3-22

WEEK 3, 8 & 9

IMPROVEMENT 23-27

HEALTH 28

& PRODUCTS 29-30

3-22

WEEK 3, 8 & 9

IMPROVEMENT 23-27

HEALTH 28

& PRODUCTS 29-30

BY SOPHIE BALDWIN

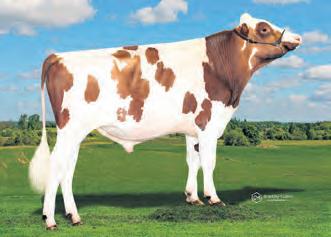

For the first time in International Dairy Week history, a Red and White Holstein has taken out Senior Interbreed and Supreme Champion Cow, Lightning Ridge CMD Dback Barbara, owned by Instyle and Rusty Red’s Juddy Jennings and Brenton Thomas.

And for Brenton, it was back-to-back wins, with Instyle Solomon Dahlia winning last year.

Both Brenton and Juddy were lost for words when Barbara took home the top award telling Around the Barn’s Casey Trealor it was a dream come true.

“Unbelievable, and a privilege to win with a cow I own with Brenton,” Juddy said.

The six-year-old took Juddy’s eye when he bought her as a heifer — Brenton bought into her at a later date.

The boys — from Cooriemungle in southwest Victoria — are hoping she is in-calf and will be back in 2026 to defend her title.

International Dairy Week was held at Tatura in northern Victoria from January 18 to 23.

For Holstein judge Mike Duckket, the entire show was great from junior animals right through to the senior champion, and he couldn’t fault the quality of cattle on show.

IDW director Declan Patten said it was great to see a Red and White take out the win for the first time.

He also said it was one of the best Holstein shows he had ever seen with regard to quality and depth of cattle.

“I think that’s what happens when you have a world-class judge in Mike Duckket in the show ring

“He is one of the most influential cattlemen in the world, and he really lifted the bar with people proud to present their cows to someone of that calibre,” Declan said.

In another first, Declan said it was great to host a celebration dinner in the main arena in honour of IDW’s 35th year.

“We managed to pull it off without a hitch, and we will look to do this again. It also gave the Power of Women in Dairy added exposure and I am a very strong supporter of that initiative,” Declan said.

On a personal note, Declan said it was a highlight to see Matt Templeton awarded the Lex Bunn award for passion, dedication and commitment to the industry.

Matt has generously shared his battle with cancer, and despite telling the Around the Barn podcast his doctor told him to go into

palliative care six months ago, he was able to judge the Jersey show and also go on to have an incredibly successful Holstein show.

Alongside his wife Nicola, the couple won Intermediate and Interbreed Champion, and went on to win Grand Champion with View Fort Lambda Butter.

“The Templeton’s success story has been my favourite part of 2025,” Declan said.

IDW 2025 was also the most successful show for Gorbro Holsteins, from Cohuna in northern Victoria, taking out Junior Champion and All Breeds Junior Champion

with Gorbro Lambda Violet, Senior Champion and Reserve All Breeds Champion with Windy View Chief Justine and premier breeder and exhibitor, along with many class wins.

“We paid $20,000 for Justine two years ago because back then we thought she was good enough – her dairy quality, width throughout and her udder — make her a milking machine,” Glen said.

For more IDW news and photos, go to pages 8 and 9, and online at: www. dairynewsaustralia.com.au

“ We struggled to recruit, so something had to change. If we didn’t have the milking robots now, we would not be milking cows.”

BY GEOFF ADAMS

THE PRESSURE of rising input costs is prompting some dairy farmers to consider leaving the industry, according to new research.

A survey of 150 farmers found that costs were the major reason for concern, followed by long working hours and then labour shortages.

The research was carried out by Curtin University in 2023, with most of the surveys carried out in Victoria, the most populous state for the dairy industry.

The number of registered dairy farms in Australia fell from 6308 in 2014 to 4420 in 2022. The study uncovered a level of dissatisfaction among dairy farmers.

“The majority of dairy farmers did not express positive levels of satisfaction with the industry,” the report found.

“However, some dairy farmers gave strong support to their industry, which reduced the likelihood of them considering transitioning away from dairy farming.

“All farmers recognised that there were significant challenges, in particular rising costs, which represented a major strain on their mental health.

“As a result of this situation, although a significant proportion of farmers were open to transitioning away from the dairy industry,

Some farmer comments from the study:

“Stage of life, extreme workload, and long hours. Shortage of labour and high stress.” (Victoria)

“I [am] just having a bad time, can’t find staff, I’m just over it. Too long hours not enough family time.” (Victoria)

“Input costs, capital outlay, return on investment and red tape which pushes our costs higher.” (Tasmania)

farming.”

especially to alternative agricultural businesses, and would value government support in making such a transition, they were not ready to take this risk because they believed that it would not be profitable compared to dairy farming or that a full transition would not be possible.

“The results indicated that the majority of the farmers, 55 per cent, did not express positive levels of satisfaction with dairy

Curtin University’s Adjunct Professor Clive Phillips said most farmers surveyed (54 per cent) were open to exploring other agricultural enterprises — primarily cropping and beef — with many believing dairy farming in Australia was not sustainable.

“The most common reason for considering transition was ageing/health problems, labour shortages and increasing costs,” he said.

“More than a third (36 per cent) were interested in transitioning to horticulture or another business venture if there was government help, however financial and technical

The peak national representative body for the Australian dairy industry is concerned the Victorian Government’s move to merge the state’s dairy food safety regulator puts the multi-billion dollar industry at risk.

The proposed reforms — part of a broader strategy to halve the number of business regulators by 2030 — would consolidate Dairy Food Safety Victoria (DFSV) with PrimeSafe, Agriculture Victoria and some Department of Health functions.

The Australian Dairy Industry Council argues this move could threaten decades of specialised, trusted food safety oversight in Victoria underpinning the state’s production of 63 per cent of the national milk pool.

ADIC chair Ben Bennett said DFSV was a self-funded, standalone, cost-recovery organisation, that did not cost taxpayers, while delivering huge value to dairy farmers

and processors across the state.

"Unlike other food regulators, DFSV licenses thousands of dairy farmers across the state as well as dairy food processors,” Mr Bennett said.

He said ADIC would seek clarification from the Victorian Government on how it sees value in consolidating DFSV with the other organisations.

“Importantly, we want to understand how the government intends to do this without putting industry quality control, compliance, and consumer food safety at risk.

“ADIC is also concerned that a prominent driver of innovation would be removed from the industry, with DFSV having developed respected initiatives like the Dairy RegTech project, which enhances efficiency and compliance across the sector.

“We’re also concerned DFSV’s respected

Reasons given for exiting the dairy industry (ranked in order):

Rising operational costs.

Long working hours and minimal down-time.

Labour shortages.

Unpredictable weather patterns.

Impacts on mental health.

Unstable milk prices.

Changing consumer demand.

Climate change uncertainty.

assistance were seen as more important than government support.”

In the study, the average number of dairy herds was 381, with the herd size ranging between 55 and 3500 cows.

The average property size for the study sample was 395 hectares, ranging from 20 to 4500 hectares.

Read more about the study, from the report’s authors, at: https://theconversation. com/new-research-reveals-why-someaustralian-dairy-farmers-are-consideringleaving-the-industry-244819

approach of industry-specific consultation informing regulatory measures could be placed on the chopping block.

“We call on the government to recognise the irreplaceable value DFSV provides to the Victorian dairy industry, maintain its role as an independent regulator focused on dairy food safety, and ensure farmers and processors have meaningful opportunity to influence the proposed changes.”

ADIC urged the government to reconsider its approach and invites further discussions to address these concerns.

ADIC deputy chair John Williams said DFSV’s success stems from its deep understanding of the multi-billion dollar industry.

Without this specialised focus, he said the unique needs of dairy farmers and processors could be overlooked and ADIC feared this could lead to weakened

confidence in the food safety system.

“Victoria’s dairy industry is built on a foundation of trust, safety and quality,” Mr Williams said.

“We cannot afford to jeopardise the standards that ensure Victorian dairy products are among the safest and most sought after in the world.”

Mr Bennett pointed out the proposal could lead to on-farm audits being conducted by inspectors unfamiliar with the nuances of dairy operations, creating uncertainty and inefficiencies for farmers and processors.

“The Victorian dairy industry deserves a regulatory body that understands its challenges and opportunities,” he said.

“We call on the Victorian Government to remove DFSV from the proposal and safeguard the innovative and effective frameworks it has established.”

BY SOPHIE BALDWIN

DROUGHT AND some of the driest conditions on record across South Australia are making it extremely difficult for the state’s dairy farmers this season.

South Australian Dairyfarmers’ Association president Rob Brokenshire said things were tough, and the situation had been exacerbated by lack of hay and consequent high prices.

“Our farmers’ cash flows have taken a hard hit as they have tried to source fodder to make up for the lack of a spring break, but that is proving to be difficult and expensive as well,” Rob said.

Rob said this year’s spring break was practically non-existent with frost, cold weather and no rain halting pasture growth and shutting the season down to just a short and unproductive 12-week window.

“It has been a green drought — there is some colour there, but absolutely no growth,” Rob said.

He said there was also concern farmers who have access to irrigation might run out of allocation due to the prolonged length of this dry spell and the hot conditions increasing transpiration losses.

Rob said SADA had been working hard to support its farmers and had successfully lobbied the South Australian Government for $18 million in drought support

The support includes a range of measures including grants for on-farm drought resilience infrastructure, mental health and community support and funding to enable donated fodder to reach more communities.

