Daniela Martinez PORTFOLIO

CONTACT

+1(615)336-7118

danielamaria.mtz@gmail.com

Linkedin Thesis Digital Work Portfolio

LANGUAGES

Spanish | Native

English | Native

French | Intermediate

SKILLS

CONTACT

+1(615)336-7118

danielamaria.mtz@gmail.com

Linkedin Thesis Digital Work Portfolio

LANGUAGES

Spanish | Native

English | Native

French | Intermediate

SKILLS

MSc in Building Technology | 2021 - 2023

Delft University of Technology | Delft, Netherlands

BFA in Architecture | 2014 - 2018

Savannah College of Art and Design | Savannah, GA

Magna Cum Laude

Minor in Architectural History

Study Abroad | Fall 2016

Savannah College of Art and Design | Lacoste, France

Earl Swensson Associates | Architectural Designer

Nashville, TN | Oct 2020 - Aug 2021

Participated in User Group Meetings for design development

Reviewed compliance with Healthcare Guidelines and Life Safety Codes

Coordinated design and constructibility with consultants and contractors

Developed BIM presentations and construction documentation

Reviewed submittals and RFI’s during construction administration

Gensler | Technical Designer

Atlanta, GA | Aug 2018 - Apr 2020

Project Architect for several fast-paced retail projects

Generated construction documentation necessary for constructibility

Coordinated and reviewed engineer’s drawings to develop design

Prepared submissions for jurisdictions to obtain building permits

Attended construction sites to produce Site Observation Reports

Eichberg Hall | Wood Shop Monitor

Savannah, GA | Oct 2017 - Jun 2018

Assisted students with tools and machinery

Operated laser cutting and woodwork machines

Heineken Collaborative Learning Course | Student Designer

Savannah College of Art and Design | Fall 2017

Worked with Heineken in the development of project sustainability

Collaborated with a wide variety of majors to facilitate design ideas

Gensler | Architectural Intern

Mexico City | Summers 2016 & 2017

Documented existing building condition drawings

Coordinated finishes and equipment with vendors and manufacturers

Produced scoping documentation for furniture and finishes

Graduation Award Nominee for Circularity

Delft University of Technology | Oct 2023

Construction Document Technologist

Construction Specifications Institute | Jul 2019 - 2024

Best Overall Award

Steelcase Table Design Competition | Jun 2019

Honorable Mention

NOMA Student Design Competition | Fall 2017

Scholarship Awards

Savannah College of Art and Design | 2014 - 2018

Guest Speaker | Alumni

SCAD Lacoste | Oct 2022

BouT Student Organization | Events Committee TU Delft | 2021-2022

Product Design Team | Designer Gensler Atlanta | 2019 - 2020

Student Mentorship Program | Student Mentor Gensler Atlanta | 2020

Client Relationship Program | Designer Gensler Atlanta | 2020

American Institute Architecture Students | Secretary SCAD | 2015 - 2017

PROFESSIONAL WORK

MARY BRIDGE CHILDREN’S HOSPITAL

Earl Swensson Associates: Healthcare

STAR METALS HOTEL

Gensler: Hospitality

ZARA

Gensler: Retail

ACADEMIC WORK | MSC IN BUILDING TECHNOLOGY

INTEGRATED DESIGN WITH RECLAIMED STEEL

Master Thesis: Circular Strategies & Computational Development

ALT(R) ALTERNATE REALITY

CORE: Computational & Structural Design

THE JUNCTION

MEGA High-Rise: Facade Design

SHINHAN EX:PACE

Bucky Lab Sun Shade: Facade Design

ACADEMIC WORK | BFA IN ARCHITECTURE

AÇIK OLMAK CENTER

Studio V: ASHRAE & LEED Applications

SAVANNAH STADIUM

Studio III: Structural Applications

PLUG-IN MAKER SPACE

Studio IV: Site & Program Applications

DESIGN COMPETITIONS

JOHN S. CHASE ACADEMY

NOMA Student Competition: Awarded Honorable Mention

NASCENE

Evolo Competition: Conceptual Skyscraper

Professional Project: Earl Swensson Associates

Role: Architectural Designer

Date: May - July 2021

Location: Tacoma, WA, USA

Programme: Healthcare

Contribution: Participate in User Group Meetings to establish client needs, revise SD and DD plan layouts, DD documentation

Software: Revit, Bluebeam

The current Mary Bridge Children’s Hospital is the only Level 2 pediatric trauma center in Western Washington. Currently, the existing children’s hospital is located within Tacoma General Hospital, one of the region’s busiest medical centers. As both hospitals are experiencing rapid growth, Mary Bridge Children’s Hospital new standalone facility will allow for dedicated space and resources tailored specifically to pediatric care. This Tacoma campus will feature a new inpatient hospital tower, a building for outpatient services including specialty clinics and urgent care, and a new parking garage to accommodate the growth.

Using Lean principles and a human-centered approach, the design aimed to optimize staff effectiveness, maximize crossfunctional spaces and enhance building efficiency. Despite the challenges of the COVID-19 pandemic, the design of the project was successfully completed virtually using the integrated project delivery (IPD) system.

Construction is set to begin on August 2024.

Professional Project: Gensler, Atlanta

Role: Technical Designer

Date: February - April 2020

Location: Atlanta, GA, USA

Programme: Hospitality

Contribution: Construction documentation for hotel, facade design development, construction and section details for facade, coordination with metal panel manufacturer

Software: Revit, Illustrator

1. RESIDENTIAL 2. OFFICE 3. HOTEL

This hotel is part of a three-building development located in the heart of West Midtown, in Atlanta. Star Metals Atlanta is a live-work-play environment tailored to the new urban lifestyle. This mixed-use district will feature 185,000 sq. ft. of class-A office space, 48,000 sq. ft. of retail and restaurant options, 409 luxury residential units, and a 176-key boutique hotel. This innovative project provides modern conveniences and sustainable designs that create the essential balance between nature and people.

The hotel will include a street level restaurant, lounge, coffee shop, meeting rooms, fitness center, and an urban-forested rooftop overlooking the Atlanta skyline. This 14-story high-rise hotel is type 1A construction, comprised of a metal panel and storefront facade.

