Mastering crosschannel logistics post-Brexit

Visibility and traceability in the end-to-end supply chain

The role of digitalisation in creating synergies

Mastering crosschannel logistics post-Brexit

Visibility and traceability in the end-to-end supply chain

The role of digitalisation in creating synergies

he CHAIN team and I are delighted to welcome you to our October edition. We guarantee an action-packed magazine this month with seven exclusive interviews for you! These include talks with Chris Fitzpatrick, Head of Innovation and Technology, at Ardmac (p6); Steinar Tafjord, Supply Chain Director, at Saferoad Group (p34); Joep Kusters, SVP, Head of Europe, at Coyote Logistics (p60); and Florent Bouguin, Chief Technology Officer, at Optel Group (p74). I think you’ll agree that that’s quite an impressive line-up!

Our first interview charts Ardmac’s 45-year journey, earning itself a reputation for exceeding client expectations by driving performance and empowering people. Huge thanks to Chris for sharing his organisation’s story.

Next up is Saferoad Group and an insight into the thinking behind its digitalisation strategy to create synergies across the group. In turn, driving digital transformation will reduce costs and lower CO2 emissions, which is great news from a sustainability perspective.

Coyote Logistics has faced massive challenges in mastering cross-channel shipping post-Brexit. Joep explains how the company has managed to stay strong in the face of adversity.

Plus, we have our report on Optel Group’s successful digitalisation of its entire supply chain from end to end, powered by traceability. Florent highlights three axis of value; sustainability, performance, and compliance.

And that’s not all! We have some fascinating reads on America’s clean energy commitments (p24), supply chain finance (p48), as well as advice on what businesses can do to shockproof their retail supply chains (p66).

Happy reading!

6

Chris Fitzpatrick, Ardmac’s Head of Innovation and Technology, on driving performance, empowering people and delighting clients

24

A report by the US Department of Energy highlighting America’s clean energy strategy

34

Saferoad Group’s ambition to create synergies across the group

48

Exploring the challenges and opportunities in supply chain finance

60

Joep Kusters, SVP, Head of Europe, at Coyote Logistics, explains how companies today are managing cross-channel shipping

66

What can businesses do to shockproof their retail supply chains?

74

We speak to Florent Bouguin, Chief Technology Officer at Optel Group, about digitising the entire supply chain from end to end

80

Orbico Group’s strategic ambition to be the leading logistics provider in Central and Eastern Europe

94

PwC’s Jens Fath and Jasmin Pennicke on prioritising ESG and sustainability

108

We talk digital with Tilo Hergarten, Head of Digitalisation at Emons

Chris Fitzpatrick

Steinar Tafjord

Joep Kusters

Florent Bouguin

Piotr Sedziak

Tilo

Jasmin Pennicke

Chris Fitzpatrick

Steinar Tafjord

Joep Kusters

Florent Bouguin

Piotr Sedziak

Tilo

Jasmin Pennicke

n the 45 years since its inception, Ardmac has earned itself a reputation not just for delivering results, but for exceeding client expectations. This has not gone unnoticed; what was once a small

Irish operation is now the leading provider of high-tech cleanrooms, data centre solutions, fit-outs, specialised refurbishments, and turn-key manufacturing facilities across Europe.

CHRIS FITZPATRICK, Head of Innovation and Technology at Ardmac, charts his company’s digital transformation journey.

CHRIS FITZPATRICK, Head of Innovation and Technology at Ardmac, charts his company’s digital transformation journey.

Group turnover within Ireland alone last year was €75million, while overall turnover was closer to €135million.

The past 12 to 18 months have seen Ardmac complete a whole range of significant projects across Ireland, the UK and Europe; these included a 15,000 square metre cleanroom facility for WuXi Biologics in Dundalk, a large microelectronic project in Kildare, several data centre projects

in Europe, and several high-end commercial fit-outs in Ireland and the UK. Key recent wins have included large pharma facilities in Limerick, Cork and Finland, data centre projects in Denmark, Germany and Austria, and battery facilities in the UK.

Modular construction is fast becoming a key part of the group’s activity. Having already delivered

several such projects across Europe, its first modular project in Africa is on track to be delivered by the end of 2022. So far this year, the company has been working on several large campus sites, securing further phases.

Chris Fitzpatrick joined Ardmac in January 2017 as IT Manager before taking on the role of Head of Innovation and Technology in 2021.

Today, his responsibilities include developing and delivering the company’s technology and innovation strategy and ensuring its platforms are secure and reliable for all staff and clients. In addition to this, Chris believes it is important to keep an eye out for future technologies that could improve the business. He says, “The second arm to my role is around innovation, building and

Eque2’s EVision enterprise level cloud-based construction ERP software is designed to manage the full lifecycle of your construction projects, from initial bid through to site final account.

Built within Microsoft Dynamics 365 Business Central, Eque2 EVision helps enhance the connections between your finance and commercial teams by allowing data to be made easily accessible and understandable across the organisation in real-time –anytime, anywhere, on any device.

Find out more: www.eque2.co.uk

developing a culture of innovation across Ardmac, being able to collect ideas and bring them into our innovation funnel, and developing new ways of working and new business models which can be spread out across the group. It is a very interesting and varied role, with a good level of visibility across the organisation, as well as support from our senior leadership team and board of directors.”

Speaking of Ardmac’s digital transformation journey, Chris

with our requirements to identify a good platform and partner that we believed would bring a lot of value to the organisation.

“Through our ERP replacement program, we were able to replace the legacy platform, and decentralise a lot of the administration and compliance work across the organisation. This was the first major transformation project we did in collaboration with our partner Eque2, moving our financial and commercial teams off

began by developing a strategy to modernise the company’s IT platforms and systems that were in place. He explains, “Our starting point was the back office where we had an existing platform. It was working quite well for the organisation, but it was very labourintensive and paper heavy. Having conducted a thorough review of the business, identifying strengths and weaknesses and pain points of the organisation, we were able to put together a pretty robust business case to move to a new ERP platform. We then approached the market

the legacy system and onto a brand new platform.”

Chris continues, “All the old paperbased processes, such as expenses, timesheets, ordering and receiving of goods, have been migrated onto web-based 24/7 online platforms that are fully integrated. It is a really slick process that has completely streamlined the financial and commercial parts of our organisation. Using our new reporting platform Jet, we have been able to decentralise that work from the finance function and out

“This was the first major transformation project we did in collaboration with our partner Eque2, moving our financial and commercial teams off the legacy system and onto a brand new platform”

into our commercial teams, giving them secure real-time access to the commercial data on their projects quickly and easily. By mirroring all of our existing reports preupgrade, it meant that we didn’t have to retrain people during the cutover.”

At an organisation level, Chris is excited by the move towards modular construction and building off-site. As part of its strategy for the future, Ardmac has now welcomed Cental – a leading and fast-growth provider of advanced modular infrastructure to the data centre, pharma, utilities, and telecoms industries – to the group. Cental’s manufacturing capability will support Ardmac’s ongoing agreement with USbased Germfree Laboratories, to provide prefabricated turnkey modular cleanrooms and biosafety

laboratories to the biopharma and healthcare sectors throughout Europe. It will provide a manufacturing base for all other Ardmac modular solutions under one roof.

Chris enthuses, “We have recently welcomed Cental to the Ardmac Group. It is a fantastic addition and really shows the ambition that exists within Ardmac.”

From a technology perspective, Ardmac works on a three-pillar strategy, which is referred to as working SMART:

1. Driving performance

2. Empowering our people

3. Delighting our customers.

Having these three pillars gives clarity around the outcomes Chris and his team are looking to achieve.

A really important part of Chris’ role is trying to find an answer to ‘What are we doing in the next two to three years, and what do we need to be getting ready for?’

It is Chris’ job to get Ardmac set for the technology that is coming down the line, and understanding and trialling what could work well for Ardmac.

Chris explains, “Can we find new technologies and processes that

All the old paper-based processes, such as expenses, timesheets, ordering and receiving of goods, have been migrated onto web-based 24/7 online platforms that are fully integrated”

CHRIS FITZPATRICK, Head of Innovation and Technology

winning network*

• Ireland’s Fastest 5G Network, 2 Years in a Row

• Ireland’s Fastest Mobile Network, 3 Years in a Row

With mobile plans, broadband and award winning customer care** on an award winning network, you can have it all with Three Business.

