8 minute read

Lifecycle Business and the new offering of

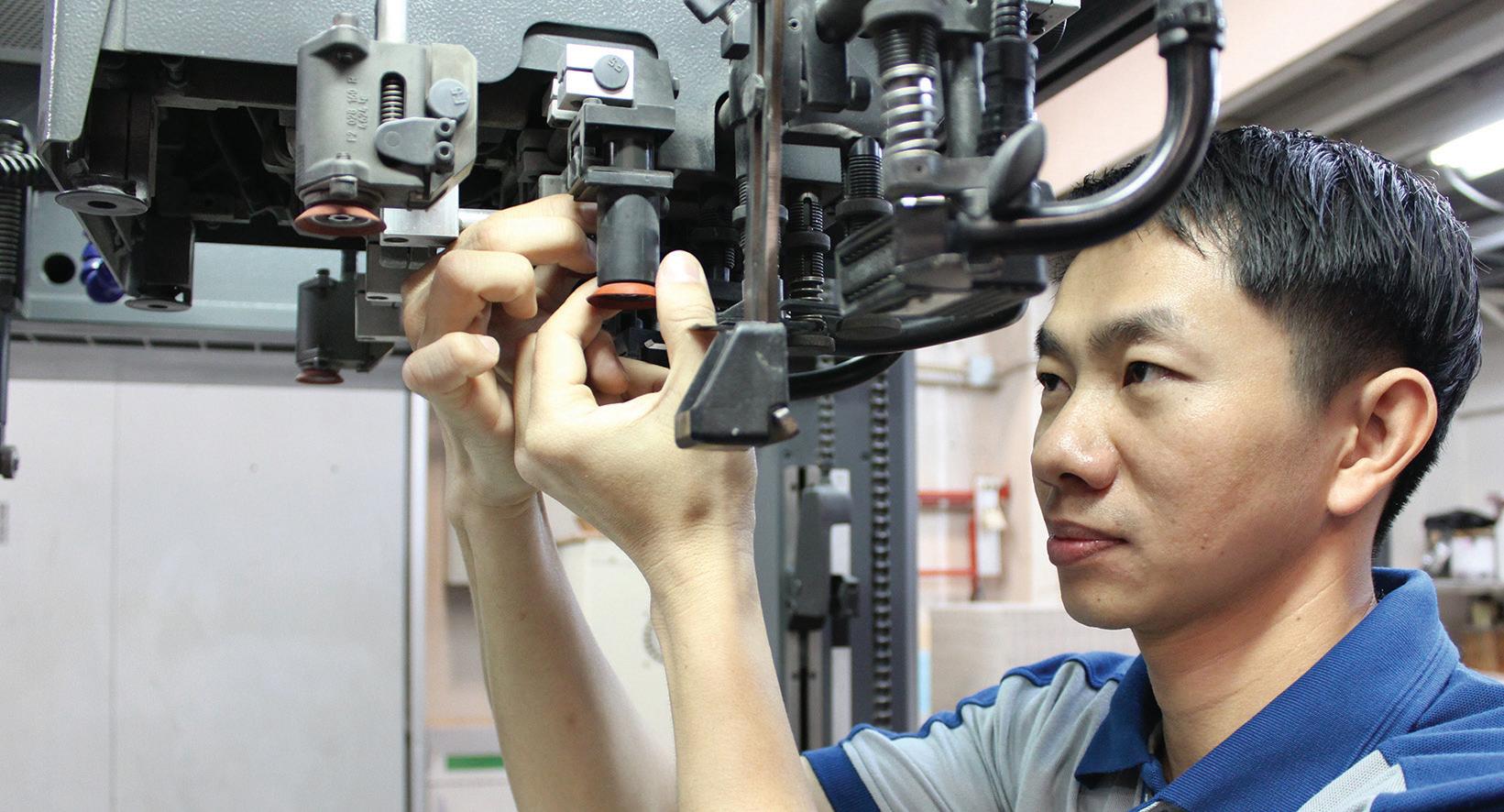

Interview with Thomas Frank, Managing Director of Heidelberg Asia-Pacific about the company’s Lifecycle Business and the new offering of Print Site Contract.

