March/April | 2014 | Vol. 4, No. 2

TPMS UPDATE

FUEL DELIVERY DIAGNOSTICS A/C RECOVERY

Circle 101 on Reader Service Card

March/April | 2014 | Vol. 4, No. 2

The Technicals

Tire pressure monitoring systems Page 14 | An in-depth look at the types and functions of today’s TPMS systems

R R/R/R roundup PPage 26 | R134a recover/recycle/recharge equipment eq for your shop

Got gas? Page 34 | Get ready for fuel delivery diagnostics

Departments Straight Talk Best of times, worst of time | Page 6

Technical Service Bulletins Cadillac, GM, Mitsubishi and more | Page 56

Tech Tips From module-to-module communication to wireless ignitions and leaking rear main seals | Page 10

Quik-Link Your connection to free information | Page 60

Tool Review Compact gun: A pneumatic air wrench for cramped spaces | Page 48

The Toy Chest New and innovative equipment for your tool chest and shop | Page 63

4 | March/April 2014

Circle 102 on Reader Service Card

Mike Mavrigian | Editor

T

Best of times, worst of times

his winter has been brutal for northern and northeastern states, with record snowfall and record temperatures, and with abnormal icy conditions even in southern states such as Georgia. In addition to the havoc wreaked by brutal blasts of arctic cold and relentless buildup of the white stuff, streets and highways are peppered with destructive potholes. The bad news for vehicle owners was delivered in terms of torn tires, bent rims, weak batteries, frozen fuel lines, snow-packed air ducts, etc., in addition to countless incidents of collision damage. Amidst the severe temperature shifts, any windshield that had a previous chip likely snapped and cracked due to the combination of below-freezing temperature and mechanical stress. The combined heavy snowfalls, frigid temperatures alternating with brief warm-ups followed by sub-zero weather created hard-packed lumps of ice in driveways, parking lots and side streets. Drivers who attempted to mush through such obstacles often found themselves impaled and stuck, requiring a push or a tow to release their vehicle from the grips of the ice monster. The results in many cases: dented or torn oil pans, damaged brake or fuel lines, torn CV shaft boots, overheated transmissions and in some cases even bent subframes and damaged suspension arms. While these horror stories presented nightmares for drivers, the recent weather has created a boon for repair shops. Though

we certainly don’t want to proft from the misfortunes of others, the recent weather attacks have generated substantial increases in repair work, which is good news for shops. While this might present opportunities for unscrupulous shops to take advantage

of such a windfall of work by charging a premium to handle emergency repairs, this winter season has served as a showcase for the integrity and empathy that reputable shops have displayed, especially for customers whose budgets have been stretched beyond the breaking point. I know of many instances where shops have saved the day for stranded drivers by working late hours and providing price breaks for those in need. We should take pride in the fact that our industry is comprised of many good-hearted folks who go above and beyond when circumstances demand. Instead of profteering and bleeding people dry, they step up to the plate and act as human beings should. â—?

6 | March/April 2014

3515 Massillon Rd., Suite 350, Uniontown, OH 44685 (330) 899-2200, fax (330) 899-2209 Website: www.autoserviceprofessional.com Editor: Mike Mavrigian Mike.Mavrigian@bobit.com Managing Editor: Lori L. Mavrigian Lori.Mavrigian@bobit.com Senior Editor: Bob Bissler Bob.Bissler@bobit.com Associate Editor: Ann Neal Ann.Neal@bobit.com Contributors: Bob Weber/Automotive Technical Writer Craig Truglia/Diagnostics & Driveability Specialist Bob Rodriguez/Hybrid & Alternative Fuel Specialist Advisory Board: Dan Paddy/Dan Paddy Service, Seville, OH Frank Dannemiller/Mobile Service & Repair Co., Wadsworth, OH Bob Fall/Fall Automotive Machine, Toledo, OH Scott Gressman/Gressman Powersports, Fremont, OH Ken Styer/Ohio Technical College, Cleveland, OH Greg McConiga/O’Daniel Automotive Restorations, Ft. Wayne, IN Art Director: Neal Weingart Neal.Weingart@bobit.com Production Manager: Karen Runion Karen.Runion@bobit.com Publisher: Greg Smith Greg.Smith@bobit.com Sales: Dan Thornton djtinc@gmail.com (734) 676-9135, mobile (313) 410-0945 Michele Vargo Michele.Vargo@bobit.com (330) 899-2200, fax (330) 899-2209 John Dyal The Dyal Company John.Dyal@bobit.com (760) 451-5026 Marianne Dyal The Dyal Company Marianne.Dyal@bobit.com (760) 451-9216 Customer/Subscription Service Tammy Katata, (800) 991-7702

Auto Service Professional is a Bobit Publication Executive offces: 3520 Challenger St. Torrance, CA 90503 Chairman: Edward J. Bobit CEO & President: Ty F. Bobit Chief Financial Offcer: Richard E. Johnson Vice President & COO: Cyndy Drummey

8 | March/April 2014

Circle 103 on Reader Service Card

Tech tips From module-to-module communication to wireless ignitions and leaking rear main seals DIAGNOSTIC MULTIPLES From an engineering standpoint, most technicians can see the logic behind moduleto-module communication. In theory, it makes sense to have a single input such as a vehicle speed sensor feed just one module, and then have that module share the information over a pair of data bus wires to other modules. Unfortunately for the technicians faced with the challenge of diagnosing and repairing these problems, module-to-module communication often makes our job signifcantly more diffcult. Not only does it increase the requirement of diagnostic equipment, since many of these problems can only be diagnosed with factory scanners, but it requires today’s technicians to be computer network diagnosticians as well. Of course with increased module-to-module communication comes increased unique and multiple simultaneous problems, and any one module shutting down can affect everything — from interior lights malfunctioning to the vehicle not starting. Recently I took in a 2007 Ford Crown Vic-

the ABS module, we found there was no communication to the scanner. The frst plan of action was to check the powers and grounds to the ABS module; the ignition power feed to the module was not showing battery voltage as it should. The fuse was checked and found to be OK. Further tracing of the circuit found a broken wire in the harness. Once the wire was repaired, communication was restored to the ABS module, the ABS light went out, and the power steering returned. When dealing with a multiplexed vehicle with multiple problems that began at the same time, the best plan is to pick one problem and concentrate on resolving it. If too many problems are tackled at once, it’s very easy to lose direction and start going in circles on a diagnosis. One useful test, if available, is to perform a “‘network” or automated test, where the scan tool attempts to communicate with all the modules on the vehicle’s networks. If a particular module is not communicating, addressing that concern is normally a good place to start.

WIRELESS IGNITION

Ford’s 2007 Crown Victoria utilizes a variable assist power steering system.

toria. The complaint was that the ABS light was on and the power steering was lacking assist. This vehicle model uses a variable assist power steering system that defaults to minimal assist in the event of a system failure. While trying to retrieve codes from

Chrysler’s newer vehicles have gone wireless. One of the new systems is the Wireless Ignition Node (WIN). This system uses a transponder remote keyless entry fob integrated key (FOBIK) which replaces the traditional metal key. With all of the functions of a traditional remote keyless entry fob, this unit also has a metal key blade for valet functions to lock the glove box and to open the door in the event of a dead battery, a remote keyless entry failure or a bus failure. This unit serves as the remote keyless entry fob and the electronic ignition key. The functions of the WIN are: •

Sentry key immobilizer (SKIM)

10 | March/April 2014

• • • • • • •

Wireless receiver for remote keyless entry Brake transmission interlock (BTSI) Clock master Steering column lock interface (BUX) for export only Tire pressure monitor (TPM) system Remote starting Electronic ignition switch

When entering the vehicle, the FOBIK is used to open the door locks and disarm the alarm system via the remote keyless entry. The FOBIK is then inserted into the WIN, much like an ignition key. But the similarity ends there. When the FOBIK is near the WIN, it transmits a secret key code via radio frequency to the WIN which in turn passes this information on to the controller area network (CAN). The WIN is hard wired to the CAN C bus. The signal is then sent to the powertrain control module (PCM). At this point, if it is a valid key, the immobilizer is satisfed and the vehicle is ready to start. The signal is then passed through the central gateway on the vehicle, usually the Totally Integrated Power Module (TIPM). This information is then gathered by the other controllers via the CAN B, the CAN Interior High Speed (IHS) or in some cases the Locale Interface Network (LIN) bus. Once the FOBIK is turned to the “start” position in the WIN, the Win again transmits a message on the CAN bus for starter engagement and when it returns to the run position, the “ignition on” functions through the PCM and the central gateway to the other modules. The WIN then monitors the tire pressures over the bus and provides the BTSI function via a hard wired input from the shifter assembly and brake switch. The system became available on some 2007 vehicles and was standard on all Chrysler, Dodge and Jeep vehicles by 2009.

LEAKY REAR MAIN ON LS A local customer makes his living by “rebuilding” late model salvage cars and reselling them. He tends to perform his own work, and he’s not exactly an expert technician, so he routinely asks us to fgure out

any problems that he can’t solve on his own. After “restoring” a food car that he bought at auction, he “rebuilt” the engine and told us that the rear main is leaking and he can’t fgure out why. The engine at hand was a GM LS1. This engine’s crankshaft features a one-piece rear main seal that’s held in at the engine’s rear cover. He had been installing the new seal to the rear cover, oiling the seal lips, and then pushing the rear cover onto the rear of the crank. When doing this, the seal’s two inner lips would fold back, allowing oil to simply walk past the seal.

