Brightspeed COO Tom Maguire, and procurement and supply chain VP Brenda Rapp, discuss how a build plan lay behind an overnight success.

THE LEADING RETAIL FOCUSED SUPPLY CHAIN + LOGISTICS EVENT RUNNING ALONGSIDE FREE TICKETS RETAILSCL.COM 1-2-1 BUSINESS ADVICE 3rd & 4th MAY 2023 LVCC, Las Vegas INSPIRATIONAL SPEAKERS 300 VISIONARY SUPPLIERS 400 INTERACTIVE MASTERCLASSES DISCOVER THE LATEST INNOVATIONS REVOLUTIONISING THE RETAIL SECTOR +AND MUCH MORE! @RETAILSCL #RETAILSCL

We are excited to be a media partner of the Retail Supply Chain and Logistics Expo taking place in London at the end of the month.

It is common knowledge that customers are increasingly asking for faster delivery times and an easier returns system. The only way retailers can achieve this is by adapting their current supply chain model. Speaking of which, this issue, we bring you four must-read interviews from key industry players who continuously strive to stay ahead of the curve.

Our lead interview comes courtesy of Brightspeed’s Tom Maguire and Brenda Rapp (p6). We learn how Brightspeed is rolling out fibre to its copper-connected customers, with a focus on honouring the spirit of service.

Next up is Manuel Brkovic, Supply Chain Director at Podravka. Manuel shares his company’s inspiring supply chain story in the year that marks its 75-year anniversary (p34). Huge congratulations to all the team!

What’s more, we learn how Franprix delivers products from supplier to store across the French capital each day (p58). Thank you to Supply Chain Director, Arthur Caron, for sharing his exciting vision for the future.

Finally, SAP’s SVP and General Manager of Digital Supply Chain MEE Andreas J. Wagner, and Chief Operating Officer for Digital Supply Chain MEE Dr. Johannes Tulusand, discuss the key trends and opportunities for the year ahead (p84)... Just what can we expect?

Plus, don’t miss our intriguing features on reducing food waste (p24), America’s plans to clean up its transportation system (p48), and environmentally-friendly textile innovations (p74).

We hope you enjoy our ninth edition!

3

+44 (0) 203 890 1189 enquiries@ithink.media d.harris@ithink.media t.barnes@ithink.media editorial@ithink.media Editor Anna McMahon Director Danielle Harris Director Tom Barnes design@ithink.media Senior Digital Designer Daniel May WELCOME All rights reserved. Every effort is made to ensure the accuracy of material published in CHAIN Magazine. However, the company cannot accept responsibility for the claims made by advertisers or contributors, or inaccurate material supplied by advertisers. CHAIN magazine is a product of iThink Media Ltd. Company Registration Number: 10933897. Company Registered in England and Wales

4 NINTH EDITION 34 Meet Manuel Brkovic, Supply Chain Director at Podravka 58 Franprix’s exciting vision for the future 74 The textile industry is going plant-based! 84 SAP on the key trends and opportunities of 2023 6 We chat to Brightspeed’s Tom Maguire and Brenda Rapp 24 How can the food system be reformed to reduce waste? 48 We uncover the steps the US is taking to clean up transportation

5 6 48 74

34 24

Tom Maguire and Brenda Rapp

58 84

Manuel Brkovic

Arthur Caron

Dr. Johannes Tulusan & Andreas J. Wagner

DELIVERING THE BRIGHTEST OF FUTURES

COVER STORY

FUTURES

Brightspeed COO Tom Maguire, and procurement and supply chain VP Brenda Rapp, discuss how a build plan lay behind an overnight success.

8

n the opening day’s business at the fifthlargest incumbent local exchange carrier (ILEC) in the US, Brightspeed’s customers barely noticed the transition from their former provider, says COO and executive VP Tom Maguire.

“People went to sleep one day as a customer of Lumen Technologies and woke up the next as customers of Brightspeed – which is good news!” says Tom, explaining it was the culmination of three years of hard work behind the scenes. Looking forward, Brightspeed will offer many of those customers stateof-the-art fibre optics networks in a service territory made up of rural and suburban communities across 20 states.

Tom, who has 40 years of experience in the telecoms business, was brought on board early in the process with fellow founding Brightspeed leaders, chief administration officer Chris Creager and chief executive officer Robert (Bob) Mudge. Tom talks through how they were approached by investors Apollo Global Management with an interesting proposition.

9

“Apollo’s leaders had a hypothesis where, if they invested in a company that had a copper infrastructure, they could turn around the fortunes of the company by moving everyone over to fibre,” says Tom. He goes on to reveal that Apollo put together a $7.5billion fund and invited the trio initially to do due diligence and identify a property that fitted the bill, and then stay on to make the process work.

10

Tom Maguire COO

Brenda Rapp, who was then Lumen’s senior director of global network equipment and technology procurement, was one of the Lumen employees who came onboard with the deal.

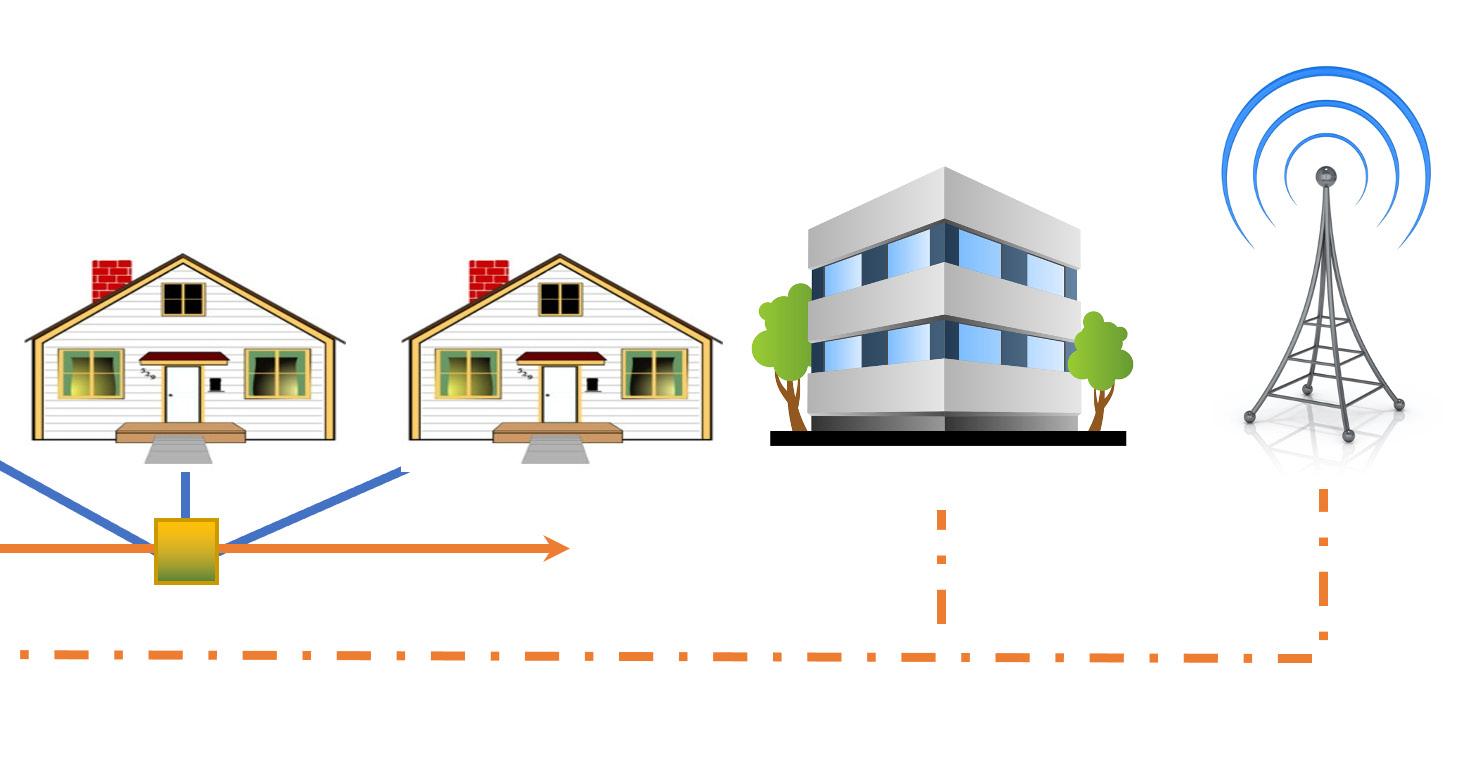

The territory Brightspeed acquired runs across the Midwest, Southeast, and parts of Pennsylvania and New Jersey, but has no major metropolis.

“We cover roughly 6.5 million households, a million or more of which use us for their residential and small business telecom needs,” says Tom. Though the objective was to bring innovation into their customers’ lives and make the business profitable, Tom emphasises that there was another key priority – service of the kind that rural communities rarely had access to.

Brenda, newly promoted to vicepresident of procurement and supply chain, says until now the focus has been on stabilising what existed and making sure that the new company has all it needs to ensure legacy business runs smoothly and good customer experience is maintained.

