EXPERT TIPS FROM MERLOT MASTERS TO HELP YOU CRAFT YOUR OWN AT HOME GETTING THE MOST FROM RED HYBRIDS FERMENTED FOODS TO PAIR WITH YOUR WINES

Keg Your Home Wine Pro Tips On Co-Fermentation The Rice Stu : Homemade Sake WINEMAKERMAG.COM APRIL - MAY 2023 VOL.26, NO.2

MERLOT WORLD AROUND THE

Wine analysis products for artisan

SO2 (Free & Total)

WINEMAKERMAG.COM APRIL - MAY 2023 1 www.lallemandbrewing.com/wine FULL RANGE OF PREMIUM WINE YEAST K1 ™ (V1116) FRESH AND

STYLES EC1118 ™ THE ORIGINAL

™

wineries

FRUITY

“PRISE DE MOUSE” 71B ™ FRUITY AND “NOUVEAU” STYLES D47 ™ FOR COMPLEX CHARDONNAY QA23 ™ FOR COMPLEX SAUVIGNON BLANCS RC212

FOR PINOT NOIR STYLES Also offering Ideal for small to medium sized

wine!

winemakers Set up your own lab and take control of your

Or send us your samples Lab Services also available

Family owned and operated for over 10 years! Located in Carlsbad, CA Vinmetrica.com • scan for additional info

Titratable acidity (TA) pH Malic acid (MLF) Residual sugar (new!) Dissolved oxygen YAN ABV%

26 RED HYBRID GRAPE WINEMAKING

Making red wine from hybrid grapes can sometimes be a challenge, but the rewards are also tremendous. The first steps? Forget what you know about making wine from vinifera grapes and embrace the unique characteristics hybrids often have.

by Zac Brown

by Zac Brown

32 MERLOT AROUND THE WORLD

Though its reputation may have been tarnished by a certain movie after the turn of the century, Merlot continues to be one of the most popular wine grapes in the world. Winemakers from France, Italy, and the United States share advice on crafting a memorable Merlot at home.

by Danny Wood

40 RICE, RICE, BABY

The ancient Japanese beverage sake has grown in popularity across North America in recent years thanks to craft sake producers. Making this unique beverage from rice is a really fun project for those who would like to expand their home fermentation hobby. Learn more about sake and the basic ingredients and steps to make your own.

by Andrew Centofante

by Andrew Centofante

2 APRIL - MAY 2023 WINEMAKER contents April-May 2023, VOL. 26 NO. 2 WineMaker (ISSN 1098-7320) is published bimonthly for $29.99 per year by Battenkill Communications, 5515 Main Street, Manchester Center, VT 05255. Tel: (802) 362-3981. Fax: (802) 3622377. E-mail address: wm@winemakermag.com. Periodicals postage rates paid at Manchester Center, VT, and additional mailing offices. POSTMASTER: Send address changes to WineMaker, P.O. Box 469118, Escondido, CA 92046. Customer Service: For subscription orders, inquiries or address changes, write WineMaker, P.O. Box 469118, Escondido, CA 92046. Fax: (760) 738-4805. Foreign and Canadian orders must be payable in U.S. dollars. The airmail subscription rate to Canada and Mexico is $34.99; for all other countries the airmail subscription rate is $49.99.

26 32 40

features

WINEMAKERMAG.COM APRIL - MAY 2023 3 888-539-3922 • waterloocontainer.com Follow us on Facebook and Linkedin Looking for Bottles, Caps and Closures? • Extensive inventory of ready-to-ship bottles, caps and closures • No MOQ on most items – we serve customers of any size • Industry expertise to guide you through the packaging process • Quality products and customization to create or enhance your brand You Can Rely on Us MOREWINE.COM • ABSOLUTELY EVERYTHING FOR WINEMAKING • Since 1995 SAVE 15% OFF OR MORE! SALE ENDS MARCH 31st PRESEASON SALE! ENDING SOON GOT GRAPES? WE GOT THE REST!

departments

8 MAIL

A reader asks if cold stabilization should be required for beginning winemakers, and another seeks advice after their vodka fermentation stopped prematurely.

10 CELLAR DWELLERS

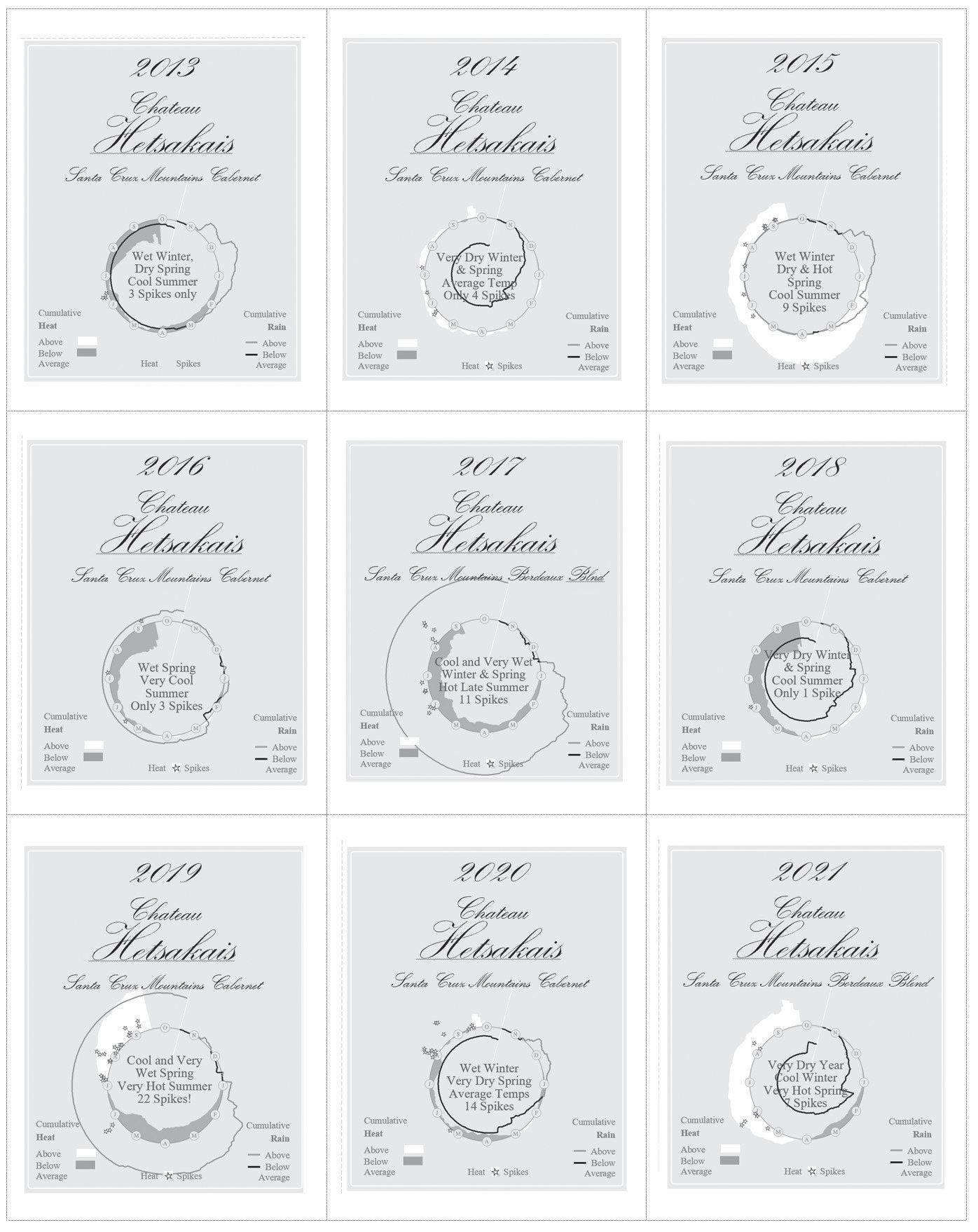

We saw a lot of cool looking amateur wine labels in our 2023 label contest but nothing quite as unique as these. Check out these labels from Chateau Hetsakais as well as some pointers for making red wines and the latest news, products, and upcoming events.

14

TIPS FROM THE PROS

Wine blends are most often created after fermenting each variety separately. However, that isn’t the only way to do it. Some winemakers choose to co-ferment certain varieties together, believing this approach adds to the complexity of the resulting wine. Get tips on co-fermentation from three pros who endorse the benefits.

16 WINE WIZARD

Winemaking may be more a science, but blending is definitely an art. The Wizard has some tips for a rookie winemaker looking to possibly blend five different wines. Also, make sure you’re up on the latest knowledge and mitigation methods surrounding the phenomenon known as smoke taint.

19 VARIETAL FOCUS

Hailing from the southern regions of Italy, Aglianico is revered as producing big and bold red varietal wines. It is finding its way across the sea and will need some taming in order to make the best from its clusters. Get the scoop.

47 TECHNIQUES

Since the start of COVID-19, the interest in fermented foods seems to have only grown in popularity. Take a walk through some easily fermented foods you can make in your kitchen and what wines may pair nicely with them.

50 ADVANCED WINEMAKING

In contemporary times beer and soft drinks have become the standard beverages to find on draft at bars and restaurants, but that is changing as wine-on-draft is a growing trend. Learn how you too can enjoy having both still and sparkling wines at home served on your own draft system.

56 DRY FINISH

Travel with us to the country of Georgia where winemaking in ancient times started and where many of those early traditions remain. Explore the techniques, equipment, and wine grapes being utilized in wine’s native land.

4 APRIL - MAY 2023 WINEMAKER

53 SUPPLIER DIRECTORY 55 READER SERVICE where to find it ® 19

courtesy of Shutterstock.com

Photo

March

Join

South

next March

-

2024

combine wine with a safari adventure in one epic vacation! We’ll tour the most famous wine regions of South Africa including Stellenbosch, Franschoek, Paarl, and the Cape. We’ll visit both small and large wineries meeting their winemakers and tasting the local Pinotage and many other great wines during the excitement of their Southern Hemisphere grape harvest season. Then we’ll head to Kruger National Park to seek out lions, leopards, elephants, rhinos, and cheetahs from an open Land Rover with a ranger and spotter on a thrilling, once-in-a-lifetime safari.

For more details visit: winemakermag.com/trip

WINEMAKERMAG.COM APRIL - MAY 2023 5 The Spring Winemaking Season is almost here! Contact Musto Wine Grape for details on the highest quality and variety of grapes and juices in New England! www.juicegrape.com 877.812.1137 sales@juicegrape.com Join WineMaker in South Africa!