Assistance includes:

$5 million for on-farm drought infrastructure grants for rebates of up to 75 per cent

(to a maximum of $5000 excluding GST) to assist with projects to manage drought.

$2 million to assist charities with freight costs to transport donated fodder.

$1 million for additional health and wellbeing support through the Rural Financial Counselling Service and Family and Business Support Program.

$4.4 million budget commitment to provide Family and Business (FaB) mentors and rural financial counsellors to link people with the appropriate assistance.

$5.5 million funding provided to the Future Drought Fund for ongoing programs to help farmers with business resilience planning, climate tools and more resilient farming practices.

SADA is also seeking to link farmers with potential fodder opportunities to help reduce

some additional stress.

Hindmarsh Tiers dairy farmer Mandy Pacitti, husband Gino and son Andrew milk around 300 Holsteins.

She said their dairy business was currently slammed on all fronts by a perfect storm — a poor spring, no fodder reserves and a broken-down main bore.

“We are getting paid good money for our milk, but the unprecedented increase in costs means we are starting to see shortfalls again,” Mandy said.

The family did manage to cut some silage of their own and source lucerne hay two months ago, however, the fodder shortage has meant they have had to source what they can.

They are currently spending around $45,000 a month on malt, brewers grain and almond hulls to help extend reserves and keep their

The Victorian Government has appointed a dedicated drought coordinator for southwest Victorian farmers to help them access the financial, technical and wellbeing support they need.

Ralph Cotter has been appointed to the role by Acting Minister for Agriculture Steve Dimopoulos. Mr Cotter has strong connections with industry and government and local service providers, and has had a long involvement with agriculture sector. He will meet regularly with industry and

local governments to understand the challenges specific to the region and coordinate tailored support and advice to impacted communities.

Since the government announced the $13.53 million Drought Support Package last September, 969 on-farm drought infrastructure grants of up to $5000 have been approved and paid to south-west Victorian farmers.

These grants are enabling farmers to complete infrastructure improvements that

A simple way to improve cow comfort in the dairy and calf sheds. As well as an easy, natural solution for odour management.

Here’s what farmers are telling us about this innovative solution:

Have tried them all –this one really works

It’s cheap and really easy to use!

Cow comfortdramaticallyimproved around feed troughs or bails

Odours are hardlynoticeableor disappearedentirely

Lessfliesobservedinthedairies,calf shed and feed lots

Onlyflyinthecalfshedistheone that came in on my shirt!

respond to the current drought and build their resilience for future droughts.

Farmer wellbeing remains a critical focus, with a $1.43 million investment in farmer wellbeing and technical advice to acknowledge the emotional toll on farmers as they respond to the drought and the recent bushfires.

As part of the Drought Support Package, $80,000 was provided to boost the capacity of the Rural Financial Counselling Service Victoria West along with a further investment

Stimulates the digestion of hydrogen sulphide and ammonia –a natural solution and game-changer for Aussie dairy cows!

Parts of South Australia have experienced their driest year on record and food producers have been counting the cost.

The Bureau of Meterology said lowest annual rainfall totals were recorded in places including Maitland on the Yorke Peninsula and Wirrabara Forest in the Southern Flinders.

The bureau has released its preliminary records for 2024, with a full report to be released next month.

BOM meteorologist Chris Kent said much of the state’s agricultural area had experienced “very much below-average rainfall”.

“Through the Yorke Peninsula and part of the mid-north, some locations recorded [the] lowest yearly rainfalls on record, so it wasn’t a good year for rainfall across the south of the state,” he said

“To top it all off, our main bore broke down just before Christmas, making any repairs virtually impossible — worst case scenario is a total rebuild and another three-week wait, making us now totally reliant on our smaller bores,” Mandy said.

“We are fortunate we can still irrigate some land, but we just don’t have the capacity to irrigate what we need and the electrical cost to run the bores is quite significant, even though we have some solar to help mitigate costs.

“It is a really difficult time for all South Australian dairy farmers.”

of $160,000 to support a full-time wellbeing counsellor working in the region.

Drought technical decision-making support continues to be delivered by Agriculture Victoria and partners, with a range of events and information available, including one-on-one consultations and group workshops.

To view the full range of support available to drought-impacted farmers, visit: agriculture.vic.gov.au/dryseasons or phone 136 186.

BY JEANETTE SEVERS

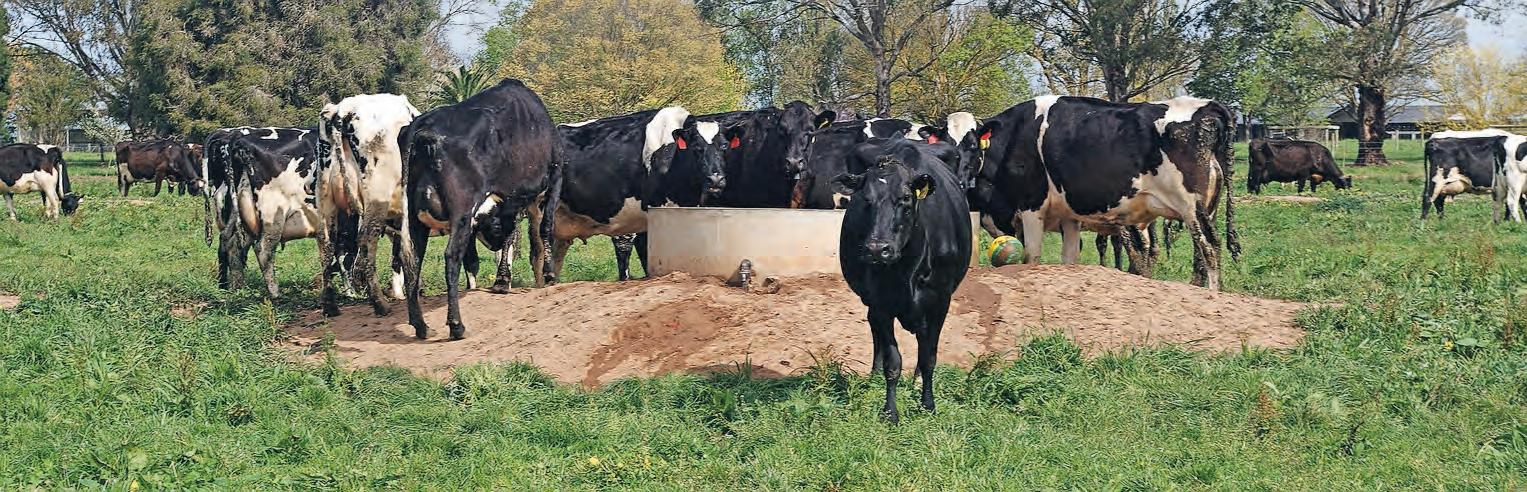

IN HOT weather, cows can cycle again, even though they’re in calf. And some breeds of cows are less susceptible than others to heat stress.

There is a lot of science around managing cows, production and pastures during hot weather, and there are effective changes Australia’s dairy farmers can implement to help their business.

Veterinarian Lauren Foster and GippsDairy extension officer Jess Blackstock led a discussion at a recent Dairy Australia field day, held at the Macalister Demonstration Farm, in Gippsland, Victoria.

The field day discussion and points raised about managing herds in hot weather are relevant to dairy farmers across Australia.

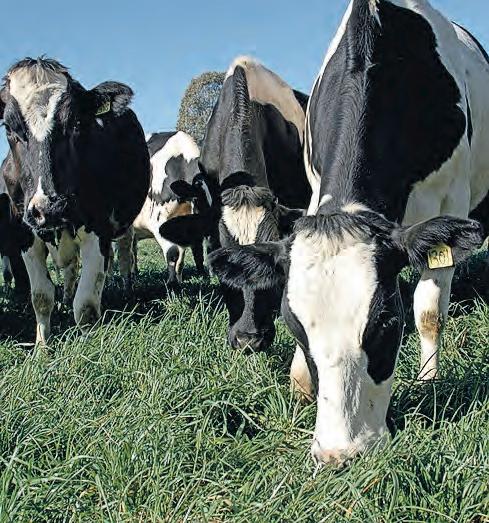

Jess said Brown Swiss and Jersey cows had a low susceptibility to heat, compared to Holstein and Friesian cattle, which had a high susceptibility.

Smaller cows, with their surface area, are potentially better at tolerating and dissipating heat.

Holsteins are larger animals and higher production cows, and require more feed, which Lauren said exponentially increased the temperature of the cow, the blood flow to its udders, and the likelihood of heat stress.

“So big cows with big udders and high production are going to experience more side effects of heat stress,” Lauren said.

Heat stress in the udder can also mean increased mastitis.

“Their immune system is not functioning as well because their whole body is under stress, so cows are more susceptible to infection,” Lauren said.

Even at 25°C, cows begin to feel uncomfortable and must start to actively burn energy to keep cool, which also lowers the energy they can put into producing milk.

Milk from even mildly heat stressed cows has been shown to have altered components, including a decline in proteins and fat content.

There is a research project under way at Ellinbank, where the cows’ environment is deliberately being manipulated to measure the effects of heat stress on the animals.

As an initial observation for farmers, the panting score of cows’ breath is a clear indicator of heat stress.

Jess said as the cow’s core body temperature started to rise and reached a critical point of 39°C, the cows’ panting will be 60 breaths per minute.

As cows start to struggle, their panting rises to 70-plus breaths per minute and the cow is noticeably panting hard.