The LS rear main seal installs to the rear engine cover. Do not lube the seal lips prior to installing the cover to the engine block.

The proper method is to install the seal dry (this may go against the thinking of many, but it’s important). Also, a new seal will include a white nylon seal guide (which this guy had been ignoring and throwing away). The guide needs to be installed to the inside of the seal and held in place while pushing the rear cover onto the crank. The guide prevents the lips from folding back. Once the seal is captured onto the crank rear fange, the guide simply pops out. Any time you install a rear main seal onto any LS crankshaft, you must use this nylon guide. It serves as a temporary installation tool. ● (All tech tips are courtesy of Identifx Inc. For more information, see www.identifx.com.)

13 | March/April 2014

Tire pressure monitoring systems By Mike Mavrigian

W

e’ve discussed the subject of TPMS (tire pressure monitoring systems) in the past, but this is a topic that can always beneft from an update. Considering the proliferation of TPMS in today’s market, it’s vital that we gain as much understanding of these systems as possible.

location is under-infated; or the warning system may indicate which location (LF, RF, LR, RR) is under-infated.

INDIRECT TPMS

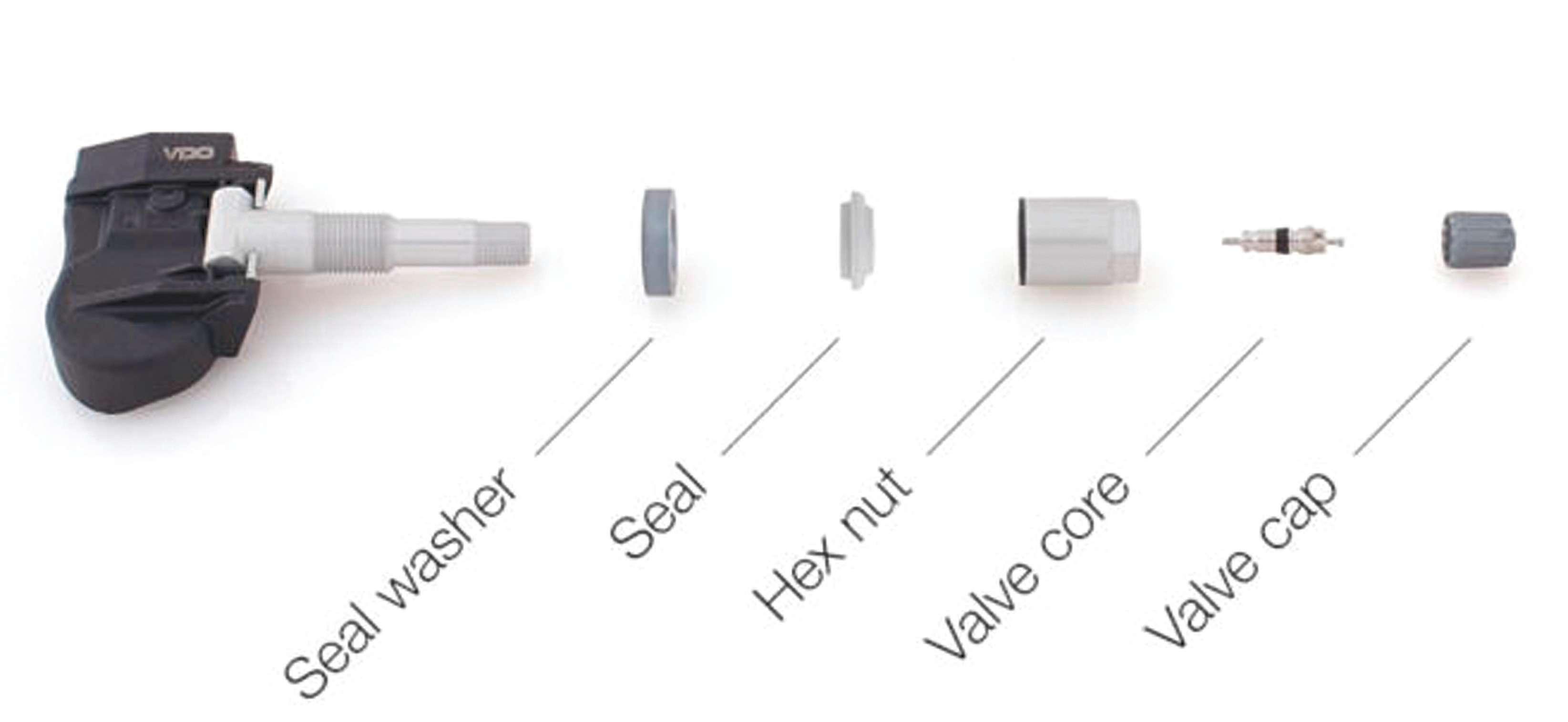

Instead of monitoring actual infation pressure, an indirect system relies on the vehicle’s ABS to monitor tire rotational speed (since a lower-pressure tire will rotate at a different speed due to the decrease in overall tire diameter). When the ABS detects a different rotational speed, it alerts the driver. This works as designed as long as the system detects a difference in rotational speed as compared to the remaining tires. However, if all four tires are under-infated by the same amount, the system may not detect a difference, and no alert warning Typical components of a “clamp-on” style may be provided. A direct TPMS is much sensor. The sealing washer seats against the inside surface of the wheel’s valve hole. more accurate by comparison. The seal is placed at the outboard side of the Indirect systems can also cause false tire hole, captured behind the hex nut. pressure warnings if/when tires spin on slippery surfaces. If this happens often DIRECT TPMS enough, the driver may be accustomed A “direct” tire pressure monitoring system to ignoring the warnings and may ignore (where a dedicated system exists that actual low-pressure alerts. monitors actual tire infation pressure) is To my knowledge, the indirect system was generally calibrated to alert the driver when no longer is use in new vehicles as of 2007, one or more tires have lost at least 20% when automakers switched over to direct to 25% of the programmed/recommended systems. infation pressure. A direct style tire presThree basic “styles” of TPM sensor/transsure monitoring system (most widely in mitters are available (NOTE: The correct use today) features a pressure sensor/ OEM term for the sensor is “wheel mounted transmitter installed inside each wheel. The sensor”): banded, snap-in and clamp-on. sensor constantly reads infation pressure. Banded sensors are affxed to the inside The sensor then sends a radio wave signal of the wheel using both a positioning to a receiver located in the vehicle. When adhesive (peel off) and a large diameter infation pressure falls below a predeterworm-drive clamp (the wheel valve is the mined level, a warning light illuminates on standard valve style that has been in use the instrument cluster. Depending on the for decades). Both clamp-on and snap-in year, make and model of the vehicle, this sensors feature the valve stem as an intewarning may simply indicate a low-pressure gral part of the sensor. A clamp-on sensor warning, leaving it up to the owner or mounts via the wheel’s valve hole and is technician to then determine which tire secured with a mounting nut and is sealed

14 | March/April 2014

Circle 104 on Reader Service Card

with a separate grommet. been replaced, and that The snap-in style features includes both OE or aftera traditionally mounted market sensors, in order rubber valve style that to ensure that the TPM allows the valve stem to system functions propbe pulled through the hole erly. The only exceptions and “snapped” into place involve some Chrysler and similar to a traditional Mazda vehicles, where the Always use the seals, valve core, valve. replacement sensor(s) is nut and cap that come with NOTE: When servicing any the new sensor. These compoautomatically relearned to TPMS sensor, do not use a the vehicle during an ininents are specifcally designed for TPMS sensors. Never use brass valve core. This can tial drive cycle. a brass valve core, as this can result in dissimilar metal Other than these exceplead to electrolysis (reaction reaction and can lead to tions, a TPMS scan tool is between dissimilar metals). corrosion issues. Use only a required. stainless steel valve core. Whenever a valve NOTE: Since relearn procedures vary core has been removed, always replace it among automaker brands, it’s necessary to with a new core. Also, only install a valve determine the correct procedure for any cap that is designed for use with TPMS. This given vehicle before starting the relearn will likely be a plastic cap and will feature process. an internal O-ring for better sealing. The CONDITIONS WHEREIN THE use of a steel or brass cap can also lead to SYSTEM MAY NOT FUNCTION radio wave signal interference.

