marketing Group, Buckner, KY; Five Star Equipment & Auction Co, Sardis, MS; G&H Petroleum, Nashville, MI; Gen 3 Dynamics, Troy, OH; Get Wet Irrigation Engines, Inc, Pocahontas, AR; Gilland Ag Service, Elkton, TN; Goanna Ag, Waterloo, NE; Grain Systems Distribution, Vincennes, IN; Greenway Equipment, Weiner, AR; Honestly Beef, Magee, MS; Ignited digital marketing, Tupelo, MS; INCO Irrigation and AG Drainage, Union City, TN; Kagmo Electric Motor, Cape Girardeau, MO; Kisco Leasing Company, LLC, Haskell, TX; Koch Agronomic Services, Greenwood, MS; Kwan Safaris, Angleton, TX; Leaf Guard, Roanoke, VA; Legacy Steel Building Inc., Fargo, ND; Metos USA, Loxahatcheel, FL; MidSouth Ag Source LLC, Paris, TN; Mississippi Agriculture and Forestry Museum, Jackson, MS; Mississippi State University Geosystems Research Institute, Mississippi State, MS; MJP, Inc. – PipeBreakUSA, Middlefield, CT; parallelarmexchange.com, Remington, IN; Parman Energy Group, Olive Branch, MS; Planter-Tech Solutions LLC, Trumann, AR; PPF Gin & Warehouse, LLC, Cooper, TX; Prinsco, Earlham, IA; Propel SDA LLC., Delphos, OH; Quail Forever, St. Paul, MN; Redfern Enterprises Inc., Las Vegas, NV; Rolling Thunder Game Calls and Rogue Ammunition, Somerville, TN; Root Cause Podcast and Financial Services, Trenton, TN; S&K Packaging, East Dubuque, IL; Schlagel Manufacturing, Torrington, WY; Seametrics, Kent, WA; Small Town Properties and Real Estate, Flora, MS; Southern Chics, Calhoun City, MS; Spraytec Fertilizers, Urbandale, IA; Stalk Knockers, Randolph, IA; T&B Welding & Trailers, LLC, Lockwood, MO; Tech Solutions Group LLC, Nashville, TN; Tex-Trude, Channelview, TX; The Cotton Store, LLC, Gould, AR; The Reluctant Beekeeper, Hickory Plains, AR; TSW Automation, Inc., Nashville, TN; University of Tennessee - Institute of Agriculture, Middleton, TN; USDA NRCS, Little Rock, AR; Vantage Mid South, Carlisle, AR; Vaughn Electric Company, Union City, TN; Weihai EzeWrap New Material Co., Ltd., Qingdao, AL; Wildfong Enterprises LTD., Craik, SK

JOHN ANDERSON is an expert in grain hedging with 30 years’ experience in rice marketing. He is a rice analyst at Firstgrain, an advisory service for the world rice industry. Prior to this role, he was the Senior Manager, Customer Development with rice buyers to adopt new technology in grain merchandising. Most of his career has been working with producers directly, buyers directly, and in management. John holds a Bachelor of Business Administration (B.B.A.) focused in Marketing/Marketing Management, General from University of Tennessee at Martin.

JOHN BARANICK, is an Ag Meteorologist, DTN. He graduated from Iowa State University with a BS in meteorology and a minor in agronomy. He has been a meteorologist with DTN since 2011. John uses his forecasts to comment on its impacts to different industries and helping customers make important business decisions. His comments have been received by clients in the aviation, transportation, energy, and agriculture industries worldwide.

LARRY BLACK is President of the National Cotton Ginners Association. His cotton ginning career began in 1981 when he joined Quanah Farmers Co-op in Quanah, Texas. He became assistant general manager in 1986, and in 1988, was named general manager. While in Quanah, he served on the city council for nine years and for seven years as mayor pro tem. He also served four years as chairman of the Quanah Economic Development Corporation. Larry was named general manager of the Central Rolling Plains Co-op in Roscoe, Texas in 2022. He is a past president of both Texas Cotton Ginners and Texas Agriculture Cooperative Council. Larry currently serves on the Texas Cotton Ginner’s Trust Board of Directors, the Nolan County Groundwater District Board, the Roscoe Collegiate High School STEM Advisory Board, the National Cotton Council Board of Directors, the US Cotton Trust Protocol Board.

RICHARD BROCK is Chairman of Brock Holding Company which is comprised of Brock Associates, an agricultural marketing advisory service and publisher of The Brock Report, established in 1980 and Brock Investor Services (futures and options brokers). The Milwaukee, Wisconsin-based firm has six offices and manages grain sales on approximately 800,000 acres throughout the U.S. and is an advisor on purchasing strategies for many large poultry, pork, dairy and food companies. Brock grew up on the family grain and pork farm in central Indiana. He received his Bachelor of Science Degree in Agricultural Economics from Purdue University and his master’s degree from Cornell University.

