Lisa Morris, Vice President of Supply Chain at Virgin Galactic on the supply chain strategies behind offering unforgettable experiences and cutting-edge research opportunities in the commercial space flight industry

JUNE EDITION also in this edition RHI Magnesita | Mammoth Freighters | MBI Brands | Imperial Brands

Stay ahead of the curve with the go to digital platform for senior supply chain executives.

Exclusive interviews with industry leaders

latest

Join our community

Captivating features on the

supply chain trends The industry events you simply can’t miss

FROM THE EDITOR

Welcome to the June 2024 edition of CHAIN Magazine!

e’re bringing you five exclusive interviews this month, together with the latest global supply chain news and features.

Let’s collaborate…

For our cover interview this month, I speak to Lisa Morris, Vice President of Supply Chain at Virgin Galactic about the supply chain strategies behind offering unforgettable experiences and cutting-edge research opportunities in the commercial space flight industry (

CHAIN is a specialist technology platform with over 211,300+ readers.

Marc Jaegers, Global Logistics Technology and Innovation Manager and Daniel Prutti, Head of Global Logistics, Planning and Procurement at RHI Magnesita join me to dive into the company’s global logistics transformation – exploring the values, strategies, technologies and partnerships that made it possible (

Our community consists of C, V and D level executives from a wide range of industries. A unique blend of thought leadership interviews and features that cover digital transformation, supply chain, procurement, logistics, technology, AI and sustainability.

I sit down with Karl Waggoner, Director of Supply Chain and Logistics at Mammoth Freighters to discuss the company’s strategy for streamlining logistical processes within the passengerp48

I chat with Fergus Byrne, Vice President of Procurement and Culinary at MBI Brands about the company’s community-focused approach to customer service, menu innovations and the importance of building strong relationships in the supply chain (p66

Vasco Lemos, Head of Global Logistics at Imperial Brands, divulges how the company is embracing new products and overhauling its supply chain strategy to drive transformation during a time of significant change in the tobacco industry ( ).

Our features this month cover choosing the right warehouse management system ( driving sustainable transformation in the supply chain (

We are thrilled to welcome David Girolami, former Vice President of Supply Chain at Interface Systems and Director of Operations at Deutsche Bank, as the guest in our spotlight feature

Please enjoy our latest edition. As always, if you would like to be considered as an interviewee or you have a story for us to include, please do get in touch.

editorial@ithink.media connect with me on LinkedIn.

+44

enquiries@ithink.media All rights reserved. Every effort is made to ensure the accuracy of material published in CHAIN Magazine. However, the company cannot accept responsibility for the claims made by advertisers or contributors, or inaccurate material supplied by advertisers. CHAIN magazine is a product of iThink Media Ltd. Company Registration Number: 10933897. Company Registered in England

(0) 203 890 1189

Digital Magazine Website Newsletters Demand Generation Whitepapers & Research Reports Webinars - Hosting & Promotion Find out more Team up with CHAIN and build media programs that deliver.

6

Lisa Morris on the supply chain strategy and innovation behind Virgin Galactic’s cutting-edge offerings in the commercial space flight industry 30

Marc Jaegers and Daniel Prutti share insights into RHI Magnesita’s journey to overhaul its global logistics operation

48 Karl Waggoner discusses Mammoth Freighters’ nimble approach to streamlining logistical processes within the passenger-to-freighter space

66 Fergus Byrne on MBI Brands’ relationship-driven approach to supply chain success 118 In the company of… David Girolami

Guide: how to choose the right warehouse management system

Vasco Lemos celebrates Imperial Brands’ approach to transforming its supply chain during a time of significant change in the tobacco industry

Five ways to improve sustainability in your supply chain

4 JUNE 2024

90

98

108

5 48 6 30

118 108

Vasco Lemos

90

Lisa Morris

66

Fergus Byrne

98

Karl Waggoner

David Girolami

Lisa Morris, Vice President of Supply Chain at Virgin Galactic on the supply chain strategies behind offering unforgettable experiences and cutting-edge research opportunities in the commercial space flight industry.

COVER STORY

Virgin AEROSPACE COMPANY VIRGIN GALACTIC, FOUNDED BY SIR RICHARD BRANSON IN 2004, LAUNCHED THE WORLD’S FIRST COMMERCIAL SPACE FLIGHT ON JUNE 29, 2023.

he company pioneers human spaceflight for private individuals and researchers with its advanced air and space vehicles. The goal? Developing a spaceflight system designed to connect the world to the wonder and awe created by space travel and to offer customers a transformative experience.

Striving towards the betterment of Earth and space exploration, Virgin Galactic’s vehicles serve as suborbital space labs for governments, commercial industry and researchers to test innovations in microgravity and conduct experiments. The company’s reusable piloted vehicles

WATCH THE STORY OF VIRGIN GALACTIC

are designed for humans and research payloads to ascend to space on affordable, frequent and safe suborbital spaceflights.

Lisa Morris, Vice President of Supply Chain at Virgin Galactic joins us today to share her insights into the supply chain strategy behind the company’s mission to pioneer research endeavours and forge unforgettable experiences for its private customers.

Launching our conversation, Lisa begins by explaining that Virgin Galactic sells experiences, not space vehicles. As such, the organisation’s supply chain gravitates around building and operating vehicles to enable research and commercial space flight ventures for the long haul.

“When we look at our supply chain, we are balancing providing out-ofthis-world customer experiences

8

Virgin Galactic

9

Photo by Monica Stanley Photography

alongside ground-breaking research opportunities,” says Lisa. “So when we build out the supply chain that's associated with these two priorities, you can imagine the complexity that comes with it. We must consider more than just being the original equipment manufacturer (OEM) and building the vehicles – we must also consider our maintenance, repair and operations (MRO). There are also many related considerations like managing ground support vehicles, hospitality provision and other customer experience dynamics. At Virgin Galactic, these diverse pieces of the procurement puzzle and supply chain come together in one, rather than just being focused on the aerospace case alone.

“It's exciting from the supply chain standpoint because we get into many different commodities that you wouldn't expect in a standard aerospace environment, which I’m thrilled to be a part of and continue to be excited about. My overall responsibilities include sourcing, procurement, planning, logistics, fleet management – it’s pretty expansive from a supply chain perspective.”

Given the dynamic nature of the supply chain at Virgin Galactic, Lisa explains how a crucial part of her role is staying on top of the latest industry trends to keep the company at the leading edge of the space tourism industry.

“We’re listening to cutting-edge research that's out there,” says Lisa. “I

do a lot of reading in several industry journals, whether that's specifics on raw materials or what's happening from a geopolitical standpoint. But as a company, we also look at ancillary industries. For example, in the medical industry, there are interesting discussions about CT scanning and imaging tools for diagnosing the human body, which could one day be relevant to us. We consider how these emerging technologies might benefit our own operations.

“So it's not just about focusing on the aerospace industry but looking laterally at some of these growing technologies that we may be able to use in different fashions as we're

10

trying to create this new environment with a space vehicle.

“Beyond the research, I'm very selective and purposeful about the conferences, gatherings and events that I go to. Who are the speakers in attendance? Are we looking for specific suppliers, certain technologies or realms of expertise? Will these events offer salient conversations with those industry leaders to help us guide our future and our strategy?

“Industry research and events help us understand the art of the possible. But there must be a balance between exploring new and exciting technologies, while being mindful

of risk and respecting the proven precedents in the aerospace industry.”

So how do Lisa and her team adapt their strategies to lean into the opportunities and obstacles of a complex supply chain at Virgin Galactic?

“The first step to understanding our supply chain strategy is to look at where we came from,” begins Lisa. “We've got a rich history of success with 11 successful space flights and more than a decade of experience under our belts. So we are a startup, but certainly not brand new to the scene. When I joined Virgin Galactic, I kept these dynamics in mind but looked at the bigger picture from a supply chain standpoint. I asked how do we take something that we've been able to demonstrate and do effectively, but then productionise it?

“It started with breaking down the strategy for how we approach the supply chain, evaluating our entire thought process. Our technology is built on the shoulders of giants and you can see it in the Virgin Galactic DNA – starting with Icarus and his father Daedalus, all the way through the space programmes in the 1960s, to what we're doing today. Due to this legacy, we do not have to do everything internally or from the ground up for the first time. How can we take advantage of the infrastructure of experience that's been in the aerospace community for more than 100 years? How can we bring in relevant experts and listen to them?

