‘A STRATEGIC ASSET’: NUROL MAKINA’S ROBUST

Melik Sevis, Planning and Procurement Director at Nurol Makina (NMS), explores the strategies driving the company’s nimble approach to supply chain sustainability and optimisation in the ever-evolving defence sector.

he company has the production capability to build these armoured vehicles in-house, with the use of tailored equipment substructures.

NMS has secured its position as a 4x4 tactical vehicles segment leader in Turkey – combining design and technology alongside principles of national and international development, social benefits and environmental protections.

For Melik Sevis, Planning and Procurement Director at NMS, the company’s success is a direct result of the work its dedicated employees have put in.

“We are acutely aware of the fact that our strength lies in our family of employees,” says Melik. “Their ability to blend new innovations in the defence sector with our values and history has made the company what it is today, and it’s an approach that has been shaped by over 40 years of engineering experience.”

Melik’s interest in supply chain management stemmed from studying industrial engineering at university, and today, his primary initiative has been integrating the company’s enterprise resource planning (ERP) system with its supply chain process – improving the company’s operational efficiency and decision-making speed.

However, Melik explains that any development in the supply chain has to align with the company’s overall mission.

“Our vision is to fulfil customer expectations globally, with a supply chain structure that efficiently transports goods from the stores to the point of conceptions,” says Melik. “This optimises both time and cost in project requirements.

“The supply chain is constantly evolving on a global scale, and our mission is to maintain a sustainable framework that satisfies the expectations of our stakeholders while continuously evolving alongside our

supply chain, our strategic partners and our solutions.”

Melik stresses that the cornerstone of NMS’s nimble supply chain is a thorough end-to-end strategic approach, where seamless integration and quality permeate the entire operation.

“Our supply chain strategy is designed with end-to-end efficiency in mind,” says Melik. “We take a quality-based approach. We’re not only focused on maximising the benefits of a product, but also the benefits of our supplier and our communications, because it integrates the functions of those related departments interconnected with the supply chain. This establishes a unified and coherent company structure.

“By taking this integrated approach, we can ensure that our supply chain operations are aligned with the main strategic goals of the company. Our priority is enhancing overall efficiency, quality and responsiveness to evolving end-user needs and operational demands.

“This comprehensive approach integrates all phases of the organisation – from day-to-day operations to the overarching strategic initiatives. It’s a holistic strategy, ensuring every element is aligned with NMS’s core objectives. This allows us to ensure that our supply chain is not just a functional aspect of the business, but a strategic asset – allowing us to reinforce our position in the international market. We are always working to guarantee that our supply chain operations are

consistently aligned to support our goals.”

However, especially in such a highstakes industry as the defence sector, there are always risks that can impact the supply chain. Melik emphasises how these potential threats have been major factors in the establishment of NMS’s supply chain strategy.

“When we talk about supply chain, we have to talk about risk,” says Melik. “Life is not a straight line, and we have risks with our supply chain and our ecosystems. You cannot plan anything without factoring in the element of risk.

By defining this risk, and developing a reliable management plan, we can minimise it and plan potential corrective and preventative actions.”

The company classifies its risks into two categories: internal and external.

“The internal analysis framework is rigorously structured around the SWOT technique, which systematically identifies the company's Strengths, Weaknesses, Opportunities, and Threats,” explains Melik. “It’s a rational risk, that we can assess with numbers. Typically, this refers to our substructures, facilities and equipment.

These are manageable risks that are reasonable to define, with a short-term solution.

“External risk is more challenging to reconcile. Every project has its unique external risks, especially when our focus is on tailor-made solutions. On an international scale, we carefully define our risks in the areas of supply chain, transport and, most importantly, lead time and economic factors.

“Ninety per cent of our import and export systems are based on defining external risks and taking the necessary action to minimise them, because you

Melik Sevis, Planning and Procurement Director

cannot manage or plan anything without factoring risk. We’re always going to have risks, but the most important thing is defining them at the right time and having a contingency plan in place.”

NMS’s approach to planning, developed over decades of operation, ensures that any potential risk is identified as early as possible.

“In our planning framework, internal processes are meticulously synchronised, supporting and reinforcing our operational activities,” says Melik. “Decentralised tracking is integral to our strategic planning, and ensures these internal operations are aligned with our overall business objectives.

“This enables a structured, cohesive approach to operational planning – making sure that every aspect is

aligned and consistently monitored for potential risks and inefficiencies. Therefore, by integrating these planning components, we can optimise operational readiness, enhance strategic decision making and maintain a proactive stance when anticipating potential challenges.”

Melik’s journey at NMS is a testament to his belief in continuous improvement and innovation. His leadership in adopting LEAN Manufacturing principles, KAIZEN and 5S methodologies across production and planning processes has fostered a culture of excellence and efficiency. Under his guidance, NMS has achieved remarkable milestones, including significant lead time reductions, cost savings and enhanced production capabilities.

For Melik, this approach is reminiscent of a quote by Abraham Lincoln.

“Abraham Lincoln was quoted as saying ‘Give me six hours to chop down a tree and I will spend the first four sharpening the axe,’” says Melik. “This quote has shaped the way I have approached planning and strategy throughout my entire career, and it’s a key mantra for the way NMS operates.

“At the heart of any proficient supply chain is detailed planning and the strategic utilisation of resources throughout the organisation. Our successful supply chain is contingent on us implementing a proactive strategy from the start of any approach and making sure any plans are dynamic, catering to both immediate and long-term objectives.”

However, while NMS has developed a robust planning strategy, Melik credits the company’s partners as being a key aspect of its efficiency and effectiveness.

