MANAGEMENT

Karl Waggoner, Director of Supply Chain and Logistics at Mammoth Freighters on the company’s strategy for streamlining logistical processes within the aerospace industry.

Launched in 2020, Mammoth Freighters was formed with the goal of taking Boeing 777 passenger aircraft that had reached the end of their commercial life and converting them into cargo freighters, keeping the planes useful for longer and helping to make the market more economical and sustainable.

peaking to us today is Karl Waggoner, Director of Supply Chain and Logistics for Mammoth Freighters, responsible for planning, logistics and procurement within the company. He discusses the complexity of procurement within the requirements of the aerospace sector and the systems Mammoth Freighters has put in place to streamline logistical processes.

Currently, the company is focusing on building its FAA supplemental type certificate (STC) aircraft in

preparation for entry into service (EIS).

“Mammoth Freighters operates in the passenger to freighter (P2F) space,” says Karl. “When an aircraft reaches the end of its service life as a passenger aircraft, carriers will often want to convert them into freighters. It’s a way to keep the plane useful without companies having to buy an entirely new aircraft purely for cargo purposes. It’s a more economical process, and less wasteful.

“Currently, we’ve placed ourselves in the Boeing 777 widebody freighter market. We convert two versions of the 777 – the 200 long range (LR) and the 300 extended range (ER). Our initial aircraft was the 200LR, and we’re the only company currently converting that model. It has a little more range because it’s a smaller aircraft, but Boeing made significantly more of the 300ER so there’s a larger market opportunity for us. The 300ER is perfect for volumetric cargo as it’s the longest aeroplane Boeing produces, while the 200LR is better for more dense cargo configurations over longer ranges. They both fit a niche, and there’s a lot of demand in the market for these models. We have 39 current orders, and we continue to book slots into the future.”

However, while the company converts specific models of aircraft, the freighters it converts can be used for a variety of cargo, as Mammoth Freighters can provide specialised transportation configurations.

“Our aircraft can be whatever the buyer wants to use it for,” says Karl. “We’ve had some interesting use cases, such as horses being transported for a race. Live cargo is a different kettle of fish, but we can offer different options for cargo handling systems. We try to work with our customers to design or

engineer specific elements they may need.”

Converting commercial planes into freighters can be logistically challenging, and Karl’s role as Director of Supply Chain and Logistics has involved stabilising, standardising and strengthening supply chain processes and functions.

“There’s more complexity in aerospace requirements than with some manufacturing sectors, and more rigour applied,” says Karl. “We’re proud of aviation’s operational record. This requires you have to have Federal Aviation

Administration (FAA) oversight on all certified parts, from a safety and conformance perspective. Another difficulty is that while Boeing builds the aircraft we use to basic configurations, there can be variation even within a minor model, which we have to take into account when modifying the aircraft.”

As with many companies, COVID-19 has also made supply chain processes more challenging for Mammoth Freighters.

“COVID-19 really threw a wrench into the supply chain from a raw materials standpoint,” says Karl.

“Working with so many highly specialised parts can be a logistical challenge, so Mammoth Freighters has developed a streamlined approach”

“All materials we use depend on the size of the aircraft, loading conditions, the model and more. So every part requires a different set of approaches from sourcing to bringing it on dock and then installing it on the aircraft. If there are shortages, it can be very detrimental across the entire value chain.

“To operate successfully within these circumstances and within the strict parameters of aerospace regulations, Mammoth Freighters doesn’t operate in large volumes, like, say, an automotive manufacturer might, but instead has turned its focus to ensuring every step of its supply chain operations is done accurately and successfully – from the sourcing of raw materials in its freighters’ components to building relationships with new suppliers.

“We have a supply base set-up and development process,” says Karl. “If

a supplier isn’t currently on our approved list, we have a quality survey that we complete with the prospective supplier to secure an overview of their facility, their capabilities and their capacity. As the supplier demonstrates consistent performance, we work with them to expand their role.

“We tend to seek out mediumsized suppliers that can respond nimbly in the developmental phase, but also ramp up production rates when needed. Some of our kits require hundreds of parts and are very process-centric – which involves a lot of expertise, machinery and coordination.”

Working with so many highly specialised parts can be a logistical challenge, so Mammoth Freighters has developed a streamlined approach to keep operations running smoothly.