11

HUMBLE BEGINNINGS TO SUPERCHARGED UNITED CNC MACHINING

Celebrating 45 years of singlegeneration excellence, United CNC has become a leading preferred partner for high-precision critical airborne components for the aerospace, space and defence industries. Founded in 1979 by the current owner, Glenn Charest, there were no computers, no cell phones and no CNC. Digital Readouts were all the rage, while NC was just around the corner!

In the beginning, with only one 1948 Bridgeport Mill, Glenn Charest handcranked out small tools and gauges for the local Detroit auto industry. The first DRO’s for his Vintage Bridgeport were earned by performing DRO installations at night for a local distributor. For every 4 installations, Charest was given one for free! Soon United had 6 Bridgeports with DROs and was considered the “high tech” of Mom and Pop shops.

IT’S A VERY EXCITING TIME FOR VIRGIN GALACTIC Background photo from press.virgingalactic.com

SUPERCHARGED 5-AXIS SHOP

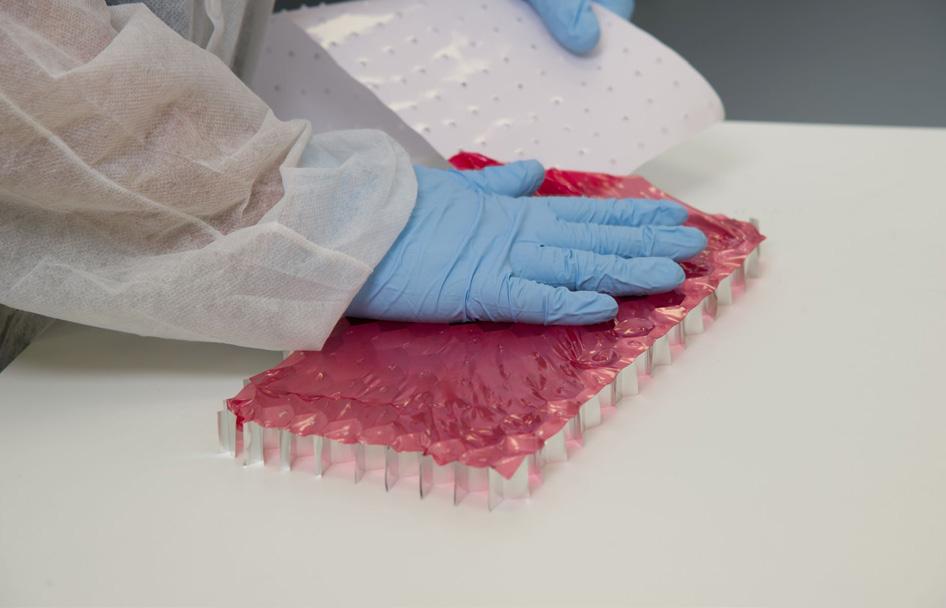

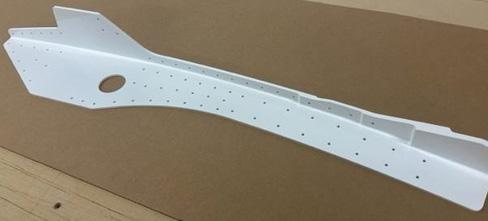

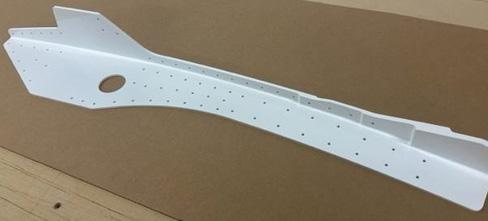

45 years have seen an amazing company transformation to what is now a premier 5-axis machining source, where the most difficult of airborne components has become daily routine. Now supercharged with more than 50 work centres, 10 CMMs and many lasers, United CNC has become the leading choice of such unique manufacturers as Virgin Galactic. Whether prototype or limited production, United CNCs customers are the most demanding, with very challenging GDT, ultra-high precision tolerances and extremely fine micro finishes. Recently, United developed a much-coveted process which yields sub4 ra micro finishes! For this, Virgin Galactic is the perfect fit for United CNC.

“Many times, one of our valued customers may be struggling with a tough part,” says Glenn. “This is when we are called in. With our unique culture, we take the near impossible and make it an everyday job. Whether high nickel exotic alloys or geometry that seems impossible, that’s what we look for, the jobs others walk away from.”

United CNC credits its success to the excellence of a refined culture. Their meticulous plant is much like a laboratory with its cleanliness and organisation. Their one-of-a-kind facility, designed by Charest,

boasts tonnes of natural light with many large windows and skylights. Although quality is built into each product starting at Engineered Op 10, all is confirmed in the 1500 Sq Ft Inspection Lab which is situated on a separately designed 30” thick floating foundation apart from the earth and the building itself. This lab can detect 10X closer than the given tolerance. Equipment is replaced so regularly, everything is like new and they can keep up with the latest and greatest of technologies. United is now a complete probing shop where the use of a traditional indicator is rare.

“We are a tight team of 45, where everyone has signed a pledge of transparency and commitment to helping each other,” says Glenn. “Everyone cares, and our customers know it! I can’t remember our last defective part escape. Our team is so transparent, it just doesn’t get out the door. We keep hearing how everyone is challenged when finding skilled help. Thanks to our culture, we do not struggle when finding or training new team members.”

Since the COVID-19 pandemic, United CNC has joined the Space Race with great success. Whether it’s colonising Mars someday or providing exciting tourism like Virgin Galactic does, we find this industry fascinating and our customers are very serious about getting vehicles safely into space and back, so our latest mission statement says it all:

“Committed to Total Transparency and Absolute Safety”

Virgin Galactic has great plans for growth in the space tourism business, and we are extremely proud to be their strategic partner for the critical parts they require, which will guarantee 100% safe flights.

GALACTIC AND UNITED CNC MACHINING.

“WE ARE DEVELOPING WAYS TO DESIGN IN A MODEL-BASED

ENVIRONMENT, UTILISING TOOLS WITH THAT DIGITAL THREAD FRONT AND CENTRE TO FOSTER COLLABORATION”

“As such we're capitalising on suppliers that have existing infrastructure and listening to their input very early in the design phases of our next fleet. We've been able to incorporate them in the end-toend process, gaining feedback and important information that can help us develop the best system and truly productionise it.

“For instance, one of the topics I’m referring to here is manufacturability. How can we produce a vehicle that can be maintained in a much more efficient manner so that we can be turning round our vehicles in days rather than months? Can we better utilise those vehicles for the long haul? So when we think about our next generation fleet, the Delta class spaceships, while they're a progression from where we've come it is in an iterative sense. The

14

15

supply chain strategy and innovation behind the iterations allow us to take things to the next level with a better producible product, a factory that can output multiple spaceships in a given year and a vehicle with a turnaround measured in days, not weeks or months. Through our innovation and iteration, we will be able to provide an opportunity for future astronauts to literally go up on a daily basis.”

For Lisa and her team, technology and partnerships are crucial enablers for the success of the supply chain strategy at Virgin Galactic. These factors are fundamentally important to the company’s vision of making space more accessible and pioneering suborbital research – but also for taking Virgin Galactic forward, with exciting prospects

on the horizon such as the Delta class vehicles and a new spaceship manufacturing facility in Arizona.

“When we think about our tools from a technology standpoint, we're leaning heavily into the digital thread,” says Lisa. “We are developing ways to design in a model-based environment, utilising tools with that digital thread front and centre to foster collaboration. During the design process, we connect with our suppliers, enabling them to see those models as they're being developed to influence our decision-making in aspects like material selection, placement of components and so on.

