13 minute read

HP unveils drupa portfolio

The portfolio will launch as scheduled despite drupa postponement. Sha Jumari reports.

In a virtual press conference, HP Inc. had announced new product launches for commercial printing and labels & packaging that was slated to be on show at drupa 2020. Organisers for drupa recently announced the postponement of the event, but HP has said that it is not reliant on it for launches or releases and that the portfolio will launch as scheduled.

COMMERCIAL There are five notable products that will be launched: HP Indigo 100K B2 digital press, HP Indigo 15K, HP Indigo 7K, HP Indigo 7eco and HP Indigo 90K and the HP PageWide T250HD. On the software end, the HP PrintOSx is a cloud platform with even more AI functionality than the drupa 2016-launched HP PrintOS. The new ‘normals’ For the past 20 years, the commercial print market has been going through a decline and under pressure. According to HP Indigo’s general manager, Alon Bar-Shany, there are new “normals” that are defining what customers are looking for, and requesting from HP.

These are the new normals that are inadvertently affecting HP’s investments in its technology: 1. Everything is online. The new generation is consuming in a different way, and they’re buying in a different way.

2. Same day delivery requires quicker turnarounds. Today’s consumers are expecting their product in one day to two hours. 3. Minimum orders are a thing of the past. Things change too quickly and brands are not willing to get tied up with too much money in inventory.

4. Eco and local mindset. Sustainability and reducing CO2 emissions will only be more important for print buyers. People are really eager to only order what they need, consume what they need, and in general reduce their negative impact on the environment.

5. The world has moved online. Online channels are great, but they are becoming increasingly confusing, crowded and expensive. More and more companies are moving some of the advertising back to print as data driven and unique print has extremely high ROI.

6. Average is over. People are looking for experiences. It is not just about products and services anymore. It’s about emotions and connecting to an experience, which is why people and businesses are willing to pay more for experiences.

HP Indigo 100K – first in new Series 5 platform One of the star products is the HP Indigo 100K digital press, a new generation B2 commercial printing solution. It is purportedly the world’s most productive B2 sheetfed in the market. The first press in HP Indigo Series 5, the HP Indigo 100K is designed for offset players to adopt highly productive, on-demand digital printing.

The commercial sheetfed press is able to do nonstop printing of tens of thousands of B2 duplex sheets every day. HP had to “go back to the drawing board” for the HP Indigo 100K, which is “born to run”. gripper-to-gripper design for precision registration, as well as unique Indigo digital advantages, including colour automation, calibration, fast switchover between jobs and media and five-input source feeder.

Delivering 6000 sheets per hour, the HP Indigo 100K four-colour press boosts margins on short-run digital production and introduces new calculations that confirm a lower total cost of ownership.

Bar-Shany added that the HP Indigo 100K is currently undergoing customer beta testing, one of which is PressUP, an Italian B2B e-commerce print service provider. Especially for Asia, HP will be introducing an option to RIP at 1600 dpi: “For countries like China, Japan and Korea this ability would be extremely important to print tiny, tiny Kanji fonts at high resolutions,” said Bar-Shany.

The HP Indigo 7K is a 19-inch digital press to fit into the busy A3 space. It is the most versatile press to be able to handle thousands of media and inks.

The HP Indigo 7eco is an entry-level press and is available immediately. Termed by Bar-Shany as being “my first Indigo”, this is an affordable press that offers all the essential HP Indigo capabilities.

“Online printers were asking for a press that is optimised for their high capacity environment. They want a press that can do non-stop production and handle thousands of jobs per day; an offset digital press,” said Bar-Shany.

The HP Indigo 100K Digital Press offers nonstop duplex digital printing, enabling PSPs to deliver more than one million B2 million duplex sheets per month. The digital press features advanced paper handling and offset-like The Rest of the Commercial Fleet The HP Indigo 15K is based on the HP Indigo 10000 platform, which has sold more than a thousand units since its launch at drupa 2012. The HP Indigo 15K is able to address a broader range of applications, higher quality, robustness productivity and automation. It is equipped with new high definition FM stochastic screens support increased sharpness for halftone text. The HP Indigo 90K is a web-fed press for simplex applications such as banners, oversized B1 posters and wallpaper. It is also suitable for folding carton applications.

