SUSTAINABILITY

REPORT 2021

REPORT 2021

Sustainability is at the core of Angelicoussis Group’s mission, values, and operations, driving our environmental, social and corporate governance (ESG) strategy.

We issued our first Sustainability Report in 2020 as part of our broader commitment to transparency and public reporting, with the promise to further integrate sustainability-related goals into our business practices and activities.

This year we are happy to report on our initiatives and progress towards achieving these goals, having adopted a strategy that recognises the fundamental importance of all ESG areas.

As 2021 brought new challenges, and with the COVID-19 pandemic still present, our resilience allowed us to adapt to meet the growing needs of our stakeholders, whilst keeping the safety and well-being of our employees as a top priority.

Needless to say, none of our achievements would have been possible without the vital contribution of our people, especially our seafarers, who once again demonstrated their professionalism, resilience and unwavering dedication to serving society.

Despite 2021 being a challenging year, we made progress on our path towards a more sustainable strategy, taking into account the imperatives of the energy transition, energy security considerations and the need to optimise our supply chains. We see our contribution to sustainable initiatives as our responsibility towards society, the environment and other stakeholders. With this in mind, we have established a dedicated function, the Green Ships department, to lead all energy transition engagements with our partners, customers, and other stakeholders across a broad range of value chains relevant to our shipping activities.

“ Our sustainability culture is deeply rooted in our core values and embraced by all our people.

Working towards the IMO’s target of halving shipping’s carbon emissions by 2050 has been a welcome challenge, since it has tested our expertise and triggered innovative solutions and alternatives. We aspire to not only meet but surpass this target and ultimately achieve net-zero GHG emissions from our operations.

As the global energy transition evolves to meet growing demands, we are focusing on reliable cleaner energy, lowering our GHG emissions and exploring transitional and destination fuel options to meet our goals and align our Group’s sustainability strategy. An integral part of this strategy is to continuously assess the variety of current and available technologies and supply possibilities, as well as manufacturing processes, in order to properly position the Group and keep our stakeholders ahead on the possible pathways to decarbonisation.

In pursuit of our twin goals of energy efficiency and vessel optimisation, a fleet renewal programme is underway accompanied by expansion across all three sectors of our operation. As we transition our fleet from conventional-only designs and explore other technologies and solutions, including carbon capture systems onboard, an increasing number of ships in our order book will be equipped with dual-fuel engines capable of burning cleaner LNG and subsequently all other forms of biomethane and/or synthetically produced methane. With appropriate regulatory levers, this will allow these vessels to reach net-zero emissions. And while the road towards carbon efficiency is a complex process, we are fully committed to this mission and aspire to be a force for shared progress and prosperity. We take great pride in running a fuel-efficient fleet with internationally recognised operational excellence.

Apart from the Group’s environmental agenda, our people and their safety will always remain our top priority.

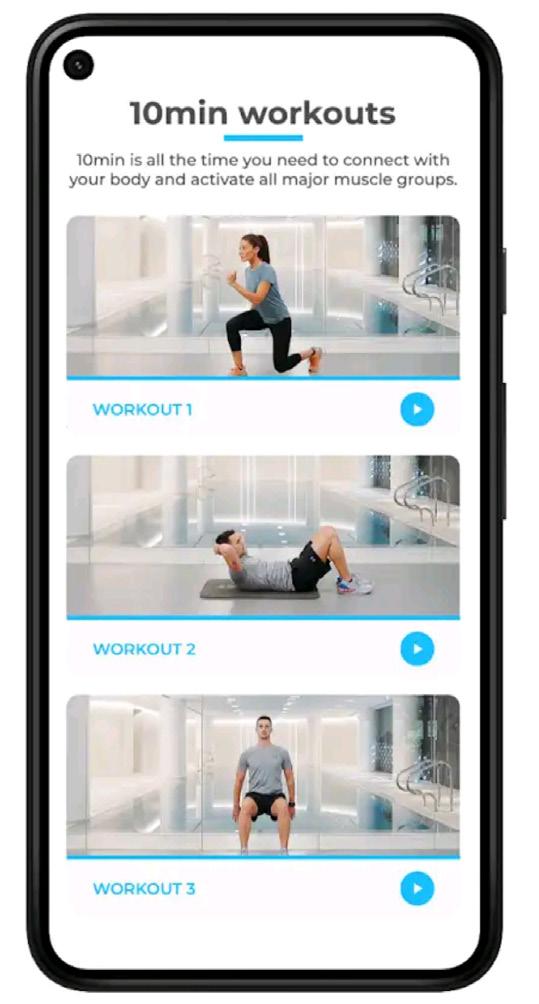

Although the pandemic is primarily a physical health crisis, it has also put the spotlight on mental health, prompting us to undertake initiatives in this area too, firstly within our own organisation. With the assistance of experts in the field, we have initiated a campaign to promote mental wellbeing, build resilience and foster empowerment among our colleagues both onboard and ashore. We have also designed and launched a custom-made well-being application, one of the first apps of its kind in the maritime industry, which provides tailored fitness, nutrition and mental health content to our people.

We want our employees to be equipped with the tools that enable them to realise their full

potential – both personal and professional – and grow within the Angelicoussis Group.

Our sustainability culture is deeply rooted in our core values and embraced by all our people. For this reason, we are moving forward with confidence and determination, committed to making meaningful contributions to the sustainability journey ahead.

We understand that no single company, industry, or nation acting alone can meet the world’s social, energy and climate goals. Accordingly, we must all work together to ensure a better future, and this is precisely what we intend to do in close collaboration with our partners and stakeholders.

Maria Angelicoussis Chief Executive Officer Angelicoussis Group

Wherever we operate, Angelicoussis Group aims to be a positive contributor to society, a supportive and rewarding employer and a mindful consumer of resources. As part of this commitment, we hold ourselves to high standards of comprehensive and transparent reporting to communicate our progress in driving increasingly sustainable practices across our organisation and beyond.

Angelicoussis Group has global operations in multiple countries. We have executive offices in Athens, operational offices in Singapore, Manila and London, and a site office in Okpo. The report covers those countries with the most significant operations and includes disclosures on vessels owned and operated by our three management companies, Maran Tankers Management, Maran Dry Management and Maran Gas Maritime.

The report reviews the performance of the Group and, where applicable, its three management companies and their activities relating to ESG topics.

Global Reporting Initiative (GRI)

The report has been prepared in accordance with GRI standards (Core option), which are widely seen as the global best practice for sustainability reporting.

Sustainability Accounting Standards Board (SASB)

We have also applied the sustainability reporting standards developed by the SASB to guide our disclosures on sector-specific ESG issues.

United Nations Sustainable Development Goals (UN SDGs)

The report additionally provides a linkage between our sustainability disclosures and the UN SDGs.

The report covers the financial year ending 31 December 2021.

This Sustainability Report was published in November 2022. Annual.

sustainability@angelicoussisgroup.com

Angelicoussis Group was founded in 1947 and provides first-class shipping services, including commercial, technical, operational and crew management. We are a dynamic multinational group consisting of several privately owned entities. Our brand is recognised worldwide by leading charterers. Our vessels transport commodities across the globe in the dry bulk, crude oil and LNG sectors.

The Group supports international trade by transferring goods and materials from where they are produced to where they will ultimately be consumed.

The products transported in 2021 include crude oil, other petroleum products, iron ore, coal and LNG.

We have operations in multiple countries including Greece, Singapore, Philippines, United Kingdom and South Korea.

As of 31 Dec 2021 the Group was:

LONDON OPERATIONAL OFFICES

ATHENS HEADQUARTERS

OKPO SITE OFFICE

MANILA OPERATIONAL OFFICES

SINGAPORE OPERATIONAL OFFICES

51

53

39 ships under management ships under management

* Excludes newbuildings

47,203,782

57,466,084

* Excludes newbuildings

53,800,220

MT cargo transported MT cargo transported CBM transported

** Discharge quantity may differ slightly due to the boil-off process and heel retention ships under management

Maran Dry Management Inc. (MDM) was established in 2001 as a unit of Angelicoussis Group to undertake the commercial, technical and operational management of dry bulk vessels.

Maran Tankers Management Inc. (MTM) was established in 1992 to manage the Group’s oil tankers.

Maran Gas Maritime Inc. (MGM) was set up in 2003 to manage the Group’s LNG transport operations.