MILO HAMILTON has been CEO of Firstgrain since 2000. Firstgrain is an advisory service for the world rice industry. For nearly 20 years at Mars Incorporated Hamilton ran one of the largest rice buying teams for retail food products in the world. He has degrees from Stanford University agricultural economics from the University of Missouri, and Minnesota. Hamilton has been involved, in one way or another in the rice markets for 42 years. He has been instrumental in the birth and development of the CME Group’s rice futures contract in Chicago. He has served on the boards of many rice associations, advises customers throughout the global rice marketing chain, and is senior editor of the weekly publication, the Firstgrain Rice Market Strategist. His book on the world rice industryWhen Rice Shakes the World, explains how the world rice market really operates and where it may be headed.

PATRICK JOHNSON is chairman of the National Cotton Council. He previously served as the NCC’s vice chairman. Johnson is a partner in Cypress Brake Planting Co., a family farming operation in the Mississippi Delta. The diversified farm produces cotton, rice, corn, soybeans, and wheat. Joining the operation in 1996, Johnson has sought to improve conservation and efficiency in the operation through the implementation of new technology and best management practices. In addition to the farming enterprise, Johnson is involved in several ag-related businesses, including Buck Island Seed Co., Three Way Gin, and Tunica Air Inc., an aerial application service. Johnson is a National Cotton Council Cotton Leadership Program graduate and past participant in the NCC’s Producer Information Exchange program. He has served as a NCC director and on multiple NCC committees as well as the American Cotton Producers chairman.

RICHARD “RICH” JOE LINDSEY, JR was born and raised in the cotton business in Cherokee County, Alabama. He has been involved in the management of Cherokee Gin & Cotton Co. since 2005, where he is now the manager and a partner. Rich oversaw the design and construction of their new state-of-the-art cotton ginning, warehousing, and marketing facility which is now the largest producing gin in Alabama, serving more than 70 cotton producers in Northeast Alabama, Northwest Georgia, and South-Central Tennessee. Rich, along with his Dad and another partner, have a 3800-acre row crop operation where cotton is the primary crop. He is also a partner in a five-house poultry farm. Rich completed the National Cotton Ginner’s Association’s Certified Ginner Program in 2014 and the National Cotton Council’s Policy Education Program in 2017. He has also served 16 years as a Director to the Southeastern Cotton Ginners Association.

DR. RYAN LOY is an Extension Economist for the University of Arkansas Division of Agriculture. He serves producers by providing education and research on relevant farm financial management topics. Loy’s research interests include agricultural finance, farm management, supply chain resilience, and value-added marketing channels. Dr. Loy earned his Ph.D. in Agricultural Economics, from Oklahoma State University; an M.S. Agricultural Economics from Oklahoma State University; and B.S. in Agribusiness, also from Oklahoma State University.

JONATHAN MCBRIDE is general manager of Bogue Chitto Gin, Macon, Miss. He started his career at Holly Bluff Gin, Silver Creek Gin and spent most of his career there. In 2017, he moved to Bogue Chitto Gin in Macon, Mississippi. Since 2017, McBride has worked to integrate RFID technology to help give producers more information about what’s happening in their cotton. He’s working with Cotton Incorporated and USDA’s Ag Research Service to further the technology, although he admits it will take installing additional automation to fully benefit farmers.

JOE NICOSIA is Trading Operations Officer and Head of the Cotton Platform for Louis Dreyfus Company, and Executive Vice President of Louis Dreyfus Company LLC. He graduated from Dartmouth College in 1981 with a bachelor’s degree in economics and joined the Group that same year as a grain trader in Minneapolis. In 1982 he transferred to Allenberg Cotton Co. in Memphis, and in 1985 assumed responsibility for cotton trading worldwide. He was CEO of Allenberg Cotton Co. from 1991 to 2012, resumed the role in 2015, and remains CEO today. From 1989 to 2000 he also served as President of Allenberg Cotton Co. He was Director of Louis Dreyfus Corporation from 1995 to 2010. Since 2010, Joe has been Director and Vice President of LDC Holding Inc. and has coordinated the trading and merchandizing activities of LDC’s cotton business. He is also a member of the board of directors of American Cotton Shippers, where he serves as Chairman of the Futures Committee.