*Based on analysis by Ookla®

Intelligence®

for Q3–Q4

Ookla

Three Business Where connections come to life.

used under license

Best

Channels at

of Contact Centre of the Year,

Customer Experience

CCMA (Customer Contact Management Association Awards) in 2021.

will drive performance, empower our people, and delight our customers? 5G is super-important to us. A lot of the tools we have deployed off-site really depend on a strong Wi-Fi connection. It is what people have come to expect these days when they are on construction sites. In terms of rolling out, Three Mobile have been a big supporter of what we have been trying to do over the last couple of years, and are one of our strongest partners.

make Ardmac leaner, safer, and ultimately more productive, with a better return on investment for the organisation.

Chris explains that some processes in the organisation are yet to be digitalised. He says the company has a strong safety-first culture –it’s Ardmac’s number one guiding principle – so it has been reluctant to digitalise processes around safety until the company knows

“Low code is something we are really excited about. We are looking at low-code platforms and being able to develop our own apps. In the past, we would have had to work with vendors to buy software and platforms for processes with varying levels of success. Low-code tools are available now, where we can develop our own processes very quickly. We take a lean and agile approach, where we can refine what we are doing as we work on different projects across the group.”

What’s more, artificial intelligence could play a role in helping to

for certain that these values will be upheld. That said, Ardmac prides itself on its forward-looking strategic approach.

But, is it a challenge to build an innovation mindset into the company culture? Chris answers, “I think one of the biggest challenges we have seen lies in trying to keep the energy levels up around innovation. People are busy doing their day jobs, delivering projects, and keeping our clients happy. Making time for innovation is difficult, but when we get diverse groups of people together in

“Three Mobile have been a big supporter of what we have been trying to do over the last couple of years, and are one of our strongest partners”

rooms discussing challenges in the business, we generally see really good engagement, some interesting ideas, and feedback on what could work best across the organisation.”

Ardmac is currently in the process of trying to reenergise the practice of bringing teams together in small targeted groups to talk about a specific topic. Chris explains, “During Covid, we lost energy because we

found it difficult to engage on Teams calls. We now want to bring this format back to life. What’s worked well for us in the past is when a group self-selects its own idea, which empowers them to go off, do their research, and identify how they can roll it out. My role as facilitator is to make sure the project gets the momentum it deserves, as well as challenging the groups to think about why an idea

is likely to be a success or failure.”

Chris’ starting point for building a strong team is to think about what he is trying to do and where he is trying to get to. He says, “As a large organisation that consists of a few hundred people, we aim to recruit likeminded people who are willing to engage and move the business forward. From an innovation perspective, if you bring people

together with similar backgrounds, you tend to get similar ideas. But, when you bring diverse groups of people together, who work in different areas of the business, you generally get much more rounded ideas that are then challenged in different ways. We are looking to work with people who want to get involved, develop their careers, and are passionate about our organisation.”

Chris adds, “We can easily find people across the organisation who buy into these principles, helping to develop new ideas into workable solutions.”

Collaboration with other organisations has been a key component to Ardmac’s success. Chris explains, “Building strong partnerships is hugely important. Without our supply chain and our partners, we would have effectively

As mentioned, Ardmac teamed up with Eque2 on its first big transformation project. Chris says, “This project set the tone across the business as to where we were going from a technology perspective. After we went live on the system, backoffice processes were faster and easier to access because everything went online. It meant that when we looked at other areas of the business, we already had a successful case study that we could show people to

“We worked with Go Contractor to digitalise and centralise this process into our main collaboration and field software”

been left to do a lot of things ourselves. From a technology perspective, we have a small team, so our vendors are critical partners. They develop the solutions, and we work together to roll them out and embed them into our processes and procedures.

“For us, being able to develop apps ourselves with low-code tools is a great step forward, but we are always going to need the platforms in terms of our core day-to-day work. Having great partners, who have bought into our journey just as much as their own, is key for us, and we have been lucky to find some excellent partners to work with.”

explain how it worked and what we needed to do.”

Go Contractor is another strong partner for Ardmac. Chris enthuses, “Go Contractor is a workforce management tool. This means that when an operative arrives at one of our sites, they have already completed their training online. They have uploaded all their health and safety information, and as all the records are digitalised, each project management team knows when their certifications are going to expire and can deal with them appropriately.”

Chris adds, “We can also put the operatives to work safely and quickly

without having to do classroombased inductions, coupled with the slow process of verifying their documents. Helping us to drive performance on our projects, Go Contractor has been a fantastic partner. We previously had a paper-based productivity tool that had been in the company for a long time. We worked with Go Contractor to digitalise and centralise this process into our main collaboration and field

best practices for our designers and engineers on the software. From a support perspective, we are able to bring any problem to them and they are happy to work with us to develop a solution. Diatec always bring us the latest and greatest platforms, challenging us on how we are using them. They are very upfront and honest in this way. We have developed a really good relationship with them over the last few years.”

software. Working with hardware devices in the field, our productivity tool is now fully integrated, allowing our project managers to get on with delivering their projects.”

The final partner Chris mentions is Diatec. He continues, “Like most AEC companies, we make extensive use of the Autodesk suite across our design and engineering teams. A key partner for us in this regard is Diatec, who provide licenses, technical support and guidance around the Autodesk suite, and

As for Ardmac’s plans for the future, Chris reinforces his excitement for the modular side of things and the move to building off-site. He explains, “If the work is moving to manufacturing facilities, how can we ensure that the technology we have in place is fit for purpose? Can we lift and fit the technology platforms into a modular environment? In some cases, it will work, but in others, the manufacturing environment will be very different from a construction environment.”

“A key partner is Diatec, who provide licenses, technical support and guidance around the Autodesk suite, and best practices for our designers and engineers on the software”

One of Ardmac’s main goals is to continue to be a learning organisation, picking up lessons learned as they go. Chris says, “We have a large, distributed company with thousands of years of experience across our workforce and supply chain. By documenting and sharing lessons from our projects and teams within the organisation, we will keep developing our platforms, so when new technology lands, we can identify them early, and where possible, modify our processes in a controlled way. This will hopefully make people’s work lives a little easier and solve some pain points along the way.”

Chris adds that there is little point in bringing in technology simply for technology’s sake. He concludes, “If the technology is not going to fit into our strategy of driving performance, empowering our people, and delighting our clients, we are unlikely to get much value out of it as an organisation. It is therefore

my role is to make sure that we are doing the right thing at the right time.”

On a personal level, Chris has recently joined the Operational Board for Ardmac and is excited to see how the executive level of the organisation operates. He concludes, “How can I bring some influence on those conversations? For me, to be included in the group and having a seat at the table shows how committed Ardmac is to having technology and innovation at the heart of the organisation going forward.”

For further information on Ardmac, visit www.ardmac.com

“We have a large, distributed company with thousands of years of experience across our workforce and supply chain”

A report by the US Department of Energy highlights the country’s strategy for a robust clean energy transition.

The strategy examines technologies and crosscutting topics for analysis in response to Executive Order 14017 on America’s

Supply Chains and is part of a whole of government approach to chart a course for revitalising the US economy and domestic manufacturing by securing the country’s most critical supply chains.

The energy sector has undergone significant changes, including rapid cost reduction and increased deployment of

solar and wind energy; widespread uptake of efficient LED lighting; significant digitisation of and strain on its electric grid; and the birth of the marketplace for electric cars, trucks, and buses, and more.

In the decades to come, the energy sector will evolve at an accelerated pace reflecting continued innovation, investment trends in private capital markets, and the urgent need to combat global climate change. Demand for clean energy is projected to increase

“DOE

THAT A SECURE,

CHAIN WILL BE CRITICAL IN ACHIEVING THESE GOALS AND

THE ECONOMIC OPPORTUNITY INHERENT IN THE ENERGY

dramatically as we work toward climate goals to cut emissions in half by 2030, create an emissions-free power sector by 2035, and achieve netzero emissions economy-wide by no later than 2050.

This energy transition creates enormous opportunities for America to:

• Reinvest in its manufacturing base and create millions of good paying, high-quality jobs for American workers.

• Strengthen its energy supply chains by making them more resilient, robust, diverse, and competitive.

• Increase global presence of US clean energy technologies.

• Increase access to clean and affordable energy for all Americans, including those who have been historically left behind.