SOUTH AFRICA

2024

18 – 26,

WineMaker Magazine in

Africa

18

26,

to

WINE

ADVENTURE

WITH WINEMAKER

& SAFARI

EDITOR

Dawson Raspuzzi

ASSISTANT EDITOR

Dave Green

DESIGN

Open Look

TECHNICAL EDITOR

Bob Peak

CONTRIBUTING WRITERS

Dwayne Bershaw, Chik Brenneman, Alison Crowe, Wes Hagen,

Maureen Macdonald, Bob Peak, Phil Plummer, Clark Smith

CONTRIBUTING PHOTOGRAPHER

Charles A. Parker

EDITORIAL REVIEW BOARD

Steve Bader Bader Beer and Wine Supply

Chik Brenneman Baker Family Wines

John Buechsenstein Wine Education & Consultation

Mark Chandler Chandler & Company

Wine Consultancy

Kevin Donato Cultured Solutions

Pat Henderson About Wine Consulting

Ed Kraus

EC Kraus

Maureen Macdonald Hawk Ridge Winery

Christina Musto-Quick Musto Wine

Grape Co.

Phil Plummer Montezuma Winery

Gene Spaziani American Wine Society

Jef Stebben Stebben Wine Co.

Gail Tufford Global Vintners Inc.

Anne Whyte Vermont Homebrew Supply

Do you have a favorite variety of red wine grape you like

to work with?

QPUBLISHER

Brad Ring

ASSOCIATE PUBLISHER & ADVERTISING DIRECTOR

Kiev Rattee

ADVERTISING SALES COORDINATOR

Dave Green

EVENTS MANAGER

Jannell Kristiansen

BOOKKEEPER

Faith Alberti

SUBSCRIPTION CUSTOMER SERVICE MANAGER

Bottling Sparkling Wine From A Keg

There are various carbonation methods for making bubbly at home including the use of a carbonating stone or specialized equipment such as a counter-pressure bottler. Here is a guide to bottling your sparkling wine from a keg. https://winemakermag.com/ technique/306-force-carbonatingwine-to-sparkle-technique

MEMBERS ONLY

EDITORIAL & ADVERTISING OFFICE

WineMaker

5515 Main Street

Manchester Center, VT 05255

Tel: (802) 362-3981 Fax: (802) 362-2377

Email: wm@winemakermag.com

ADVERTISING CONTACT:

Kiev Rattee (kiev@winemakermag.com)

EDITORIAL CONTACT:

Dawson Raspuzzi (dawson@winemakermag.com)

SUBSCRIPTIONS ONLY

WineMaker

P.O. Box 469118

Escondido, CA 92046

Tel: (800) 900-7594

M-F 8:30-5:00 PST

E-mail: winemaker@pcspublink.com

Fax: (760) 738-4805

Special Subscription Offer

6 issues for $29.99

Cover Photo: Charles A. Parker/Images Plus

My favorite red varietal might sound cliché, but it’s Cabernet Sauvignon. I make three very different style Cabernet wines in my portfolio and I am always impressed with the huge differences in style based on growing region. I love trying various yeast strains and blending them post ferments to coax the most complex array of flavors out of the Cabernet as possible.

I love the way Norton ripens in the warm climate of Clarksburg, California. It comes in with balanced acidity, rich color, complex aromatics, and soft, round texture. It contains 1.5% unfermentable solids, so the alcohol is always below 13%.

In the springtime I love making Malbec. Fermentation smells like cotton candy and usually doesn’t require a lot of adjustments up front. I like that Malbec’s a red wine I can drink young or age, it’s always bright and fruity. In the fall it’s hands down Petite Sirah. Petite Sirah is a gorgeous inky color, can handle fermentation without temperature control really well, and produces a delicious bold wine every time. I can bottle it straight or use it as a blender to perk up any of my red wines that need a little help.

Anita Draper

Meritage Roundtable

Like most things in winemaking, bring four winemakers together and you’ll get four different opinions. Which is exactly what we’ve done here. We asked four commercial winemakers the same series of questions about keys to making a great red meritage blend and got several different thoughts. https://winemakermag. com/technique/meritage-roundtable

Red Hybrid Color Stabilization

All contents of WineMaker are Copyright © 2023 by Battenkill Communications, unless otherwise noted. WineMaker is a registered trademark owned by Battenkill Communications, a Vermont corporation. Unsolicited manuscripts will not be returned, and no responsibility can be assumed for such material. All “Letters to the Editor” should be sent to the editor at the Vermont office address. All rights in letters sent to WineMaker will be treated as unconditionally assigned for publication and copyright purposes and subject to WineMaker’s unrestricted right to edit. Although all reasonable attempts are made to ensure accuracy, the publisher does not assume any liability for errors or omissions anywhere in the publication. All rights reserved. Reproduction in part or in whole without written permission is strictly prohibited. Printed in the United States of America. Volume 26, Number 2: April-May 2023.

Red wines from hybrid grapes can be frustrating — one day you have a deep garnet wine and the next you are wondering where the color went. Color stabilization is the key, and there are techniques to help. https:// winemakermag.com/technique/redhybrid-color-stabilization

MEMBERS ONLY

The Science of Food-Wine Pairings

Approaching foodwine pairings can be complex given the nearly endless options available . . . but there is a science to it. Learn the basics to matching a wine with a food course to impress even the sticklers in the group. https://winemakermag.com/ technique/delicious-endeavors-thescience-of-food-wine-pairings

MEMBERS ONLY

* For full access to members’ only content and hundreds of pages of winemaking articles, techniques and troubleshooting, sign up for a 14-day free trial membership at winemakermag.com

6 APRIL - MAY 2023 WINEMAKER WINEMAKERMAG.COM suggested pairings at ®

WineMakerMagazine @WineMakerMag @winemakermag

FILL YOUR PASSION.

BOTTLE FILLING MADE EASY!

XPRESSFILL BOTTLE AND CAN FILLERS are handcrafted and custommade to order in the USA. We offer five types of fillers: Volumetric Filler, Level Filler, Carbonated Beverage, Counter Pressure Filler, and a Hot Fill Level Filler. With ten models to choose from, there is an XpressFill that will fit your needs. Order yours today!

844.361.2750 (toll free) sales@xpressfill.com XPRESSFILL.COM

THE PINNACLE OF LAFAYETTE

6 Tofflemire Drive, Lafayette CA 5BD | 4BA | 2HfBA | 8,080 sq. ft.

Ascend through a forest and leave behind city hustle and bustle. This magnificent home offers commanding views of Mount Diablo and adjoins the Lafayette Reservoir open space and trails. The lot, with vineyard, is impeccably landscaped throughout.

Three separate buildings complete the grounds: an equipped winery with a tasting area; a building with a full bath that can be used as a gym or guest room; and a greenhouse. This estate is an incomparable idyllic retreat.

Offered for $4,950,000

6TofflemireDrive.com

WINEMAKERMAG.COM APRIL - MAY 2023 7

XF460 VOLUMETRIC FILL Scan this code to view all of our products!

Each Franchise Is Independently Owned And Operated. Ann Newton Cane 415.999.0253

Lic.#02084093

a.newtoncane@ggsir.com

WHAT ABOUT COLD STABILIZATION?

I really enjoyed Bob Peak’s article “Let’s Start Making Wine” explaining beginning winemaking in the February-March 2023 issue. It was easy to follow and thorough; but he left out an essential step for us users of cold-climate grapes— cold stabilization. Without doing this, the beginner will be spending a lot of time explaining that sludge that showed up in the bottled wine!

Steve Grubba • Corning, Iowa

Thanks for the feedback, Steve! Bob certainly had some tough decisions to make when we assigned him this subject (for which entire books are published) and asked him to keep it below 3,000 words! Cold stabilization (also called bitartrate stabilization) is one of the subjects we decided wasn’t a necessity to cover in this story for a couple of reasons. One, we ran a story on the subject of cold and heat stabilization in the December 2022-January 2023 issue (which we encourage everyone who wants to learn more about this subject to check out!). But a second reason is because cold stabilization is a choice winemakers have and forgoing it will have minimal, if any, impact on the aroma or flavor of the wine. What it may lead to if bottles are chilled is the formation and precipitation of potassium bitartrate crystals in the bottle, often called “wine diamonds” as they look like small diamonds or sea salt.

VODKA FERMENTATION

I have the Alcotec vodka kit, I checked the room temperature before I started and it was 66 °F (19 °C), the fermentation started after about 18 hours, when I checked the liquid was at 75 °F (24 °C) so I tried to lower the room temperature and I got the liquid down to 66 °F (19 °C) but the fermentation has stopped (after 6 days). Will it still be OK or should I add some restart yeast to it?

Tony Kast • via email

Aaron Hyde, our distilled spirits expert, responds: “It sounds like your fermentation was going quite well. Your fermenting liquid heats up due to all the yeast’s biological activity during fermentation. Typically with turbo yeasts, the manufacturer recommends an ambient temperature to ferment at, not a wash or liquid temperature. Cooling the ambient temperature likely slowed or stopped fermentation (which shouldn’t affect quality). I’d bring your room to the recommended ambient (or fermentation) temperature and ferment for at least five more days to make sure fermentation is complete.”

Zac Brown learned winemaking 25 years ago while working with a small family winery and vineyard in Moravia, Czechia. He later honed his skills in Western Australian wineries and then Montreal, Quebec, as an amateur winemaker or “garagiste.” For years, he has studied the science of enology and he has been an active teacher and mentor to other winemakers. In 2017, he and his wife, Julie, purchased Alderlea Vineyards in the Cowichan Valley on Vancouver Island, British Columbia. Since taking over, Zac has focused on vineyard health and improving Alderlea’s wines, consistently winning national awards.

Zac makes his WineMaker debut on page 26 sharing his experience and advice for making high-quality red wine from hybrid grapes.

Danny Wood is an Australian-based journalist who lived in Kansas City, Missouri, for a decade before moving home with his family. He’s made wine in his basement, worked in wineries, and is a former editor of Midwest Wine Press. He also studied enology while in the United States and judged the occasional wine competition, but was really smitten by vino (and his American wife) while living in Spain, reporting for BBC News. In past issues of WineMaker, Danny has profiled Joel Peterson and Ravenswood Winery, as well as written stories on fermenting with wild yeast, essential winemaking techniques, the varieties of Chardonnay, Malbec, Tempranillo, and many other topics.

Beginning on page 32, Danny travels the world (or speaks with winemakers across the world, at least) to get their advice on making a memorable Merlot.

Andrew Centofante is the Co-Owner and Head Brewer of North American Sake Brewery (NAS) in Charlottesville, Virginia. Andrew first fell in love with sake on a trip to Japan where he was exposed to high-quality sake for the first time. As a homebrewer for many years, he soon began dabbling in making sake at home. This sent Andrew down a rabbit hole of research and experimentation that turned one batch into many as he fell in love with brewing sake. He and business partner Jeremy Goldstein traveled across America and to Japan to learn more about this craft, which would eventually lead them to opening NAS in 2018. Andrew is also the Chair of the Board of Directors for the Sake Brewers Association of North America.