BY WHITNEY SHANNON HAIGWOOD AND JOSHUA BAETHGE whitney.haigwood@farmprogress.com Joshua.baethge@farmprogress.com

There’s little doubt U.S. Sen. John Boozman loves agriculture. The three-term Arkansas Republican has raised Polled Hereford cattle and grown cotton. His daughters were active in 4-H and grew up showing heifers.

He continues to advocate for agriculture because it is such a huge part of his state’s economy. While the ag industry represents a quarter of Arkansas’s economy, for most rural communities it is their lifeblood.

“We are blessed. We have the safest, cheapest food supply of any place in the world and that has taken a lot of hard work of many generations of Americans to get us in that position,” he said. “We have to be careful about making sure that we preserve that.”

While farmers can certainly relate to that sentiment, what they really want to know is how Boozman plans to pass a new farm bill this year. As the new chair of the Senate Agriculture Committee, he has more influence on that process than any other lawmaker.

Boozman makes no bones about the dire conditions many farmers are facing. While the 2018 Farm Bill may have been adequate when it was first enacted, he believes it has more than outlived its usefulness, especially following the pandemic and ensuing inflation.

“The safety nets, the risk management fields that farmers have just don’t work,” Boozman said. “Because of that, there’s lots of uncertainty in farm country.”

He is among the many lawmakers who spent more than a year and a half crisscrossing the U.S., seeking input from stakeholders. He expects to do more of that this year as a new congress, with new committee members who bring their perspectives to the table. He says he is looking forward to working with Sen. Amy Klobuchar, the new top Democrat on the Ag Committee, to get the ball rolling.

Of course, many hurdles remain before a new bill can get passed. 2025 marked the beginning of a new congressional session. Thus, any bill must be introduced from scratch.

Last year, the House Ag Committee passed a farm bill introduced by Rep. Glenn “GT” Thompson. That bill was never voted on because Speaker Mike Johnson knew it did not have the votes to pass.

Boozman introduced a similar farm bill framework that never made it out of the then Democrat-controlled committee. While the work that was put into those two proposals could serve as the blueprint for a new farm bill, other factors could force changes.

Any bill must first be scored by the Congressional Budget Office. President Trump has indicated he plans to cut spending and lower taxes. If he follows through with those plans, there may be fewer dollars available for the farm bill. This, after Chairman Thompson’s bill last year already exceeded the farm bill’s baseline budget.

House Republicans dispute that math.

Still, Boozman believes growing calls from the agriculture world to deliver a new bill will ultimately persuade lawmakers to get a deal done. Higher input costs coupled with lower commodity prices have created an environment where many farmers simply cannot make a living.

“I think just the necessity of getting these things done is such that members of Congress are understanding of that,” Boozman said. “Certainly, the farm community is becoming more vocal.”

Speaking of vocal, President Trump has repeatedly vowed to impose tariffs on major agriculture trading partners, including China, Mexico, and Canada. Boozman said he is not necessarily inclined to impose across-the-board tariffs. Still, he believes something needs to be done to address countries that are not playing by the rules. That, he says, is something President Biden failed to do.

Boozman plans to take a wait and see approach to exactly how Trump intends to protect agriculture while imposing new tariffs. He believes incoming Secretary of Agriculture Brooke Rollins will play a key role in ensuring that any new trade deals will benefit all countries involved, while protecting farmers.

Boozman met with Rollins a few weeks after she was nominated to lead USDA. He said he came away impressed with her love and understanding for rural America. Just as importantly, Boozman believes she has the ear of the president and will be able to effectively advocate for agriculture.

“I think she has the opportunity to make herself a great secretary of agriculture at a time when we desperately need leadership in that area,” Boozman said.

Q

New leadership brings new questions and farmers are not bashful about asking them. During a recent interview with Farm Progress, Senator Boozman addressed some of the important questions farmers asked us to relay to him.

In December 2024, the USDA announced $30 billion combined in economic and disaster relief to our U.S. farmers. In the past when this kind of relief package was passed, many did not think the dollars were distributed fairly.

“We were prescriptive in this bill and how it gets done. It is just a matter of getting the paperwork in place and getting the mechanism in place,” Boozman said.

While he doesn’t have a timeline, Boozman said it is forthcoming and will be done as soon as possible. “We are pushing the USDA to get the dollars out the door.”

Boozman underscored how important this monetary relief is, not only to farmers, but also to lending agencies.

“The farmers need the money. It is also important because the bankers and lenders need to know that source of income is coming in, to help farmers in getting their loans for the next crop.”

Boozman has been named the 2025 A.L. Vandergriff Cotton Pioneer Award winner by the Southern Cotton Ginners Association. He has been a great advocate of Midsouth agriculture and its farmers. He has provided much needed support to the agriculture community at large.