Star Metals Hotel is scheduled to be completed and ready for travelers by 2021. 1 2 3

Professional Project: Gensler, Atlanta

Role: Project Architect

Date: September - November 2019

Location: The Mall at Green Hills - Nashville, TN, USA

Programme: Retail

Contribution: Construction drawings, coordination with project engineers, construction administration

Software: Revit, Illustrator

This Zara retail store is situated in a newly developed section of the Green Hills Mall, spanning two stories with a total area of 40,000 square feet. The schematic design phase involved multiple meetings with both the client and the landlord to ensure compliance with local building codes and the landlord’s Design and Construction Guidelines. Structural and MEP work, including the installation of vertical transportation systems such as an escalator and an elevator, are featured in this project.

The project team consists of a Project Lead and myself serving as the Technical Architect. During the review of the existing mall drawings, a post-tension slab construction and an expansion joint on the first level were identified. Consequently, careful coordination was necessary to avoid locating vertical transportation penetrations on any post-tension beams. Additionally, existing utility locations were coordinated to be connected to plumbing services and water source heat pumps for the mechanical systems.

Construction on this project commenced in March 2020.

Coordinate utility connections to existing sanitary and vent pipes

Implement water source heat pumps to heat and cool the mechanical air system

Secure expansion joint on ceiling and soffit to align with existing slab expansion joint

Coordinate slab penetrations for elevator and staircase with the post tension beam tendon locations

Ensure ceiling construction to be non-combustible material per landlord requirements

Collaborate with structural engineer to design storefront connection to existing bulkhead

Individual Academic Project: Master Thesis

Date: November 2022 - June 2023

Location: Delft, Netherlands

Programme: Research & Circular Strategies

Work: Led interviews, proposed a design workflow, created stock list template, developed a computational tool, tested both the workflow and tool with a case study

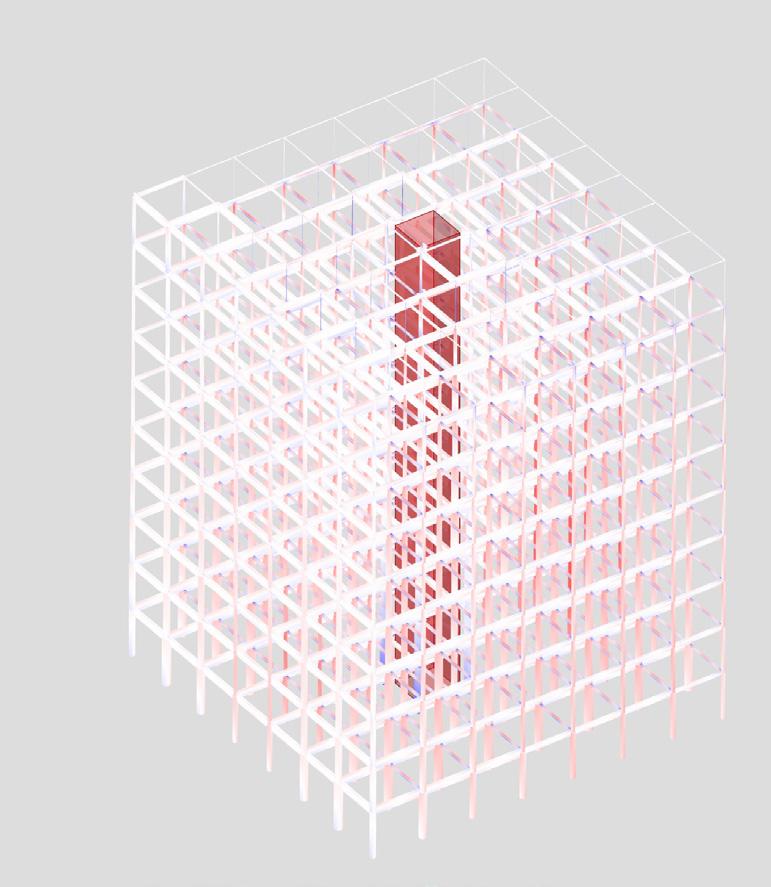

Focusing on the reuse of structural steel, the project aims to advance circularity in the built environment in response to challenges such as material scarcity, waste production, and environmental impact

Through a comprehensive research approach, including literature review and interviews, the project developed a design workflow that incorporates strategies to address the identified challenges and provides a framework for future projects. In order to support the design workflow and facilitate the integration of reclaimed steel, a computational tool was developed composed of a digital stock inventory and a matching algorithm. These tools enable efficient utilization of reclaimed steel by providing potential substitutions based on project needs. This was seamlessly integrated into a user-friendly web interface to create a comprehensive one-stop platform and foster collaboration among stakeholders.

Software: Rhino, Grasshopper, Karamba 3D, Python

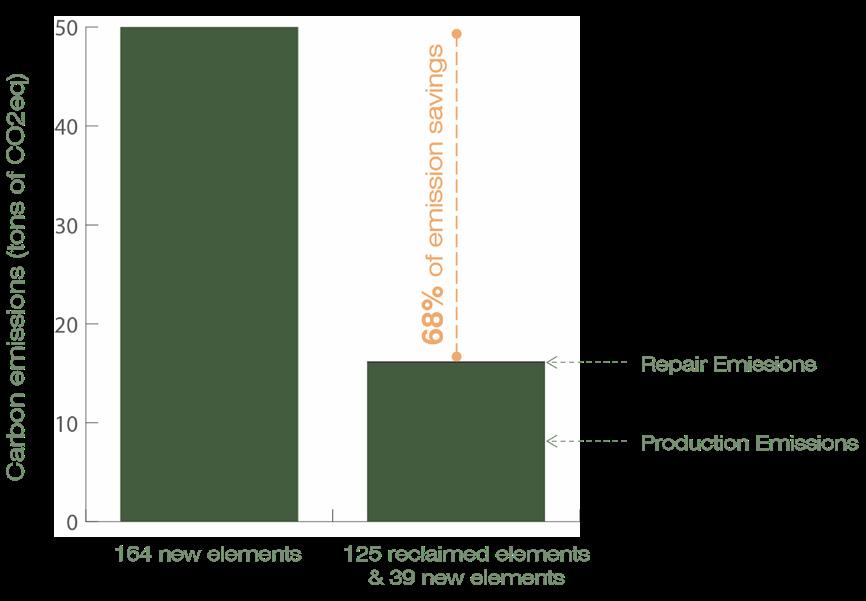

The design workflow and computational tool were successfully tested through a case study, which demonstrated reduced carbon emissions and significant time and labor savings. By quantifying environmental emissions within the web interface, users are able to make informed decisions to minimize environmental impact and promote resource efficiency in the construction sector.