RELEARN VS. PROGRAMMING Vehicle relearn and sensor programming are completely different procedures. Confusion is common due to the availability of aftermarket TPMS sensors that are offered as “programmable,” “universal” or “cloneable” sensor units. These sensors must be programmed with the proper protocol/application information for the vehicle before they can be installed on the wheel. An exception is VDO’s Redi-Sensor which does not require programming prior to installation (these sensors are already loaded with the programming needed to function with the vehicle’s system). Regardless of the brand of sensor, once programmed and installed, the sensors must then be relearned to the vehicle, even if only one sensor has been replaced. It’s not uncommon for shops to overlook the necessary relearn step, proceeding under the assumption that the sensor programming was all that was required. This misunderstanding can result in comebacks and customer complaints. Vehicle relearn is a standard and mandatory procedure whenever a sensor has

PROPERLY

1. Similar radio frequencies in the immediate area may interfere with the system. 2. A radio device of similar frequency is being used in the vehicle. 3. Excessive snow/ice on the vehicle (especially around wheels and wheel wells) may cause poor transmitter radio signal operation. 4. The tire pressure warning valve subassembly’s sensor battery may be depleted. 5. Wheels may be installed on the vehicle which do not feature a tire pressure monitor valve sub-assembly. 6. Use of studded snow tires or tire chains may disrupt radio signals. 7. If non-specifed wheels are used, the system may not function properly because the radio waves are transmitted at different angles from the pressure sensor. 8. Depending on the type of tire used, the system may not function properly even if the correct specifed wheels are used. NOTE: The average life of the grommet of the tire pressure monitor valve sub-assembly is about fve years, at which time the grommet should be replaced.

16 | March/April 2014

Circle 105 on Reader Service Card

TIRE MOUNTING

2. Press and release the brake pedal once. 3. Cycle the ignition button from OFF to RUN three times, ending in the RUN position (this is the same procedure that would be used if the vehicle is key-ignition equipped). 4. Press and release the brake pedal again, and press the ignition button to the OFF position. 5. Cycle the ignition button from OFF to RUN three times, again ending in the RUN position. When the vehicle horn honks, this indicates that the relearn procedure has been initiated. You are now ready to begin the relearning procedure. 6. Using a TPMS scan tool, trigger each sensor, starting with the LF wheel and working clockwise (LF, RF, RR, LR). If the vehicle is equipped with a spare tire, be sure to trigger that wheel’s sensor as well (after triggering the LR). The TPMS scan tool is held at the tire valve/sensor during triggering. 7. Once the relearn process is complete, the vehicle horn will honk to confrm.

NOTE: The tire should be completely removed from the wheel before installing any new sensor. When dealing with a sensor that is secured to the wheel with a mounting nut, BE SURE to tighten at the specifed torque value. Over-tightening can easily damage the stem. When mounting the tire onto the wheel, install the inner tire bead frst. Position the main body of the valve sensor approximately in the 7 o’clock position relative to the mounting machine’s bead pusher arm. If the valve sensor is positioned outside this area, it may create interference with the tire bead with resulting sensor damage. Install the upper bead, being careful not to damage the valve sensor (make sure that the valve sensor is not clamped by the bead). After the tire beads have been seated and the tire has been fully infated, recheck the valve nut and retighten to the vehicle manufacturer’s specifcation (this will likely be in the 35 in.-lbs. range. Valve stem damage can easily result from overtightening, so ALWAYS refer to the torque specifcations! Check for air leaks with a soapy water solution.

GM VEHICLES EQUIPPED WITH DRIVER INFORMATION CENTER

TPMS SENSOR RELEARN EXAMPLES

This includes Camaros and other models that feature an information display on the dash.

Following are a few examples of the steps required for TPMS relearn. If the replacement sensor(s) require programming, sensor programming must be performed prior to the relearn procedure. The following examples were provided courtesy of VDO for their Redi-Sensor.

FORD WITH PUSH-BUTTON IGNITION Ford vehicles that are equipped with a push-button ignition switch require a specifc sensor relearn procedure. Once the replacement sensor(s) has been installed and all four wheels/tires are mounted to the vehicle, infate all tires to the recommended pressure and follow these steps: 1. Ignition OFF.

1. Place the ignition in the ACC or ON position (do not start the engine). 2. Use the turn signal arm to display the infation pressures of all four tires. 3. Hit SET on the wiper arm to reset the TPMS. 4. A screen pops up displaying “Are you sure you want to relearn?” At this point, push the wiper arm inward to toggle to “YES.” At this time, the vehicle horn will honk twice to alert you to begin sensor triggering. 5. Using your TPMS scan tool, begin triggering the sensors, starting at the LF and working clockwise (LF, RF, RR, LR). Don’t forget to trigger the sensor in the spare tire if so equipped. You’ll hear a single horn honk as each sensor is successfully

18 | March/April 2014

triggered. You’ll hear a double-honk when the relearn procedure is fnished.

CHRYSLER, MAZDA AND SOME EUROPEAN VEHICLES This procedure applies to TPM systems that are otherwise auto-relearned once the vehicle is driven. If driving the vehicle is impractical at the time, a TPMS scan tool may be used to perform the relearn in the shop. 1. With wheels/tires installed to the vehicle and infation pressure adjusted to specifcation, trigger all sensors using an OBD II-compatible TPMS scan tool, starting with the LF and working clockwise (LF, RF, RR, LR). Trigger the spare (if so equipped) last. 2. Once all sensors have been triggered, place the ignition switch to the ACC or ON position (do not start the engine). 3. Connect the TPMS scan tool to the vehicle’s OBD II port in order to upload the sensor ID. The TPMS scan tool displays a confrmation once the process is complete, which may take several minutes. If your scan tool is not capable of performing this process, the vehicle must be driven in order to complete the relearn.

GM KEY FOB RELEARN NOTE: Not all GM vehicles are enabled from the factory with the key fob vehicle relearn initiation method. (For reference, see www.autoserviceprofessional.com for the chart on applicable vehicles that can use the key fob relearn method.) 1. Ignition ACC or ON (do not start the engine). 2. Press and hold the unlock and lock buttons on the key fob at the same time. When you hear two horn honks, this indicates that the vehicle has entered the relearn mode. 3. Using your TPMS scan tool, trigger each wheel sensor, starting with the LF and working clockwise (LF, RF, RR, LR). The turn signal lamps will illuminate as you go. As each sensor is triggered and the sensor ID is captured, you should hear a

single horn honk. Remember to trigger the spare. 4. When relearn is complete, you’ll hear two horn honks. A “Relearn successful” message may also be displayed on the driver information center.

Before installing a sensor, make sure that the wheel well is cleaned of dirt, debris or oils.

UNIVERSAL SENSORS The OEs, in their usual fashion, have created an incredibly vast proliferation of pressure sensors (there are no industry standards, so everybody apparently felt the need to devise their own proprietary sensors in terms of data transmission protocol, with an estimated 75 versions currently in OE use). As a result, it’s impossible (or least extremely impractical) for any shop to stock enough sensors to accommodate all makes/ models/years (you’d go broke just trying to stock these things in an attempt to achieve full coverage). The solution: universal tire pressure monitoring sensors. These universal sensors allow you to basically grab a new “blank” sensor and program it for the application. Currently there are three sources for universal sensors: Continental’s Redi-Sensor, Schrader’s E-Z Sensor and Myer Tire Supplies’ Sens-It. While none of these universal sensors will accommodate 100% coverage, we’re told that they will cover roughly 85% to 90% of the current market. The makers are continually trying to obtain protocol information from the automakers, so if certain application information hasn’t yet been made available to the aftermarket, it’s a waiting game for the sensor makers.

20 | March/April 2014

Circle 106 on Reader Service Card

CONTINENTAL VDO REDI-SENSOR This sensor is akin to a universal TV remote control unit, in that it’s designed to cover all (available) protocols in a “shotgun” approach. The sensor is already pre-programmed with all system protocols. It sends out all frequency protocols (multiple data commands in a continuous wave), allowing the vehicle’s ECU to grab the one that fts. These sensors are preprogrammed, and are not programmable (similar to a read-only CD that can’t be over-written). Basically, install and go.

Circle 107 on Reader Service Card

The up-side: The sensor is already programmed with multiple protocols, so no programming is needed. The down-side: You can’t update it with new programming in the future (if a newer/different protocol is required).

SCHRADER EZ-SENSOR This sensor was jointly developed by Schrader and Bartec (Bartec has long been involved in TPMS, making test/verifcation equipment for OE vehicle production, and now offers hand-held units for shops). The