To be a leader in seaborne solutions.

To provide world-class shipping services to our clients across the LNG, tanker and dry bulk markets in a safe, reliable and sustainable manner, whilst embracing the energy transition through innovative solutions for zero-carbon vessels.

Our core values inspire us to execute all our operations with excellence and have enabled us to build a culture of resilience and continuous improvement.

Integrity

We have integrity as the foundation for our business conduct.

Reliability

We deliver cargo in a reliable and efficient manner to our clients and partners.

We promote a culture of innovation to create the vessels of the future.

Our core values - integrity, reliability, innovation, care and endurance - are the cornerstone of our culture, setting us apart and clarifying our identity.

The value we place on environmental and social responsibility was instilled by our founders. The challenge of living up to and advancing those high standards has today been taken up by our leadership and embraced across the organisation.

We care about our employees by promoting equality, diversity and continuous learning.

Endurance

We take a longterm view when investing in our people, partners and vessels.

From long-standing board members to new joiners at every level, all Angelicoussis Group employees commit to our rigorous Code of Conduct. This commitment is reinforced through regular training, workshops and an annual forum dedicated to achieving even higher standards in environmental, social and governance practices.

It is our goal to promote safe and environmentally friendly seaborne trade. To help achieve this objective, the Group is an active member of multiple maritime industry partnerships, associations and committees, including:

Operating in the maritime sector, our Group is a member of the International Transport Workers' Federation (ITF) and the Panhellenic Seamen's Federation (PNO).

As a leading player in the industry, we also actively participate in several non-binding voluntary initiatives, some of which are listed below:

• High Impact Low Frequency (HiLo) Maritime Risk Management

• Shell's Maritime Partners in Safety

• Equinor's Working Safely With Suppliers

• Hellenic Marine Environment Protection Association (HELMEPA)

• Women's International Shipping & Trading Association (WISTA)

• International Tanker Owners Pollution Federation (ITOPF)

• Baltic and International Maritime Council (BIMCO)

• International Association of Independent Tanker Owners (INTERTANKO)

• International Association of Dry Cargo Shipowners (INTERCARGO)

Angelicoussis Group supports research and innovation in the maritime sector. We partner with a number of leading academic institutions, including Massachusetts Institute of Technology (MIT) and National Technical University of Athens (NTUA).

Angelicoussis Group’s reputation is founded on an unshakeable commitment to honest business conduct. This approach is enshrined in a rigorous framework designed to minimise the risk of bribery, corruption and illegality.

Angelicoussis Group conducts business in a lawful and ethical manner and is committed to acting professionally, fairly and with dignity and integrity in all business transactions and relationships. Effective systems are in place to counter bribery and corruption.

As each function has a different susceptibility to corruption, we deploy targeted approaches across the Group. Functions which pose a higher risk of corruption, such as procurement and contracting, are subject to a stronger compliance focus.

Group procurement and project engagement are subject to internal controls. We enter into agreements with third parties in the framework of the ‘Know Your Customer’ (KYC) verification process, followed by contract negotiations and documentation. In the case of spot ordering, a competitive selection process, which is subject to reviews and approvals, minimises the risk of corruption.

To assess this risk when recruiting, we pose pertinent interview questions but also obtain references and police reports. After recruitment, our induction and familiarisation processes, Code of Conduct, training, whistleblowing mechanisms and values hierarchy serve as effective safeguards.

The Group further enhances its anti-bribery and anti-corruption framework through workshops with key stakeholders and management.

Legal actions for anti-competitive behaviour, anti-trust, and monopoly practices

All employees are made aware of our firm position on business ethics. Anti-bribery and anti-corruption are discussed during familiarisation training, office forums and workshops, as well as during office personnel attendances on board our vessels. In addition to dedicated training, these issues are also addressed at other awareness-raising sessions.

All shore and shipboard employees in all regions receive and confirm receipt of our Code of Conduct which highlights the Group’s zero-tolerance stance on bribery and corruption. The code is also available to employees on the Group’s intranet.

External contractors are also fully briefed on our anti-corruption policies.

We have set up confidential reporting lines for employees to raise any concerns they may have about fraudulent or dishonest behaviour, which are included in the Code of Conduct and the onboard complaint procedure.

The Group also has confidential email addresses for shore and shipboard personnel to report any complaints or grievances, including concerns about unsafe acts and conditions; as well as identified non-compliance cases. These email addresses are listed in the Code of Conduct of each company in the Group. They are also provided to fleet and shore personnel during their pre-joining and onboard familiarisation.

In addition, each company’s Designated Person Ashore (DPA) is available 24/7 to receive any officer and crew complaints or information related to health, safety, environmental and other concerns. The DPA’s contact details are posted on each vessel for easy access by anyone onboard. For office employees, we have a grievance policy which clearly explains how formal complaints are raised, investigated and handled.

Angelicoussis Group engages the services of Trace International, a leading anti-bribery standard-setting organisation, to independently assess all facets of its business, including ownership and key management, financial transactions and results, management and operations of all vessels, as well as feedback and references from third parties and media. No significant risks have been identified in internal audits or the external audits by Trace International.

The dry bulk sector is certified by Trace (certificate TC41726181, valid 1 March 2022 to 28 February 2023), while in other sectors our key agents are Trace certified.

Our business partners wishing to confirm the successful completion of Trace due diligence can directly contact https://tpms.tcompliance.com/ IntermediaryDirectory

Maintaining a robust, resilient and sustainable supply chain is central to our long-term business goals. We look forward to continuing our long-standing relationships with key suppliers and working with them to promote transparent and responsible procurement practices.

The Group's supply chain is built on both longterm contracts and spot ordering to meet our needs and enable us to deliver first-class shipping services. Our supply chain partners range from shipyards to suppliers of stores, provisions, marine fuels, lubricants, spare parts and logistics, as well as providers of brokerage, agency, survey, repair and other services.

Supplier selection is dependent on several factors, most notably ongoing and upcoming shipbuilding, drydocking and maintenance projects. Charter arrangements, specific voyage routes and the varying global availability of products also influence purchasing decisions. All decisions take into account the broader regulatory environment, including international and local restrictions, pandemic developments and political disruptions.

In 2020 and 2021, for instance, the Group had a busy newbuilding and drydocking programme. So, to maximise economies of scale and accelerate delivery time, we consolidated multiple orders from the same supplier.

Knowing that consolidating multiple deliveries into fewer bulk orders can significantly reduce logistics-related emissions, a dedicated team was set up in 2021 to take full advantage of these economies of scale across the Group and enhance its sustainable practices.

2,462

The Group bears a social responsibility to ensure our ethics and values are also upheld by our suppliers, and we take this duty seriously.

All suppliers with which Angelicoussis Group aims to develop long-term relationships are initially placed on a one-year probation period, after which they are periodically re-evaluated.

In 2021, the Group reviewed its evaluation process for suppliers. The new process, anticipated to start in 2022, incorporates our updated Ethical Sourcing Policy into our selection, onboarding and continu-

ous assessment procedures. The aim is to create a database with easily accessible information on our suppliers and their adopted governance practices.

Demonstrating our commitment to continuous improvement, not only internally but also within our immediate and broader environment, the Group additionally developed an action plan for evaluating spare parts suppliers. The new process will come into effect in 2022 and uses a combination of manual record keeping and automated analysis to categorise suppliers on the basis of sustainability factors.

The Group works closely with key suppliers to raise their ESG awareness and collaborate with them to build a more sustainable supply chain. To further reduce the environmental impact of our procurement activities, we continuously seek more effective ways to assess the environmental compliance of our suppliers and communicate to them possible areas for improvement.

Angelicoussis Group recognises that the best way to minimise the climate and environmental impact of

transportation is to source from closer to where supplies are needed. Where feasible therefore, we prioritise the procurement of materials locally and in bulk.

The Group aims to minimise landfill waste and maximise recycling across our operations. Specialist contractors are employed to recycle waste generated by our fleet and at our offices. At our warehouses, packaging materials and pellets are recycled where possible. Angelicoussis Group refrains from supplying single-use plastics on its vessels and has installed water filtration systems to minimise water and plastic waste.

new suppliers assessed for environmental impacts

Our purchasing quotations and order confirmations include text urging suppliers to package goods in materials other than plastic, as follows:

PROTECTION OF THE ENVIRONMENT – PLASTIC MINIMIZATION

“Our Company is committed to the protection of the environment and to the promotion of practices that minimize any adverse environmental impact.”