Q1. As symbolized by the word “We are more than machines. “, nowadays Heidelberg is really focusing on fields like service and consumables, you call Lifecycle Solutions, as well as equipment. Can you please explain why you are taking this direction more than before?

A1. Yes, frankly the business model for print equipment manufacturers used to be simpler. Sell the press, provide training, furnish parts and field service support when needed, and sell the customer another press when the time arrived to replace the equipment with something newer. And that, more or less, was the extent of the manufacturer’s involvement. What the customer actually did with the press wasn’t always the vendor’s primary concern. When it comes to operating the equipment efficiently and profitably, the end-user was often on his, or her, own. This “hands-off ” model prevailed for a long time, but now printing businesses need more than just a reliable machine for prosperity in today’s ultra-competitive environment. This is what has prompted Heidelberg to reconnect with its customers in an entirely new role: as a partnering provider of coordinated resources it calls Lifecycle Solutions.

Q2. Ok, so what actually is Heidelberg offering with Lifecycle Solutions?

Thomas Frank, Managing Director of Heidelberg Asia-Pacific

A2. Lifecycle Solutions deliver ROI by bringing together consumables, technical support, workflow, training, and business advisory services in coordinated packages that are specific to each customer’s situation and need. The common denominator is performance: helping customers do whatever it takes to maximize overall equipment efficiency (OEE) and achieve optimal productivity goals.

In Heidelberg’s experience, the first step toward “optimal productivity” is often the customer’s recognition that additional capabilities or capacity may already be there. This is why a Lifecycle Solutions projects typically starts with an individual analysis of how the plant is operating and where opportunities for improvement lie.

Thomas Frank, Managing Director of Heidelberg Asia-Pacific

In this way, Heidelberg specialists can help set realistic benchmarks for the customer to work towards: spending less time in makeready, for example, or running the press closer to its toprated speed. Included in the analysis are calculations that quantify what the customer stands to gain in terms of jobs produced per shift, profit per job, and other key performance indicators (KPIs). These KPIs become the key building blocks in developing the printer’s targeted return, providing a benchmark for the success of the project.

Now the Lifecycle Solutions consulting team can make the right recommendations for the package of products and services that the customer will need in order to hit the targets. That could include a recommendation for new equipment, but might also include Saphira consumables, preventive maintenance, operator evaluations and training, repairs to existing equipment, parts replacement, or some combination of these services.

Q3. It sounds like Heidelberg is not just selling consumables and services passively on top of the machines. Could you please explain how you are doing Lifecycle business more specifically?

A3. We are expanding our contract business placing greater emphasis on a partnership-based approach. This is in line with the Smart Print Shop concept developed by Heidelberg. The now available “Print Site Contracts” provide a variable combination of consumables, services, software, training and performance consulting in a single package with the aim of further improving printing press availability and overall performance.

Print Site Contracts are very much scalable and available in the form of a lifecycle agreement or subscription agreement. Customers have a choice of four packages with different scopes of services and methods of payment.

They range from a “Lifecycle Smart” contract that includes services and consumables to a “Subscription Plus” package that covers consulting, training, service, consumables, Prinect software, and even the printing press itself. All packages aim to maximize our customer’s overall equipment efficiency (OEE), which represents a big added value when compared to purchasing individual components.

Customers opting for one of these contracts can rest assured that only coordinated consumables and services with highest Heidelberg quality standards are used. They also avoid the considerable expense, time and effort of obtaining all these elements separately from each other.

The Heidelberg Assistant digital portal plays a key role, too, providing contract customers with a digital link to additional services such as a vendormanaged inventory, important real-time information relating to their company’s performance, and easy access to the Heidelberg eShop.