The likelihood of death increases exponentially as panting increases to 90-100 breaths per minute. The cow’s tongue will protrude, there is excessive drooling, and her neck is extended.

“Moderate heat stress in your cows can produce a 25 per cent reduction in milk yield,” Lauren said.

“In severe heat stress, that can be up to about 40 per cent.

“The 40 per cent drop in milk yield is also noticeable on the first hot day of summer, if there are no factors to mitigate heat stress.”

Sources of heat gain and heat stress include direct radiation from the sun and sky, reflected off the ground (for example, bare earth and laneways), reflected from built infrastructure, and conducted through warm surfaces (feed pads and the walls of the dairy shed) into the cow’s body.

Cows reduce their heat load by panting, sweating and evaporation – hence the need for ready access to water and shade – and by shedding heat to the ground when they are standing on cool pasture at night.

Cows also get hotter when their internal metabolic processes are working, particularly with feed intake.

“High quality digestible forages that are low in fibre are ideal on heat stress days,”

Lauren said.

“Fibre takes the longest to digest and produces more heat per kg of dry matter than any other nutrient.

“But I think the timing of feeding is the quickest change you can make to reducing the impact of heat on cows.”

When the heat load reaches a critical point, changes start to occur in metabolism, hormonal regulation and feed intake, and affects milk production, milk quality, fertility and health.

“We’ve seen cow heat stress become more of an issue, including in dairy regions where it hasn’t been an issue before,” Lauren said.

What the cow needs is opportunities to

Advertising Rachel Fowles 0429 675 962

rachel.fowles@dairynewsaustralia.com.au

Editor Sandy Lloyd (03) 5820 3252 editor@dairynewsaustralia.com.au

Regional editor news@dairynewsaustralia.com.au

avoid increasing its heat load and to shed heat. Each cow needs a minimum of four square metres of shade each day.

“You can make some management changes quickly to keep your cows comfortable, and then longer-term think about nutritional strategies and looking at breeding decisions.”

Ensuring good nutrition to ensure production is easier to achieve by providing cows with access to quality feed during the night, when temperatures are cooler.

“Night time is when cows are going to want to try and compensate for the daytime heat,” Lauren said.

“Provide cows with the highest quality pasture to graze overnight, when they are cooler.

“In terms of diet, there are many ways you can manipulate to compensate for hot weather, but I think the timing for feeding is probably the quickest change that you can make,” she said.

Initial changes included retaining and planting tree breaks, moving the cattle into paddocks with good shade and using a shaded feed pad.

Fans, solid roofs and shade sails can also be installed in the dairy yard.

Lauren recommended early milking so the complete milking herd can be grazing in the paddock by 9am, before the heat of the day kicks in.

“Send cows out to graze in the first part of the morning, then they’ve time to fill their bellies on quality feed,” she said.

“Then bring them into the shade, or where they can stand close to sprinklers.

“Installing sprinkler systems in the dairy yard is a really positive change.”

While the sprinklers or centre pivot in the

Publisher Shepparton Newspapers Pty Ltd

Printed by Newsprinters Pty Ltd

Head Office

7940 Goulburn Valley Highway

Shepparton, VIC 3630

Phone (03) 5831 2312

Postal address PO Box 204

Shepparton, Victoria 3632

Australia

paddock can be left on, providing spray drift to cool cows – subject to water allocation –Lauren said a sprinkler in the yards should be turned on for a while to cool down surfaces, then turned off for a while.

The water drops can cause their own issues for cow comfort.

If the sprinkler in the dairy yard produces too fine a mist, that can increase humidity, also increasing cow distress, and have increased implications for infection contamination and mastitis in the udder.

“Cows tend to stand next to where the water is falling, where the air temperature is cooler, rather than under the water droplets,” Lauren said.

She also recommended the cows have ready access to clean drinking water.

“A water trough at the entrance and exit to the dairy and water troughs in all paddocks also helps cow comfort,” Lauren said.

“Up to 40 per cent of the cows’ water intake is at the exit trough at the dairy, so it’s worth having a trough there and ensure ready access, with an automatic refill mechanism.

“Longer term, tree breaks to provide shade along laneways and in paddocks and your infrastructure in sheds and shade sails are things you can think about installing if you’ve not already got a lot of natural shade.”

Lauren said there had been an increase in the past decade in sheds being built for shade on dairy farms.

“We’ve seen them being built more in the hotter for longer regions, but they also use them in winter time as a shelter set up against cold and wet weather,” she said.

“We’re heading towards more built infrastructure for shade and shelter for cows.”

Lauren also recommends delaying the afternoon milking for as long as possible, until the air temperature is cooler and more comfortable for cows.

Hose down the dairy and yard before the cows arrive to reduce the temperature of the air and built infrastructure.

“Then it’s not too hot for the cows to walk into the dairy and they’ve got that cooler temperature to walk back to the paddock,” Lauren said.

“Make sure they have access to good quality feed at night time. That’s when they are going to utilise it best.

“They’re also going to enjoy standing on grass overnight because grass is cooler than concrete.”

Shade and environmental protection should also be extended to calves.

Dairy Australia has produced a range of resources detailing strategies for managing heat stress in dairy cows.

These resources including analysing the efficacy of built infrastructure including fans, shade sails, sprinklers, sheds and farm planning to incorporate vegetation for shelter and shade.

ɋ More stories on pages 7 and 22.

Dairy News Australia welcomes contributions from stakeholders in the dairy industry, and particularly from organisations wishing to advance the industry.

Contributions and photos can be sent to: editor@dairynewsaustralia.com.au

Letters to the editor on topical issues are also welcome.

Letters should be concise and carry the name and town address of the author, as well as a contact phone number, not for publication.

BY JEANETTE SEVERS

JASMINE KNEEBONE manages the Macalister Research Farm, reporting to a community consultative committee.

The Macalister Research Farm was the venue for a field day to discuss heat stress in cows and how to mitigate hot weather impacts in the herd.

The research farm is 64 hectares, milking 234 cows in a herringbone dairy.

The farm is heavily vegetated with shade trees and irrigated by sprinklers and flood irrigation.

“We’ve got quite a lot of trees around here,” Jasmine said.

“We’ve got a lot of gum trees and cypress trees, and then we’ve got quite a lot of tree breaks.

“Having the shade helps us a lot.”

Unfortunately, the old dairy was built without consideration for shade in the yard.

During hot weather, Jasmine has monitored the air temperature, and chosen to milk the herd early in the morning, then delay afternoon milking until late.

“On hot days this summer, I just kept walking out to the dairy and going, the air doesn’t feel right yet,” she said.

“I didn’t have a time in mind. We normally start milking cows at 3pm, but we didn’t get cups on until 5pm.

“Before then we hosed the yard to cool it down before the cows arrived.”

Jasmine has also chosen strategic paddocks with shade for the herd to graze and shelter in during the day.

“We also keep them in paddocks closer to the dairy so they don’t have to walk very far to and from the dairy,” she said.

“We also opened up a second paddock, that had already been grazed, to provide a second water trough for the cattle. That meant the herd could access water more easily.”

Veterinarian Lauren Foster said environmental changes had the largest positive effect on cows during hot weather.

“Over time, cows will get better at tolerating hot weather if it’s hotter all the time,” she said.

“But when you get a few hot days, then it cools down, then heats up again, that’s when you’ll really see cows knocked around.

“The best thing you can do is invest in shade for your cows.

“Changing your breeding for better heat stress, that’s going to take a long time to see the effects of, and has about a one per cent difference.

“Changing your feeding strategy has about a five per cent difference.

“The infrastructure you invest in to provide shade, all that type of stuff is what makes the most difference for your cows on a day-to-day term and long term.

“Get them into paddocks with shade and a couple of water troughs.

“And cool down the dairy platform before the cows arrive, by washing it down, using sprinklers, fans and shade infrastructure such as shade sails or roofs,” Dr Foster said. More stories on pages 6 and 22.

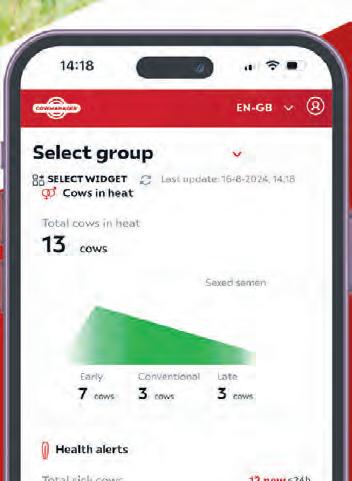

You’ve got all you need in the palm of your hands with the CowManager app. Precise conventional and sexed semen use with the insemination window, early health alerts for mastitis and pneumonia - 24/7 herd insights.

We help you stay ahead of the herd with more accurate and earlier alerts.

BY SOPHIE BALDWIN

To celebrate its 35-year milestone, International Dairy Week held a special anniversary dinner in the main arena on January 21.

The dinner included a slideshow of IDW highlights by former founder Brian Leslie and presentation of the annual Power of Women in Dairy award to Fiona Hanks.

IDW director Declan Patten, who took over running the event in 2021, said it was an honour to reflect on the success of this incredible event which had become a cornerstone of the global dairy industry.

“I want to thank Brian for his guidance in carrying forward the legacy of this event and I look forward to what the future holds,” Declan said.

Since jumping on board, Declan has introduced some small but powerful changes to the event, including the introduction of the popular social media platform Around the Barn, which interviews participants and winners, and takes IDW and the Australian dairy industry to the world.