The award is presented annually to an exceptional individual whose efforts have supported ag producers and the ag industry. Leading up to the Mid-South Farm and Gin Show, the award presentation takes place at the Southern Cotton Ginners Honors Banquet at the Peabody Hotel on Feb. 27.

2. What can we expect with reference prices?

Farmers make great yields. The yields are so high at times that their hard-earned efforts are not necessarily reflected when the grain or the protein is delivered.

Reference prices are supposed to provide a safety net. Farmers are at the mercy of the markets, and they cannot set their own prices. They need a stable safety net. Instead, current reference prices do not trigger as an effective risk management tool. By the time PLC or ARC payments do trigger, a farm is already going under.

Increasing reference prices is a big part of the next farm bill. But it has also been a holdup. Past proposed farm bills have included price updates.

Boozman said, “Now it is making sure those risk management tools like reference prices are updated because of the way the farm economy is right now.”

3. Are there mechanisms in place for crop quality?

What happens when a farmer raises his highest bushels per acre for a crop, like rice, then takes the highest quality loss when the crop is delivered? The farmer takes the hit. That happened this year across the Midsouth. Farmers took it on the chin. Quality loss is expensive, and crop quality is largely dependent on environmental factors.

Boozman said compensation for quality is a possibility, and it is something he heard throughout listening sessions held across the U.S.

As far as the recently passed economic relief package, Boozman said the disaster relief portion would kick in and account for some of the quality loss due to extreme weather like drought and hurricanes farmers experienced in 2024.

4. Looking ahead, 2025 looks grim for farm country. What is next?

Crop prices are historically low, and input costs are historically high. Farm economists from across the nation are predicting the situation to be worse in 2025. The best solution is a farm bill, and Boozman said it is top priority going into 2025.

“We are going to get this thing done as soon as possible,” he said. “We are talking about a five-year contract with our farmers. As I have said over and over again, we have to have more farm in the farm bill.”

BY BRENT MURPHREE

Lewis Rone will represent the Rone family farm when he accepts the 2025 Ag Achievement Award from the Southern Cotton Ginners Association on February 27.

His family’s operation is a picture of the cooperation between the growers in the Missouri Bootheel and the University of Missouri. And, he is the first to tell anyone that nothing gets done without the partnership of growers in that area.

“There are a lot of families who have supported the Delta Center for decades. Across our bootheel counties you’ve got dozens of families who are part of what we affectionately term ‘the bootheel mafia’ who have been steady supporters of the Delta Center. And fortunately that support has continued with the current generation in the ag community,” he said.

The Fisher Delta Research, Extension and Education Center in Portageville, Mo., was facing some hard times as the university cut back support to the center.

“We went from having seven PhDs at the center to one PhD,” he said.

Area growers were disappointed with the results of the cutbacks by the university and determined that action needed to be taken. Lewis’ brother, Don, was in his last term as a Missouri state representative and chairman of the house ag committee. He teamed up with freshman state senator Jason Bean, who is also a farmer in the Bootheel, to address the situation.

“When my term came up because of term limits, Senator Bean kept the ball rolling,” said Don Rone. “Our goal was to bring the station back to what it was when Jake Fisher was there. You have to keep the researchers there to support the growers.”

T.E. “Jake” Fisher served as superintendent of the center and was employed by the university for over 50 years. He retired in 2011 but continued to serve as an advisory board member.

“We were at one time on par with Texas, Purdue and Mississippi State in doing research

for the growers and for the ag industry as a whole,” Don said.

Through meetings with university president Mun Choi and Dean of the College of Agriculture, Christopher Daubert, the advisory board of growers was able to get funding reinstated to support more researchers at the Fisher Delta site.

“We now have six PhDs out here and we’re back,” said Don. “It was only because of the support from those families Lewis mentioned earlier – our bootheel mafia. Everyone came together with one goal - the Delta Center. And today the center is strong. They’re doing great research.”

The center was originally established in 1959 in Portageville to provide research and education focused on the Missouri Bootheel. Consisting of 1,119 acres at five locations, research is conducted on cotton, corn, rice grain sorghum, wheat, peanuts and other crops with an economic impact on the region.

“There are three things I’d like to mention about the Delta Center,” Don said. “One is that it exports a lot of people to the industry”

Which is one of the issues that arose as personnel moved away from the center and necessitated the move to ensure funding and personnel remain at the center. “

Number two is the cyst nematode research,” he said. “A lot of transformational cyst nematode research has been done here at the Delta Center.”