Also introduced is the HP PageWide Web Press T250 HD. It is a new flagship 22-inch continuous inkjet press which features HP Brilliant Ink and expanded media versatility. It is targeted for high-volume commercial, publishing, transaction, and direct mail applications.

HP PageWide Web Press T250 HD.

On the software front, HP PrintOSx is a level up from PrintOS, which was first introduced in drupa 2016. The HP PrintOSx is a cloud platform which highlights automation. Artificial Intelligence (AI) processes are a major feature on the platform, to help customers build towards a “print factory of the future”.

“With the platform, every week it is updated. It is the future for business in general. All our customers are connected in real time and are able to work remotely,” said Bar-Shany. This has shown to be more of a possibility in recent times of COVID-19 outbreak, when businesses are forced to work remotely.

“Our philosophy for success is grounded in two key principles – innovation and automation – and how they play together to build a profitable business for customers. All this is underpinned by a view towards reducing waste with a genuine concern for the environment. As we develop our product repertoire, we keep these guiding principles in mind. Our new portfolio reflects a range of products that offer unprecedented productivity, as well as new levels of quality and versatility, to inspire the unbounded creativity of our customers and the brands they serve,” said Alon BarShany, general manager, HP Indigo.

Availability The B2 HP Indigo 100 and HP Indigo 15K, HP Indigo 7K and HP Indigo 7eco for commercial will all be available in June or later in 2020. Value packs with various upgrade options will allow the existing customer base to benefit from new features and capabilities. The HP PageWide T250 HD will be available later in 2020.

LABELS & PACKAGING HP Indigo currently offers converters the industry’s widest portfolio of digital presses. HP Indigo offers converters the industry’s widest portfolio of presses, along with new colour and workflow automation solutions, to efficiently deliver diverse, on-demand print orders with low waste.

“The digital labels and packaging market is growing and evolving as converters move to support market needs for on-demand production, SKU diversification, customization and printing with reduced waste,” said Bar-Shany. “Labels and packaging converters using HP Indigo are growing their Indigo volume four times faster than the market and are consistently generating new opportunities. The new labels and packaging portfolio unveiled today is a blueprint for customers to create a digital print factory so they can stay ahead of the curve and deliver a wider range of jobs faster, with less labour, all while keeping the environment top of mind.”

Value packs with various upgrade options will allow the existing customer base to benefit from new features and capabilities. Since drupa 2016, more than 1000 HP Indigo labels and packaging presses have been installed at converters worldwide.

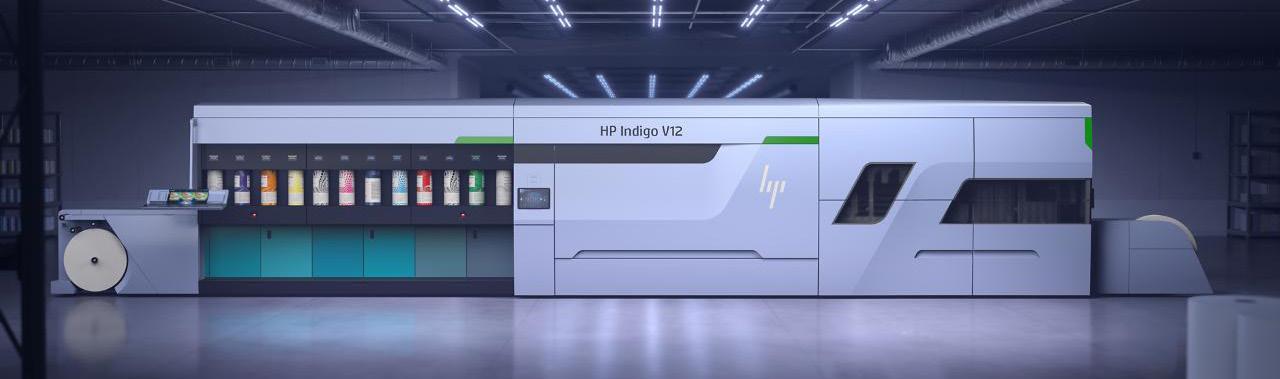

Labels In a major step toward extending analog-to-digital conversion, HP announced the, HP Indigo V12 Digital Press, the first HP Indigo built on next-generation HP Indigo LEPX architecture. Poised to disrupt the label market ecosystem, this is the first of Indigo’s Series 6 platform and is a narrow-web label press.