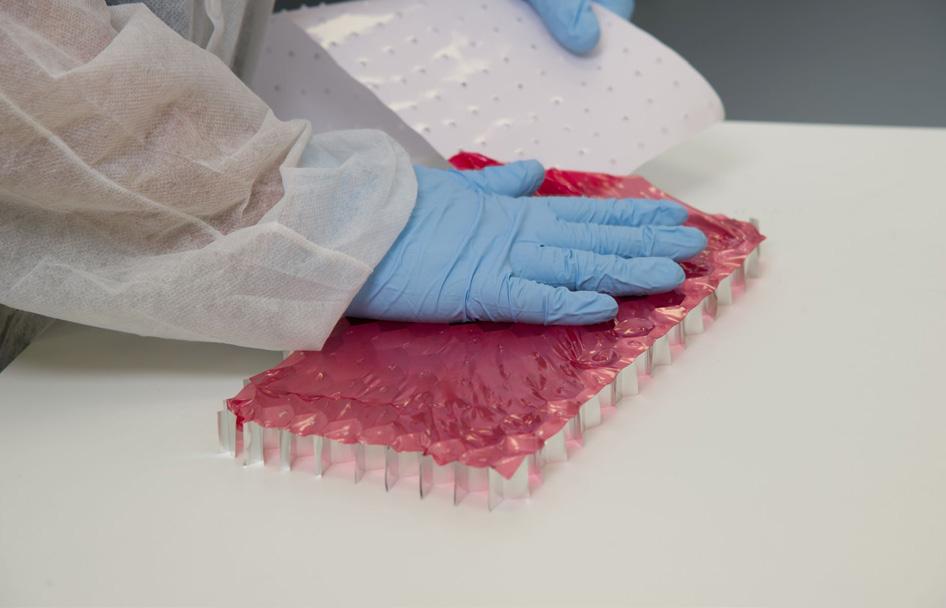

“Another crucial aspect of our supply chain strategy focuses on automation technology. Here, it's all about precision and we aren't automating

16

for the sake of automating. We are looking at some of our suppliers and their capabilities for machining, striving for near-determinate assembly. Again, this is connected to our ability to produce our vehicles in a reliable and repeatable fashion. Automation allows us to lay up our composite structures before doing the final machining so that the assembly can be done in a much more refined and consistent manner.”

On the topic of bringing in technology partners, Lisa explains how a robust ecosystem of trusted partnerships helps Virgin Galactic thrive as a business and bolsters its supply chain.

“First, and foremost, it's about risk management,” says Lisa. “We value working with partners who can help

us see around the corners and predict where we may have issues. When setting up our systems, we want to be as agile as possible and adjust to those predictions proactively. A good example of that is working with machine shops that are building some of our mechanical assemblies. How are they sourcing raw materials and looking at market conditions and lead times? For us, we look for clear communication on these fundamental topics and a relationship built on trust where we receive this information to ensure the efficiency and reliability of our processes.

“In building those relationships with a supplier, we are bringing that information to our designers to inform their decisions about material selections and manufacturing

17

FirstKem Soars Beyond Expectations with Chemicals and Consumables Approach

FirstKem, a leading chemical and consumables company, has been revolutionising the industry since its inception in 2017. Founded by Mario Catalano, FirstKem aims to provide exceptional customer service, reliable support, and unparalleled industry knowledge to its clients in the aerospace, military and industrial sectors.

With a focus on reviving and fostering fresh ideas in the business world, FirstKem has quickly made a name for itself by going above and beyond for its customers. As a result, the company has experienced exponential growth over the past six years, adding major manufacturers like 3M Aerospace, AeroWipe, AkzoNobel, Castrol, CAIG, Polyken/Patco, PPG and Syn-Tech to its extensive repertoire.

However, what truly sets FirstKem apart is its mission to provide an experience rather than just a transaction.

In an industry that often prioritises efficiency over personal connection, FirstKem places an emphasis on responsiveness and strategy tailored to their customers’ unique needs. Their team is passionately dedicated to customer success and takes great pride in ensuring every opportunity is handled with care.

With strategic locations in the USA, UK, and Singapore, FirstKem boasts a global reach, ready to support the consumable requirements of clients worldwide. As the cornerstone of their business, service lies at the heart of everything they do. Their key objective is to save customers time and money by stocking the right products at the optimal price. Regardless of the size project, FirstKem understands that ‘aircraft need to fly!’ and is committed to supporting their clients needs.

FirstKem is not content with simply offering industry-mainstay products. They go the extra mile by providing value-added services such as:

• Exclusive Distributor of AeroWipe

• Custom Kitting

• Chemical Paint and Repackaging

• Composite Film Converting

• Custom Tape Slitting and Converting

• Clean Room and Walk-in Freezer Storage

• Advanced Technical Support and Specification Cross-Referencing

with Revolutionary

“Regardless

of the size project, FirstKem understands that ‘aircraft need to fly!’ and is committed to supporting their clients needs”

FirstKem’s success can be attributed to their unwavering commitment to exceeding customer satisfaction, through an extensive product lineup, staying ahead of industry trends and providing Superior Solutions. By constantly expanding their offering and ensuring their customers have access to the latest and greatest aerospace and industrial products, FirstKem can provide a one-stop solution for all their clients’ needs.

As the company continues to grow at a fervent rate, FirstKem remains focused on delivering exceptional service and fostering strong relationships with their customers. With a team of industry experts who are always ready to go the extra mile, FirstKem is poised to become the industry standard for chemical and consumable procurement experience.

Contact us today for more information at Solutions@FirstKem.com

firstkem.com

processes. For instance, the end goal might relate to choosing a composite or a metal, considering their merits in terms of performance and weight, which is a high-end decision point in the world of aerospace. But by trusting our partners and embracing the risk management side of the equation, we can make informed decisions like these with the longevity and success of our programme in mind.

“We strive to build close relationships as an OEM and a customer when we engage with our partners. What we want to do is make sure that we're a customer of choice. Our volumes are low, so we've got to build those close relationships and carefully select partners and suppliers that share our dream. We seek partners who want to be a part of what we're doing in our mission to make space accessible for everyone and to be able to have on-demand research opportunities in space.

20

“The other piece of that is to watch our peer communities to see what they're learning and doing. I say peer communities and not competitors, because that's a really good way to think of it. Our model for what Virgin Galactic is doing in space varies very much from some of the other commercial companies out there. There's an opportunity to learn from each other and how we are all approaching problems or addressing technology concerns. We feel that

“AS WE CONTINUE TO EXPAND OUR FLEET, WE WILL ALSO CONTINUE TO SEEK OUT SUPPLIERS WHO WANT TO ENGAGE WITH US IN BUILDING FOR THE FUTURE AND FOLLOWING OUR MISSION”

success alongside those other entities comes together for the benefit of all involved. The goal is to foster an open environment where we can have an exchange of ideas for a better outcome altogether.”

Turning our attention to the future of Virgin Galactic, Lisa shares her insights from the supply chain side of the business into the company’s next-generation Delta class vehicles and the new spaceship production facility in Arizona where the final assembly of these vehicles will take place.

The Delta class spaceship is Virgin Galactic’s latest production vehicle that is designed to fly two to three times per week, supporting the company’s target of 400 flights per year from Spaceport America. Based on current schedules, the first of these ships is expected to commence flight test in late 2025, progressing to revenue-generating flights in 2026.

21

“For us, it's about looking at the total cost analysis and understanding the lifecycle of what we're building,” explains Lisa. “It's about understanding what we've done successfully and iterating from these foundations. We look at how we are engaging in our advanced technology development, alongside optimising proven technologies that are already out there.

“With the Delta class vehicles, we are looking to optimise for maintainability and longevity, with the ability to turn them around in a timely fashion. Ideally, we're looking for systems that are going to reflect the total lifecycle of the new vehicles. If we were building the Delta class vehicles to ship them out as a product, we would have to consider the aftermarket space as well.

“But with our business model, we are the aftermarket space and we ultimately operate our own vehicles – so we must consider the longevity of the Delta class vehicles when we make decisions with our suppliers or how we incorporate technology. We're striving for very tight tolerances and high-end quality outcomes for our mechanical systems and composite materials because we want them to last the same lifecycle as that vehicle. This

is the biggest advance between what we're flying today successfully and what we're going to be flying in the future.

“By building the Delta class vehicles with longevity, quality and maintainability in mind, we are working towards the ultimate final outputs of creating incredible research opportunities and customer experiences.”

Alongside deploying the new Delta class vehicles this year, Virgin Galactic is also opening a new spaceship manufacturing facility to produce them. Located in Mesa in the Greater Phoenix area, adjacent to the PhoenixMesa Gateway Airport, the facility will bring highly skilled aerospace engineering and manufacturing jobs to the area.