University research includes identifying genetic lines of resistance, as well as seed treatments that help keep the pest at bay.

“Number three is high oleic soybean research. That started right here in Portageville,” he said.

High oleic soybeans produce an oil that contains at least 70% monounsaturated fat, making the oil more stable at high temperatures. It is edible, with zero trans fats, for heart-healthy baking and frying. It also has a longer shelf life.

In addition to funding from the university, the center takes in support funds from commodity research groups like Cotton Incorporated, Missouri Soybean Merchandising Council, USA Rice and more.

“We know the importance of keeping research funding down here in the bootheel because our production is high and our soils, weather and drainage are unique.,” Lewis said. “It’s research that matters to the farmer.”

Variety yields are organized through researchers at the center in different parts of the

bootheel to determine which variety yields best in a particular soil type or region.

“We keep our variety testing to tell when our varieties are keeping up with the yields of other private or public researchers,” he said. “They report their yields at 100%, 105%, or 115% of a check, so that you know they’re doing better than the check.”

The Rone family farm is just north of the Portageville university center and they lease land in the surrounding area. Currently, soil testing is conducted in Columbia, Mo.

“Columbia is 300 miles away,” he said. “I can be at Mississippi State before I can be at my own soils lab.”

With the help of the advisory board and former Missouri Senator Roy Blunt, that will now change.

“We are in the process of building a two and a half million-dollar soils lab here at the Delta Center to meet not just the needs in the bootheel but for the entire southern Missouri ag community,” he said. “We are going to be able to test water samples, and do petiole tests in additional to soils tests. And do it all locally.”

BY BRENT MURPHREE

The Southern Cotton Ginners Association has named their 2025 Memorial Scholarship in the honor of John Edmonston, a longtime SCGA member and 1997 association president.

Edmonston was a third-generation cotton ginner and managed the family gin in the Bootheel of Missouri. He passed away on September 12, 2024.

He was active in the cotton industry as a delegate to the National Cotton Council and a member of the National Cotton Ginners Association, as well as SCGA.

When he was president of SCGA, Dunklin County where he lived, farmed and ginned, was one of the largest cotton producing counties in the Midsouth. It still is today, even though Edmonston Gin is now closed.

“Our county never really left cotton back in the ‘60s and ‘70s, when a lot of areas dropped cotton and went with a grain,” he said in 1997 as he was starting his year as association president. The same rings true today as growers continue to farm cotton in Dunklin County.

“I’ve come to believe that any ginner not involved in the (ginners) association is missing

out - if for nothing else than for the information it provides to members,” he said. “With all the government regulations, changes on the trade front, and everything else, things can sometimes be scary. The association helps to make sense of all these things.”

Almost 30 years ago he pointed to advancing technology and the constantly evolving nature of the industry.

Even back then he acknowledged that ginners who don’t stay on top of the new technology can face problems keeping up in their operation. He sited SCGA as useful for keeping ginners on pace with the changes.

Both brothers kept returning to a central point.

“The success of the Delta Center has been a massive group effort, and our family has just been fortunate to be part of that effort,” Don said. “My grandpa told me a story one time and he said, ‘You know what a good leader is?’ And I said, ‘no, Papaw, what is a good leader?’ He said, ‘It’s a man that finds out the way the people want to go, and he gets out in front.’”

The Rones, and their fellow farmers in the Bootheel, are helping to lead by getting out in front for the University of Missouri and the Delta Center.

The Southern Cotton Ginners Association Agriculture Achievement Award will be presented to the Rone family and the University of Missouri at the annual honors banquet on February 27 at the Peabody Hotel in Memphis, Tenn.

The award is presented each year prior to the opening of the Mid-South Farm and Gin Show, which takes place February 28 to March 1.

Current members of the association agree as they honor Edmondston after his passing.

“The association helps to make sense of all these things,” he said.

Association Executive Vice President Tim Price said, “What John said 28 years ago are so true today. He was a forward-thinking president and the association benefited from his leadership.”

Edmondston was also active in the community of Hornersville, Mo., as a member of Hornersville United Methodist Church, the Masonic Lodge, Farmers & Merchants Club and as a veteran of the National Guard.

He is survived by is wife, Becky, his sons Aaron Lance (Jackie) and John Leonard II, his daughter Becca Christine (Stoney) Cook, and nine grandchildren.

The University of Missouri’s (MU) College of Agriculture, Food and Natural Resources (CAFNR) is continually investing in the right faculty, facilities and collaborations to provide Missouri farmers with the research, demonstrations and outreach they need to keep the agriculture industry in the state thriving.