The press has all of the Indigo’s quality and versatility, but at significantly higher speeds. As a result, the HP Indigo V12 can print as fast as analog with greater production agility, redefining digital label printing.

According to Alon Bar-Shany, general manager for HP Indigo, feedback from some beta customers has been that they see a real possibility to stop investing in flexo: “The V12 is designed to take jobs from flexo. Think three V12s running non-stop; it has the ability to run the massive campaigns.”

In LEPX architecture, six imaging engines operate inline simultaneously, instead of LEP’s single engine, multiplying speed to match analog with the added benefits of digital printing. As a result, LEPX offers the speed and efficiency for PSPs to profitably produce large print volumes than previously possible.

Additionally, the HP Indigo 6K Digital Press is the new model of the highly successful, high-versatility HP Indigo 6000 series. The press can deliver more applications using higher opacity white for shrink sleeves, new inks including silver, fluorescents, invisible red and green for brand protection applications and new varnishes from leading partners for higher durability.

The HP Indigo 8K offers increased productivity, reduced waste and easier transitioning between media types and jobs.

With HP Indigo Secure and partner solutions, converters can provide brand protection solutions using special inks, anti-counterfeiting marks, microtext fonts and protected track and trace solutions. Digital embellishment solutions from HP Indigo and partners offer ways to stand out, including the inline KURZ DM-JETLINER® digital metallization solution, HP Indigo ElectroInk Silver for metalizing the color gamut, and HP Indigo GEM, a digital print-and-embellish, one-pass solution integrated with the HP Indigo 6K Digital Press.

Flexible Packaging HP Indigo customers created the digital flexible packaging market with the capability to offer on-demand and sustainable flexible packaging. The new mid-web HP Indigo 25K Digital Press is designed to help converters meet brand needs with an even more attractive total cost of ownership, a wider media range to deliver compostable and recyclable pouches and more choices to create a digital pouch factory.

The HP Indigo 25K is also designed for high-capacity label production, supported with a new slitter for labels. Folding Cartons