“We're thrilled to be opening the new facility in Phoenix,” says Lisa. “The facility is sized to be able to build upwards of six spacecraft in a given

22

C A R E E R

W I T H U S

The Structures Company - your trusted aerospace staffing partner

We are a leading engineering and technical staffing agency specialising in the aerospace industry. We assist talented aerospace, engineering and technical professionals nationwide in discovering premier career opportunities and engaging projects within the industry.

At The Structures Company, we pride ourselves on our deep understanding of our clients’ needs and what top-tier talent seeks in their next opportunity. This insight allows us to forge connections between employers and candidates with the technical qualifications, cultural alignment and potential to bring significant value.

The Structures Company handles talent sourcing and screening, presenting you with only the most qualified and aligned professionals. We find, attract and screen the best people so you can focus on other priorities.

By fostering enduring partnerships and offering strategic solutions, The Structures Company is a highly sought-after resource for organisations grappling with immediate and long-term technical staffing challenges

ctures Company facilitated my n with an excellent company that perfectly aligns with my skill set, resulting in a swift and seamless hiring process. I would highly recommend their services.”

Partnering with The Structures Company means being paired with a recruiter specialising in your field

Our primary focus is to connect skilled individuals with exceptional opportunities.

While we have a national presence, connecting talented individuals, our hallmark is personalized attention, ensuring you can effectively reach your goals.

Together, we will map out a path for career success as you define it.

By enhancing your team with our skilled professionals, you can meet project demands with ease and gain access to elusive technical expertise, thereby boosting your project's success

Whether the project requires a single expert for a fixed period or a full team, our recruiters match clients with talent whose skills, experience, values and priorities align with the project.

Our team is fluent in your needs and will support you every step of the way.

24

Welcome onboard, John!

Contact us by scanning the QR code, or visit: www thestructurescompany com

E L E V A T E

Y O U R

“WE ALL BELIEVE IN WHAT WE'RE DOING AND MAKING THE SEEMINGLY IMPOSSIBLE A REALITY FOR EVERYONE”

year and we cannot wait to open our doors later this year.”

Beyond these two exciting developments, Lisa adds that fleet expansion and seeking new suppliers will be essential to the future of Virgin Galactic from the supply chain side of the business.

“As we continue to expand our fleet, we will also continue to seek out suppliers who want to engage with us in building for the future and following our mission,” says Lisa. “As we learn from the Delta class test flights and start putting them into operation, it will be a question of nurturing our partnership ecosystem, building new relationships and developing our hardware and operations.

“We'll continue to partner with those suppliers that can help us build on what we have from the design perspective, working with companies that have either cutting-edge technology or highend quality output offerings, and who

are as excited as we are to look for iterative improvements – whether that is generated by weight savings or an ability to offer new and advanced technology to researchers.

“In the coming years, we will be asking how do we capitalise on those types of innovative offerings in our future. And what does that mean for the supply chain? Where can we explore feedback from our researchers? How can we expand the fleet and our operations even more while taking a look at future international opportunities?”

Wrapping up our conversation, Lisa rounds off the discussion by highlighting the major achievements at Virgin Galactic in recent years.

“Virgin Galactic has been able to achieve some tremendous milestones

25

as a company, and the effect that we've had on our customers and astronauts has been profound,” beams Lisa. “We've had 11 space flights thus far and we've just

completed our sixth and seventh commercial spaceflights.

“We are breaking down barriers and when we say ‘Space for All’

Erik Bond +1 (818) 636-7207 Bond@spinimaging.com 1379 Obispo Ave. Long Beach Ca, 90804 spinimaging.com PAINTLESS AVIATION LIVERY COMMERCIAL - GENERAL - LARGE SCALE - SPECIALTY

as a business, we mean it – and our efforts towards inclusion are phenomenal.

“From sending the first astronauts from countries like Antigua, that have never been to space, to sending the first Olympian and second person with Parkinson’s disease, we are helping people to realise that profound childhood dream of going to space and reaching the stars. One of the achievements which resonates most with me is when we coordinated a galactic flight with the most women flown in a single space mission.

“Before, people saw space as something reserved for the top percentile of the human population. But with our work, that’s not the case anymore.

“It is an honour to be involved with growing our team and bringing talent to Virgin Galactic, seeking people that are also very excited about striving towards that mission – it is something that keeps us going every day.

“Let's face it, getting to space is hard. This is not easy stuff. And we've got some extremely intelligent and talented engineers, technology staff, planners and certainly from my team, experienced professionals in the supply chain that are ready to tackle issues and seize opportunities. We all believe in what we're doing and making the seemingly impossible a reality for everyone.”

For further information about Virgin Galactic, visit virgingalactic.com.

“For me personally, this is a huge driver for why I want to be a part of the experience at Virgin Galactic and see the company succeed because I truly believe in our mission. It doesn't matter how many space flights I've seen, every time I witness it, the phenomenon still gives me the chills. To be able to see the joy on the faces of the individuals who are experiencing it themselves, it’s incredibly touching to see it all unfold and know that my team and I had a part in making it happen.

Turn over for Added Value with Lisa.

27

ADDED VALUE

Connecting with the past to appreciate the present

Lisa has always had a passion for history, and she is particularly interested in the evolution of technology and the impact this has on our lifestyles.

“I’m in that generation where we’re used to having cell phones and being able to communicate at any given moment, but when I grew up there was no such thing,” says Lisa. “Sometimes it’s easy to take the technology available to us for granted and forget what life was like without it.

“If we look at emerging technologies over the last 100 years there are so many inspiring stories to draw strength from. Personally, this resonates with me because it deeply applies to what we’re doing at Virgin Galactic since we’re a product of evolving technologies in the past century.

“Before automobiles were all around us, people believed the ‘horseless carriage’ would never take off since the infrastructure and technology

Lisa has a busy schedule ahead of her for the remainder of 2024 with the supply chain team working full steam ahead on the next-generation Delta class vehicles and opening the new spaceship manufacturing facility in Calendar

“As recently as the 1940s and 1950s, very few people could experience air travel and that was the norm. Now a journey that might have taken days or weeks at sea can be completed in a few hours.

“Expectations change as technology evolves and this inspires me in my role at Virgin Galactic. Looking to the future, we are working towards redefining space travel to become part of everyday human life. Right now, it might be hard to wrap our heads around this prospect. But I find it helpful to look back at history, putting myself in the shoes of those individuals who were part of new waves of technologies which totally changed their outlooks. I get a lot of my inspiration by contemplating the dreams of our forebears and marvelling at how they came to fruition.”

Arizona. However, she is very much looking forward to attending the Aerospace & Defense Manufacturing & R&D Summit hosted by the Marcus Evans Group on June 24-25, 2024 in Westlake Village, California. weren’t widely available. Now we take roads, gas stations and cars for granted.

28

Connect with Lisa

Follow Virgin Galactic:

“I am excited to be attending because Marcus Evans brings together high-level industry leaders and decision-makers, so in terms of the relationships you can forge there, you know you’ll be meeting top-tier suppliers and future partners,” says Lisa.

29

IGNITING TRANSFORMATION AT RHI

BUSINESS INTERVIEW

IGNITING TRANSFORMATION RHI MAGNESITA

Marc Jaegers, Global Logistics Technology and Innovation Manager and Daniel Prutti, Head of Global Logistics, Planning and Procurement at RHI Magnesita share insights into the company’s journey to overhaul its global logistics operations.

GLOBAL SUPPLIER OF HIGH-GRADE

REFRACTORY PRODUCTS, SYSTEMS AND SOLUTIONS WHICH ARE CRITICAL FOR HIGH-TEMPERATURE PROCESSES EXCEEDING 1,200°C

IN A WIDE RANGE OF INDUSTRIES, INCLUDING STEEL, CEMENT, NONFERROUS METALS AND GLASS.

he company strives to leverage its leadership in terms of revenue, scale, product portfolio and diversified geographic presence to target strategically those countries and regions benefitting from more dynamic economic growth prospects.

With a vertically integrated value chain, from raw materials to refractory products and full performance-based solutions, RHI Magnesita serves customers around the world, with around 16,000 employees in 47 main production sites, 8 recycling facilities and more than 70 sales offices.

This vertically integrated value chain not only protects RHI Magnesita from external disruptions – it

provides a resilient foundation for innovation. In recent years RHI Magnesita has embraced a journey of comprehensive global logistics transformation – revolutionising its culture, strategic partnerships, supply chain, procurement, technology and regionalised approach to globalised operations in the process.