22 | March/April 2014

Circle 108 on Reader Service Card

sensor is “blank” (like a blank CD), requirBy using the vehicle identifcation number, ing a Bartec TPMS tool for programming. you end up programming the new sensor The tool reads data from the original sensor with exactly the same data as the original (reading the sensor’s “fngerprint”). A new sensor that was installed during vehicle EZ-Sensor is then placed in the tool’s cradle. production. The tool then imprints the original sensor’s The up-side: The sensor is easily proinfo (it’s fngerprint) into the new univergrammed (and can be re-written up to about sal sensor, in effect, creating a replicate 15 times). The programming base plugs (clone). If you screw up into the PC via a during the imprinting USB cable. Protocol process, you can start data is continually over, since the EZ-Sensor updated on the site is “re-writable.” In order (hourly), so you get to implant the original the latest info at sensor’s info onto the the moment instead new blank sensor, the of waiting for an Bartec tool is required. annual update. Plus, However, down the road the programming during future service, and updates are any TPMS tool may free. be used if vehicle ECU The down-side: relearning is needed. Your shop must The up-side: The sensor Any of the major TPMS scan tools can be have a PC and is easily programmable access to the used for a relearning procedure. and can be re-proInternet in order grammed at whim. to program the sensor and to obtain the The down-side: This sensor is dedicated continually available free updates. Program(for programming) for use with only the ming only takes a few minutes. Bartec tool, and the tool must be updated DENSO SENSOR PROGRAM annually at a cost of about $300/year (in DENSO Products and Services Americas order to update the programming capaInc. has launched a TPMS sensor program bilities to meet ever-changing OE vehicle with 16 part numbers covering more than protocols). 100 popular passenger cars, sport-utilities, MYERS SENS-IT trucks and crossovers, or more than 25 milThis system’s sensor is blank. Programming lion vehicles on the road. is accomplished via the Internet by going to Additional DENSO TPMS sensor part numthe Sens-It website. A docking station pad bers will be announced later this year. connects to your PC via a USB cable. Simply Two DENSO TPMS sensor part numbers lay the blank sensor onto the pad, go to cover 73% of Toyota, Lexus and Scion vehithe website, and follow the simple prompts. cles, and an additional two part numbers Enter the vehicle’s VIN to obtain the correct cover 36% of Honda and Acura vehicles. protocol information, assign a wheel locaDENSO TPMS sensors maintain diagnostic tion (a simple drag and click deal on the capabilities, enabling quick and accusite’s illustration), and hit a button. The rate troubleshooting. Other benefts are a info uploads, and presto... the new sensor is 10-year battery and quick, direct-ft instalnow programmed for the vehicle. Here’s the lation, with no need for time-consuming really sweet aspect of using the VIN as the cloning or programming. DENSO says its OE reference — during a production run of the experience ensures that First Time Fit senvehicle, the OE may have changed the pres- sors provide performance, reliability and sure sensor model from one run to another. ft. ●

24 | March/April 2014

Circle 109 on Reader Service Card

R/R/R roundup R134a recover/recycle/recharge equipment By Bob Weber

T

he world of automotive service continues to change at an accelerated rate. That includes mobile air conditioning service challenges for service technicians. Currently, techs and shop owners must deal with electrically driven compressors found in hybrid and plug-in electric vehicles. That means recover/recycle/recharge (R/R/R) equipment must be up-to-date beyond compliance with Environmental Protection Agency (EPA) rules and the Society of Automotive Engineers standard J2788. Briefy, the purpose of the standard, which was revised in January 2013, as stated by SAE, “... is to establish the specifc minimum equipment performance requirements for recovery and recycling of HFC-134a that has been directly removed from, and is intended for reuse in, mobile air-conditioning (A/C) systems. It also is intended to establish requirements for equipment used to recharge HFC-134a to an accuracy level that meets Section 9 of this document and SAE J2099. The requirements apply to the following types of service equipment and their specifc applications. a. Recovery/Recycling Equipment, b. Recovery/Recycling-Refrigerant Charging, c. Refrigerant Recharging Equipment Only.” If you service hybrid or plug-in electric vehicles, make sure the equipment you use is certifed for these high-voltage systems. If you are looking for the latest R/R/R service equipment, we want to help. Following is a roundup of equipment to better help you make an informed decision. Here is the latest on SAE J2788-compliant equipment.

Robinair Cool-Tech 34988 The Cool-Tech 34988 from Bosch Automotive Service Solutions LLC’s Robinair

division combines simple operation with superior accuracy. It recovers, recycles, evacuates, leak tests, and recharges R134a quickly and accurately. A fully automatic function allows the technician to recover, vacuum and leak test, charge, and then walk away. Other features and functions include automatic refrigerant refll, automatic air purge and oil drain, refrigerant charging and refrigerant management According to the company, the model

Robinair’s Cool-Tech 34988 is highly effcient.

34788 is a UL-listed, single-pass system that meets SAE specifcations for recycled refrigerant. Follow the SAE-J2211 recommended service procedure for the containment of R134a. The unit includes a 1.5 cfm vacuum pump for fast, thorough evacuation. The compressor pulls the A/C system to 0 psig, then

26 | March/April 2014

works in series with the vacuum pump to achieve highly effcient recovery and immediate recharge. The company says it recovers 20% more refrigerant than other models, and has a charge accuracy of +/–0.5 ounce. There are two large tool storage areas and storage for an extra flter and compressor oils. The control panel fips down when not in use. Features include full automation to recovery, vacuum, leak test and charge without operating any panel valves; automatic UV dye inject into a vehicle’s system; and automatic oil measure and inject that determines how much lubrication oil is needed based on how much oil was taken out during recovery. It fushes a vehicle’s A/C system with refrigerant, eliminating a residual oil or other liquid. (Flushing adapters sold separately.) The save and print feature lets the user store before-and-after service information and print it for the customer. There is an indicator light and notifcation alarm when service is complete, or if a problem has occurred. Oil injection has less than 1% cross-contamination, and a vacuum leak test informs the tech of a possible leak. Automatic air purge eliminates damaging air without monitoring gauges or opening valves. An automatic refrigerant refll maintains a user-selectable amount of refrigerant in an internal tank and signals when it is time to change supply tank. For more information, go to the company’s website at www.robinair.com.

High voltage oil fush

Many automotive air conditioning systems contain PAG (polyalkylene glycol) oil, but high-voltage hybrid systems require POE (polyol ester) oil. Although it acts as a lubricant, more importantly, POE oil isolates the high voltage from the automobile’s chassis. When doing an oil fush on one of these systems, it is important to make sure there is no residual PAG oil in the service hoses and couplers. System damage or technician electrocution are possible. Circle 110 on Reader Service Card

28 | March/April 2014

Circle 111 on Reader Service Card

Matco Tools AC788 and AC789H Matco Tools’ AC788 and AC789H R/R/R machines are certifed for compliance with SAE J2788. Both models include a refrigerant database, auto air purge, auto vacuum leak test, auto oil discharge, oil injection low and full refrigerant alarm with a large graphic display and thermal printer. The 6 cfm vacuum pump allows technicians to quickly and effciently remove air and moisture from the A/C system with the dual flter design. Matco Tools’ AC788. For added protection against moisture and contaminants, the machines also include an auto flter alarm which warns the technician of the percentage of remaining flter life. For more information, see the company’s website at www.matcotools.com.

when the pressure of the fuid in the circuit reaches 290 psi (20 bar). The recovery operation is then automatically interrupted. A beeper and LCD advises when the bottle is flled to more than 80% of maximum capacity (40 pounds); when the quantity of refrigerant fuid contained in the bottle is low; whenever the total recovered refrigerant amounts to 132 pounds (60 kg); when there is insuffcient gas and when the charging quantity set exceeds the amount available. A code for resetting the service alarm is supplied with the spare flters. For more information, see the company’s website at www.fodynamics.com.

Flo-Dynamics CCST 388 The CCST 388 Clima/cs machine from Flo-Dynamics Inc. is design certifed for compliance with SAE J2788. It features fast, effcient refrigerant recovery and recycling and can transfer liquid refrigerant at the rate of one pound per minute. It can be operated in full automatic or assisted mode. The unit’s display provides menu-driven operation in multiple languages. A vehicle charging capacity reference database is included. Automatic air-purge and automatic oil purge are standard. The CCST 288 features integrated oil injection and heated power charging upon demand. Audible notifcation alerts the tech when the service is completed, when the flter needs changing and when the vacuum pump needs an oil change. It features a printout following each service stating the refrigerant recovered, oil recovered, oil charged, refrigerant charged and time for vacuum. Features include visual and audible alarm

The CCST 388 Clima/cs can be operated in full automatic or assisted mode.

RTI ActicPRO RHS 980H MAHLE Aftermarket Inc.’s RTI Division’s R134A Recovery, Recycling, Evacuation and Recharging station is a digital refrigerant handling system for hybrid and conventional vehicles. The model 980H is SAE J2799H certifed for high voltage compressor service. The unit can be used to service hybrid and non-hybrid powered vehicles. RTI’s RHS 980 series machines

30 | March/April 2014

consistently outperform competitive models with the fastest service times and best charge recovery accuracy because it has one of the highest useable refrigerant capacities available, states the company. The machine is designed for use on vehicles having R134a refrigerant and is compliant with the SAE J2788 standard. The unit reportedly recovers 95% of automobile refrigerant systems and has a refrigerant recharge accuracy of +/– 0.5 ounce. It features fully automatic operation. All control functions of the RHS980 are designed to provide intuitive and rapid interaction with the service technician. Features include full-automatic recovery cycle, system oil capture, vacuum, leak test, charging (includes automatic air purge); multilingual (English, Spanish and French) display; and a low-side combination flter which includes a full capacity alert. The unit comes standard with an integral printer; high-pressure leak detection function; and liquid refrigerant fush function; micron vacuum level sensors and ambient air humidity sensors. It also features technician and/ or service manager password protection On-board diagnostics check solenoids, transducers, compressor, vacuum pump, and calibration functions and internal date/ time clock. Options include a printer and refrigerant identifer. For more information go to the website www.rtitech.com.

Mastercool 69789-H Mastercool Inc.’s 69789-H features a large graphic display 4.3 inch x 2.4 inch and is design certifed for compliance with SAE J2788 and certifed for use on all hybrid and conventional R134a vehicles. The unit reportedly charges systems within 0.5 ounce and recovers 95% of the refrigerant. The 69789-H can be programmed to complete a continuous recovery/recycle, vacuum, vacuum leak test and recharge. The machine can also be set to run each operation individually. Features include information on refrigerant capacities for domestic and import vehicles from 1995 to present. The 69788-H is

31 | March/April 2014

Circle 112 on Reader Service Card

Mastercool’s 69789-H offers detailed reports.

