Do you work with a disruptive and innovative company that’s going places?

We want to hear from you.

Tell us all about the startup or SME by emailing enquiries@ithink.media and we’ll consider them for inclusion in an exciting project we have lined up in 2024.

Subscribe and keep your eyes peeled. More to come soon…

FROM THE EDITOR

Welcome to the April 2024 edition of INNOVATION Magazine!

Spring is in the air here at the iThink Media head office – the longer, lighter, warmer days are lifting spirits all around. We have a stellar line-up this month of three exclusive interviews along with a wealth of tech news and features for you to dive into.

In our cover interview, I welcome senior executives from the SAP Digital Supply Chain organisation in the Middle and Eastern Europe (MEE) region to explore the empowering and energising potential of digital transformation, the cloud and fully automated manufacturing. My conversation with Dr. Johannes Tulusan, Chief Operating Officer, Digital Supply Chain (MEE); Ralf Lehmann, Vice President, Global Head of Industry 4.0; and Dominik Metzger, Global Head of Software Engineering – Digital Supply Chain also offers readers a sneak peek of the ground-breaking technology SAP will be showcasing later this month at HANNOVER MESSE 2024 (p6).

I sit down with Simon Bullimore, Head of Group Procurement at Norse Group, the largest Local Authority Trading Company (LATCO) in the UK, about the company’s organisational approach to public sector procurement and striving to improve people’s lives while generating ethical, sustainable profit (p38).

Sven Müller, Director of Innovation at the SaarGummi Group and Managing Director of SaarGummi Neo, joins me to discuss the development of product and material innovations while embracing digitalisation and sustainability. Sven shines a light on how he and his teams are injecting new ideas and fresh approaches into supplying high-performance rubber to the automotive industry worldwide (p58).

We share five global tech features this month on transforming sleep habits with AI (p28), connecting the agricultural industry to the cloud (p68), deploying AI to transform oil and gas exploration (p92), bolstering inclusiveness in the publicly secure funding opportunities for women (p80) and expanding NATO’s DIANA programme to Finland (p46).

Our Startup of the Month is Shape Technologies – the company looking to disrupt the global payments market with its platform-as-a-service solution (p100).

Before you dive into this month’s magazine, we are launching an exciting project to celebrate startups and SMEs in 2024. If you work at or with a company that’s going to disrupt its industry with new technology or innovation – we want to hear from you! Contact us at enquiries@ithink.media.

Please enjoy our latest edition. If you would like to be considered as an interviewee or you have a story for us, please get in touch.

+44 (0) 203 890 1189

enquiries@ithink.media

3

editorial@ithink.media Editor Ben Craske Director Danielle Harris Director Tom Barnes design@ithink.media Senior Digital Designer Daniel May

d.harris@ithink.media t.barnes@ithink.media

All rights reserved. Every effort is made to ensure the accuracy of material published in Innovation Magazine. However, the company cannot accept responsibility for the claims made by advertisers or contributors, or inaccurate material supplied by advertisers. Innovation Magazine is a product of iThink Media Ltd. Company Registration Number: 10933897. Company Registered in England and Wales

APRIL 2024

6

Dr. Johannes Tulusan, Ralf Lehmann and Dominik Metzger from SAP on the future of cloud technologies and fully automated manufacturing

92

How are AI and machine learning disrupting European oil and gas exploration?

Simon Bullimore on robust partnership strategy a more efficient supply in public sector procurement at Norse Group

68 The cloud-connected Bayer’s LLM pilot could the agricultural industry

46 machine European exploration?

NATO’s DIANA programme expands to Finland

80

38

embracing strategy for supply chain procurement

cloud-connected acre: How could transform industry

Blockchain4Her: Bitget’s ambassador programme is designed to secure funding opportunities for female-led startups

100

Meet Shape Technologies, our Startup of the Month

28

Can AI fix your sleep schedule?

58

We speak to Sven Müller about SaarGummi’s focus on promoting innovation and sustainability to benefit the global automotive industry

5

APRIL 2024

COVER STORY

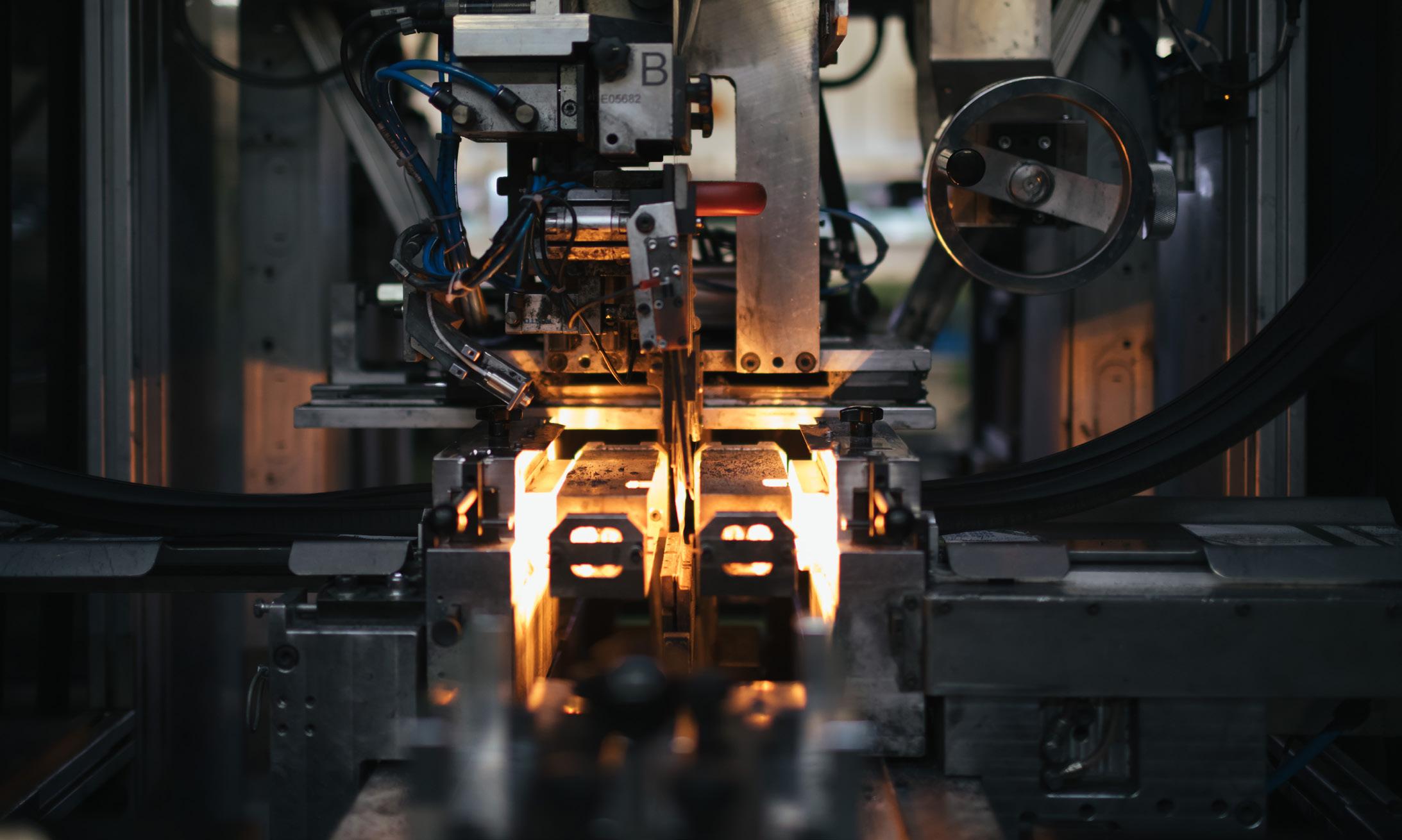

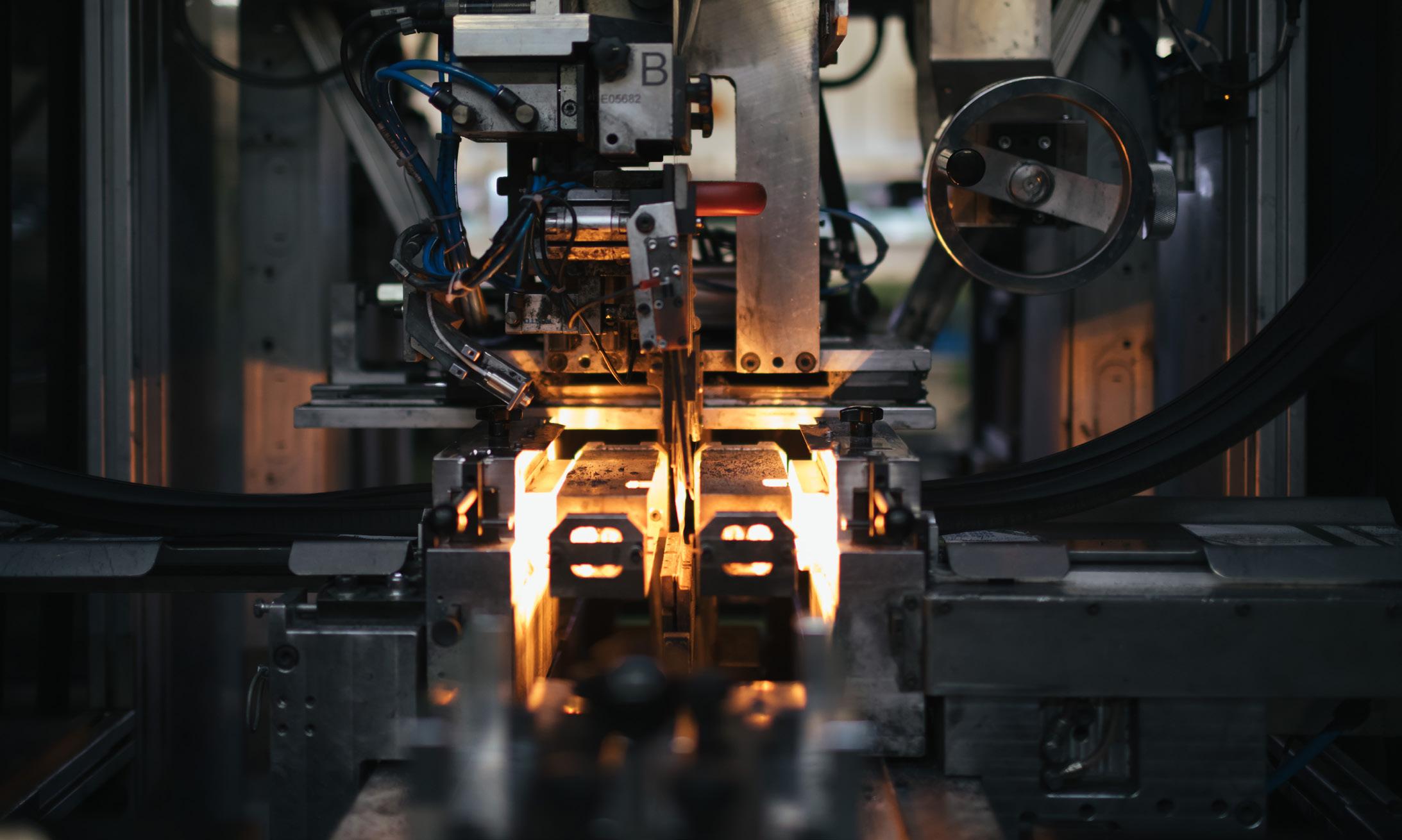

Accelerating our success together by unleashing the power of automated manufacturing with business AI

We welcome senior executives from the SAP Digital Supply Chain organisation in the Middle and Eastern Europe (MEE) region to dive into the empowering and energising potential of digital transformation, the cloud and fully automated manufacturing. Read on for a sneak peek of SAP’s showcase at HANNOVER MESSE 2024, along with the latest and greatest insights into how SAP is the provider and partner to help businesses.