UNMATCHED I T EMS: CASE

MATCHED ITEMS:

125 sections

(utilizing 89 reclaimed steel elements)

39 sections

RESULTS

Group Academic Project: AR3B012 CORE (COmputational REpertoire for Architectural Design and Engineering)

Role: Structural Designer and Analyst

Date: September - November 2022

Location: Delft, Netherlands

Programme: Mixed Use

Individual Work: Concept design, design development, material study, structural design and analysis, rendering

Software: Rhino, Grasshopper, Karamba 3D, Python

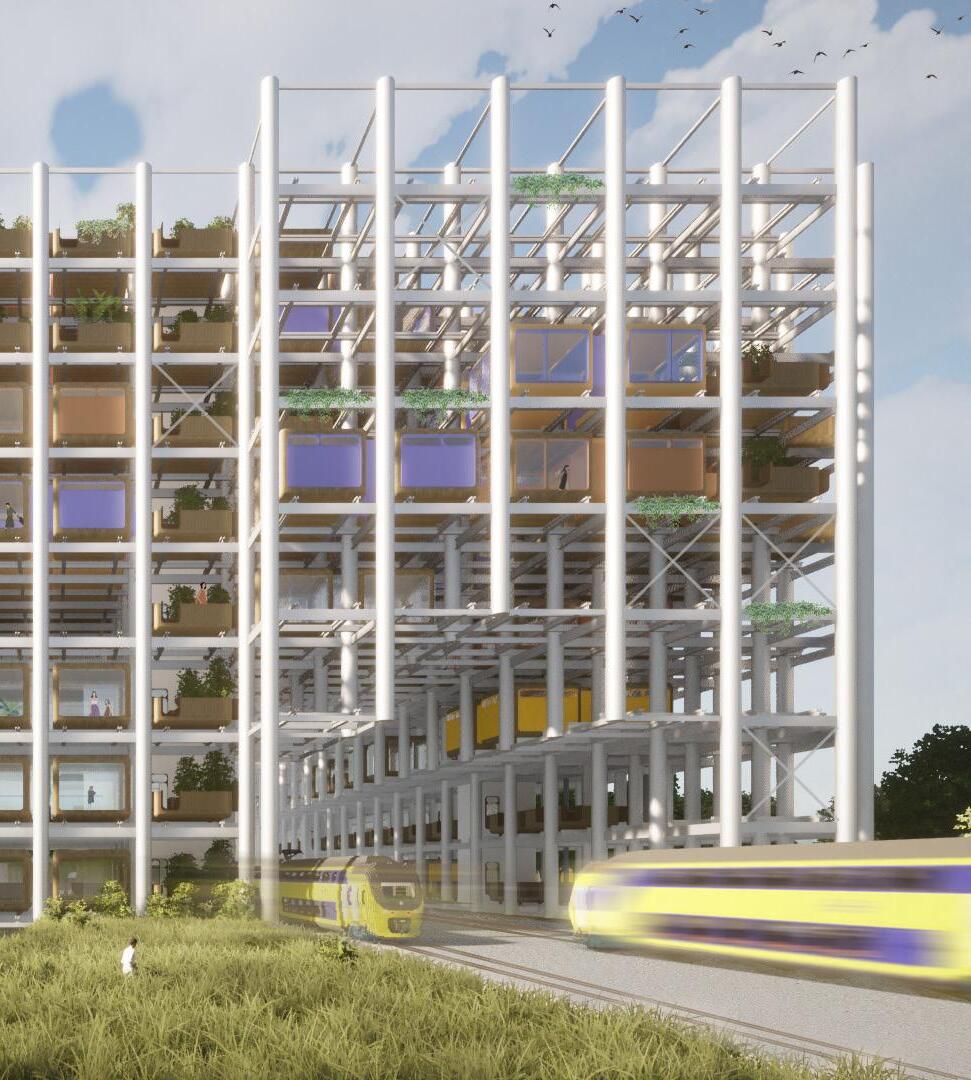

The setting of the project in the “future” city of Delft in 2050 proposes a transformation of the transportation network, embracing a forward-looking vision of urban dynamics. Addressing the challenge of congestion in the city center, the focus lies in dispersing functions across the city. This decentralization aims to distribute activities more evenly, reducing reliance on the city center. At the core of the concept are strategically placed “hubs” across the city, serving as multi-functional nodes offering diverse amenities. By spreading functions across these hubs, the aim is to promote a more balanced distribution of users and alleviate congestion.

Complementing the hubs is a sophisticated transportation system connecting them seamlessly. This network facilitates efficient movement between hubs, enabling easy access to various functions across the city. Within each hub, modular “pods” are envisioned to adapt to user needs, offering flexible spaces for different activities. These pods contribute to a vibrant urban landscape that evolves to meet the city’s changing demands. In summary, the concept aims to create a modular and dynamic urban environment where transportation networks and multi-functional hubs work together to enhance connectivity, promote sustainability, and enrich the urban experience.

Group Academic Project: MEGA High-Rise

Role: Facade Design

Date: April - June 2022

Location: Rotterdam, Netherlands

Programme: Mixed Use High-Rise

Individual Work: Architectural concept, design development, facade design, 3D modeling, construction details & assembly Software: Rhino, Grasshopper, Revit, Enscape, Photoshop

The MEGA project fosters collaboration among students from various disciplines, such as architecture, management, facade design, climate design, computational design, and structural design, with a particular focus on high-rise and complex buildings. The architectural design derived from an initial site and climate data analysis, revealing prevailing wind direction and solar exposure. The tower’s form was shaped with the aim of orienting a green facade toward the south to effectively manage primary solar radiation. The concept of the green facade incorporated balconies adorned with greenery to mitigate solar heat gain while ensuring optimal daylight exposure.

To address the remaining tower facades, a unitized sawtooth facade design was explored, allowing for angling of the panels to be different from the orientation of the building. Opaque panels integrated with PV panels were strategically oriented to capture direct sunlight for solar energy generation, while glazing panels were angled to optimize daylight and views. Computational analysis guided the sawtooth facade’s infill orientation to achieve optimal solar radiation on PV panels while complying with daylight and irradiance standards. The implementation of a unitized facade system offered several advantages, including improved construction efficiency, cost reduction, and time savings. In addition, off-site assembly and testing of panels provided greater quality assurance for thermal insulation and weather tightness.