Circle 113 on Reader Service Card

capable of software upgrades as well. It can be programmed to perform a vacuum leak test and will inform the technician of possible leaks. Oil is automatically discharged during the recovery process. If oil is present, it will drain into a graduated container clearly displaying the amount removed. Automatically purges non-condensable gas (NCG) from the storage tank during recovery. The machine’s LCD and alarm will warn that a flter change is required. It notifes the operator when the tank is full and when refrigerant is low. Automatic oil injection with electronic scale protects the contents against contact and ambient humidity. A thermal printer provides a complete, detailed report. Fully integrated real loop fushes service hoses only by refrigerant circulation. Flushing eliminates the risk that residues of different (non-insulating) oils may be injected into the A/C system. For more information, go to the company’s website at www.mastercool.com. ●

32 | March/April 2014

Circle 114 on Reader Service Card

Got gas?

Get ready for fuel delivery diagnostics By Craig Truglia Truglia is the owner of Car Clinic, a stateof-the-art repair facility in Mahopac, N.Y. He is ASE certifed with a M.A. from Columbia University. In the automotive world he has been trained by Technicians Service Training and Automotive Technician Training Services. Car Clinic’s facility is fully equipped with factory-level equipment and services American, European and Asian vehicles, including diesels and hybrids.

Tip Number One: Give up on current ramping, or don’t even start if you have heard about it. Back in the day, when 90% of vehicles were made by three American companies, there was not a lot of diversity in what fuel pumps these vehicles had. Not coincidentally, when the amperage of these pumps was ascertained using an amp clamp and a labscope, they produced neat looking waveforms, such as the one seen in Figure 1.

T

he present-day is an interesting time for the automotive technician. Perhaps now more than ever, the vehicles that are on the road resist breakdown, and with the help of a few repairs can routinely last about 200,000 miles. This is a far cry from the day when vehicles had carburetors or early versions of fuel injection. While it appears that fuel-saving technologies such as direct fuel injection and the increased use of turbocharg- Figure 1: This 1987 Pontiac Grand Am creates a nice and neat amperage waveform when running the fuel pump. ers may also break down quicker in the future, many of these vehicles are so new they have not Many technicians think that all fuel yet reached the point where they have pumps can be diagnosed this way. However, breakdown-related issues. if they actually tried the technique on vehiSo, the question service technicians need cles made after the year 2000, they would to ask themselves is whether or not they see that the fuel pump waveforms don’t are prepared to deal with a fuel-related no- lend themselves to such easy interpretation. start or misfre. Take a look at Figures 2 and 3. Does this Because the truth is, it has been about vehicle have a bad fuel pump? 20 years since OBD II technology hit the Many current ramping gurus would say market and aside from General Motors “most defnitely.” The problem is, the vehicles, it is not very common to run into actual answer is no! This fuel pump is fne one of these issues. and this is not even a new vehicle, it is a

34 | March/April 2014

Figure 2: A 1998 Chevy Malibu with a driveability problem. See waveform on next page.

1998 model year GM. Further, as one can see in Figure 4, the vehicle’s fuel trim is not highly positive, compensating for a bad fuel pump. It is well within normal range. Quite frankly, the fuel pump is fne. Further, to effectively current ramp fuel pumps the technician is required to undergo the impossible task of taking specs of every new car he fnds. And it is not always easy to access fuel pump relays. Rents and taxes are too high and labor is too expensive to waste time doing this, especially when, quite frankly, it does not work anyway. Tip Number Two: Checking fuel volume is the only way to test for a bad fuel pump or restricted fuel flter. Many technicians have a fuel pressure gauge and the vehicle usually has a fuel pressure sensor on the rail. Both the gauge and the scan tool can help us test for fuelpump drain back and an underperforming pump, so they can be quite useful. However, it should be known that just because a vehicle has low fuel pressure, it does not mean that the fuel pump is bad. For example, a vehicle with a bad fuel flter may have barely any fuel pressure, especially if it is causing such a restriction that the vehicle will not start. Yet, the fuel pump can still be good.

Circle 115 on Reader Service Card

Figure 3: A fuel pump waveform on a 1998 Chevy Malibu.

Figure 4: Shown here is fuel trim on the same 1998 Chevy Malibu at +3%. Essentially, anything below 8% to 10%, positive or negative, indicates a normal running vehicle and does not warrant further investigation regarding there being a fuel metering-related issue.

38 | March/April 2014

Circle 116 on Reader Service Card

Figure 5: Before replacing the fuel flter on this 2004 Ford Taurus 3.0L, the observed fuel pressure on the vehicle was acceptable. However, the engine did not have enough fuel volume to start, let alone run.

So, if the shop can spring for the bucks, a fuel volume gauge is the way to go. It is simply placed in line, preferably before the fuel flter, and it tells us both fuel pressure and fuel volume in gallons-per-minute. Better yet, there is no need to memorize fancy specifcations. Every single vehicle that’s a four cylinder will fow at least 0.4 gallons per minute (gpm) and any other vehicle with a turbo or larger engine will fow at least 0.5 gpm. To be honest, do not be surprised to see even a known-good Honda four cylinder fowing at least 0.6 gpm. If a fuel pump is good, it will generally fow even above these numbers, but when it is bad it will fow below these numbers. Just remember, if you fow after the fuel Circle 117 on Reader Service Card

40 | March/April 2014

Circle 118 on Reader Service Card

flter (even though most flters are in the tank anyway these days), a bad fuel flter can cut both your pressure and volume. How can you measure fuel volume without the gauge? If you can command on the fuel pump by jumping the connectors where the relay goes and disconnect the fuel line, you can take an empty windshield washer fuid bottle and see how much fuel you get in a minute. If about half of that bottle gets flled up, your fuel pump is fne.

Figure 6: Even BMW endorses this technique, as can be seen in the repair information available to us from Mitchell 1’s ProDemand software. The Germans give us the specifcation “one liter every 30 seconds” in order to confuse technicians across the ocean. Being that a gallon is 3.89 liters, the technician can surmise that every minute there is about half a gallon of fuel fow on a known-good BMW.

However, sometimes this is too messy and inaccurate. There is one other way to get the job done without purchasing a fuel volume gauge. If you are performing fuel system cleanings in your shop, chances are you have a tool that connects to the fuel rail in order to fush the injectors out with a cleaning solvent. If this is the case, you can test fuel volume indirectly. Circle 119 on Reader Service Card

42 | March/April 2014

Circle 120 on Reader Service Card

Figure 7: This is an example of how to hook up even a new vehicle for indirect fuel volume testing. Pictured here is a 2009 VW Jetta 2.0 Wolfsburg Edition.

Simply connect the tool to the fuel rail and fll it up with gasoline instead of solvent. Then, put the tool at about 40 psi

(which may be risky so be sure to wear glasses or a face shield) and start up the engine. If the engine runs normally, then what you have essentially done is proved that there was a fuel volume issue. Why? Because if the vehicle runs normally hooked up in this fashion when it did not before, the only thing that changed was the volume of fuel that reached the fuel rail. So, the problem has to be something fuel volume related farther down the fuel system, likely the pump or flter. John Thompson of Thompson Automotive Labs has been known to Figure 8: A leaking fuel tank on a Honda Civic. Not liking the say, “Use a new fuel flter price of a new fuel tank, the owner went to a junkyard and got his second cousin to install it for him. as a $10 tool.� If it fxes

44 | March/April 2014

Circle 121 on Reader Service Card

the problem, then you saved a lot of diagnostic time. If it doesn’t, a nice and proftable fuel pump job is in order. Tip Number Three: Be on the lookout for obvious stuff. Here, on this 1998 Honda Civic, the customer had a bad fuel tank (see Figure 8). He put a junkyard fuel tank on and, not surprisingly, a few months later, the engine starts running funny. Figure 9: Here is an example of a rusted-up fuel sock, thanks After testing at a fuel to the junkyard fuel tank used on this Honda. See also how volume of 0.15 gpm the caked-on the rust was on the fuel pump sock. technician ascertained the junkyard tank must have had rust in it and even if you are a little “rusty” with fuelclogged the pump. Lo and behold, it did! delivery problems, they will help make what (See Figure 9). can be a much more complicated diagnosis Just remember these three tips, because into a simpler one! ●

Circle 122 on Reader Service Card

The M7 1/2-inch-drive air wrench from King Tony of America features a head that’s a mere 4-3/8 inches long. The comfy cushioned grip provides a nice tactile feel, and the grip length and angle provides an ideal balance point. The gun doesn’t feel top heavy at all.

Compact gun A pneumatic air wrench for cramped spaces By Mike Mavrigian

W

hat appealed to me about the M7 (Mighty-Seven) 1/2-inch-drive air wrench from King Tony of America is its ultra-stubby size. It’s the cutest, shortest 1/2-inch-drive air wrench that I’ve had the pleasure to try. The M7 offers a beefy, solid feel and is well built. I put this pro-level gun through

its paces over a week’s worth of repair and restoration work, and I’m impressed. While the size and balanced feel is what frst drew me to this gun, I did my best to beat it up and it never whimpered. It feels like a tool that will last. I measured the wrench at 3-5/8 inches in length, from the back plate to the front nose housing. Overall length from the rear plate to the tip of the anvil measured at

48 | March/April 2014

Circle 124 on Reader Service Card

The forward/reverse switch is easy to access without digging and hunting around with your thumb, with positive detents. Breakaway torque in reverse is a hefty 500 ft.-lbs.