Declan has continued to focus on encouraging young people into the industry through IDW, with the youth event increasing in popularity.

Brian reflected on the amazing journey that he was at the helm of from 1996 until 2020.

The original dream was to hold the event in Shepparton, but after it was determined to too expensive, they pivoted to Tatura.

The event has come along way from the early days, where show cows at the time were walked around a gum tree, now dairy cows from across the country and every breed are represented at IDW.

Brian acknowledged the guidance and support of many people involved in the industry including mentor Daryl Brown, Ayrshire breeders and brothers Ian and Lex Bunn and Don Blackmore.

He also acknowledged the support of his own staff including Robyn Barber who ran IDW from 2011-20.

There have, of course, been many highlights over the years and so many great cattle to talk about, including the record price of $251,000 paid for Lightning Ridge CMD Jedi Gigi at the WWS Evolution Sale in 2017.

Brian also mentioned the prowess of Lyndon

champion cow, while Llandovery JR Joan 982 Ex-95-3E, owned by Gorbro and C. Rapley, was reserve champion.

POW president Jade Sieben presented Fiona with her award.

Clearly surprised, Fiona was a popular winner, with the crowd cheering loudly.

Fiona is a familiar face around the IDW show ring, local shows and calf days in the western districts of Victoria.

She has prepared cows, shown cows and photographed cows. Work ethic and drive have seen her work with some of the greats of the dairy industry over the years.

Fiona said she was humbled to receive such recognition.

Fiona is the ninth recipient of the Bette Hall award and she joins other winners Lyn Boyd,

Udder

BY GEOFF ADAMS

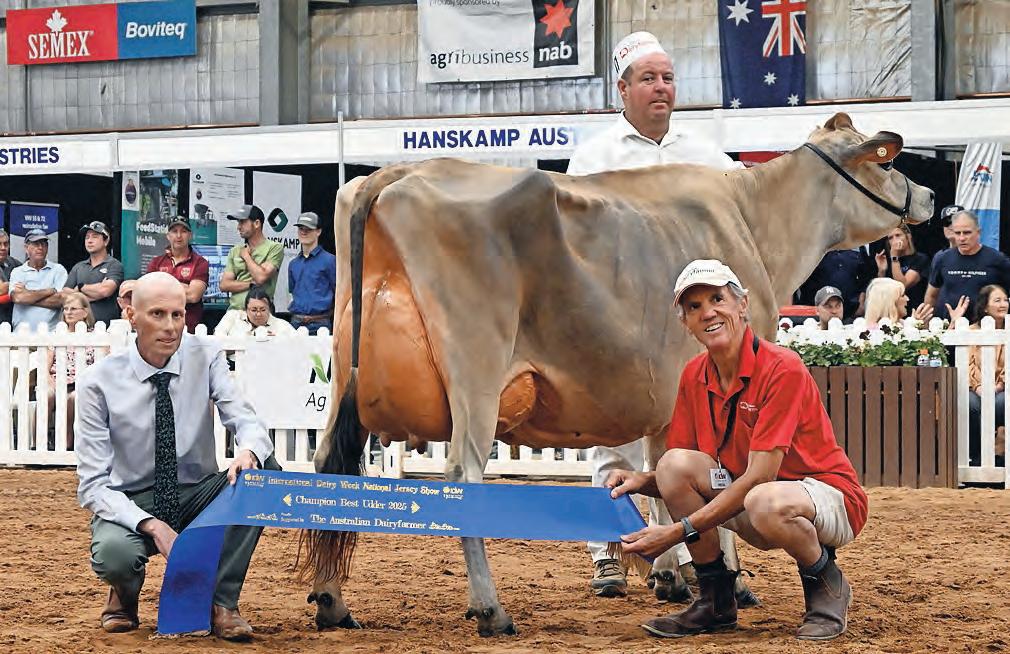

A COW shown by Riverlane Dairy from NSW has taken out the Grand Champion sash in the National Jersey Show.

Rivendell Victorious Vienna was also judged Senior Best Udder and Senior Champion at International Dairy Week in Tatura.

Also at the Jersey show, Premier Breeder and Exhibitor was the Bacon family at Brookbora Jerseys, from Tennyson; the Exhibitor Encouragement award went to T. and L. Smethurst from Gippsland; and premier sire was River Valley Victorious from World Wide Sires.

Jess and Brad Gavenlock from Tallygaroopna, with the winner of the Intermediate Champion Jersey class, Lightning Ridge Mb Victorious Tesla 1 Imp ET . She was also named Best Udder in the intermediate division. Brad said the Jersey was born at the family’s place, but was owned by friend and competitor Declan Patten. “We convinced him to sell at one of our sales and we bought her”. Was this a deliberate plot? “Absolutely!”

The youth events continue to be one of the most successful and popular sections of International Dairy Week.

Held at Tatura Park on January 19 and 20, the youth show attracted a record number of entries.

BY RICK BAYNE

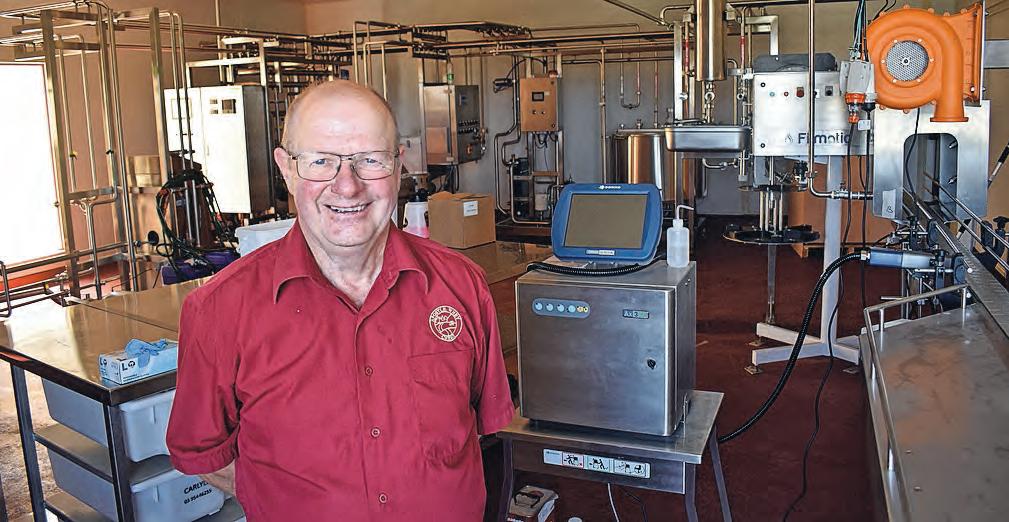

JULIAN AND Dianne Benson’s Apostle Whey Cheese in south-west Victoria makes all the staple dairy products like cheese, milk and gelato.

And now there’s gin — the latest product added to the mix that came as much out of left field as it did out of necessity.

When Julian and Dianne last year subdivided their Apostle Whey Cheese business from their dairy farm, they had to find a way to use the whey on site.

Gin has provided the solution.

Last year, their youngest son Luke purchased the dairy farm, after working for a few years on a 50-50 share agreement, leaving Julian and Dianne to concentrate on the production and hospitality side of the Apostle Whey business just inland from the Great Ocean Road near Port Campbell.

While they were overjoyed to have one of their children take over the farm business, the subdivision left them with a dilemma about what to do with their whey — the by-product liquid left from the manufacturing of cheese.

Before the subdivision, they had been depositing the whey back on the farm for the cows

“The installation of robots enabled us to milk nearly double the amount of cows with the same amount of staff”

- Jeff McCauley

to drink. Whey is considered a good addition to adding energy to the diet of cattle, and it proved popular with their herd.

Now that they have subdivided the 1.5 hectares used for the Apostle Whey production facility, restaurant and shop, they have to keep all waste produce on site.

“It can’t cross over the boundary into the dairy farm,” Julian said.

An approach from Otway Estate about using the whey and turning it into alcohol for gin production provided an environmentally friendly and potentially lucrative solution.

“It’s what they call the circular economy,” Julian said.

“We’re trying to make a product out of the by-product of cheese making.”

The whey is collected by Otway Estate which adds yeast and then ferments it to produce about four per cent alcohol, with botanical flavours then added to the mix.

“We’re sending off about 2000 litres a week and they’re creating about 80 litres of alcohol from that,” Julian said.

Apostle Whey Cheese has two flavours available — Rose Rubellion, with a touch of rose and rhubarb, and Pepper Berry.

“You could add citrus in or other things to make different flavours, but I think we’ll keep

Increase farm efficiency with the Lely Astronaut milking robot Save hours of cups on/off labour every day with the introduction of robotic milking on your farm. No fixed milking times, fewer staff issues and reduced physical strain on your body, are just a few of the benefits we hear from our robotic milking farmers. Are you looking for more efficiency on your farm, more quality family time and less impact on the body? Then get in touch and explore your possibilities.

Bright farming is yours by choice

it to three or four types,” Julian said.

Julian admits that prior to the approach from Otway Estate, he didn’t know that whey could be used in making alcohol.

“Sometimes you’ve just got to look outside the square,” he said.

“It’s just another product we can use to take advantage of what we’ve got; a way of using the by-product and making money out of it.”

He is aware of a Tasmanian distillery making gin from sheep whey, but not of any others using dairy whey.

In the first few weeks of stocking the gin, Julian has had a positive response to the offering, including three women each leaving with an $80 bottle, although nearly half of that is lost to tax.

“Gin is quite an expensive product; we’re hoping it could be quite lucrative,” Julian said.