PROTECTION OF THE ENVIRONMENT – PLASTIC MINIMIZATION

“Where practical options exist, provisions packaged in or made of materials other than plastic should be selected.”

The Group has a strong preference for suppliers who apply environmentally friendly practices aimed at minimising the generation of waste. Where practical alternatives are available, we strongly urge our suppliers to select packaging materials other than plastic. Moreover, in the ’Evaluation of Suppliers‘ form, one of the criteria is to check that the volume of plastics associated with the packaging material is as low as possible.

The business of shipping has many risks. Managing them well represents a major opportunity and adds value for our customers and other stakeholders.

We deploy our risk management process with value creation in mind. We recognise that both systematic and unsystematic factors can trigger risks under different conditions. We identify and anticipate potential risks which may affect our ability

to attain our objectives and we set up our internal controls to minimise their impact and achieve operational efficiency and effectiveness. As part of this process, we are increasingly looking at the impact of sustainability issues.

We maintain the following certifications for our internal control process:

Health and safety of our people onboard and ashore

Business interruptions caused by marine disasters, wars, adverse weather conditions, mechanical failures, or piracy

Cargo loss or damage

Technological obsolescence which would require additional capital expenditure to avert the declining competitiveness of our fleet

Cyber attacks

Piracy

Geopolitical conditions that could affect international trade routes and regional stability

Changes to the laws and regulations of governments and international organisations which could lead to: a) inability to operate b) unavailability of bunker products c) new emission taxes (GHG or C02)

Reduced access to capital

An adverse global economic outlook could trigger:

a) A decrease in demand for shipping transportation services

b) Changes in interest or foreign exchange rates and increases in bunker prices with impacts on our cost structure

c) Market liquidity constraints affecting our ability to finance or refinance projects

An improved global economic outlook could upset the equilibrium by resulting in oversupply of tanker, bulker and LNG carrier tonnage.

Customers

Beneficial Owners

Seafarers and Shore-based Employees

Financial Institutions

Authorities and Industry Organisations

Suppliers and Service

Providers

We use the latest innovations in vessel, and operational technology to ensure that our charterers receive first-class service and their cargoes are carried safely and efficiently.

• Charterparty agreements

• Tender participations

• Service feedback

• Charterers’ audit results

hoc Strategic

Service quality, business ethics, safety standards, vessel condition, fleet age, experience of results vs expectations.

In 2021, the Group carried out a full review of its Competency Management System and set more stringent criteria to update procedures to achieve optimum operational performance without incidents and commercial delays.

A ‘Requisition Status Report’ has been created to monitor the status of all requisitions in real time up to final delivery. The report is automatically updated with information inputs from all linked systems.

The financial support that enables our growth and industry leadership is driven by our shareholders’ passion for the shipping industry.

• Board meetings

• Management meetings

Quarterly Strategic Daily

Healthy financial performance, business strategy, governance, regulatory compliance, brand and market leadership

A live budget dashboard and monitoring system was developed to track each department’s live budget at the time of approval of any order.

Live comparative analysis for all our fleet vessels and management companies’ budgets has been made available to our principals.

We look for motivated, hard-working individuals who are as excited as we are about transporting commodities across the globe in a safe, efficient and sustainable manner. We invest in our people and support their professional growth within the organisation.

• Briefings

• Debriefings

• Performance feedback

• Smartphone apps

• Training

• Open communication channels

Daily Pre- and postembarkation Annual

Performing each role to the highest standard, duty of care, health & safety, crew and employee welfare schemes, mental health initiatives/training, remuneration and benefits, career development

The Group’s Covid Outbreak Management Plan is continuously updated to include any new developments, restrictions and safety measures. To protect our shipboard and shore personnel, remote audit procedures were developed in compliance with Flag Administration guidance. Remote audits and inspections were carried out by qualified personnel and external contractors. Crew changes were made in compliance with charterer and port/terminal requirements.

The medical inventory supplied to all our vessels was reviewed in line with Flag Administration requirements. Dedicated personnel were also assigned to the supply and monitoring of onboard medical inventories.

The ’Maritime Well-being Campaign' was launched in response to the pressing issue of mental wellness of seafarers, with the aim of ensuring that our onboard employees remain happy and healthy. The campaign was further elaborated in 2021 with support and guidance from external experts to make certain that it is carried out in a proper and verified manner.

Financial institutions enhance the Group’s strengths by providing support across the lifecycle of shipping activities, not only by funding vessel purchases but also by offering risk management solutions and investment.

• Loan agreements

• OTC agreements

• Quarterly reports

• Audited F/S

Ad hoc Quarterly Annual Strategic

It is the company’s intention to use credit facilities that incorporate emission reduction targets. During the past year, we held a series of discussions focusing on sustainability-linked loans and initiated an internal process to define the appropriate Key Performance Indicators that would facilitate any application for such finance.

KYC and regulatory compliance, financial performance, business strategy, governance, risk assessment

This was the second year in which the Group was asked by its financiers to report on the fuel consumption and emissions of its vessels, in line with the Poseidon Principles on green ship finance. Angelicoussis Group is fully supportive of this initiative.

Striving to go beyond basic compliance, the Group is at the forefront of efforts to achieve the more challenging goals enshrined in standards and frameworks set by regulators, authorities and other organisations, whose statistical data, certifications and external audits validate these endeavours.

• Audits

• Data submissions Health & safety, ecologically sensitive approach, business ethics and culture, regulatory compliance

The Group actively participated in the development of a new industry inspection questionnaire designed to enhance the risk assessment process and support shipowners/managers in improving dry bulk standards beyond compliance. One of our vessels was used for the project's first pilot inspection using the new questionnaire.

In cooperation with trusted partners, one of our vessels was selected for a biofuel blend (B30) trial to evaluate the emissions impact of using this promising alternative fuel. The trial enabled us to evaluate a number of parameters relating to the consumption of the reduced-carbon fuel.

In the year under review, we transitioned to an electronic planning and monitoring system for heating cargoes during transit which, combined with a library of cargo parameters, will ensure that heated cargoes are delivered safely with the minimum fuel consumption and CO2 emissions.

The Group also used monitoring and reporting software to improve the efficiency of discharge operations and identify any technical issues at an early stage. This will help further improve the quality of service to our customers, while additionally reducing fuel consumption and emissions.

We select suppliers with great care and seek to build longterm relationships, fully recognising that procurement choices have social, environmental and economic impacts on our industry, global logistics and society as a whole. Over the next two years, we will continue to improve processes to bring greater sustainability to our supply chain.

• Supplier acceptance process

• Invitation to tender

• Contracts

• Spot purchasing

• Supplier evaluations

• Exhibitions

Business ethics, evaluation criteria, volume, financial position, product development and improvement, planning

To further improve the sustainability of its supply chain, the Group has strengthened its focus on reducing waste from packaging in the procurement stage. Accordingly, whenever feasible, we require that provisions packaged in or made of materials other than plastic should be selected.

This requirement is specified on all purchase orders. In addition, our vessels are prompted to report the packaging materials they receive from each supplier when completing their supplier evaluations. Packaging material is also monitored and inspected during onboard audits by company personnel.

In view of society’s move towards net-zero greenhouse gas emissions, the Group has initiated discussions through periodic technical meetings to examine the potential use of alternative fuels that could advance the decarbonisation of shipping.

The Group is in constant communication with ship technology providers to implement solutions for upcoming legislative requirements. Close communication with ship designers and shipyards is maintained to evaluate new designs powered by alternative fuels and technologies which can be installed in vessels to reduce fuel consumption and emissions, such as wind propulsion and air lubrication systems. Additionally, shipyards have shared plans outlining the main design features for alternative fuel ships which are currently being considered by the Group.

We take steps to ensure the submission of IHM certifications from our suppliers as required by regulations and follow up on any overdue certificates. To facilitate the follow-up, an IHM Online Portal was developed in 2021. Suppliers are notified via an automated email and are able to log in and use the portal to easily submit their IHM forms. As a result of the portal upgrade, the IHM certificate submission rate increased from 10% (beginning of 2021) to 91% (end of 2021). IHM compliance has also been added to the criteria used for our supplier audits.