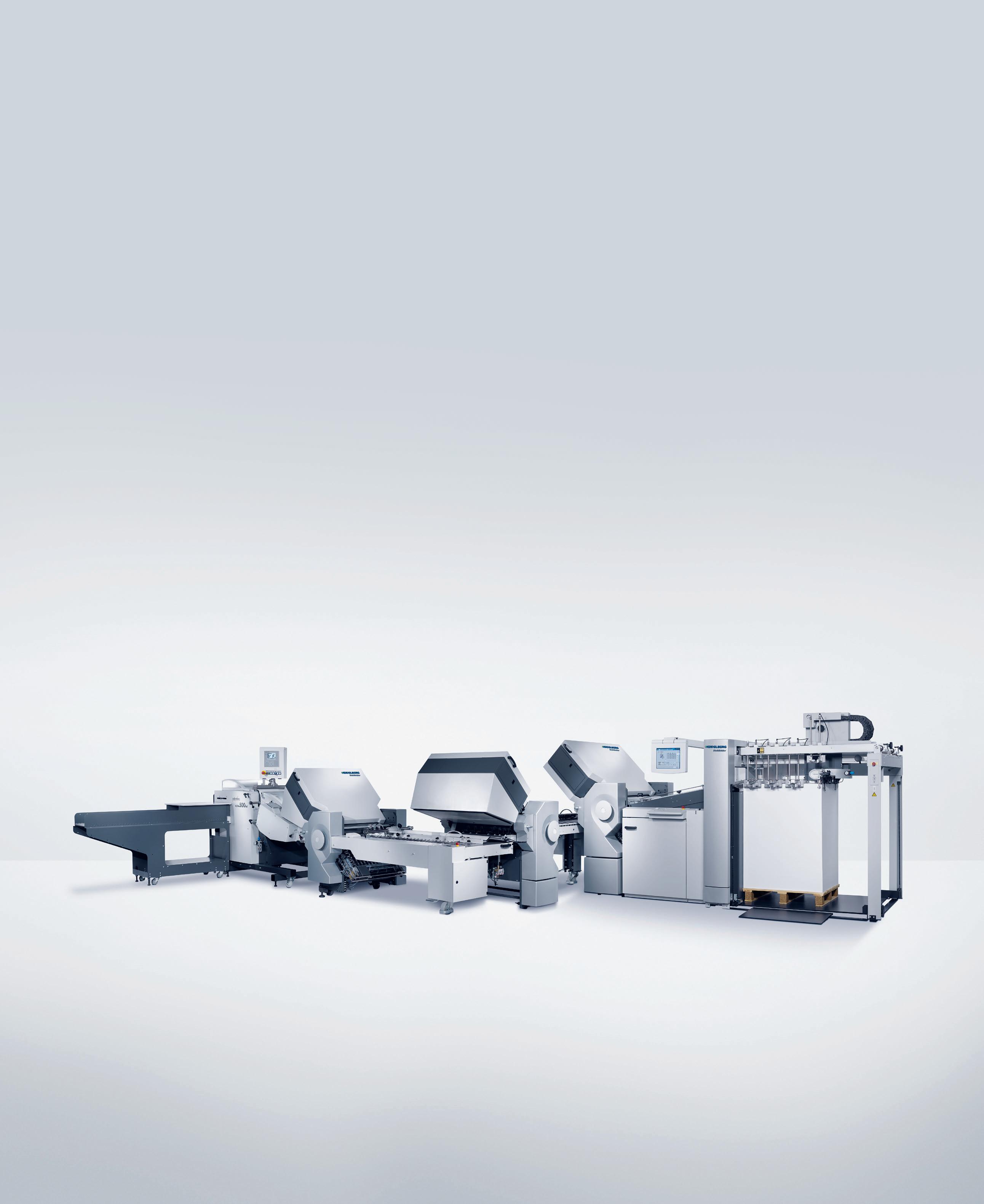

For folding cartons, HP introduced the new sheetfed B2 HP Indigo 35K for high-value folding cartons, the new sheetfed B2 HP Indigo 15K for mixed commercial print and packaging production and the new B1 HP Indigo 90K roll-to-sheet solution with an inline water-based/UV coater and sheeter.

Software - Advanced workflow and colour automation tools A new colour automation solution, Spot Master, will enable converters to reach brand colours within minutes, making it the industry’s fastest time-tocolour solution.

Spot Master enables converters to deliver high colour consistency and uniformity across the entire print frame using a new patented algorithm for fast and accurate colour matching, ensuring every package looks the same no matter when or where it was printed. Spot Master will be available for the HP Indigo 35K, HP Indigo 25K, HP Indigo 6K and HP Indigo 8K presses. Brand Beat, a new application offered in HP PrintOSX, delivers real time color reports directly to converters and brands.

PrintOS Production Pro for Indigo Labels and Packaging, featuring HP Indigo’s fastest HP Indigo Raster Image Processor (RIP), is seamlessly integrated with the new Esko Automation Engine for HP Indigo, allowing converters to process more jobs per day. HP PrintOSX unites the cloud platform applications with AI-driven service and support infrastructure to help customers get the most out of their press investment. With its suite of tools and applications, customers can start building the digital Print Factory of the Future and reach operational excellence by automating production and minimizing operator touchpoints. Availability

The HP Indigo 6K, HP Indigo 8K, HP Indigo 25K, HP Indigo 35K, and HP Indigo 90K digital presses will be commercially available in June or by the end of 2020. The HP Indigo V12 is scheduled for commercial availability in 2022.

HP Indigo 7eco Digtial Press

HP Indigo 7K Digital Press

HP Indigo 15K Digital Press

HP Indigo 25K Digital Press

HP Indigo 35K Digital Press

MICRO RUN THE EVOLUTION OF DIGITAL TEXTILE PRODUCTION

The fashion life cycle: From short to shorter

The fashion industry works at a furious pace. Trends and styles shift and evolve, and production capabilities must follow suit. From a single seasonal collection, designers now produce inter-seasonal items, while e-commerce and a desire for individuality drive the demand for one-of-a-kind garments. Many fashionforward items are now one-offs, requiring a shorter but still profitable printing cycle.

No matter how you turn this, the consumers have spoken their minds. Personalized fashion is here to stay, and thus redefines industrial short runs. The industry demands printing in ever-smaller quantities. Production technology must answer that need.

What is a micro-run? Since the one-off trend is becoming the norm, short runs simply aren’t enough. The industry is searching to define the solution for personalized fashion. Kornit Digital has the answer: the micro-run.

Shorter than the short run, the microrun enables an inexpensive run for fabric lengths as small as a meter. Extreme, inexpensive customization is now available to fashion designers and manufacturers around the world.