“When we make the cheese, what’s left is the whey and that’s about 90 per cent of it.

“They make about 80 litres a week, or about 4000 litres a year, and I can’t drink it all, so I’ve got to try to sell most of it,” he jokes.

Actually, Julian prefers non-alcoholic drinks, but he has had a sip of the gin and likes the taste and aroma.

The circular economy philosophy of trying to turn waste products into something meaningful also applies to the dairy farm under Luke’s management, with recycled effluent making a splash this season.

“It was very dry in the first few months of 2024,” Julian said.

“Luke put effluent on his pastures and sowed some grass and then on April 1 we got 40mm of rain and the grass just shot out of the ground,” he said.

The same happened at the start of this summer.

“We got 34mm at the end of November

which put some moisture into the crops, which is really good and the grass is still green, so it’s going to kick it along.

“It also puts more bugs in your soil to make it healthy, so you’re saving on buying in fertiliser.”

Now in his mid-70s, Julian is happy to step back and let Luke take over the farming reins more than 50 years after entering the industry.

Although he grew up in Broadmeadows, Julian was inspired to become a dairy farmer by visiting his uncle’s farms in school holidays.

He bought the farm in 1981, and the idea of making cheese happened after some tough seasons in the early 2000s.

Julian and Dianne completed a cheese making course, introduced Jerseys to the previously all-Holstein herd to produce more protein and butterfat, and changed from July to split calving systems to ensure good milk supply year-round.

They started in 2005 with a batch pasteuriser, only allowing cheese to be made twice a

week, but later installed a high temperature, short-time pasteuriser to make cheese four times a week to keep up with demand. They continued to expand, introducing gelato and their own bottled milk to the market in

addition to a variety of cheeses.

“Having developed the farm, bred the animals and made a product that people enjoy, as a farmer you don’t get more satisfaction than that,” Julian said.

Designed to combat the spread of disease and help protect your investments, Shoof Disinfection Mats integrate seamlessly into your biosecurity protocol. They provide a first line of defense that’s both effective and easy to maintain. Ideal for poultry, sheep and dairy farms as well as equine. Available in 5 sizes to meet all your needs, including ‘Mat-In-A-Box’, the portable mat.

Get yours today by visiting www.shoofdirect.com.au or contact your local dealer.

sales@shoof.com.au | 1800 121 801

What if you could proactively improve calf and cow health sothey can better withstandchallenges, including those caused by mycotoxins?

What if you could control calf diarrhea before an outbreak, and reduce the incidence, severity and duration of other common diseases that affectthe feedconversion efficiency of lactating cows and your bottom line?

What if you could add nutritional insurance to every stage of your cattle’s lives resulting in healthier heifer calves that join the milkingherd ready to contribute at a high level, and lactating cows that spend less time off feed.

Has been shown to:

•Agglutinates and binds E. coli and Salmonella enterica.

• Agglutinate and bind E. coli and Salmonella enterica

•Reduces the incidence, severity and duration of mastitis and cryptosporidiosis infection.

• Reduce the incidence, severity and duration of mastitis and cryptosporidiosis infection

• Reduce blood stress markers during and after transport and temperature stress.

•Reduces blood stress markers during and after transport and temperature stress.

• Minimise cytotoxic damage caused by a variety of mycotoxins and carryover of aflatoxins in milk

• Improve weight gains and performance in calves and milk yields in lactating cows

•Minimises cytotoxic damage caused by a variety of mycotoxins and carryover of aflatoxins in milk.

•Improves weight gains and performance in calves and milk yields in lactating cows.

Distributed By:

After seven years with Dairy Australia, David Nation has made the decision to move on from his role as managing director and will finish in June 2025.

With Dairy Australia’s current fiveyear Strategic Plan concluding and a new strategy starting in July, Dr Nation sees this as an opportunity to leave the organisation in a strong position for a future leader.

“Leading Dairy Australia has been an immense privilege, and I am proud of what I have achieved together with outstanding people in the organisation who show genuine passion for delivering outcomes for farmers each day,” Dr Nation said.

“There are many standout achievements that I will reflect on fondly, from expanding our presence in the regions and improving our connection with farmers through to strengthening our domestic and export markets.”

Dairy Australia chair Paul Roderick congratulated Dr Nation on his achievements and acknowledged his contributions during his time as managing director.

“David’s leadership combined with his deep knowledge and understanding of dairy research and innovation has been a major contributor to the Australian dairy industry,” Mr Roderick said.

Dr Nation joined Dairy Australia in 2018 with extensive experience across the dairy industry, including serving as co-director of DairyBio and DairyFeedbase, and CEO at Dairy Futures CRC.

The Dairy Australia Board has engaged executive recruitment firm Pacific Search Partners to manage the process of hiring Dr Nation’s replacement, with the search expected to take up to six months.

That search could lead to Dairy Australia’s next corporate leader being a chief executive officer rather than a managing director.

The Dairy Australia AGM at Warrnambool on November 27 endorsed a resolution developed in conjunction with Australian Dairy Farmers to amend its constitution to provide an option for the board to appoint either a managing director or a CEO.

Dairy Australia’s constitution had stipulated the board must appoint a managing director.

Outgoing chair James Mann said the change would give DA greater flexibility to get the best person for the position.

Mr Mann told Dairy News Australia at the AGM that DA did not propose to change its current arrangement with Dr Nation.

He said that by virtue of their appointment, a managing director became a member of the board, while a chief executive officer may or may not be a member of the board at the board’s discretion.

BY GEOFF ADAMS

SAPUTO SUPPLIERS got some Christmas cheer with the announcement of a small stepup in farm gate milk prices.

But they had to wait until January before it hit the bank.

The company has advised its suppliers of a

step-up in minimum milk price of 15¢ per kg of milk solids for the 2024-25 season.

The step-up increases the weighted average farm gate milk price to between $8.15/kg MS and $8.30/kg MS for exclusive supply in the southern milk regions.

This payment will be automatically applied to all qualifying milk supplied under an exclusive Saputo Dairy Australia milk supply

agreement from July.

Payment will be made to suppliers with their December 2024 proceeds, during January 2025.

The milk prices quoted are a weighted average across Saputo’s supply base. Milk prices achieved at individual farm level will vary.

BY RICK BAYNE

GRAEME GILLAN looks at genetics as an invisible but invaluable additive to the dairy industry.

“Everyone thinks about fertiliser and feed inputs, but genetics are like compounding interest,” he said.

“You keep building on it and it’s incredible what can be achieved.”

And he should know. Graeme recently retired after a 50-year career in the genetics industry, a field that he believes will continue paving the way for Australian dairy success.

In fact, he said his last decade had been his most fulfilling — highlighted by his roles with the National Herd Improvement Association, Herd Improvement Industry Strategic Steering Group and eight years with DataGene, where he served as chairman until his recent retirement.

During this time, Graeme developed a growing appreciation of the benefits of good governance and was impressed by the acceleration of benefits stemming from genetics.

He remains impressed by the value DataGene brings to the industry and encourages all farmers to understand the value of good genetics.

“Every time there was a downturn people would buy cheap semen even though it’s a small percentage of their budget,” he said.

“But it costs them, because once it’s in the system, it never goes away.”

Graeme was something of an accidental entrant to genetics back in 1974, but once he had the connection, it became a passion that was hard to resist.

His parents were dairy farmers in South Gippsland and Graeme “grew up with all the good things like feeding calves and milking and doing all those tasks”.

His brother John continues to run the farm.

Graeme planned to be a teacher, but that changed when his family decided to register their Holstein herd, which became a catalyst to start his genetics journey.

In November 1974, Graeme took on a temporary role as a registration clerk with what was then known as the Friesian Cattle Club (later Holstein Australia), with support from David James, who remained a close connection throughout the following five decades.

“I wasn’t too sure, but I was 18 at the time and it was paid work so I gave it a go,” he said.

The six-week trial lasted 11 years and Graeme ended up as the executive officer.

“For whatever reason during that time, I fell in love with breeding,” he said.

“It was all done manually at that stage and I

would explore pedigrees and try to chase information. I really enjoyed that aspect of it.”

During this period, Graeme joined others in a partnership to buy a bull (Murribrook Starlite Loyalty MBSL) that found great success at Victorian Artificial Breeders (now Genetics Australia).

After 11 years, Graeme went home to farm; however, that didn’t last long.

“I don’t have a practical bone in my body, so I was quickly found out on the farm, so left and got a position with Riverina Artificial Breeders,” he said.

His lack of practical skills extended to his career in genetics during which he never actually AI’d a single cow, but he made up for it with other skills.

In 1991, Graeme and well-known Holstein breeder Phil Malcolm created ABS Australia, the precursor to the current ABS, which he continued until 2007.

“That was really enjoyable, spending a lot of time on the road creating relationships with people at farm and reseller level and trying to work out what worked best for what people were trying to achieve,” Graeme said.

It was also a time of learning life lessons that have stuck with him.

“One farmer said: If you come down my driveway and haven’t thought of some way you’re going to make my business better, the best thing you can do is turn around.”

Another lesson came at a bull night.

“A young lady about 13 or 14 turned up asking questions, but was basically ignored by everyone in the room,” he said.

“I got talking to her father later and he asked

We have designed a simple but very effective Feed Trough, to cut your feed wastage and save you money. The endless troughs can be laid in a continuous length, they are also stackable, so you can move them easily from one paddock to another. The frame is made from Australian Steel, with repurposed rubber conveyor belt used to make the trough, its nylon based and will last a lifetime.