4-3/8 inches. Overall height (not including the air nipple) measured 7 inches. Thickness at the front of the housing measured 2.360 inches, tapering at a rear thickness of 2.185 inches. As far as I know, this has to be the shortest 1/2-inch-drive pneumatic wrench on the market, obviously designed to accommodate tight spaces. The tactile rubber-coated grip area features fnger grooves, with the fnger height area of about 2.760 inches, which provides an ideal fnger grip area for an average-size hand (full grip space with no pinky fnger overhang). If I were forced to come up with a complaint (considering how much I like this little bugger, pointing out anything negative was diffcult), it would involve the trigger. While the plastic material seems tough enough for heavy-duty use, the very top of the trigger is open/hollow. In an ultra dirty environment I can see the Circle 125 on Reader Service Card

50 | March/April 2014

Circle 126 on Reader Service Card

You’ll fnd the M7 1/2-inch-drive air wrench comes in handy for tight access use.

The nose is short and rounded to minimize obstruction and maximize utility.

possibility for debris to enter and possibly restrict movement. However, I’m not overly concerned, since the top of the trigger is shielded by the head. As long as you don’t immerse the gun into a bucket of sand, I don’t see this as something to worry about. The M7 quickly earned a special place in my heart. For me, it’s one of those “must have” tools for dealing with cramped work areas. While I have 3/8-inch-drive guns of similar size, having something this tiny with a 1/2-inch-drive capability and plenty of gutsy reverse torque is a real blessing. Every time I picked it up, I couldn’t help smiling. It’s just so darned cool. By the way, since the M7 specifcally addresses the subject of space-savings, the maker also offers sets of “stubby” socket wrenches in both fractional and metric formats. The sockets measure a scanty 1-7/64

52 | March/April 2014

Circle 127 on Reader Service Card

You don’t need to buy the stubby sockets, but they certainly come in handy to minimize the working package. The six-sided hex sizes range from 1/2-inch to 7/8-inch.

inches tall, regardless of the hex size. When coupled with the M7, this makes for a super-short working package to address those annoying tight spaces where nothing else wants to ft. The wrench package supplied to us for this review included six-sided hex sizes of 1/2-inch, 9/16-inch, 5/8-inch, 11/16-inch, 3/4-inch and 7/8-inch. M7 AIR IMPACT WRENCH MODEL NC-4611Q

The space-saving “stubby” sockets at a mere 1 7/64-inch in length offer a nice complement to the M7 pneumatic air wrench.

Max. operating air pressure Square drive Bolt capacity (shank dia.) Torque range Max torque

90 psi 1/2-inch 5/8-inch (16 mm) 200-350 ft.-lbs. 500 ft.-lbs.

(delivers 500 ft.-lbs. of reverse torque in only fve seconds) Free speed Avg. air consumption Overall length Net weight Air hose Sound level

10,000 rpm 4.0 cfm 4 3/8-inches 3.3 lbs. 3/8-inch 85.0 dba

TEST TOOL SOURCE: We tried out the wrench during the replacement of a right rear wheel bearing on a Pontiac Torrent, which has miserable access to the inboard mounting bolts. The M7 wrench was the only pneumatic gun we had in the shop that would ft into the tight space.

KING TONY OF AMERICA 2432 Peck Rd. City of Industry, CA 90601 (877) 708-6657 www.kingtonyamerica.com ●

54 | March/April 2014

Circle 128 on Reader Service Card

Cadillac COOLANT TANK LEAK Some 2012 Cadillac Escalade, Chevy Avalanche/Silverado/Suburban/Tahoe, GMC Sierra/Yukon/Denali vehicles may experience a coolant leak. The cause may be traced to an ill-ftting coolant overfow tank nipple. The leak is caused by excess plastic at the parting seam on the tank nipple, preventing proper hose sealing. The repair involves sanding the plastic seam on the nipple to create a more uniform sealing surface for the hose. Do not replace

the overfow tank, since sanding the seam will fx the problem; and the replacement tank might have the same excess plastic on the nipple.

General Motors TICKING HEAD

This concern applies to a variety of GM vehicles equipped with the 2.0L LSJ, 2.0L LNF, 2.2L L61, 2.2L LAP, 2,2L LE8, 2.4L LE5, 2.4L LE9, 2.4L LAT and 2.4L LAF engine (vehicles include Buick Regal and LaCrosse, Chevy Cavalier/Cobalt/Equinox/HRR/Malibu, GMC Terrain, Olds Alero, Pontiac G5/G6/Grand Am/Sunfre/Pursuit/Solstice, Saturn Aura/ Ion/L Series/Vue). A ticking noise at the cylinder head may be heard, which may be traced to a loss of oil pressure. The concern may be caused by debris clogging the oil feed restrictor in the cylinder head passage. The oil feed hole has a small inner diameter and may clog if debris or excessive RTV/sealer has dislodged and has become stuck in this passage. WhenLook for traces of coolant leak at the hose-to- ever RTV (or other gasket sealer) is used, care must be taken coolant overfow tank nipple. to avoid excessive amounts that can become dislodged. This restrictor is located in the oil feed passage to the cylinder head and cannot be inspected or cleaned without removal of the The oil restrictor (2) can eascylinder head. NOTE: ily become plugged with Notice the raised rib at the mold seam on the debris. Removing one of the overfow tank nipple. This excess plastic may Per typical GM policy, the restrictor is oil galley plugs (1) allows oil be enough to prevent proper hose seal. not available sepa- pressure gauge testing. rately from the cylinder head. To diagnose this concern, use a mechanical oil pressure gauge. Check and compare oil pressure in the block with oil pressure in the cylinder head. The block can be checked by removing the oil pressure sender. The oil pressure in the cylinder head can be checked by removing one of the oil galley plugs in the head. If no oil pressure is evident in the cylinder head, the head must be removed and Don’t disturb the barb at the tip of the nipple, but use sandpaper to reduce and smooth out thoroughly cleaned. Inspect the valvetrain for wear/damage and repair as necessary. the excess plastic found at the seam.

56 | March/April 2014

Circle 129 on Reader Service Card

BASIC BRAKE SYSTEM On-vehicle service

Attachment 1.

14-inch rear disc brake

Vehicle outside

Right side

Old

Left side

Deleted

New

3

1

2

3 New

Old Wear indicator 2

1

3

16-inch rear disc brake Vehicle outside

Vehicle outside

Deleted

3 Right side

Left side 3

3

2

1

1

Wear indicator 2

3 3

2. Remove the following parts from the caliper body. (1) Shim (2) Brake pad assembly (3) Clip

Vehicle outside

NOTE: • The brake pad assembly with wear indicator is installed only to the inner side of the brake disc of the left-side brake at the factory. • As for the accessary pad set, the brake pad with wear indicator has been installed to the inner side of the brake disc on both right side and left side brakes.

Mitsubishi’s revised rear disc brake service now requires only one shim at the outer pad only.

Mitsubishi FEWER BRAKE PAD SHIMS Mitsubishi notes that they’ve changed the rear disc brake pad shim requirement for the 2008-2009 Lancer. The number of rear brake pad shims (per wheel location) has been reduced from four to one. A single shim is now installed at the outer pad only. The inner pad now uses no shims. The bulletin also applies to earlier models where the shims are replaced with new parts.

Jeep JEEP REAR END Replacing the rear axle ring and pinion on the 8-1/4 inch axle with a 3.21 gear ratio has specifc and unique service procedures. This applies to 2007-2008 Nitro and 2008 Liberty vehicles. Follow procedures available in

DealerCONNECT > TechCONNECT under Service > 3 – Differential & Driveline > rear Axle – 81/4 > Gear-Pinion/Ring > Removal and Installation > Gear-Pinion/Ring: a. Removal of the ring gear from the differential requires pressing the ring gear off of the differential with Plug 8926-2 and Remover 10126-1. b. Installation of the ring gear onto the differential requires the use of a bearing heater and left hand threaded Pins 10126-2. These service special tools are required for the 8-1/4 inch ring gear in addition to standard rear axle service special tools: Plug Remover Pins

58 | March/April 2014

8926-2 10126-1 10126-2 ●

Circle 130 on Reader Service Card

Instant information from ASP advertisers You’re mere seconds away from receiving product information at your fngertips. free product information. Just go to the Of course, you can always use the Reader website(s) listed to the right of each Service Card to the right and send it to us, advertiser below and you’re there! Instant and we’ll connect you to the advertiser. Advertiser

Page

31 Incorporated

46

ACDelco

7

R.S # 122

Quik-Link www.aspquiklink.com/12122

ADVICS North America Inc.

43

120

www.aspquiklink.com/12120

Aftermarket Auto Parts Alliance Inc.

17

105

www.aspquiklink.com/12105

Aftermarket Auto Parts Alliance Inc.