• Build a clean energy economy that drives economic growth, protects the climate, and improves public health in communities across the country.

DOE recognises that a secure, resilient energy supply chain will be critical in achieving these goals and capturing the economic opportunity

“THE STRATEGIES AND RECOMMENDATIONS IDENTIFIED IN THE REPORT ARE DESIGNED TO PROPEL THE UNITED STATES FORWARD TO A MORE SECURE AND EQUITABLE CLEAN ENERGY FUTURE FOR ALL AMERICANS”

inherent in the energy transition. In addition to the comprehensive strategy report, DOE developed 13 deep-dive assessments on specific technologies and crosscutting topics conducted by researchers from DOE and several of its national laboratories, in consultation with energy sector stakeholders.

‘America’s Strategy to Secure the Supply Chain for a Robust Clean Energy Transition’ is informed by these 13 issue-specific priority assessments and focuses on key findings that will maximise opportunities to strengthen the energy supply chain and develop a world-class American energy

manufacturing base and workforce. The report also builds upon a 100day review of the supply chains of critical products, including semiconductor manufacturing and advanced packaging; large capacity batteries; and critical minerals and materials.

The strategies and recommendations identified in the report are designed to propel the United States forward to a more secure and equitable clean energy future for all Americans.

To read the report in full, visit www.energy.gov

Saferoad Group’s Supply Chain Director, Steinar Tafjord, explains how digitalisation has played a key role in creating synergies across the group, thus reducing costs, increasing efficiency and cash flow, and lowering CO2 emissions.

teinar Tafjord joined Saferoad Group 18 months ago as Global Category Manager Logistics before being promoted to Supply Chain Director when he was tasked with investigating the synergies between the companies within the group. Steinar reflects, “When I realised how much work there was to do across the whole supply chain, it was natural to take on more responsibility.

The main project is to achieve a transparent supply chain throughout the group to gain more control, insights and recover costs. Saferoad Group consists of more than 50 business units, so our aim is to gather all the data into one platform.”

Having control over all of Saferoad Group’s costs enables the company to take steps to

reduce them. The supply chain in Saferoad is data rich, but information poor. Due to the highly complex and fragmented nature of global supply chains, moving things from A to Z is more complicated than ever before. Steinar continues, “It’s when you have control of your data and total spend, you can do something about it. You can also reduce your CO2 emissions by combining and consolidating transport and creating synergies between the companies. With digitalisation, you get insights

into the operations within seconds or minutes. It is about creating dynamic KPIs and being more transparent.”

When it comes to reducing your carbon footprint and making it a priority, Steinar says that is one of the key elements that the next generation of employees really cares about when choosing a company to work for. He says, “We are focused on sustainability and getting the data on it, but most importantly,

“We are focused on sustainability and getting the data on it, but most importantly, we are trying to do something about it”

Steinar Tafjord, Supply Chain Director

we are trying to do something about it. This is very important for the next generation of young people when they are looking for a job today. They are aware of who their employer is, and theirs effort to become more environmentally-friendly with green logistics.”

Sustainability is therefore a key driver of digitalisation for Steinar and his team, as well as a focus on innovation. Steinar continues, “Our companies produce road

safety equipment, so being more innovative will create safer systems. At the same time, the system will also be lighter and stronger, and in doing so, we are reducing our total weight. When we deliver a full truck of finished goods, our load will not be as heavy, which is good for the environment. Our team is continually looking for better systems to help us improve for tomorrow. We work together with customers and partners to meet the future needs of mobility and

“Things are happening today at a speed that we have not seen before. If you make a decision, you have to make it based on facts and comparative analytics”

improve the infrastructure quality for travellers on the roads. Our team of experts is dedicated to making life on the road safer. Through resilient road infrastructure products, indepth expertise, vast experience and innovation as part of our DNA, we contribute to shape the future of infrastructure.”

Being data-driven enables Saferoad Group to make decisions much faster. Steinar explains, “Things are

happening today at a speed that we have not seen before. If you make a decision, you have to make it based on facts and comparative analytics. Without these insights, you will lose the race. Companies with access to data can make fast decisions, giving them a great advantage. We see that the global supply chains are changing from one day to another. For example, when trying to buy steel from a company that suddenly no longer exists, we need to find new

ways to import it, as well as faster and more effective transportation. In addition, prices of electricity, gas, transport, raw materials etc are increasing at the speed of lightning. We need to create better synergies to keep ahead of the pack.”

Steinar believes the Covid-19 pandemic taught companies a lesson that they needed to change the way they planned. He says, “We need better forecasts and control over all

our supply chain to be able to track products all the way. When Covid came along, Saferoad Group was not able to meet with suppliers and customers, and therefore had to rely on the systems. In doing so, you really need to have control over your systems. After Covid, we focused heavily on having good forecasts, so we can now plan ahead much better, and in the event that something happens, we can react much faster. It is obvious that S&OP, good sales and production forecasts give us the benefits of better and more strategic purchases, while at the same time, reducing costs, improving liquidity, and ultimately providing a better EBIT.”

Saferoad Group views all the companies within the group as part of a team, but the challenge lies when the companies are using different ERP systems and have different ways of working. Steinar adds, “The volume of data is enormous, so we need to collect the data together into one shared platform. In doing so, we will create a heatmap, and we will be able to see where we are transporting, what we are transporting, the type of transport (train, short-sea, pram etc), the transport company, how heavy the load is, and the consolidation rate.”

According to Steinar, supply chain collaboration is an essential

“We aim to increase circularity and reduce our climate impact, to produce and deliver sustainable products, to ensure health safety satisfaction of our employees, and to achieve a transparent supply chain”

Steinar Tafjord, Supply Chain Director

As one of the world’s largest transport and logistics companies, we at DSV carry a great responsibility for the green transition. With core services like consolidation, modes shift and loading optimisation, we are already contributing to lower down the CO₂ emissions in our day-to-day business, but to protect our climate we need go further. That is why we have developed Green Logistics. A set of solutions ranging from CO₂ reporting and strategic supply chain optimisation to emission compensation and sustainable fuel offerings.

Our Green Logistics solutions explained:

CO² reporting:

CO₂ reporting offers you the insight and analysis to drive reductions of your supply chain emissions. DSV’s CO₂ Reporting solution offers you a comprehensive overview and data analysis of your supply chain emissions, with reliable and accurate reports collaborating with one of the leading companies in cargo transport emission calculations.

Green supply chain design & optimisation:

Whether you want to meet ambitious climate targets or improve the efficiency of your supply chain, a full supply chain analysis will help you achieve this. DSV offers holistic green value-added services to help reduce costs and CO₂ emissions and design sustainable supply chains for the long-term.

Sustainable fuel offerings:

Reduce emissions without changing your operations. DSV is focused on meeting the immediate needs of its customers. We are committed to helping you find the right mix of fuel solutions. Whether by road, air or sea, you can benefit from our knowledge as we manage the process from start to finish.

Carbon offsetting:

Compensate your CO₂ emissions with DSV Green Logistics by funding an equivalent CO₂ saving elsewhere, supporting important sustainable projects worldwide. Carbon Offsetting projects extract or save CO₂ from being released into the atmosphere.”

ingredient in order to be successful. He says that the focus needs to shift to viewing suppliers as partners, and that companies must collaborate to make themselves stronger. Three such partners Steinar mentions are Softlogs, NShift and DSV Global Transport and Logistics. He continues, “We transport more than 200,000 tonnes of steel and finished products every year, not to mention the other materials we transport. Hundreds of trailers head across the

“In logistics, transport businesses are not very ahead when it comes to data sharing and digitalisation. For us, when we enter into a collaboration, the forwarding company needs to share information and be data transparent. DSV is ahead of the curve in this respect, so they are a very important partner for us”

continent every day, so we need to have a system to select, book and control all the transport. We need to be able to book the right transporters at the right time, and have as much as possible into one system. NShift has the world’s biggest carrier library, so they are a key player for us. When we are up and running, we will have more control over all our transport across Europe. The data will also help us to get on top of our Scope 3. For example, we will be able to see where we can create synergies between the companies to reduce our CO2 emissions. NShift is playing a huge role in our digitalisation process.

“As far as deep-sea transport is concerned, we transport thousands of containers every year, especially from the Far East. In logistics, transport businesses are not very ahead when it comes to data sharing and digitalisation. For us, when we enter into a collaboration, the forwarding company needs to share information and be data transparent. DSV is ahead of the curve in this respect, so they are a very important partner for us.