8m $1760 Inc GST • 6m $1320 Inc GST

how my conversation went with his daughter because she was the one making all the decisions on the breeding program.

“The lesson I got was that you never ignore people and don’t take things for granted.”

“I like everyone until they prove differently.

“Another piece of sage advice was ‘you have two ears and one mouth - use them in that proportion’.”

Graeme spent time with Eli Innovation and in 2010 joined Alta Genetics before returning to Holstein Australia for six years as CEO before retiring from full-time work in 2020.

During his various career incarnations, Graeme always felt the need to contribute to industry growth.

He was on the advisory committee for ADHIS, a director for NHIA for more than 10 years, including time as chairman, and HISSG, the industry committee that helped formulate DataGene, and was nominated by NHIA as one of three inaugural directors of DataGene, alongside Dairy Australia and Australian Dairy Farmers representatives.

In earlier years, many farmers looked offshore for reliable genetics, but Graeme said that had changed dramatically since the inception of DataGene.

“The major overseas companies have invested in the Australian industry and strongly support the Australian breeding values,” he said.

The introduction of ABVs more than 40 years ago and the more recent development of genomics rank as the most significant changes Graeme has witnessed.

“It’s not something that stands still,” he said.

“The work that has been done to constantly

improve the system is quite significant.

“The last eight years of DataGene and the years leading up to it brought me great satisfaction and pride in what has been achieved.

“Bringing all the data together and providing breeding values that are credible results in a $16 return for every dollar invested.

“Genomics has given the industry the opportunity to accelerate what we’ve been trying to achieve and to focus on fertility, polled cattle and other important traits. It started with some scepticism but the changes that have occurred because of genomics are amazing.”

Graeme said the introduction of ABVs was another huge stepping stone, replacing the previous state-based systems.

And he said the breeding indexes would continue to evolve to address emerging issues, such as heat tolerance, sustainability, survival, calf vitality and reducing methane emissions.

Production remains an important part of the equation and Graeme points out that while new indexes have been added and developed, production has also been increasing.

With the demographics of the dairy industry constantly changing, Graeme said DataGene would continue its close relationship with researchers in Australia and around the world to stay ahead of the game.

Graeme said there was “no comparison” between the cows of 1974 and today.

“The ability of these animals to produce milk and respond to the changes is amazing,” he said.

Despite the technical advances, Graeme sees some headwinds.

“There are challenges ahead and the industry has stalled in some respects when you look at milk production.

“A lot of places where our herds were at one stage might have a golf course or market garden on them now.

“Staff has always been a challenge, but the dairy industry is still an amazing way to accumulate capital, though it can be an asset-rich and cash-poor industry, which is not a great.”

At 68, Graeme wants to spend more time with his wife Mary, who has been his backbone support for the past 37 years, and let the next generation tackle the evolving challenges.

“I think you should contribute when you can and move aside when people are there to continue,” he said.

Graeme welcomed the election of Tim Jelbart as the new DataGene chair and the election of new directors, Queensland dairy farmer and nutrition consultant David Barber and Gippsland beef producer and agribusiness banker Josie Zilm.

A TOTAL of 18.2 million dairy cow records are now contributing to genetic improvement in Australia’s industry.

And thanks to a new DataGene initiative called DataConnect, there will be even larger volumes of historical and daily data as well as fresh information to improve the breeding objectives of dairy farmers in future years.

Reporting a six per cent annual increase in the number of cows in Australia’s Central Data Repository was a highlight of DataGene’s Annual General Meeting in Melbourne on November 21.

In addition, close to a million further records for health and fertility were added thanks to farmers with a passion for connecting their data.

The number of records is expected to grow exponentially in the coming years as more data flows in from on-farm software including in line meters.

DataGene chief executive officer Matt Shaffer told members there are many projects under way that are contributing to improvements in genetic gain at the farm gate.

“DataGene’s value is in its data, that’s how we deliver to the industry,” he said.

“The quality and quantity of our data enables, for example, the development of better and new Australian Breeding Values, so it’s vital we expand data sources beyond information from herd test centres with projects such as DataConnect.”

DataConnect is a multi-year project that

explores ways the industry can work, pre-competitively and collaboratively, to tackle the challenges farmers experience when exchanging and integrating data.

DataGene has been working with a variety of milk equipment manufacturers, on-farm software providers and farmers to identify the best mechanisms to connect their data to the CDR and provide customised solutions as needed.

Proof-of-concept data connections were made last year and this year DataGene has continued to add connections from various businesses and farms.

“A significant amount of work has been

completed to automate connections and work through the variety of challenges encountered when merging various data sets,” Matt said.

“In parallel, DataGene continues to progress its work with the International Dairy Data Exchange Network which is building better pipelines with overseas equipment manufacturers.”

This comes as DataGene reported a 10-year trend, 2013-23, rate of genetic gain for Holstein Balanced Performance Index of $29.18/cow/ year, with this rising to $31.24/cow/year more recently.

The 10-year trend of Jersey genetic gain is $16.59/cow/year.

DataGene also welcomed two new directors to its board, Queensland dairy farmer and nutrition consultant David Barber and Gippsland beef producer and agribusiness banker Josie Zilm.

The two new directors are replacing retiring directors, outgoing chair Graeme Gillan and western Victorian farmer Daniel Meade. Graeme has served on the board of DataGene since its inception in 2017 and has dedicated 50 years to the Australian dairy industry.

Gippsland dairy and beef producer Tim Jelbart was elected to the role of DataGene chair following the AGM. Tim is the Jelbart Dairy general manager and director.

BY JEANETTE SEVERS

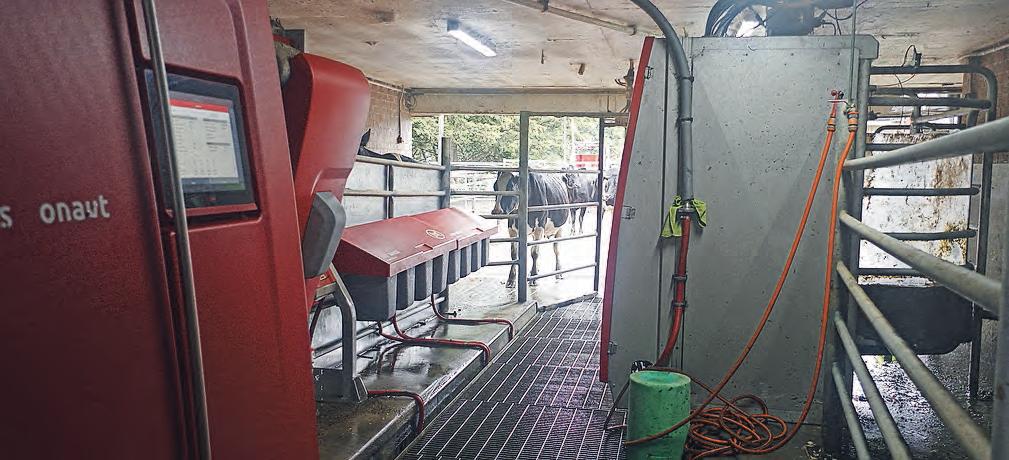

LARISSA AND Peter Joyce retrofitted their herringbone dairy into a two-bay robot dairy.

Peter said it was surprisingly easy to do and considerably cheaper than putting a new milking shed.

Larissa and Peter are now milking less cows for higher production, feeding less grain, and are looking forward to remaining in the dairy industry.

“In spring, the cows peak at 30.5 litres, where before the robot units were installed, they’d peak at 27 litres,” Peter said.

“That’s a significant improvement, and it’s probably because the cows are more relaxed when they come in to be milked.”

Peter and Larissa milk 120 Holstein-Friesian cows off 89 hectares of steep to undulating dryland country at Strzelecki, in Gippsland, Victoria.

The country is split into 40 paddocks for grazing.

Peter grew up on the family farm established by his great-grandparents, left to complete a small engine mechanic apprenticeship, then returned to work on the farm when he was 22 years old.

Peter started off as a farm worker for his parents, Don and Kathleen Joyce, then progressed to sharefarming with them.

He started building equity in the herd, and by the time Peter purchased the 89ha dairy farm from Don and Kath, he owned 60 milking cows.

When Peter and Larissa bought the farm in 2001, they purchased the other half of the milking herd.

At the time, they were still milking out of a 12-swing-over herringbone dairy built by Don in 1986-87.

It replaced a walk-through milking shed that Kath’s family milked their herd in.

After buying the farm in 2001, Peter and Larissa grew the herd to 150 milkers.

“I started thinking about robot milking units in 2018, and it took me a few years before I pulled the trigger and committed to changing to them,” Peter said.

“I wasn’t quite sure I wanted to continue milking cows, so I held off making a decision for a little bit.

“Once I decided I was going to continue milking, I contacted Lely about retrofitting robot units into the herringbone dairy.”

Technicians from Lely Center Gippsland measured and planned the layout and Peter and Larisa organised for their 40 autumn

calved cows to be transported to Rob and Marita Pandolfo’s farm at Lardner for milking during the rebuild.

“Retrofitting in the same shed saved us a significant amount on building a new shed,”

Peter said.

The pit was covered with grate, that was welded down.

Some concrete was laid to level out the entry to the dairy shed from the yard.

Very little was done to change the layout of the yard as the cows came from the laneway onto the dairy platform.

“We gutted the dairy and we retrofitted a robot milking unit either side of the pit,”

Peter said.

It took about 10 weeks to complete all the work.