11

“The Brightspeed Fibre product is a fairly new architecture with a new suite of operational and building support systems. That’s the start-up piece of the equation and things are going well”

Tom Maguire COO

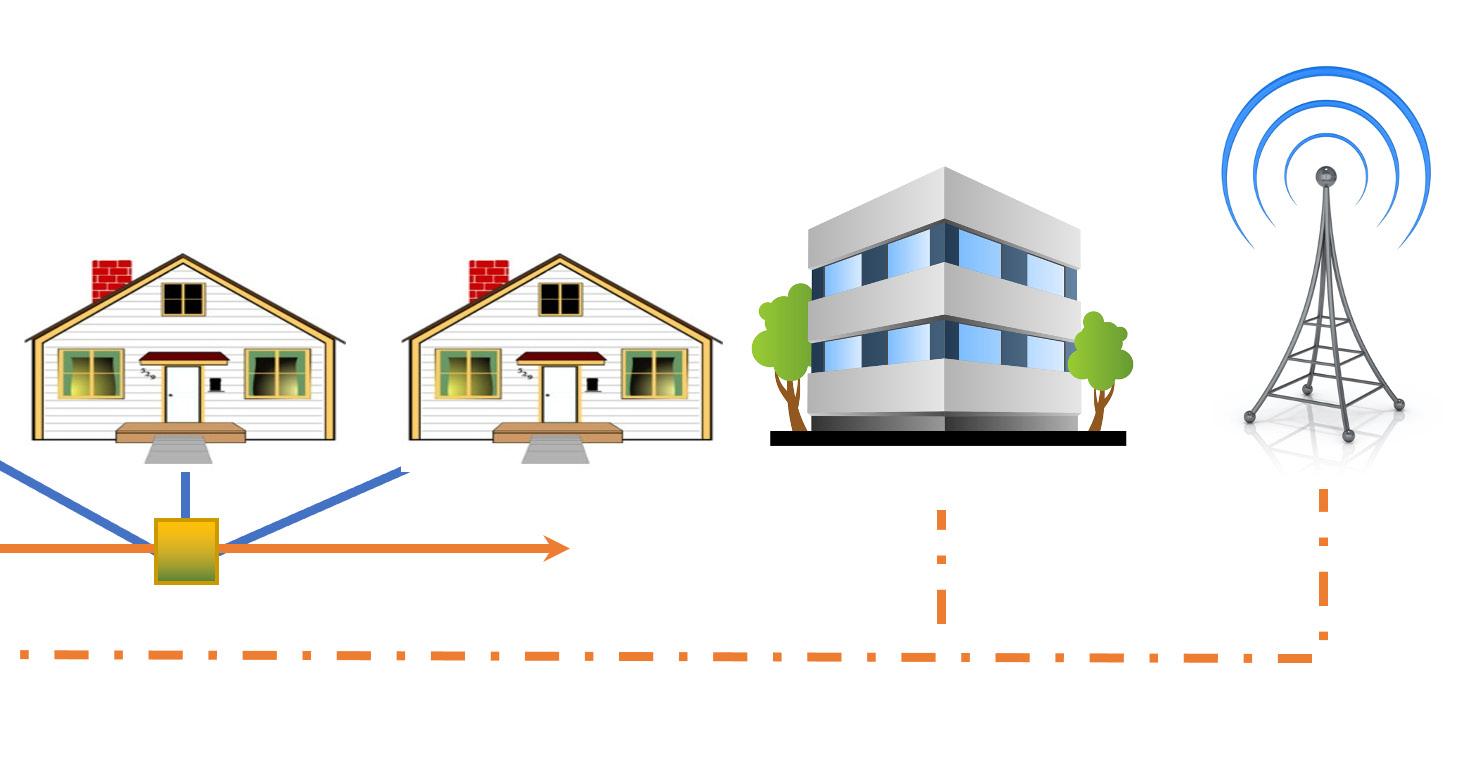

“We are doing that by getting critical spares to the field quickly. A lot of my focus right now is on our supply chain. Tom’s team put together a five-year build plan, which makes it a lot easier for us to plan for equipment, supply and everything else we need. With a build plan in place for 2023 to 2027, we know exactly what locations, markets, and wire centres Tom’s teams plan to build. We have standard architecture, standard equipment bill of materials and we can provide accurate forecasts, put purchase orders in and get the deliveries to support the fibre build teams,” explains Brenda.

Tom likens the process to an iceberg, where only a tip is visible. The biggest part of the preparation to make such a deal work lies below the waterline, unseen.

Running the fifth-largest ILEC in the US clearly gives Tom a buzz. Delighted with the transition he says, “We pulled all of this off despite being in the middle of a pandemic when the vast majority of our teams were never in the same room.” He has never lost his enthusiasm for telecoms.

“It’s an interesting industry,” he says. “It involves legal, regulatory

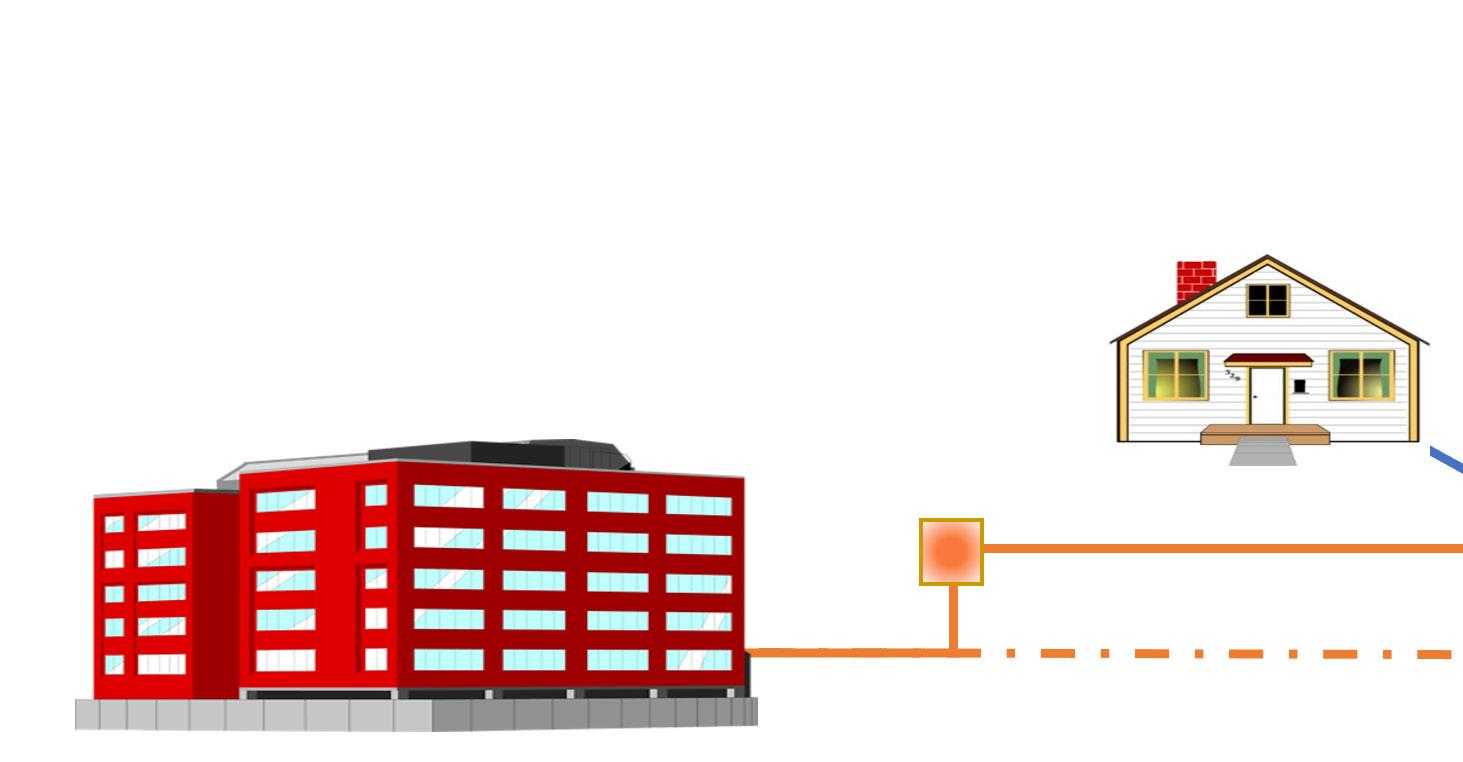

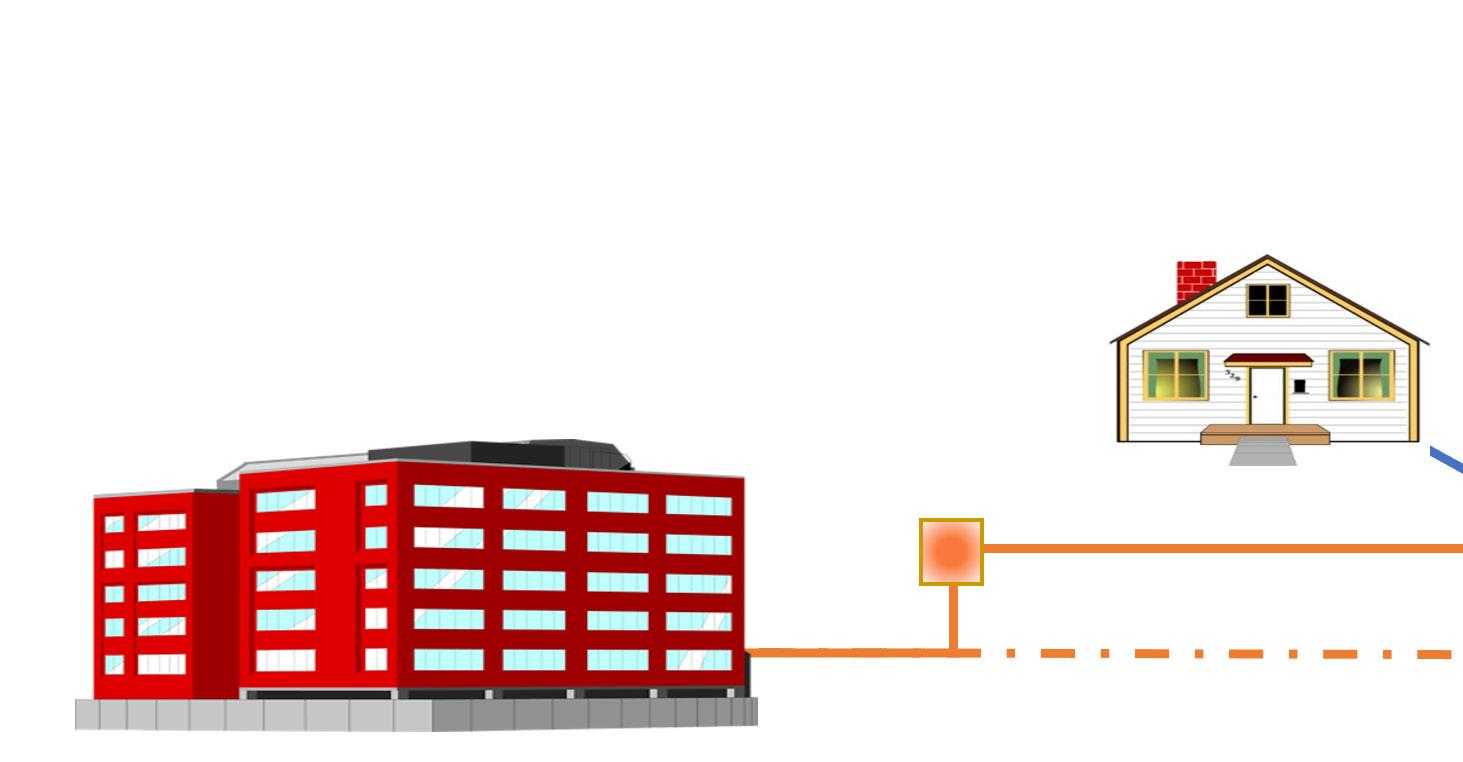

Central Office

• Calix OLTs

• Network Routers

• Backhaul Network

12

How Brightspeed is rolling out fibre to its copper-connected customers

Feeder and distribution fibre Calix WiFi6

D-Tap Splitter

and supply chain and it’s a highly integrated, highly diverse business.”