7

With

24,000 partner companies

around

the world, SAP customers generate 87% of total global commerce. SAP’s goal is to be the number one enterprise application and business artificial intelligence (business AI) company, powered by its leading platform and 107,000 employees in 156 countries.

oining us today are key members of the SAP team supporting this effort: Dr. Johannes Tulusan, Chief GTM & Customer Advisory Officer, Digital Supply Chain (MEE); Ralf Lehmann, Vice President, Global Head of Industry 4.0; and Dominik Metzger, Global Head of Software Engineering –Digital Supply Chain.

Launching our conversation, we’ll be exploring the key trends and opportunities for digital supply chain actors in 2024. Then we learn more about the potential of SAP’s public and private cloud ERP solutions, the importance of moving towards fully automated digitalised manufacturing and the power of

8

“To bring out the best for our customers, manufacturing and supply chains must be more agile, more collaborative and more integrated”

Dr Johannes Tulusan

9

business AI. Our guests will hint at the groundbreaking technology SAP will be showcasing at the HANNOVER MESSE later in April 2024, before wrapping up our conversation by looking ahead to the future of SAP’s digital supply chain strategy.

State of Play

As we enter 2024, digital supply chain professionals are still grappling with the demands of post-COVID resiliency and must come to terms with digital transformation to thrive. Resilient supply chain management to address unforeseen events remains imperative and technologies like artificial intelligence (AI), blockchain, data analytics and the Internet of

Things (IoT) are here to stay as key tools toward that end. Sustainability is the ever-present elephant in the room and businesses envision the need for end-to-end transparency throughout the whole supply chain. These discussions are fundamental, but they are not entirely new. So what is the current state of affairs now we’ve flipped the calendar from 2023 to 2024? And how is SAP adapting to ongoing changes to empower its customers –helping them expand, digitalise and scale their businesses?

“In 2024, there are four major areas in the supply chain which have entered the horizon or evolved for companies in many industries,” begins Johannes. “First, there’s a need for increased automation and agility in supply chain processes. Labour shortages in highly skilled roles plague many businesses, for example in the manufacturing industry. Experts who have been working at companies for many years are starting to retire. The resulting knowledge gap can be closed by increasing the role of automation. Here, SAP can help customers automate and integrate the production, logistics and maintenance areas of their operations.”

Weighing in, Ralf emphasises that promoting automation does not mean

10

“One of the goals for enterprises is leveraging and conserving the skills of experts while building institutional knowledge, but simultaneously bringing younger workers up to speed quickly so they can operate proficiently at a high level in less time”

Ralf Lehmann, Vice President, Global Head of Industry 4.0

removing humans from processes or jobs. Instead, it is about optimising the effectiveness and efficiency of people working alongside machines, together. Moreover, he insists automation can help employees refocus on the more complex tasks that require human ingenuity.

“One of the goals for enterprises is leveraging and conserving the skills of experts while building institutional knowledge, but simultaneously bringing younger workers up to speed quickly so they can operate proficiently at a high level in less time,” says Ralf. “Automation is a highly valuable resource in this pursuit. In recent years, agility in the supply chain has become even more important for our customers. They typically have a dynamic mix of products they're assembling on multiple lines. Businesses need to look from an enterprise performance perspective to identify an efficient production strategy and embrace agile working practices.”

“The second important topic for 2024 is visibility and

transparency within and across the company,” notes Johannes. “Endto-end processes from enterprise resource planning (ERP) to supply chain are a key requirement for digital business. Equally critical is the ability to interact with trading partners in a business network and share relevant data – and this is fast becoming a reality.”

“Third – and this has been an important topic in recent years – is striving for sustainability,” adds Johannes. “Many stakeholders discuss this topic at length, but implementing it is becoming increasingly urgent, in light of the increasing number of new

11

policies and regulations regarding the issue. We are at the stage of moving away from hopeful thinking to making sustainability a reality for every business, but there is still more work to be done –an endeavour which SAP is committed to supporting its customers in.”

“The final hot topic on everyone’s lips is AI, and in particular generative AI,” continues Johannes. “Specifically at SAP, we are enriching all our applications with business AI capabilities to help our customers autonomously enhance their business processes or to optimise business outcomes.”

Transformation Trio: Cloud, Automation and AI

In light of these emerging and evolving trends, what technologies, software solutions, and strategies do Johannes, Dominik and Ralf believe are fundamental for enabling supply chain resilience in 2024? They all agree that it starts with cloud-based solutions, gravitates around fully digitalised, automated manufacturing and weaves in business AI.

Cloud

Elaborating on the importance of the cloud, Johannes stresses that innovation in the cloud is easier than the alternatives and that staying with onpremise systems holds companies back.

“The RISE with SAP offering and the GROW with SAP offering help our customers who have on-premise ERP move into the cloud,” begins Johannes. “Maintaining an ERP system in its own

local data centre becomes quite cumbersome and deploying new innovations like artificial intelligence is only possible in the cloud environment. In 2023, there was a breakthrough in the MEE region where many customers decided to bring their entire business software landscape into the cloud.”

So what is the difference between RISE with SAP and GROW with SAP?

“RISE with SAP is essentially for our customers with existing SAP ERP software landscapes and who want to keep most of their customisations but merge and transform into the cloud,” says Johannes. “GROW with SAP is our ERP solution to encourage customers in what we call ‘greenfield’ approach, where customers want to start afresh, to move all processing into SAP S/4HANA Cloud, public edition. Customers also apply hybrid approaches with RISE with SAP and GROW with SAP, transitioning to the cloud with their existing ERP landscape while at the same time implementing SAP S/4HANA Cloud, public edition for new sites.”

“In relevant industries, digital supply chain professionals have a strong stake in the RISE with SAP and GROW with SAP transformations, since certain key functions they oversee, such as manufacturing, production planning, logistics and product lifecycle management are already embedded within the ERP software solutions from SAP. A resilient supply chain has become a keystone function of any

14

“The first purpose of AI is to empower business users to handle disruptions by delivering all the critical information for rapid decision right to their fingertips”

Dominik Metzger, Global Head of Software Engineering – Digital Supply Chain

business, since it goes hand in hand with growth and transformation.

“Within the next month, SAP plans to announce the offering of supply-chain-specific RISE with SAP packages for our customers, to help them identify the most suitable supply chain solutions alongside their cloud ERP transformation.”

Fully Automated, Digitalised Modular Manufacturing

Ralf adds the agility and scalability of RISE with and GROW with SAP make them ideal solutions for new innovations, particularly in production.

“Clearly supply chain cloud solutions have become much more important in recent years in our MEE region,” reaffirms Johannes. “Before, for instance, we saw digitalisation and production as separate silos, but now we see an amazing trend toward adoption of the scalability of cloud in the digital supply chain and the manufacturing area in tandem, breaking down the silos. The power of cloud solutions lies in their agility in this rapidly evolving context.”

Ralf goes even one further step ahead, by highlighting the importance of fully automated and digitalised modular manufacturing as the future

15

of production. As the technologies facilitating production evolve around end-to-end integration – including cloud ERP, digital manufacturing solutions, automated guided vehicles (AGVs), traceability software, AI and business AI – businesses must lean into the trends, driving and bolstering the global economy, adds Ralf.

AI

Johannes recalls how since 2013, when big data became part of his role at SAP, there has been a developmental journey towards AI as we know it today. Back then, it started with handling vast quantities of master data, turned towards looking at prescriptive data then predictive maintenance before arriving at machine learning and emulating data today.

“Now the focus is moving beyond using data analysis to generate predictions to realise the potential of generative AI and business AI, by training algorithms so we can ask for recommendations, not just summaries or forecasts, while also steering the technology towards learning and improving itself,” explains Johannes. “At SAP, we are developing our business AI to apply artificial intelligence in a business industry context. We realise AI is more than just validation or algorithm analysis, it’s about facilitating learning within the system itself and generating insights and suggestions we might never have come up with ourselves. This is incredibly important in all solution areas, not just digital supply chain.”

Dominik insists that for today’s businesses, AI has two main purposes.

“The first purpose of AI is to empower business users to handle disruptions by delivering all the critical information for rapid decision right to their fingertips,” says Dominik. “The second, and let’s consider this a long-term purpose, is to transform supply chains to become near autonomous and selflearning. Near autonomy, as with self-driving cars, means that a vast majority of essential decision-making is automated, and only the most critical disruptions are managed by expert business users. Automation clearly facilitates supply chain optimisation.

“Optimisation is not a new concept in the supply chain arena, and many companies have already optimised supply planning in several ways. They use forecasting for demand planning and machine learning algorithms for predicting demand for spare parts. Machine learning algorithms help with planning transportation routes and choosing suppliers.

“But what is really tough for many companies is to build trust in the system. If a worker has done their job for 20 years on a manual spreadsheet, why should they trust this new digitalised system? And that's really a sweet spot for generative AI. One example is our generative AI assistant Joule, which revolutionises how we interact with SAP business systems, making every touchpoint with the system simpler by just asking to get

16

tailored results for a business process step. As an end user, once I’m included in the discussion, I have much more faith in my optimised system and its output supported by generative AI capabilities.

“The role that generative AI can play then is to lower these adoption hurdles for users of optimisation and advanced forecasting,” summarises Dominik. “When we look at logistics, we can specifically talk about automation. What’s in the logistics space today can still be a very manual process. For example, in many warehouses and shipping yards of this world, whenever a truck or a container rolls up, someone still needs to check that the paperwork matches the contents, by comparing paper documents in their hand to a screen display. Using generative AI to automate these processes can actually be a game changer.”

Taken together, cloud, automation and AI technologies will revolutionise the future of the digital supply chain – which is why they form crucial components of SAP’s exciting showcase for HANNOVER MESSE 2024.

Hannover Messe 2024

There’s a tangible buzz in the air as we turn our conversation towards the HANNOVER MESSE 2024.

HANNOVER MESSE is the world’s leading industrial trade fair, showcasing cross-industry solutions and interface technologies for the

entire business ecosystem. The aim is to energise sustainable global industry. More than 4,000 companies will be acting as an interconnected industrial ecosystem and attendees from all industries, looking for trusted partners to help them become more resilient and sustainable, are warmly invited to explore SAP’s leading supply chain solutions.

But what can HANNOVER MESSE attendees expect from SAP at the event?

Setting the scene, Johannes shares the theme for SAP’s presence at HANNOVER MESSE: ‘Bring out new manufacturing excellence’.

“Manufacturing is one of the growth engines of the global economy,” begins Johannes. “Successful, innovative manufacturing has a ripple effect across the economy by stimulating growth in related industries.

“Industry 4.0 is about integrating digital and physical worlds, changing the way manufacturers operate, collaborate and engage with customers. Adapting to Industry 4.0 requires a new kind of intelligence –with data at its core – that uncovers new insights, automates operations and optimises decisions.

“To bring out the best for our customers, manufacturing and supply chains must be more agile, more collaborative and more integrated.

18

Business processes need to be as smart as the products we’re making and the customers we’re selling to.”

Ralf weighs in and adds that today’s manufacturing leaders need to know how to combine data from machines, processes and the full ecosystem to make better, more holistic decisions, adapt to changing market demands and harness new technologies – such as generative AI and machine learning – to design, manufacture, deliver, operate and maintain products more efficiently and sustainably.

Offering a sneak preview of SAP’s showcase on modular manufacturing at HANNOVER MESSE 2024, Ralf describes the company’s demonstration of worker and shop floor orchestration including on-hand AGVs from multiple vendors.

“When we go to HANNOVER MESSE, our approach is unique compared to

other events,” says Ralf. “Our goal is to enable attendees to understand the power of the SAP solutions at a deep level, in a tangible, real-world context. How exactly can SAP solutions help them drive better business results? To answer that question, we showcase a vast range of customer examples and demonstrate in person and in real time how those elements interact with real assets.”

Without spoiling any surprises for the big event, we can say that the SAP showcases at the big event in Hannover covers the manufacturing end-to-end process comprehensively: from designing a product and planning projects, to building, delivering, operating and maintaining them.