They put the A5 robot units in where the cows entered the old herringbone.

“I think some cows have got their favourite side for entering the dairy,” Peter said.

“So those cows who went in the left side, they still enter the left side and go through that unit.

“The cows that entered the dairy on the right side, still go through that side.

“The transition was pretty smooth.”

Only a few spring calving cows dropped their calves before the new dairy was set up.

“We timed it to work out really well,” Peter said.

“We brought back the 40 autumn calvers and switched on the robot units and trained those cows to go through them.

“Then as the spring calvers started calving, we just ran them through the dairy as normal and taught them to go through the robot units.

“Heifers outperformed cows early on. The heifers that calved three weeks out from the opening of the robot units, they absolutely dominated early on.

“We opened the gate at night one, after the first milking, and the heifers absolutely charged back to the dairy — they beat me back there — and started milking themselves. So that felt pretty good.

“Now the herd come and go as they please. The cows come to the dairy, get milked, and then they go to a fresh paddock after every milking.

“They do really well on a pasture-based system.”

The same grain silos remain just outside the dairy yard. An auger feeder was constructed to move the grain from the silo to a hopper that goes through the roof of the dairy, to feed bins over the robot units.

“We didn’t have to add or get rid of a silo, or shift them,” Peter said.

“Now the cows are getting exactly the amount of grain they need, rather than eight kilograms each a day.

“Now, they’re fed to production. So the cows that are milking 40 litres, they will get 8kg of grain. The cows that are producing 20 litres are getting 4kg of grain.

“That’s considerably reduced the amount of grain we feed out, so that’s been a cost saving.”

A new innovation for Peter and Larissa as part of installing the robot units, was putting collars on their cows, which has helped them reduce the amount of grain they feed each cow. The collars also provide a lot of rumination, health and reproductive information for Peter to make decisions about.

“I don’t have to visually identify the cows that are on heat or a high cell count,” he said.

“When they come in for milking, they’re automatically drafted for me to check them.” Peter has become comfortable using the technology.

“When it comes to computers, I didn’t know a lot, so I wouldn’t say I’m a whiz, but I know my way around it a lot better now,” he said.

“The collars provide a lot of information.

“There’s more information available than you actually probably need. But if you want it, it’s there.

“I use it daily to check udder and cow health.

“When we’re joining, the collars play a big role in heat detection, and it’s a lot more accurate than me identifying cows.”

The milking herd remains split-calving, with about 40 per cent autumn and 60 per cent spring calvers.

The herd is on a prostaglandin program followed by two rounds of artificial insemination, followed by mop-up bulls.

“We try to get as many cows as possible in calf through the PG and AI program,” Peter said.

“That’s why we do two rounds of AI.”

With the drop-off of the export heifer market, he has reduced his reliance on sexed semen to 50 per cent.

All heifer calves are reared, and the surplus sold in-calf.

With the new system, Peter has turned off his alarm and wakes each day re-energised for dairy farming.

“I get to enjoy farming now,” he said.

“I wasn’t a big fan of milking. It was painful on my legs. No longer milking frees up a lot more time.

“I can be a lot more efficient in all the other areas of dairy farming.”

He spends time each day washing down the robot units and the yard.

Peter also spends more time raising his calves, and watching his children play sport. He has also rejoined the local football club as a junior coach.

“The kids are all involved in sport,” he said.

“Before the robot units were installed, I’d be up at four o’clock in the morning to try and get everything done before taking the kids to junior sport, that starts at 8.30am.”

Peter and Larissa have also retained the same workforce, again because their input frees up more family time for the couple.

“Now I get down to the dairy and most of the cows have milked, and I just have to wash up, feed a few calves, set the paddocks up for the day, and then I can take off and get the kids to sport.

ɋ For more of Jeanette Severs’ pictures, go to: https://www.dairynewsaustralia.com. au/news/robot-dairy-lifts-production-andkeeps-farmer-in-industry/

Pac Cool Dealer - Australia

Packo & Pac Cool Spare Parts PACKO has a new

- A milk vat to suit all herd sizes, pick up schedules & entry temperatures

- Cooling & wash controls - user friendly, simple & effective

- Glycol chiller cooling & traditional direct expansion cooling systems

- New & secondhand sales, spare parts & wash system upgrades for all makes

Call Dairy-Tech Refrigeration today for a no hassle quotation

PHONE: 03 5662 3277

EMAIL: pgoiris@dairytechrefrig.com.au

WEB: www.dairytechrefrig.com.au

Refrigerant Trading Licence - AU34439

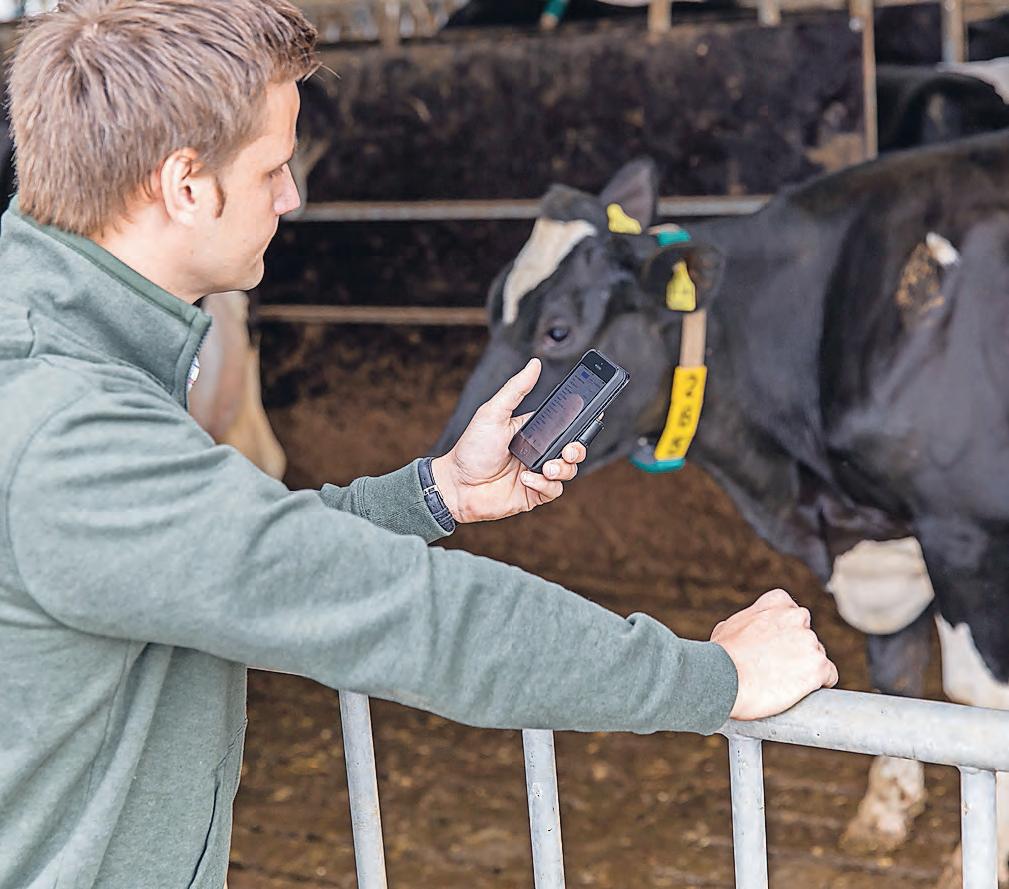

ONE OF the most critical aspects of managing a dairy herd is ensuring optimal reproduction.

Successful breeding not only impacts milk production but also contributes to the genetic improvement of the herd.

Traditionally, heat detection has been a challenging task, requiring constant vigilance.

But advances in technology are changing that.

GEA CowScout is a state-of-the-art system designed to monitor the health and reproductive status of dairy cows.

Using advanced sensors, it tracks vital behavioural patterns such as activity levels, rumination, and posture to detect signs of heat with pinpoint accuracy.

By continuously collecting data, the system provides dairy farmers with alerts when a cow is in heat, ensuring that insemination is carried out at the optimal time for conception.

Additionally, it helps identify health challenges before they escalate, allowing for timely intervention.

GEA says with CowScout, you’ll have all the data you need to make informed decisions for your herd, ensuring a healthier, more productive dairy farm year-round.

GEA says the key benefits of CowScout are:

Accurate, real-time heat detection 24/7.

Identify health concerns earlier.

Improve overall herd management.

Monitor cows individually and as a group.

Gain greater control over every cow’s health and production with less labour.

Access data from anywhere via computer, phone or tablet.

Receive alerts if a tag is incorrectly fastened.

Flexible options to suit any herd size or management style.

Improve conception rates through accurate and timely heat detection.

Detect metabolic disorders early in newly calved cows.

Identify cows with mastitis more quickly. Reduce labour costs and time spent on heat detection.

Identify and treat health issues early, reducing recovery time.

Detect fertility problems sooner.

Improve herd profitability by enhancing fertility.

For more information, visit: https://www. GEA.com/dairyfarming

INNOVATIVE SENSOR technologies, such as those used on dairy cattle, are generating large data sets that open up new research opportunities.

The Dairy UP team is taking advantage of this, in a project that aims to improve the accuracy of the Heat Tolerance Australian Breeding Value.

Under the supervision of Dr Anna Chlingaryan, Dairy UP PhD student, Alice Shirley is using data from rumen sensors to explore how cattle respond differently to heat events.

The team is using artificial intelligence tools to develop a hybrid AI-based model to improve the assessment of heat tolerance in dairy cows.