“No company can operate in a vacuum,” says Melik. “In today's fastpaced world, staying ahead of new innovations is crucial. Consequently, partnerships and supplier relations are a key focus for us.

“Every one of our strategic partners has a unique approach and an area of expertise that is instrumental for our success. For instance, in our partnership with CM Automotive we’re able to access specialised automotive technologies and innovations, helping us implement more sophisticated solutions in the production process.

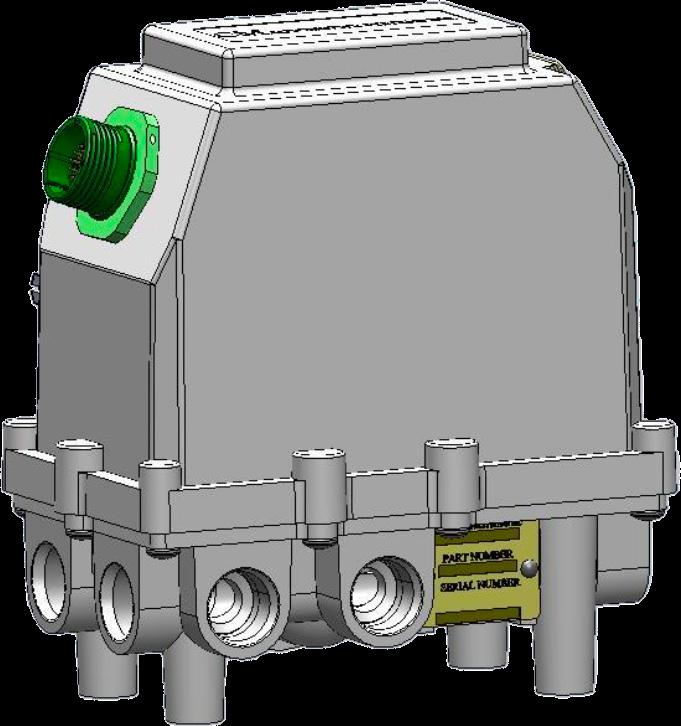

We manufacture and design the best Central Tire Inflation (CTI) systems in the world, with over twenty-five thousand units in the field today across 15 applications. Military trucks, fire engines, tractors and commercial buses have all benefited from deploying our all-terrain mobiliser.

Current challenges in the marketplace and new applications have motivated CM Automotive System Inc. to redesign its CTI system. This new effort will provide a wheel valve to improve the warfighter’s survival when operating a vehicle in the combat zone. The wheel valve isolation feature will shut down and isolate a flat tyre for inflation and deflation. The warfighter can then inflate the remaining tyres to the survival tyre pressure for escape.

Similar design modifications are needed to include other applications. Such applications provide for driving through rivers or saltwater exposure. The manifold and the wheel valve require water-tight assemblies and internal treatment of all surfaces. In a similar application for a 4x4 vehicle, the dash did not have enough room to mount the CTI controller. We replaced our standard controller with a newly designed eight-button switch-pack controller, at approximately half the size.

Moreover, these operating buttons on the switch-pack are large: .908” x.908” and, therefore, can be activated from the cab with the warfighter using arctic gloves. The switch-pack controller is compact, lightweight and has multiple built-in LEDs for each button, indicating the position.

“Our strategic partnerships are crucial for enhancing operational efficiency and leveraging diverse expertise. Another particularly notable partnership has been with Skydex. Skydex facilitates the integration of advanced materials and technologies into new products.

“Their expertise – particularly in the defence industry – enables us to build durable products and rapidly adapt various technological solutions. Because of this collaboration, we’ve

been able to get products to market quicker and strengthen our position in the industry.”

According to Melik, now the company has forged a prominent position in the defence industry, NMS’s natural next step is sustained growth – with plans to expand on a global scale.

“Our headquarters are based in Ankara, but our current focus is on developing our international presence,” says Melik. “We founded NMS UK last

Proudly Partnering with Nurol Makina to Provide our Industry Leading Blast Mitigating Floor Mats.

For

year, and our base in Hungary was founded three years ago. We’re actively expanding our supply chain network in a global arena and strategising our future development.

“These coordinated efforts are pivotal in enhancing the company’s operational reach and establishing a robust, interconnected supply chain. We have our vision, and now we need to nurture that for the decades to come.

“By leveraging the strengths of each location, the company is not just broadening its competition capabilities but reinforcing its market process and responsiveness to regional demands. The strategic integration of these facilities allows us to build a cohesive operational framework, enabling our knowledge to better allocate resources, streamline our supply chain process and enhance the efficiency across borders.

“This expansion is a key component of the company’s long-term vision, aligning our commitment to innovation with the value we place in customer satisfaction. As we move into this new phase, NMS is positioning itself to capitalise on global opportunities, anticipate market trends and respond proactively to the dynamic demands of the industry –ensuring our sustained growth as a competitive player in this sector.”

Learn more at nurolmakina.com.tr/en.

“Every year, I try to be a part of educational programmes, conferences or seminars with my former university,” says Melik. “I’ve been in the student’s position, and I want to try and show them shortcuts and give them some information on what to expect. I’ve worked in supply chain and production for 18 years, so showing people different paths into this industry is a hugely rewarding experience for me.

“When I’m giving these talks, I always try to emphasise the importance of being well-rounded. It’s not just about the knowledge or the expertise you have, but your life experience, your communication skills and your personality. If you’re interested in management positions in this industry, it’s not just about your technical knowledge, but your emotional intelligence as well.”

Connect with Melik

nurolmakina.com.tr/en