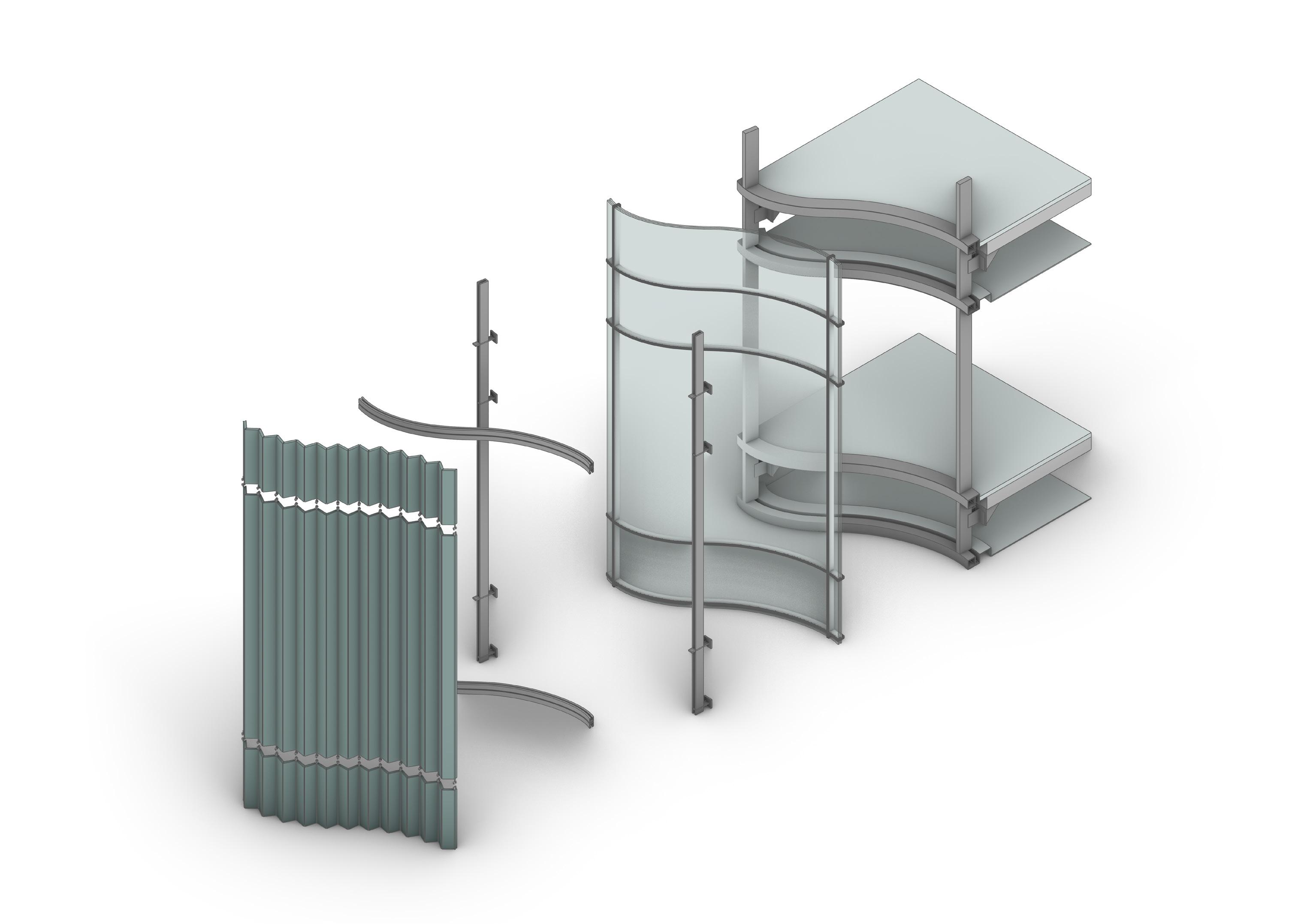

Group Academic Project: AR1B011 Bucky Lab Design

Role: Technical Designer

Date: September 2021 - February 2022

Location: Seoul, South Korea

Programme: Office

Individual Work: Design through research analysis, applied mechanics exploration, 3D modeling, development of rail and node design, rendering,

Software: Rhino, AutoCAD, Illustrator, Photoshop

This course focused on designing and developing an innovative sunshade system for irregular façades. This design was developed through a research process in which design and technical aspects like applied mechanics, material properties, parametric design, and production techniques were analyzed in order to obtain an integrated final design.

The chosen case study is the Shinhan EX:PACE in South Korea. The building has an irregular single curved façade where the radius of the curvature changes along the elevation. It is constructed with curved-glass modules composed of triple-layered insulating structure. The structure supporting the glass façade is made of high-strength steel.

This shading system effectively protects the interior from excessive solar heat gain and glare. It comprises a steel frame anchored to the building’s facade and perforated aluminum panels, offering visibility to the exterior. Both the steel frames and aluminum panels can be customized in size to accommodate the building’s height and the radius of the curved facade. The system is designed to offer mechanical user control, ensuring flexibility according to user needs. Alternatively, automated controls can be integrated, responding to the sun’s position for daylight control and solar radiation management.

Primary Mullion (Proposed)

100 x 50 C-Section in Mild Steel

Curved Rail (Proposed)

50x50mm mild steel double box section curved along building profile

Shading (Proposed)

3400 x 200mm frame

fabricated in Powder Coated 30x30 mm box section

Nodes (Proposed)

Slab and Flooring (Existing)

200mm thick. RCC

(Existing)

50x150 Aluminum Box Section

70x150 Angle Section

Pelmet (Existing)

Neoprene Gasket (Existing)

15 mm wide Sealant

Transom (Existing)

150 x 150 MS Box Section

Glazing (Existing)

45 mm double glazing with insulation

Anchor Plate (Proposed)