This is evident across the Missouri Agricultural Experiment Station’s four Research, Extension and Education Centers (REECs), including at the bootheel’s Fisher Delta REEC, where new faculty positions, building projects and outreach activity has exploded over the last five years.

The FD-REEC was established in 1959 in Portageville, Mo., to provide research and educational programs unique to the Southeast Delta Region of the state. Facilities include 1,119 acres of land at five locations representing the major soil types of the region.

The number of resident faculty at the FDREEC has grown considerably to assist needs of local producers.

A partnership between MU and the Missouri Rice Research and Merchandising Council created a position focused on rice agronomy in 2021. Additional staffing areas for Extension specialists/resident faculty at Fisher Delta REEC include soybean breeding, cotton agronomy, soil and cropping systems, crop protection and weed science.

Researchers at the FD-REEC have gained recognition for developing improved soybean varieties, especially those with soybean cyst nematode resistance. Research also focuses on the improvement of yield and resistance to stressors, and on enhancing the seed composition of soybean.

Research at FD-REEC also includes studies focused on improving irrigated crop man-

agement systems for humid and sub-humid climates; evaluation of herbicide programs, products and resistance management strategies; applied agronomic research focused on innovative crop production systems for southeast Missouri; and applied research to improve sustainability and profitability of rice and cotton production.

Having a team of resident faculty at the Fisher Delta REEC has led to an increase in outreach opportunities; recent years have seen the addition of an Ag Expo for producers, social media accounts directly from each programmatic area, and a monthly newsletter dedicated to showcasing activities at the center.

In the spring of 2024, ground was broken for the Roy Blunt Soil Testing and Research Laboratory at the FD-REEC. The building is named for former U.S. Sen. Blunt, who was integral in bringing together federal, state and local funding to build the new facility.

This $4.6-million facility will enhance agricultural research programs housed at the center, offering advanced soil, water and planttissue testing – some currently unavailable in the region.

“The addition of this laboratory at the Fisher Delta REEC will be crucial to enhancing the quality of research conducted at the center, thus enhancing the agricultural production and profitability of Missouri farmers,” said CAFNR Vice Chancellor and Dean Christopher Daubert.

In addition to new construction, updates have been made to current spaces at the FD-REEC in recent years, including the soybean breeding laboratory and the greenhouse.

“It is crucial to continue these improvements to enable our researchers to conduct groundbreaking research, and provide farmers

and producers with critical knowledge to improve their production practices and bottom line,” said Aaron Brandt, director of the FD-REEC. “This is more important than ever as farmers and producers are continually faced with the task of producing more with less resources.”

An update to the cotton program’s microgin aims to provide the industry in Missouri with a comprehensive, visual understanding of the ginning process, mirroring large-scale operations. This educational tool will allow viewers to follow the journey of cotton from harvest to useable lint. By simulating real-world ginning procedures, the program enhances industry knowledge and helps improve cotton lint quality in Missouri.

Additional cotton storage and office space is also currently in the works.

New initiatives and collaborations across the Missouri Agricultural Experiment Station aim to keep farmers more productive and efficient with time and resources – and producers in southeast region of the state are benefitting.

Mizzou’s new Digital Agriculture Research and Extension Center (DAREC) looks to enhance research, education and outreach in emerging digital technologies for farming; the goal is to help producers’ efficiency by using data-driven strategies for decision making.

Formed by a partnership between CAFNR, MU Extension and the United States Department of Agriculture (USDA) Agricultural Research Service, the center will explore key areas including crop production, soil health, precision livestock farming and engineering innovations through research and collaboration with industry partners and agencies.

A signature program is a grant from the Missouri Department of Higher Education and Workforce Development for agricultural drone training through the REECs, DAREC and MU Extension.

“This technology is just going to keep advancing, and it’s going to keep getting better and better, and we want to make sure we are working to harness that to help people farm better,” said Jay Chism, director of the Southwest REEC and program coordinator.

Finally, a partnership with the USDA’s Natural Resources Conservation Service (NRCS) has placed staff members across the REECs to work directly with landowners in their area.

“The purpose of this project is to enhance the adoption of conservation practices that will increase crop productivity, improve adoption of water management practices and enhance water quality,” said Jeff Case, director of the Northern Missouri REEC and of the project.

These forward-looking, creative and collaborative initiatives look to benefit Missouri farmers and ranchers for years to come.

Throughout 2024, the National Cotton Council (NCC) worked diligently to amplify U.S. cotton’s presence across various platforms. NCC leadership from the seven segments of the U.S. cotton industry were engaged in numerous issues ranging from trade to regulatory. However, our primary focus remained the development of the new farm bill.