But fortunately for us, there is one main SAP showcase around automated and modular manufacturing at HANNOVER MESSE

19

1

Discover two powerful assets to accelerate your digital transformation

Transforming business processes through immersive experiences

In the ever-evolving landscape of industry supply chains, BearingPoint takes a bold step forward with its Virtual Reality Platform, revolutionising the way business processes are implemented. The uniqueness of BearingPoint’s approach lies in its ability to provide clients with a better understanding of new workflows and IT systems through immersive experiences. By turning

2

Leveraging the Equipment-as-a-Service demands with Lease & Rent to obtain new revenue stream

BearingPoint’s Lease & Rent solution is an answer to today’s dynamic business landscape, where the global equipment leasing and rental industry faces a paradigm shift. Increasing demands for new business models, flexibility, sustainability, financial risk management, cost efficiency, technological innovations, maintenance and evolving regulations require adaptation. Businesses in this sector,

complex processes into tangible, virtual encounters, the platform plays a pivotal role in fostering a more profound willingness to embrace change within project and business operations teams. This, in turn, becomes a critical success factor in driving larger corporate transformations.

Our platform offers a distinct advantage in the SAP® partner ecosystem. Unlike any other provider, we seamlessly integrate a solution that combines virtual reality expertise with indepth knowledge of SAP® solutions.

including construction, OEMs, and equipment dealers, are transitioning to models like Equipment-as-a-Service. Inspired by the automotive sector, they explore new avenues, being challenging for both startups and established companies.

BearingPoint leads this digital transformation with a revolutionary SAP cloud solution. Lease & Rent modernises management to accommodate new business models, going beyond traditional software by integrating end-to-end leasing and rental processes, covering all the relevant aspects – from request, quotation, invoicing and

By engaging users in immersive experiences, we aim to translate the abstract benefits of SAP® solutions into tangible and experiential encounters, fostering innovative approaches for SAP® sales and transformative SAP® S/4 HANA projects.

Let’s delve into the possibilities together.

throughout the contract lifecycle to maintenance, logistics, and even refinancing.

By harnessing SAP technology, we empower organisations to embrace new models, streamline operations, and stay ahead in an era of constant change and innovation.

Scan the QR code to discover how Lease & Rent can streamline your Leasing and Rental operations:

www.bearingpoint.com

2024 that Johannes, Ralf and Dominik can offer early insights into for our conversation. With all the buzz around fully digitalised modular manufacturing and the role of automation within it, we would be remiss to overlook a full discussion of automated guided vehicles (AGVs).

As it stands in global industry today, AGVs from different manufacturers must run on separate systems in manufacturing and production operations. However, there is growing awareness of the need for interconnectivity and interoperability to support a unified approach to advanced planning, data sharing, visibility and ERP enhancement. And

this is precisely where SAP is going to transform how its customers and partners conceptualise and execute manufacturing and production, with full automation and digitalisation – driven by data, to bring out new manufacturing excellence.

“AGVs perform a crucial support role in logistics, the supply chain and manufacturing operations – to name just a few use cases,” says Ralf. “But the situation today is that each type of AGV needs its own driving arena. Imagine if every type of car needed its own road to drive in – it would be chaos, right? But to bring the metaphor back to AGVs, we are exploring how to

“At HANNOVER MESSE 2024, attendees will see what we’ve achieved: AGVs from three distinct vendors – MiR, Omron and symovo – work simultaneously and safely, in the smallest driving area we could force them into, to prove the concept”

21

create a new environment where AGVs from all manufacturers can operate interconnectedly in the same environment, without needing separate systems to run them.

“Large companies with multiple production slides and several AGVs in their manufacturing processes need to set up intralogistics from one flow. At the moment, joint orchestration is not possible and we want to change this situation.”

“The first step is to be able to orchestrate the AGVs jointly,” continues Ralf. “The second step – and this is where the true innovation potential lies – is to apply business context to the AGVs and share data seamlessly, throughout the entire manufacturing process, to fully automate the production line. The appetite among our customers for such a revolutionary AGV system is staggering, so we have worked with our partner KINEXON to meet this pressing business need.

“At HANNOVER MESSE 2024, attendees will see what we’ve achieved: AGVs from three distinct vendors – MiR, Omron and symovo – work simultaneously and safely, in the smallest driving area we could force them into, to prove the concept. We co-innovated with KINEXON and the AGV manufacturers to develop hardware-independent fleet management system, running multiple devices orchestrated through a KINEXON solution and integrated with the SAP Digital Manufacturing solution.”

Ralf explains the system: “All the AGVs are controlled from a central layer that can talk to each of the devices within the fleet management system. This capability goes well beyond the requirements of the 5050 standard from the German Automotive Industry Association (VDA from its initials in German), the current industry benchmark for AGV communication.”

In fact, SAP solutions harmonise all the technologies that will be

22

© www.joanna.nottebrock.de

proaxia Seamless Service.

With our seamless service approach, you can increase your service efficiency and customer satisfaction!

We are designing and implementing processes & solutions that lay the foundation for a consistent and efficient service experience across all service channels.

Boost your customer engagement through integrated digital self-services!

With our packaged Customer Self-Service (CSS) solution you can create a state-of-theart B2B service portal that supports your business processes with innovative digital selfservices, fully integrated into your processes and SAP landscape.

Our Customer Self-Service enables real-time communication between you, as a manufacturing company (OEM), and your customers.

The digital involvement of your B2B-customer enables direct service relations and strengthens customer loyalty.

Accelerated service processes save valuable time and increase productivity.

Get more information:

www.proaxia-group.com

info@proaxia-group.com

Higher transparency through shared processes and information helps innovate business models and establish new revenue streams. For

23

SAP Industry Cloud

demonstrated at the company’s modular manufacturing showcase at HANNOVER MESSE 2024.

“SAP S/4HANA Cloud is the core digital backbone for discrete manufacturing, and we are demonstrating how SAP Digital Manufacturing integrates with SAP S/4HANA Cloud, public edition running the modular manufacturing showcase,” continues Ralf. “We cannot wait to show attendees this revolutionary seamless integration applying open industry standards and orchestration by KINEXON to enable multivendor AGVs to drive in shared spaces.

“On top of this, we will show attendees how generative business AI and

advanced machine learning will reshape supply chain execution in the way products are designed, planned, manufactured, delivered and maintained. SAP provides the next generation of business applications infused with business AI and empowers manufacturing leaders to leverage unique data assets from manufacturing execution systems, marrying large-scale machine data and ERP data with data from the wider industrial ecosystem to push manufacturing efficiency to the next level.

“We live in a disruptive world these days,” Ralf summarises, “and for most companies, the question is how to best handle and optimise all their flows, infusing every business application and

‘Digital Core For Enterprise Supply Chain’ - Powered By Capgemini

Supply chains have always been complex, and the last few years have taught us how fragile these can be. At Capgemini, we focus on collaborating with our clients to identify and enhance critical elements unique to each customer and their supply chain by leveraging our expertise in processes and technology. We partner with SAP to integrate cutting-edge technology solutions like AI, ML, IoT, blockchain and advanced analytics to enhance supply chain offerings. Our focus areas include Sustainable Supply Chain Strategy, Smart Forecasting, Procurement, Order Orchestration and Reverse Supply Chain Management. Through collaboration with SAP, we drive innovation in supply chain resilience and optimise end-to-end performance management. Our approach integrates these technologies seamlessly, ensuring efficient and agile supply chain operations for clients.

“Intelligent supply chain prioritises resilience, performance and sustainability – enhancing augmented customer-centricity.”

As a partner in Business Technology and Digital Services Transformation for Supply Chain Management (SCM), we drive business outcomes:

• Up to 15% reduction in inventory costs

• Up to 20% improvement in demand forecasting accuracy

• Reduction of overall transportation costs by 10% - 15%

To know more, please visit - www.capgemini.com

24

process with the latest technologies for digitalisation, data management and artificial intelligence – transforming the end-to-end value stream with SAP’s support.”

Connect with SAP’s experts in digital manufacturing at HANNOVER MESSE 2024, April 22-26 at booth E17 in Hall 15.

Elevating solutions with strategic partnerships

After our whirlwind discussion of the SAP showcase at HANNOVER MESSE 2024, a key topic arises in the conversation. The fundamental importance of strategic partnerships and a robust partner ecosystem stands out. It is for instance, after all, a collaboration between SAP and KINEXON that will transform the AGV solutions currently available on the market.

SAP embraces its prominent position in the global market to invest in, and thereby empower, its partners – benefitting the entire supply chain ecosystem in the process. Here, Johannes, Ralf and Dominik highlight some partners as demonstrative of the power of collaboration: All for One, BearingPoint, Camelot ITLab, Capgemini and proaxia all add tremendous value as SAP partners. For further insights into how these companies collaborate with SAP as partners, explore the spotlights dotted throughout this article.

“All our partners, whether they’re related to supply chain or to SAP more broadly, have always been fundamental to us as

a business,” says Johannes. “But now more than ever we recognise that these strategic alliances will continue to grow in importance as we develop together. We have many different types of partners, from system integrators to software partners. All of them are relevant today and into the future, because we realise within SAP that due to the high demand from our customers, we have to entrust our partners with further responsibilities along the customer value lifecycle.

“One of our fundamental beliefs as a company is we can only expand our expectations and ambitions when we also grow with our partners: together and in all aspects.”

Ralf reiterates the notion of the responsibility SAP embraces towards its partners.

“Since we are a leader in the market, customers expect SAP to talk and engage with our huge ecosystem,” explains Ralf. “By working with an amazing partner ecosystem we can tailor and amplify our solutions for our customers, across industries and lines of business, understanding and then meeting customer needs and helping them thrive in the process.”

Where next?

Looking ahead to the future, Johannes, Ralf and Dominik offer their insights on the direction of digital supply chain strategy at SAP in the coming years.

25

“First, the future of the digital supply chain strategy at SAP is to embrace business AI and generative AI, with an end goal of improving our supply chain offerings,” says Johannes. “Second, this goes hand in hand with the transformation of ERP into the cloud. Our goal is to show our customers the distinct, industryspecific value proposition of cloud ERP transformation. Third, within our entire design-to-operate solution area the goal is to be the best-inclass solution, offering an end-toend seamless experience. Fourth, an important SAP message for 2024 is ‘Accelerating our success together.’ We are driven by the idea that we can only be successful in concert with the entire SAP ecosystem, including our partners, SAP employees, and customer base. Finally, we will continue to listen to our customers through feedback sessions, so we can continuously improve our offerings in relevant, industry-specific and profound ways.”

Ralf highlights the burgeoning importance of risk management and visibility for customers, while simultaneously encouraging them to consider all external and contextual factors in their operations.

“Of course, we must prioritise our customer’s internal integration with SAP, but we cannot neglect external forces,” notes Ralf. “For instance, with risk management, how can we

help our clients untangle challenges and perceive them in a simple, understandable way? How can we help them consider all the global economic factors that impact their business? Ultimately, how can we wield analytics and the insights it brings to secure the best performance and outcomes for our customers? We expect AI, and specifically business AI, to play a crucial role in these areas in the coming years.”

Dominik believes the future of supply chain is near autonomy, powered by artificial intelligence and a wealth of data.

“For me, this means that the silos in supply chains will continue to converge,” says Dominik. “Because if you have all the data at your fingertips – whether you’re a business expert, supply chain planner, demand planner, logistical dispatcher, service technician or purchaser – having all of this data at your fingertips while running autonomous processes means that teams can converge. I believe this means we can cover much more intelligence and empower our customers to do what they can do best.”

For further information about SAP, visit sap.com.

To meet and connect with SAP at HANNOVER MESSE 2024, April 22-26, at booth E17 in Hall 15 – head on over to the event overview page on their website.

26

Added Value

Johannes

Johannes embraces being value-driven, compassionate and open-minded during a customer lifetime value journey.