Here to walk us through the transformation journey are Marc Jaegers, Global Logistics Technology and Innovation Manager and Daniel Prutti, Head of Global Logistics, Planning and Procurement at RHI Magnesita.

Marc and Daniel set the scene for the company’s transformative journey by rewinding to 2017, when RHI AG merged with Magnesita, based in Brazil. The combination

32

MAGNESITA

RHI

IS THE LEADING

of two world-leading refractory companies catalysed a need for a comprehensive global logistics transformation at the newly formed RHI Magnesita.

Daniel has been with RHI AG and RHI Magnesita for a total of 12 years, and in the last two he has headed its global logistics team – which started with just three people, but has now upscaled its capabilities tremendously by appointing internal talents to key roles as well as hiring external ocean trade experts. This growth reflects the company’s

burgeoning focus and attention on global logistics. In April 2024, this global logistics team merged with the procurement department –bringing planning, logistics, supply chain and procurement under one banner.

Marc joined RHI Magnesita in 2019 and his background is in logistics, technology and consulting. Marc thrives on creating road maps to bring value to a company, and he saw a tremendous opportunity for comprehensive change – driven by technology, expertise and strategic

33

overhaul – when he joined the business.

So what were the values underpinning the strategic roadmap for RHI Magnesita’s transformative journey?

The process began with a period of self-reflection and mindset change, according to Daniel.

“Our first conclusion was that, as a world-leading refractory company, our success depends on global logistics – but we are not a freight forwarding company,” says Daniel. “This realisation led us to identify a need for choice and value. Therefore, our first objective was strategic alliances: finding the right partners who could work with us long term.

“Closely related to this was the second objective, where we began the process of overhauling our partner performance analysis and management.

“The third objective within the global logistics transformation hinged on process excellence. Because many of our competitors are regional or even local players, we recognised this gave them a degree of agility based on proximity as we initiated the self-reflection stage of the transformation. We wanted to match this agility and responsiveness by developing our process excellence and joining this endeavour to the first objective of wielding strategic partners. As a vertically integrated company, one of our key strengths is we are now able to orchestrate globally but execute regionally and locally.

“The final piece of the puzzle in those early days, when we prepared to embark on our transformation journey, was the establishment of a strong relationship with asset owners. If you look at the ocean market these days, the asset owners (ocean lines) have an incredible command of the freight industry. If you consider the dozens of freight forwarders offering freight services, in reality, they are all beholden to a small handful of major ocean asset owners.

34

“WE KNEW WE NEEDED TO HAVE THE RIGHT TECHNOLOGY IN PLACE FOR US TO SUPPORT ALL THE CHANGES THAT WE WANTED TO ENACT”

Marc Jaegers, Global Logistics Technology & Innovation Manager

“Once we realised this, we changed our approach radically and sought to deal with the ocean lines directly, as much as possible, to enhance our freight network and bring in new concepts to transform our operations and thrive as a business. In 2021, only 5% of our business was contracted with ocean asset owners. Now, in 2024, that number is closer to 50%.”

Once these priorities had been identified, RHI Magnesita turned its attention to the technology and strategies which would enable progress towards them. However, as Marc notes, while there were IT components to the transformation – it was not a purely IT project. Instead, it had to be a businessdriven rather than an IT-driven initiative.

“We knew we needed to have the right technology in place for us to support all the changes that we wanted to enact,” says Marc. “But the momentum for the project stemmed from the business organisation and not

the IT organisation alone. While we of course aligned closely with the IT department along the way, we built a comprehensive change management support mechanism around the project, drawn from stakeholders in multiple teams across the company, to enable the deep, meaningful transformation and the new ways of working we were striving towards.”

How did Marc, Daniel and the global logistics team tie the transformation into broader corporate strategies and start bringing in the new technologies to enable it?

“When we started this project, we considered how can we ensure that we support the company in various areas but also align the transformation with broader corporate strategies,” explains Marc. “One of the drivers at the corporate level was we wanted to avoid what we call ‘value leakage’ from the business.

“One example is in transportation management. If you have limited

35

control over your transportation management, you can end up spending money where you don't want to spend money, for instance, on demurrage costs.

“As such we had to connect the global logistics transformation project to the broader company strategy for facilitating better cost control measures.

“Another contextual factor for the project was the company’s concurrent mindset shift to endto-end value chain thinking, with a strong emphasis on customer centricity.

core component of the global logistics transformation. We have a very complex and expansive supply chain because we move a large part of our goods around the world. But they're ultimately managed and distributed locally. We wanted to ensure that by having the right technology and collaboration platform in place, we could facilitate closer interactions between our global and regional teams. In the process, we have forged a deeper tactical and operational connection between all levels of the company: using the same data on the same platform, seamlessly.”

The need to deploy a new enterprise resource planning (ERP) system, which can be a major disruptive experience for companies, added extra impetus to the global logistics transformation, shares Daniel. However, the success of the transformation project placed RHI Magnesita in a strong position to begin its ERP transition this year, he notes.

“Lastly, the broader corporate strategy for shifting to a more regional and local focus was a

“Most traditional ERP setups are too complex to drive value and benefits,” argues Daniel. “In conjunction, as with many other companies relying on SAP R/3, we knew change was imminent with the transition to S/4HANA. In light of all this, we wanted to mitigate the risks of transformation to a new ERP as much as possible.

36

“WE KNOW THAT INTEGRATED SYSTEMS OFFER ADVANTAGES, BUT OUR COMPANY CLEARLY SAID WE ARE NOT AFRAID OF BRINGING IN THE BEST SYSTEMS IN EACH FIELD”

Daniel Prutti, VP - Head of Global Logistics, Planning and Procurement

“We asked ourselves how we could offset the risk of such a big programme, and it became clear that we needed to deploy the changes related to our transportation, foreign trade,

logistics transformation and technology up-scaling first.”

Elaborating on the role of technology upscaling within the transformation journey at RHI Magnesita, Daniel

37

“WHEN WE CONSIDERED WHAT WOULD OFFER US THE BEST OVERALL VALUE CASE FROM A TECHNOLOGY MATURITY LEVEL, ORACLE OFFERED THE BEST SOLUTION”

highlights the need to balance developing integrated systems while recognising where it would be best to outsource technological dynamics or software solutions with strategic partnerships.

“We know that integrated systems offer advantages,” begins Daniel. “But our company clearly said we are not afraid of bringing in the

best systems in each field. With the current state of digitalisation we see today, there are very powerful software solutions and integrator or orchestrator tools available on the market. Also, there comes a point where you need to recognise your strengths as a company and bring in external experts or products to support your operations – so you can focus on what you do best. We

Unlock Growth Potential with Oracle Transportation Management!

Oracle was thrilled to collaborate with RHI Magnesita on their transportation initiative. Together, we're rede�ning logistics processes and delivering a �exible, agile global transport operation.

Customers demand solutions that evolve with their dynamic supply chain needs. That's why we're investing in AI, Machine Learning, Sustainability and Tactical Modeling capabilities. Join us on this transformative journey!

Ready to revolutionise your transportation strategy? Click below to learn more and partner with Oracle today!

Learn more

38

are not a freight company or an IT business, for instance – so therefore we need to find the best solutions to meet our business ambitions. We also realise that as we have digitalised our company, upscaling our own integrated systems and technology solutions, we have become even more attractive as prospective partners in the process. In this way, we can drive down the total cost of ownership because our processes and technology offer mutual benefits of efficiency and effectiveness to both us and our partners.”

Marc weighs in here to emphasise the importance of RHI Magnesita’s approach to partner selection and how the company envisions its technology solutions as a platform for the future.

“When we started the selection process, we did not want to go through a traditional paper-based request for quote (RFQ) process,” explains Marc. “For instance when we sought a new transportation management system (TMS), we spoke to a vast number of relevant vendors, created a shortlist and called a meet and greet session. Here we explained our needs and our guests had the opportunity to explain their solutions and offerings in response. Compared to the paper-based approach, which can be cumbersome, we

quickly identified a shortlist of three leading companies we felt could meet our requirements. Then, we invited all of them to a two-day workshop to meet representatives from the functional areas of RHI Magnesita, who were stakeholders in the new TMS. Following this, the various stakeholders were invited to contribute to the final selection by ranking the tools from their perspective. After embarking on this comprehensive selection process, we concluded that Oracle offered the best overall value for the company to become our new TMS provider.