We have identified our sustainability priorities based on a comprehensive materiality assessment study carried out with the involvement of our internal and external stakeholders.

Employee Health & Safety, Regulatory & Legal Compliance, Operational Excellence & Assurance and Environment Protection have been identified and ranked with the highest relevance and importance for the Group’s activities.

Reflecting one of our core values, namely care, Angelicoussis Group has always maintained and openly stated that it is our people that make our organisation. The health and safety of all our employees, both ashore and at sea, is a priority that will always remain at the forefront of our commitments.

Our strong business ethics and integrity allow us to deliver operational excellence and assurance for customers, as we continue to build our reputation and cement our position as an industry leader.

Environmental

Environmental Protection

Toxic & Hazardous Materials

Water Conservation & Management

Energy & Emissions Management

Responsible Supply Chain

Employee Health & Safety

Labour Conditions

Career Development & Benefits

Community Engagement Governance

Regulatory & Legal Compliance

Operational Excellence & Assurance

Business Strategy & Resilience

Governance & Leadership

Research & Innovation

The content disclosed in this report refers to Angelicoussis Group’s sustainability performance in the context of Environmental, Social and Governance (ESG) material topics. These topics have been prioritised by our internal and external business stakeholders and reflect but do not limit our focused efforts towards fulfilling our commitments, strategic outlook and sustainability policy.

Having established ethical and sustainable practices across our activities, we understand that sustainability must be integrated in all processes and at all organisational levels, always taking into account the perspective of our stakeholders.

Meaningful engagement with our stakeholders has allowed us to assess and upgrade our ESG strategy, especially with regard to business risk and opportunities identified. In support of our sustainability reporting, a new materiality assessment will be conducted periodically to ensure that our material topics are validated and accurately reflect trends in our stakeholders’ concerns.

Underlining our commitment to transparency, we plan to report our sustainability metrics and performance annually, with the aim of developing the relevant disclosures and promoting sustainability within our organisation and beyond.

8,460

5,598 5,323 EMPLOYEES

8,052

seafarers

275

495

shore-based personnel

Our employees are the cornerstone of our operational excellence and high-quality services. At Angelicoussis Group, we strive to provide an inclusive, diverse, and trusted workplace in which employees can continuously develop and thrive.

To expand our competence and further enhance service quality, it is important to maintain a qualified, innovative talent pool and attract highly skilled employees. Our recruitment strategy focuses on hiring the best candidates with the necessary skillsets and abilities for the particular position. We treat each candidate with respect and fairness.

Respect for diversity and inclusion is something that has been deeply embedded in our corporate values by our founders. We are strong advocates for our people and believe that they provide the foundation on which our reputation is built.

Everyone working at Angelicoussis Group is expected to foster a positive, fair and open environment by encouraging and valuing different ideas and perspectives. We are committed to enhancing diversity across all levels within the Group, including our board members and senior management.

Our Board of Directors is made up of one executive and one independent member, representing different age groups, professional backgrounds, cultures and genders.

The Group is already an active member of the Women’s International Shipping & Trading Association (WISTA) and is currently considering participation in several industry initiatives to promote and enhance equality, diversity and inclusion in the workplace, both onshore and offshore.

<

8,052

Angelicoussis Group has a long-standing culture of mentoring and investing in its people. We value our talented workforce, which delivers the highest standards of performance across all our operations and activities.

7.1

average training hours per shorebased employee

19.3 100%

average training hours per seafarer return-to-work rate after parental leave

Our seafarers receive training in line with the requirements of the STCW Convention. The training is provided in the framework of our company training matrix, which forms part of the Safety Management System. The matrix consists of mandatory courses to satisfy embarkation requirements, but also includes optional courses that can serve as powerful propellers for career development and progression.

All training courses are delivered by in-house verified trainers or accredited external providers. Training sessions are held at our in-house training centre or at sea through the online Seagull platform.

In addition, our seafarers are given specific assignments to familiarise them also with shore-based operations.

6,855

seafarers provided with training

132,303

total training hours

Training programmes are regularly updated to keep abreast of industry developments and new regulations.

Comprehensive training matrix for each management company. The matrix includes mandatory and optional training relevant to the employee’s role.

19.3

avg. hours of training per seafarer hours of e-learning

17,390

We document training in an online system for our office employees. Training can also be requested by employees through the performance management process.

Employees have the opportunity to request additional training not included in the regular schedule.

To ensure that all personnel are given the training required to fulfil their roles to the highest standard, the Group regularly assesses training needs through various mechanisms. Each employee has a personalised career development plan, and results of appraisal reports and competency assessments are used to update training requirements.

At management level, quarterly management review meetings ensure that new regulatory or industry requirements, trends and best practices are taken into account, as well as changes in the technological, legal and general operating environment of the Group.

The Group strives to continuously improve the training it provides in order to ensure that employees have the skills they need to deliver best-in-class operations and service. Several methods are used to measure and improve the effectiveness of training, including:

For vessel crews, masters’ reviews, drill reports and individual competency assessments complement the results of simulation-based programmes to identify training needs. Evaluation of incidents, near misses and non-conformities are also taken into consideration.

Other factors used to evaluate training needs include:

• Internal and external audits and inspections, including superintendent attendances

• Evaluation of manager and employee direct requests

• Company forums and departmental workshops

Interviewing / testing trainees to verify competence

Company representation at training courses

Reviewing appraisal records

Reviewing vessel performance, audit and inspection trends

Investigating non-conformities, incidents and near misses

Angelicoussis Group’s DELPHIC Maritime Training Centre was the first in-house training facility established in Greece by a major shipping company.

The Group's objective is for DELPHIC to remain a leading in-house training facility that develops and delivers company-specific courses. The aim is to:

• Continue to deliver high-quality courses

• Improve the technical and soft skills of seafarers and shore-based personnel

• Develop a series of reliable tools for assessing competencies

• Satisfy all future training needs in line with industry developments

Serve the core values of the Angelicoussis Group

DELPHIC Maritime Training Centre established

Training centre equipped with full-mission bridge simulator and state-of-the-art tanker cargo and engine simulators

Electronic Chart Display and Information Systems (ECDIS) simulator added in 2012; LNG cargo simulator introduced in 2013

New bridge and engine simulators with latest technology installed at DELPHIC’s new facilities

State-of-the-art training facilities at the DELPHIC centre include:

Full mission bridge simulator with four workstations

1 4 2 5 3 6

ECDIS simulator

Engine simulator with giant touch screens and six workstations; three engine models connected to the bridge simulator

Full mission bridge simulator with six workstations

PC-based cargo simulator for tankers, with six workstations

PC-based cargo simulator for LNG carriers, with six workstations

Training is crucial for ensuring the highest standards of occupational health and safety onboard. In order to make training courses accessible to all our seafarers, we conduct courses not only at our in-house facilities, but also via job training onboard and Computer-based Training (CBT).

• Specialised Oil Tanker Training Certificate

• Medical Care

• In-house Medical First Aid

• Advanced Fire Fighting

• Food Safety-Hygiene

• Shipboard Safety Officer

• Safety Management System (SMS) Seminar

• ISO 14001

• ISO 45001

• Risk Assessment

• SMS Training

• Reflective Learning

• Incident investigation

• Soft skills training

SMS policies and procedures

Emergency preparedness and response

Impact of work activities and risk assessment

Consequences of nonconformance with operating procedures and requirements

The occupational safety technician is responsible for carrying out a series of training programmes at our Athens offices, including Fire Safety, Earthquake Protection and Building Evacuation. These programmes are mandatory for all shore-based personnel, while advanced training is provided to the Fire & Safety team leaders. Present on each floor of the building, these team leaders are

Safe operation and preservation of the environment

Importance of identifying near misses, unsafe acts/conditions

responsible for their designated area and colleagues. In 2021, 46 employees participated in the advanced safety training.

In addition to the above programmes, we offer optional First Aid training which is provided by the Fleet Medical Advisor to enhance the life-saving knowledge among our shore-based personnel.

The Group actively invests in the professional advancement of our shore personnel by conducting relevant training and skill development sessions. The training provided to our office staff is broadly classified into two categories:

Technical & business skills

Programmes focused on personal capability development, building leadership capacity and enhancing communication skills. 65 10

Programmes for improving the technical and/or business skills of an employee. Examples include training in Occupational Health & Safety (ISO 45001, Cyber Security Awareness, Fire Safety).