Tom goes on to detail how Brightspeed is running its new network. “The Brightspeed Fibre product is a fairly new architecture with a new suite of operational and building support systems. That’s the start-up piece of the equation

and things are going well,” Tom continues, adding that the whole enterprise is feel-good. The planned architecture includes a ‘plug-and-play’ model to minimise the expense associated with traditional fibre splicing.

“Reducing our cost per location allowed us to do more build,”

13

“With a build plan in place for 2023 to 2027, we know exactly what locations, markets, and wire centres Tom’s teams plan to build”

Additional fibre capacity pushed to customers

Calix In-Home ONT and WiFi6 Mesh Towers

says Tom, highlighting that on top of the $7.5bn Apollo paid to set up the company, it invested another $2bn to roll out the fibre infrastructure that Tom says will be transformative.

“There are a lot of studies around people’s educational or business opportunities, but I talk to customers living in rural America whose lives depend on really strong connectivity that just doesn’t exist in the copper world,” says Tom.

Brenda says that the new procurement, purchasing and supply chain organisation involved collaborating with 35 fellow professionals while negotiating and executing more than 450 supplier contracts. As Tom puts it, you can’t just go to a local hardware store to pick up telecoms company supply needs, so he credits the early faith of partners such as Calix with being part of that enablement. “Calix

is providing our OLTs or optical line terminals and ONTs, optical network terminals, and wifi-6 mesh towers,” he says.

“We standardised on things because of supply chain issues, especially relating to fibre infrastructure. There’s a lot of demand for electronics associated with fibre, so about a year before the transaction [with Lumen] closed we went

15

“Calix is providing our OLTs or optical line terminals and ONTs, optical network terminals, and wifi-6 mesh towers”

Brenda Rapp, Supply Chain VP

to major providers and told them what we wanted,” Tom continues. “There are only a few manufacturers and we had certain criteria for who would work best for our planned fibre build.” The pandemic led to the decision to near-shore and avoid transportation issues that were dogging existing providers. “We wanted to stick with certain companies and manufacture in North America as much as possible,” he says. Having a long employment history in the industry, Chris, Bob and Tom already knew many suppliers.

“We sat down with them and told them what we were looking for,” he says. “We were trying to build as quickly as possible and we are still looking to ramp things up,” says Tom. The same kind of process is in place with partner Corning. “We told them what we needed and how much we thought we would need, and they said they could support us as well.”

Having made the transition between Lumen and Brightspeed herself, Brenda emphasises that in her area of work good planning is a key to

16

17

success. “It is refreshing to know that the investment for growth is here,” she says. “The company culture, financial backing and management support to execute and place orders far in advance, to ensure that we have what we need when we need it – well, that doesn’t happen in a lot of companies.”

Brenda says, “It’s really nice to go to work for a company that has a higher purpose rather than one that focuses just on making money and putting products ‘out there’. There’s a higher mission in terms of delivering high speed internet and infrastructure based on investment in infrastructure that these underserved areas haven’t seen previously.”

A former New Yorker who now lives in Florida, Tom admits he had assumed everybody in the US had cell phone connectivity, laughing

as he adds: “Even my 87-year-old mother has a cell phone!” On a more serious note, Tom points out that in his experience his mother’s demographic has embraced online and side lined old-style voice service. “They shop, and they don’t worry about getting to a store because they click on something and order it, and it just shows up!” he says.

Brenda is quick to credit Brightspeed’s partners for helping the company provide such customers – existing and future –with the right equipment to make interconnectivity the stuff of the everyday. To illustrate, Tom pulls up a graphic showing the fibre network running in parallel with the copper network. He highlights Zyxel as a key partner in this.

“Zyxel has been around a long time and is very reliable in supporting our legacy business,” he says. “Even once we are done with the initial fibre plan, assuming that we don’t add to it, we can only build out to about half of the households that we have and that means some customers will still be served with copper, so it’s important to me that we maintain relationships with them,” he says. Even with capital made available through the US

18

“

Zyxel has been around a long time and is very reliable in supporting our legacy business”

No

technology leadership and trusted partnerships, Nokia is helping industries digitize to be more connected, productive, safe and sustainable.

Through

Delivering critical networks to help address global issues Learn more: www.nokia.com Fixed Networks Optical Transport Cloud & Network Services IP Routing

green without Digital

government and grants from the Broadband Infrastructure Fund, a copper-based service will continue for many households for some time, Tom predicts.

“We are still investing in our legacy copper and Nokia is our ethernet core edge equipment provider. They also provide some software to monitor our copper network

territory, there could be miles between households.”

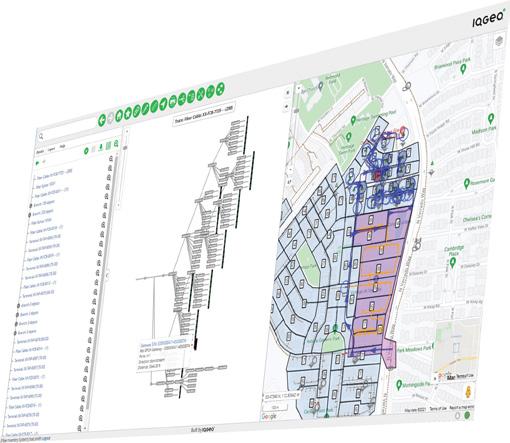

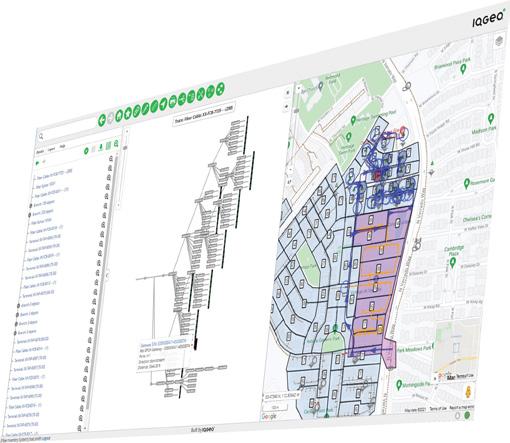

That vastness is one of the reasons Brightspeed has found IQGeo’s geospatial software solutions for telecoms and utilities invaluable. Tom says engineers used to take days and weeks to accomplish what IQGeo’s engineering platform can do in minutes.

in our legacy copper and Nokia is our ethernet core edge equipment provider. They also provide some software to monitor our copper network adequately and make sure we run that as efficiently as we can for customers who remain on copper”

adequately and make sure we run that as efficiently as we can for customers who remain on copper,” says Tom.

A recent first visit to Europe brought home to Tom just how vast the territories in the US could be. “I went to Venice, and it struck me there was a lot of water, but every household had fibre,” says Tom. “Venice is a densely populated area, however, in our

“Outside plan engineers make records and keep databases of where telephone poles and cables are, where the rocks and manholes are. Typically, it was a manual process for an engineer to go out there and over time, some records were maintained more accurately than others,” Tom says.

“We started working with IQGeo, a company that draws information from golden sources

21

“We are still investing

and databases and uses satellite imagery. As it’s an electronic platform, when people are actually doing the physical work associated with the engineering design, they can make changes and edits on a tablet while they are out and that will trigger equipment and materials orders necessary for that particular build. It helps us from an inventory management perspective because we know how many ‘widgets’ are out in the field,” says Tom. In addition, outside plan contractors who

Building better networks

IQGeo’s network management software is helping innovative fiber operators like Brightspeed to rapidly and e ciently deliver vital broadband services to homes and businesses. Our award-winning enterprise solutions are used around the world to plan, construct and maintain the networks of the future.

• Model anything

• Use anywhere

• Integrate everything

• Innovate constantly

22 Copyright © 2023, IQGeo UK Limited. IQGeo is a registered ® trademark. iqgeo.com Carbon Neutral Organisation

TM

“IQGeo is an electronic platform, when people are actually doing the physical work associated with the engineering design, they can make changes and edits on a tablet while they are out and that will trigger equipment and materials orders necessary for that particular build”

complete certain segments of the build get paid more quickly because all the invoicing is triggered electronically, as well.

He explains that the information gathered also helps Brightspeed secure funding. “In North Carolina, for example, we received $90million in grant funding, which sounds like a lot of money but when you are

building infrastructure it is not,” says Tom.

“The reason we're able to do this innovation is because when we took over this particular territory, it didn't have a lot of fibre; we were effectively starting from scratch. That allows us to do things differently and it's actually a strength of our business.”

HONOURING THE SPIRIT OF SERVICE

The spirit of service is still an important ethos for the people who work for Brightspeed.

Tom is quick to bring up the name of Angus MacDonald, the legendary US lineman who epitomised employee devotion to maintaining telephone connectivity during the snowstorms of 1888. Tom also points out that Angus would not have the snowshoes, flashlight, rope and equipment to get his job done without procurement teams, and that fact has not changed. “It’s the people in Brenda’s side of the business

that enable us to carry on,” he says, adding, “I was talking to somebody in the wireless world one day and he mentioned a big storm was coming and that everybody in his wireless business was going to work from home thanks to technology and connectivity. And I said, ‘Yeah, well, we'll be out there making sure your connectivity works,’ and sure enough, despite weather issues, the next day our team all showed up for work.”

For further information on Brightspeed, visit www.brightspeed.com

23

FOOD WASTE

Food production and climate change are inextricably connected: that is a fact. So is food waste. When a foodstuff is binned uneaten its entire carbon footprint from cultivation, harvest, transportation, retail and home storage, is also being dumped. So how can the food system be reformed?

FOOD SYSTEMS ARE RESPONSIBLE FOR NEARLY A THIRD OF ALL GREENHOUSE GAS EMISSIONS, YET A THIRD OF EVERYTHING GROWN FOR HUMAN CONSUMPTION NEVER MAKES IT TO THE TABLE.

t is composted, dumped in landfill or turned into animal feed instead.