150 x 150 T-Plate Welded to Existing Facade Transom

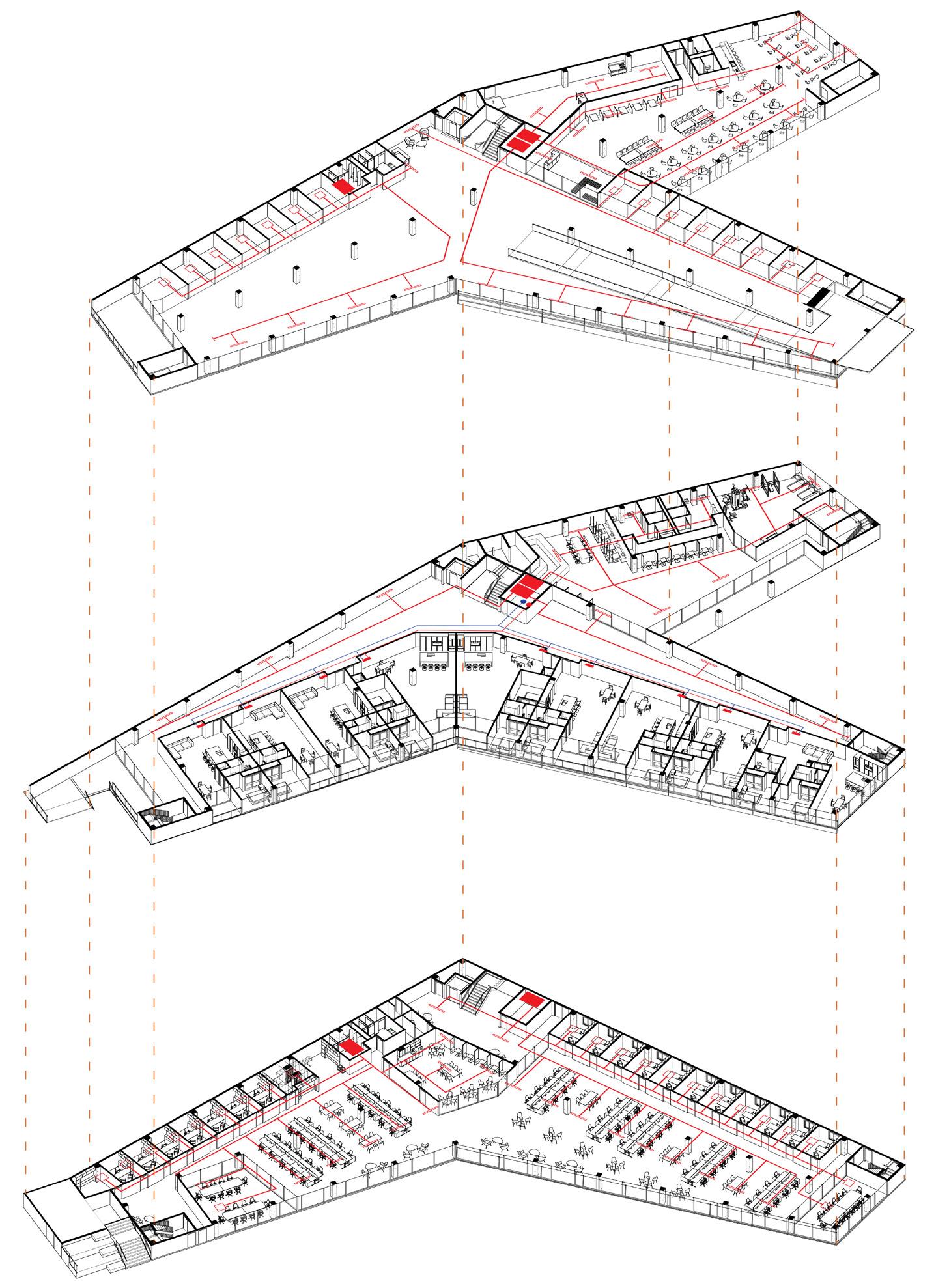

Individual Academic Project: Studio V / VI

Date: January - May 2018 (20 weeks)

Location: Karaburun, Turkey

Programme: Mixed Use

Work: Preliminary research, master planning, building code and LEED integration, mechanical system layout, design development and construction documentation.

Software: Revit, AutoCAD, Illustrator, Photoshop

Açıkolmak - to be receptive

Açık Olmak Center is the nexus of urban and economic growth in a small district of Izmir, Turkey. Located near a tourist village, this development encourages urban distribution and attracts international business. This multi-purpose center provides residential, retail, and workplace opportunities for tourists and the local community.

The project delivers a resilient and contextual design based on the concept of “receptiveness”: to be open and responsive. The multi-faceted form is angled towards prevailing winds and open to maximize views and sunlight. The building’s skin is composed of double-glazed facades and external dampers that allow natural ventilation to assist mechanical cooling, thereby lowering energy demands and enhancing indoor air quality. Additionally, to minimize the heat island effect, the natural topography extends over the building to create a green roof that reduces internal temperatures and improves storm-water management.

The mixed-use building is designed to comply with ASHRAE’s Human Thermal Comfort, Indoor Air Quality Requirements, as well as Energy Conservation Standards. An initial assessment of the project indicates that it will qualify for LEED Platinum certification.

The HVAC systems were selected based on a Life Cycle Cost Analysis as well as an air quality and energy conservation criteria that delivers the performance levels needed to maintain a space comfort within specifications set forth by ASHRAE. HVAC zones were selected based on the specific loading and occupancy of each space.

RESTAURANT - This space uses a Multi-Zone System to control the temperature in the various assigned zones (kitchen, dining, and bar area).

RETAIL STORES - Each tenant has a Variable Air Volume System to allow the users to control the airflow within each individual store.

MARKET PLACE - This open area has an Economizer Cycle System that uses natural ventilation from the exterior and is then filtered through the double-glass facade and recycled through the space.

AMENITIES - This area uses a Multi-Zone System to control the temperature in the various assigned zones (cafe, spa, and gym area).

RESIDENTIAL HALLWAY - The hallway is lined with linear diffusers controlled by a Multi-Zone System

RESIDENCES - Each residential unit has a Fan Coil System that circulates hot or cold water through a coil in order to condition the space per the users thermal comfort.

INDIVIDUAL OFFICES - Each office has a Variable Air Volume System to allow each individual user to control the airflow within each individual office.

OPEN SEATING AREA - This open area has an Economizer Cycle System that uses natural ventilation from the exterior and is then filtered through the double-glass facade and recycled through the space.

THERMAL PERFROMANCE:

The air-side economizer uses cool outside air to either assist mechanical cooling or, if the outside air is cool enough, provide total cooling. The Economizer Cycle System will reduce the mechanical cooling load and water pump energy requirements. This type of system improves indoor air quality by allowing natural ventilation to enter the building through a controlled mechanical system. The system controls the vents that allow exterior air into the building depending on the temperature and humidity levels. This system meets ASHRAE 62.1 Standards.