The NCC took proactive steps to communicate its priorities to Congress and the Administration, advocating for a meaningful farm bill that includes an effective safety net and comprehensive risk management tools. Throughout the year, NCC staff educated numerous new Congressional Members about the contributions of production agriculture to the national economy, the necessity of robust farm legislation, and the challenges facing U.S. agriculture.

Last year’s crop was covered by the 1-year extension approved by Congress and signed by President Biden late in 2023. However, as the NCC stressed to Congress, simply extending the current bill did not provide an adequate safety net given the costs of production. It remains critical that a new farm bill be passed to increase reference prices to a more meaningful level.

NCC staff has been actively involved at every stage, acknowledging that this process will extend further into 2025. For many producers, current cotton prices still fail to cover production costs, inhibiting grower profitability. Growers cannot afford another season without resolving the current deficiencies in the cotton safety net.

In September, the NCC led an initiative by sending a letter to House and Senate leaders advocating for a new farm bill with improved safety net provisions for producers. The letter, endorsed by over 300 organizations representing commodities, lenders, and other rural interests, highlighted that the current Title I safety net had not kept pace with inflation.

In addition to the letter, the NCC coordinated multiple commodity groups and lenders visits to nearly 100 House and Senate offices, including key Congressional Leadership offices in both Chambers. Participants noted that this was the first multi-commodity advocacy campaign

in recent memory, which added significant momentum to the process. Additionally, several state and regional cotton groups made separate visits to Capitol Hill, meeting with over sixty offices. All groups emphasized the urgent need for Congressional action and provided lawmakers with firsthand accounts from farmers about the challenges they face and the potential consequences of inaction.

In August of last year, the Council convened a Strategic Planning Task Force, consisting of eighteen industry members representing all segments and production regions. The Task Force continues to assess the global economic landscape and competitive forces facing the U.S. cotton industry, identifying strategies, policies, and initiatives to enhance the competitiveness of U.S. cotton, U.S. cotton textile products, and U.S. cottonseed.

The Task Force identified significant challenges facing the U.S. cotton industry, with the most pressing issue being the alarming gap between rising production costs and falling market prices. Discussions also highlighted the increased competition in global fiber markets from Brazilian and Australian cotton production, as well as the influx of Chinese polyester flooding the market.

Regarding issues that could harm the reputation of U.S. cotton, the Council is carefully observing reports of lint contamination from our textile customers, with most cases involving plastic contamination. This contamination is adversely impacting the economic well-being of the entire industry. Therefore, we are persisting with our educational efforts to prevent contamination.

Since exports are crucial for the sustainability of U.S. cotton, the industry is set to gain from the U.S. Department of Agriculture’s announcement of an additional $300 million in competitive grant funding through the Regional Agricultural Promotion Program (RAPP). This program targets applicants aiming to open markets in Africa, Latin America, the Caribbean, and South and Southeast Asia. This announcement marked the second RAPP application period of the year. In May, the USDA awarded $300 million in the first round of grants to 66

organizations, with Cotton Council International receiving $19 million, the third largest award among agricultural organizations.

The NCC also continues to support the U.S. Cotton Trust Protocol, a sustainability initiative that will greatly enhance the marketability of our cotton. This initiative presents a significant opportunity for our industry to offer the data and supply chain transparency that brands and retailers require. The NCC is pleased to announce that the planted acreage enrolled in the Trust Protocol has increased to 2.1 million acres, a 31% rise from the previous year, showcasing the industry’s strong commitment to responsible production. For more details, visit TrustUSCotton.org to learn more about the program.

The NCC will build on its longstanding service to the U.S. cotton industry by addressing challenges in farm policy, international trade, regulatory requirements, and appropriations in the coming year.

The National Cotton Ginners Association continues to address important regulatory issues that could significantly impact ginners. One important issue is the OSHA Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings August 30, 2024 Proposed Rule, which is the first-ever national heat stress rule that is aimed at protecting workers from heatrelated illnesses and fatalities. This proposed rule requires employers to implement measures to safeguard employees from extreme heat in both indoors and in outdoor setting. This proposal could greatly impact your workplace safety protocols regardless of your industry, and therefore would affect agricultural operations and cotton gins. As we see it, there are several problems with this proposed rule, including a nationwide heat index triggers of both 80° and 90°, which most Southerners can easily withstand.

Just a few of the requirements are break areas with cooling measures, indoor work area controls, acclimatization protocols for new and returning unacclimatized employees, and paid rest breaks, if needed, to prevent overheating. The 90° trigger adds other layers to this proposed rule, including mandatory rest breaks of fifteen minutes at least every two hours. National Cotton Ginners posted comments regarding this proposed rule. In fact, there were some 30,000 comments posted, and we are hopeful that this rule will never be finalized, as employers are already doing what it takes to keep employees safe from the heat.