“In order for us to be able to use digital solutions and TMS (Transport Management Systems) such as

nShift and Softlogs for land-based transport, we must have carriers that are receptive to such solutions. There is no more booking via email and telephone. It will be done via digital systems, and preferably via our own ERP systems. Everything that is booked manually loses valuable insight and data, and fortunately our partner DSV Road (among others) is fully aware of this. I also believe that carriers which facilitate such solutions are the ones which will do best. Those which continue with the manual method will not have a bright future.”

Steinar adds, “During a calendar year, we book up to 15,000 trucks around Europe and the Middle East. About one third of these are FLTs (Full Load Trucks), which deliver raw materials and finished goods to factories, projects and customers. This, in turn, involves a large amount of invoices (approximately 20,000 yearly) that must be checked, allocated and approved. Each invoice

can have up to 20 pages, and it goes without saying that this is timeconsuming, expensive and provides no added value. On top of this, there are CMR documents, customs clearance costs and many manual procedures that are necessary for the trucks to enter and exit countries that are not part of the EU. In 2022, this should not be necessary.”

Saferoad has therefore entered into a collaboration with Softlogs, to gain control over all these procedures, and not least, the costs. Steinar says, “We want to know with 100 per cent certainty whether what we pay is in line with what has been agreed and stipulated in the contract and lead timetables. With the help of Softlogs’ cloud-based solutions, we precisely get this control and insight. Automation for invoice checking, accounting, cost allocation and freight deposition are keywords for their solutions. This provides a good and secure basis for Saferoad's freight analyses, reports and BI.

“NShift has the world’s biggest carrier library, so they are a key player for us. When we are up and running, we will have more control over all our transport across Europe”

Our Transport Management System provides full visibility and control of your supply chain:

Precise management of shipments between multiple sites, inbound from suppliers, via plants and warehouses, to customers, keeping costs in control and customers satisfied

Built for collaboration across teams and organizations with one common goal - an efficient supply chain

Pre-built carrier connectivity is at the core of our solution, making implementation fast and carrier communication effortless

We offer full process support and enable your organization to build an agile, sustainable supply chain For more information

We at softlogs work exclusively to simplify everyday life for transport buyers and carriers. Our solutions are hundred percent cloud-based and focused on automatic processes. Full digitisation of freight costs gives the customer good control and overview of all freight related elements.

Automation for invoice checking, accounting, cost allocation and freight deposition are keywords for our solutions. This provides a good and secure basis for freight analyses, reports and KPI’s.

With the help of advanced algorithms and machine learning we analyse deviations over time and find unprofitable processes.

Proud to explain key elements in our collaboration with Saferoad :

Freight invoice management

EDI integration with more than 250 carriers gives a flexibility to have the same process for freight invoice management independently of carrier. Full visibility and transparency both for Saferoad and the carrier.

Cost allocation

Collecting and consolidating information from multiple sources (orders, booking, freightinvoices) to be able to allocate, connect or split the cost on various detail levels. Giving Saferoad the possibility to look at freightcost on all levels – legal entity, department/store level, order, products etc

With softlogs cloud solution - Saferoad holds an automated invoice posting functionality , not only on invoice level but on shipmentlevel and/or charge level. This is made available through an advanced rule engine which can capture freightcost, shipments and connect it to correct costcenter and account. The same ruling is valid for depositions – get full control even though invoice is not received in accounting.

Carbon Footprint

With Softlogs carbon footprint report along with other KPI reports, Saferoad can easily supplement their environmental accounting. Softlogs offers visualisation of Saferoad’s carbon footprint focusing on what actions sub-companies needs to take - to create a greener world.

“This means that Softlogs is sitting on a lot of transport data, which will give us a good foundation for reporting our transport CO2 footprint. But as I said earlier, we are not content to simply report our present values. We will optimise, consolidate and find the best possible environmentally-friendly solutions to reduce our emissions. To achieve that, we must also have control over our transport data. And this is what we get with Softlogs.”

can appreciate live data, and having a target to reach together with your teammates adds a bit of excitement.”

As for Saferoad Group’s vision for the future, Steinar says the main priority is on its ESG commitments. He concludes, “We aim to increase circularity and reduce our climate impact, to produce and deliver sustainable products, to ensure health safety satisfaction of our

“We want to know with 100 per cent certainty whether what we pay is in line with what has been agreed and stipulated in the contract and lead timetables. With the help of Softlogs’ cloud-based solutions, we precisely get this control and insight”

Steinar highlights the importance of bringing fun into the workplace because logistics departments only typically receive feedback when something doesn’t go to plan! He explains, “You don’t get all the positive feedback because when you don’t hear anything, it just means that things are running as expected. We want to create KPIs that show all the positive things that are going on. It is more fun for our colleagues in operations (warehouse, production, procurement etc) to see how things are running and to be able to measure the effect live of the various initiatives they are doing. Everyone

employees, and to achieve a transparent supply chain. When we are buying, producing and delivering heavy goods globally, it is very energy-demanding with high CO 2 footprints. We must and can do something about it. We will not only be measuring our carbon footprint, but we also want to measure it to improve it. Period! Doing things faster and more effectively also gives bigger and better turnover rates, so at the end of the day, green logistics is also commercial and positive for the economy.”

For further information on Saferoad Group, visit www.saferoad.com

FinancePeter Burnett OBE, Senior Managing Director of the Standard Chartered Bank (Hong Kong) and Chairman of the British Chamber of Commerce in Hong Kong, outlines the key trends in global trade.

ne major change has been in the direction of trade routes. Supply chains have traditionally operated across an ‘east-west’ axis. Much of trade financing was focused on ensuring the requisite infrastructure in the US, Europe and Asia.

Now, some of that supply chain is shifting from North Asia and into Association of South Eastern Nations (ASEAN) countries, such as Vietnam, Cambodia and Indonesia.

Peter Burnett OBE, Managing Director of Standard

Peter Burnett OBE, Managing Director of Standard

Chartered Bank in Hong Kong, says, “China has developed beyond being a cheap manufacturing hub, and is now in a position where it is actually developing some quite advanced IP. North Asia has outsourced some more basic manufacturing to ASEAN and this has influenced a market shift towards northsouth. Supply chain finance has been reconfigured to accommodate this trend.”

Supply chains are also digitising rapidly. Trade finance has historically been a paper-intensive process, but it has moved towards digitised models, improving efficiency

and removing human error. The use of blockchain technology is also a more recent phenomenon and has had some beneficial effect on financial inclusion. A car manufacturer, for example, can use a blockchain to issue tokens to businesses within its supply chain, which, in turn, are able to use that credit to get financing they would have otherwise been excluded from, using the car manufacturer’s credit position and history as the basis for lending.

Trade finance credit analysis is also changing with the use of technology. It is able now to move away from historically valued collateralbased pledges and work on ‘tech-based’ creditscoring models, including real-time transaction data and machine learning technology.

There has been a growth in the use of offshore renminbi (RMB) in trade finance. China is now the world’s second largest economy, and it befits such a large economy to develop its own current account currency

for use in offshore trade settlement.

Finally, the sustainability agenda is driving change across supply chains, which is enhancing due diligence across the whole supply chain to ensure every link is fulfilling sustainability criteria.

Peter says that the technology and sustainability trends within supply chains are interlinked; accelerated technology adoption is increasing efficiency across many factors, including due diligence, much of which can be automated. Banks and lenders are looking for moves towards achieving net-zero objectives and are shifting investment away from carbon-intensive supply chains, such as those that use coal in the manufacturing process. This approach cannot currently be taken for all materials – coal is needed for steel production – but the market is looking for viable alternatives. Peter adds, “It’s partly because we think it's the right thing to do, and it’s partly because our

“Trade finance has historically been a paper-intensive process, but it has moved towards digitised models, improving efficiency and removing human error”

stakeholders and employees think it’s the right thing to do. We spend quite a lot of time talking about it.”

The pandemic has also had some hopefully shorter-term impacts, with a shift from ‘just in time’ to ‘just in case’ encouraging the hoarding of commodities. This has had a negative impact on prices

throughout the supply chain.

And it’s not the only negative to come out of the pandemic. It’s been well documented that the war in Ukraine and the effects of inflation are impacting supply chains, but the backlash towards globalisation is also exacerbating the situation.