Danielle Nierenberg is the president of Food Tank, a non-profit organisation aimed at reform. She has produced a food and tech policy platform to engage and empower people working in agriculture, food and public health policy. Data-driven tech in the food system could provide answers. The truth is, everyone needs to make more effort to drive down food waste and loss. Food waste is the official term for food that is left to spoil or else discarded while still edible. Reasons could be poor stock management, confusion about the difference between sell-by and

best before expiry dates, or just forgetfulness. Food loss is the term used to describe food that spoils before it even gets to someone who can eat it, and is usually the result of transportation challenges, poor storage or weather damage.

The United Nations (UN) targets world hunger as part of a sustainable development plan. There is a direct link between farm-to-retailer food supply chain issues, and food loss and food waste, according to an autumn 2022 report published by global management consultancy McKinsey. Following on from its 2016 report, which detailed how big data would revolutionise world food chains using advanced analytics,

McKinsey experts are examining ways that grocery retailers, manufacturers and the food production industry can tackle the loss and waste issues together. The experts, based in Cologne, Paris, London and New York, point out in their report that the cost of food loss can be equivalent of, or greater than, a retailer’s annual net profit. In a small and informal poll, two-thirds of the industry leaders questioned agreed weak governance was the biggest roadblock to the implementation of food loss programmes in their companies.

C-suite executives should be viewing food loss reduction as a strategic priority, says McKinsey.

“One of the most important enablers for significant and sustained change, therefore, is a strong governance model – with cross-functional accountability encompassing procurement, research and development (R&D), the supply chain, manufacturing, marketing, and finance; clear responsibilities and objectives; and key performance indicators (KPIs) at the individual, functional, and

enterprise level,” the report authors state. “Designating an owner for each food loss initiative and aligning on measures of success will help ensure progress. New performance metrics might include, for instance, the volume of food lost, the profit from upcycling, or the

revenue gained from saving food that would otherwise be lost,” they continue.

Winnow, a company that helps commercial kitchens and chefs manage and monitor their food waste and costs, states that

"ONE OF THE MOST IMPORTANT ENABLERS FOR SIGNIFICANT AND SUSTAINED CHANGE, THEREFORE, IS A STRONG GOVERNANCE MODEL"

food waste costs the hospitality industry more than £100billion annually. It calculates that its technology has helped users save £42million, or the equivalent of 36.5m meals, and 61,000 tonnes of CO2.

There is a financial incentive for the retail, horticulture and agriculture sectors to improve their processes and performance. But where are the domestic solutions? Smart fridges can prompt owners to eat what they contain by bringing up a visual list on the door and monitoring vegetables’ lifespan. At the top end of most people’s fridge-purchasing budget, these internet of things (IOT) devices can also keep contents fresher for longer using optimised temperatures, humidity and even a sun cycle, and allow owners to order and restock via connections to online shops. Food waste apps like Nosh are a less pricey alternative to a smart fridge. They monitor shopping and eating

"FOOD LOSS IS NO-ONE’S PROBLEM, AND NO INDIVIDUAL OR TEAM OWNS AND CHAMPIONS THE ISSUE. BUT IT MAY SOON BECOME AN ISSUE THAT NO-ONE CAN AFFORD TO IGNORE"

- McKinsey

habits by helping users keep an inventory, suggesting recipes for food already in the house, and issuing alerts when food is about to go off. As an alternative solution, OLIO enables users to pass on food and non-food items to neighbours also using the app. OLIO calculates that 58million portions of food have been shared (so far) as a result.

Householders can only make so much difference by curbing food waste, however. The drive to curb food loss still has far to go. As McKinsey’s experts put it, the unfortunate reality is that food loss is no-one’s problem, and no individual or team owns and champions the issue. But it may soon become an issue that noone can afford to ignore.

A People-Sensitive Supply Chain Transformation

Manuel Brkovic, Supply Chain Director at Podravka, shares his company’s supply chain story in the year that marks its 75-year anniversary.

34 BUSINESS INTERVIEW

Transformation

People-Sensitive

Podravka is one of the largest food manufacturers in Southeast, Central and Eastern Europe and is proud to be celebrating its 75th anniversary this year.

s well as the food processing side of the business, the group has a pharmaceutical company, which has been in existence for 50 years. There are over 1,800 different products in Podravka’s impressive portfolio, with around 6,500 employees. The company has 17 production sites in four countries, serves over 70 markets and its revenue in 2021 was around 600 million euros.

Manuel Brkovic, Podravka’s Supply Chain Director, tells us more; “If you look at the Podravka supply chain itself, we have 17 manufacturing sites and over 1,000 SAP warehouse/ storage locations all over the world.

36

37

When you consider the size of our market, which is the whole world, you can understand the complexity we are facing. Our long history and the fact that our region is still in a transition to a developed democracy and modern productive society means our supply chain transformation has brought about big changes.”

Manuel talks about three main pillars of Podravka’s transformation journey – lean excellence, digitalisation, and modernisation/automation, and all of them surrounded by a green/sustainability agenda. He continues, “Such a large company started facing the global problem of finding the right employees, but also finding enough of them to cover our growth. Additionally, with the development of Croatia, labour costs are going up, which impact our bottom line. About 20 years ago, Croatia offered cheap labour, great knowledge, and people that knew how to make high-quality products, and this was easily bringing jobs from more developed countries. We are now finding that we are losing workers because salaries are going up in other industries, but the food industry is not closely following this trend, and competition is also getting stronger and stronger.”

The aforementioned pillars were chosen to remove non-productive work from employees, enabling them to focus on producing the value. Manuel says, “With lean and digitalisation, data is available on screen and paperwork can be removed. People can lose up to two hours per day setting up the machines, preventing them from producing real value in this

38

time. The automation of production machines enables them to cut down on the time they spend on mundane tasks and be more productive. If a robot can do something, why shouldn’t it?”

These changes ultimately serve the buyers i.e. the retail stores. Manuel explains, “Our production needs to be planned and runs at one to one

and a half months, so that orders can be delivered 24 to 48 hours after they are placed. We need to be able to forecast to prevent shelves from being empty because the production time is too long to produce an order straight after it is placed. That is why we introduced sales and operations planning and stock control. To be such a big manufacturer, you need stock

39

availability, which means hundreds of millions of euros in stock. It can put a great strain on the business without proper planning.”

Better planning and stock control also amplify a sustainability element. Manuel elaborates, “If a machine is 10 per cent more

40

“If a machine is 10 per cent more productive in a specific timeframe, you are using less energy to get the job done”

productive in a specific timeframe, you are using less energy to get the job done. Less paperwork is also better for the environment, and if the machine has to be higher in energy class, it will make the same product with less energy consumed. This is what we call our green strategy for the supply chain transformation.”

What challenges has Manuel faced in implementing his supply chain strategy? He answers, “Lean is a modern method that is still not completely understood in this area of the world. Technology and digitalisation face the same problem because the workers in Podravka are typically 45 to 50 years old. They are not used

41

“Digitalisation and technology are running through Podravka, age of the company, it is always with a human approach. Industry 5.0 is about, putting the people at the centre”

to touchscreens. But, if we work across the three pillars with better planning in place, we can slowly and continuously approach training our people to be more productive.”

This challenge in changing the mindset is perhaps the biggest obstacle for Manuel and his team. He explains, “With a 75year old company and employees who have been here for over 25 years, the new technology, new methodology and new ideas can be frightening. The operations and technology team is socially-sensitive and fast to explain that the people will be doing much more valuable work.

Instead of noticing only when there is a mistake, they can now see how they can save money and improve the productivity, so they are understanding that they are increasing their value, together with increasing the company value. It is easy to transform through technology, but you need to have the people on board. Our sociallysensitive approach show the

43

Podravka, but due to the approach. This is exactly what

employees how they can use their time for much better things.”

Manuel says Podravka’s biggest achievement in its 75-year history is the fact that it is still going strong. He continues, “After switching from communism and socialism to the free market, too many companies in our region disappeared from the market. With the growing competition and the big global players cornering the market, it is a huge achievement to be still here.”

to implement SAP, and with the help of our partner Atos, one of the first regional companies to use BW (Business Warehouse) that connects and shows all important financial and business data. We are further developing our technology to switch to the newest SAP software available, and Atos is continuing to support us on the reporting side.

“The founder of Culmena was one of the first people in Croatia to start talking about lean. We brought

Podravka’s strategy for the future involves collaboration with key partners such as SAP (Atos) and Culmena. Manuel highlights, “Our partners are the core of our transformation. Our ERP system connects all the dots in our company. Without it, the supply chain, sales, finance, and all other departments would have their own software and not be able to see the entire impact on business. Podravka was the first company in Croatia

Culmena here to Podravka to help bring that knowledge. The project is all about trying to teach our people how to think lean. Culmena understands the mentality of the Croatian people, so we are able to take a psychological approach to slowly convincing them that these changes are for the better.”

Leveraging the opportunities of Podravka’s transformation will be Manuel’s next job. He says, “We

44

“Podravka was the first company in Croatia to implement SAP, and with the help of our partner Atos, one of the first regional companies to use BW (Business Warehouse) that connects and shows all important financial and business data”

The art of intelligent warehouse operations

Logistics and supply chain management are a finely integrated art. Recent disruptions have made it even more important to have accurate, real-time information about every part of your supply and delivery chain — including your warehouses.

Intelligent, automated warehouse management solutions from Atos and supported by SAP provide a unified, integrated way to monitor and control your critical warehouse operations. We integrate consumption predictions for superior stockkeeping, plus track-and-trace on large warehouses and yards, delivering:

• Optimised control of day-to-day operations

• Easy storage and retrieval, even on very large sites

• Real-time updates and visibility

• Full traceability of all operations

Learn

Logistics warehouse management from Atos is fully integrated into your warehouse concept and the entire supply and delivery chain, helping achieve the speed, reliability and cost efficiency you need. more at atos.net/industries/logistics

have just finished our production digitalisation project in our pilot factory, so we will now need to add 16 factories in the next two years to make all of Podravka’s manufacturing part digitalised. Every department will be able to read the same information from the same dashboard, which will be automatic. Modernisation is going on all the time. We are building new factories and renewing the machines. With the global energy crisis, being green and sustainable is so important.

We have one of the biggest solar plants in the country. Our five-year plan is to have 90 to 95 per cent of our energy produced in-house

LEAN DIGITALISATION GREEN

by solar and biomass in our main production zone.”

LEAN DIGITALISATION GREEN

by solar and biomass in our main production zone.”