“We use our enterprise resource planning (ERP) system to track our inventory and maintain our certifications and traceability for all parts,” says Karl. “Having this knowledge is extremely important. If there are any issues later on, we need to know where that part came from, and what

MilCom Aerostructures Consortium is providing novel solutions for the aerospace and defence industries. We bring decades of aerospace supply chain experience for the commercial, military, airframe, and space programmes.

MilCom’s leadership team has firsthand working experience with Fortune 100 Companies. Our expertise includes managing and interfacing with operations, engineering, quality assurance, and supply chain team leaders.

Our goal is to continuously offer OEM and TIER 1 aerospace manufacturers cost effective solutions at ONE STOP SHOP. Our team includes the following premier aerospace companies:

3D Aerostructures Inc. specialises in precision CNC machining of aluminium and exotic alloys, development, startup programmes, and lights out manufacturing.

Experts with small to large aerospace and aircraft structural parts. Space programmes, commercial, and defence programmes made from composites such as Nomex Honeycomb, Kevlar Honeycomb, Aluminium Honeycomb as well as Titanium, Stainless Steels, Aircraft Grade aluminium materials. We have over 30 years of experience with providing tight tolerances as low as .0001”, true positions, and an understanding of large parts CNC machining. AS9100 certified and ITAR registered utilising industry standard software such as Catia V5 and ICAM to allow smooth hand off of data from our customers to minimise data translation concerns.

3D Aerostructures Inc. focuses on high quality, low cost and on time CNC machined precision parts. Varying from large structural aerospace components to smaller assembly components with very tight tolerances. Customers are our number one priority!

A trusted supply chain partner, FMI Aerostructures manufactures critical structural components and complex assemblies. We understand our customer needs and have minimised risk through the development of capacity, resources, redundant capability and a full service mindset.

• Unique large part capability

• In-house programming

• Tooling design

• Assembly

• Supply chain management

FMI Aerostructures is proud to serve key A&D (Aerospace and Defence) customers including Mammoth Freighters, Lockheed Martin, Northrop Grumman, Boeing Defense and Space, and Blue Origin.

With over four decades of aerospace manufacturing experience, Prism is a leader in aero-structure manufacturing for the military, space, and commercial aerospace customers. Specialising in various types of forming: stretch (extrusion and sheet), hydro, brake, roll, hot forming, machining, sub assembly, kitting, fabrication, tooling and design. All of our equipment can accommodate oversized material to standard envelope sizes. As a AS9100 business, Prism works tirelessly to manufacture first class aerospace products while meeting customer’s stringent quality and delivery requirements.

Regal is a trusted partner for complex electronic systems design and manufacturing solutions. Regal’s experienced team transforms ideas into solutions using adaptive methods and practical mindsets, offering our customers distinct competitive advantages to meet the toughest of industry standards for the success of mission critical applications. Including transition to production, manufacturing services, cable plus wiring harness, and testing.

MilCom quicky discovered that there is POWER AND SYNERGY in teaming together to offer our aerospace customers and OEMS a “ONE STOP SHOP Total Solution” with multiple commodities, technical services and bundled disciplines. This concept has evolved into MilCom Aerostructures Consortium.

We discovered quickly that there is truly strength in numbers. As MilCom Aerostructures Consortium grows, we have selectively aligned ourselves with the strategic consortium team members including 3D Aerostructures, FMI Aerostructures, Prism Aerospace and Regal Partners.

Our team proudly serves our many aerospace customers and we are thrilled to be selected as a partner for Mammoth Freighters.

“MilCom's consortium group comprising of 3D Aerostructures, FMI Aerostructures and Prism Aerospace, builds critical components for us”

manufacturing lot it was, so we can find out if it’s been used anywhere else.

“We would love to procure products as and when they’re needed, but that isn’t always practical due to the discontinuous nature of lead times on a lot of our parts. Some of the products we use have a long lead time on them, so we’ve built up a safety stock to avoid production shortages.”

Due to recent global disruptions in the supply chain, many of the materials Mammoth Freighters uses have become more challenging to procure. To combat

this, the company has focused on building up key partnerships with industry leaders.

Two partnerships Karl spotlights are MilCom Aerostructures and Collins Aerospace.