Andrew shares advice on how home winemakers can make their own sake beginning on page 40.

8 APRIL - MAY 2023 WINEMAKER contributors MAIL

WINEMAKERMAG.COM APRIL - MAY 2023 9 Our Red Star range is evolving. New names, the same tradition. PREMIER CUVEE • PREMIER BLANC • PREMIER COTE DES BLANCS • PREMIER CLASSIQUE • PREMIER ROUGE A Fermentis brand FIND OUR PRODUCTS IN YOUR LOCAL HOMEBREW /HOME WINE MAKING SHOP ©2014 Plantra, Inc. www.plantra.com 800-951-3806 RUINED FRUIT FLAVOR AND LOST TONNAGE LOST PROFITS Protect blueberries, grapes, cherries, raspberries, blackberries and other crops 24/7 with AviGard ® Bird Netting from Plantra! Harvest Math 101 Professional Grower Supplies for Vineyards, Orchards, Nurseries and Wildlife Habitat Grow Tubes • Bark Protectors • Weed Mats • Fertilizer Packets • Deer Repellent 651-686-6688 ©2017 Plantra, Inc. Free shipping on all wine kits www.HomeBrewIt.com or Call us at 574-295-9975

New Irrigation Suggestions For Drought-Prone Regions

Research out of Oregon State University (OSU) has the following advice to offer up to wine grape growers in more drought-prone environments: Irrigate early when water is available, but not too much to promote a giant canopy. Then cut back later in the growing season when water is more scarce. What OSU’s viticulturist Alec Levin found working in Oregon’s Rogue River Valley was that more irrigation early in the season led to higher yield and fruit quality.

This is a balancing act because if grape growers irrigate too much too early, the canopy will be excessive leading to higher water consumption later in the season. But his conclusions were clear that the longer they waited to start irrigation, the lower the yield. The irrigation rate used was 17 gallons (64 L) per week per vine. Fruit quality among the deficit irrigation programs was a little less straightforward as other factors came into play such as viral, fungal, or pest stress. Also, the effects on harvest Brix was a little more variable; a slight delay in starting the irrigation program did increase Brix, but Brix was reduced in the later start vines.

These studies will continue in 2023 with continued work on grapes and how fruit quality from the different irrigation strategies makes its way into the finished wine.

RECENT NEWS

UPCOMING EVENTS

https://www.goodfruit.com/thirst-management-for-wine-grapes/

https://www.goodfruit.com/thirst-management-for-wine-grapes/

New Products: Still Spirits Air Still Pro

A new upgrade is available for the Still Spirits Air Still, an air-cooled countertop home distillation system (this system does not require water to cool the distillate). The new Air Still Pro is an improvement on the design by adding a reflux column so users can more easily produce clean distillates. For users of the Still Spirits Air Still, there is an available upgrade so that they don’t need to purchase an entirely new unit to gain the same benefits of the reflux column. The Air Still Pro allows users to switch between pot-still and reflux mode. Another new feature is a built-in botanicals basket and a foreshots collection vial for automatically collecting the first heads of the distillate.

https://bsghandcraft.com/still-spirits-air-still-pro

JUNE

1 & 4, 2023

Small Class WineMaker Boot Camps — Full-day Boot Camp sessions will run pre-conference and post-conference in Eugene, Oregon. Each Boot Camp runs from 10 a.m. to 4:30 p.m. and includes lunch. Attendance is limited to just 35 attendees per session and sessions do sell out. These add-on Boot Camps beyond the conference registration are a great opportunity to get an in-depth learning experience in a small audience setting and learn hands-on from experts. To learn more about what classes are available: winemakerconference.com

JUNE

2–3, 2023

2023 WineMaker Conference — The 14th annual WineMaker Conference will be held in Eugene, Oregon, located in the world-famous Willamette Valley wine region. Join fellow hobby winemakers from across North America for full days packed with dozens of seminars and special events to help you make your own great wine. The event has several optional side events including small-class Boot Camps, winery tours, and the WineMaker International Amateur Competition Awards Dinner. Spots do sell out, so don’t wait to register. winemakerconference.com

10 APRIL - MAY 2023 WINEMAKER

News

AWARD-WINNING KITS

SILVER

RJS Craft Winemaking En Primeur

Winery Series

Malbec

Winexpert Selection Chilean

Carménère

BRONZE

Mosti Mondiale Originale Nero

D’Avola

Winexpert Limited Edition Nerello

Winexpert Limited Edition

Barbaresco Nebbiolo

Winexpert Private Reserve

Piedmont Nebbiolo

Winexpert Reserve Argentina

Malbec

Winexpert Reserve Italian Dolcetto

Winexpert Reserve Montepulciano

Winexpert Vintners Reserve

Bergamais

Red Vinifera Bordeaux Style Blends

BRONZE

Winexpert Private Reserve

Languedoc

Winexpert Reserve Cabernet Merlot

WINEMAKERMAG.COM APRIL - MAY 2023 11

Here is a list of medal-winning kits for the Other Red Vinifera Blends and Red Vinifera Bordeaux Style Blends categories chosen by a blind-tasting judging panel at the 2022 WineMaker International Amateur Wine Competition in West Dover, Vermont:

Other Red Vinifera Varietals

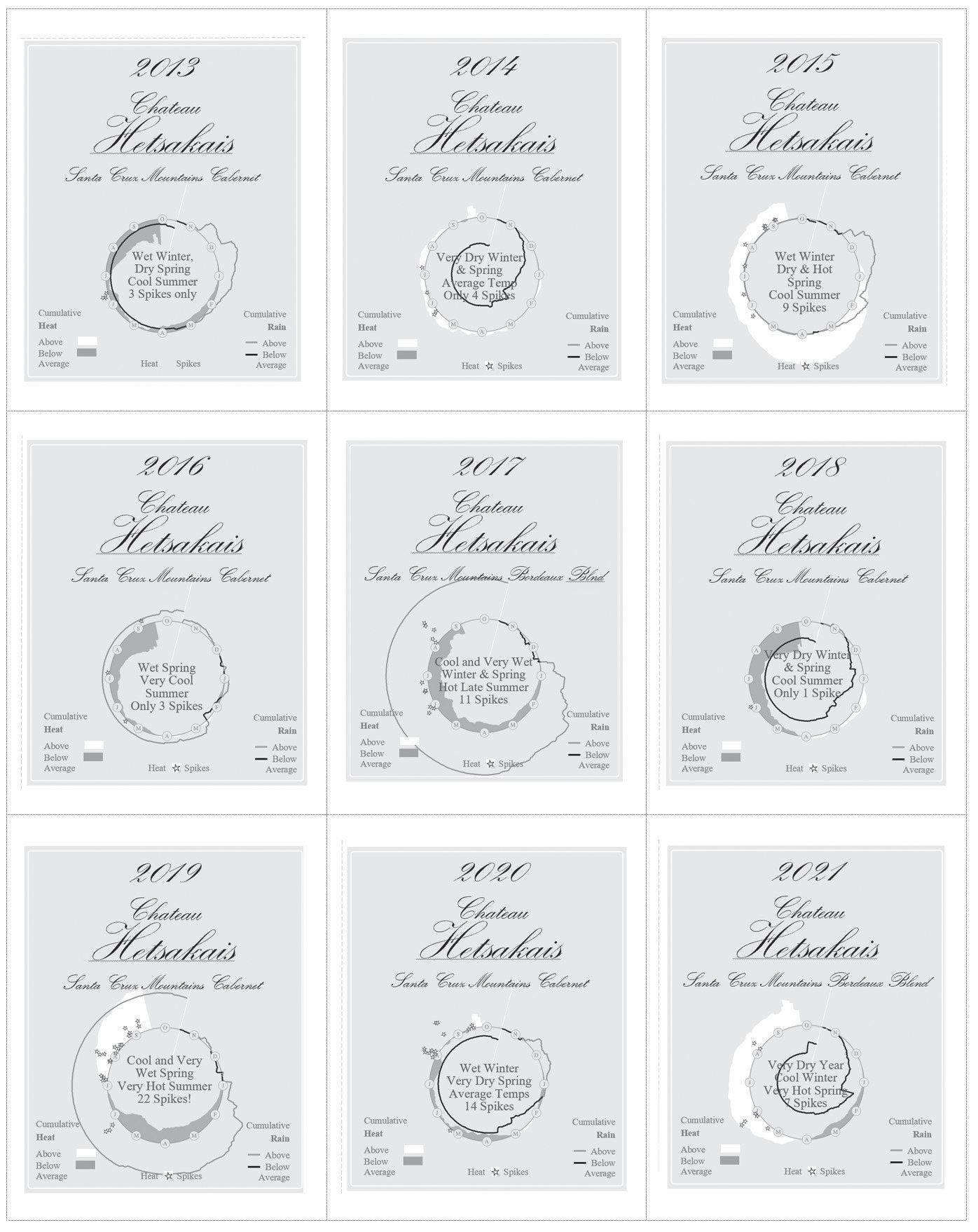

TILL GULDIMANN • CHATEAU HETSAKAIS — SARATOGA, CALIFORNIA

We decided to design and print our labels in-house and affix them to the bottles ourselves, as with all other steps. This required equipment (label printer, software, and labeler).

Equipment Choices: We purchased a special-purpose label printer in 2012 (Zeo! from QuickLabel Systems, www. quicklabel.com) with an associated spooler, label design and printing software, plus rolls of label stock. But the printer was poorly designed, and the software couldn’t be updated to work on Windows operating systems beyond XP. The company introduced a new printer at twice the price. So we ditched the printer and in recent years have switched to an external label-printing service Epic Labeling Solutions in Mountain View, California (www.fernqvist.com/); the material and printing costs for a simple design are around 50 cents per label.

We bought a basic electric labeler (Bottle-Matic II, from Dispensa-Matic, www.dispensamatic.com/) that works very well, is ideal for our requirements, is reliable, and is easy to operate. With it, we can easily label around 150 bottles per hour.

In 2022 we redesigned the front labels for the vintages of 2013 and beyond. The central idea was to add more information about the weather patterns influencing the grapes we grow and wine we produce. We boiled the weather data down to three critical parameters:

• Relative Rainfall: How much rain fell during the vintage year (for the 2015 vintage, this would be from November 2014 through October 2015) and relative to the average for all years on record (2013 through 2021). This measure summarizes the availability of water.

• Relative Sunshine/Temperature: This relays what’s known as the Cumulative Growing Degree Days (CGDD) for the vintage year and how it compared to the average for all the years on

record. This measure summarizes the presence of sunshine.

• Distribution of Heatspikes: When the average hourly maximum temperature during the day exceeded 95 ºF (35 ºC). Heat spikes show when excessive temperatures force the vines to shut down.