Angelicoussis Group is very supportive of employees who seek to upskill themselves and advance their knowledge. In 2021, we co- funded higher education programmes for nine of our employees.

Soft skills

316

3,505

7.1

The Group re-launched its “Open Business Skills Seminars” in 2021. First introduced in 2019, the programme includes a series of intensive, short-duration seminars, also referred to as ‘micro-learning sessions’. The objective is to educate and inspire employees by emphasising the importance of business skills in improving an individual’s performance and productivity.

The seminars, lasting from one to three hours, can cover a wide range of topics. In 2021, seminars were held on the themes of “Mental Toughness” and “Accountability”.

The Group has in place a robust performance management process to accomplish Specific, Measurable, Achievable, Realistic and Time-Bound (SMART) goals, competencies, and personal development targets. The purpose of this process is to give employees a clear understanding of their role, as well as ongoing feedback on how they are performing relative to expectations, while at the same time identifying development opportunities.

In 2021 we resumed our summer internship programme, which had been disrupted for one year due to COVID-19. Over the two-month course, interns gain exposure to and hands-on experience in the latest technologies of the maritime industry and the different processes of each different department within a ship management company. By enrolling, they have the opportunity to enhance not only their skills but also their employment prospects.

During the summer of 2021, 19 individuals joined the internship programme.

Other initiatives we are taking to enhance the skills of our shore-based employees include:

Personal development plans for our employees take into account their own ambitions and the Group’s mission, vision and strategic goals. Performance management is not a one-time event but a continuous process that is core to achieving the Group’s goals.

The annual process has three phases:

1 2 3

Flexible working hours for employees attending higher education courses, as well as in-house or third-party training programmes.

Training and coaching sessions to help managers improve their skills.

Memberships and subscriptions to professional bodies.

Vessel visits and a ‘simulator week’ for office employees to deepen their understanding of shipboard operations.

Easy access to the training calendar, which is managed by our in-house training centre (DELPHIC). Employees can see which training sessions are scheduled and request to attend.

Fostering an open communication culture and encouraging employees to share their feedback and suggestions with management.

Encouraging attendance at industry conferences and forums.

Angelicoussis Group is acutely aware of the importance of retaining high-quality, talented individuals and fostering employee loyalty. Our culture and values generate a high level of employee satisfaction, and we continuously strive to provide our personnel with a dynamic, stimulating workplace.

We offer industry-competitive salaries, which are reviewed on a regular basis to keep up to date with market trends. But we also provide our employees with attractive benefits that exceed the requirements of local legislation.

We offer our employees an advanced life insurance programme (since 2018)

We provide financial support to employees who are unable to work for health reasons

Our office employees in Greece enjoy all the benefits of a comprehensive health care programme, including Medical services and annual hospitalisation deductible

We go beyond legislative requirements for parental leave by giving extra days and greater flexibility (since 2021)

* Applicable only to shore-based office employees in Greece

In 2021, we developed a Performance & Remuneration Plan (PRP) that aims to align our people, organisational structure and overall strategy in order to help achieve our vision and drive sustainable growth for the Group.

The PRP is a comprehensive reward system aimed at:

1. Aligning individual efforts with the Group’s overall strategy

2. Creating a clear link between performance and rewards

3. Fostering a high-performance culture

The PRP also aims to ensure fairness and objectivity, eliminating personal bias and enabling all employees to reach their full potential. The PRP will be released in 2022 and it’s effectiveness will be evaluated.

In addition, a goal-setting process has been launched for all office employees for 2022, further underlining the Group’s strong belief that each individual has an important role to play in its success.

It is the priority of Angelicoussis Group to incorporate the highest safety standards in every aspect of its operations while protecting both our onshore personnel and seafarers from health and safety hazards.

Angelicoussis Group maintains a robust safety management system (SMS) to safeguard our employees’ work environment. The SMS was designed by qualified professionals to the highest international standards and is in compliance with the requirements of the International Safety Management (ISM) Code, ISO 14001 Environmental Management System, ISO 45001 Occupational Health and Safety Management Systems, ISO 9001 Quality Management System, and ISO 50001 Energy Management System.

of our employees and activities are covered by the Safety Management System

The SMS sets out detailed procedures and measures for each operational process to ensure comprehensive safety monitoring. Senior managers, shore and shipboard personnel participate in the development, implementation and continuous improvement of the SMS. To verify ongoing suitability, adequacy, and effectiveness, the SMS is revised and updated at least twice a year to stay abreast of forthcoming regulations and industry best practices. Additionally, fleet and interdepartmental audits are carried out regularly by both internal and external independent auditors to monitor compliance with the SMS throughout the organisation.

Both our shipboard and shore-based personnel are encouraged to submit suggestions regarding the effectiveness of the SMS and potential improvements through various channels, including company forums, master’s review reports, regular debriefings, ship/shore exercises and tabletop drills.

Our people are encouraged to share their opinions and communicate feedback related to the SMS by participating in the twice-yearly company forum. All concerns and suggestions about improving work conditions are discussed. Both ship and shore personnel use this as a platform to share experiences and collaborate to further enhance health and safety standards.

The master’s review report is an essential part of the continuous improvement process. It contains a brief assessment of shipboard activities and identifies areas for improvement in procedures from the viewpoint of officers and crew.

Our safety risk management process is primarily focused on risk identification, assessment and treatment. The Group systematically identifies any weaknesses and hazards in order to build a proactive safety culture, with the use of validated risk assessment tools and the implementation of risk mitigation measures. Risk assessment is an ongoing process, so we regularly update the library of approved risk assessments and Job Hazard Analysis (JHA) for both routine and non-routine tasks. A risk assessment can be initiated by any Group personnel onboard or ashore. The active involvement of seafarers in the review and updating of the Group’s risk assessment library is strongly encouraged, given that shipboard personnel have practical knowledge and first-hand experience of activities onboard.

Our ‘no-blame’ culture means personnel feel at ease reporting any unsafe conditions or work-related hazards. The Health, Safety, Quality and Environment (HSQE) department actively encourages near-miss reporting, which is followed up with appropriate corrective and preventive measures. To further improve safety, a set of Key Performance Indicators (KPIs) has been developed, which additionally prompts the initiation of new risk assessments by vessel personnel.

The ’Take-Five‘ process is a practical risk assessment tool that is used by all crew members during dayto-day activities onboard and especially for routine tasks for which there is no available Job Hazard Analysis (JHA) report. To assist in the identification of hazards, a Take-Five card provides a list of common hazards that could be present in operations aboard a vessel. The cards are available to all seafarers for use during daily activities onboard.

stop & think

1 assess the level of risk complete the job safely identify any hazards 2

4

5 decide and implement risk control measures

3

The ’Safety Inspector of the Week' programme facilitates the identification of potential and actual hazards onboard through the proactive reporting of unsafe acts/conditions and near misses. For any given week, the Safety Inspector is selected on a rotation basis that is inclusive of all ranks onboard to underpin our 'Speak Up' policy and elevate our safety culture.

The JHA is a simplified risk assessment process specifically designed for user-friendly and practicable implementation onboard. All seafarers can review the hazards listed in the JHA and submit any additional risks along with proposed control measures for consideration by the HSQE department.

The COVID-19 pandemic has brought unprecedented challenges to our business operations. In response, the Group has implemented all the measures required by the World Health Organization (WHO), Greek public authorities and the National Organisation for Public Health, but has also taken additional initiatives to protect the health and safety of our employees.

We have issued a COVID-19 Outbreak Management Plan to provide guidance to both shipboard and shore-based personnel and mitigate the risk of the pandemic. The plan is regularly updated with the latest COVID- 19 developments, restrictions, and actions taken within the Group.

We have provided our employees with teleworking facilities to ensure effective communication.

We have set up a COVID-19 Crisis Committee to lead and oversee the comprehensive management and control of the pandemic.

VACCINATION PROGRAMME

We have initiated a vaccination programme for our seafarers, arranging and paying for all crew members and officers onboard to be vaccinated in one of the ports they visit.

We fund diagnostic tests for employees, as required.

The aim was to vaccinate as many of our seafarers as possible to minimise the spread of COVID-19 and safeguard our people onboard. The programme has been a huge success, with the majority of our seafarers now fully vaccinated. For those not yet vaccinated, the programme will continue in 2022.