“Ultimately I see this approach as the best way to engage with our customers,” says Johannes. “When we work with customers, we have high ambitions for bringing them the optimal end-to-end solutions for their needs. But we also need to remember they are often embarking on a new journey, which can be intimidating. By being compassionate and openminded as well as value-driven, we foster trust and encourage customers to embrace change.”

Connect with Johannes

Ralf

Ralf emphasises the importance of teamwork and relishes the opportunity to embrace a leadership role at SAP.

“It’s a pleasure to be ‘the captain of the boat’ and guide my team. It’s about navigating new waters and I love this side of my role,” says Ralf. “Working with new companies and new challenges is energising. But you can only reach new destinations with collaboration – internally but also with your partners and customers on board too.”

Connect with Ralf

Dominik

Dominik inspires creativity to address complex business challenges.

“I am deeply passionate about fostering creativity and empowering individuals to unlock their full potential,” says Dominik. “Guiding professionals is not just about providing direction, but also about cultivating an environment where innovation flourishes. Through compassion, collaboration and a commitment to nurturing diverse perspectives, I aim to inspire and lead creative individuals towards meaningful outcomes that push boundaries and drive positive change.”

Connect with Dominik

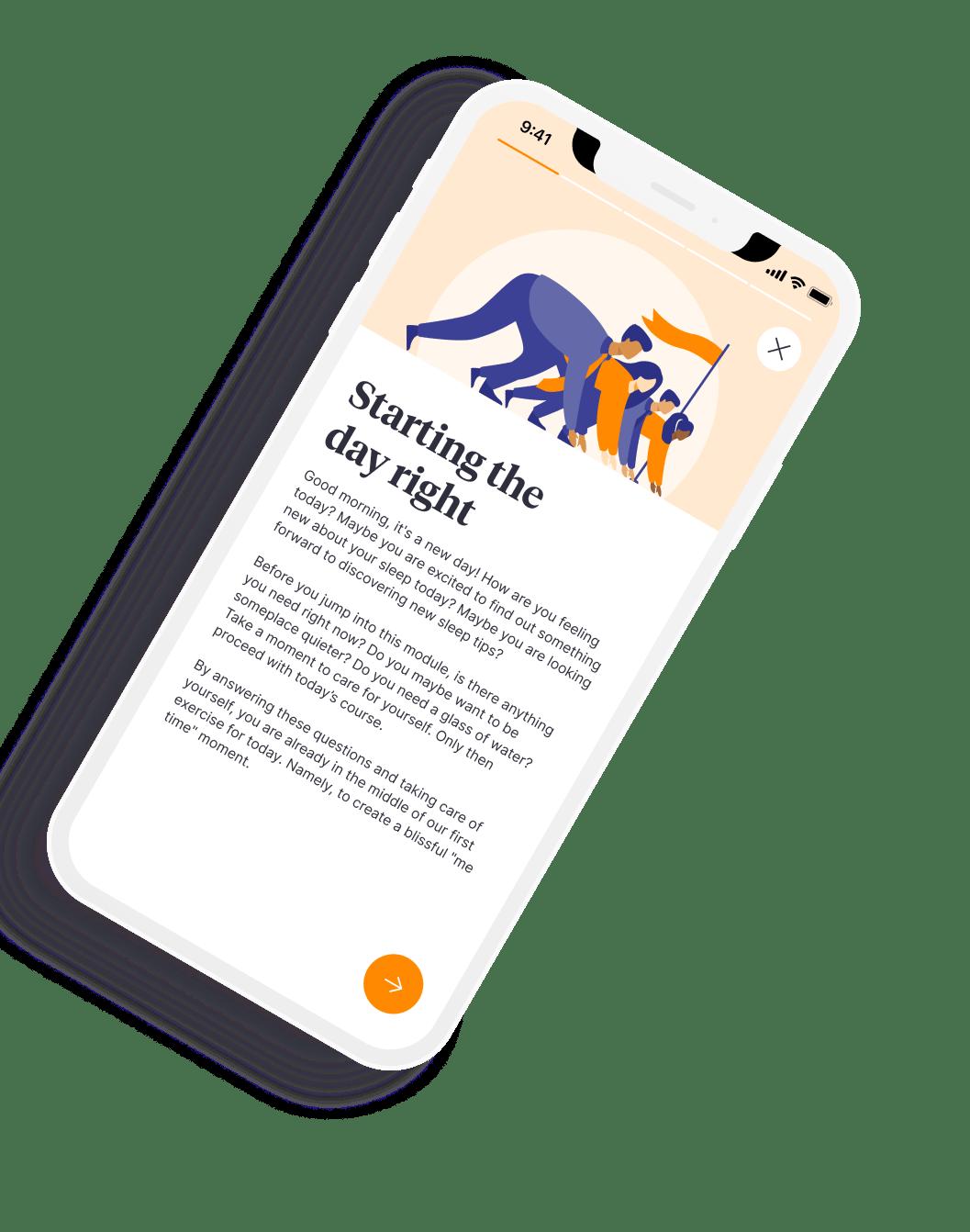

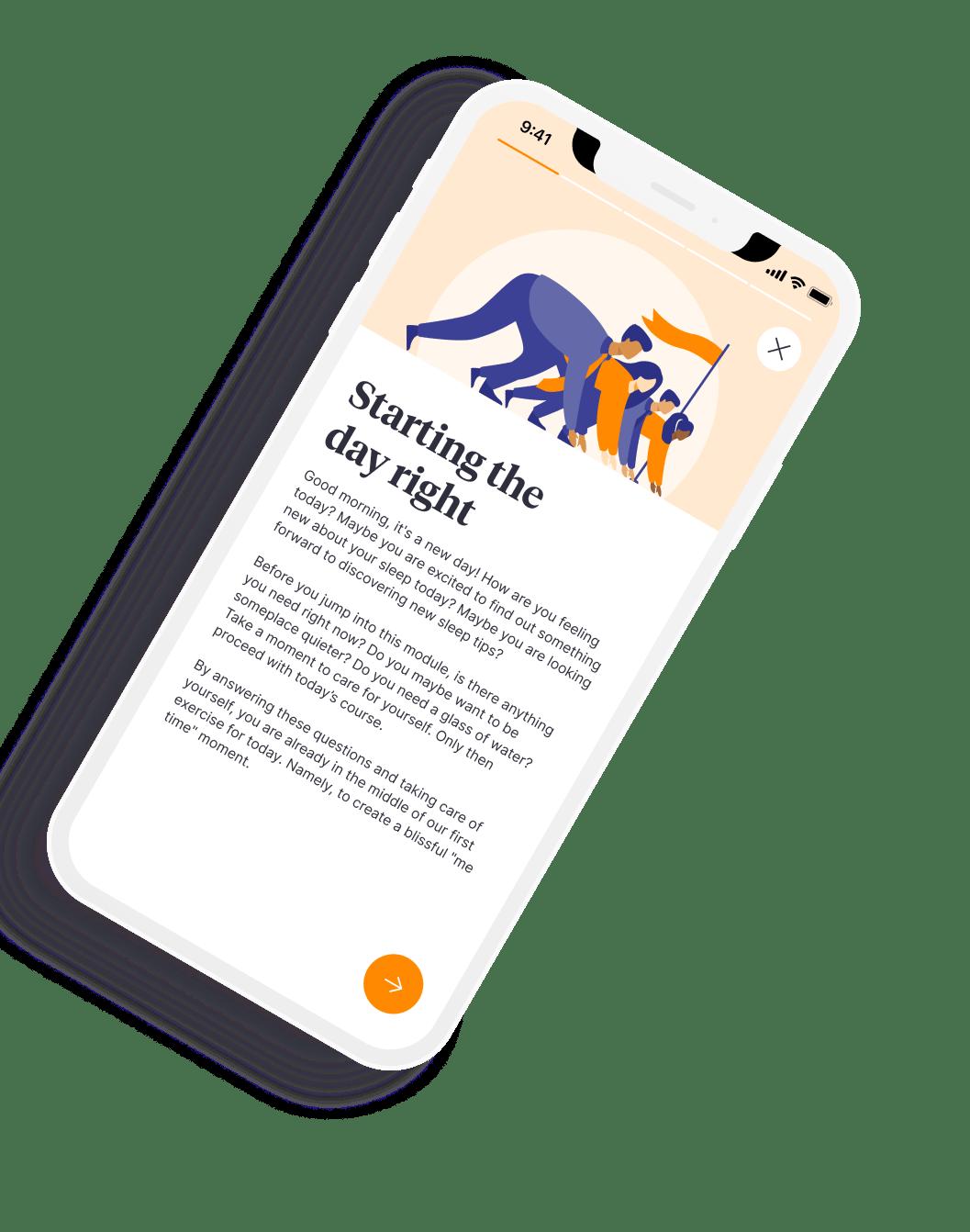

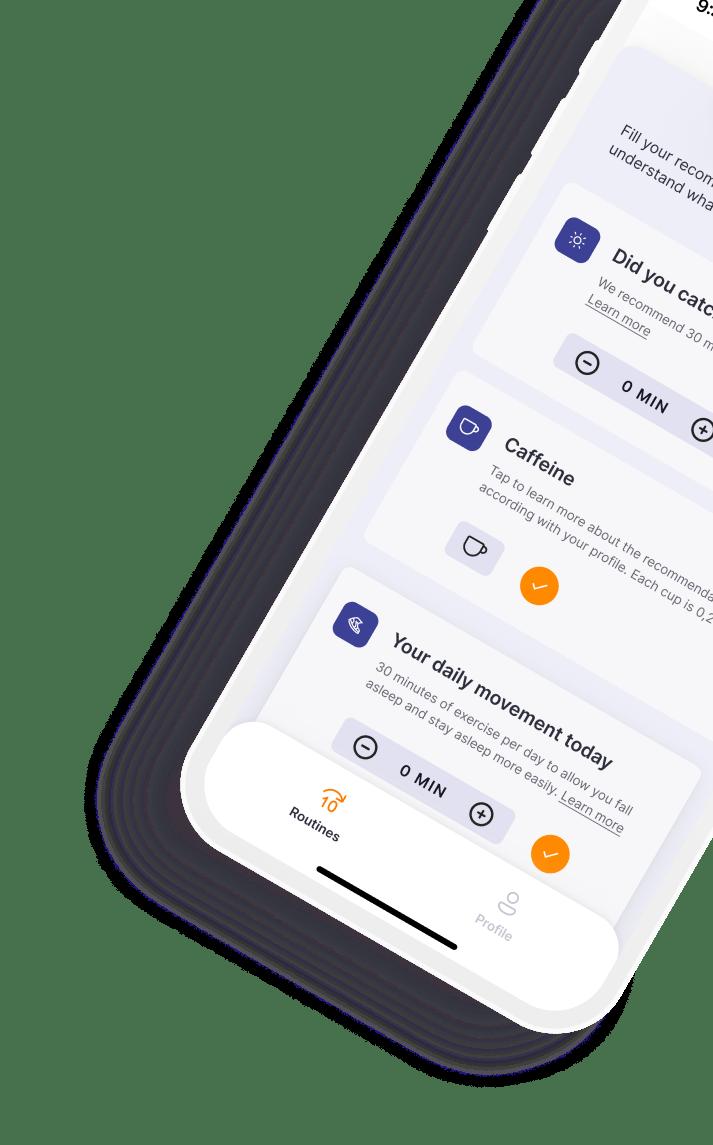

Photos from www.app.emma-sleep.co.uk TECH

How AI can improve your sleeping habits

Introducing Emma Up: a revolutionary sleep solution powered by action-oriented AI coaching.

Securing adequate, quality sleep is essential for day-to-day functioning –with a lack of sleep being linked to both physical and mental health issues.

recent global study conducted by

Emma – The Sleep Company found that many people are attempting to fix their sleeping problems, with nearly threequarters of respondents expressing a strong desire to improve their sleep quality, with a primary goal of waking up feeling rested and refreshed. However,

this is proving difficult as over half of all participants reported frequent awakenings throughout the night, and 47% answered that their sleep problems negatively affect their daily activities and productivity levels.