55

128

www.aspquiklink.com/12128

Airtex Products LP

23

108

www.aspquiklink.com/12108

ANCO

29

111

www.aspquiklink.com/12111

ANSED Diagnostic Solutions

28

110

www.aspquiklink.com/12110

AutoPride

53

127

www.aspquiklink.com/12127

CARQUEST Auto Parts

OBC

132

www.aspquiklink.com/12132

Champion Spark Plug

57

129

www.aspquiklink.com/12129

DENSO Products and Services Americas Inc.

27

Drew Technologies

41

118

www.aspquiklink.com/12118

Eastern Manufacturing Inc.

40

117

www.aspquiklink.com/12117

Federated Auto Parts

5

102

www.aspquiklink.com/12102

Fel-Pro

9

103

www.aspquiklink.com/12103

Ford Parts

19

GMB North America Inc.

32

113

www.aspquiklink.com/12113

Homak Manufacturing

21

106

www.aspquiklink.com/12106

IMC Parts

IFC-3

101

www.aspquiklink.com/12101

Intermotor

45

121

www.aspquiklink.com/12121

Mahle Aftermarket Inc., RTI Division

51

126

www.aspquiklink.com/12126

Monroe Shocks & Struts

50

125

www.aspquiklink.com/12125

MOOG Steering & Suspension

47

Nissan North America Inc.

49

124

www.aspquiklink.com/12124

O’Reilly Auto Parts

33

114

www.aspquiklink.com/12114

Philips Automotive Lighting

42

119

www.aspquiklink.com/12119

Robinair

15

104

www.aspquiklink.com/12104

SKF USA Inc.

IBC

131

www.aspquiklink.com/12131

Toyota Motor Sales U.S.A. Inc.

35-37

115

www.aspquiklink.com/12115

Tracer Products

22

107

www.aspquiklink.com/12107

TRICO Products

39

116

www.aspquiklink.com/12116

VDO OE Replacement Parts

25

109

www.aspquiklink.com/12109

Wagner ThermoQuiet

69

130

www.aspquiklink.com/12130

Walker Emissions Control

31

112

www.aspquiklink.com/12112

60 | March/April 2014

ACDelco adds Professional remanufactured alternators, starters ACDelco has released an additional 143 Professional remanufactured alternator and starter part numbers covering 1992-2012 models from GM, Toyota, Chrysler, Ford, Honda, Nissan and other manufacturers. The expansion consists of 64 additional Professional remanufactured alternators and 79 Professional remanufactured starters. In total, the ACDelco Professional remanufactured alternator and starter line now features more than 2,500 SKUs, providing a competitively priced aftermarket service solution for most makes and models.

ACDELCO

ANSED video scope ANSED Diagnostic Solutions is offering a full-featured video scope packaged with the company’s Hyperion technology 5.5 mm x 1 m probe. The scope has three unique modes to enhance viewing capability: the light boost improves image clarity; mirroring and image rotation allows the image to be viewed in proper orientation; and particle-free and anti-refection reduces image glare and impurities for improved image quality. The tool features a shock-resistant 3.5 inch screen. Screen images can be recorded in inspection, snapshot and video modes. Date and time is displayed and transferred to picture and video recordings. A 3x and 5x digital zoom allows for close-up inspections.

ANSED DIAGNOSTIC SOLUTIONS Circle 150 on Reader Service Card www.aspquiklink.com/12150

ATP cable coverage ATP is a one-stop source for all types of automotive cables, including hard-to-fnd applications. ATP offers a full line of speedometer cables and speedometer cable core kits. Also

available are cables for the accelerator, clutch release, detent, transhift, manual shift and tailgate applications. Universal detent and choke/throttle cables are also supplied by ATP.

ATP INC. Circle 151 on Reader Service Card www.aspquiklink.com/12151

TPMS application and parts guide Standard Motor Products has released its printed TPMS Application and Illustrated Parts Guide. This comprehensive catalog includes many new items as well as updates to existing product coverage for both the Standard and Intermotor OE-matching, clone-able TPMS sensor lines. Catalog highlights include: numerical index for TPMS sensors, service kits and sensors grouped together by vehicle application, additional details on valve stem applications for Audi, BMW and Mercedes, expanded frequency applications for Toyota and new sensor illustrations with enhanced features and service kit applications.

STANDARD MOTOR PRODUCTS INC. Circle 152 on Reader Service Card www.aspquiklink.com/12152

AutoTex Windshield Wipers catalog The 2014 AutoTex Windshield Wipers catalog contains comprehensive information and images on the company’s three aftermarket lines, AutoTex Automotive, AutoTex Pink and AutoTex Heavy Duty. Each line has its own section with application information, cross reference data and industry-specifc insight.

AUTOTEX WINDSHIELD WIPERS Circle 153 on Reader Service Card www.aspquiklink.com/12153

63 | March/April 2014

Bosch expands QuietCast brake rotor line The Bosch Group has expanded its line of premium QuietCast brake rotors. QuietCast brake rotors are manufactured using a heat fow casting process that produces high carbon, vehicle-specifc castings to ensure a smooth ride and quiet braking. Bosch QuietCast brake rotors feature 100% factory mill balancing with lowest run-out for safe, smooth operation. An OEM-style vane confguration provides effcient heat dissipation, reduces vibration that can cause noise, and extends the life of the rotor.

THE BOSCH GROUP Circle 154 on Reader Service Card www.aspquiklink.com/12154

Bartec software update Bartec USA’s tool update 51 includes the ability to program Alligator sens.it sensors, Huf IntelliSens sensors, and integrated programming of Cubelec sensors using the Tech500 tool. Alligator sens.it consists of three blank sensors that cover up to 95% of TPMS vehicles to provide maximum coverage with minimum inventory. The Huf IntelliSens sensors software update adds IntelliSens confgurable sensors to the Bartec Tech500 and Tech400SD TPMS tools. The software update enables both tools to program the IntelliSens sensor using Bartec’s make, model, year look-up system.

BARTEC USA LLC Circle 155 on Reader Service Card www.aspquiklink.com/12155

Blackburn features WheelFinder

is linked with www.blackburnswheelfnder.com, a site that features a Wheel Finder function that goes back 50+ years.

BLACKBURN’S HUBCAP & WHEEL INC. Circle 156 on Reader Service Card www.aspquiklink.com/12156

Cardone expands coverage A1 Cardone remanufactured master cylinders have a total of 2,164 SKUs with coverage of over 217 million vehicles. Cardone Select All New Master Cylinders have a total of 1,097 SKUs which cover 97% of reman sales with coverage of over 187 million vehicles including popular Chevy trucks and Toyota Camry/Avalon. Cardone Service Plus Master Cylinder Reservoirs have 136 total SKUs which cover 57% of reman sales that require a plastic reservoir. Coverage includes over 87 million vehicles including popular GM trucks.

CARDONE INDUSTRIES INC. Circle 157 on Reader Service Card www.aspquiklink.com/12157

Centric Parts releases brake catalog Centric Parts has released its 2014 mediumduty brake systems catalog which details brake, clutch hydraulic, wheel bearing, hub and seal components for medium-duty truck applications through 2014. Brake system components listed include brake pads and shoes; rotors and drums; hydraulic cylinders; remanufactured loaded and semi-loaded calipers; caliper kits, wheel cylinder kits and hardware kits; and adjusters, brake hoses, hubs, bearings and seals.

Blackburn’s Hubcap & Wheel Inc.’s corporate website at www.blackburnwheels.com features descriptions of the company’s products including OEM alloy and steel wheels, late-model hubcaps, TPMS components, center caps/trim rings and antique/classic caps. The site also describes CENTRIC PARTS Blackburn’s alloy wheel refnishing services, as Circle 158 on Reader Service Card well as bumper and parts rechroming. The site www.aspquiklink.com/12158

64 | March/April 2014

CP7732 impact wrench Chicago Pneumatic’s 4.4inch CP7732 Stubby 1/2inch impact wrench is an ultra-compact, powerful impact wrench designed for diffcult work in confned spaces. It provides 450 ft.-lbs. of torque and weighs only 2.9 lbs., and can easily remove or tighten fasteners in the most diffcult to reach spots. The single-handed trigger offers three power settings in both forward and reverse. The tool features the Jumbo Hammer impact mechanism that provides both power and durability at 9,000 rpm.

CHICAGO PNEUMATIC TOOL CO. Circle 159 on Reader Service Card www.aspquiklink.com/12159

Elgin PRO-STOCK push rods The Elgin PRO-STOCK line of one-piece thickwall performance push rods now includes onepiece 5/16-in.-diameter push rods featuring 0.110-in. wall thickness and 3/8-in.-diameter rods with 0.137-in. wall thickness. Available lengths range from 7.900 in. to 9.400 in. for 3/8-in. push rods and 6.250 in. to 8.800 in. for 5/16-in. push rods. The push rods are manufactured from seamless, aircraftquality chrome-moly material, then throughhardened and black oxide coated for strength and durability.

ELGIN INDUSTRIES Circle 160 on Reader Service Card www.aspquiklink.com/12160

EnerSys introduces Group 65 battery E n e r S y s E n e rg y Products Inc. has expanded its ODYSSEY Performance Series battery product offering to include the Group 65 battery. The ODYSSEY Performance Series 65-760 battery features 762 cold cranking amps, 129 reserve

capacity minutes and deep cycle capability up to 400 cycles at 80% depth of discharge. Engineered with Thin Plate Pure Lead technology, the batteries feature rugged construction, high reliability and deep cycling capabilities.