The vision for continuous improvement means Manuel is always looking at what is coming next. He concludes, “Digitalisation and technology are running through Podravka, but due to the age of the company, it is always

with a human approach. This is exactly what Industry 5.0 is about, putting the people at the centre. We have to slowly show them that technology can improve their work and their lives, which is not so easy. It is something you have to do continuously.”

For further information on Podravka, visit www.podravka.com

47

“Culmena understands the mentality of the Croatian people, so we are able to take a psychological approach to slowly convincing them that these changes are for the better”

The Biden-Harris administration’s country’s transportation system where no other administration

TRANSPORTATION

administration’s blueprint to clean up the system steers the US in a direction administration has dared to go.

he blueprint sets out plans to eliminate almost all greenhouse gas (GHG) emissions by 2050 in the transportation sector, a bold move since the sector is the largest source of GHG emissions in the US.

Published in January 2023, the blueprint will shake up the US transportation system. Transportation forms the backbone to

the nation’s economy and connects people, countries and cultures.

But it also contributes to a climate crisis that is worsening the quality of life in cities, towns and rural communities throughout America. The US National Blueprint for Transportation Decarbonisation addresses ways to provide better transportation options, expand affordable and

America’s love affair with the combustion engine is a relationship of necessity: the opening lines of the US National Blueprint for Transportation

Decarbonisation admit as much.

accessible options to improve efficiency, and how the nation can manage the transition to zeroemission vehicles and fuels. Achieving the goals will require close cooperation with industry, local, regional, state, and Tribal governments, non-profits, and other stakeholder groups, as well as allies around the world, it is clear. But bold action will result in a clean transportation system that is safe, secure, accessible, affordable, and equitable, for all Americans to help create a more sustainable future for generations to come, it states.

Here is a summary of how the blueprint will lead the country towards those goals.

>>> Light duty vehicles

Currently cause 49% of transportation emissions

GHG emissions targets

• 50% of new vehicle sales will be zeroemission by 2030, with a supported pathway for full adoption. New internal combustion engine vehicles will be as efficient as possible.

• 500,000 EV chargers will be deployed by 2030.

• 100% federal fleet procurement will be zero-emission by 2027.

>>> Medium and heavy-duty trucks and buses

Currently cause 21% of transportation emissions

GHG emissions targets

• 30% of new vehicle sales will be zero-emission by 2030 and 100% by 2040.

• 100% federal fleet procurement will zero-emission by 2035.

>>> Off-road vehicles

Currently cause 10% of transportation emissions

GHG emissions targets

• More work is needed to establish specific targets.

• Resources will be focused to develop technology pathways and set efficiency and zero-emissions vehicle and equipment targets.

>>> Rail

Currently causes 2% of transportation emissions

GHG emissions targets

• More work is needed to establish specific targets.

• Resources will be focused to develop technology pathways and set efficiency and zeroemissions vehicle targets.

• Greater use passenger and freight travel will be encouraged to reduce emissions from road vehicles.

>>> Maritime

Currently causes 3% of transportation emissions

GHG emissions targets

• Support will continue for ZeroEmission Shipping Mission (ZESM) goals to ensure that 5% of the global deep-sea fleet is capable of using zero-emission fuels by 2030 and that least 200 of these ships primarily use such fuels across the main deep sea shipping route, and 10 large trade ports covering at least three continents can supply zero-emission fuels by 2030.

"The blueprint sets out plans to eliminate almost all greenhouse gas (GHG) emissions by 2050 in the transportation sector"

• More research development and demonstration (RD&D) will go into sustainable fuels and technologies to support the US domestic maritime sector and to incentivise US commercial vessel operators to move towards lower GHG emissions.

• There will be more work with countries in the International Maritime Organisation to adopt a goal of achieving zero emissions from international shipping by 2050.

>>> Aviation

Currently causes 11% of transportation emissions

GHG emissions targets

• To reduce aviation emissions by 20% by 2030 when compared to a business-as-usual scenario.

• To achieve net-zero GHG emissions in the US aviation sector by 2050.

• To catalyse the production of at least 3billion gallons of sustainable aviation fuel (SAF) per year by 2030 and around 35bn gallons by 2050 – enough to supply the entire sector.

>>> Pipelines

Currently cause 4% of transportation emissions

GHG emissions targets

• To continue work to establish specific targets.

• By 2036, repair or replace 1,000 miles of high-risk, leak-prone,

community-owned legacy gas distribution pipeline infrastructure, as well as an estimated reduction of 1,000 metric tons of methane emissions.

• To continue to eliminate leakages and enable use of pipelines for clean sustainable fuels.

= GRAND TOTAL

Sector total 100%

GHG emissions targets

• 80–100% emissions reductions by 2050 (in line with the US LTS).

Source: The US International Trade Administration supply chain services

Assortment

Optimisation & Automatic Replenishment

Arthur Caron, Supply Chain Director at Franprix, shares his company’s exciting vision for the future.

BUSINESS INTERVIEW

Franprix is a French convenience store chain, headquartered in Paris and owned by Casino Group.

60

Supply Chain Director

Arthur Caron has been at the company for around six years, and is responsible for both the upstream and downstream parts of Franprix’s supply chain. He explains, “My team and I deal with the products from suppliers coming into our warehouses, making sure

we have the right inventory and stock available for the stores to order. On the other side, we drive the order process from the stores to the warehouse, supporting them with their orders, whether that is through automatic solutions or manual processes, so they are able to sell all the products that they need to sell.”

61

With four warehouses to its name, Franprix’s supply chain strategy is based on simplicity, but there are a number of challenges in delivering to central Paris each day. Arthur continues, “Most of our stores are in the same region within Paris, but we are talking about replenishing

small convenience stores in a densely urban area. When it comes to our strategy, we need to deliver almost on a daily basis because the convenience stores are roughly between 150 and 600 square metres in size, so there is no room for local storage. It is about frequent deliveries of small quantities, so the supply chain strategy has to be extremely intricate and precise. You cannot afford to make mistakes regarding delivering the right products to the right stores on time. You need to have an agile supply

chain to do that, and this is where Franprix excels.”

Franprix’s warehouses are situated close to Paris, where most of its convenience stores are located, which enables it to make daily deliveries. Once an order from a store has been received, fresh and ultrafresh products can be delivered within 24 hours (sometimes 12 hours), and dry products can be shipped within

62

“One of our strengths is our ability to deliver in a dense area whilst avoiding traffic jams; for 10 years we have been using a barge to transport goods down the Seine from our warehouse just outside of Paris”

36 hours. Arthur enthuses, “One of our strengths is our ability to deliver very quickly, compared to our competitors. Part of our urbanisation strategy was to find the right path through cities to efficiently navigate dense traffic, working closely with local authorities. Being first to do so in Europe, we have been using a barge for 10 years to transport goods down the Seine from our warehouse just outside Paris. The containers are offloaded in front

of the Eiffel Tower onto small delivery trucks at around 5am each morning to deliver to more than 300 Parisian stores.”

The customer experience is front and centre of Franprix’s supply chain strategy. Arthur says, “With convenience stores, people tend to purchase small items here and there on a daily basis. At Franprix, the average basket is around 12 euros, and there is

63

64

a store every 300 metres within Paris. From a supply chain perspective, we aim to supply everything people will need at a given time. We have to offer a wide assortment within small stores, which is not easy, so we must replenish stores with exactly the right SKUs that the customers need whilst ensuring that we are not providing products that do not meet their requirements. For the optimisation of our assortment, it is important to be precise on what we are fulfilling to the stores.”

With more than 10,000 SKUs in its warehouses, Franprix is confident that it can make the right selection for each store. Arthur adds, “Based on a centralised recommendation, each store tends to have its own assortment, so we have to be sure that we don’t just replenish the right amounts, but that we select the right assortment for the right store based on its customer base. We adapt

the assortment by analysing the customer purchases and behaviour in a particular neighbourhood.”

So, what are Franprix’s plans for future growth? Arthur answers,

“For the next four years at least, our strategy will be growth-focused. We feel that tomorrow will be centred around convenience stores and online retail, so we are planning to open more convenience stores (250 stores per year), doubling the size of Franprix within the next five years. We would also like to address other regions, expanding to the suburbs around 30 kilometres from Paris and across the Rhone corridor. We believe there is room for convenience stores in this area, as well as the big French cities such as Lyons, Marseille and Bordeaux.”

The challenge that Arthur faces is that all of Franprix’s warehouses are based around Paris. He explains, “Any

65

“For the next four years at least, our strategy will be growth-focused. We feel that tomorrow will be centred around convenience stores and online retail”

new store outside the Paris region is a challenge. There are no plans to open new warehouses right now, so we will do our best to optimise the current network. We could also benefit from using other warehouses within the Casino Group.”

Franprix’s online activity is based on a ship-from-store model, leveraging its great assets within city centres. Arthur adds, “We are steps from our customers, so they can order online and receive their delivery within 30 minutes. We are

66

“Relex helps us to select the most efficient assortment for each store”

working on this model because we would like to increase online retail sales from 3 to 10 per cent.”

For Arthur, you can have the best technology and digital experience, but it will not work if you do not have the right operational excellence when it comes to delivering the order to the customer. He adds, “We are going back to basics by looking at the

process and making sure we are doing what we say we will.”

There are a couple of key projects that are exciting Arthur at the moment around automatic store replenishment. He says, “We have more than 1,000 convenience stores, and a quarter of them are on a centralised automatic replenishment platform provided by our partner Relex Solutions.

67

Case Franprix Improving Operational Efficiency through AI-Driven Forecasting and Replenishment

A leading convenience store retailer, Franprix has some 900 store locations throughout France, mainly around the Paris area. While the majority of these locations are franchised, about one third are centrally owned and operated.

The Challenge: Decentralised Ordering Led to Operational Inefficiency

Franprix’s replenishment process was decentralised and time-consuming, with store associates placing replenishment orders manually. A lack of optimisation led to unnecessary stock-outs, waste, or over-stock. This decentralised ordering model also led to delivery peaks on their typically high-volume weekends, causing capacity issues in both stores and the distribution center. Store personnel struggled to replenish shelves and deliver customer service at the same time, while excess stock often spilled out of crowded back rooms onto sales floors.

Realising their business could no longer be supported by their existing processes, Franprix sought a supply chain solution that could:

• Automate previously manual store ordering, including for challenging fresh products

• Optimise forecasting and replenishment to increase availability and reduce food waste

• Increase operational efficiency by leveling out the flow of goods into stores so that store personnel could focus on clients and added-value services

Change Management Was Key to Rapid Transformation

Embarking on an ambitious supply chain transformation initiative, Franprix evaluated RELEX through a fresh replenishment pilot in three stores and, after strong results, chose RELEX to provide their 270 centrally managed stores with AIdriven forecasting and replenishment. They were compelled by the ability to optimise forecasting and replenishment for short shelf-life products like fresh bread to increase availability and reduce food waste.