Many participants reported implementing changes to their sleep environment such as investing in blackout curtains or changing the

“Emma Up, is a digital AI coach designed to help individuals improve their sleep quality by providing personalised step-by-step programs and action-oriented advice”

temperature of their rooms to little effect. In fact, many adults resort to unsustainable solutions to ‘fix’ their sleeping problems, such as sleeping pills, while existing sleep apps and trackers offer limited assistance, failing to provide actionable steps for lasting improvement to user’s sleep health.

From this research, Emma – The Sleep Company has recognised an urgent need for a more effective solution. Founded in 2013 by Dr. Dennis Schmoltzi and Manuel Mueller, the company has become the world’s leading direct-toconsumer sleep brand. Its recently released app, Emma Up, is a digital AI coach designed to help individuals improve their sleep quality by providing personalised

Dr. Dennis Schmoltzi

Dr. Dennis Schmoltzi

Manuel Mueller

step-by-step programs and action-oriented advice. Developed in collaboration with sleep experts from Oxford University, the app goes beyond traditional sleep-tracking methods by identifying and addressing the underlying causes of sleep problems, positioning it as the most advanced sleep app on the market.

The app works by using sound-based sleep tracking – an approach that has been proven to be more precise than the use of physical sleep trackers such as smartwatches. By analysing this data, Emma Up can identify what is holding the user back from healthy sleep patterns. The AI-based sleep

“Our goal with the Emma Up app is to empower users to take control of their sleep health by offering personalised, actionable insights”

Felix Focken, CEO of the Emma Up app

coach then provides highly personalised recommendations that are tailored to the specific habits and needs of the user. And the longer a person uses the app, the more individualised the advice becomes, as the AI coach learns from each user's specific experiences within the app. This in turn enables the coach to provide increasingly accurate, effective and bespoke guidance.

Emma Up also offers an interactive chat function, which allows users to communicate with the AI sleep coach. This means that the coach can provide continuous support, in the same way a human sleep coach would. By providing this hyper-personalised support alongside scientific expertise from Emma Up’s sleep research team,

Emma Up has the ability to deliver industry leading sleep advice and help users maintain healthier sleep routines in the long term.

“Our goal with the Emma Up app is to empower users to take control of their sleep health by offering personalised, actionable insights,” says Felix Focken,

CEO of the Emma Up app. “By leveraging AI technology, Emma - The Sleep Company can create tailored programs that address each user's unique sleep challenges, making it easier for them to achieve sustainable improvements in their sleep quality.”

For more information about Emma - The Sleep Company, visit team. emma-sleep.com.

BUSINESS INTERVIEW

Consolidating procurement in the public sector to drive innovation and sustainability

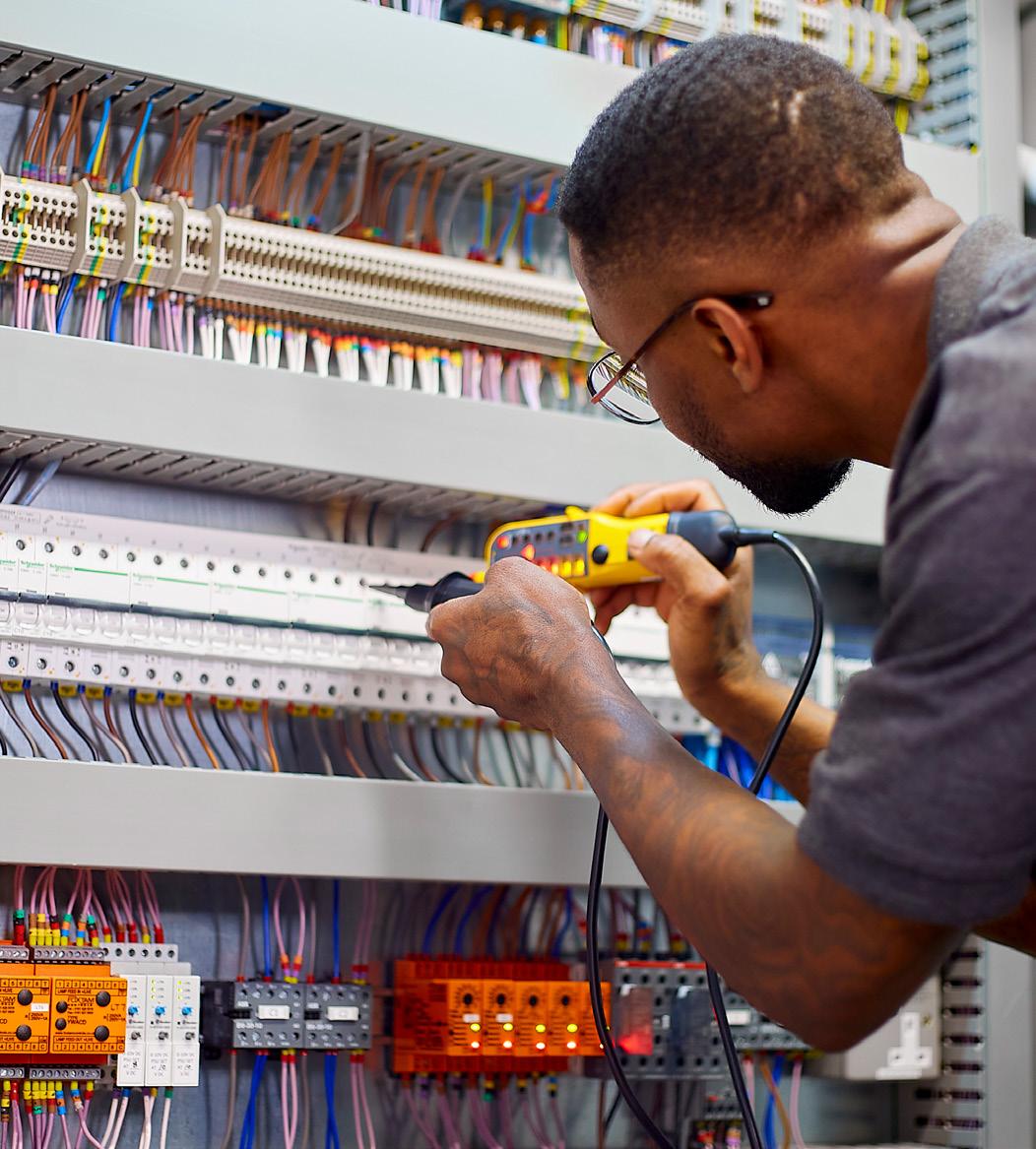

Simon Bullimore, Head of Group Procurement at Norse Group on the company’s organisational approach to procurement in the UK public sector.

he Norse Group is the largest Local Authority Trading Company (LATCO) in the UK, and it aims to improve people’s lives while generating ethical, sustainable profit for the public sector. In a context of cost pressures posing significant service challenges for councils and public bodies, Norse Group’s unique partnership approach to flexible service provision provides abundant opportunities to design and execute collaborative solutions.

Norse Group supplies a significant number of services including catering, grounds maintenance,

highway maintenance, transport, security, fleet management, facilities, cleaning, consultancy and adult social care.

Each one of these areas has its own supply chain, and Simon Bullimore, Head of Group Procurement at Norse Group oversees all of them. Simon joins us today to discuss the Group’s complex supply chain network and how it embraces consolidation, technological innovation and sustainability in its operations.

“So not only do we supply an array of services and sectors, but we also do it by what we call joint ventures

“We are developing a new computer system across the Group which will give us much better management of the information and data from our supply chain”

with several local councils in the UK,” begins Simon. “A joint venture model is a dynamic and reliable model for local councils. We spend in the region of £187m per year on products and services, and given the number of sectors we're in, we've got an extremely diverse supply chain. As such, cost control, governance, sourcing, tendering and the whole procurement cycle sits with me and my team –there’s no real element we don't cover.”

Simon explains that Norse Group takes a consolidated approach to procurement to ensure success in light of its expansive and complex supply chain.

“Since the Group merged in 2019 to gain efficiencies and improve services for customers, breaking down silos and integrating the business has been a priority,” says Simon. “This is understandable as all these areas have their own profits and losses to consider, plus they are trusted to run their own areas of the Group.

“But procurement is a function that touches and helps empower every single part of Norse Group. We cover a huge amount of ground and it's only recently that we are starting to really pull together and leverage our spend. Part of my role is to laud the benefits of joined-up procurement, especially while we're trying to achieve progress and results in the current economic climate.

“A consolidated approach to procurement is essential due to the nature of public sector governance and also meeting the commitments we make to ESG. Our targets simply cannot be achieved across a widespread and non-controlled supply chain.

“Our colleagues are starting to realise as well that everyone across the business wants to deal with the best suppliers, and the reliable

aspects of volume and spend still shout the loudest for attention. But our consolidated approach to procurement makes us an attractive organisation to work with and that's the key: be that in how we handle supplier management, consolidated group spend or streamlining our supply chain.”

So what are some of the key projects underway at Norse Group where the consolidated approach to procurement is unfolding? Here, Simon highlights the Group’s approach to ESG.

“As with all businesses, we take the ESG side of our operations very seriously,” says Simon. “We've always had obligations as a Group because of our position as a LATCO and our Norfolk County Council ownership. So we've always been up to speed on aspects like sustainability and the Slavery Act or Bribery Act, right from the beginning.

“A recent project within our supply chain governance relates to one of the biggest risks with modern day slavery: the overseas textile market,” says Simon. “Here we've worked to engage with businesses that are SA8000® accredited and part of the Sustainable Textile & Leather Production scheme (STeP scheme). STeP accreditation recognises adherence to best practice approaches to safety, ethics and sustainable production within all manufacturing facilities.

“Our CEO, Justin Galliford, drives a lot of our ambitions in net zero and carbon emissions – our target is to

reach net zero by 2050 and we have long since had a robust sustainability policy in place. The role we have in procurement is to make sure we take these values into the work we do, in the back end of the business. We cannot promote ourselves as an ESG thinking business if we do not demonstrate an ESG thinking supply chain, all the way from our suppliers through to client delivery.

“We value suppliers that can bring ESG relevance to our business, whether it be our workwear made from recycled fabric or removing the single-use plastics with the help of our partner Bunzl.

“They are ahead of the curve when it comes to sustainability, and what they are able to do is take a look at your product range and give you an idea of what sort of products can be removed and which ones you can replace. Bunzl also helps us as partners by assisting us with reporting. They have a strong understanding of demonstrating

the tangible outcomes of making sustainable swaps in our product range.

“This level of collaboration is the ideal partnership that we look to put in place where we're not just analysing price. We're looking at the total cost of ownership, which is an old-fashioned term, but it's still a relevant term.

“Everywhere we turn, I believe there is opportunity for sustainable choices. We need to make sure we grab the right ones, ignore the non-creditable ones and deliver everything we can into the business in the process. This includes taking care of really simple things like reducing supplier deliveries, wherever possible. I think that's often forgotten, but it's a very simple fix, which comes with very little risk.

“Another project we’re working on is we're looking to add a social value tool into our supply chain and procurement process. Essentially, when companies are bidding for our contracts, they will need to

complete a special social value tool which calculates that all-important social return on investment and helps us quantify exactly what is being achieved. Our current and future clients want to see these actions from us because it's essential work for all. The road to genuine and measurable sustainability is complex, but it starts with your supply chain.”

According to Simon, there are unique opportunities and challenges arising within public sector procurement and the Norse Group leans into them to meet its goals of generating ethical, sustainable profit and ultimately improving people’s lives.

“In terms of challenges, the actual discipline of procurement is broadening and deepening all the time. It used to be about doing great deals, putting suppliers and contracts in place for the right price and that was it.

“Now, as we all know, it’s so much more than this which is obviously great for the profession but creates ever greater challenges, such as incorporating the many things that the government wants to see in public sector spending, such as awareness of sustainability and social value. There are also carbon reduction requirements and very specific rules around bid submissions. On top of all this, we are required to make opportunities accessible for SMEs.