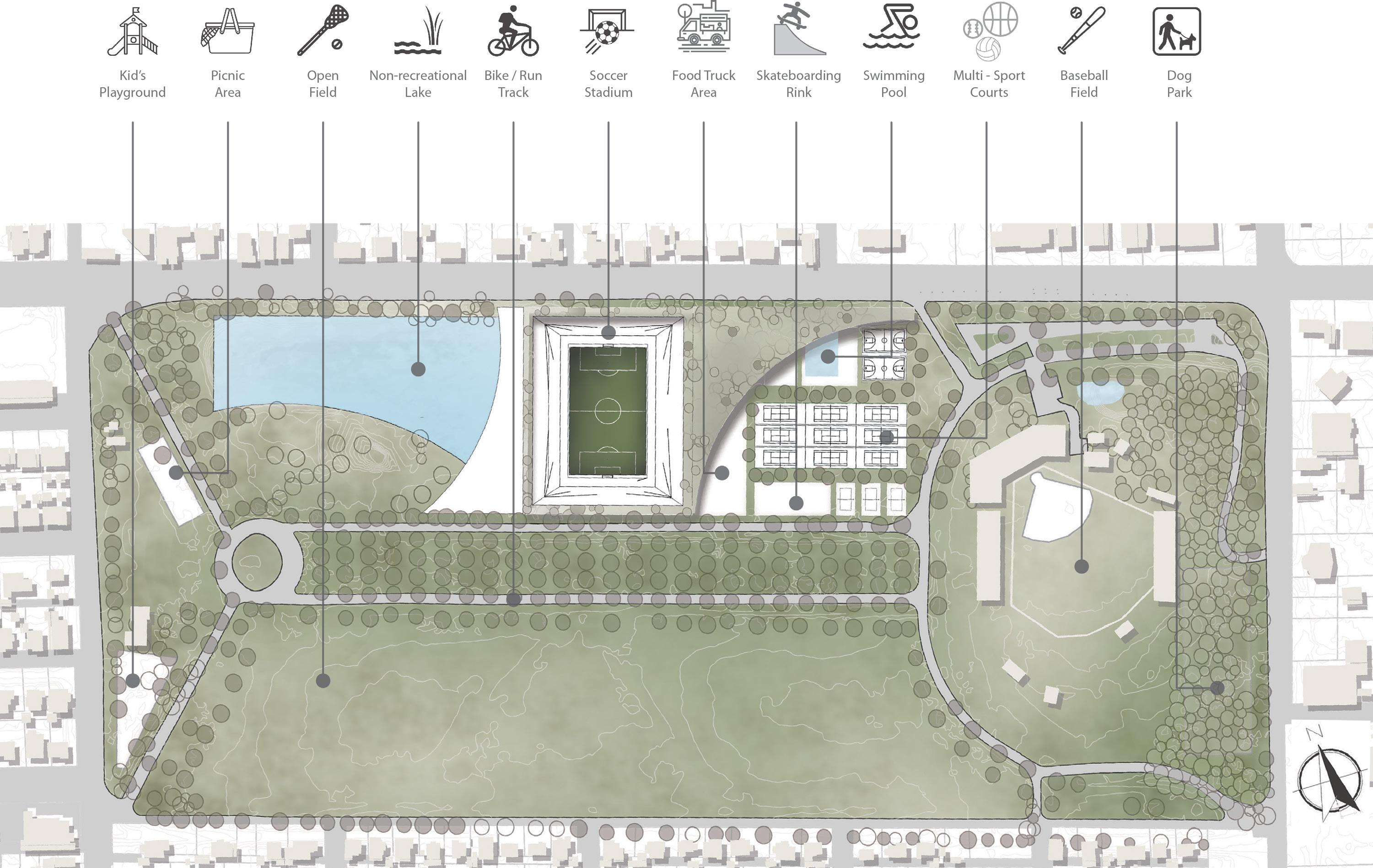

Individual Academic Project: Studio III

Date: March - May 2017 (10 weeks)

Location: Daffin Park - Savannah, GA, USA

Programme: Sports Stadium

Work: Site and climate analysis, design development incorporating existing programmatic conditions, structural composition

Software: Revit, AutoCAD, Illustrator, Photoshop

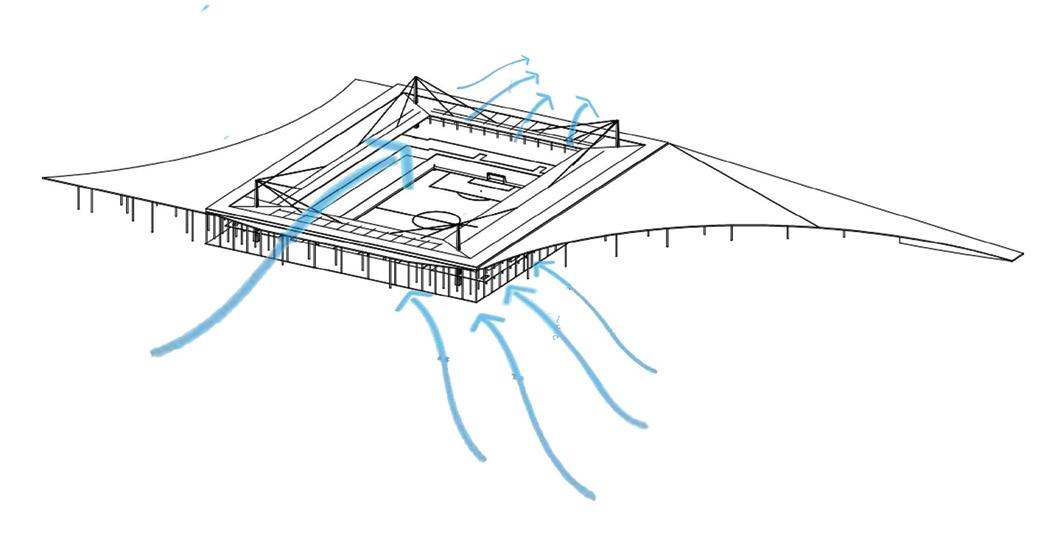

This stadium draws inspiration from the context of Daffin Park, aiming to complement rather than overshadow the existing environment. Accordingly, the stadium is, quite literally, open to the surrounding site. The openness of the colonnade structure fosters a connection to the natural environment, with the green ramp extending the park onto the stadium grounds, along with a green track on the roof. This integration strengthens the relationship between architecture and nature.

Extensive site analysis informed the strategy to enhance the underutilized park area. Factors such as sensory experience, cultural significance, and natural features were carefully considered to determine the placement and program of the various facilities required. While the majority of the park remains untouched, the area adjacent to the stadium underwent redevelopment to accommodate new and renovated facilities. The design incorporates a paved strip, shaded by the green ramp, intended for farmer’s markets and food trucks, thus contributing to the local economy. This revitalized design of Daffin Park not only celebrates the natural environment but also reinforces social cohesion.