Caring about our employees is a core value of Angelicoussis Group, which is dedicated to promoting their physical health and social well-being. The Group is equally committed to the principles of equality and diversity in employment, as we strive to ensure that our shipboard personnel are happy and engaged, both in and outside the workplace.

The Group has a formal agreement with several recognised and accredited health facilities, in compliance with Flag State and P&I requirements, covering the geographical locations of our seafarers.

All seafarers are required to undergo pre-embarkation medical tests as per the Group's Medical Examination Scheme, free of charge, at one of the recognised health facilities. These tests exceed Flag Administration requirements, in order to meet the company's high standards and provide additional health and safety protection. In addition, our inhouse medical advisors or contracted facilities provide medical assistance to all seafarers if any health issues or emergencies arise. Medical records and related data are only communicated to the respective advisor when medical attention is necessary.

In 2021, the Group launched a series of campaigns to further cultivate skills and knowledge regarding health and safety aboard our vessels. The campaigns are specifically designed for shipboard personnel, and all guidance/recommendations given relate to conditions onboard. Our seafarers are actively engaged in the selection of campaign themes through periodic surveys carried out by all departments within the Group. In the framework of these surveys, they are invited to provide their honest feedback and make suggestions about health and safety services or campaigns.

Fatigue can easily lead to human error and pose a serious safety risk or cause damage to the environment and property. The ‘Fatigue Risk Management’ campaign was designed along the lines of Shell's ‘Maritime Partners in Safety’ programme to help mitigate the effects of fatigue. Our seafarers are given advice about how to manage sleep and reduce fatigue on a daily basis. In addition to individual and group activities, the campaign also offers practical tips to help seafarers identify and control key contributors to fatigue.

PPE is essential for protecting employees from workplace hazards. One of the main objectives of this campaign was to highlight the dangers of working without wearing appropriate eye protection, with the aim of preventing personal injuries.

The 'Safety Starts With Me’ campaign was launched to promote a proactive safety culture in the workplace by raising awareness and encouraging our people to initiate discussions about possible improvements. The Group takes steps to identify Safety Critical Tasks (SCT) and human factors as potential hazards and raises barriers to mitigate the risk of human error in all processes, improving safety through leadership, task planning, and equipment design.

The ‘Maritime Well-being’ campaign was launched at the end of 2020 and further enhanced in 2021 to improve and encourage physical and mental health by building a resilient and empowered team of shipboard personnel, well prepared to overcome all personal and professional obstacles. We invited external experts to provide peer support and guidance to ensure the appropriate development of the campaign.

The primary aim of this campaign is to cultivate skills that enable each seafarer to assess their personal mental health status and take the necessary measures to nurture their mind and body. The campaign was initiated with the publication of the first volume of a monthly well-being newsletter which features information and exercises relevant to the campaign's three main focus points: Mental Health, Nutrition & Diet, Physical Fitness.

An in-house mobile application was also released to cover the three focus areas. The application enables custom workouts and mental exercises for each seafarer based on the information provided in the setup stage. Smart TVs were supplied to all fleet vessels so that the application can be used in communal areas, thereby creating a team approach to seafarer wellness. In 2021, we collaborated with a third party to carry out an initial wellness survey on our vessels to assess the mental health status of our seafarers. A key component of the campaign, this survey is used as a well-being monitoring tool to identify focus areas and indicate where support is needed.

Our safety performance reflects the effectiveness of our SMS. We carefully record and track the details of each work-related incident and carry out appropriate, in-depth investigations to prevent reoccurrence. We use industry software (see below) to help us learn from accidents and high-potential events and generate a severity matrix through a detailed analysis of incidents. The preparation of an action plan and implementation of measures to avoid incident reoccurrence is based on the outcome of the analysis and investigation carried out. Department heads are responsible for the follow-up and verification of corrective and preventive actions. Finally, the conclusions from the investigation reports and assessments are used to reduce the risk of any recurrence or related incidents and further enhance the Safety Management System.

We have set up a safety committee on each vessel for discussion of matters related to safety, quality, health and pollution prevention. Crew representatives are invited to participate in the monthly committee meetings on a rotating basis to share their thoughts and suggestions on ways to improve health and safety management procedures onboard.

The Group has invested in industry software that facilitates risk management for marine incidents using the Marine Systematic Cause Analysis Technique (M-SCAT). This powerful tool helps us learn from accidents and high-potential events to prevent further human injury, environmental damage, quality degradation and other adverse impacts. Events with high potential for loss are assessed using root cause analysis and improvement actions are then identified to prevent the reoccurrence of incidents. The software combines 50 years of experience in incident investigation with step-bystep instructions and tested analytical tools.

Ensuring the health and safety of our employees at all times is our highest priority. We are committed to providing our shore-based personnel with a quality work environment and effective safety management.

We care about the health and wellness of our shore-based personnel and take all necessary steps to identify and eliminate any work environment risks. The Group has an occupational doctor and occupational safety technician, as well as two fleet medical advisors at our Athens headquarters, to oversee health and safety issues and concerns.

The Occupational Safety Technician serves as the Group’s consultant in matters of safety at work. The purpose of his/her advice and consulting is to contribute towards the prevention of accidents at work, the management of emergencies and the implementation of workplace methods and procedures that are essential for the improvement of employee safety.

The Occupational Doctor is primarily responsible for ensuring the good health of our shorebased personnel, providing advice and recommendations on measures to be taken for the physical and mental health of employees.

The Fleet Medical Advisors are general physicians employed by the Group to advise employees on medical matters and support the fleet when there are medical incidents onboard.

To help prevent health risks and promote physical activity among our employees, we provide a gym and pool area at our headquarters. We also have two in-house trainers who design tailor-made programmes to meet each employee’s personal needs.

During COVID-19 restrictions, our trainers provided outdoor training sessions in a nearby park. Employees were able to use the gym facilities only after booking appointments throughout the day to avoid congestion and ensure compliance with COVID health and safety protocols.

We work with high-quality food service providers that fully meet our standards, enabling us to offer our employees fresh and nutritious food every day.

The Group offers one voluntary medical check-up per year to each employee in Athens.

Additionally, all new employees are provided with a free pre-employment medical examination.

Angelicoussis Group has been working towards the vision of a better and fairer world by supporting the Antonios and Ioannis Angelicoussis Foundation since its establishment in 2013. The Foundation, which shares common values with our Group, was founded with the objective of providing practical assistance and financial support to the community. Its activities are focused on the following four key areas:

• Distribution of food, medicine and other basic goods to various institutions.

• Charitable initiatives aimed at providing shelter to children and adults.

• Financial support to municipalities and public services, enabling them to carry out their own charity programmes.

• Support for the Greek public health system through financial aid to hospitals and associations. In 2021, the Foundation assisted the Ministry of Health with the purchase and quality control of COVID-19 consumables.

• Improvement of school facilities through support for renovation projects.

• Facilitating digitalisation in schools by supplying technological equipment.

• Scholarships to individuals seeking a career in the maritime industry.

• Financial support to NGOs committed to the promotion, development and enhancement of cultural life.