Peter continues, “We’ve seen

most economies win as a result of globalisation, but what we’re now seeing is a concern about an over-dependency. Food, medical supplies, finance – there are a number of areas where countries are questioning whether they have become overly dependent on third parties for these critical supplies for their economy and infrastructure.”

Some analysts predict that the worst of this will be over in quarter one of 2023, but there could be a lasting deflationary impact, which could extend the period of recovery. Peter explains, “There are a number of variables that are very difficult to control.”

The developing world will probably bear the brunt of the

“In Asia, the Greater Bay Area initiative in China is more closely integrating Hong Kong, Guangdong and Macau, allowing for the free movement of capital, people, goods and services”

longer-lasting impacts of these factors; there is already a risk of food shortages across SubSaharan Africa. The western world will be able to weather the storm, despite impacts on the cost of living, Peter explains.

Meanwhile, in Asia, the Greater Bay Area initiative in China is more closely integrating Hong Kong, Guangdong and Macau, allowing for the free movement of capital, people, goods and services. Peter says, “At a basic level, Hong Kong is the financial centre, Shenzhen is the IT centre, and Guangzhou is the advanced manufacturing centre.”

Trade only works if there’s a high degree of trust. Peter concludes, “We’ve lost quite a bit in the last two years. Hopefully that trust will come back and we can return to proper globalised, sensible trading.”

Source: www.icaew.com

JOEP KUSTERS, SVP, Head of Europe, at Coyote Logistics, explains how companies are managing cross-channel shipping challenges post-Brexit.

JOEP KUSTERS, SVP, Head of Europe, at Coyote Logistics, explains how companies are managing cross-channel shipping challenges post-Brexit.

he impact of Brexit on cross-channel trade between the UK and the EU has had devastating effects for many companies on both sides of the English Channel. Shipping freight across international borders is challenging, with lots of paperwork, customs requirements and delayed crossings, and in the last few years, hurdles to shipping international freight have dramatically increased. Both the Covid-19 pandemic and the conflict in Ukraine have severely disrupted international supply chains. It has not gone unnoticed that this resulted in rising energy and fuel costs, and a shortage of talented young logistics professionals. Complexities like these have impacted many logistics service providers, especially in the transport sector.

European shippers in particular have been struggling with the

difficulties of shipping goods across the English Channel. Since the UK withdrew from the single market and customs union, freight shipping has required more time and effort, increasing the risk of costly errors and delays. Brexit has fundamentally changed the way goods are shipped between the UK and EU. Quite a few transport service providers stopped accepting cross-channel shipments two weeks after Brexit because they could not manage the

“After Brexit, our customers struggled with the unknown and had to adjust their supply chains accordingly.

Our aim at Coyote Logistics is to help them solve their post-Brexit hurdles”

JOEP KUSTERS, SVP, Head of Europe

additional workload. For shippers, there is a growing need for logistics service providers with the expertise to manage the complex challenges of shipping cross-channel freight.

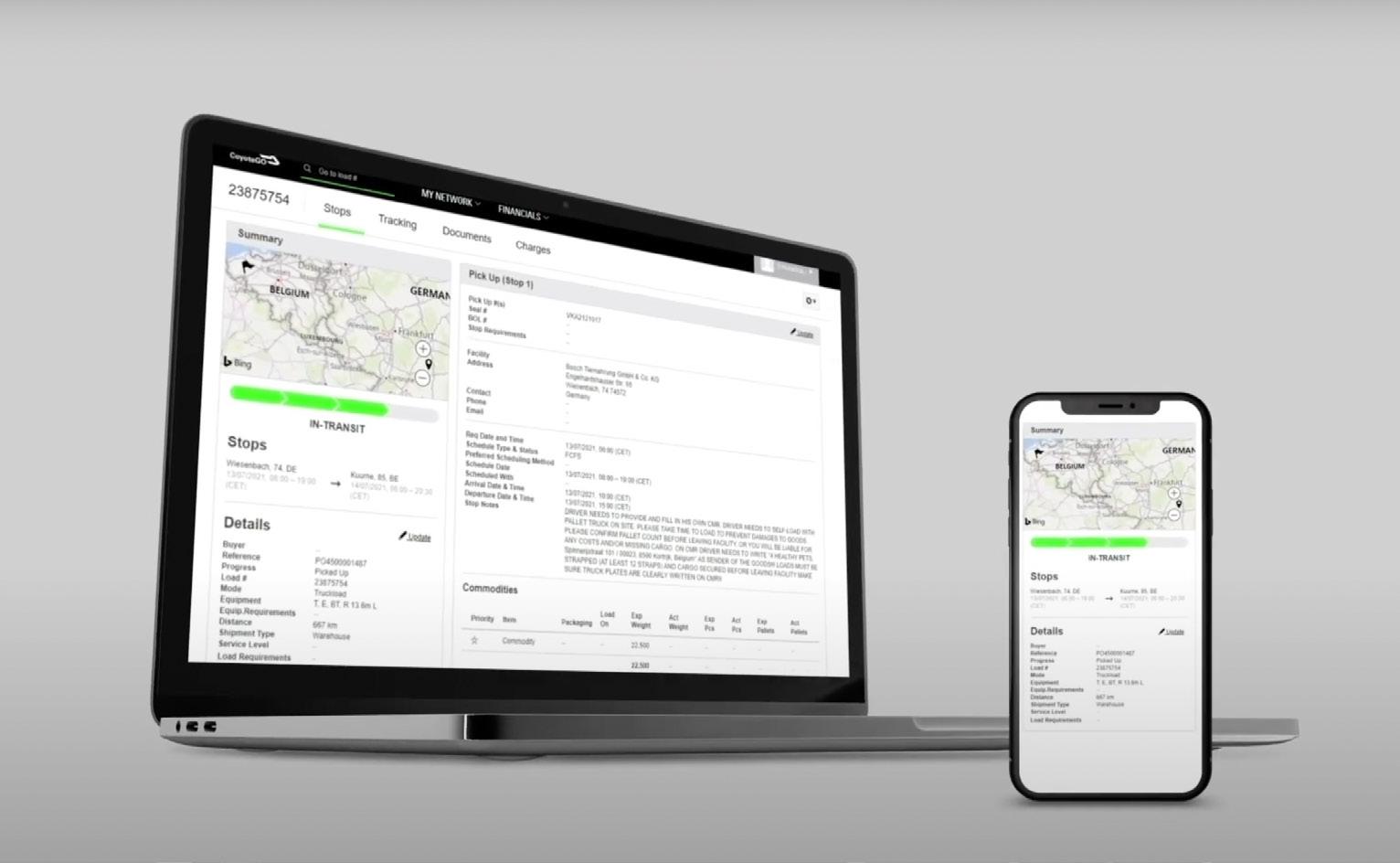

With both technological innovation and a dedicated service team, Coyote Logistics helps traders and manufacturers to master their shipping hurdles. A leading global logistics service provider with headquarters in Chicago and Amsterdam, Coyote Logistics connects shippers and carriers worldwide, handles more than 10,000 shipments per day, and employs more than 3,300 people in 20 offices worldwide. The company’s European service portfolio includes not only Full Truck Load (FTL), Express Van freight, customs brokerage and 4PL services, but also a full-service cross-channel logistics solution. With its expertise

and over 20 years of experience in the European freight market, Coyote Logistics helps shippers to overcome their cross-channel shipping challenges.

Joep Kusters is SVP, Head of Europe, at Coyote Logistics. He says, “After Brexit, our customers struggled with the unknown and had to adjust their supply chains accordingly. Our aim at Coyote Logistics is to help them solve their postBrexit hurdles. After all, managing crosschannel freight for many companies in the UK and the EU is a rather existential concern for their businesses.”

Stateside Skates was one of the companies that benefited from Coyote Logistics’ cross-channel solution. The British company is an award-winning, worldwide distributor of extreme sports products, importing, designing and distributing roller skates, skateboards and scooters all around the world.

“With the current investment in our carrier relationships and our people, we at Coyote Logistics are building on our strong industry legacy. We connect our innovative technology with dedicated customer service, enabling us to support our customers even better in the future”

Stateside Skates’ trade relations with the EU were particularly important, as it used to export more than half of its volume – 65 per cent – to customers within the EU. The company therefore needed to find a solution to continue with its business.