“We were a bit late in automating forecasting and replenishment compared to our main French competitors,” admitted Franprix’s Head of Operational Excellence Arthur Caron. “However, this allowed us

to move straight on to using the latest technology available, which gives us a clear competitive edge.”

Preparing for a technological step-change, Franprix developed a cohesive change management plan that ensured employees developed trust in the new tool and processes. During the roll-out phase, the company assigned up to ten “on-the-ground” employees to travel continuously to Franprix stores and speak with store managers. Mostly former store managers themselves, these change management facilitators were able to understand and speak directly to store personnel’s concerns and wishes—a key part of any change management project that is too often bypassed.

Franprix also assigned more than ten central employees to respond to store personnel during roll-out, checking store-level sales and other data in RELEX to quickly answer staff questions and adjust system parameters as needed. Much of the success of their RELEX implementation can be attributed to the investment they made in bringing store personnel on board. It took time, but it was worth it.

Results

Results at a Glance

• 67% decrease in stockouts

• EUR 1.7M (USD 2.2M) reduction in inventory value

• 30% decrease in product spoilage

• 2 pp margin improvement

Due to their thoughtful change management campaign, Franprix has seen remarkable improvements from the adoption of RELEX. The solution’s AI-driven demand forecasts have improved replenishment accuracy by automatically capturing store-SKU-level sales patterns impacted by weekday variation, seasonality, market trends, and even local weather forecasts.

The ability to leverage machine learning algorithms

68

Watch a RELEX Demo

to automatically calculate the impact of weather data on demand has proven quite valuable for Franprix, as the impact on products and stores varies depending on a store’s location or customer base. “I noticed on the news that a heat wave was coming and thought to myself ‘shoot, I should have seen this earlier, I need to let my planners know,’” said Caron. “But when I reached out to the team, they told me not to worry. RELEX had already adjusted our forecasts based on the latest weather forecast.”

Forecast accuracy also drove improvements in store replenishment. Though Franprix stores are small, they carry a large inventory of fresh products, including meat and fish, salads and sandwiches, bread, and dairy. Taking store-level demand data into consideration, RELEX automatically optimised Franprix’s fresh and ambient product replenishment, reducing stockouts by 67%, fresh food waste by 30%, and inventory value by €1.7M.

Franprix has also benefitted from RELEX’s proactive “delivery flow smoothing,” which autonomously considers future order projections and pulls orders for long shelf-life products forward to smooth out flow of goods. With a more level, manageable flow of goods into stores, they no longer experience overwork and stress from store personnel having to replenish shelves while also meeting customer needs during footfall peaks. The risk of congesting small stores with big deliveries is much lower, and they’ve also seen improvements in DC capacity management, which was struggling with more than 500 stores placing their largest order of the week every Friday. This smoothing helped reduce DC workload by 20% on Fridays.

Improved store replenishment

RELEX’s AI-driven demand forecasts allowed Franprix to increase product availability and reduce food waste.

Beyond forecasting and replenishment, Franprix has leveraged RELEX’s powerful analytics for continuous assortment optimisation. The system monitors each SKU’s sales and profitability and automatically provides recommended assortment adjustments for each store on a weekly basis. Franprix is now able to quickly excise poorly performing products and replace them with products that both better meet local demand and maximise store profitability.

“RELEX’s flexible automation makes it simple and straightforward to implement changes in accordance with our company strategy,” said Caron. “I continue to be impressed by the flexibility. The range optimisation that we do with RELEX, for example, would not have been possible with any other tool.” Using that same flexibility, Franprix has been able to analyse and systematically drive down stock for long-tail products as well.

As Franprix looks to the future, that flexibility will serve them well as they continuously adapt their supply chain practices to the dynamic conditions of modern retail. RELEX will help them evolve their business well into the future, but RELEX’s team will also be there every step of the way. “The collaboration with RELEX is a true partnership,” said Caron, “and we’re going to make incredible strides together for years to come. We have many projects in mind!

Advanced assortment optimisation

Franprix is now able to maximise store profitability by leveraging RELEX’s powerful analytics in replacing poorly performing products with products that better meet local demand.

69

Meet us at Euroshop! February 26 - March 2, 2023 Düsseldorf | Hall 6 / 6C24 Register Now

“This means each store doesn’t have to place an order, but software gathers and analyses the data, making a forecast based on the stock, sales and delivery expectations, to avoid any shortages and maximise sales. It is a very efficient way to replenish the stores. The software works with three years’ worth of historical data, so it can notice trends and events at

certain times of the year, specific to each SKU within each store. Relex also provides external data for automatic replenishment purposes, such as customer behaviour based on the weather. It is all about the machine estimating what a human would have done manually.”

When it comes to assortment optimisation, Relex assists in selecting the right products for

70

each store to meet the local customer demands. Arthur explains, “Relex helps us to select the most efficient assortment for each store. On a weekly basis, the software detects the products that are not efficient enough by analysing the sales, pricing and cost, suggesting which SKUs should not be replenished because they are taking up too much valuable

space. If a product is performing well in a similar store, you have the opportunity to optimise the store assortment by replacing it with this SKU. It is a step-bystep process, leveraging the personalised data for each store.”

For the 750 stores that are not using automatic replenishment, Franprix is working on a new tool to allow them to order products from the warehouses more easily. Arthur elaborates, “In a nutshell, we want to give stores a full B2C customer experience using the website for ordering from the warehouses. It is about creating an enhanced, interactive online experience and customer journey with relevant images, product descriptions and order suggestions based on popular products and the store’s order history. The stores that order every day want something easy to use that taps into their everyday technology use. That is our vision, but it is still very much early days.”

With so many fantastic projects in the pipeline, we look forward to seeing Franprix’s future plans come to fruition.

For further information on Franprix, visit www.franprix.fr

71

CAROLINE CIOE

CAROLINE CIOE

72

73 CIOE CIOE

by NEVER MISS AN ISSUE SIGN UP FOR FREE! SUBSCRIBE

Produced

RESILIENCE & AGILITY

The textile industry is facing up to supply chain challenges by innovating its technology, looking for new resources and improving environmentally friendly practices.

AS A GLOBAL BUSINESS THE TEXTILE INDUSTRY IS COMPLICATED, BUT IT IS TURNING TOUGH CHALLENGES INTO A POSITIVE ECONOMIC BENEFIT BY SOURCING PLANT-BASED ALTERNATIVES TO PETROCHEMICAL FIBRES.

The cellulose fibre market is set to post healthy growth over the next four years, according to leading analysts. In January 2023, market research company Technavio announced predictions that Asian Pacific (APAC) countries will contribute 40% of the sector’s market growth over the next

four years. The market growth for cellulose fibre worldwide is expected to top $15million and Technavio projects a compound annual growth rate (CAGR) of 9.18% during the forecast period.

Textiles are used in a wide range of applications from clothing, furniture and furnishings, to automotive interiors, medical

dressings and more. The industry crosses continents, since an item can be made from raw materials grown or manufactured and spun into fibre in one country, then woven and dyed into a fabric in another. A designer working in Europe selecting a fabric to suit their product could have it shipped from a warehouse in India, cut, sewn and finished in Hong Kong, and transported to retailers anywhere in the world, from where it will go on to customers.

Fashion alone has an estimated global market value of €1.5trillion, and the fashion and textile industry employ 430m people, or around 1 in 8 workers globally, according to figures compiled by PwC, the global professional services firm. Many industries have a goal of zero waste to landfill, and use technology to help with that quest, but few are as high profile as textiles and fashion. Knowing that cheap garments are made in sweatshop factories, then discarded after a short lifespan, has guilt-tripped customers into changing their habits. PwC calculates that the resale, rental and secondhand markets will

become almost twice as large as fast fashion by 2029.

Cellulose fibre has been making headlines because, although it encompasses both natural (eg cotton, hemp and linen) and manufactured (viscose, rayon, Lyocell and modal) textiles, it is a more environmentally friendly choice than many other materials. At the end of its useful life, a cellulose fibre can be composted because it is 100% biodegradable, unlike plasticbased fibres that can take 100 years or more to decompose. But not all cellulose fibres are equal. Lyocell, which is created from wood cellulose, most often eucalyptus, can also be made of oak, bamboo and birch. The process takes around 150 minutes from chopping

“CELLULOSE FIBRE HAS BEEN MAKING HEADLINES BECAUSE, ALTHOUGH IT ENCOMPASSES BOTH NATURAL AND MANUFACTURED TEXTILES, IT IS A MORE ENVIRONMENTALLY FRIENDLY CHOICE THAN MANY OTHER MATERIALS”

the wood to carding, and uses less energy and water than other processes. The synthetic chemicals needed during the manufacture are recycled in a closed loop – ie recycled and reused with little loss. Viscose, a similar plant-based fabric, generates by-products, according to the Lyocell information hub. On the downside though, Lyocell’s specialised production makes it pricier.

Even traditionally natural fabrics may not be as eco-friendly as

they seem. CottonUP, a guide to sourcing sustainable cotton, says farming practices vary hugely depending on geography. In the US, Australia and Brazil, cotton is farmed and weeded largely using mechanised technology and systems, but in places like India and Mali, much of the work is done by hand. Cotton is also a hungry crop, using 3,644 cubic metres of water per tonne and tends to need a lot of pesticide and fertiliser as it grows. By contrast, eucalyptus trees are unfussy about their soil conditions,

do not need irrigation or pesticides, and use five times less land than cotton. Lyocell fibres produce fabric that is soft, like silk, does not wrinkle and is both strong and flexible (it is used for conveyor belts and medical dressings, for example) and it can be blended with other fibres.

No wonder global production is expected to reach more than 830kg tonnes by 2027.

Though seen as the next big thing, cellulose fibre and textiles will still have to meet international regulations and standards as they

“LYOCELL FIBRES PRODUCE FABRIC THAT IS SOFT, LIKE SILK, DOES NOT WRINKLE AND IS BOTH STRONG AND FLEXIBLE. NO WONDER GLOBAL PRODUCTION IS EXPECTED TO REACH MORE THAN 830KG TONNES BY 2027”

TO

SNEAKERS/TRAINERS UNDER A NEW PROCESS – MICROBIAL WEAVING”

are being developed. Technavio’s report, which offers information about 15 market vendors and textile manufacturers across the world, points out that in the US, the use of cellulose fibres is monitored and regulated by the US Environmental Protection Agency (EPA) and the US Food and Drug Administration (FDA). In the EU, this falls within registration, evaluation, authorisation and restriction of chemicals (REACH) regulations.