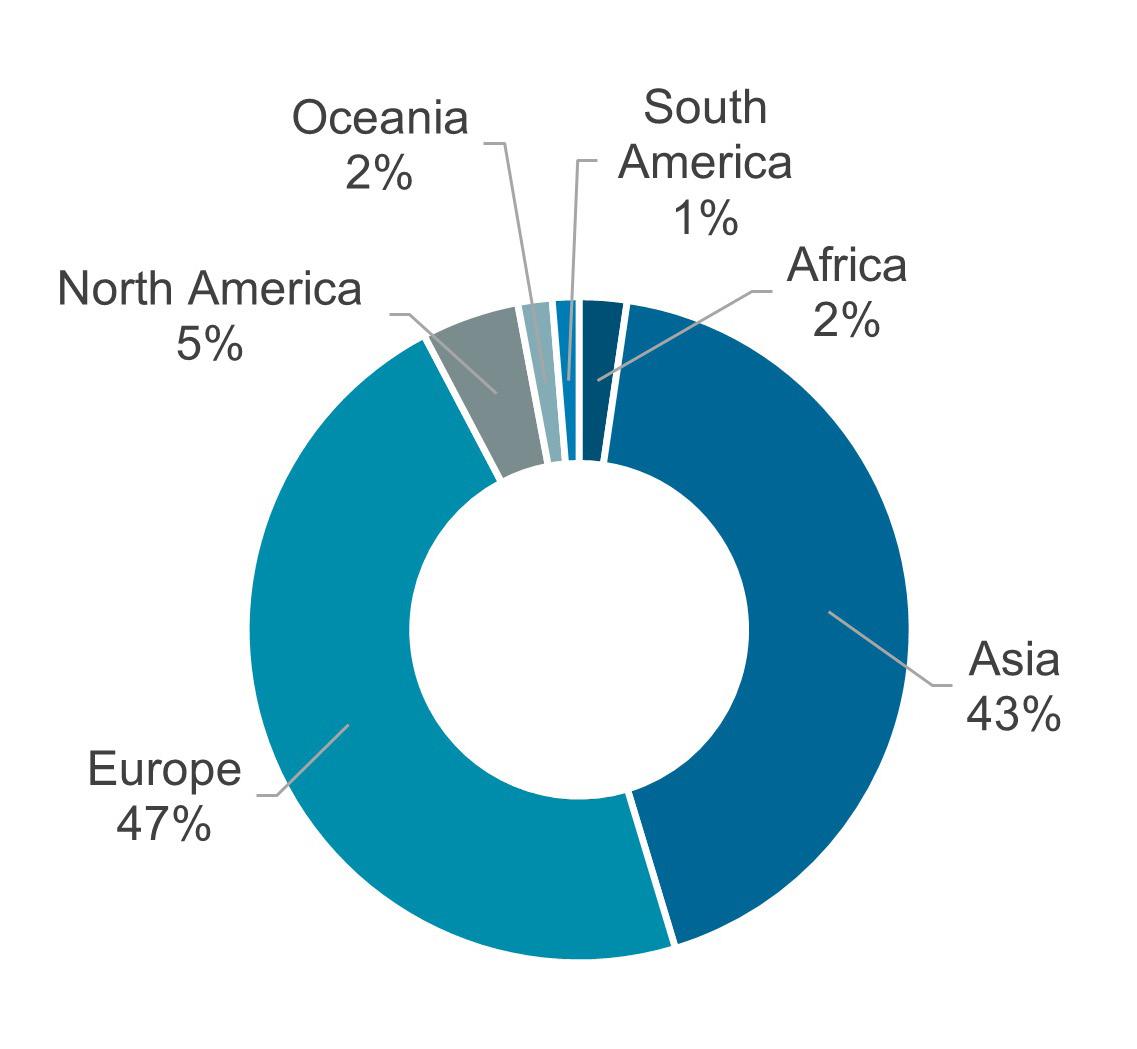

Percentage of funding across our four pillars of community engagement

Financial support was provided to the Greek Guiding Association for the construction of fire safety facilities at the Agia Marina camping site in Nea Makri, Attica, and the construction of two prefabricated buildings. One of these buildings is specifically designed for children with special needs. It is estimated that more than 750 children will be accommodated in the house every year.

At the request of the Evening Vocational High School of Syros, the Foundation approved the donation of a number of Automatic External Defibrillators (AED). The defibrillators were placed in plain sight in public places on the island (beaches, central square, port) with the cooperation of the school and the municipality. These AEDs are easy to operate and have already been used to resuscitate people suffering cardiorespiratory arrest.

A blood donation drive was organised at the Group’s Athens headquarters during the festive season, in which our seafarers were also invited to participate.

All COVID-19 protocols were followed to ensure the health and safety of participants. The initiative proved to be a huge success, with plenty of volunteers stepping up to help the community.

Whenever the need arises, we also arrange blood donations for the families of our seafarers. This reflects the spirit of the Group, which sees its employees as an extended family and is always ready to offer its support to the community.

Responding to the concerns of the world’s governments and societal stakeholders, the imperatives of investing in a sustainable future and reducing our carbon footprint are at the forefront of our business processes globally. The Angelicoussis Group, understanding the importance and complexities of achieving the world’s sustainability ambitions and net-zero GHG goal, has created a dedicated Green Ships Department to lead all energy transition engagements. The Group’s strategy includes new cargo vessels in support of lower-carbon ventures and green energies, the exploration of alternative fuels and energy-efficient technologies, as well as close monitoring of the latest developments in regulations to facilitate the energy transition.

Enhancing our vessels’ efficiency is a key component of the drive towards net zero. We are currently working with shipyards to explore alternative ship designs and technologies, in order to continuously improve our fleet and meet emerging industry requirements. As a Group, we are technology- and fuel-agnostic, and aim to be amongst the early adopters of new technologies once they become commercially available and can be safely used. We are pleased to note that there are quite a few credible options emerging which should allow us to substantially reduce our GHG footprint on a well-to-wake basis in the coming years, subject to a supportive regulatory and economic environment.

Atthispoint,weareassessingthesemultiplepathways towards developing our net-zero strategy, in-cluding LNG, e/bio-LNG, ammonia, on-board carboncapture,e-andbio-methanol,withtheaim

of pursuing the most appropriate options in the future fuel mix. Working closely with our trusted partners, we are currently conducting an in-depth analysis of our projected GHG emissions and GHG intensity. This detailed analysis of each potential net-zero pathway allows us to identify the implications of these choices for the development of our fleet. As part of our fleet renewal programme, the vessels we have on order have shifted from conventionally fuelled ships to those capable of using alternative fuels, including LNG, biomethane and synthetic LNG. Since these zero-carbon alternatives are fully fungible with fossil LNG, they can be introduced gradually in step with increased supply, allowing us to make significant emission reductions on existing vessels without the need for modifications. For our older vessels, biofuels are being tested with the aim of providing flexibility to our fuelling options and reducing emissions.

As LNG is a clean-burning fuel which offers an immediate reduction of our GHG footprint, we believe it has an important role to play in our energy transition. However, we acknowledge the importance of keeping adequate control of our methane emissions across the entire value chain. For this reason, we have become a founding member of the recently launched ‘Methane Abatement in Maritime Innovation Initiative’, which is aimed at reducing methane slip from ship engines and accelerating a roll-out of methane measurement and control technologies. In terms of long-term alternative fuelling options, the Group is currently evaluating newly developed fuels to determine their suitability and assess the potential supply volumes that will be available over time. The relative cost of different fuel pathways and how these could evolve as the technology is scaled up are important factors we are considering with our fuel supply chain partners.

The financial impact of decarbonisation will be substantial, and our resources need to be directed prudently. We see an increasing realisation that cross-industry partnerships will be required to progress the development of new fuel systems, run pilots, plan and implement infrastructure in ports around the world. We are supportive of ‘Green Corridor’ initiatives as we believe they will stimulate the initial use of new fuels and kick-start infrastructure development in some key ports, initiating the S-curve roll-out of new technologies. However, it should be acknowledged that it will be more difficult to enlist ships engaged in tramping service in such early implementation projects. Nevertheless, we endeavour to go beyond IMO requirements wherever it is technically and economically feasible and the regulatory framework allows.

Ultimately, our goal is to achieve net-zero GHG operations and we are currently plotting a realistic pathway to deliver this target. But how quickly we attain it is dependent on external factors too.

The international shipping industry is closely following discussions at the IMO, anticipating a revision of the initial GHG strategy and the development of Market-Based Mechanisms to support the transition to net zero. Indeed, a stable longterm global regulatory framework will be essential to foster investments in vessels capable of running on zero-carbon fuels and provide some certainty to manufacturers of such fuels that there will be a growing demand for their products. It needs to be recognised that very substantial investments in these fuels will be necessary – in terms of both capacity and infrastructure – in order to achieve the IMO’s long-term objectives. We support the efforts of national and international shipping trade associations to engage with regulators to help them arrive at sound and effective regulations that will bring the clarity needed for their enforcement at a global level. The alternative of a patchwork of different regional regulations would only add complexity and risk dilution of efforts towards the overall decarbonisation goal.

We are contributing directly to the decarbonisation process through our active participation in a number of global fora and initiatives. Amongst the many considerations on the table concerning GHG regulations, I would like to highlight just a few which we consider important to enable us to progress on our collective pathway to net-zero operations:

- IMO GHG measures will need to be based on well-to-wake emissions;

- A carbon pricing mechanism is required, either through a global fuel standard, a carbon levy, or a balanced combination of both;

- Any GHG fuel standard should have a gradually increasing level of ambition coupled with fleet pooling incentives; this would provide a strong stimulus for early movers toward zero-carbon fuels;

- If a carbon levy is introduced, it should be at a level commensurate with what is imposed in other industries in different regions around the world;

- The reality of the relationship between shipowners and charterers should be recognised in the design of regulations.