“Our assessment at the time was that, first of all, Oracle was very clear about what they could offer us from day one. Second, we also felt that Oracle had a deep understanding of what our company needed. Lastly, when we considered what would offer us the best overall value case from a technology maturity level, Oracle offered the best solution.”

Daniel adds that Oracle’s focus on best practices related to cloud technology and the support from their knowledgeable sales representatives were clear differentiators which set them apart from the other candidates in the selection process. But Daniel also stresses it took working with the right implementation partner to make deploying the new TMS system from Oracle an even greater success. This

39

is where Tata Consultancy Services (TCS) stepped in to assist with the process.

“Our initial implementation partner in the TMS project was very strong and created a comprehensive solution for land freight, but the journey towards a scalable ocean freight product was taking too long and at certain key moments we lacked the internal knowledge to implement effectively,” says Daniel. “We needed fresh wind in our sails. We took our problem statement to the market and asked a simple question: how would you help us solve this situation?

“After engaging with several vendors, the speed and the innovative thinking TCS brought to the table was outstanding. They came in with the best resources from a range of backgrounds and disciplines from all over the world to help us. And it wasn’t just the speed of TCS that was remarkable, but also the accountability they took from day one which was really impressive. They analysed the problems we presented to them, came back with solution proposals and once we decided on a course of action, they went after it 100%. They have forged a place as one of our key partners for digitalisation.”

Speaking about the partnership from the TCS side, Brian Popoff, Managing Partner, Supply Chain

Consulting, adds “TCS brought both functional knowledge of ocean transportation and the technical expertise of OTM to RHI Magnesita to create a modular and scalable global template. This effort was complemented by RHI Magnesita’s in-depth business and SAP knowledge coupled with their very collaborative and transparent way of working on complex programmes such as this.”

Turning to the concept of technology as a platform for the future, Marc continues with the example of RHI Magnesita’s strategic partnership with Oracle as their TMS solution provider.

“From the outset, we knew we wanted to develop long-term, multiyear partnerships as part of our global logistics transformation and for the company’s benefit more broadly,” explains Marc. “We saw value in developing our technology solutions as a platform for the future, a foundation we could build on in the years ahead and take in multiple directions if we needed to. For instance, we see our TMS as a core component of our management activities. We had already connected additional functionality elements to our TMS such as real-time visibility, diversion tracking and specific marine traffic monitoring tools. But we know that in the future we might want to connect more functionality dynamics into it, such

40

“AFTER ENGAGING WITH SEVERAL VENDORS, THE SPEED AND THE INNOVATIVE THINKING TCS BROUGHT TO THE TABLE WAS OUTSTANDING”

as 4PL, machine learning and AI. Any solutions we bring in have to integrate backwards with our ERP environment as well. Or, if we place certain aspects of logistics under different management, we want to be able to connect the systems seamlessly. This is why we conceptualise our technology as a platform, not a standalone tool, so we can evolve and adapt in the years ahead.”

Deploying technology solutions as a platform for the future requires holistic support from the right partners, Daniel reiterates.

“We have learned throughout this transformation journey that we don't need to do this all by ourselves,” says Daniel. “We place trust in external partnerships and alliances as we have seen the tremendous

Our multi-model transportation management solutions can help shippers manage logistics processes reliably and efficiently

TCS provides tailored solutions for all transportation modes that provide seamless execution and visibility of shipments, globally. These solutions provide optimal planning and utilisation of freight volumes and capacity that can result in substantial cost savings. Our in-depth knowledge of logistics processes, expertise in Oracle Transportation Management®, and years of transportation domain experience are key factors for an innovative and cost-optimising solution

Contact us austria.info@tcs.com to learn what we can do to meet your logistics management needs

benefits of these co-development arrangements firsthand since 2020. If you look externally, there are helping hands available to support you from companies that have already been through what you’re looking to achieve. We have grown considerably in our approach to partnerships and alliances by putting smart architecture, consistent analysis and robust performance management mechanisms in place.”

Here Marc emphasises that the transformation programme underway at RHI Magnesita is a multi-year, long-term project.

“While we have a clear vision of where we are going, we must also be careful not to try and realise it prematurely because the company might not be ready for it,” says Marc. “It is a process of reaching milestones and progressing along the journey intelligently, reflectively and intentionally.”

As with any long-term project though, broader company buy-in is crucial. Daniel and Marc agree that the organisational support and company culture at RHI Magnesita have been essential to the success of the global logistics transformation project.

shift behaviour, before looking at processes and then finally technology. In the case of the transformation project at RHI Magnesita, the preliminary behavioural change goal was to create a company culture driven by “customer obsession,” as Marc puts it. But without the organisational support behind him, Daniel and their team – it would not have been possible.

For Daniel, there were four main ways the organisational structure and company culture supported their mission.

When it comes to change management, Marc insists that the first step of the journey is to

“First, we started the transformation with the global process owner model, but more importantly in 2021,

42

we spent extensive time clarifying people’s roles within the process,” says Daniel. “Even though it’s super bureaucratic, it is fundamental to document responsibilities and accountabilities.

“Second, we enshrine diversity within our company culture at RHI Magnesita because it fosters vibrant innovation. In our global logistics teams, 40% are female leaders and we have 10 nationalities represented in a team of less than 20 colleagues. Third, we secured companywide support by bringing in experienced change managers from within the business, with a track record for successful projects, to elevate the endeavour and support us almost as ‘transformation cheerleaders.’

“Lastly, in a large global company of more than 16,000 employees, we could not have done this without the patience and support from the very top. Our executive team trusted us to guide the company through this transformation and we are incredibly grateful to them, and our team, for making it possible.”

So what have been the tangible outcomes of the global logistics transformation at RHI Magnesita?

“If you look at the business case, we have over-achieved on our savings commitment,” says Daniel. “Our freight rates have returned to relatively normal levels, within the post-COVID-19 context and with market adjustments in mind. We have also made efficiency gains especially when it comes to how we deal with our customers. To share a demonstrative example here, when the Ever Given blocked the Suez Canal in 2021, it took us two or three weeks to assess the situation and relay the projected impact to our customers. Compare this to the Houthi attacks on commercial vessels in the Red Sea at the end of 2023, we were able to share impact assessments with our customers in 24 hours and share further insights and predictions within three working days.

“Another huge victory for us tied to the global logistics transformation project is we opened a container

43

“WE STILL HAVE A WAY TO GO, BUT OUR GOAL IS TO PROVIDE AUTOMATIC INSIGHTS WHILE ALSO PROVIDING OUR CUSTOMERS WITH SELF-SERVICE”

depot with a rail connection in 2023. In my early years at the company, this would have been inconceivable. But now we believe in such ambitious goals as a company – the sky is the limit.”

Looking ahead to the future and the next steps of the transformation journey, Marc adds that several new initiatives are on the horizon in the next few years.

“We will continue to strive for better organisation of our logistics networks with even more control and visibility with technology,” says Marc. “In the near term, our roadmap focuses more directly on customers. We are looking to enhance our engagement with them with more direct notifications, so we can proactively inform them as early as possible to avoid surprises. We are exploring ways to tailor our services to the

44

customer depending on where they sit in the value chain. Lastly, as a company, we want to make meaningful contributions in terms of our sustainability. As such we are working to reduce our carbon footprint but also designing carbonneutral services for our customers, with detailed insights into emissions so they can have a better overall experience with us.”

For Daniel, a major aspiration is to build a self-service model for RHI Magnesita’s customers.

“We still have a way to go, but our goal is to provide automatic insights while also providing our customers with self-service,” says Daniel. “As it stands, we have built the foundation so our customer service representatives can provide these insights. One thing we must consider as a business is we make

deals and enter negotiations onsite, not via auctions or online tools. In a sense, we still operate commercially in a more traditional environment. But we still want to incorporate digital processes and technology where we can and ultimately work towards self-service.

“Part of this will be to wield data even better and we’re doing a lot of testing on this front. At the moment the insights are focused towards our internal commercial management teams, which they then take to the customer. The next step will be to replicate the immediate access to information we have in our private lives and make that the status quo for our customers, so they have the best experience possible.”