Note that what matters most for characterizing how the weather influenced each vintage is the deviation from the average weather. The absolute weather is a characteristic of the location and part of the terroir. The deviation from average is a characteristic of the vintage

in that time and place. All the data was collected from Davis weather stations located in the vineyard.

With the help of Gregory Niemeyer, Professor of Media Innovation at UC-Berkeley (https://www.gregniemeyer. com ), we developed a circular graphic to represent a visual thumbprint of the relative weather conditions for each vintage. To learn more about it or about our labels, weather data, weather monitoring systems, or the rest of our vineyard and winemaking endeavors, check out our website at:

http://chateauhetsakais.com

12 APRIL - MAY 2023 WINEMAKER

STORY BEHIND THE LABEL

BY DAVE GREEN

BEGINNER’S BLOCK KEYS TO MAKING RED WINE W

hen it comes down to it, crafting red wine is basically a class in itself. Making whites, rosés, and most sparkling wines can all be clumped together to one set of rules, but making a good red wine from grapes is a different beast. Yeast selection, handling of grapes and must, fermentation protocols, and oaking are just a few ways that red wines go their own way. Let’s take a brief dive into some ways that a winemaker can assure that they are making the best with what they are provided when it comes to red wine production.

HAPPY YEAST

Great wine starts with happy and healthy yeast. There are several keys to coaxing the most out of your yeast for red wines: Nutrient levels, oxygen in early punchdown cycles, proper yeast selection, and using an appropriate amount of yeast. If you are making wine from a kit most of these have already been done for you. We recommend the use of a commercially produced yeast strain for beginners. Natural fermentations can be finicky.

If you are using juice or fresh grapes, sending a sample of juice away for testing its YAN (yeast assimilable nitrogen) is a great way to assess your starting parameters. If you don’t have a pH meter or a way to measure TA (titratable acidity), there is even more reason to get the sample tested professionally at a lab.

GRAPE SKINS

We can’t talk about red wine production without a discussion on grape skins and all that they provide. This is going to be the source material for color (anthocyanins) and structure (tannins) in red wines. These are gained during fermentation for reds, when the heat of fermentation allows these compounds found in the skins (tannins are also found in stems and seeds)

to transfer into the wine and alcohol helps facilitate this assimilation.

Why is this important? If you are starting with red juice or concentrates, you may want to look to add grape skin packs to the fermentation to help boost these characteristics in the wine, especially if you’re going for a bigger style of red wine. Grape skin packs are available for purchase if additional palate weight is desired.

Also if you are dealing with thinnerskin grapes like Grenache, Gamay, or Pinot Noir, or looking for a big wine, there are tricks more advanced winemakers can utilize to coax a more concentrated level of these compounds from grapes such as an extended maceration or the saignée method. Saignée will produce a small batch of rosé wine and a more concentrated red wine.

On the other side of the coin, fresh grape winemakers may want to shorten the time spent on the grape skins when working with grapes that have excessive levels of these compounds — grapes like Tannat or Nebbiolo. But if it is noticed too late and the finished wine is excessively tannic then winemakers have several fining choices to help strip some from solution. Or, as many Nebbiolo producers in the Old World know, time will also tame tannins as they will slowly polymerize (link together) and fall out of solution.

ACIDITY

The acidity of red wines can act as a counterbalance to residual sweetness or general jamminess that can come from some fruit, especially overly ripe clusters. For beginner winemakers, having the equipment to test for acidity parameters such as pH and TA may be out of reach. But you can still use taste as your guide to determine when a little acid addition may be needed or deacidification in other cases.

It is important to note that wine kits have been carefully tested to

produce a balanced wine. That doesn’t mean that as you progress in the hobby you cannot make these adjustments. But I find it’s just like with a new cooking recipe, it’s best to stick to the supplied ingredients and instructions the first time, then you can possibly adjust for future creations if you feel compelled.

You need to be keenly aware that acidity will change over time with the wine. Alcoholic fermentation, malolactic fermentation, and cold stabilization are potential causes for shifts in TA and pH. Backsweetening the wine is another way to balance the wine when acidity levels are too high.

Bench trials can be utilized for those with the patience. If you do decide to make an acid adjustment, work slowly towards the goal with small incremental additions, tasting as you go to make sure you don’t overshoot it. Tartaric acid is the best choice for acid additions and potassium bicarbonate will often be used to deacidify.

THE GRAPE DILEMMA

In the first section we talked about ways to boost the body of a red wine made from juice or kits with the aid of skins. If you are using fresh grapes, finding good quality grapes is paramount. Try your best to exclude grapes and clusters that you wouldn’t want to eat because of damage or rot. The cleaner your fruit that goes into the wine, the better your chances that a clean wine will be the result.

THE OTHER FACTORS

There are a lot more decisions you will need to make as a winemaker to guide a red wine towards your goal. What kind and how much oak to add (if at all), malolactic decisions, aging considerations, sulfite levels, fining and/ or filtering . . . the list goes on. The best advice is to take it one step at a time and just enjoy the ride.

WINEMAKERMAG.COM APRIL - MAY 2023 13

BY RYLEY HOUGLAND

CO-FERMENTATION

Fermenting different grape varieties together

Winemakers most often ferment each grape variety separately and then create blends after conducting precise blending trials. However, some winemakers believe fermenting varieties together results in more complex wines.

We co-ferment

Zinfandel along with Petite Sirah and Carignane. The Petite Sirah lends some weight, tannin, color, and dark fruit character, while the Carignane contributes bright red fruit character and vibrant acidity. We also do a small amount of Syrah that we co-ferment with Viognier, which is a common practice in France’s northern Rhône region.

We farm a number of estate vineyards that were planted well over a century ago. It was common practice back then for California grape growers to deliberately plant various varieties intermixed in the vineyard. For instance, our Lytton Estate – East vineyard is broken into 18 blocks, and years ago we went through and identified every single vine in the field and were able to assign a percentage of each variety to each block. For example, a block we’ve designated North Flat 1 is planted to 85% Zinfandel, 5% Carignane, 5% Petite Sirah, 3% Mourvèdre, and 2% Alicante Bouschet. Another block designated Hill 3 is 75% Zinfandel, 25% Petite Sirah.

As part of our commitment to traditional, or “pre-industrial” winemaking, we honor the practice of planting a mixed bag of grape varieties by picking whatever is planted out in the vineyard all together. This is known as a “field blend.” When we decide to harvest we’ll pick all the different varieties within the block together and co-ferment them.

There is some kind of alchemy that happens when you co-ferment. A number of years back we harvested one of our vineyard blocks in two ways. We first went through a portion and picked the Zinfandel, Carignane, and Petite Sirah separately. We then went through the rest of the block and picked

everything together like we normally do. We then fermented the three varieties separately and blended them after the fact and compared the results of that wine against the co-fermented wine in a blind tasting. Literally everyone participating in the tasting preferred the co-fermented wine. The most common reason given for the preference was “greater complexity.”

At our Montebello location where we produce our Bordeaux blends we ferment varietals separately. The main reason Bordeaux varietals are better suited to blending post-fermentation is that, particularly in cool-climate regions like the Santa Cruz Mountains, the grapes ripen at different times. Here at Lytton Springs things tend to ripen all at once. There may be an argument that the small amount of Mourvèdre in a block is going to be well behind the Carignane, but their ripening times are not so disparate to have a negative impact on the resulting wine. In fact, a little variation in ripeness within a block may even be part of the alchemy that makes co-fermented wines special.

Just because you’re co-fermenting doesn’t necessarily mean you have to pick all at once; there’s nothing in the rulebook that says you can’t add new grapes to already fermenting grapes. If, for example, you’re making a Zinfandel at home and it’s halfway through fermentation but you’re not getting the color you want, go find some Petite Sirah and toss it in the mix.

I think anyone making red should consider co-fermenting with a little white thrown in the mix. It really works wonders when it comes to aromatics and acidity. And if you’re looking for a bit more structure and color in a home wine, a little Alicante Bouschet goes a long way.

14 APRIL - MAY 2023 WINEMAKER

TIPS FROM THE PROS

I think anyone making red should consider co-fermenting with a little white thrown in the mix. It really works wonders when it comes to aromatics and acidity.

Michael Bairdsmith found his love for winemaking after working in the restaurant industry of California’s Sonoma County after college. He took a cellar intern position at a small Dry Creek Valley winery in 2003 and has since worked his way up, serving as Assistant Winemaker at Ridge Vineyards’ Lytton Springs, California, location since 2014.

R W

ecently we have cofermented Syrah with Mourvèdre, as well as a fruit wine of Sauvignon Blanc with pears. Previously we’ve done Pinot Noir with Chardonnay, Carignane with apple, and Carignane with pear.

The only combination we’ve repeated so far has been 50/50 pear-Sauvignon Blanc. It hits a nice balance of ABV, acidity, and residual sugar, so we’ve decided to stick with it. Whether or not we co-ferment often depends on the vintage and if both varieties are ready to be picked at the same time.

The benefit of co-fermentation is that there’s likely to be greater complexity and a more seamless integration to the finished wines. We’ve never

e typically co-ferment Syrah and Viognier. This is an Old World style of winemaking that we implement at Paraduxx for our Winemaker Series Co-Ferment Napa Valley Red Wine.

Co-fermentation is not usually a standard practice for us other than with this Syrah/Viognier blend, but this past year we co-fermented some Petite Sirah and Zinfandel and had great success. Petite Sirah is a very tannic grape, and Zinfandel can be very juicy and fruit-forward. We were pleasantly surprised how the Zinfandel tamed the big, bold tannins of the Petite Sirah and made the post-fermentation wine smoother and more complex. We enjoyed the result with these grapes so much it may become a standard practice for us going forward.

The determining factor of how much Viognier we used in these co-ferments for many years was our supply of Viognier. We only had a limited supply from our estate ranch, with the majority used for our Proprietary White Wine. Recently, we acquired another vineyard with a small block of Viognier on it, which has allowed us to increase the amount of Viognier we can co-ferment with. The 2019 vintage of the Paraduxx Co-Ferment Red Wine had 7% Viognier,

done an experiment where we do the same grapes co-fermented and blended, it’s just a feeling from experience tasting co-ferments versus blends.

If the harvest dates line up, we’ll always be interested in trying co-fermentation. We have to choose a harvest date that works for both varieties. So, often you have to split the difference and one variety might be slightly over or under your ideal ripeness. Sometimes this gap is too big and the logistics just don’t work out to do a co-fermentation. Don’t force it. If the grapes aren’t ready to be picked at the same time then it’s not likely to work out well.

I’d consider co-fermenting anything that you plan on blending. You have to give up a little control, but the results can be interesting.

with 84% Syrah, and 9% Grenache. When co-fermenting Viognier with Syrah, the Viognier will naturally stabilize the Syrah’s dark purple red color and make it appear almost glossy and bright while softening the larger tannins Syrah can contain. Additionally, it will add aromatic complexity to the wine. Putting a glass of dark red wine to your nose and getting white flower aromas can be perplexing yet alluring at the same time.