Coyote Logistics offered Stateside Skates full-service support including export documentation and import clearance. The company benefitted from Coyote’s in-market and freight specialist team, with over 20 years of experience and covering 30 different languages, as well as Coyote’s digital transport platform CoyoteGO®, which offers many features to make the processes of booking and tracking of freight easier.

Alistair Crichton, CEO at Stateside Skates, says, “The solution offered by Coyote seemed like a very elegant way of dealing with the issue of cross-channel freight. What Coyote presented was how we envisaged it always working postBrexit, and they had the solution that we thought

was the best one. It’s very easy to liaise with the staff at Coyote, whether in the UK or abroad. Our teams work very closely together on a daily basis. All the paperwork and the forms were easy enough to follow and create.

Coyote Logistics allows businesses to go back to the way they were trading before Brexit.”

In order to provide its European customers with the same level of dedicated service in the future, Coyote Logistics is expanding its activities on the European market. With an investment in its carrier network, it continues to drive its growth strategy.

Coyote Logistics has set up a new service centre in Wroclaw, Poland, and significantly increased its number

of employees in Europe. The centre offers 24/7 customer support and services for the US, as well as the other three European Coyote Logistics branches in Amsterdam, Dover and Frankfurt/Main.

Joep continues, “With the current investment in our carrier relationships and our people, we at Coyote Logistics are building on our strong industry legacy. We connect our innovative technology with dedicated customer service, enabling us to support our customers even better in the future.”

So, what are the biggest challenges for the European logistics and transportation market at the moment? Joep answers, “Players in the market are facing a variety of challenges right now. Many of them are struggling with rising fuel costs. For me, however, capacities are what matter most and will be the key issue in the next couple of years. We have seen a steady decline of capacity over the years, not just because of the driver shortage, but also because of the new EU regulations. While the current

“We offer close support, including both logistics and customs services in 30 languages! For our crosschannel logistics solution, this enables our customers to successfully manage their shipping challenges and continue their business in the future”

economic situation does not permit any reliable statements on further developments, existing customers of Coyote Logistics demand more capacities for their businesses.”

The last two years have shown that many companies need to invest more time and energy in making their supply chains fit for future challenges and in order to remain competitive. Technological innovation plays a key role here, from track and trace technology to big data management and artificial intelligence. Joep adds, “Technology is just one part of the equation. Human expertise is equally important for remaining successful in logistics. It is about finding the balance between the two factors. The combination of technology and human expertise is part of Coyote

Logistics’ DNA. With our innovative platform CoyoteGO®, we offer our clients a centralised marketplace, where we bring together carriers and shippers.”

At the same time, the Coyote Logistics team is constantly growing in order to help customers with their individual needs and challenges. Joep concludes, “We offer close support, including both logistics and customs services in 30 languages! For our cross-channel logistics solution, this enables our customers to successfully manage their shipping challenges and continue their business in the future.”

For further information on Coyote Logistics, visit www.coyotelogistics.com

A RSM report reveals what businesses can do to protect themselves from future disruptions.

he resulting gain on margins made it inevitable that these extended supply chains would become the norm. Yet a recent barrage of seismic events mean that this way of operating is not as profitable or reliable as it once was.

Businesses in 2022 are working in a volatile geopolitical environment. Increasing numbers of retailers cite supply chain woes as the main factor in delaying core promotional events and cutting revenue forecasts.

For those retailers at the lower end of the market, the current environment

will feel unsustainable. With business models built on low costs and tight margins, fast-fashion retailers turn product around quickly, aiming to sell high volume at very low prices. Their survival will be a challenge when most retailers are factoring in a minimum three-week delay to delivery, not to mention the inability to pass these soaring costs on to their customers, who are looking for great value.

RSM recently surveyed over 400 middle market business leaders, including those in retail, on their supply chains. The findings showed significant disruption at every major link in the supply chain.

Over the last 50 years, UK retailers have committed to complex global supply chains that allow for goods to be sourced, manufactured and shipped cheaply.

63 per cent of businesses that experienced negative effects due to upstream supply chain issues saw this carry through to their customers. Around half of these had to delay customer orders, and 43 per cent had to increase prices

The top five issues for supply chain disruptions were:

1. Delays with orders (48 per cent)

2. Increased costs (46 per cent)

3. Missed deadlines (37 per cent)

4. Unfulfilled orders (35 per cent)

5. Poor communication (34 per cent).

63 per cent of businesses that experienced negative effects due to upstream supply chain issues saw this carry through to their customers. Around half of these had to delay customer orders, and 43 per cent had to increase prices.

In an environment where the customer is king, retailers can little afford this kind of disruption. A quarter of those who had experienced upstream supply chain issues believed their reputation deteriorated, and 38 per cent experienced a decline in overall customer satisfaction.

Eventually, it all comes down to the bottom line.

Unanticipated supply chain issues led to 44 per cent of respondents experiencing a significant increase in operating costs, and 42 per cent saw a reduction in profitability.

So, what’s the answer? The report outlines five practical steps for retailers: Have end-to-end visibility

Many retail supply chains are tracked and governed through multiple – and often disconnected – data systems. Retailers must embrace technology that offers a single view of their supply chain, and that allows teams to collaborate across functions.

A single data funnel can accelerate response times.

Teams will be able to reduce bottle necks by navigating, identifying, and solving problems quickly.

Reduce risk through multiple suppliers Volume discounts used to make committing to one supplier an attractive prospect. But now a singlesupplier approach can cause an entire supply chain

to break. Having multiple suppliers mitigates the risk of capacity constraints and allows retailers to augment capacity as consumer demand fluctuates.

Your business is rich in data. Make sure you harness forecasting tools, customer demand signals and information from primary suppliers to manage inventory intelligently. Holding a buffer will become the norm, but overstocking also exposes retailers to losses as consumers continue to feel the cost-of-living crisis.

Traditional hierarchical leadership can lead to delays in decision making. Problems are referred upwards until the situation is critical. When supply chains are disrupted, long chains of command may mean missed opportunities. Matrix management and decisionmaking authority at multiple levels in the organisation can counteract these delays, and keep operations running efficiently.

Sustainable buying and planning

Collaboration across the supply chain, merchandising,

To read the Real Economy Report on Global Supply Chains in full, visit www.rsmuk.com

planning, and buying functions will be key to securing the right assortment of products with minimal disruption.

What have we learnt?

Retailers can employ tech to strengthen their go-to-market strategy and improve profitability. Integrated data analytics platforms are where retailers can gain the most value from tech adoption in their supply chain. These platforms give end-to-end insight through supply chain, merchandising, planning, and buying functions. Employing a single digital control tower creates

a shared fact sheet that allows for streamlined decision making, saving valuable time in the process.

Meanwhile, investment in warehouse automation offers a range of benefits, from increased productivity to reduced labour risks, and mitigates the risk of lost sales from out-of-stock items.

The key to employing these technologies will be for retailers to have a clear vision for what they want to achieve. They can then draw this down into objectives, mission statements and implementation strategy.

