3 minute read

CUTTING NATURE CUTTING NATURE

Since 1961 among the best players in cutting tools for converting industry: paper, plastics, flexible, non-woven and aluminium. Totally in-house production.

Advertisement

Dr. Schenk Hall A5 Stand 1644

Dr. Schenk GmbH presenterà le soluzioni di Ispezione Ottica per il controllo automatico e completo della qualità dei materiali flessibili nel converting; quotidianamente verranno effettuate dimostrazioni dal vivo con telecamere proprietarie e ad alta velocità, illuminazioni dedicate e software di ispezione basati sull’intelligenza artificiale. I produttori di materiali flessibili di alta qualità come film, nontessuti e tessuti devono conciliare alta qualità, prezzi più bassi e pressione sul time-to-market.

I film plastici per l’imballaggio alimentare, il settore delle nuove energie con i fogli per le batterie al litio, le celle a combustibile e i film per i moduli solari organici (OPV), gli OLED, il settore automobilistico, quello medico e molti altri condividono due caratteristiche: gli elevati requisiti di qualità dei materiali dei film e le complesse configu- razioni degli strati. Pertanto, il controllo preciso del processo produttivo è essenziale per ottimizzare i costi di produzione.

Il controllo della qualità in linea delle proprietà dei film, utilizzando sistemi avanzati di ispezione ottica automatica come

EasyInspect e EasyMeasure di Dr. Schenk, è un fattore chiave di successo per il controllo completo del processo.

Dr. Schenk mostrerà come i produttori di film possono trarre vantaggio dal rilevamento dei difetti locali, ad esempio per individuare e identificare in modo affidabile le mancanze di coating nei film rivestiti di silicone, in combinazione con il monitoraggio delle proprietà del film su vasta scala, come l’omogeneità dello strato di rivestimento:

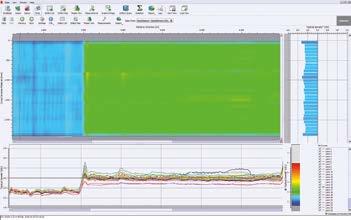

Le soluzioni di ispezione Dr. Schenk offrono il rilevamento di difetti locali, ad esempio mancanze coating, e il monitoraggio delle proprietà su vasta scala, ad esempio l’omogeneità dello strato di rivestimento.

Figure 1: Dr. Schenk inspection solutions offer detection of local defects, e.g. coating voids, and large-area properties monitoring, e.g. coating layer homogeneity

ENGLISH Preview ICE 2023

ink systems, particularly homogeneous transfer of white, varnish, gold and silver.

Dr. Schenk – Hall A5 Stand 1644

Dr. Schenk GmbH will showcase optical inspection solutions for comprehensive automatic quality control of converted flexible, web-based materials; live demonstrations of proprietary high-speed cameras, dedicated illuminations and AI-based inspection software are conducted every day Producers of high-quality flexible materials such as films, nonwovens and textiles must reconcile high quality, lower prices and time-to-market pressure. Plastic films for food packaging, the new energy sector with foils for Li-batteries, fuel cells and films for organic solar modules (OPV), OLEDs, automotive, medical and many more share two characteristics: high quality requirements regarding the film materials and their complex layer configurations. Therefore, precise control of the production process is essential to optimize production costs. Inline quality control of the film properties using advanced automatic optical inspection systems such as EasyInspect and EasyMeasure from Dr. Schenk, is a key success factor for complete process control.

Film manufacturers benefit from local defect detection, for example reliable detection and identification of coating voids in silicone coated film, combined with large-area monitoring of the film’s properties, such as coating layer homogeneity:

• The same inspection solution used for detection and classification of defects can also monitor large-area properties of the film – without requiring additional hardware.

• Dr. Schenk high-speed cameras and extra-bright illuminations are developed in-house and perfectly matched to each other; they deliver defect images from multiple views (MIDA) - the basis for complete defect analysis;

• MIDA X, a powerful AI-based segmentation and classification software, then analyzes every defect and its surrounding area to accurately and automatically classify it; no defect goes unnoticed and critical defects are not misclassified;

• This is combined with monitoring overall material properties to ensure e.g. that coating layers are thick enough to perform their desired function but no thicker than necessary. How do manufacturers benefit from Dr. Schenk inspection solutions?

• They can simplify their work life by optimizing detection, segmentation and classification of any defects in their materials

• They can save expensive coating material by not applying more than necessary and excluding material that does not meet their quality standards from further processing.

• They can ensure the functionality of their film by applying exactly the necessary amount of coating material.

• The quality data from a Dr. Schenk inspection solution creates a flexible, expandable basis from which to derive various strategies: process optimization, machine service actions, and even supply administration – all complete with data for product planning and yield optimization.

• Tool-to-tool matching capability helps manufacturers whenever their production is enlarged by delivering a system that is the same as the one they are already using; this makes ramp-up very efficient and minimizes time and cost for staff training.