By eliminating many of the traditional pre- and post-care steps, the micro-run requires only a digital file and a single operator. A single versatile ink adapts to different materials and encompasses a full colour gamut.

Short runs: 6-8 pre- and post-treatment steps. Micro-runs:

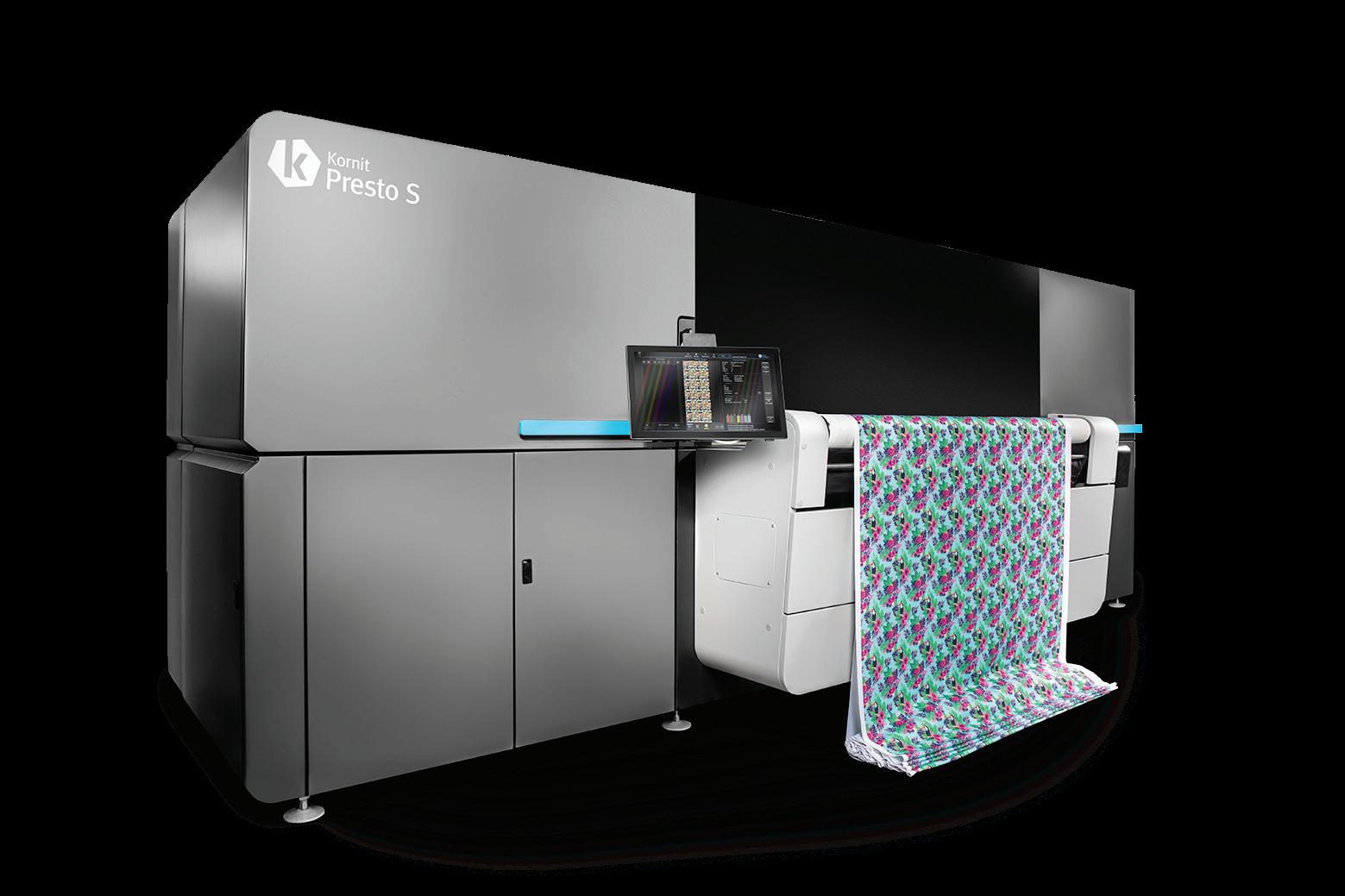

1-step solution for small printing jobs. The solution – Kornit Presto

Kornit Presto a single-step solution for long, short, and micro-runs. Like its former Allegro, the Kornit Presto