The challenge of reaching net zero has set a sustainable foundation which has prompted the growth and development of innovative solutions, tested and advanced our capabilities, and spurred us to find alternative sources and solutions to drive the energy transition and meet growing energy demands. In all these endeavours, we are committed to observing the highest safety and environmental standards. With our actions we aim to respond to the needs and expectations of our stakeholders, of governments and of society at large. We truly believe this is key to maintaining our ’license to operate‘ and will provide a solid basis on which to grow and prosper in an increasingly complex world.

Stelios Troulis Director of Energy Transition & Sustainability

We aim to constantly improve energy efficiency across our fleet, with the twofold target of reducing fuel consumption costs and minimising the GHG impact of our business operations.

Αngelicoussis Group continually invests in both technical and operational advances in energy efficiency, including optimisation of the fleet’s energy performance through constant monitoring, evaluation and follow-up, an ambitious fleet renewal programme to introduce modern, more efficient ships, and the retrofitting of existing vessels with energy-saving devices and other new technologies.

How vessels are operated has a dramatic impact on fuel consumption. Optimising fleet efficiency through careful planning and monitoring ensures lower emissions from our ships across all stages of a voyage.

All our vessels are monitored by fully automated data collection and vessel performance platforms. These analyse data from multiple sources, including onboard sensors and weather and environmental information from satellite services, while also comparing real-time vessel performance against parameters established during vessel sea trials and engine factory testing.

This focus on monitoring and benchmarking performance enables us to identify areas where energy consumption and GHG emissions can be further minimised. It also allows us to implement a range of improvement measures including hull fouling management, auxiliary load optimisation, vessel trim, speed, weather routing and optimal cargo heating.

Frequent vessel maintenance to ensure vessel and machinery optimisation.

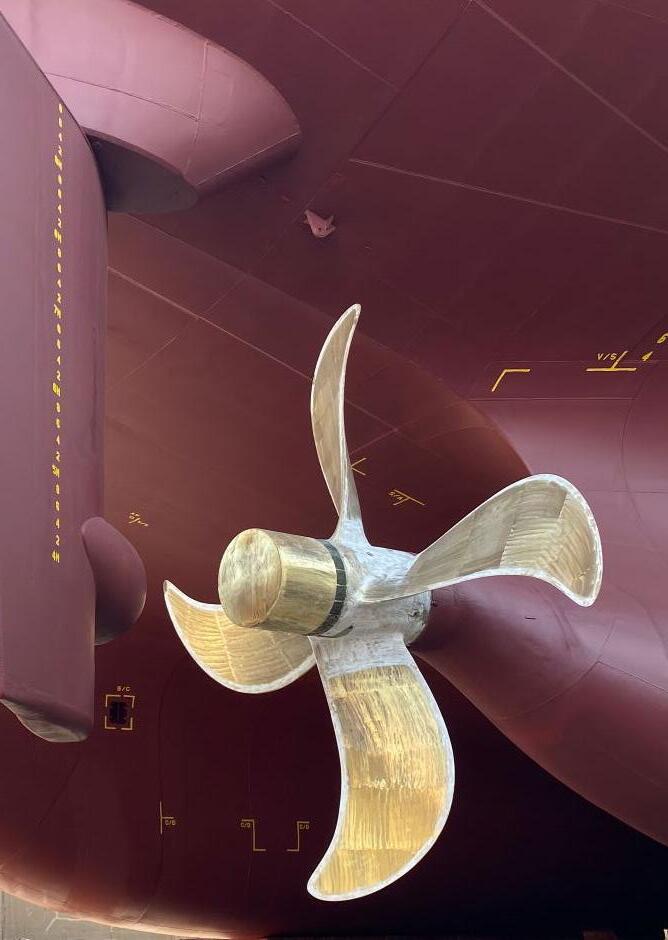

Careful selection of antifouling paints and the scheduling of hull and propeller cleaning in the framework of regular drydock inspections.

Analysis of vessel emission and carbonintensity performance to ensure compliance and identify potential for further optimisation.

Improvement of sailing efficiency through real-time analysis to minimise engine speed fluctuations.

Optimisation of vessel trim using machine learning algorithms.

Regular monitoring of electrical load to enhance diesel generator efficiency.

Minimizing of excess CO₂ emissions and thus fuel consumption, through continuous monitoring of hull, propeller and engine performance, while ensuring optimal fleet operation through propeller polishing, hull cleaning and use of diesel generators and boilers.

Implementation of optimum gas management and modern containment systems to reduce the boil-off rate significantly below normal level. A novel air lubrication system was installed onboard an LNG carrier. The system was put in operation, tested and the expected savings were confirmed.

Minimizing of excess CO₂ emissions and thus fuel consumption, through continuous monitoring of hull, propeller and engine performance, while ensuring optimal fleet operation through propeller polishing, hull cleaning and optimal use of engines.

When designing our newbuildings or modernising our current fleet, we consider the very latest innovations and technologies. In order to keep abreast of technological advances and regulatory developments, we constantly engage with a wide range of stakeholders in the industry, including shipyards, makers, classification societies and other institutions, to explore new ideas and practices which improve the efficiency of new and existing ships.

We ensure all vessels reach the highest standards of fuel efficiency and performance by installing technologies and making design modifications that reduce our fuel consumption and GHG emissions. By maintaining a highly efficient fleet, we are able to reduce the costs associated with fuel use and invest more in innovative technologies with greater potential to mitigate our carbon footprint.

Vessel Technologies

•Utilisation of waste heat from exhaust gas

• Use of shaft generators to reduce reliance on less efficient auxiliary engines to produce electricity

•Air lubrication systems to enhance propulsion efficiency

•Retrofitting of energy-saving devices such as wake equalising ducts and propeller hub caps to reduce fuel use

•Trialling of innovative technologies such as wind-assisted propulsion for future fuel savings

•Installation of effective scrubbers and Variable Frequency Drives (VFDs) to improve fleet efficiency

•Close monitoring of developments in carbon capture onboard

Hydrodynamics

Measures to reduce excess fuel use due to hull resistance, including:

•Innovative hull and propeller design on newbuildings

• Frequent hull inspections and propeller polishing

•Use of advanced anti- fouling paints to prevent marine growth

• Trim optimisation for improved hull performance

Vessel Fuels

•Dual-fuel engines using LNG as a marine fuel will cut emissions from the vessels in the Group's orderbook

Fleet Energy Consumption refers to the total energy consumed during the reporting year which is directly linked to the fuel consumed onboard and the corresponding CO2 emitted which is the numerator of the IMO’s Carbon Intensity Indicator - AER.

Transport work refers to the product of total miles travelled by the vessel during the reporting year and her scantling deadweight. The DWT-mile metric is defined as the denominator of the IMO’s Carbon Intensity Indicator - AER.

Angelicoussis Group recognises the importance of decarbonising its fleet and reducing overall GHG emissions across its activities. We are committed to adopting and enacting an ambitious emissions reduction strategy that goes beyond the regulatory requirements of the IMO’s 2050 target.

Greenhouse Gas (GHG) emissions generated by our vessels are regularly monitored by a fully automated system. All necessary actions are taken to ensure minimum emissions, which includes limiting the use of aerosols.

Appropriate preventive measures and corrective actions are promptly taken to maintain a high level of

• Several vessels in our fleet use LNG as fuel, which generates less carbon emissions than other conventional fuels.

• We ensure that a high standard of energy efficiency is maintained during vessel operation, which also contributes to minimising carbon dioxide emissions.

• A major proportion of our fleet is equipped with Exhaust Gas Cleaning Systems, while the use of LNG as a fuel also reduces PM emissions.

fleet performance and energy efficiency. Frequent inspections are conducted to ensure the proper maintenance and efficient operation of all vessels.

In addition, office and shipboard personnel receive targeted training to ensure the most efficient operation of vessels and their machinery in order to achieve minimum energy consumption.

• Several vessels in our fleet operate on LNG, which does not produce significant levels of sulphur oxides (SOx).