With the intention of preserving Daffin Park, minimal changes were made to incorporate the soccer stadium and new facilities. When conversing to various park users while observing the site, I was able to understand what kind of facilities are used the most and what facilities are needed. Additionally, due to the large number of kids skateboarding on the streets of Savannah, the redeveloped site incorporated a skateboard rink. The plan north portion of the park includes the stadium and new facilities along with a remodelation of the existing lake. The green ramp creates a shaded area for the pool and yoga area.

FLOW SHAPE

CONCEPT FORM

GREEN ROOF

The form strives to create a smooth connection between Daffin Park and the soccer stadium.

SUN SHADE

SUN SHADE

This extrusion serves as a sun shade to block the afternoon sun. This allows for a friendlier usage of the green area around the lake.

VENTILATION

VENTILATION

VENTILATION

The open structural grid allows for natural ventilation to flow into the stadium and provide cooling. In addition, the park’s lake creates an evaporative cooling effect.

GREEN ROOF

GREEN ROOF

GREEN ROOF

Along with creating an extension of the park, the ramp allows for users to walk onto a green track on top of the stadium. The ramp’s vegetation helps with storm water control.

Individual Academic Project: Studio IV

Date: September - November 2018 (10 weeks)

Location: Pittsburgh, USA

Programme: Maker Space / Residential

Work: Concept research, demographic studies, programmatic and design development, detail drawings, rendering Software: Revit, Illustrator, Photoshop

According to United Nations Statistics, more than half of the world’s population lives in urban areas and these numbers are expected to increase. Pittsburgh was named one of the “Top 10 Cities for Millennials” due to the urban wave (CNBC). Based on this research, I took an interest in the newer generations, like millennials, and their desire to move around and seek change in their lifestyles. In this age where change is wanted and creativity is thriving, how can I attract more people to Pittsburgh without negatively impacting the city’s density?

Plug-In Maker Space is a dynamic mixed-use building that encourages change and provides new opportunities within the built environment. The main program use for this building is the residential apartments operated by a central structural crane. However, to adapt to a futuristic city, the design includes: food markets, public galleries, retail pop-up shops, as well as educational facilities that inspire creativity and collaboration.

Located in one of the most industrial cities, this midrise timber building stands out among Pittsburgh’s steel bridges and concrete architecture. The cross-laminated timber construction is sustainable and reduces building time and costs. This modular building is adaptable to the user and the diversification of different functions.

To better understand the site and how people move throughout the city, research was conducted on population demographics and the development of Pittsburgh. The Population Density map illustrates the most concentrated areas around the city. The Housing Density map indicates the most habitable zones around the downtown area. Lastly, the Median Residents Age map depicts the age distribution within the city.

These maps were overlaid to integrate the gathered demographics and conduct a multiple-layer analysis. This information was utilized to ascertain the potential users of the mid-rise building and to assess how the architecture can accommodate their culture and fundamental needs.

01. Available Lots 02. Plug-In Residential Units

Modular laminated timber panels are pre-fabricated and flat packed

01. Pop-Up Workshop Space 02. Communal Kitchen

Gym

01. Exterior Terrace

02. Communal Workspace

03. Robotics Lab

04. Wood / Metal Shop

05. Textile Studio

06. Recycling Storage

07. Classrooms

2. ASSEMBLY

Panels are assembled off site; furniture and systems installed

01. Exhibition Space 02. Atrium

03. Pop-Up Retail Shops 04. Administrative Office 05. Leasing Office

3. DELIVERY TO SITE

Residential plug-in units are shipped to site

01. Food Market

02. Plug-In Food Trucks

03. Interior Courtyard 04. Grocery Store 05. Plug-In Unit Storage

Residential Lobby

4. PLUG INTO FRAME

Plug-in units are loaded by crane and inserted into structured lots

The crane acts as the core structure of the building and operates the insertion and removal of the plug-in units.

The structural grid creates vacant “lots” for the plug-in residential units.

The plug-in system creates a modular building that is adaptable to the users and the diversification of different functions.

Group Extracurricular Project: NOMAS Competition

Role: Designer

Date: September - October 2017 (4 weeks)

Location: Sunnyside, Houston, TX, USA

Programme: Educational

Individual Work: Initial analysis, double skin system design, floor plan development, rendering of interior spaces

Software: Revit, Illustrator, Photoshop

The proposal for the John S. Chase Academy of Architectural Design and Sustainability aims to address generational struggles through a learning environment that keeps students highly attuned to sustainable concepts, good design, and technology. The academy also strives to serve as a hub for the entire community, and was designed with that extended purpose in mind. Through appropriate programming and flexible spaces the school can provide essential educational facilities along with communal areas.

During the conceptual design phase, optimizing circulation emerged as a core value for how the rest of the building would resolve. Kinetic energy floor tiles were introduced to harness energy generated by foot traffic, converting it into usable electricity. Other sustainable strategies integrated into the design included a double-skin facade system, green roofs and gardens, a substantial array of photovoltaic cells, and ample glazing on the southern exposure.

The building’s program was structured to function securely as a school, but can be easily transformed into public spaces for the surrounding neighborhood. In envisioning the ideal realization of the design, additional supportive programs such as communal kitchen events, theater performances, a public library, and an open gym were planned to be readily available, fostering a sense of community engagement.