We use specific yeasts and fermentation tanks for certain wines. Since our typical co-fermentation is with Syrah and Viognier, we tend to ferment this in an open top, which allows more oxygen into the fermentation. We are using a pneumatic punch-down device that is very gentle in terms of extraction and a yeast strain that accentuates floral notes to increase the aromatics.

All of our other wines are fermented and aged as separate varietal lots and then blended pre-bottling. This allows far more control over the flavors we strive to highlight in the final product. We can always do blend trials and see if we want more Cabernet Sauvignon in our Zinfandel.

Winemaking is exploration. You don’t really know if it is worth it unless you try. Start small. Be curious and adventurous. That is what makes winemaking fun!

WINEMAKERMAG.COM APRIL - MAY 2023 15

Cardiff Scott-Robinson earned his degree in wine-focused business marketing and strategy, working primarily in the business and hospitality side of the industry to start his career. After joining Napa, California’s Paraduxx’s winemaking team in 2009, he has worked his way from cellar worker to Winemaker, where he specializes in making Napa Valley blends.

Jason Phillips has worked in the wine industry since 2008, spending time at premium wineries in Napa, Sonoma, and the Santa Cruz Mountains of California before joining Jumbo Time Wines in Los Angeles in 2022.

BY ALISON CROWE

WINE WIZARD BLENDING GUIDANCE

Smoke taint mitigation

QI’VE HAD THE GREAT LUCK TO BELONG TO A HOME WINEMAKING GROUP IN WASHINGTON STATE WHERE A LOT OF MY FELLOW MEMBERS MAKE MANY DIFFERENT KINDS OF WINE ( I’M JUST STARTING OUT ). WE’VE GOT ACCESS TO VARIETIES LIKE CABERNET SAUVIGNON, CABERNET FRANC, MERLOT, SYRAH, AND EVEN PETITE SIRAH, WHICH ALL GROW PRETTY WELL HERE. IN ORDER TO USE UP SOME OF OUR SMALL LOTS, AND TO MAKE A CREATIVE CHALLENGE FOR OURSELVES, WE’VE DECIDED TO POOL OUR ODD - DUCK KEGS AND CARBOYS TOGETHER AND HAVE A “MAKE THE BEST BLEND” CONTEST. THE WINNING BLEND WILL BE DISTRIBUTED AMONGST THE PARTICIPANTS WITH THE WINNER GETTING BRAGGING RIGHTS AND A SLIGHTLY LARGER NUMBER OF BOTTLES.

WE’RE ALL GOING TO BE GIVEN ABOUT 375 m L s OF EACH POSSIBLE COMPONENT, A 10-m L PIPETTE, AND A 100-m L BLENDING CYLINDER. OUR COMPONENTS ARE ALL OF THE VARIETIES I LIST ABOVE AND THEY’RE DIFFERENT AGES TOO ( LIKE I SAID, IT’S KIND OF THE SCRAPS ) SOME OF THEM HAVE SOME AGED CHARACTER BUT MOST ARE PRETTY FRESH. WE’RE NOT FORCED TO USE ALL OF THEM, BUT I NEED TO CREATE THE BEST BLEND I CAN USING WHAT I’VE GOT. HELP ME, WINE WIZARD, YOU’RE MY ONLY HOPE!

DENISE PACKARD PROSSER, WASHINGTON

AI think that’s a pretty cool idea! How many of us are lucky enough to hang out with such an obviously collaboratively minded group of folks? And, though it may seem daunting, there’s nothing like jumping in and getting started. At the very least you’ll learn something going through the process yourself and I’m sure you’ll learn a lot from your fellow winemaking club team members! Here are some of my top pieces of blending advice:

• Work Small: My first piece of advice is definitely not to do your trial blends in quantities more than 50 mLs! You’ve only got a small amount of wine to work with so you need to keep your samples very small. This means that you’ll have to be working in really tiny volumes. Can you get a 5-mL pipette (or even a 1-mL?), which would mean you can work in smaller quantities and save wine as you

go along? For just one person, for beginning tastes, you really only need 25 mLs.

• Make a spreadsheet: Don’t just randomly toss bits of wine here and there. You’ve only got a little bit of wine so you don’t want to waste it. What I like to do is make a spreadsheet where I list all of the components down the left-hand side and then next to them list the # of mLs/25 mLs (if you can go that small) and then next to that calculate the percentage that each component is in the total blend. Cut and paste that mini-calculator for every iteration of the blend you do and label each one A, B, C and so on. That way you’ll have a track record of what works and what doesn’t.

• Be aware of what every wine brings to the party: Taste and evaluate a small amount of each of your blending components on their own and assess what their strengths and weaknesses are. Are there any holes/are they missing something?

16 APRIL - MAY 2023 WINEMAKER

Taste and evaluate a small amount of each of your blending components on their own and assess what their strengths and weaknesses are.

Photo by Alison Crowe

Blending wines is a skill set that winemakers should learn and the more wines to potentially blend in, the more challenging it can be.

Does the Petite Sirah bring the fruit whereas the Cabernet is the structure hero? What about the Merlot? Don’t be afraid to not use a component if it doesn’t bring anything to the party.

• Think about filling the holes: Start mixing and matching to make a “complete” wine without any holes, i.e., pair that fruit-bomb Petite Sirah with some Cab for structure, then some Merlot for body . . . and a little something else if it’s really oaky . . . you get the idea. See if you can line up the positive attributes to make a satisfying whole wine without letting anyone’s possible negative sides stick out. Work iteratively — that is, add a little bit of something to see if it makes your blend better. If it doesn’t, use less, or don’t use any at all.

• Think about finishing tannins and other products: Most of the big commercial wine-supply companies are selling these new and innovative liquid and powdered finishing tannin products. They can be used in the last month or two before bottling and can really improve a wine’s oakiness, finish, or mouthfeel. I think every home winemaker should have a small

selection of these dropper bottles and powders to trial — they can make all the difference in filling in holes if you happen to find one in a blend.

• Never blend a loser: My long-term readers know that this is one of my mantras. Never force that square peg into a round hole or give that high-VA (volatile acidity) Zinfandel a home in a final blend just because you feel bad for it. Since this is a contest, if there’s something you don’t like, don’t feel like you have to use it. Do be aware, however, that in blends sometimes tiny amounts of “flaws” really do help an overall blend. VA is one of these things; sometimes a small amount of a high-VA lot can really elevate the fruit. Just be sure to filter the final blend in the cellar because you don’t want to spread around that bacteria that’s causing the high-VA issues.

I hope this helps and I hope you have enough wine to play around with! Also, I hope you have fun experimenting; learning is what blending is all about and once you start doing it I’m sure your confidence will improve for each subsequent blend.

QI LIVE IN SONOMA COUNTY, CALIFORNIA, AND WE’VE HAD SOME PRETTY BIG WILDFIRES DURING A FEW OF THE LAST HARVEST SEASONS. WHAT’S THE CURRENT THINKING ON HOW WE MAKE WINE IF THERE’S A POSSIBILITY THE VINEYARDS WHERE WE’RE GETTING OUR GRAPES ARE AFFECTED BY SMOKE? I’VE HEARD PLENTY OF MENTIONS OF SMOKE TAINT BUT STILL DON’T KNOW THE DETAILS. I WOULD APPRECIATE YOUR OVERVIEW.

AIndeed, the last few years (2017 and 2020 especially) grape growing areas in Northern California and other parts of the state including the Central Coast have experienced historically large wildfires. If grapes are exposed to smoke, winemakers should be alert to the possibility of smoke taint damage to grapes and to finished wines during and after these events. You’re right — it’s an important topic for almost all of us, most particularly winemakers in Mediterranean climates where falls are warm and dry, to have a handle on the current information.

Volatile phenols (which I’ll abbreviate as VPs) are released when wood burns during wildfires. VPs exist in both free and bound forms in grapes, juice, and wine and can cause a smoke taint defect in the aroma and taste of finished wines. These sensory defects have been described as “campfire,” “medicinal,” “earthy,” or “smoky,” among other terms. While some of these descriptors are common in red wines, especially those aged with toasted oak, smoke taint is especially characterized by an ash tray sensation at the back of the throat, on the finish of the wine, and is observed retro-nasally. Please note: Smoke taint in wine is not a danger to human health and many “smoke taint markers” that can be measured are naturally-present in wines aged with toasted oak.

There is no cure for smoke taint, in the vineyard or cellar. Growers and winemakers can do their best to use the limited means of mitigation available (see more in the following paragraphs) . . . and it’s still a very evolving topic! If your vineyard is in a fire zone and/or exposed to smoke, you should assume you

are at risk for smoke taint, so harvest and make wine accordingly. At the same time, there are anecdotal tales of vineyards being very close to fire zones yet still yielding perfectly normal and acceptable wines. It is extremely difficult to predict a finished wine’s final sensory and chemical analysis.

Some wine labs have “smoke taint panels” where they measure VPs like guaiacol and 4-methyl guaiacol. That’s all well and good but in my personal experience, and in the anecdotal experience of many of my winemaking friends, the numbers are truly meaningless as predictors of final wine quality and intensity of possible smoke taint.

Smoke Taint in Processing and Winemaking —

Some Basic Information:

• Skin contact time: Free and bound VPs are hydrophilic and extract very quickly into musts — within a day, estimated 30%, within 5 days, over 80%. Current guidance for red winemaking is not to press off early, and shorten skin contact time, etc. Unless you can make rosé (which is not always economically possible), try to make the best red wine you can. Optimizing positive traits in a wine can help cover up volatile phenols. Whites and rosés benefit from being separated from the skins as soon as possible.

• Picking early/unripe fruit: Picking early (especially if pyrazines are present — Cab, Merlot, etc.) doesn’t help as studies are showing that pyrazines (present in unripe grapes) actually make it worse and pyrazines (bell pepper aromas) are equally a red wine defect that people are sensitive to. Pyrazines are difficult to remove as well. Now you have two wine defects,

WINEMAKERMAG.COM APRIL - MAY 2023 17

FRANCISCO GUERRA ROHNERT PARK, CALIFORNIA

WINE WIZARD

not just one.

• Aging: Studies are ongoing but some scholars believe that at one year of age the vast majority of VPs in wine will be stable, i.e., the problem will not get worse at this time.

Mitigation in the Vineyard — Can anything help?

• Minimize MOG (material other than grapes): Do everything possible to exclude MOG (leaves, stems, etc.) as smoke taint compounds are also metabolized into leaves, petioles, and stems.