“When it comes to public sector procurement and the opportunities it presents, I feel many people get unsettled by the regulations and how

“We embrace deploying new technology and taking innovation forward wherever we can, where the business case makes sense and we can reduce total cost of ownership”

rigid they can be, especially if you’re coming from the private sector like I did,” explains Simon. “The regulations themselves can be a challenge but the procurement sector is fantastic for offering support.

“There are consortiums, frameworks, and mechanisms in place, such as those provided by ESPO, CCS and YPO. There's often guidance that can help people who benefit from economies of scale and leverage. So when it comes to these public buying consortiums, I've always seen them as another element of my department.

“Moreover, a well-run public tender will more often than not yield the right supplier for your business. Take the core elements like the standard selection questionnaire that carries out your due diligence for you. You are forced to have open and transparent evaluation criteria making you give particular focus well ahead of your tender and the timescales that are required to be followed, which ends up adding real structure to the process.

“At Norse Group, we look to take the rules and regulations and use them to our benefit as much as possible.”

Looking ahead to the future of public sector procurement for Norse Group, Simon emphasises the impact of new regulations and policies alongside the economic circumstances as influential factors.

“The Procurement Act 2023 that landed last year will continue to shape what we do in public sector procurement,” says Simon. “In my opinion, the bill will deliver significant benefit to the public sector. The production of the new procedure, namely the competitive flexible procedure, completely changes the landscape. We will be readdressing how we compile our tenders and taking an approach that means each tender we do will have the ability to shape the nature of what we're procuring.

“I think for far too long the first interaction with winning bidders in the public sector has been the handshake and signing of the contract. With the new procedure, we plan to engage with the supply chain early and we want to design a procurement exercise that means we get as full a picture as possible before we award contracts. It also means your key stakeholders can

become better engaged and you get a better feel for the people you may well be working closely with in the future.

“It relies on the supply chain wishing to engage on a higher level than just bid writing, but in my opinion, it's an opportunity for the supply chain to persuasively sell their services. If you speak to most commercial and salesorientated people, they will tell you a chance to get in front of the process early on is what they really want. So from this aspect, I think the new legislation is a massive positive step.

“Another element worth noting here is it's not always easy to demonstrate things like ESG when writing a bid, so if people are given the chance to come

and demonstrate to you what they can do earlier on, this will give you a better impression of their services.

“The last dynamic which will be important for the coming years is the fact that prices are rising in all manner of areas. We combat this through techniques of consolidation to leverage spend and to focus on supplier relationship management (SRM) more, meaning we get closer to our suppliers. We understand the challenges coming up and we work to mitigate them in a mutually beneficial way. We want to be a business that the supply chain wants to work with – you cannot just dismiss all the issues on cost at the moment, price increases are a shared challenge. We strive to work with people who are aware of

We are proud to partner with Norse Group to create a cleaner, safer and more sustainable world

Cleaning

Using our expertise to help our customers clean better and faster while controlling costs. Smart Cleaning Solutions Offering the latest smart technology including robotics fleet management and integrated customer digital portals. The Latest Cleaning Innovations Bringing first-to-market cleaning innovations to increase capability and performance. Pioneering Sustainability We’re shaping the industry with market-leading sustainable solutions that don’t cost the earth. Local Service, National Strength www.bunzlchs.com | Telephone: 0121 326 8921 | Email: info@bunzlchs.com

Expertise in

& Hygiene

our challenges, as well as their own, so we build a relationship-driven and data-driven business.”

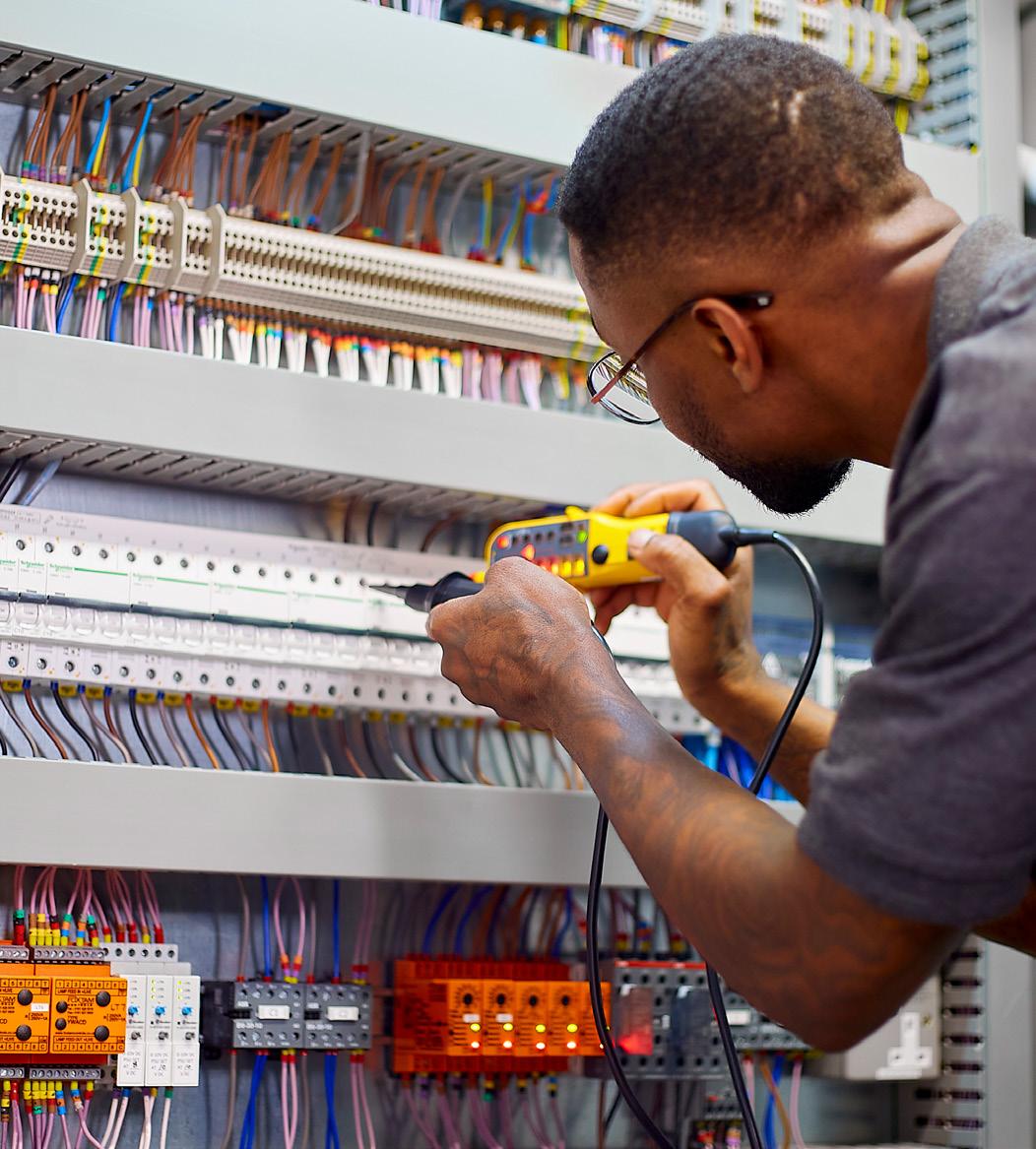

In light of the legislative and economic circumstances impacting public sector procurement, Simon describes the importance of wielding technology and innovation to enhance and streamline operations at Norse Group.

“For instance, if you look at all the vehicles that we support, we have a vendor-managed inventory system,” says Simon. “When it comes to all the spare parts that are managed by our suppliers on-site, we use technology to asses our stocks and demand which is a real driving force for us.

“We've also invested heavily into our specialist cleaning equipment, reducing our labour costs significantly. Since COVID-19, there have been a lot of technological advancements and innovations in that area, especially in our health and social care settings.

“We are developing a new computer system across the Group which will give us much better management of the information and data from our supply chain. We still spend a lot of time securing Management Information from our suppliers, and with our new system, we will be able to use this to drive strategic decisionmaking. We embrace deploying new technology and taking innovation forward wherever we can, where the business case makes sense and we can reduce total cost of ownership.”

For further information about Norse Group, visit norsegroup.co.uk.

ADDED VALUE

‘Quality time with my boys’

For Simon, spending time with his twin sons is a calming and deeply rewarding experience.

“I find whenever my mind feels a little scrambled, I will sit down with my two 5-year-olds and talk to them,” says Simon. “Their uninhibited, fearless and carefree outlook on the world is a real leveller: they keep me grounded and aware of the truly important things in life.”

Reading Recommendation

“Many people have read it, but if you haven’t I highly recommend Atomic Habits by James Clear,” says Simon. “I have a demanding role and balance this with having young twin boys. For me, the book really helped me bring positive change and habits into my relatively hectic life.”

Connect with Simon

45

DEFENSE

Finland joins

NATO’s DIANA network

NATO’s DIANA (Defence Innovation Accelerator for the North Atlantic) programme expands to Finland with the establishment of an accelerator and two test centres.

NATO's DIANA (Defence Innovation Accelerator for the North Atlantic) programme is

expanding its network with new sites.

Finland has now become part of the network after the board of the DIANA initiative approved a proposal to establish an accelerator and two test centres in the country. Their mission is to help companies develop technology, innovation

and business for the civil and defence sectors.

The initiative aims to identify future challenges in the defence and security sector and work with companies to find technological solutions. More specifically, it focuses on new technologies

such as artificial intelligence, autonomy and quantum technologies, which are dual-use in nature, meaning they can be commercially exploited in both the civil and defence sectors in NATO countries.

Preparatory work began in the spring of 2023, and operations have now reached their desired

conclusion. A DIANA accelerator is being set up by the VTT Technical Research Centre of Finland in Otaniemi, Espoo, in collaboration with Aalto University and the University of Helsinki.

This will focus on the communication systems and quantum technologies of the future, providing a special training

programme to help companies develop deep technologies and innovations for commercial and defence purposes. It will also provide companies with extensive and varied training on how to develop business opportunities in the defence sector. These services will be specifically targeted at start-ups and SMEs with limited experience in the defence and security sector.

“A DIANA accelerator is being set up by the VTT Technical Research Centre of Finland in Otaniemi, Espoo”

“It will be possible for all companies in NATO countries to purchase the test centre services, regardless of whether or not they belong to a DIANA accelerator”

"The long-awaited decision is significant for Finland as it is the first time that Finnish operators will be able to harness their cuttingedge expertise for NATO's DIANA innovation activities on such a large scale,” says Sauli Eloranta, Vice President of Defence at VTT.

“Our country has a large number of technologically advanced and innovative start-ups and SMEs, which have found it difficult to invest in export in the defence sector. DIANA will support this activity free of charge by using the accelerators to train companies in NATO technical and procurement requirements and by developing company-specific business training programmes. Such a mechanism provides a high-speed lane for companies to enter a difficult

but fastest growing industry internationally – I hope Finnish companies will participate as widely as possible."

Test centres will also be established at the University of Oulu and VTT’s Otaniemi site, designed to provide tools for further technological development. The Otaniemi site will focus on secure connectivity, space

and quantum technologies, while the test centre at the University of Oulu will offer companies the opportunity to test 6G network technologies.

These test centres offer a valuable place where companies can strengthen their technological expertise and competitiveness. The research infrastructure and

54

experts provided by the test centres will allow companies to evaluate their own concepts or technologies and secure support to develop them. In practice, the test centres will consist of a comprehensive set of existing research facilities and equipment, as well as top-level expertise in the sector. The centres will also support the development of start-

ups participating in the accelerator programme.

It will be possible for all companies in NATO countries to purchase the test centre services, regardless of whether or not they belong to a DIANA accelerator.

To learn more, visit the DIANA website diana.nato.int.