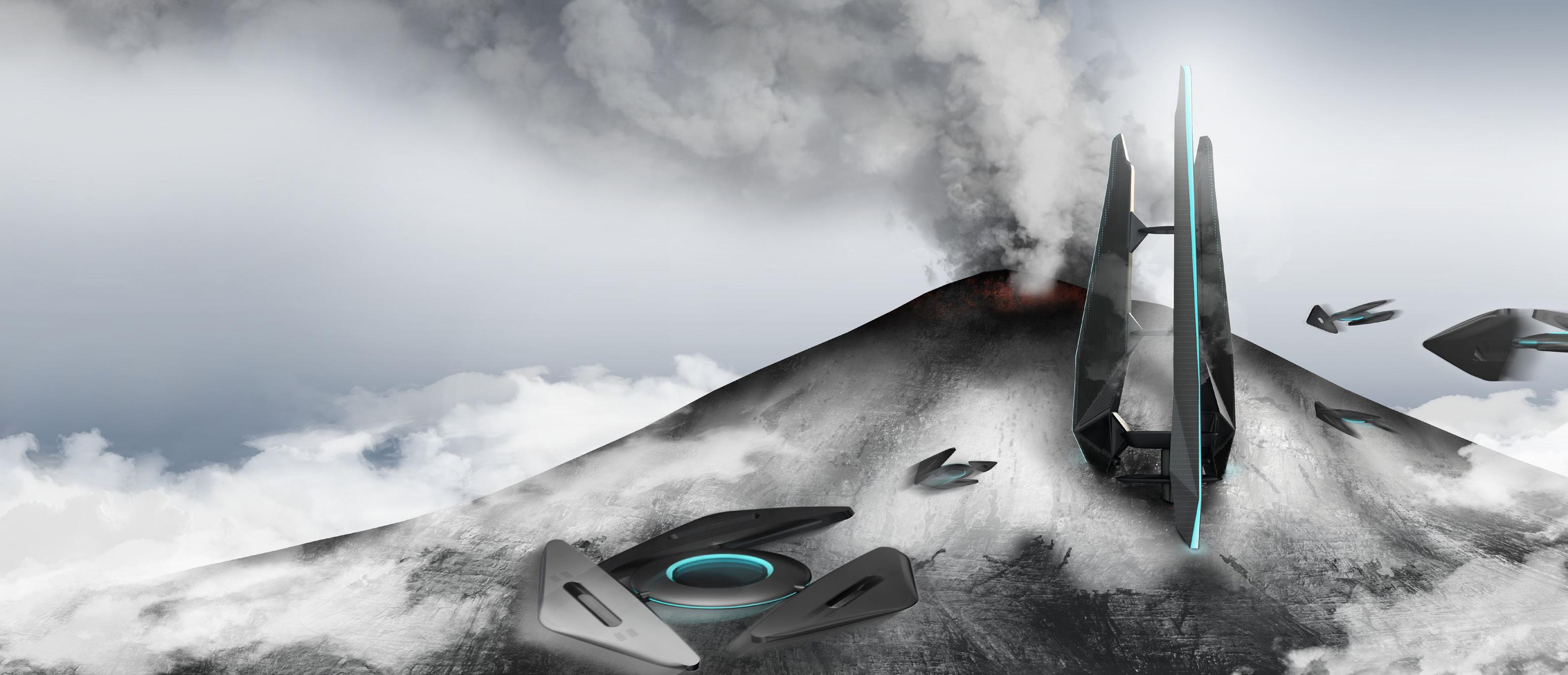

Group Extracurricular Project: Evolo Competition

Role: Designer

Date: January - February 2018 (5 weeks)

Location: Mexico City, Mexico

Programme: Skyscraper

Individual Work: Concept development, 3D modeling and diagrammatic illustrations, air filtration research, drone design and technical components.

Software: Rhino, Illustrator, Photoshop

Nascence - to come into existence for the first time

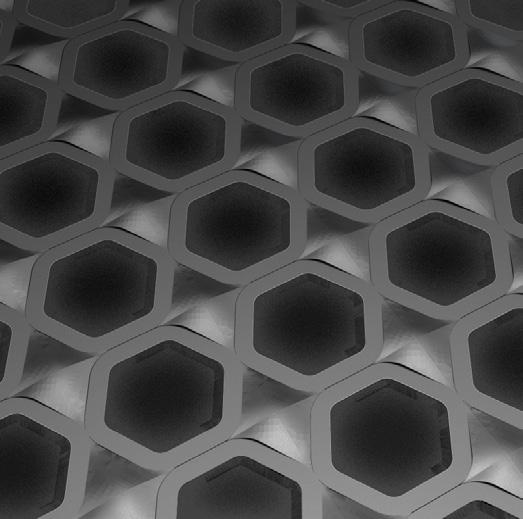

This design combats the issues of energy pollution by generating clean energy and filtering the air, thus alleviating the burden of dense pollution. The design is located on the outskirts of Mexico City, perched upon Popocatépetl Volcano. This location allows for the building to collect renewable energy from a geothermal volcanic plant. The geothermal plant provides energy to charge and power the air filtration drones, which travel daily to and from Mexico City.

The form of the building arose from the design development of an extruded drone. The angled facades of the building are composed of hexagonal filters as well as docking stations for the drones. The drones are designed to dislocate from the skin of the structure and soar through the sky to filter the air of Mexico City. Each individual docking station is connected to a central vacuum, which collects all of the dirt particles from the filters. The drones are composed with technology that can track and detect concentrated areas of pollution. The addition of Nascence to Mexico City will enhance both air quality and the capacity to generate clean energy, fostering the development of a healthier and more livable metropolis.

The second layer is a carbon filter that traps odor and gases in the surrounding air.

The joint allows for the rotation of the three propeller stabilizers which defines direction and allows the sentinel to dock vertically onto the facade of the structure.

The interior is lined with an ultra-violet lamp, which kills the bacteria from the filters and stops micro-organisms from reproducing.

Intake valves draw air internally to an impeller fan.

FILTER 1:

The first layer is a fiberglass filter that removes large air particles. This is 99.7% effective at catching particles as small as 3 micrometers.

FILTER 3:

The third layer is a fine fiberglass filter that will remove smaller air particles like pm2.5 and bacteria. These fine atmospheric particles come from volcanic eruptions, motor vehicles, and power plants.

STAINLESS STEEL IONIZER:

This electro-static technology produces negative ions to clump particles together and magnetically attracts them to the filters to be removed from the air.

POLLUTION TRACKER:

This sensor is combined with GPS electronics to track pollution hot-stops on the principle of light scattering.

PROPELLER STABILIZERS:

Blade-less propellers take advantage of headwind and forces it through internal ducts to generate a downward flow and allows the sentinel to lift. Its angled design creates a negative pressure causing the air to accelerate.

OUTTAKE VENTS:

Outtake valves extract moving air when flying.

AERODYNAMIC DESIGN:

The aerodynamic design allows for induced wind to be drawn in.

The recessed design of the docking station allows for the sentinels to be flush with the skin of the structure when attached.

EXTERIOR COATING:

The sentinel is coated with a superfine titanium dioxide, which is activated by ambient light and can fight against pollution.

DOCKING CONNECTION JOINTS:

These joints provide energy to re-charge sentinels. Additionally, these joints allow for a connection between the sentinel and the central vacuum structure.

VACUUM DUCTS:

These ducts connect the central vacuum structure to the sentinels in order to clean the particulate matter from the filters

danielamaria.mtz@gmail.com