3 minute read

Driving innovation in Saskatchewan potash

saskatchewan’s potash industry has for many decades been a stable and important element in our region’s economy. since 1965, bit service has been a strong supporter of this growth, as a locally owned and operated organization providing key elements to each operating mine’s underground needs.

from humble beginnings, bit service provided service and boring machine bit sharpening, expanding capabilities shortly after with bit manufacturing, repair and cutting assembly fabrication services. Not long after, the high-quality products of long-established mining manufacturers Cincinnati Mine Machinery Co. and the bowdil Company were brought onboard, aiding bit service to grow alongside the needs of the industry.

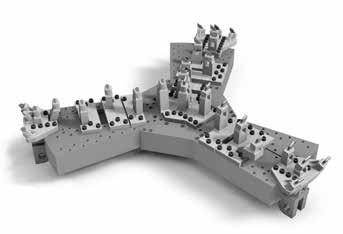

Cincinnati Conveyor Chain. Bowdil Trim Chain. the experienced and knowledgeable personnel at bit service work with mine staff and management to help eliminate problems they face with mine consumables and to maximize production. from the design stage, aided with 3-D modelling software, through production and warehousing they continually fulfill customer needs. Constantly striving to innovate and improve on the products they service and provide, bit service has seen 55 years of strong partnerships in saskatchewan potash. the two- and four-rotor boring machines have long been the primary mining machines in the conventional saskatchewan potash mining market. Instrumental in the cutting and production of the ore are the radial bits on the front of the machine and bit service saw a need for an upgraded and purpose-built product in this area. over the course of decades and hundreds of prototypes, employing several different carbide grades and profiles, as well as dozens of braze formulas and procedures, a line of bits specific to the needs of saskatchewan potash mining were refined and put into production. technological innovations and robotics in the production methods have pushed the capabilities to new levels, and to this date, they are the most prominent and well-received bits in use in our

province’s potash industry.

Robotic work cell in our production facility.

building on the value provided to their mining customers, early in 2020 bit service finalized an agreement to be the exclusive distributor of kennametal’s underground mining products for our saskatchewan potash clients. through the partnership with bit service, kennametal is committed to providing superior products to the mining end user customers. In addition to providing a way to market, kennametal looks forward to the opportunity to collaborate with bit service in order to support their lo-

cal manufacturing and design expertise. this relationship allows for ongoing product development and innovation of new mining tools, as well as continuing to support the local productivity and economy of the saskatoon and esterhazy regions.

recently, through a partnership with UlMa Conveyor Components, bit service has been working diligently to introduce a revolutionary, high-quality conveyor roller system to the saskatchewan potash industry. starting with highly engineered and thoughtfully designed rollers and idlers, with some of the industry’s most advanced r&D and testing laboratory facilities, through to the industry-first digitally monitored roller system, UlMa Conveyor Components is a world leader in the field. the uncompromising design and manufacturing quality of UlMa’s products, along with technological innovations never before seen in these applications are the start of an exciting new chapter in potash mining.

ULMA Conveyor rollers at work in cold weather environment.

Customer service and satisfaction has always been the primary goal and their extensive warehouse stock is an illustration of this. Due to constantly changing customer needs resulting from machine alterations and geological differences, bit service works closely with mines to stock what they need in quantities to maintain maximum productivity. these partnerships are strong and bit service looks forward to continuing them for many decades to come. s

bitservice.ca

Proudly Serving the Potash Industry Since 1965

MINING EQUIPMENT & SUPPLIES SPECIALIZING IN BITS AND CONVEYING COMPONENTS Bit Service Company offers full cutting assembly design, fabrication and repair

Bit Service Company Ltd. | Phone 306-653-0988 | Fax 306-244-2262 | E-mail admin@bitservice.ca