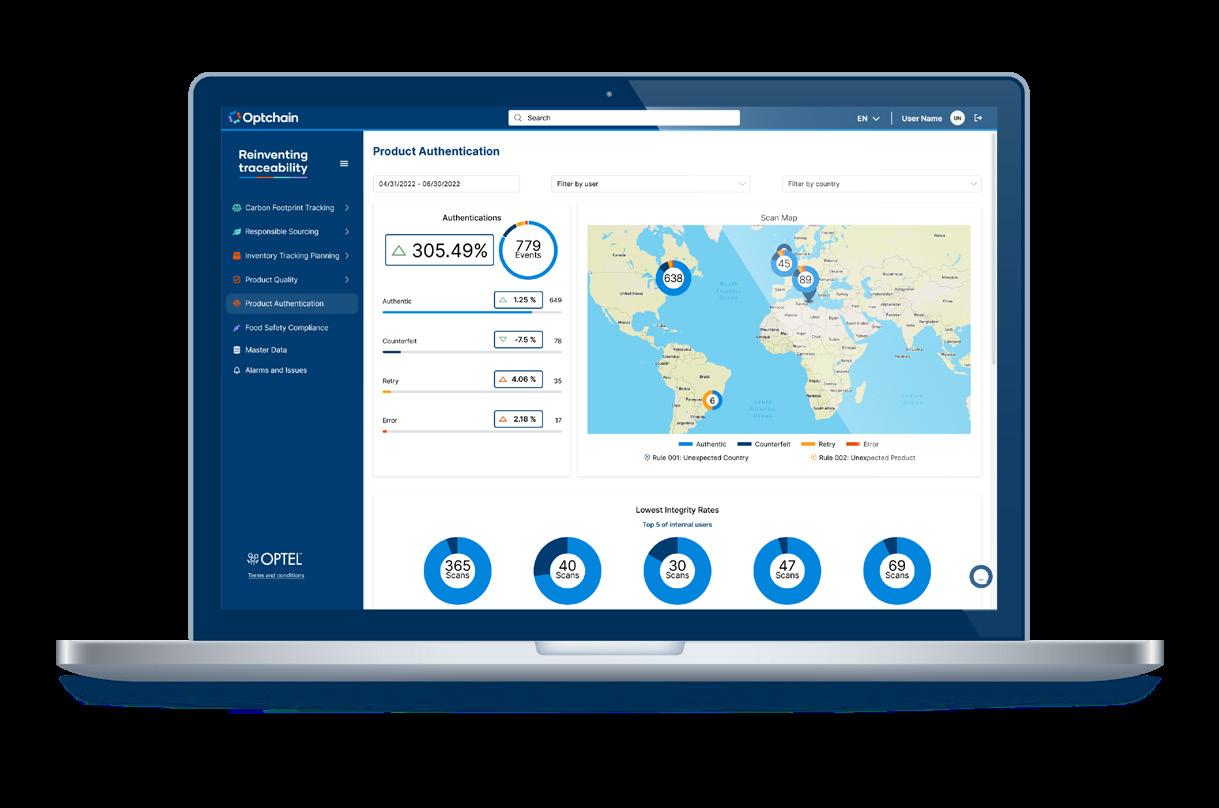

ptel Group is a leading global supplier of traceability, track-andtrace and vision systems for a growing number of industries, including pharmaceutical, food and beverages, and metal and mineral mining. Florent Bouguin, Chief Technology Officer at Optel Group, explains, “We have been in business for almost 35 years now. What we are doing is digitalising the entire supply chain from end to end, powered by traceability. We started inside the manufacturing plants, and then we went upstream and downstream the supply chain.”

Upstream refers to the raw materials, the active pharmaceutical ingredients, and all the suppliers that are part of the procurement of a product, whilst downstream comprises the warehouses, retailers, contract manufacturing organisations, distribution centres, and hospitals, for instance. Florent says, “Across all nodes of the supply chain, Optel Group is capturing the data, and we value this data. Our unique value proposition is bringing visibility on what is happening in the supply chain and helping businesses to make the best decision.”

Florent Bouguin, Chief Technology Officer at Optel Group, charts his company’s success story in digitising the entire supply chain from end to end.

“The third axis is compliance. With all the data that we are capturing, we are able to help our clients to respect pharmaceutical safety standards. And with the push on sustainability, more and more companies are now using our traceability platform to comply with local and international regulations.”

Florent highlights three axis of value; sustainability, performance, and compliance. He continues, “In terms of sustainability, we provide the tracking of the unique carbon footprint of a product across its entire lifecycle, empowering our client to have a more responsible supply chain, meet their energy targets, promote the circular economy, and reduce the plastic content of their packaging.

“As far as performance is concerned, our starting point was to help our clients to secure on-time delivery, have visibility on their inventories across the entire supply chain, and measure the quality of their product, thus reducing recalls. In a nutshell, that value works towards improving the profitability of the business.

Florent says forming connections with external partners plays a key role in Optel Group’s business strategy. He continues, “It is all about collaboration and creating the network. To do that, you need to partner with other companies. We have technology partnerships to enable us to connect to all the different enterprise systems and warehouse management systems. We also need to collaborate with distribution and logistics partners, as well as the contract manufacturing organisations. Silos, such as the hospitals, contract manufacturing organisations and logistics partners, are present in the supply chain. With collaboration, we do not see them as silos anymore, but we are linking them together. This is the future of traceability for the pharmaceutical industry.”

Optchain is the intelligent supply chain solution suite, powered by Optel Group’s traceability technology. In

short, it is the control tower that the company is putting onto the market. Florent explains, “For all of the axis, we provide different solutions, and you need a control tower to see what is happening. When you open Optchain, you have access to all these solutions, giving the visibility on your supply chain. And to feed Optchain, we need various data capture. We have a strong stack of technologies to bring that data to Optchain, whilst it also has the capacity to connect to competitors, collaborators, and

governmental bodies, because to see, you need to collaborate.”

According to Florent, the pharmaceutical industry is not as advanced as it could be when it comes to digitalisation. He says, “Pharma is not the leading market segment for the digitalisation of the supply chain due to the silos. Given the sensitivity of the data, it is an industry that does not see the value in collaboration. You do not have one big player at the top to push digital transformation, but a number of big players, so perhaps only governments enforcing regulations can drive collaboration.”

“For all of the axis, we provide different solutions, and you need a control tower to see what is happening. When you open Optchain, you have access to all these solutions, giving the visibility on your supply chain”

Another pain point of the pharmaceutical sector for Florent is in the last-mile deliveries. He elaborates, “You can have full visibility along the supply chain until you reach the hospital. When you go from the warehouse of the hospital to the distribution of the medicine to the patient, it then becomes a nightmare. The medicine might have to travel between four floors in the hospital and 10 different nurses, and you lose all visibility. When it comes to on-time delivery, everything is lost in the last mile, and the cold chain is not respected, so the integrity of the product is compromised. Having the right product, at the right time, in the right location, is the difficulty of the pharmaceutical supply chain.”

First Expired, First Out (FEFO) is a new concept used in field inventory management to describe a way of dealing with products that have a limited shelf life, such as medicines. Florent adds, “Warehouses, especially those in hospitals, are not geared towards FEFO. When we developed our solution for the distribution of the Covid vaccine a few years ago, the cold chain was a huge challenge. You do not have room for mistakes, but there are many ways in which it can go wrong. The supply chain is becoming more complex based on time sensitivity and the cold chain, so this is where digitalisation comes in. If you do not have the digital tool, you will not have visibility, and you need visibility in order to have traceability.”

According to Florent, traceability is essential for giving you the accuracy, precision and trust you need in the data, processes and methodologies. He adds, “Traceability ticks all these boxes. It is the right tool for helping in this journey because I don’t think any other technology does everything we want.”

Besides technology, Florent believes a change in behaviour is part of the answer to tackling the problem of last-mile pharmaceutical deliveries. He says, “A change in people’s approach and in their working practices will help towards streamlining the last mile of the pharmaceutical supply chain. Trust is a big part of this. If the technology is working well, you will win the trust of the participants, helping to onboard them. Another barrier is the cost of ownership of any new type of technology. It needs to be reduced in order to generate more interest.”

Optel Group’s roadmap for the future is focused on personalised medicine and cell gene therapy. Florent explains, “Cell gene therapy is big news for pharmaceutical manufacturers because it needs investment and is the future of their business. With the big data we are collecting, we are running AI tools to help the supply chain to be more efficient. When they started their digitalisation journey, all our clients installed track-and-trace to be compliant. They now have all this data, which can be used to find the value. The hard work has been

done! We are therefore working with our clients to show them how they can better manage their inventories.”

The last advancement that Florent is working on is in accelerating the transformation of the pharmaceutical industry to be more sustainable. He concludes, “Pharma is a huge polluter of our planet, generating copious greenhouse gas emissions and wasting water. The problem is that pharma previously did not have a sustainability agenda. Times are changing, but not fast enough. I am focused on pushing our clients hard to change. I want to prove to the market that it is possible, as it is working in other markets. If you improve your sustainability and source more responsible packaging, you will make cost savings. This is the other big technology push we are putting onto the market.”

For further information on Optel Group, visit www.optelgroup.com

“Times are changing, but not fast enough. I am focused on pushing our clients hard to change.

I want to prove to the market that it is possible, as it is working in other markets”

Florent Bouguin, CTO

rbico Group is a leading distributor of a diverse range of products, as well as being a 3PL provider, working across 20 different countries.

Headquartered in Croatia, the company primarily focuses on the regions of Central and Eastern Europe. Piotr Sedziak, Supply Chain Director at Orbico Group, explains, “The distribution part is divided into two main streams – the first is related to

FMCG goods, and the second relates to beauty products.