• Avoid picking avenue rows and row-end fruit: In 2017, side-by-side experiments I did in one of my vineyards in Sonoma showed that not picking avenue rows (exterior facing rows) or row-end fruit helped reduce the amount of smoke taint in the final wine by a significant amount. It did not 100% prevent it of course but reduced it by about 20%. This is possibly because the avenues and row-ends carried higher levels of vineyard dust and ash kicked up by passing vehicles. This happened in the 2017 event, on the Napa Valley floor, when fire was quite close to the vineyards and it’s possible this ash was quite fresh, which is why there was a significant difference.

• Minimize time between field and press: For whites and rosés especially, VPs increase with skin contact.

Mitigation in the Cellar — Reducing perception

• Press more gently: It is clear that the maximum VPs are released into the juice (whites/rosés) and musts (reds) at greater pressure. Try to press more gently, separating out free run from press fractions, keeping pressing to a minimum. For reds, separate everything over 0.8 bar and treat press fractions separately. For whites, maximize free run and minimize rotations and length of press cycle. Wineries will have to balance acceptance of lower yields vs. higher smoke taint risk. However, don’t be afraid of maceration in reds — you’re still going to have more success by getting full extraction and “masking” by having lots of good stuff in your wine as well as potentially a little bit of bad stuff.

• 100% de-stem all reds: Destemming all red fermentations is recommended. No studies have been done regarding VPs in grape stems, but if they can be present in leaves and petioles it seems likely that VPs will be present in stems. Green stem character (pyrazines) can make smoke taint appear worse, so it seems helpful to exclude them.

• Blending: Blending smoke-tainted wine with non-tainted wine can work to reduce smoke taint character, but only if you have enough non-tainted wine to blend levels down. But be cautious — why ruin 100 gallons of smoke taint-free wine with 10 gallons of tainted wine? Do bench trials and test for free and bound VPs. Do short-term aging in bottles or bench scale if possible.

• Masking — maximize fruitiness: Using residual sugar (RS) in final blends can help. Anything that points up fruitiness, like blending with fruity wines like Zinfandel and Petite Sirah for reds or Riesling and Gewürztraminer for whites, can help lessen the sensation of smoke/ash characters. This will only work in wines with a low level of smoke taint.

• Masking — oak and tannin products: Sometimes fruity oak or tannins can mask low levels of smoke taint. Do bench

trials — Oak products will never contribute to bound VPs, only free. The only time a VP can become “bound” is during the berry ripening process.

• Partial removal — activated charcoal: Activated charcoal products (available from industry-supplying companies like AEB, Laffort, and Scott Labs) can help remove lower levels of smoke taint aromas. But be aware, additions larger than 1 g/L really start to strip good things from the juice/wine as well. Again, you need to do bench trials.

Does it work? Maybe . . .

• Washing grapes: Unless there is visible ash under 24 hours old (which can release volatile phenols), washing grapes will likely not help, as most of the VPs will already have been absorbed into the grapes.

• Washing grapes with ozonated water: There are ongoing studies being done, but the anecdotal evidence so far points to it not helping. It’s also very expensive and might impact the fruit in negative manners.

What has been shown not to work?:

-Adding bentonite

-Settling out white wines to low % solids

-Adjusting fermentation temperature

-Brix/potential alcohol differences

-Enzyme treatments on juice

-Picking green/early (then you have bad/green wine on top of possible smoke taint!)

-Pressing off early for reds (in other words, make the best wine you can)

-Treating heavily smoke-damaged wine. Carbon treatments, blending, masking, etc. are all worthless against heavily smoke-damaged lots, i.e., lots that are already exhibiting bad and off aromas early.

Bottom line: If a vineyard is exposed to smoke, it is possible there will be some smoke taint risk in the finished wines made from those grapes. On the other hand, just because a vineyard experiences a smoke event, it does not mean the wines made from those grapes will all exhibit detectable or even objectionable levels of smoke taint. Decisions must be made in real time as much as possible and on a case-by-case basis. I’ve largely found that taking berry and cluster samples to a wine lab for volatile phenol analysis to be largely futile. The “numbers” didn’t seem to correlate between guaiacol levels and the final amount of olfactory smoke taint in the final wine.

As there is no cure for smoke taint, vineyard and winemaking teams alike must assess the situation as best they can and then work together on strategy and mitigation to produce the best wines possible.

I’ve been pretty lucky. In 2017 and 2020 both, I picked some Cabernet that were under very smoky conditions and, by following the advice I’ve provided, made some really great wines. The deodorizing carbon treatments, in particular, seemed to work well. It’s very important, as always, to do bench trials so you’re not adding too much and stripping the wine. I’m glad I picked those grapes as opposed to leaving them on the vine. There were a lot of winemakers in Napa and Sonoma that should’ve picked grapes in those years but didn’t.

18 APRIL - MAY 2023 WINEMAKER

VARIETAL FOCUS

BY CHIK BRENNEMAN

BY CHIK BRENNEMAN

AGLIANICO A tannic and rich Italian variety

As I ponder the variety for this issue, I reflect back on over 20 years of winemaking experience and how my mentors Ben Zeitman and Katie Quinn of Amador Foothill Winery in the Shenandoah Valley of California influenced me. Ben and Katie always told me that, “If we were not going to make good wine, then why bother?”

They were also aficionados of Italian wines and always strived to do justice to their varieties grown here in California. They brought in some of the best consultants from Italy to look at their site and advise on what varieties would do well. Sangiovese was a no-brainer; easily recognized in the marketplace, but challenging to grow in California without overcropping. The consulting group helped a lot with that.

But there was another variety they recommended as we contemplated pulling out an older portion of the Sauvignon Blanc vineyard. Ben and Katie were just coming off a trip to Italy and reflecting on their notes and some bottles of wines they brought back. During their reflection, they decided they were going to plant Aglianico. My response was, “What’s that?”

It was early in my career; I did not have a lot of “varietal knowledge” and in their explanation of its characteristics, I was grasping for a comparison that I could relate to. Ben, of course, started extolling on the wonderful qualities of Aglianico —where it was from, its firm and balanced wines, and its general richness.

But something I couldn’t grasp was what do we make that I can relate to? Ben’s response was, “think Syrah, but only a Syrah that the Italians can make.” As bizarre a response as that

was I got my moment of comparison, and now all the pieces of the puzzle were starting to come together . . . without a single plant in the ground. And typical of my curiosity curve, I started to seek out Aglianico wines in local bottle shops.

BACKGROUND

Aglianico thrives in southern Italy, where it is described as the most widespread black variety in the provinces of Avellino and Benevento in the Campania. It also grows very well in the cool but dry sunny mountain conditions of Potenza and Matera in Basilicata. These areas have soils of volcanic origins that result in dark and concentrated wines that are quite age-worthy.

It was once thought that Aglianico was introduced to Italy from Greece, but the DNA folks have shown it is not related to any modern Greek variety. It is closely related to many varieties cultivated in Campania and Basilicata, in particular to Aglianicone. Scientific evidence suggests it could be one of its parents, although nicknamed Aglianico Bastardo as it is known to be inferior to its parent in wine production. Given the current level of information, Aglianico is likely one of the most ancient varieties of grapes grown in Italy.

So what to do with a grape with such a storied past? The real challenge, at least in my winemaking experience with this particular variety, is that you really need to focus on tannin management. Some varieties are just plain loaded with tannins and others are not. As a winemaker, you are tasked with trying to find the right balance. Those with lower tannin levels, you seek to express them, and others, like Aglianico, and for the pur-

WINEMAKERMAG.COM APRIL - MAY 2023 19

Given the current level of information, Aglianico is likely one of the most ancient varieties of grapes grown in Italy.

Photo courtesy of Shutterstock.com

AGLIANICO Yield 5 gallons (19 L)

INGREDIENTS

125 lbs. (57 kg) fresh Aglianico fruit

Distilled water

10% potassium metabisulfite (KMBS) solution (Weigh 10 grams of KMBS, dissolve into about 50 mL of distilled water. When completely dissolved, make up to 100 mL total with distilled water.)

5 g Lallemand Syrah yeast

5 g Diammonium phosphate (DAP)

5 g Go-Ferm

5 g Fermaid K (or equivalent yeast nutrient)

Malolactic fermentation starter culture (CHR Hansen or Equivalent)

EQUIPMENT

15-gallon (57-L) food-grade plastic bucket for fermentation

5-gallon (19-L) carboy

(1–2) one-gallon (3.8-L) jugs

Racking hoses

Destemmer/crusher

Wine press

Inert gas (nitrogen, argon, or carbon dioxide)

Ability to maintain a fermentation temperature of 81–86 °F (27–30 °C)

Thermometer capable of measuring between 40–110 °F (4–43 °C) in one degree increments

Pipettes with the ability to add in increments of 1 mL

Tartaric acid – addition rate is based on acid testing results

STEP BY STEP

1. Clean and sanitize all your winemaking tools, supplies, and equipment.

2. Crush and de-stem the grapes. Transfer the must to your fermenter. During the transfer, add 15 mL of 10% KMBS solution (This addition is the equivalent of 50 ppm SO2). Mix well.

3. Take a sample to test for Brix, acidity, and pH. Keep the results handy.

4. Layer the headspace with inert gas and keep covered. Keep in a cool place overnight.

5. The next day sprinkle the Fermaid K directly to the must and mix well.

6. Go back to those lab results you took yesterday. Typical Brix for this style is 24–25 °Brix. Typical pre-fermentation acid levels will be 5–7 g/L. Adjust as necessary using tartaric acid to pre-fermentation level of 7.5–8.0

g/L. Don’t worry here; the malolactic conversion will drop the acid levels.

7. Prepare yeast: Heat about 50 mL distilled water to 108 °F (42 °C). Mix the Go-Ferm into the water to make a suspension. Take the temperature. Pitch the yeast when the suspension is 104 °F (40 °C). Sprinkle the yeast on the surface and gently mix so that no clumps exist. Let sit for 15 minutes undisturbed. Measure the temperature of the yeast suspension. Measure the temperature of the must. You do not want to add the yeast to your cool juice if the temperature of the yeast and the must temperature difference exceeds 15 °F (8 °C). To avoid temperature shock, you should acclimate your yeast by taking about 10 mL of the must juice and adding it to the yeast suspension. Wait 15 minutes and measure the temperature again. Do this until you are within the specified temperature range. Do not let the yeast sit in the original water suspension for longer than 20 minutes. When the yeast is ready, add it to the fermenter and mix.

8. You should see signs of fermentation within about one to two days. This will appear as some foaming on the must surface and it will appear that the berries are rising out of the medium. This is referred to as the “cap rise.” You need have on hand the ability to push the grapes back into the juice to promote color, and tannin extraction. This is called “punching down” and this should be done three times per day. Use a clean and sanitized utensil or your hand to mix.

9. Monitor Brix and temperature twice daily during peak fermentation (10–21 °Brix). Morning and evening is best and fermentation temperature maintained between 81–86 °F (27–30 °C).