Source: www.newsroom.technavio.org/ news/cellulose-fibermarket

That has not stopped scientists looking for new sources of cellulose, and one that is particularly innovative is the production of nanocellulose, which can be extracted from algae, bacteria, fungi and invertebrates. Start-up company Modern Synthesis recently used bacteria from agricultural waste to create prototype sneakers/ trainers under a new process –microbial weaving. The team behind the company made the uppers by growing bacteria into a scaffold in a manner like 3D printing. Modern Synthesis is unlikely to have any short-term impact on the world’s global trainer/sneaker market, which is predicted to be worth $102bn by 2025, but every journey begins with a first step.

“MODERN SYNTHESIS RECENTLY USED BACTERIA FROM AGRICULTURAL WASTE

CREATE PROTOTYPE

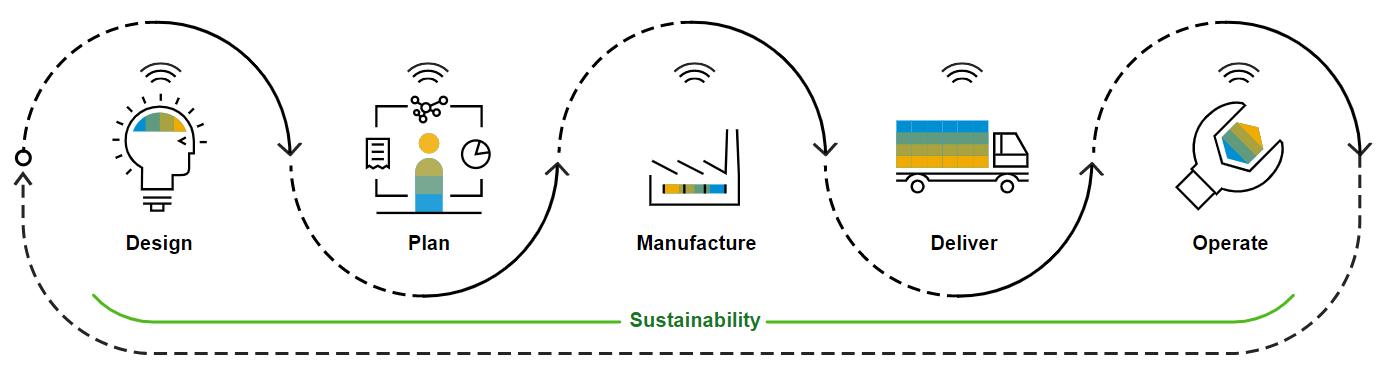

Experiencing End2End Digital Supply Chains with SAP and their Partners

The senior executives who manage the SAP Digital Supply Chain organisation in Middle and Eastern Europe (MEE) provide us with insights into the enabling power of digital solutions, collaboration and technology. As they align these hot topics to SAP’s expertise, capability, and partnership-led approach to solving challenges, they lead us through the key trends and opportunities of 2023.

Digital Supply Chain MEE

Andreas J. Wagner, and Chief Operating Officer for Digital Supply Chain MEE

Dr. Johannes Tulusan deliver their cautiously optimistic view of the year ahead.

AP’s optimism is founded in business projects that were planned and being executed long before the current economic shakeup. Across SAP, teams are looking to improve the solutions they already offer clients, switching from on-premise to cloud-based options, for example, and demonstrating how to increase product traceability and improve environmental, social and governance (ESG) performance.

Dr. Johannes Tulusan remains cautiously up-beat and explains, “You have to see the glass half full. Global circumstances might not improve in the near-term, but they give decisionmakers the chance to rethink how to operate their business. Resilience in supply chains is already very important, and sustainability will definitely become important too. We at SAP are in a good position to support our customers on those fronts.”

Andreas J. Wagner starts his assessment by saying that supply chain visibility and supply chain flexibility are key differentiators in business. “The supply chain function is not a backoffice function any more,” he explains. “It can either be a source of strength or weakness. Think about the loss of sales because of stockouts and the loss of loyal customers.”

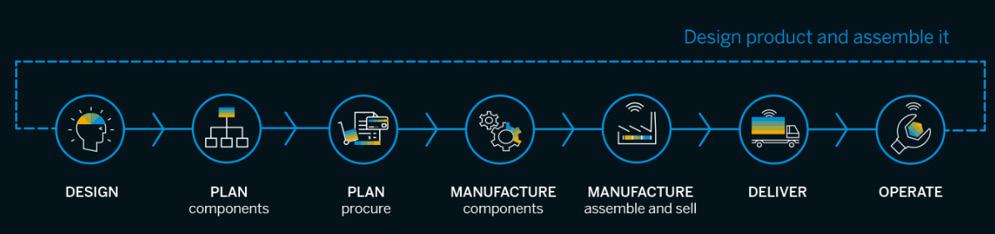

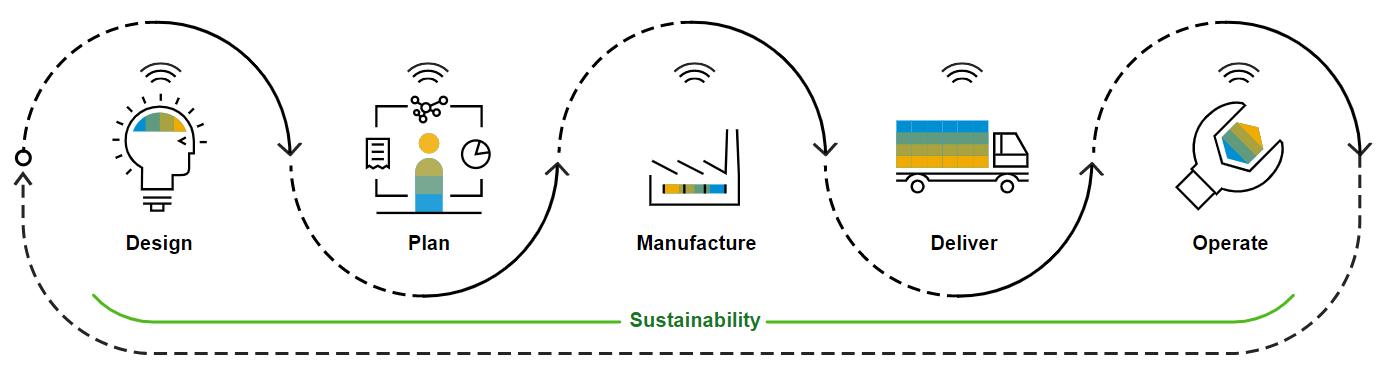

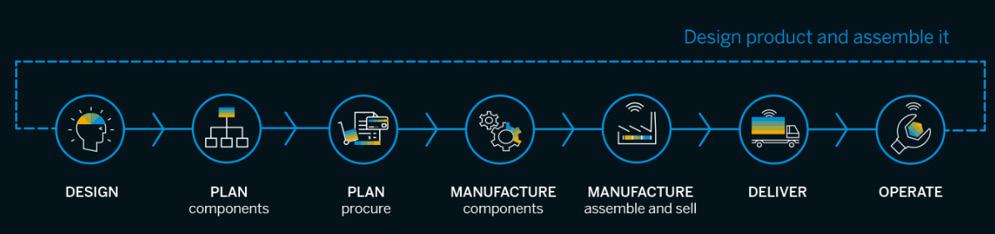

He continues, “It has really become a strategic topic for our customers. Championing the design to operate process in the market can be a key differentiator because you will have digital and integrated processes and can really showcase the end-to-end value of the solutions within your key processes.”

This is about not only innovating and breaking down silos within a company, Andreas states. “You also need to standardise your connections with

86

There is a feeling fizzing out of SAP right now: enthusiasm. SAP’s SVP and General Manager of

the outside world,” he says. “It's a very important process. For example, in the area of design innovation you already need to check early in the process whether the necessary suppliers are

available and whether they can support needed quality and quantity before you even produce master data in an enterprise resource planning system,” he says. “And you also need

87

Dr Johannes Tulusan Andreas J. Wagner

Camelot’s Supply Chain

Resilience Center is not only sustaining and improving our business processes every day but also working with us towards our goal of achieving a balance between supply chain maturity and supply chain operations cost.

Claud Noh, Corporate CIO / Vice President at Zinus

End-to-end Digital Supply Chain Transformation

A Key Success Factor in the New Now

To achieve an efficient, agile, risk-resilient, and sustainable supply chain, organizations need an end-to-end process vision, and they require to embrace cloud innovation cycles to enable continuous improvement.

Supply chain issues are in the spotlight right now – disruptions, material shortages and rising costs made it abundantly clear that today’s supply chains have become more complex and hyperconnected than ever. Often, when disruptive events occur, the result is a reactive and uncoordinated response that puts achieving margin, profitability, sustainability, and service level goals at risk.

Digitalizing the Design-to-Operate Process

The new supply chain complexity requires close collaboration between lines of business and stakeholders as well as transparency and flexibility across the supply network, making it mandatory to have enterprise systems to be digitally connected, coordinated, and operated. This constitutes a so-called intelligent enterprise. In the context of supply chain this means digitalization of processes from Design to Operate (D2O).

The overall goal of D2O is to be resilient to adapt to the next threat and to be flexible to embrace the next innovation. It starts with how you design new products in an innovative way, followed by a resilient planning process that drives sustainable manufacturing and logistics to deliver products to your customer and ultimately, maintaining these products.

As a long-standing implementation partner of SAP with more than 25 years of experience, Camelot ITLab supports customers on their journeys to realize the full potential of SAP Digital Supply Chain solutions. "In our experience, the key to every successful transformation is to follow this end-to-end vision for D2O processes and to cover all aspects from strategy to process, implementation, and continuous improvement," says Aseem Gaur, Executive Vice President at Camelot ITLab.

The digital transformation to build resilient supply chains is a continuous process and customers require, both an innovative solution and services approach to support this journey.