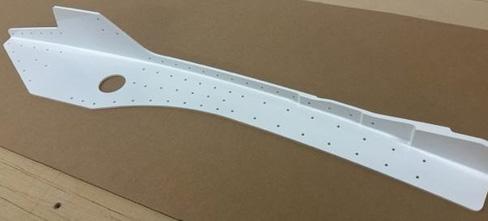

“MilCom's consortium group comprising of 3D Aerostructures, FMI Aerostructures and Prism Aerospace, builds critical components for us,” says Karl. “Most importantly, the large skins for reinforcements around the cargo door openings. They also build various other parts for us, such as large floor beams, which are twenty-foot-long aluminium beams

“We work extensively with Collins Aerospace. They produce piece parts for us, such as machining or metallic parts”

that require specialised machines and controls to keep them from warping over long distances.

“We also work extensively with Collins Aerospace. They produce piece parts for us, such as machining or metallic parts. However, our larger partnership with them is based predominantly on the building of cargo handling systems.”

Within both its partnerships and its operations, Mammoth Freighters makes sure it’s taking the most innovative approach, and Karl believes this innovation is helped by the company’s positioning as a startup and the resilience of its team.

“It’s all new for us,” says Karl. “We have some basic processes in place and we have experienced people within the organisation that bring in techniques from the other places where they’ve worked, but it can be like assembling the bicycle you’re riding on.

“I like to fail fast and then adjust. We don’t have anything sacred, we

just try to keep forward momentum and learn. If it doesn’t work, we’ll examine it and then build on it. Because we’re a smaller company, we like to be agile in the way we approach things, so we don’t overprescribe and prefer to do things at the minimum dose for maximum effectiveness. We don’t want to be wasteful in the way we do things.”

This less wasteful approach extends to Mammoth Freighters’ stance on sustainability as a company.

“One of our core principles is to try to keep our physical distance between suppliers as low as possible,” says Karl. “We might be able to save a few dollars on an item by sourcing it across the globe, but we want to keep our carbon footprint low, so we try to keep things local or domestic. If there are specialised parts that we have to ship internationally, we try to ship them in larger batches to reduce our carbon footprint.

“The interesting thing about my job is that the freighters we’re creating are more fuel efficient and can carry more cargo than

previous generations of freighters. As a supply chain professional, it is exciting to supply parts to a product that is actually a link in the supply chain. By ‘upcycling’ an existing airframe we become a more efficient option for helping to transport cargo within the global supply chain more sustainably.”

So, what does the future look like for Mammoth Freighters?

For Karl, it’s all about consistent innovation.

“I have the best job at Mammoth because of the quality of my team. I want us to get into that ‘lather, rinse, repeat’ mode, where we can produce high-quality aircraft quickly and consistently,” says Karl. “As we get the engineering and the kits stabilised, it’ll provide more opportunities for other engineering that we could be doing. More and more aircraft models are coming to the end of their commercial life in the next five to ten years, and we’re exploring starting engineering for them as well. As our orders increase, we’re also considering expansion to other regions for maintenance, repair and overhaul (MRO) capabilities. It’s all about assessing the current market and finding the best opportunities for growth.”

Learn more about Mammoth Freighters visit mammoth777.com.

“Being able to leverage knowledge is really important to me,” says Karl. “A book I found extremely helpful was Building a Second Brain: A Proven Method to Organise Your Digital Life and Unlock Your Creative Potential by Tiago Forte, which is based on the concept that your mind is made for thinking, not remembering. The author builds on a framework that helps you curate information and keep it at your fingertips to free up the cognitive overhead needed for doing the thinking that you need to operate in an increasingly complex world.

“I was also recently recommended the book Algorithms to Live By: The Computer Science of Human Decisions by Brian Christian and Tom Griffiths, which is a practical application of data analytics in your everyday life. One of the techniques they have in there is about optimising your time. For instance, when looking for a place to live, if you’ve looked at a certain number of houses and you have a frontrunner you probably don’t need to go look at another twenty, maybe two or three to find a good one, because they’re not going to get markedly better as you go on. I love to use maths in everyday life, and this book has been a very useful tool for me.”

Karl will soon be defending his dissertation for his law and policy doctorate at Northeastern University, which explores how supply chain complexity impacts ESG scoring.

Karl recently featured on The Emoji Chat podcast, available here.

“My friend Roberto R. Bugatto is a successful executive business coach and an expert on neurolinguistic programming,” says Karl. “He invited me onto his podcast to discuss liminal spaces and emotional intelligence, which was a very exciting opportunity.”

Karl encourages people in the industry to connect with him on LinkedIn.

“Networking is a wonderful thing,” says Karl. “I’ve been blessed to meet people from all over the world, and everyone I meet has something fascinating to share about them, their background, their life. I love it.”

Connect with Karl