10. At about 19 °Brix, sprinkle in the DAP and punchdown.

11. When the Brix reaches 0 (about 5–7 days), transfer the must to your press and press the cake dry. Keep the free run wine separate from the press portion for now.

12. Transfer the wine to your carboys or one-gallon (4-L) jugs. Your press fraction may only be a gallon or two (4–8 L). Make sure you do not have

any headspace. Place an airlock on the vessel(s).

13. Inoculate with your malolactic (ML) bacteria. Check the manufacturer’s instruction on how to prepare and inoculate.

14. Monitor the ML fermentation using a paper chromatography assay available from most home winemaking supply stores. Follow the instructions included in the kit.

15. When the ML is complete, measure the residual sugar through tasting or by sending a sample to the lab.

16. Add 2 mL of fresh KMBS (10%) solution per gallon (3.8 L) of wine. This is the equivalent to ~40 ppm addition.

17. Measure the pH and titratable acidity. Most importantly you want a finished TA of about 6.5 g/L. The pH is secondary but should be around 3.7. Consider adding acid to adjust the TA prior to settling, but taste the wine first to make sure it is not too tart. Do not add any more acid if the wine is too tart. Place the wine in a cool place to settle.

18. After two weeks, test for SO2, adjust the SO2 as necessary to attain 0.5 ppm molecular SO2. (There is a simple SO2 calculator at winemakermag.com/ sulfitecalculator). Check the SO2 in another two weeks and adjust. Once the free SO2 is adjusted, maintain at this level. You’ll just need to check every two months or so and before racking.

19. Rack the wine clean twice over 6-8 months to clarify. Consider using some oak chips to add some oak flavors, but don’t expose the wine too long to the oak. 1–2 weeks is sufficient for this volume. Fining and/ or filtration are generally not needed if SO2 is maintained and there are no surface films or indications of subsequent fermentations.

20. Once the wine is cleared, it is time to move it to the bottle, roughly eight months after fermentation completion.

21. Make the project fun by having a blending party to integrate the press fraction back into the free run. You may not need it all, use your judgment.

22. Maintain sanitary conditions while bottling. Once bottled, you’ll need to periodically check your work by opening a bottle to enjoy with friends. Have fun!

20 APRIL - MAY 2023 WINEMAKER

pose of comparison Syrah, are higher and your job is that of the tannin tamer.

VITICULTURAL TIPS

As mentioned, Aglianico is a historically Italian red grape variety. You can find plantings in several warmer, sunnier microclimates in California. As a varietal, it can be described as a high-quality, age-worthy wine that can be tannic. In the vineyard, it is early budding and very late ripening, sometimes as late as November.

Yields need to be controlled to prevent overcropping. It has good resistance to powdery mildew but given its long growing season, is quite susceptible to Botrytis bunch rot. But the reality of it is, the long growing seasons are necessary to adequately ripen the rich tannins.

In the vineyard is the first time a winemaker can help tame the excessive tannin load that can come with these grapes. Tannins take time to mature. Indirect exposure to sunlight and adequate time spent on the vine through the growing season can go a long way. But sometimes nature plays with the winemaker and taming these grapes can’t all happen in the vineyard.

AGLIANICO IN THE WINERY

As the fruit comes into the cellar, your next opportunity as tannin tamer is at the destemmer/crusher. As a home winemaker, sometimes you do not have good options here, but in general, physical removal of the berries from the stems is recommended to not damage the stems and possibly extract green tannins.

Crushers without destemmers are generally the more affordable versions of this piece of equipment, but spending a little more for one that will destem and have the ability to adjust the crushing rollers will pay off in the long run. I like to set my rollers as wide as possible. That setting allows the crusher to damage the bigger berries somewhat while the small berries drop right through. When pressed, these smaller berries express themselves as “alcoholic fruit-bombs” that add a different dimension to the wine (think carbonic maceration). I like to pick through the pomace when pressing and find these. I affectionately call these berries “adult candy.”

The maceration process is another approach to tannin

management with Aglianico. If a little is good, then a lot is better some folks would say. Not the case here. A standard practice I like to use with all of my red wine fermentations is once I get the color I want, I move the wine to press. Very rarely do I take a wine past seven days on the skins. I move the wine to the press, collect the free run juice and then press the remainder, keeping that separate, at least for now. My philosophy is to keep the free run and press fraction separate. You can always add them back together, but I do not want to be tasked with removing tannin through fining if I do not need to.

The other option available to the home winemaker is barrel aging, which promotes micro-oxygenation, or MOX as it is collectively known in the winemaking world. Regular topping of the barrels to replace the evaporative losses introduce small amounts of oxygen into the wine that aid in polymerizing the shorter tannins, thus softening the wine.

This is hard to do, especially with small-batch winemaking, so if you are working with a quantity less than a barrel focusing on a kinder, gentler fruit processing and limited maceration time goes a long way to keeping your tannins tamed. If you do have the ability to barrel age your Aglianico wines, taste them over time and be patient. They will come around. Small-batch winemaking could also benefit from some limited racking from carboy to carboy and the use of oak chips that impart a bit of sweetness.

Circling back to my days with Ben and Katie . . . after I moved on to another job, Ben called me one day and asked if I would come up and oversee the planting of the new vineyard. It was a wonderful experience that I thought helped me bring to full circle those early discussions and steep learning curve. In the end, I never had the opportunity to make the Aglianico that Ben and Katie planted.

As I moved on to the university, we had some test blocks where it was grown and we brought the fruit in to see how it would do in the UC-Davis climate. I think our biggest challenge was the tannins. The advice I give here is based on experience. In the end, I never made the perfect batch, but that is what I love about winemaking. There is always next time, as long as in the meantime you have something to ponder and enjoy in your glass. Life, like wine, generally gets better with age.

WINEMAKERMAG.COM APRIL - MAY 2023 21

Photo courtesy of Shutterstock.com

Mount Vesuvius provides a dramatic backdrop to the vineyards found among the ancient ruins of Pompeii in the region of Campania in Italy.

22 APRIL - MAY 2023 WINEMAKER DON’T WAIT! Our conferences sell out EARLY Home Winemaking Seminars Hands-On Workshops Special Wine Events Winery Tours June 1-4, 2023 Eugene, Oregon Join fellow hobby winemakers from across North America in the world-famous Willamette Valley wine country for full days packed with dozens of seminars, workshops, and special events to help you make your own great wine. WineMakerConference.com Save for a Limited Time

DON’T MISS OUT ON:

• 24 Big Seminars

• Group Interactive Workshops

• Tasting Party

• 8 Hands-On Winemaking Boot Camps

WINEMAKER LEARNING TRACKS

ADVANCED WINEMAKING

• Advanced Malolactic Techniques

• Maximizing Cold Soaks

• Willamette Valley Pinot Panel

• Post-Modern Tools to Build Wine Structure

• Crafting Age-Worthy Wines

• Making Brandy

GRAPE GROWING

• Canopy Management

• 5 Biggest Grape Growing Mistakes

• Backyard Grape Growing Q & A

HIGHLIGHTS

• Willamette Valley Winery Tours

• WineMaker Competition Awards Dinner

• Sponsor Exhibits

GENERAL WINEMAKING

KIT WINEMAKING

• Keys to Wine Clarity

• Troubleshooting Q & A

• Award-Winning Country Fruit Winemaker Panel

• Crafting Italian Reds

• Calibrating Wine Equipment

• Basics of Wine Analysis & Testing

• Making Limoncello & Other Citrus Liqueur

GROUP INTERACTIVE WORKSHOPS

• Advanced Kit Techniques

• Award-Winning Kit Winemaking Roundtable

WINEMAKER BOOT CAMPS

• Side-by-Side Oak Trials

• Winemaking Table Topics

• Winemaking Hot Subjects

• Willamette Valley Winemaking

MEET WITH WINEMAKING SUPPLIERS

• Advanced Winemaking from Grapes

• 2-Day Fundamentals of Modern Wine Chemistry

• Winemaking from Grapes

• Distilling

• Small Winery Start-Up

• Home Wine Lab Tests

• Backyard Grape Growing

• Judging & Scoring Wines

• Willamette Valley Winery Tours

As an attendee, you’ll have the opportunity to check out the latest equipment, products & supplies from many of these leading winemaking vendors Friday & Saturday.

TITLE SPONSORS

SUPPORTING SPONSORS

RJS Craft Winemaking Winexpert

And more sponsors to come!

WINEMAKERMAG.COM APRIL - MAY 2023 23

SMALL-CLASS WINEMAKER BOOT CAMPS

2 BIG DAYS & NEW CAMPS!

THURSDAY, JUNE 1 • 10 AM – 4:30 PM

Maximize your learning by taking two different Boot Camps. Full-day, small-class Boot Camps will run pre-conference on Thursday and post-conference on Sunday from 10 AM to 4:30 PM and include lunch. Attendance is limited to just 35 people per session and do sell out. This add-on Boot Camp beyond the conference registration is a great opportunity to get an in-depth learning experience in a small-class setting and learn hands-on from experts.

ADVANCED WINEMAKING FROM GRAPES

Go beyond the basics and understand complex techniques to get the most from your winemaking using fresh grapes. This workshop intended for intermediate and expert home winemakers will tackle a range of tips: From dialing in extraction levels on the front end all the way to protecting your wine with advanced tips through bottling.

DISTILLING

Walk through the small-scale distilling process. You’ll leave understanding the various types of small still equipment, as well as the small-scale distillation process for brandy, whiskey, rum, and gin. Get your questions answered throughout the full day as you learn the art of distillation using a small still.

WINEMAKING FROM GRAPES

Learn all the steps of making wines from grapes including crushing and fermenting all the way to bottling. You’ll work with fresh grapes and operate the different pieces of equipment and the tests you’ll have to run on your wine.

BACKYARD GRAPE GROWING

You’ll learn site selection, vine choice, planting, trellising, pruning, watering, pest control, harvest decisions plus more strategies to successfully grow your own great wine grapes.

HOME WINE LAB TESTS

Step-by-step teaching on how to properly test your wine for sulfites, malolactic, acidity, and pH. You’ll have the chance to run these different tests yourself to give you a valuable hands-on learning experience so you can accurately run these tests on your own wine at home.

WILLAMETTE VALLEY WINERIES INSIDER TOUR

Tour several wineries as you explore the world-famous Willamette Valley and have plenty of opportunities to ask their professional winemakers your winemaking and grape growing questions. You’ll be served lunch along the way and have tastings of award-winning wines.