The inability for ginners to find and keep labor continues to be a major issue and gins are increasingly relying on the H-2A program to fill this need. Over the past few years, there have been several changes, including the methodology to calculate the Adverse Effect Wage Rate (AEWR) that has impacted the H-2A program.

The AEWR methodology change that has significantly increased the H-2A wage rates and has contributed to wage inflation in agriculture, as all employees who are hired by an employer using the H-2A program must be paid that same rate if the employees are performing corresponding labor. Changes also stated that to avoid paying higher wages than necessary, it was very important to include the correct AEWR Standard Occupational Classification Codes. Furthermore, several new rules and regulations, such as the 2024 Farmworker Protection Rule, are directed at employers using the H-2A program. This rule has a number of focuses on strengthening protections for agricultural work-

ers and on enhancing the Department of Labor’s capabilities to monitor H-2A program compliance and to take necessary enforcement actions against program violators. The problem is that the thrust of the rule is on protections for the employee and that there is nothing in this rule to address the needs of the employer. Users of the H-2A program should be aware of the new Department of Homeland Security Rule - Modernizing H-2 Program Requirements, Oversight, and Worker Protections that went into effect on January 17. The purpose of this rule is to modernize and improve the DHS regulations relating to the H-2A temporary agricultural worker program and the H-2B worker programs. The main purpose of the rule is focused on program integrity and worker protections, but the rule also includes strict requirements and penalties for employers who violate the requirements of these programs.

Another important issue that we are closely monitoring is the recent lowering of the National Ambient Air Quality Standards for fine particulate matter, or PM2.5, and the recent lowering of the annual standard from 12 to 9 micrograms/cubic meter. Ginners are concerned because the standard is set at such low levels that we are approaching the background levels that could put many additional areas into “nonattainment.” In fact, the average background monitor reading for PM2.5 across the U.S. is 8 micrograms/cubic meter. While EPA states that the earliest year that States will likely need to come into compliance with this standard is 2032, it is important to note that the standard went into effect last April, which means that state agencies will use the new annual standard of 9 micrograms as the limit if you are required to submit modeling for a new or a modified facility. Gins are seasonal operations, and how this new annual standard will impact the ginning industry is still being assessed.

Obtaining property insurance for gins considering increases in deductibles and premiums, and securing coverage are ongoing problems, and ginners must do everything that we can to detect and prevent fires. National Cotton Ginners has worked with insures and has developed the best management practices to help prevent fires, and these best management practices are available on the National Cotton Ginners’ website https://www.cotton. org/ncga/. Fire prevention research continues, and the committee heard an update on research that is being conducted by Greg Holt, with USDA, to determine if chemical precursors can

Harrison Ashley Vice President, Ginner Services National Cotton Council

be detected that signal that a fire in cottonseed is imminent, with a goal of developing an earlier warning detection system for a potential fire.

During the 2025 Ginning Conference in New Orleans, and in the National Cotton Ginners’ Technology Committee meeting, a major topic was discussions involving the vast amount of data that gins have available to them. Discussions involved the best way to capture this data and how the data can be utilized to increase ginning efficiencies, reduce costs, and provide benefits to farmers. One set of data that ginners have been collecting for years is the variable ginning costs that are documented in the Cotton Gin Cost Survey, and we need your gin to complete the survey. That survey is now webbased, and the link to the survey is available on the National Cotton Ginners’ website. This survey will allow you to track your individual gin’s variable ginning cost and to compare your cost to other gins in the region and in the rest of the Cottonbelt. However, if you would rather use a paper survey, that too is available on the National Cotton Ginners’ website. Just complete the paper survey and email it to hashley@ cotton.org. I will enter the survey data and will destroy the document. Your data is strictly confidential and will be shown only in aggregate. The data for ginning costs that includes energy use also may become an important discussion point in sustainability programs, such as the U.S. Cotton Trust Protocol.

BY RANEY RAPP

Raney.Rapp@FarmProgress.com

Agricultural trade is often broken down into dollars and cents. Twenty percent of U.S. agriculture is exported. Some commodities like cotton, for example, reach 70%-80%. Even more limited exports, like beef or milk at less than 15%, all cumulatively add up to billions of dollars for the economy.

In 2025 it is more critical than ever to know international trade markets and opportunities more intimately than simply numbers on a page – and visitors at the Mid-South Farm and Gin Show will have the opportunity to connect with trade more closely during the Mid-South Agricultural Trade Conference.