Q4. Consumables play an important role in the Print Site Contract, even outside of Print Site Contract. Let me ask now about Heidelberg’s consumable business. What kind of consumables do you have? Can your customers get every consumable from Heidelberg? And how are these consumables optimized for

Heidelberg machines?

A4. Heidelberg has a complete range of consumables for sheetfed offset printing - the only thing we do not have are substrates. From plates to ink, coatings, and blankets, chemistry for wash and founts, rollers and stitching wire, glue and cutting knives - we have a very broad offering. Heidelberg source consumables from the world’s leading manufacturers, we test them and trial them in all production applications and environments and on the broadest range of jobs. Our consumables are optimized for the best print result and the most efficient production. We know how to make them work together and can solve any problems using our in-house expertise. Printing is not easy, and our customers know there are problems from time to time. When things go wrong, we know how to fix it, we take responsibility for the outcome. There is no finger pointing between suppliers when you work with Heidelberg.

Our products are not the cheapest, but we are competitive. Using our expertise and products from world leading manufacturers, we are certain that by the time our customers produce a saleable sheet that the cost of that sheet will be same or less than sheets printed with cheap consumables. While the price of plates and ink for example is a high proportion of the input cost – waste from excess makeready sheets, additional wash ups or plate re-makes, add substantially to “hidden” costs.

Reliable, consumables that work every time keep the overall cost of production down. We are proving to customers in Asia-Pacific that paying a little bit more per sqm, kilo or liter but driving higher efficiency with less waste actually saves money. A sheet printed with Heidelberg consumables on a Heidelberg press is most likely the one with the lowest overall cost.

Q5. What are some of the consumables that are moving well currently? For what applications are they used for?

A5. We have aligned our range to ensure we can look after packaging as well as commercial. A few years ago, Heidelberg’s consumables business was prepress focused, we established our business on plates bundled with imagesetters and processors. Plates are still around half our revenues and we are moving more towards low chemistry and processless plates (DOP) as that technology improves.

But more and more our growth comes from Pressroom consumables and products specifically for UV printing. One of the reasons is because nowadays we need to help our customers maximize overall equipment efficiency and achieve optimal productivity goals as mentioned above. Our attention is drawn towards new press configurations our customers are interested in, e.g. longer presses for packaging and label printing.

They want to go into special applications including opaque whites, specialty coatings or multicolor technology. And as a consequence the demand for the associated consumables is on the rise.

Q6. Ok, let’s get back to the story of Lifecycle solutions. Understood that you, Heidelberg, want to help your customer through the life of your equipment with Lifecycle solutions i.e. a variable combination of consumables, services, software, training and performance consulting in a single package called “Print Site Contract”. Does that sound like the installation of a machine is another start of your business from then on?

A6. Yes, the Lifecycle Solutions relationship can begin with the purchase of a new press, or it can be built around existing Heidelberg equipment. Either way, with our Print Site Contracts the customers can increase their profits by raising the productivity in their pressrooms and extending the life of their Heidelberg machinery.

The “Life” in Lifecycle Solutions means a cooperation throughout the entire life span of equipment use, delivering measurable benefits to the printer at every stage. After more than 150 years of serving customers in virtually every country on earth, Heidelberg has learned that there aren’t many printing plants where “good performance” can’t be turned into “peak performance” if the management really wants to go for this. With the right combination of technology, service, consumables and technical advice this is achievable.

And Heidelberg is surely the best partner on this journey as we provide that end-to-end support with Print Site Contracts. In this way, closing the order for a press opens a door to a new kind of engagement between vendor and end-user – a realignment that delivers benefits all around. Now, in and after the Corona pandemic, printers have all hands full to do rebuilding and maintaining their customer relation. With Print Site Contracts we can keep their backs free by implementing production costs savings through waste reduction and productivity increase.