For further information about RHI Magnesita, visit rhimagnesita.com

46

ADDED VALUE

Team effort

Daniel and Marc laud the collaboration, courage, creativity and conviction it took to embark on the global logistics transformation. They both express deep gratitude to the executives, senior leaders and members of the multiple teams involved at the company for delivering such an expansive transformation project.

“I am particularly proud of Marc, he lived the transformation and channelled the customer obsession as a project manager and he never lost sight of the final destination,” says Daniel.

Marc responds in kind, celebrating Daniel’s management and leadership style. “Under Daniel’s leadership, the global logistics team has been able to thrive because he offers the luxury of space, trust and time to guide the journey forward. Our executive team and Daniel as the Head of the Global Logistics Team have been willing to invest the time and resources to make such an enormous and ambitious project possible. It has been key to the success of the transformation.”

Daniel

Daniel likes to share a quote from Aristotle Onassis: “We must free ourselves of the hope that the sea will ever rest. We must learn to sail in high winds.”

For Daniel, this sentiment is particularly pertinent to the maritime industry and global logistics more broadly.

“The disruptions during COVID-19, for instance, were crazy,” says Daniel. “Costs went up as a result of a spike in demand after a huge drop and operations had to change drastically. But from my perspective, you cannot let yourself become nervous, panicked or overwhelmed.

“Throughout our transformation, I have been tremendously proud of our team and how they remained calm during the ups and downs, creating the psychological conditions needed to navigate the journey. We have created a cultural environment where we understand that failure is not final, and this mindset is essential when you embark on transformation.”

Marc

Marc enjoys staying in touch with the industry by educating and immersing himself in the latest innovations.

“I like to read up on new developments and consider how they might inform our roadmaps for the future,” says Marc. “I dive into a range of topics, like machine learning, artificial intelligence and virtual reality. I explore these subjects through trade magazines, conferences and discussions with colleagues to share information in diverse fields. It is particularly fascinating to see where other companies and your peers are in their journey, while seeking to understand their line of thinking. I think of it as a cross-pollination of ideas.”

MAMMOTH FREIGHTERS’ APPROACH TO MANAGEMENT

BUSINESS INTERVIEW

MANAGEMENT

FREIGHTERS’ NIMBLE TO SUPPLY CHAIN

IN THE P2F MARKET

Karl Waggoner, Director of Supply Chain and Logistics at Mammoth Freighters on the company’s strategy for streamlining logistical processes within the aerospace industry.

49

Launched in 2020, Mammoth Freighters was formed with the goal of taking Boeing 777 passenger aircraft that had reached the end of their commercial life and converting them into cargo freighters, keeping the planes useful for longer and helping to make the market more economical and sustainable.

peaking to us today is Karl Waggoner, Director of Supply Chain and Logistics for Mammoth Freighters, responsible for planning, logistics and procurement within the company. He discusses the complexity of procurement within the requirements of the aerospace sector and the systems Mammoth Freighters has put in place to streamline logistical processes.

Currently, the company is focusing on building its FAA supplemental type certificate (STC) aircraft in

preparation for entry into service (EIS).

“Mammoth Freighters operates in the passenger to freighter (P2F) space,” says Karl. “When an aircraft reaches the end of its service life as a passenger aircraft, carriers will often want to convert them into freighters. It’s a way to keep the plane useful without companies having to buy an entirely new aircraft purely for cargo purposes. It’s a more economical process, and less wasteful.

“Currently, we’ve placed ourselves in the Boeing 777 widebody freighter market. We convert two versions of the 777 – the 200 long range (LR) and the 300 extended range (ER). Our initial aircraft was the 200LR, and we’re the only company currently converting that model. It has a little more range because it’s a smaller aircraft, but Boeing made significantly more of the 300ER so there’s a larger market opportunity for us. The 300ER is perfect for volumetric cargo as it’s the longest aeroplane Boeing produces, while the 200LR is better for more dense cargo configurations over longer ranges. They both fit a niche, and there’s a lot of demand in the market for these models. We have 39 current orders, and we continue to book slots into the future.”

However, while the company converts specific models of aircraft, the freighters it converts can be used for a variety of cargo, as Mammoth Freighters can provide specialised transportation configurations.

“Our aircraft can be whatever the buyer wants to use it for,” says Karl. “We’ve had some interesting use cases, such as horses being transported for a race. Live cargo is a different kettle of fish, but we can offer different options for cargo handling systems. We try to work with our customers to design or

engineer specific elements they may need.”

Converting commercial planes into freighters can be logistically challenging, and Karl’s role as Director of Supply Chain and Logistics has involved stabilising, standardising and strengthening supply chain processes and functions.

“There’s more complexity in aerospace requirements than with some manufacturing sectors, and more rigour applied,” says Karl. “We’re proud of aviation’s operational record. This requires you have to have Federal Aviation

52

Administration (FAA) oversight on all certified parts, from a safety and conformance perspective. Another difficulty is that while Boeing builds the aircraft we use to basic configurations, there can be variation even within a minor model, which we have to take into account when modifying the aircraft.”

As with many companies, COVID-19 has also made supply chain processes more challenging for Mammoth Freighters.

“COVID-19 really threw a wrench into the supply chain from a raw materials standpoint,” says Karl.

“Working with so many highly specialised parts can be a logistical challenge, so Mammoth Freighters has developed a streamlined approach”

“All materials we use depend on the size of the aircraft, loading conditions, the model and more. So every part requires a different set of approaches from sourcing to bringing it on dock and then installing it on the aircraft. If there are shortages, it can be very detrimental across the entire value chain.

“To operate successfully within these circumstances and within the strict parameters of aerospace regulations, Mammoth Freighters doesn’t operate in large volumes, like, say, an automotive manufacturer might, but instead has turned its focus to ensuring every step of its supply chain operations is done accurately and successfully – from the sourcing of raw materials in its freighters’ components to building relationships with new suppliers.

“We have a supply base set-up and development process,” says Karl. “If

53

54

a supplier isn’t currently on our approved list, we have a quality survey that we complete with the prospective supplier to secure an overview of their facility, their capabilities and their capacity. As the supplier demonstrates consistent performance, we work with them to expand their role.

“We tend to seek out mediumsized suppliers that can respond nimbly in the developmental phase, but also ramp up production rates when needed. Some of our kits require hundreds of parts and are very process-centric – which involves a lot of expertise, machinery and coordination.”

Working with so many highly specialised parts can be a logistical challenge, so Mammoth Freighters has developed a streamlined approach to keep operations running smoothly.

“We use our enterprise resource planning (ERP) system to track our inventory and maintain our certifications and traceability for all parts,” says Karl. “Having this knowledge is extremely important. If there are any issues later on, we need to know where that part came from, and what

55

MILCOM AEROSTRUCTURES

CONSORTIUM

MilCom Aerostructures Consortium is providing novel solutions for the aerospace and defence industries. We bring decades of aerospace supply chain experience for the commercial, military, airframe, and space programmes.

MilCom’s leadership team has firsthand working experience with Fortune 100 Companies. Our expertise includes managing and interfacing with operations, engineering, quality assurance, and supply chain team leaders.

Our goal is to continuously offer OEM and TIER 1 aerospace manufacturers cost effective solutions at ONE STOP SHOP. Our team includes the following premier aerospace companies:

3D Aerostructures Inc. Oklahoma City, Oklahoma

3D Aerostructures Inc. specialises in precision CNC machining of aluminium and exotic alloys, development, startup programmes, and lights out manufacturing.

Experts with small to large aerospace and aircraft structural parts. Space programmes, commercial, and defence programmes made from composites such as Nomex Honeycomb, Kevlar Honeycomb, Aluminium Honeycomb as well as Titanium, Stainless Steels, Aircraft Grade aluminium materials. We have over 30 years of experience with providing tight tolerances as low as .0001”, true positions, and an understanding of large parts CNC machining. AS9100 certified and ITAR registered utilising industry standard software such as Catia V5 and ICAM to allow smooth hand off of data from our customers to minimise data translation concerns.

3D Aerostructures Inc. focuses on high quality, low cost and on time CNC machined precision parts. Varying from large structural aerospace components to smaller assembly components with very tight tolerances. Customers are our number one priority!

FMI Aerostructures – Valencia, California

A trusted supply chain partner, FMI Aerostructures manufactures critical structural components and complex assemblies. We understand our customer needs and have minimised risk through the development of capacity, resources, redundant capability and a full service mindset.

