1 minute read

TUO-11 Paradigm Shift Towards Digitalisation TUM-11 Digitalising Operation with Manufacturing

from CDTI Brochure

by Linda Khong

TUO-11 Paradigm Shift towards Digitalisation

Course Description

Advertisement

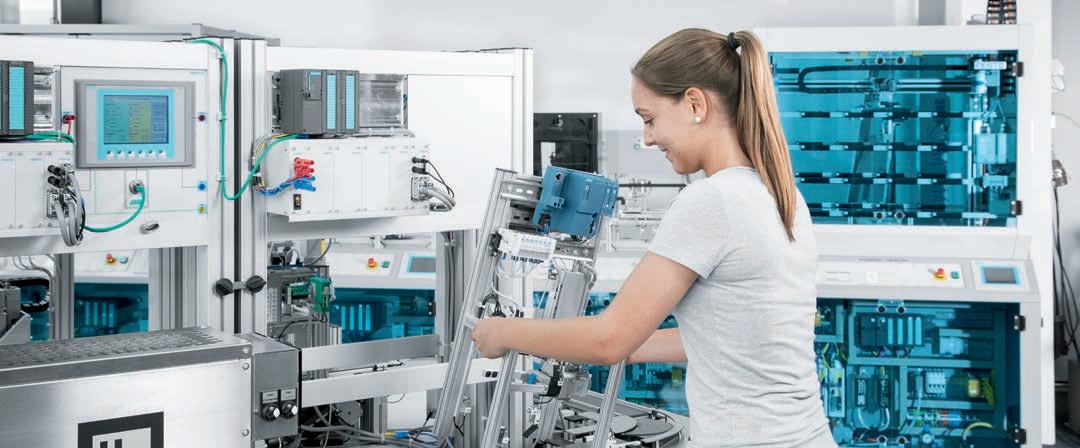

In this course, it provides the exploration of the profound positive impact of digitalisation on the way manufacturing competes, improves efficiency, and boosting the speed of time-to-market for products and services.

Participants will learn the holistic view of digital transformation process and the concrete steps to be taken – a step-by-step approach that gives the essential understanding for a successful adoption of Industry 4.0 concept towards business transformation.

Course Outcomes

Participants are able to • Understand the digital transformation process in the practical way • Understand the benefits of digitalisation for manufacturing productivity and efficiency • Embrace the combined benefits of IT and OT for smart manufacturing practices • Understand the importance of vertical and horizontal integration for an immersive business process flow • Differentiate the various stages of digitalisation process • Identify essential manual manufacturing processes to be digitalised • Understand how real-time production data is used at higher organisational levels when making decisions. • Understand how to retrofit sensors for predictive maintenance and condition monitoring.

Course Contents

• Overall digitalisation strategy for business resilience and sustainability in manufacturing • Digitalisation process with Manufacturing Execution

System (MES) in the practical way • Conversion from an automated production line to data-driven automated production line • The concept of IT and OT convergence • Vertical and Horizontal Integration • Utilising digital technology for visibility on machine and business operation • Use of production data between systems for lower production cost and reduced wastages • Data-driven business insights

Course Duration – 8 hours

In collaboration with