55

Coppelmans to discuss the innovative intelligence at HERE Technologies the future of connected mobility with transport solutions at Siemens Mobility. MIGUEL PEREIRA

"The team were professional and diligent throughout"

Leigh Feaviour, CTIO for BT’s Supply Chain

"Absolute pleasure working with the Digital Innovation team"

Mun Valiji, Chief Information Security Officer at Sainsbury’s

"A highly professional approach"

Andy Brierley, Vice President, Cloud Application Modernisation at IBM

"Digital innovation Magazine is a very flexible and professional team"

Kim Larsen CTIO, T-Mobile Netherlands

‘Sealing innovation global

BUSINESS INTERVIEW

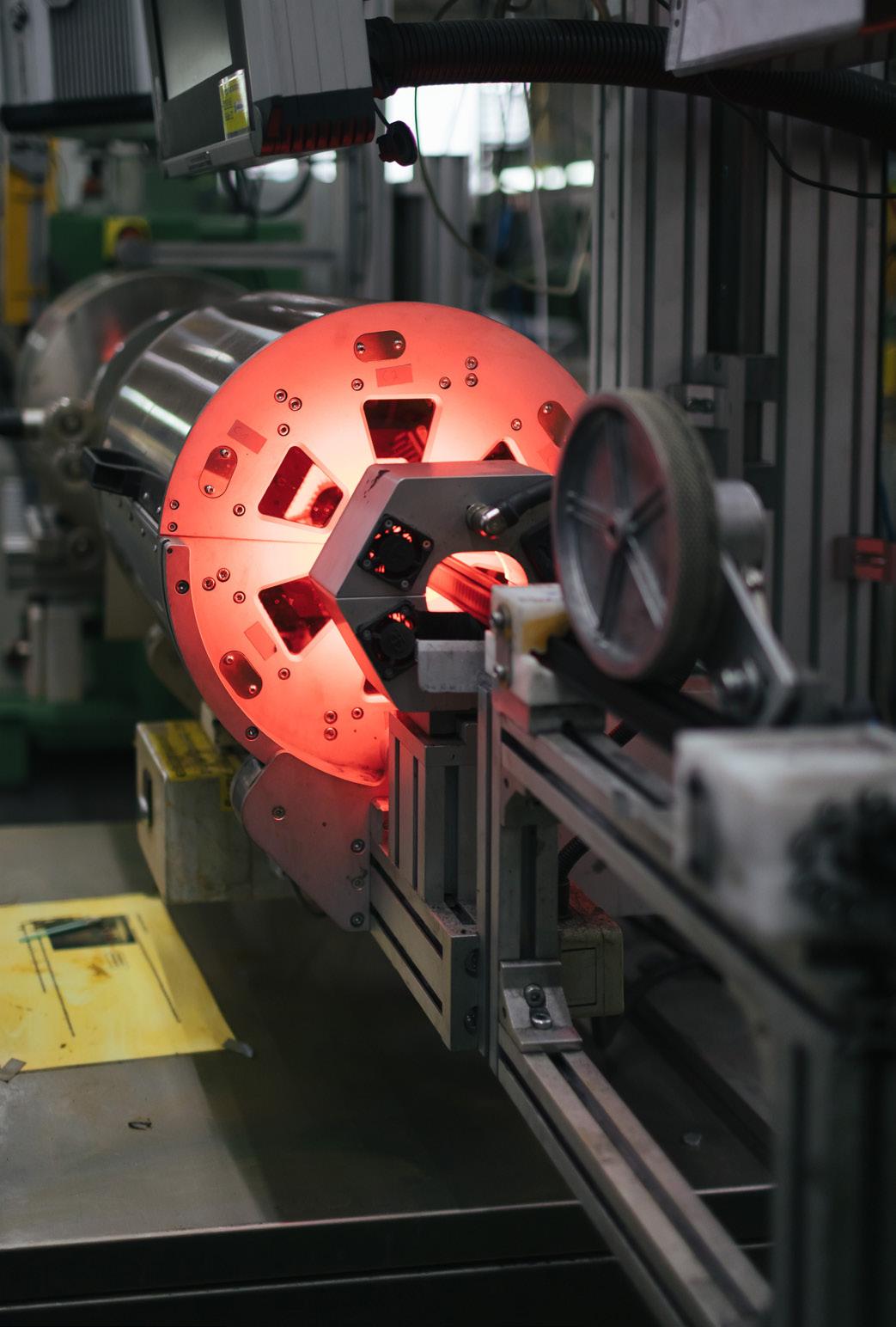

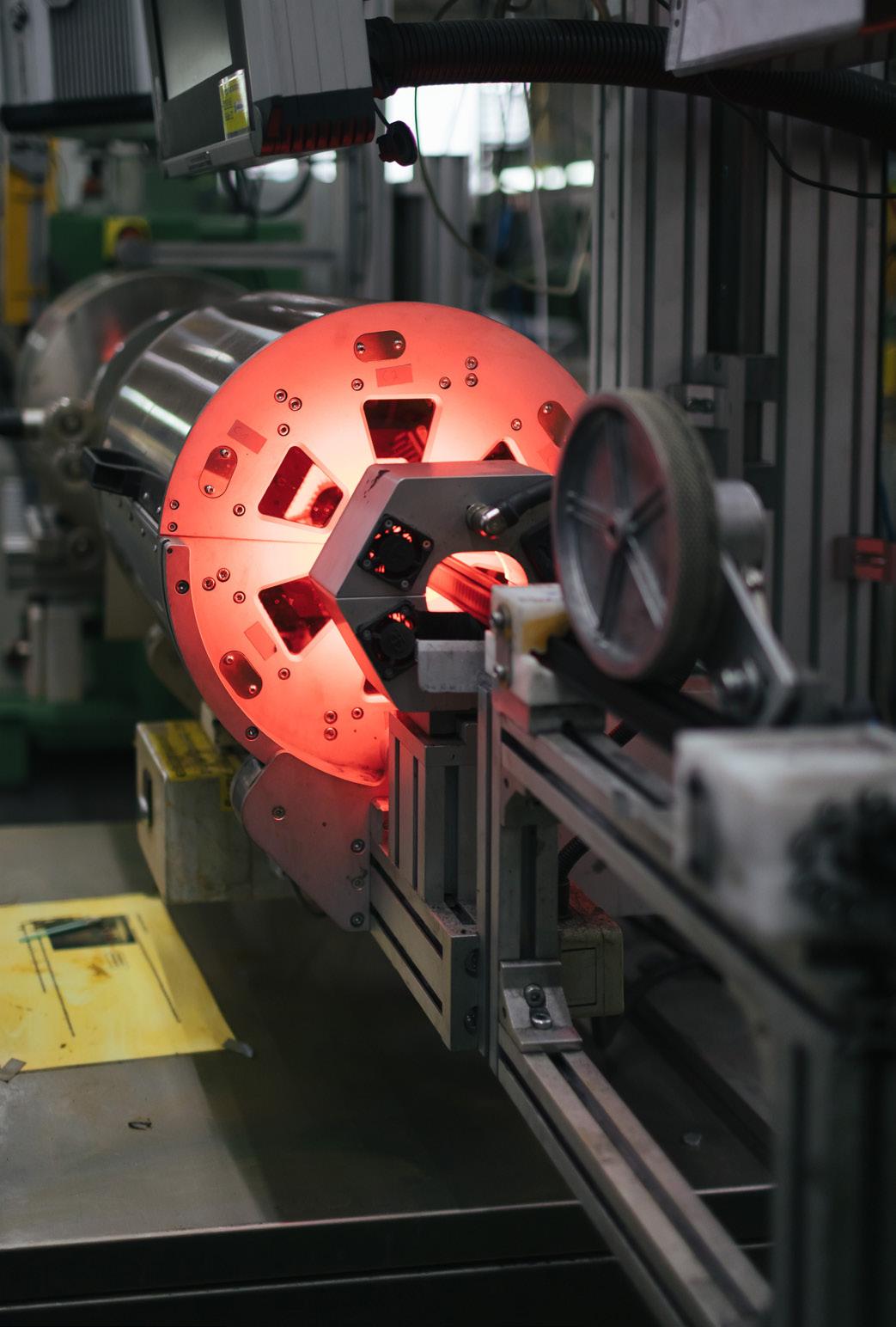

‘Sealing the future’: Promoting innovation and sustainability in the

automotive industry

Sven Müller, Director of Innovation at the SaarGummi Group and Managing Director of SaarGummi Neo, on tapping into new ideas and fresh approaches, without losing sight of established principles or quality, when supplying high-performance rubber to the automotive industry worldwide.

global

Originally founded in Germany more than 75 years ago, the SaarGummi Group is now a global powerhouse operating wherever you find the automotive industry.

t its core, the SaarGummi Group produces sealing and weatherstrip products made from rubber material (ethylene propylene diene terpolymer – EPDM) for the automotive industry. Its products include door sealing, trunk lid seals, sunroof or glass runs and much more besides. With 5,400 employees and 17 production sites worldwide, the organisation turns over roughly €650m per year in sales.

While the design of the products and manufacturing technologies have always been fine-tuned over the years, the fundamental principles of the company – such as reliability, the highest quality standards and working in close partnership with customers – have remained the same. This heritage creates trust among customers. Nevertheless, it sometimes presents a challenge when cultivating new ideas and introducing them to the customers.

Here to elaborate on how the SaarGummi Group and its sub-division SaarGummi Neo develop process, product and material innovations while embracing digitalisation and sustainability is Sven Müller, Director of Innovation at the SaarGummi Group and Managing Director of SaarGummi Neo.

“We are a traditional business in some regards,” begins Sven. “There have been some changes in the recipes of the rubber material alongside design changes over the years. But in general, it’s quite an established industry in terms of the process as well as from the product point of view. However, one of the dynamics which separates us from our competitors and similar businesses in other industries is we produce various rubber compounds ourselves, before embarking on the manufacturing phases.

“In terms of our innovation and sustainability, this control over our

60

processes is a crucial factor – helping us to lead the industry in terms of our practices because we have direct influence on them.

One of Sven's core responsibilities is to guide the innovation strategy for the SaarGummi Group and lead the SaarGummi Neo team as well as the company's global innovation centre, which is located in Germany.

“We officially started our innovation journey in 2016 with the founding of the SaarGummi Neo team, which I joined as Managing Director in 2018,” recalls Sven. “We are effectively the innovation department for the whole SaarGummi Group. But unlike many companies who declare themselves innovative just because they created an innovation department, we decided

to be deliberate and different by making ours its own legal entity. We did that on purpose, as I like to think of it, to build a speedboat rather than a big cruising ship which is slower and harder to turn. We wanted to be as agile as possible within the rules and procedures of the Group.

“But the big challenge is even though we are a separate entity, technically, we never wanted to be disconnected from the Group since this would undermine the very innovation we are trying to promote. We need to stay as close as possible to the rest of the organisation, while simultaneously existing as far away as possible from the daily operations of the business. In my dual role as Director of Innovation at the SaarGummi Group and Managing Director of SaarGummi

61

“One of our major tasks is to analyse the trends or technologies to see what might be a good fit for us, now or in the future”

Neo, it is my job to strike this balance. It is sometimes not an easy job, but it also fosters our strength in the Neo team.”

Sven explains there are four main categories of innovation at the SaarGummi Group: process, product, materials and digitalisation. But Sven reiterates these are not distinct silos since different categories often overlap within the same project or initiative.

So how is the SaarGummi Group approach injecting innovation into its operations within these four categories? Sven insists there are external and internal factors worth

noting when it comes to embracing innovation at the SaarGummi Group.

“In terms of external factors, there are megatrends which come along which we have to adapt to as a company,” says Sven. “You might be able to ignore them for a little while, but ultimately you have to react to these trends, or you’ll be left behind.

“For instance, digitalisation is a crucial megatrend for us which we had to incorporate. There have been a range of buzzwords flying around related to ‘digitalisation,’ but for us, it’s about asking how can

62

we actually use it? How should we adapt new technologies to meet our needs? Are we exploring this because there is a business case and it will generate profit, or are we being led by the hype? After careful consideration, we decided to explore digital twin technology in our journey towards building fully digitalised factories while weaving data analytics and algorithms into our processes. Also under the umbrella of digitalisation, we consider new technologies for use. For example, we are exploring how to integrate XR solutions (VR, AR, MR) in order to support employee training or communication between employees but also to have virtual 3D meetings where necessary.