INNOVATIVE SOLUTION APPROACH

INNOVATIVE SERVICES APPROACH

Innovative Solution Approach: Smart Factory at Kellogg’s Realizing the value of SAP Digital Manufacturing Suite

One such innovative solution approach is the development of accelerators and extensions to the SAP solution portfolio on SAP Business Technology Platform (SAP BTP) in order to address industry challenges and augment SAP functionality. Following this solution approach, Camelot is realizing Kellogg’s Smart Factory vision by leveraging SAP Digital Manufacturing Suite and extending existing functionalities with industry specific accelerators: contributing to Kellogg’s sustainability goals while at the same time offering tailored industry-specific extensions for organizations.

Another example for an innovative solution approach is to extend SAP Integrated Business Planning (IBP) with cloud-based concurrent Production Planning & Detailed Scheduling (cPP&DS) capabilities

Innovative Services Approach: Supply Chain Resilience Center Embracing resilience and continuous innovation

Realizing the value of SAP Digital Manufacturing Suite powered by Smart Factory

Summary

Accelerating the digital transformation by embracing resilience and continuous innovation

With Supply Chain Resilience Center (SCRC) as innovative services approach Camelot is offering a framework where all stakeholders can collaborate to improve and accelerate delivery of business value. It allows customers to sustain their supply chain transformation on an ongoing basis by addressing key challenges around technology, talent and processes. SCRC was leveraged at Zinus not only improving business processes to be more resilient every day but also facilitating supply chain maturity.

The SAP Digital Supply Chain portfolio offers interoperability between business processes and systems as well as frequent feature updates (cloud-based). Therefore, supply chain transformation is not a one-time activity. Instead, resilience and continuous improvement or adoption must be incorporated into the overall strategy. It is crucial to tackle a digital supply chain transformation with an end-to-end vision in mind. Camelot ITLab offers end-to-end supply chain consulting, services and innovations in the context of the SAP Digital Supply Chain portfolio, thus realizing the Design-to-Operate vision for our joint customers.

to think about how you can quickly qualify a second or a third source in case of supply chain shortages of existing suppliers. You can only become successful with the close collaboration between sourcing and design – so between an internal function and the network outside of the company.”

What software solutions, technologies and strategies do SAP executives deem to be critical for enabling supply chain resilience in 2023? The benefit of cloudbased solutions, Andreas and Johannes agree.

Johannes considers Scandinavia and North America to be well advanced in adopting cloud solutions, while Switzerland is picking up adoption quickly; in comparison, Germany and Austria are somewhat behind. He acknowledges that there are businesses and industries that are not yet ready to use a full cloud approach for a critical key process, understandable when there is a highly automated production line, for example. He says the adoption process starts when there’s a need to improve flexibility or find better ways to address issues such as global supply chain shortages and higher energy costs. As decisionmakers assess the right time to make the switch, they are balancing multiple factors against each other. A cloud approach means embracing change in the way software architecture is hosted. Continuing capital investments in data centres versus new cloud

innovation investments can be quite a big stumbling block, Johannes acknowledges. “Businesses do realise innovating is key to staying competitive,” he says.

Another challenge comes when deciding which cloud software vendor to work with. There are so many newer ones to choose from that finding the right solution for a business’s existing

90

products, processes or production can be difficult without expert guidance.

Johannes says, “Something that seems to be the ‘best’ solution might not actually be easily integrated into, say, an existing application landscape.” This is where SAP’s proven capability, established reputation, experience and network offer

confidence when compared with less well-known “challenger” suppliers.

This is another area where SAP capabilities can add value in terms of cloud services, security and innovation. Together with its strong partner ecosystem, SAP has been helping business leaders respond to a constantly changing world, and recover from supply chain disruptions.

91

Strategic Co-Development Partner of SAP for SAP IBP Supply Chain Planning – Digital Manufacturing –Production Planning & Scheduling – Logistics –Industry 4.0 Innovation. Resilience. Maturity. CONTACT Aseem Gaur · Executive Vice President · asga@camelot-itlab.com Julia Hauri · Strategic Alliances & Sales · jhau@camelot-itlab.com Camelot ITLab GmbH · Phone +49 621 86 298-800 Theodor-Heuss-Anlage 12 · 68165 Mannheim · Germany www.camelot-itlab.com Camelot ITLab is intelligently accelerating and sustaining organizations' end-to-end digital supply chain transformation with innovative solution and services approaches: GET MORE INSIGHTS INNOVATIVE SOLUTION APPROACH Realizing the value of SAP Digital Manufacturing Suite powered by Smart Factory INNOVATIVE SERVICES APPROACH Accelerating the digital transformation by embracing resilience, sustainability and continuous improvement

The advantages of SAP’s partner ecosystem are discussed with the leadership of SAP’s MEE regional digital supply chain partner organisation on page 113.

Considering other challenges to face in 2023, Andreas points out the issues of security and the rise in the number of hacking attempts. “If you have your IT server in the ‘basement’ of your factory, it is at higher risk of hacking right now. There’s also a risk that in the long run you won’t have the right resources any more, or enough IT staff to maintain it overall. We are seeing labour shortages,” he warns.

The lack of data centre knowledge is partly the result of a shift to cloud solutions, and while fewer younger workers are entering the labour market, there are more older workers retiring. The imbalance between generations is affecting many industries and services. In January 2023, the German Chambers of Commerce and Industry (DIHK)

reported that more than half the nation’s companies were finding it difficult to fill vacancies due to a lack of skilled workers. In DIHK’s survey of 22,000 companies, 53% reported such shortages.

Next, Andreas and Johannes highlight the trends of nearshoring (bringing manufacturing operations or supply closer to a company’s headquarters or end customers), onshoring (basing operations in a company’s home country), and reshoring (returning operations to a home nation) as key components to maximising risk-resilient supply chains that are backed by technology.

After the challenges of the pandemic years, the vulnerability of the global supply chain has been further exposed by geopolitical unrest. For a very long time, the focus has been on building lean, low-cost operations that were predominantly offshore, but this left companies defenceless against the supply and demand issues that the

93

“Something that seems to be the ‘best’ solution might not actually be easily integrated into, say, an existing application landscape.” This is where SAP’s proven capability, established reputation, experience and network offer confidence when compared with less well-known “challenger” suppliers”

Dr Johannes Tulusan, Chief Operating Officer for Digital Supply Chain MEE

Synchronized Planning with IBP & PPDS

What to do when turnover and production fall apart?

Economic and political upheavals pose major challenges for companies in all sectors. Buzzwords could be extreme weather conditions, disruptions to important waterways, pandemic-related closures of port facilities or airports, as well as rising energy and commodity prices. However, for a proactive response to short-term and unforeseeable market situations, the classic ERP logistics modules are not appropriate. Such situations call for digitally networked end-to-end solutions that offer maximum transparency and real-time information.

Market researcher Gartner predicted disruptions in the global supply chain as early as 2021. Unfortunately, their forecasts turned out to be more than accurate. To effectively meet these challenges, users need suitable solutions. Although digital tools can’t overcome hurdles, they help to evaluate the risks along the entire value chain realistically, making them transparent and controllable. This optimal balance between responsiveness, delivery, stock, lead times, sustainability (circular economy) and customer satisfaction enables a proactive response to volatile markets.

Getting departments on board

Integrated company planning connects sales, marketing, finance, procurement, and production to optimise costs, service and stock levels. It focuses on all areas of planning, from long-term and strategic planning to medium-term planning and right through to the execution. Segmented and synchronized end-to-end planning to match supply to customers helps to separate demand signals from market noise and facilitate incremental changes in service, inventory and overall equipment effectiveness (OEE). Digital planning transformation, progressive monetisation, integrated business planning (IBP) and scenario modelling by using leading technologies such as robotic process automation (RPA), simulation and artificial intelligence (AI) help to improve forecasting and planning outcomes and reduce the planning effort required.

Rough and fine planning go hand-in-hand

With the experience gained from hundreds of implementation projects with well-known companies from discrete and process-orientated manufacturing, CONSILIO’s experts master all aspects of the supply chain repertoire and know which SAP solutions can be used to successfully meet the challenges ahead – keywords here are, for example, the cloud-based SAP IBP and S/4HANA Manufacturing for planning and scheduling (embedded PP/DS).

94

Sustainability achieved

CONSILIO’s experts, together with their client BLG LOGISTICS – Europe’s leading logistics service provider - use IBP to make the sustainability of goods flows in a global network trans-parent and controllable at a granular level. With this solution, BLG LOGISTICS is boosting its competitiveness in the automotive logistics sector by digitalising the strategic planning processes with SAP IBP. Simultaneously, with CONSILIO’s support, BLG has implemented CO2 balancing in IBP to calculate volume planning, thereby documenting and actively modelling the company’s sustainability.

Production under control

In addition to rough planning, CONSILIO is also an expert in detailed planning. For the wellknown German engine manufacturer MTU, CONSILIO implemented detailed planning with SAP Embedded PP/DS for the first time globally. The manufacturer is delighted and reports that they are able to comprehensively coordinate the production plan to match market requirements, purchasing restrictions and manufacturing capacities by means of a smoothed and feasible production plan.

SAP also values the skills of the SAP specialists from CONSILIO in Munich. CONSILIO is not only a certified SAP Gold Partner, it also supports the Walldorf company as a strategic development partner with its know-how in further developing and modernising the tank planning process. Tank planning is predestined for fine planning in PP/DS.

Partners - no ifs, no buts

CONSILIO provides excellent consulting services when it comes to digitising and automating business processes. The specialists combine functional-technical SAP application expertise with industry and business process know-how. Our experts aim to improve their clients’ compe titiveness through the effective and efficient use of standard software. Well-known national and international companies from different branches place their trust in CONSILIO and build on the company’s 25 years of experience, expertise, and innovative strength.

“Thanks to the consulting expertise provided by CONSILIO staff and the advanced planning and simultion functionalities of PP/DS, we now have coordinated, smoothed and feasible production programs throughout the company.”

Sebastian Kraus, Lead SAP MRO and OEM Production & Control, MTU Aero Engines

Sebastian Kraus, Lead SAP MRO and OEM Production & Control, MTU Aero Engines

The forward thinkers. The process optimizers. The solution developers. More Details?

www.consilio-gmbh.de

Visit our trend blog on

pandemic created. It is not surprising, therefore, that the benefits of nearshoring, onshoring, and reshoring are hot topics for 2023. By moving supplier sources closer to key markets, supply chain – and business leaders are able to mitigate risk, manage cost, optimise time to market, improve visibility and communication, and increase flexibility in response to disruption. But before eradicating existing production facilities, supply routes, or manufacturing chains, it is essential to bring key data into the picture. It was once a relatively straightforward decision to locate a factory in Asia based on overall costs. Since the pandemic, however, so much is being reconsidered. There