We offer 3PL logistics services across all our geographies, with our main markets of Poland, Romania, Croatia, Bulgaria, and Slovenia, and with the aspiration to grow in the future. We are a three billion euro turnover company, spanning over 200,000 square metres, with more than 2,000 people inside our logistics organisation, and over 1,200 vans and trucks in our network.”

From a supply chain perspective, Orbico Group’s mission is to be a digitally and operationally synchronised supply chain solutions provider across Europe. Piotr continues, “Our vision is to deliver efficient supply chain solutions for our internal and external customers, supporting both distribution and development of the 3PL service. We have three strategic ambitions including excellence of the supply chain solutions for our internal and

external customers, significant growth of the 3PL service scale, and development of the transport services across our organisation. This is the direction in which we are going.”

On the contract logistics development side, Orbico Group works across a number of different industries, from FMCG, beauty, tech and electronics, to tobacco, food and beverages, fashion and toys. Piotr says, “We

specialise in providing inventory management, value-added services, transport management, ecommerce, and complete supply chain solutions across these sectors. All services are supported by our IT solutions and reverse logistics solutions. If a customer does not have their own IT infrastructure, we can provide the complete IT infrastructure needed to realise their transport and logistics services. Combining the role of distributor and contract logistics provider for both internal and external customers is one of our challenges, but at the same time, it allows us to have synergies. A good distribution network, sharing the costs between distribution and with our 3PL customers, gives us the opportunity to offer our new customers a more competitive proposal.”

As far as automation and infrastructure are concerned, Piotr elaborates, “It is important to understand that we have different levels of automation –we have software automation and we have hardware automation. The former has a high level of integration across the systems, with at least three different types of software

including WMS, TMS and extended automation systems inside the warehouses. In the last year, we have launched solutions supported by automated software in both Poland and Bulgaria. Automated hardware includes conveyor systems, pick by cart,

and cargo systems. We are also looking into autonomous mobile robots and voice picking solutions to support the picking efficiency of our warehouses.

“For me, the software should be determined by well-designed

process flow and act like the nervous system of the overall logistics. It must work efficiently and react quickly to any changes. The distribution part is more predictive than contract logistics, so the software must be flexible enough to support the changes

“For us, it is important to get full profit from our regional presence. My vision is that we will be a leading logistics provider in Central and Eastern Europe, supporting any distribution request whilst providing general solutions based on the country or region”Piotr Sedziak, Supply Chain Director

expected by the contract logistics customers. It is about creating a digital ecosystem, making sure all our systems across Europe are standardised and talking the same language, without the need for any manual transfer of data. We are working hard on extending our warehouse network, with new distribution centres in Poland and Bulgaria, both with automation in place. We are also planning a new site in Croatia, and implementing automated solutions, so it is fair to say the network is growing.”

Customer-centric orientation refers to Orbico Group’s 3PL distribution role, finding the right formula for supporting both streams of the business. Piotr says, “It is necessary to support different business models, as illustrated by the Covid situation, which saw huge pressure for the transformation of the logistics function from B2B to B2C. The challenge now is to create one network supporting B2B, B2C, wholesalers, modern trade, traditional trade, and

all the different types of product. On top of the adaptation of the supply chain network supporting the different business models is quality management. This refers to the visibility of the operations for customers, and the consolidation of the software that is used to support this.”

The main streams of activities related to cost effectiveness include operational excellence, productivity

increase, and innovations implementation. The latter involves looking at what is available on the market, testing it, and implementing it if it has proven to have value. Furthermore, people is about making the workplace a safe place for Orbico Group’s employees, creating a culture of high performers, the feeling of being part of a team, and developing the reputation of being a competitive employer in the marketplace.

The final pillar, but perhaps one of the most important, relates to

sustainability. Piotr explains, “There are three reasons why sustainability is important right now. The first is the fact that we can all see climate change is happening and we need to react. We need to have some sustainability ambitions to meet ESG targets. The second point is that legislation is changing, which is imposing new regulations either now or in the future, so companies must be prepared to adapt. The third reason refers to customer expectations. Customers increasingly want companies to respond to sustainability challenges.”

“We encourage cooperation, and we are currently in talks with Stamh on how we can work together on other projects in the future”

Piotr says the five pillars are helping to create a resilient, operationally and technically efficient supply chain for Orbico Group. The projects underpinning the pillars are now in their second year of execution, with several larger projects planned within this phase. So, how important is it to work with partners to maximise success? Piotr answers, “It is very important to work with partners given the demands of the marketplace. We are all facing shortages in the supply chain, longer delivery times, and greater costs. The right selection of partners and long-term cooperation are key to achieving the right level of support. Having a relatively extended network of partners can therefore help in realising the business strategies.”

Two of Orbico Group’s partners include Stamh and Mach. Stamh was responsible for the implementation of the solutions in Orbico Group’s new logistics centre in Bulgaria, whilst Mach played a role in designing the distribution centre in Romania a few years ago. Piotr adds, “We encourage cooperation, and we are currently in talks with Stamh on how we can work together on other projects in the future.”

As a final point, Piotr shares Orbico Group’s vision for the future. He concludes, “For us, it is important to get full profit from our regional presence. My vision is that we will be a leading logistics provider in Central and Eastern Europe, supporting any distribution request whilst providing general solutions based on the country or region. Our future supply chain must be well-recognised in this part of Europe and synchronised, so as to be able to support the needs of the customers which expect a regional approach. We will create a strong logistics network comprising transport and warehousing, which will support our distribution activities and increase the 3PL part of the business.”

For further information, visit www.orbico.com

“Mach played a role in designing the distribution centre in Romania a few years ago”

discuss how future business models need to be adapted to prioritise ESG and sustainability.

ens Fath is one of the responsible partners for the operations transformation team at PwC, and has a keen interest in how top floor and shop floor play together in exploring possibilities for digitalisation, plus how integrated and businessled end-to-end architecture can support sustainability, as well as digitalisation and IoT. Besides the

product complexity and structure, Jens believes processes and how to define them is having a direct impact on sustainability questions. He also considers that we need to prioritise the organisation, people mindset and IT architecture, with strong core and systems of differentiation, to form a stable foundation for sustainability.

Jasmin Pennicke is Manager in the Operations team and looks after PwC’s sustainability offering in the operations practice, coordinating and bringing together all operations functions in terms of sustainability. She explains, “Looking at our service offering, how can we leverage that in terms of ESG? It is applicable to the entire value chain, so you cannot look

at ESG in a silo. It is important to link all the functions in order to reach your goals. My role is to bring all the people together, and link our services offerings to our colleagues’ offerings, so we can have a full view.”

Jens and Jasmin believe it is essential for companies to address the topic of ESG and sustainability

“WE ARE IN A LEARNING CURVE BECAUSE ESG AND SUSTAINABILITY IS SUCH A NEW – BUT HIGHLY RELEVANT – TOPIC. IT FEELS SIMILAR TO DIGITALISATION WHEN IT FIRST CAME TO THE FORE. THE IMPORTANT POINT TO REMEMBER IS THAT WE WILL ONLY ACHIEVE SUCCESS IF WE ARE DOING IT END-TO-END AND INTEGRATING PRODUCTS, PROCESSES, ORGANISATION AND IT”

Jens Fath

Jens Fath

in order to be successful and future-ready. Jasmin says, “Sustainability appears to be the next big trend, but we think it is more than that. Companies need to address it because it is mandatory for us as a society. On the regulatory side, following the European Green Deal, there will be a lot coming up in the next few years. Also, customers want to have sustainable products, and investors want to see green investments. A lot of companies see it as their responsibility to create new business models and new solutions, gaining new market fields, because there are new possibilities arising from that.”

So, what does Jasmin anticipate will be the impact of ESG and sustainability on businesses in terms of their future business models? She answers, “ESG and sustainability will have a big impact on how decision making will be carried out in the next few years. Before sustainability, you had to address costs, time and quality in your processes. Now, you have to consider new factors and how to apply them. It is more than just putting a sustainability label on your products, but reshaping your business model, because you

can only be successful in terms of sustainability if you reshape your business in total. It is not only the reporting part, but rethinking how your products work, how you want to introduce them to the market, and how you balance ESG factors with previously relevant factors such as costs etc. It is a big opportunity for new business models.”