“So besides our daily innovation projects, one of our major tasks is to analyse the trends or technologies to see what might be a good fit for us, now or in the future. We do that not only to be ready for new technologies but also to select the right projects for us. It doesn’t make sense to invest in innovation if it will become redundant in the near future – we have to keep the long-term goals of the Group in mind.”

When it comes to internal factors impacting the innovation strategy at the SaarGummi Group, Sven describes the need to consider the values and objectives of the organisation while also convincing internal stakeholders to see the merit in the projects. Here, he uses sustainability and process innovations as examples.

“You could see sustainability as an external factor if you consider the rising regulations and legal requirements at play,” says Sven. “But we see it as an internal priority since we have a duty as a company to make our products and processes more sustainable. We also want to be carbon-neutral in the coming years. It is then a case of presenting sustainability innovation to internal stakeholders in terms of these values or objectives. Or, if we consider process innovations it is again a question of presenting the projects or initiatives as vehicles for improving production speeds, lowering scrap rates, increasing practicality or helping towards KPIs.

“For us, sustainability is more than just a phrase. There is a high impact on our

63

“We are certainly creative in our approach, with an array of experts who have diverse knowledge in different areas”

footprint coming from the material side of the organisation. The big challenge in our business is that the vulcanised rubber material we use cannot easily be recycled. Compared with metal or plastics which can be re-melted, our finished material is vulcanised which is a non-reversible process. In the last few years, there have certainly been steps forward

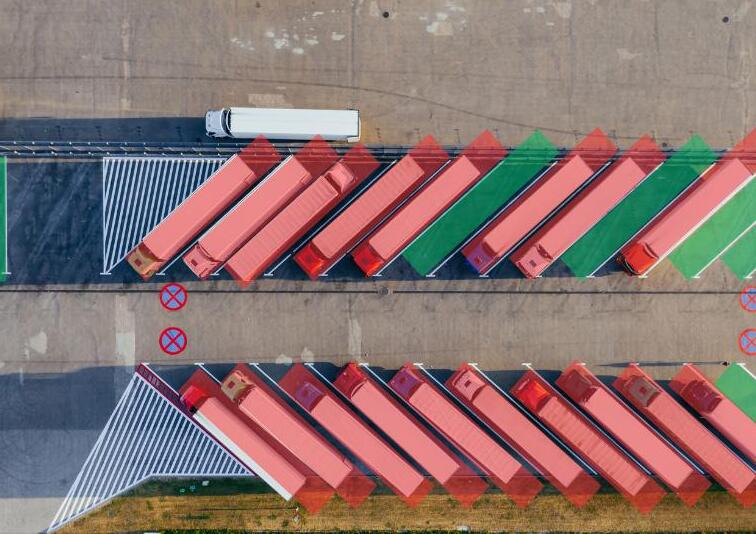

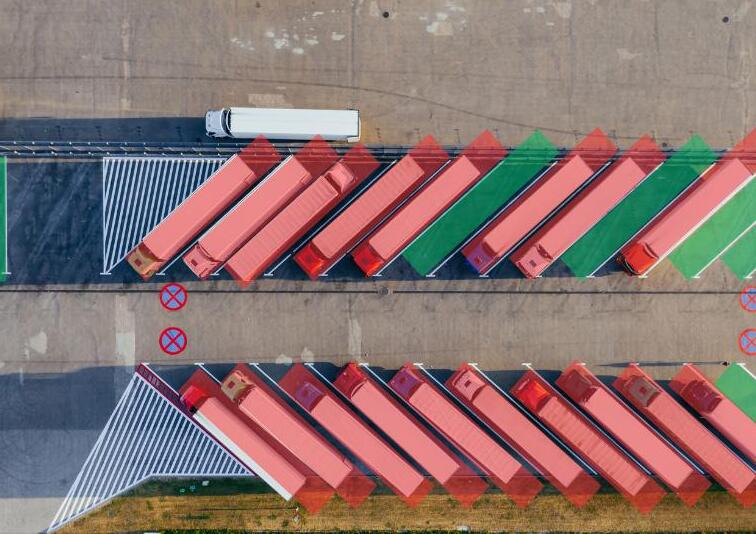

ACHIEVE OPTIMISED TRUCK PROCESSING

Install an automated entry system to reduce backlog.

Utilise live occupancy data for immediate truck navigation.

Use parking data analyses to detect and reduce process-disrupting downtimes.

Apply historical occupancy data to plan management of pick-ups and deliveries.

Integrate live data into yard management systems to enhance logistic insights.

but it remains a challenge. Therefore we are working actively, especially on the material side, towards more sustainable ingredients and recycling or re-using methods. We also incorporate our sustainability agenda into innovation projects with promising overlap, for instance within our digitalisation strategy.”

However, Sven relays how SaarGummi Neo does not monopolise innovation for the SaarGummi Group – regardless of whether the inspiration for it arises externally or internally.

“We implemented our Innovation Committee Meeting which meets bimonthly,” says Sven. “Here, the C-level board of SaarGummi Group

Smart City System Parking Solutions GmbH offers digitalisation, installation, operation and data provision as well as maintenance and support. It has locally developed and installed reliable, low-maintenance parking systems for more than 66,000 parking spaces in Europe.

join dedicated representatives from across the organisation in different departments to hear me present on the status of our innovation projects, but also discuss strategic topics and the other members of the meeting can offer feedback. What is new? Where do we want to go? Are projects succeeding or do we need to put them on hold? We come together and judge what is most beneficial for the organisation and take things from there.”

While the innovation strategy is deeply embedded into the SaarGummi Group and SaarGummi Neo, Sven explains it is not undertaken in isolation.

External collaboration and strategic partnerships are crucial as well.

“Innovation is not created in thin air,” says Sven. “We are certainly creative

in our approach, with an array of experts who have diverse knowledge in different areas. Nevertheless, we also need input from the outside. For us, this is generated in several ways. We work with universities or institutes when it comes to the scientific developments and research side of things. We also collaborate with startups or emerging companies that are interesting to us as an organisation due to their products, processes or digitalisation offerings.

“One such example is our partnership with Smart City System, which offers a clever way for getting a live overview of logistics movements on site. They provide sensors for recognising if a loading point is blocked or free for the next truck. All information is provided in a customised software where

65

additional functionalities can be added. We made a pilot project with them not only for this ‘daily business’ solution, but also to get a better understanding of sensors, data exchange, and the integration of different parties to come to a digital twin of the factory in the long term as part of our digitalisation strategy.

“If we look at our digitalisation strategy, we are always striving for ways to improve our processes. We have about 150 process parameters which can be complex and challenging, so we need the right data analytics and solutions in place to make them efficient and effective – whether this is in loading sensors, capacity analysis, production lines or digital twin technology.

“Our pilot project with Smart City System is a piece in the puzzle, the starting point for ultimately working towards a fully digitalised factory system. We gain so much from these types of projects because both sides learn so much in the process. Working with companies like Smart City System is a terrific example of the collaborative partner approach to innovation.”

Looking ahead to the future and the role of technology in promoting innovation at the SaarGummi Group, Sven wraps up our discussion by focusing on additive manufacturing.

“For several years, we have made a lot of progress on integrating additive

manufacturing methods into our business,” says Sven. “There is an uncountable amount of potential use cases which have been identified either in plastics or metal printing. Additive manufacturing has huge potential as a technology to transform the traditional processes in our industry.

“At one level it can lower costs because it is cheaper to print products in certain cases than it is to take the traditional manufacturing approach. But if you look closer at the new technology of additive manufacturing, it is a real game changer because it allows us a completely new kind of freedom when it comes to the design of objects.

“I think there will be a lot of changes and progress in the future with additive manufacturing in the background. It allows you to build different styles of support tools and offers a greater level of customisation for specific parts that require it.

“Fortunately, we already realised the potential of additive manufacturing several years ago, and since then we have implemented it very successfully in the Group and look forward to realising even more of its potential in the coming years.”

For further information about the SaarGummi Group and SaarGummi Neo, visit their websites: saargummi.com and neo.saargummi.com.

66

Hobbies ADDED VALUE

When he isn’t at work, Sven prioritises spending quality time with his wife and two children. But if he gets a bit of spare time, Sven likes to experiment and play with the 3D plastics printer he has at home – for his own curiosity and creativity, but also to have fun with his kids and make them objects to play with.

Recognition

Sven takes great pride in SaarGummi Neo’s recent recognition as one of the top 100 innovators in Germany as a testament to the hard work and collaboration among his team and the entire organisation.

Connect with Sven

Unique generative agriculture

Bayer set to pilot new technology agricultural industry by enabling

ARTIFICIAL INTELLIGENCE

generative AI tool for agriculture unveiled

technology to transform the enabling the ‘cloud-connected acre’.

Leading biotechnology company Bayer’s Crop Science division has announced the pilot of an expert large language model (LLM) system to benefit farmers and uplevel agronomists in their daily work.

he LLM contains centuries of aggregated experience from Bayer agronomists from around the world, resulting in an expert system that can quickly and accurately answer questions related to agronomy, farm management and Bayer agricultural products. Instead of a time-consuming process, the intuitive system responds to natural language and can generate expert information within seconds.

“Our unique GenAI system has the potential to serve agronomists and benefit farmers all over the world, further advancing AI as an indispensable technology for

agriculture," says Amanda McClerren, CIO and Head of Digital Transformation & Information Technology for Bayer's Crop Science division. “We'll continue to use traditional AI to develop better products, and we're also committed to harnessing new GenAI technology in a thoughtful way that augments and supports knowledgeable experts across the industry, bringing value to farmers and those who serve them.”

Developed in collaboration with Microsoft as the leading technology partner and Ernst & Young (EY) as an industry partner, Bayer hopes to integrate the expert GenAI system into its

70

digital offerings, and the company anticipates broad opportunities for collaboration with other agricultural offerings and partners. The tool has been designed as a global capability, and looks to benefit millions of smallholder farmers in the future by democratising access to agronomic advice and product information critical to feeding communities and improving global food security.

“AI and automation are helping farms of all sizes produce more while using fewer natural resources, and we're starting to see how they can enhance decision-making on almost any plot of land,” says Ranveer Chandra, Managing Director, Research for Industry & CTO, AgriFood at Microsoft. “With Bayer's strengths in data science, digital, and especially agronomic expertise, we're pleased to be contributing

72

to an expert system that will make agronomic understanding more accessible and empower those responsible for feeding the planet.”

Looking ahead, Bayer aims to expand the pilot of the expert GenAI system to selected agronomists and potentially farmers as early as this year, while continuing to advance a separate GenAI prototype allowing users to directly query their own farm

data. Because they also pull insights from closed data sets, these GenAI tools are unique for agriculture and will bring more meaningful value to farmers, agronomists and other industry users, compared to out-ofthe-box LLMs that only use opensource data.

The company also hopes to bring new cloud technologies to the agrifood industry with its ‘AgPowered

73

“Whether you are a farmer using digital tools or a company that operates downstream, you need technologies that can help your business adapt to a changing landscape”

Jeremy Williams, Head of Digital Farming for Bayer's Crop Science division

services.’ This includes Bayer Historical Weather, a comprehensive weather dataset that spans the last 40 years and provides detailed, field-level weather insights across global agricultural regions. This can inform weather risk assessments and actuary processes, and will be used to forecast crop seasonality and production changes year over year, as well as train agronomic models.

“Whether you are a farmer using digital tools or a company that operates downstream, you need technologies that can help your business adapt to a changing landscape,” says Jeremy Williams, Head

“With our AgPowered Services, we are making access to digital tools easy and convenient, benefiting the industry and driving innovation”

Jeremy Williams, Head of Digital Farming for Bayer's Crop Science division

76