The model draws upon more than 20 years of historical climate and dairy cattle production data the model to improve the identification of more heat-tolerant animals.

By collaborating with DairyBio and DataGene, Dairy UP researchers aim to contribute to a better tool for breeding dairy cattle with improved heat tolerance.

The current Heat Tolerance ABV, published by DataGene, allows farmers to identify and breed animals with greater ability to tolerate hot, humid conditions with less impact on milk production.

However, it is derived only from genomic DNA testing and has relatively low reliability, leading to slow uptake by farmers.

The research will develop phenotypes — indicators of animal performance that can be

measured in commercial animals — to add to the model for the Heat Tolerance ABV.

Combining genomics with traditional and new measures of heat tolerance should improve the reliability and accuracy of the Heat Tolerance ABV.

The research used data (supplied by SmaXtec) from three Australian pasture-based dairy farms with more than 1400 cows fitted with rumen sensors to monitor core body temperature, every 10 minutes, 24 hours a day.

A water threshold model has been developed to track the impact of drinking on core body temperature. Climate data from the past 20 years obtained from the Bureau of Meteorology has been used to match observations from the cows.

Initial research has found significant variation between animals’ core body temperature and their drinking behaviour and demonstrated core body temperatures increased at lower Temperature and Humidity Index levels than

previously thought.

The research will continue with a collaborative project undertaken by DairyBio and La Trobe University PhD student Laura Jensen under the supervision of Professor Jennie Pryce, that will combine the animals’ genetic and performance data with a variety of approaches, including the sensor technologies from the Dairy UP project.

ɋ For more information, go to: https://www. dairyup.com.au

Australian Dairy Farmers has congratulated Brett Hosking and Peter Star on their election as Victorian Farmers Federation president and vice-president, and Bernie Free on his appointment as United Dairyfarmers of Victoria president.

“The comments made by Mr Hosking prior to and subsequent to his election already demonstrate a willingness to work with peak commodity councils and the National Farmers’ Federation,” ADF president Ben Bennett said.

“I consider this reassuring and importantly his comments demonstrate a sound understanding of the functions of peak commodity bodies with respect to issues such as biosecurity, trade, and oversight of research and development corporations.

“The dairy farmers within Victoria have also demonstrated their ongoing support for ADF through UDV’s continued participation in ADF’s National Council and Policy Advisory groups.

“The appointment of new VFF Board directors affords both organisations the opportunity for a ‘circuit breaker’ to sit down and, hopefully, amicably resolve the

dispute between the previous VFF Board and ADF that has been ongoing over the last 18 months.”

Mr Bennett said he would reach out to the VFF’s new board and president with an offer to meet at a mutually convenient time to discuss how the two organisations can work together into the future.

“If media reports are correct regarding VFF membership and finances, the new VFF directors clearly have a huge recovery task ahead of them,” he said.

“However, it is my intent that our respective organisations work collectively and collaboratively towards a mutually beneficial outcome for all Victorian farmers and dairy farmers in particular.”

The ADF and VFF have a long-running dispute over dairy farmers’ levies, collected by the VFF and due to be remitted to the ADF.

The VFF said ADF membership fees were ‘unfair’ and did not represent value for money for all Victorian dairy farmers and UDV members.

The VFF notified the ADF in October 2022 that it would no longer pay fees under its current membership structure.

THE REINTRODUCTION of an agricultural field day at Koroit is filling a void in south-west Victoria and exceeding organiser expectations.

The field day will be held on Saturday, February 22 as part of the Koroit Show and has attracted more than 25 exhibitors with more expected in coming weeks.

The positive response could lead to the event being extended next year.

The field day will fill a gap left by the Sungold Field Days that were last held at Allansford in 2020.

The event had run since 1981 and was recognised as the one of Victoria’s premier agricultural shows.

Koroit field day coordinator Julie Houlihan said the response to the new event had shown the need for a local agricultural field day.

“When the much-loved Sungold Field Days stopped, we knew there was a gap in the market,” Julie said.

“We decided to have a go and combine it with the show and we’ve been overwhelmed with enquiries and bookings.

“Because it’s the first year, we didn’t know if it would take off, but with the response we’ve had, next year we might have to run two days or look at running the show separately.”

The field day will feature more than 25 exhibitors, including tractors, drones, contracting and irrigation equipment, dairy innovation and feed and pasture companies.

The event will cover all agricultural fields but with a special focus on dairy.

All the usual agricultural show events will be also held, including horses, cattle, poultry,

cooking, flower/vegetable and photography classes.

“The field day is just adding another dimension and making sure we remain relevant to the community, especially agricultural industries,” Julie said.

Most of the field day will be based on land owned by the agricultural society on the side of Victoria Park, with the oval being kept for traditional show activities.

Julie said the field day would provide a platform for farmers to learn about new technologies, techniques, and products; facilitate networking opportunities between farmers, suppliers, and industry experts; showcase the latest research and development in agriculture, including new crop varieties, farming methods, and equipment; offer hands-on demonstrations and trials of agricultural products and services; and provide a forum for discussions on key industry issues, such as sustainability, climate change, animal husbandry and environmental management.

“Koroit Agricultural Field Days aim to promote the development of sustainable and productive agriculture, and to support farmers in improving their operations and contributing to the growth of the agricultural industry,” Julie said.

Innovation technical presentations and workshops will run through the day where selected suppliers and service providers can outline how their products features are innovative and would be useful to attending farmers.

DemoDAIRY Foundation is assisting with this activity.

The presentations/workshops will be in the basketball stadium.

DAIRY FARMERS are urged to seize opportunities to evolve their businesses for the future at the Australian Dairy Conference on the Gold Coast from February 12 to 14.

ADC 2025 theme is ‘The Opportunity of Milk’, and programming chair Monique Bryant said they were throwing down the gauntlet and encouraging the industry to be aware and grasp opportunities at their disposal.

“ADC 2025 is all about opportunity — exploring, embracing and taking hold of what is on offer,” Monique said.

“Whether you are a veteran of the industry or

Registrations are now open for the dairy herd improvement industry’s conference, Herd ’25, on March 12 and 13 at Bendigo in central Victoria.

Held every two years, the Herd ’25 conference addresses topics through speakers who are leaders in their field, including scientists, farmers and service providers.

The 2025 program has a strong futureready theme, with a particular focus on the application of data technologies in herd improvement.

James Buzzard from Microsoft Australia/NZ will update the audience on the latest uses of artificial intelligence in agriculture; Todd Janzen from Schroeder Ag Law will share the US experience of the legal issues associated with agricultural data collection; and Dr Jeff Bewley from Holstein USA will discuss the challenges and opportunities in making farm technology work — from innovation to implementation.

The program also includes leading Australian presenters. Professor Ian Lean will share recent findings from research into beef from dairy; and the latest drivers of current and future market pricing will be discussed by Jo Bills of Ever Ag Insights.

The conference will open with Strategies for a happier, healthier you, presented by Michael Williams from Fat Farmers and Jacqui Suares, a Holstein Australia member.

DataGene CEO Matt Shaffer said Herd ’25 conference offers a rare opportunity for people working in dairy herd improvement to get together and share ideas.

“The sense of community and connections forged at this event are just as valuable as the presentations,” he said.

Herd ’25 is a joint initiative between DataGene, Dairy Australia, Holstein Australia and the National Herd Improvement Association.

ɋ For more information and to register, go to: https://www.trybooking.com/ events/landing/1315268

an up and comer, there are countless opportunities to grow, thrive or evolve your business and we want our industry to take off the blinkers and explore these frontiers and possibilities,” she said.

“We are in such a privileged position as an industry here in Australia where we can be bold, adventurous and build multi-faceted operations with significant advantages over other farmers across the world.

“Our message in 2025 is to embrace the opportunities available to you — but as farmers we need to be informed, knowledgeable and creative in bringing those opportunities to fruition.”

The 2025 ADC program line-up boasts big names, pioneers, experts, innovators and opportunists.

“In 2025 we also welcome a new master of ceremonies to lead the delegation, Channel 7 presenter and media personality Kimberley Busteed, who with her own agricultural connections will bring a fresh perspective and outlook to the event,” Monique said.

“Musician John Schumann is also the special guest of the ADC Gala Dinner hosted by Rabobank, with the legendary singer-songwriter will deliver a moving oration followed by a live

performance of his iconic anthem, I Was Only 19.” Gold Coast Convention and Exhibition Centre will be the central hub for ADC 2025, with plenary, social functions and extra activities including tours to southern Queensland and northern NSW operating from the central location.

ɋ For more information and to register, go to: https://www.australiandairyconference. com.au/ ɋ View the program at: https://www. australiandairyconference.com.au/ wp-content/uploads/2023/10/ADC_ program2025_29NOV.pdf

BY JEANETTE SEVERS

WHERE THE management strategy is to dry cows off during summer, Dairy Australia research indicates cows that experience heat stress during late pregnancy have smaller placentas with reduced blood flow through the uterus and umbilical cord.

The calves tend to be born earlier and lighter than the calves of cows that are kept cool during their dry period.

These cows also experience a higher incidence of mastitis and retained foetal membranes, because their immune function is already distressed.

Calves born in hot weather also experience lower growth rates and are less productive and fertile in their first lactation.

They are more susceptible to illness and have higher mortality rates.

In heifers and cows, heat stress decreases oestradiol production, a major female sex hormone that regulates oestrous, leading to ovarian inactivity.

Hormone imbalance impairs oocyte development, resulting in lower conception rates.