• Unique large part capability

• In-house programming

• Tooling design

• Assembly

• Supply chain management

FMI Aerostructures is proud to serve key A&D (Aerospace and Defence) customers including Mammoth Freighters, Lockheed Martin, Northrop Grumman, Boeing Defense and Space, and Blue Origin.

MILCOM AEROSTRUCTURES, COST EFFECTIVE ONE STOP TOTAL SOLUTIONS

Prism Aerospace Inc. Riverside, California

With over four decades of aerospace manufacturing experience, Prism is a leader in aero-structure manufacturing for the military, space, and commercial aerospace customers. Specialising in various types of forming: stretch (extrusion and sheet), hydro, brake, roll, hot forming, machining, sub assembly, kitting, fabrication, tooling and design. All of our equipment can accommodate oversized material to standard envelope sizes. As a AS9100 business, Prism works tirelessly to manufacture first class aerospace products while meeting customer’s stringent quality and delivery requirements.

Regal Technology Partners Santa Ana, California

Regal is a trusted partner for complex electronic systems design and manufacturing solutions. Regal’s experienced team transforms ideas into solutions using adaptive methods and practical mindsets, offering our customers distinct competitive advantages to meet the toughest of industry standards for the success of mission critical applications. Including transition to production, manufacturing services, cable plus wiring harness, and testing.

MilCom quicky discovered that there is POWER AND SYNERGY in teaming together to offer our aerospace customers and OEMS a “ONE STOP SHOP Total Solution” with multiple commodities, technical services and bundled disciplines. This concept has evolved into MilCom Aerostructures Consortium.

We discovered quickly that there is truly strength in numbers. As MilCom Aerostructures Consortium grows, we have selectively aligned ourselves with the strategic consortium team members including 3D Aerostructures, FMI Aerostructures, Prism Aerospace and Regal Partners.

Our team proudly serves our many aerospace customers and we are thrilled to be selected as a partner for Mammoth Freighters.

Shareen Young, Milcom Aerostructures Contact us @ LinkedIn:

Whether it is carrying precious cargo or protecting your country, MilCom Aerostructures Consortium partners can help you solve your most challenging commercial and military aircraft supply chain needs. With our AS9100, ITAR, and quality-driven team let us help meet your needs serving your customers or defending your country. www.milcomaero.com Aerospace Total Global Supply Chain Solutions

“MilCom's consortium group comprising of 3D Aerostructures, FMI Aerostructures and Prism Aerospace, builds critical components for us”

manufacturing lot it was, so we can find out if it’s been used anywhere else.

“We would love to procure products as and when they’re needed, but that isn’t always practical due to the discontinuous nature of lead times on a lot of our parts. Some of the products we use have a long lead time on them, so we’ve built up a safety stock to avoid production shortages.”

Due to recent global disruptions in the supply chain, many of the materials Mammoth Freighters uses have become more challenging to procure. To combat

this, the company has focused on building up key partnerships with industry leaders.

Two partnerships Karl spotlights are MilCom Aerostructures and Collins Aerospace.

“MilCom's consortium group comprising of 3D Aerostructures, FMI Aerostructures and Prism Aerospace, builds critical components for us,” says Karl. “Most importantly, the large skins for reinforcements around the cargo door openings. They also build various other parts for us, such as large floor beams, which are twenty-foot-long aluminium beams

59

“We work extensively with Collins Aerospace. They produce piece parts for us, such as machining or metallic parts”

that require specialised machines and controls to keep them from warping over long distances.

“We also work extensively with Collins Aerospace. They produce piece parts for us, such as machining or metallic parts. However, our larger partnership with them is based predominantly on the building of cargo handling systems.”

Within both its partnerships and its operations, Mammoth Freighters makes sure it’s taking the most innovative approach, and Karl believes this innovation is helped by the company’s positioning as a startup and the resilience of its team.

“It’s all new for us,” says Karl. “We have some basic processes in place and we have experienced people within the organisation that bring in techniques from the other places where they’ve worked, but it can be like assembling the bicycle you’re riding on.

“I like to fail fast and then adjust. We don’t have anything sacred, we

just try to keep forward momentum and learn. If it doesn’t work, we’ll examine it and then build on it. Because we’re a smaller company, we like to be agile in the way we approach things, so we don’t overprescribe and prefer to do things at the minimum dose for maximum effectiveness. We don’t want to be wasteful in the way we do things.”

This less wasteful approach extends to Mammoth Freighters’ stance on sustainability as a company.

“One of our core principles is to try to keep our physical distance between suppliers as low as possible,” says Karl. “We might be able to save a few dollars on an item by sourcing it across the globe, but we want to keep our carbon footprint low, so we try to keep things local or domestic. If there are specialised parts that we have to ship internationally, we try to ship them in larger batches to reduce our carbon footprint.

“The interesting thing about my job is that the freighters we’re creating are more fuel efficient and can carry more cargo than

60

When your business is delivering tonnes of cargo around the world, you need three things: speed, efficiency and reliability. Collins Aerospace designs, manufactures and globally supports cargo handling systems that deliver all three. It’s why those systems are on many of the hardest-working wide-body platforms. See what our expertise can do for your operations. Learn more at collinsaerospace.com © 2024 Collins Aerospace MADE TO MOVE YOU FORWARD

previous generations of freighters. As a supply chain professional, it is exciting to supply parts to a product that is actually a link in the supply chain. By ‘upcycling’ an existing airframe we become a more efficient option for helping to transport cargo within the global supply chain more sustainably.”

So, what does the future look like for Mammoth Freighters?

For Karl, it’s all about consistent innovation.

“I have the best job at Mammoth because of the quality of my team. I want us to get into that ‘lather, rinse, repeat’ mode, where we can produce high-quality aircraft quickly and consistently,” says Karl. “As we get the engineering and the kits stabilised, it’ll provide more opportunities for other engineering that we could be doing. More and more aircraft models are coming to the end of their commercial life in the next five to ten years, and we’re exploring starting engineering for them as well. As our orders increase, we’re also considering expansion to other regions for maintenance, repair and overhaul (MRO) capabilities. It’s all about assessing the current market and finding the best opportunities for growth.”

Learn more about Mammoth Freighters visit mammoth777.com.

62

Recommended

“Being able to leverage knowledge is really important to me,” says Karl. “A book I found extremely helpful was Building a Second Brain: A Proven Method to Organise Your Digital Life and Unlock Your Creative Potential by Tiago Forte, which is based on the concept that your mind is made for thinking, not remembering. The author builds on a framework that helps you curate information and keep it at your fingertips to free up the cognitive overhead needed for doing the thinking that you need to operate in an increasingly complex world.

“I was also recently recommended the book Algorithms to Live By: The Computer Science of Human Decisions by Brian Christian and Tom Griffiths, which is a practical application of data analytics in your everyday life. One of the techniques they have in there is about optimising your time. For instance, when looking for a place to live, if you’ve looked at a certain number of houses and you have a frontrunner you probably don’t need to go look at another twenty, maybe two or three to find a good one, because they’re not going to get markedly better as you go on. I love to use maths in everyday life, and this book has been a very useful tool for me.”

Reading Academic achievement

Karl will soon be defending his dissertation for his law and policy doctorate at Northeastern University, which explores how supply chain complexity impacts ESG scoring.

Learn more from Karl

Karl recently featured on The Emoji Chat podcast, available here.

“My friend Roberto R. Bugatto is a successful executive business coach and an expert on neurolinguistic programming,” says Karl. “He invited me onto his podcast to discuss liminal spaces and emotional intelligence, which was a very exciting opportunity.”

Connections encouraged

Karl encourages people in the industry to connect with him on LinkedIn.

“Networking is a wonderful thing,” says Karl. “I’ve been blessed to meet people from all over the world, and everyone I meet has something fascinating to share about them, their background, their life. I love it.”

Connect with Karl

63

64 also in this edition RHI Magnesita | Mammoth Freighters MBI Vice President of Supply Chain at Virgin chain strategies behind offering unforgettable experiences research opportunities in the commercial also in this edition RHI Magnesita | Mammoth Freighters MBI Vice President of Supply Chain at Virgin chain strategies behind offering unforgettable experiences research opportunities in the commercial