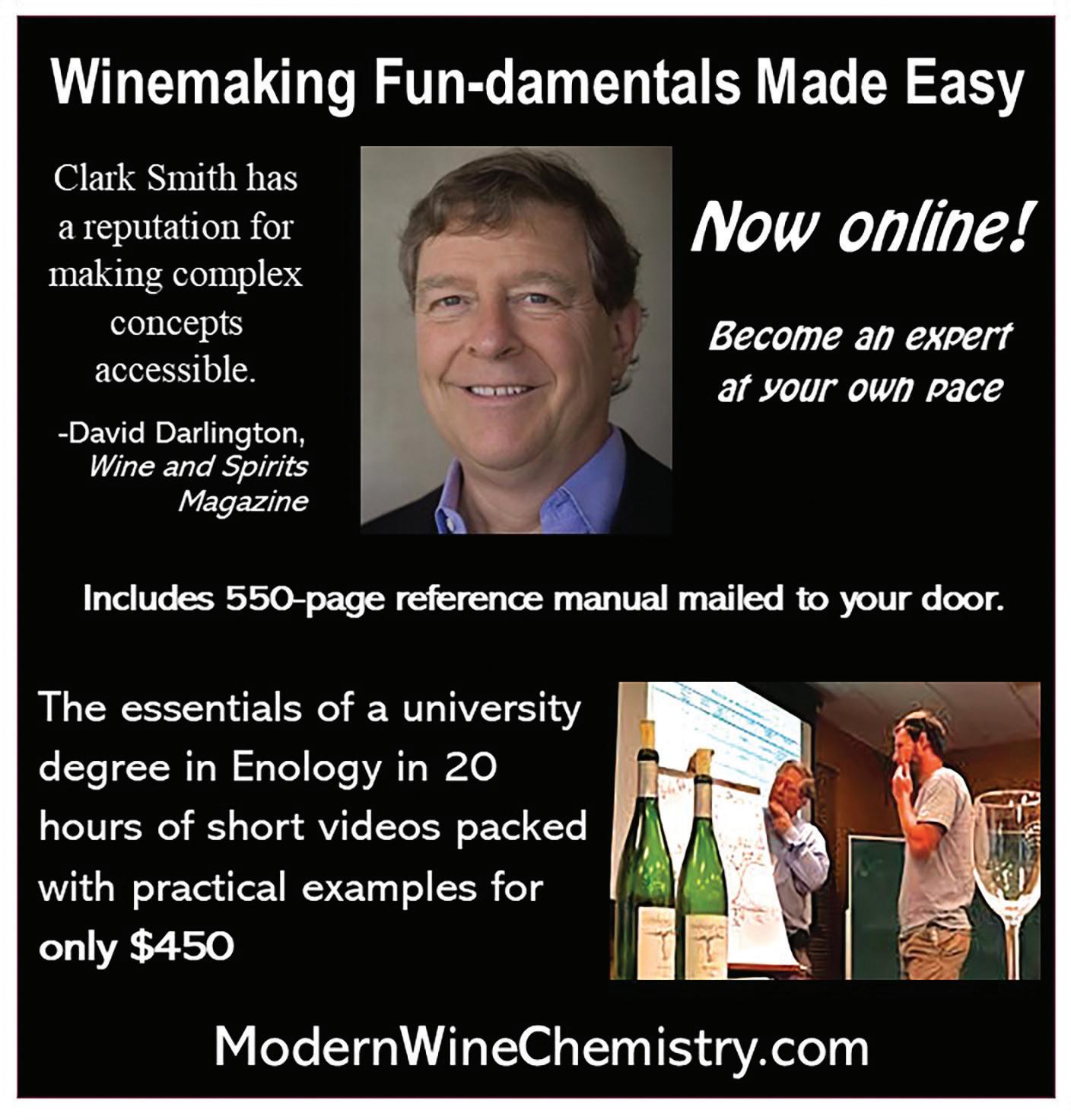

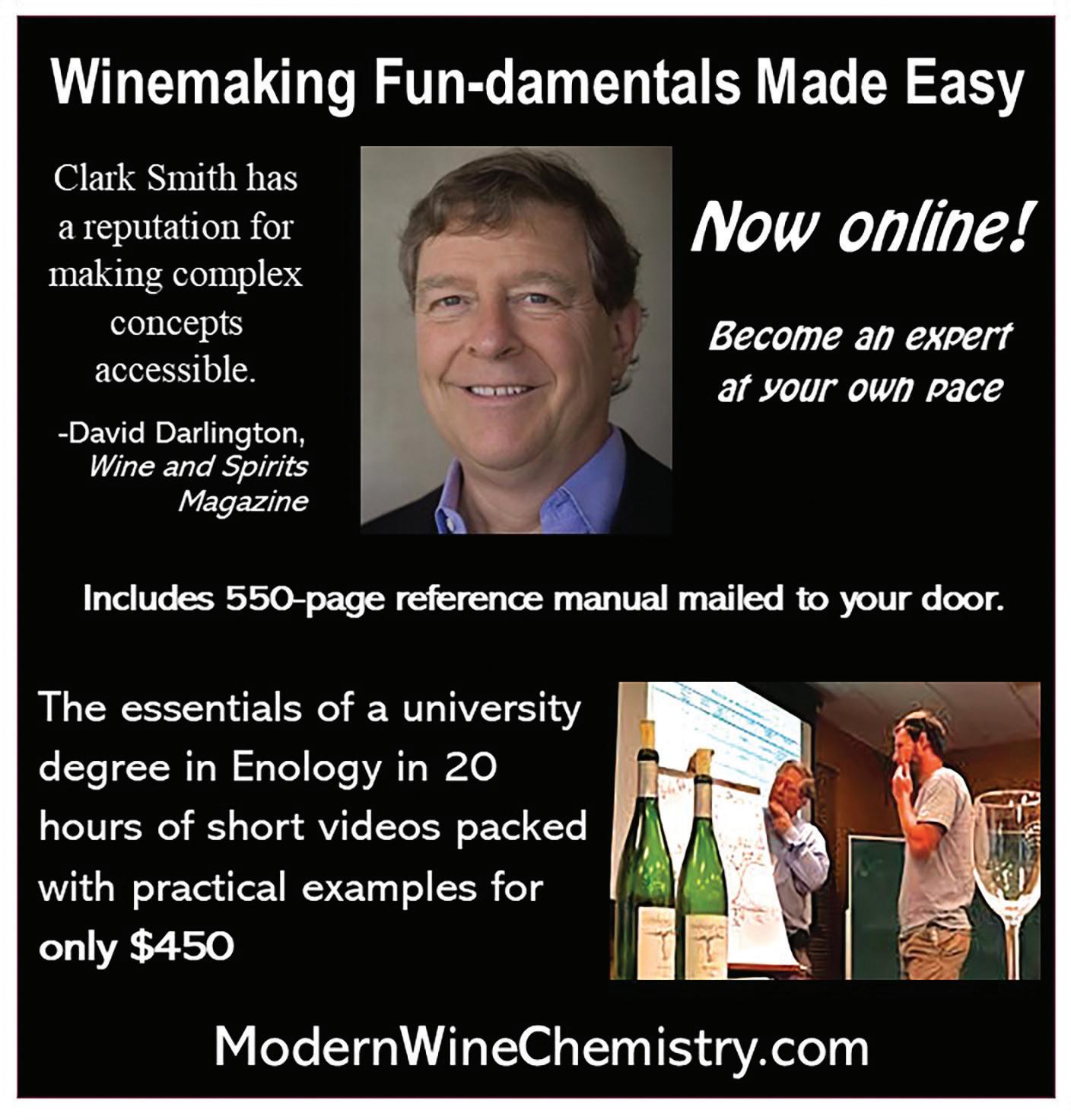

2-DAY FUNDAMENTALS OF MODERN WINE CHEMISTRY

Learn on Thursday and Sunday from wine expert Clark Smith how to use wine chemistry as a practical tool to improve your winemaking. You’ll cover wine chemistry from crush to bottling and how it can inform better decisions resulting in better wine. *This 2-day boot camp includes a 550-page manual that will be a valuable wine reference for this 2-day workshop and for years to come.

JUDGING & SCORING WINES

Learn how to evaluate your own and other wines in the same way as a trained wine judge so you can use these skills to help your own winemaking. Gain a sensory appreciation for various common faults and how to properly use the 20-point UC-Davis judging sheet as a foundation for evaluating wines.

SMALL WINERY START-UP

Walk through the steps, planning decisions, and key financial numbers you need to know if you want to open a smaller-scale commercial winery. Learn how to better achieve your dream of running your own small winery.

WILLAMETTE VALLEY WINERIES INSIDER TOUR

Tour several wineries as you explore the world-famous Willamette Valley and have plenty of opportunities to ask their professional winemakers your winemaking and grape growing questions. You’ll be served lunch along the way and have tastings of award-winning wines.

SAVE WHEN YOU REGISTER NOW: winemakerconference.com

THURSDAY, JUNE 1 • 10 AM –4:30 PM SUNDAY, JUNE 4 • 10 AM –4:30 PM

SCHEDULE AT-A-GLANCE

Pre-Conference WineMaker Boot Camps & Winery Tours • Thursday, June 1, 2023

Fundamentals of Modern Wine Chemistry – Day 1 of 2

10 AM – 4:30 PM

Winemaking from Grapes

Day #1 Friday • June 2, 2023

8 – 9 AM

9 – 9:15 AM

9:30 – 10:45 AM

10:45 – 11:15 AM

11:15 AM – 12: 30 PM

12:30 – 1:45 PM

–

PM

Calibrating Wine Equipment

Advanced Winemaking from Grapes

Backyard Grape Growing

Distilling

Home Wine Lab Tests

Willamette Valley Wineries Tour

Breakfast & Registration

Welcome & Introduction

Canopy Management Keys to Wine Clarity

WineMaker Exhibits

Making Brandy

Advanced MLF Techniques

Award-Winning Kit Winemaker Panel

Lunch & Keynote: Southern Willamette Valley Winemaking with King Estate

WineMaker Exhibits

–

Basics of Wine Analysis & Tests

Willamette Valley Pinot Panel

WineMaker Exhibits

WineMaker Workshop: Side-By-Side Oak Trials

WineMaker Tasting & Wine Sharing Party

DAY #2 Saturday • June 3, 2023

8:30 – 9:30 AM

9:30 – 10:45 AM

10:45 – 11:15 AM

11:15 AM – 12:15 PM

12:15 – 1:45

WineMaker Exhibits

5 Biggest Grape Growing Mistakes

WineMaker Exhibits

WineMaker Exhibits

WineMaker Workshop: Winemaking Table Topic Talks

International Amateur Wine Competition Awards Dinner

1:45

2:15

2:15

3:30

3:30

4

4

5

PM

–

PM

–

PM 6:30 – 10 PM

PM Lunch

& Keynote Address: WineMaker Columnists Live – Winemaking Hot Subjects

WineMaker

Maximizing Cold

Grape Growing Q&A Making

1:45 – 2:15 PM 3:30 – 4 PM 2:15 – 3:30 PM 4 – 5 PM 7 – 10 PM

Crafting Age-Worthy Wines Making

Advanced

Troubleshooting Q&A

2023

Soaking

Italian Reds