ENERSYS ENERGY PRODUCTS INC. Circle 161 on Reader Service Card www.aspquiklink.com/12161

Moog steering and suspension line Federal-Mogul has added dozens of part numbers to its Moog steering and suspension brand. The latest expansion includes 14 new Moog R-Series control arm assemblies, six ball joints, four link kits and a variety of other components. Six of the new Moog parts are the first available in the aftermarket for their respective applications. They are: sway bar bushing for the Land Rover Range Rover Sport; lower front ball joints for 1998-2000 Lexus LS400; lower front ball joint for the 1999-2001 Honda Prelude; and lower front ball joints for the 2008-2013 Audi TT Quattro; 2008-2009 TT. The expanded Moog line of complete strut assemblies now includes four new units covering 2003-2005 Honda Civic and 2000-2006 Toyota Tundra models.

FEDERAL-MOGUL CORP. Circle 162 on Reader Service Card www.aspquiklink.com/12162

Wagner sealed beam headlamps Federal-Mogul’s Wagner Lighting brand has introduced long-lasting, maintenance-free LED sealed beam replacement headlamps for commercial applications and some passenger vehicles. The new LED lamps dramatically improve driving visibility in a full range of operating conditions. The new lamps’ bulb-free LED design eliminates damage caused by road shock and vibration while projecting a brighter, whiter and crisper light that extends the driver’s feld of vision.

FEDERAL-MOGUL CORP. Circle 163 on Reader Service Card www.aspquiklink.com/12163

65 | March/April 2014

Heavy-duty coolant tubing The Gates Corp. has added five heavy-duty coolant tubes that help to minimize the effects of corrosion. This product features Gates proprietary Tuffcoat plating for better rust resistance on straight tubes. Stateof-the-art bending and forming technology and thicker wall tubing withstand the rigors of installation and harsh over-the-road conditions.

differential pressure sensors; engine position sensors; crankshaft sensors; camshaft sensors; throttle sensors; knock sensors; air management sensors; mass air fow sensors; manifold intake pressure sensors; and temperature sensors.

ROBERT BOSCH LLC Circle 166 on Reader Service Card www.aspquiklink.com/12166

Guardair Gun Vac extension

THE GATES CORP. Circle 164 on Reader Service Card www.aspquiklink.com/12164

General Tools product catalog General Tools & Instruments’ 2014 full-line tools and instruments catalog features more than 1,300 items in categories such as specialty tools, video inspection and electrical. The two sections of the catalog — one for tools and the other for instruments — are organized by product category and formatted for easy product look-up. The catalog also introduces several new products such as the expansion of General’s line of electrical instruments and video inspection systems. The electrical line includes new clamp meters, multimeters, electrical testers and multi-component kits.

Guardair Corp.’s pneumatic hand-held Gun Vac features a new tapered 18-inch fexible metal extension that accommodates standard 1 1/4-inch vacuum accessories and attachments. The fexible metal extension makes cleaning easy in hard-to-reach areas by capturing debris versus blowing it around. Powered by compressed air, the lightweight Flexible Gun Vac has no electric motor to burn out. The high fltration collection bag makes it ideal for cleaning metal chips, dirt, dust and fner materials.

GUARDAIR CORP. Circle 167 on Reader Service Card www.aspquiklink.com/12167

Innova QUICKLINK virtual dashboard

Innova Electronics says the award-winning QUICKLINK device pairs with a smart device for immediate access to a virtual dashboard of information that can help keep vehicle owners GENERAL TOOLS & INSTRUMENTS safe, save time and money, and provide peace Circle 165 on Reader Service Card of mind. It can be used to solve check engine www.aspquiklink.com/12165 problems, check for road trip readiness, doublecheck automotive repair Bosch engine shop estimates, improve sensors fuel economy and more. The Bosch line of It is compatible with engine manage1996 and newer import ment sensors inand domestic cars, light cludes 370 part trucks, minivans, SUVs numbers covering 89.4 million vehicles in operation in the U.S. and hybrids. QUICKLINK Featuring high accuracy in measurement with fast users also have easy acresponse times, these sensors are all exactly the cess to RepairSolutions online free basic reports. same as those manufactured for OEMs. The line INNOVA ELECTRONICS CORP. includes: pressure sensors; low pressure sensors Circle 168 on Reader Service Card (oil, fuel, coolant); high pressure sensors (fuel); www.aspquiklink.com/12168

66 | March/April 2014

the ducts and reduced the connectors, reducing the size to half compared to previous models. DENSO’s new unit needs only one motor and one sensor.

DENSO PRODUCTS AND SERVICES AMERICAS INC. Circle 171 on Reader Service Card www.aspquiklink.com/12171

IPA trailer lights and brake tester Innovative Products of America Inc. has expanded its line of trailer testers with the #9102 Heavy Ranger MUTT, a portable and lightweight solution for testing lights and electric brakes. The trailer tester is compatible with seven-way round pin connection types and is designed to simulate all electrical circuits while providing short protection on industry standard pin confgurations.

INNOVATIVE PRODUCTS OF AMERICA INC. Circle 169 on Reader Service Card www.aspquiklink.com/12169

Kaeser variable speed drive screw compressors Kaeser Compressors says its SFC 30S and SFC 30 variable speed drive rotary screw compressors deliver “built-for-a-lifetime” reliability including simple maintenance and sustainable energy savings. The SFC 30S has a fow range of 37-171 cfm at 125 psig and is available with pressures up to 190 psig. The SFC 30 has a fow range of 47-202 cfm at 125 psig, with pressures up to 217 psig.

KAESER COMPRESSORS INC. Circle 170 on Reader Service Card www.aspquiklink.com/12170

DENSO develops EGR valve unit DENSO has developed an exhaust gas recirculation (EGR) valve unit which integrates an air intake throttle valve and an EGR valve, is half the size of conventional models and requires fewer components, thus reducing costs. By integrating the two valves into one unit, DENSO combined

KYB expands MonoMax line KYB Americas Corp. has expanded the coverage of its truck and SUV MonoMax shock absorber lineup. New part numbers for this release cover nearly 12 million pickup trucks and SUVs on the road today, including the most popular late-model Ford, General Motors and Dodge applications. KYB’s MonoMax shock absorbers are large bore monotube shock absorbers built to handle the demands of working trucks, vans and SUVs. The MonoMax line also has been popular among the off-road vehicles market.

KYB AMERICAS CORP. Circle 172 on Reader Service Card www.aspquiklink.com/12172

Lisle expands its Davco line of diesel flter wrenches Lisle’s line of Davco wrenches are designed for removing and replacing the main flter collar and vent cap on aftermarket diesel fuel flter systems. The 5-, 6- and 8-inch wrenches feature a halfmoon design for easy access to the fuel flter. High strength steel prevents the wrench from flexing while loosening stubborn flter collars. Four teeth grab the vent cap securely to prevent damage. A thick padded grip cushions the technician’s hand.

LISLE CORP. Circle 173 on Reader Service Card www.aspquiklink.com/12173

67 | March/April 2014

Bosch pin-to-pin spark plugs The Bosch Group has added “pin-to-pin” spark plugs to its OE Fine Wire Iridium line designed to provide better ignitability, especially in today’s high-tech engines. The new Bosch pin-to-pin spark plugs have a fne-wire tipped center electrode and a fne-wire pin on the ground electrode — the pin-to-pin design allows for better ignitability in engines optimized for this design, and requires less fring voltage. These highperformance spark plugs are tailored to match the OE design spark plugs of specifc Asian vehicles such as Hyundai and Infniti.

THE BOSCH GROUP Circle 174 on Reader Service Card www.aspquiklink.com/12174

Matco Tools offers R/R/R machines Matco Tools has introduced its AC788 and AC789H R/R/R machines which are certifed for compliance with SAE J2788 for the recovering, recycling and recharging of 134a. Both models include a refrigerant database, auto air purge, auto vacuum leak test, auto oil discharge, oil injection low and full refrigerant alarm with large graphic display and thermal printer. The 6 cfm vacuum pump allows technicians to quickly and effciently remove air and moisture from the A/C system with the dual flter design.

and lower spring isolators, upper spring seat, coil spring, boot kit and a premium strut engineered to address the vehicle’s unique ride and handling characteristics. The Quick-Strut assembly design reduces installation time by eliminating the need to disassemble components and compress the coil spring and helps to eliminate ride control comebacks commonly caused by failure to replace worn parts.

TENNECO INC. Circle 176 on Reader Service Card www.aspquiklink.com/12176

Philips lighting application catalog Philips Automotive North America, a division of Royal Philips, offers its latest Automotive Lighting Application Catalog for replacement and upgrade bulbs as well as automotive accessories. The catalog covers applications for all types of domestic and import cars, SUVs, light trucks, and vans from model years 1999 to 2013. The Philips Classic Catalog offers coverage from 1969-1998.

PHILIPS AUTOMOTIVE NORTH AMERICA Circle 177 on Reader Service Card www.aspquiklink.com/12177

Rotary Lift Mach series