11 minute read

Beacons On

BeacoNs oN! AR’s New CEO Knows Real-Time Towing

By Steve Calitri

Steve Calitri

Editor-in-Chief scalitri@towman.com

Note: Editor-in-Chief Steve Calitri interviewed Jerry Carnahan by phone in April for this article. Jerry Carnahan’s background and experience was tailor made for the job he’s taken on as the new CEO of AutoReturn (AR), known by towers as a national dispatcher of police tows; as Carnahan details it, “the nation’s leading provider of a full-service, lawenforcement, towing management solution for municipalities.” AR’s tow-management system combines leading edge technology with 24/7 support to keep law enforcement, dispatchers, towing companies, and citizens connected from dispatch to impound. This system, says Carnahan, has proven to reduce crash-scene, tow-truck response times by two-thirds to an average of twelve minutes.

Carnahan grew up in the towing business, operating trucks for his father in Great Falls, Montana. Jerry’s “little brother,” Mel, runs Carnahan’s Towing today and “Dad still operates a truck and goes on calls at age eighty-seven,” said Carnahan, knowing full well how towing can get into one’s blood.

Carnahan’s resume covers law enforcement, towing, incident management, and risk management. He was a Secret Service agent at age twentyone on President Jimmy Carter’s detail. When he left the Secret Service, Carnahan became an adjustor for Farmers Insurance and led its towing program. Later, he was a deputy sheriff in Weber County Utah, involved with accident scenes and disabled vehicles. Adding to his incident management credentials, he served five years with Metro Las Vegas’ Critical Incident Review Team.

Carnahan began consulting with AutoReturn in 2016. Eventually, AutoReturn’s founder, John Wicker, decided that Carnahan had some important bonafides for running a towing-technology company that served law enforcement and municipalities; he saw that Carnahan could contribute to AutoReturn’s success in a big way. So Wicker made a shrewd executive decision; he handed the helm to Carnahan. Meanwhile he continues to be involved in planning for the company’s future as AutoReturn’s chairman.

AutoReturn is now contracted with over thirty cities, counties and states in the U.S., plus, Rome, Italy. Its responsibilities to both the municipalities and towing operations are unique in this industry.

Some towers over the past ten years have been misinformed regarding AutoReturn, assuming AutoReturn’s business model was similar to that of a motor club. But the two models couldn’t be more polar opposite. AutoReturn does not set rates and the more calls dispatched the merrier; AutoReturn’s revenue is driven by the number of calls it dispatches and the more the tower makes the more AutoReturn makes.

Jerry Carnahan

Still, the wrong assumptions persisted around how AutoReturn operated.

AutoReturn would drive down non consensual tow rates, the misinformed towers feared. “AutoReturn never sets rates that towers are paid,” Carnahan said. Towers interviewed by American Towman over the past several years have been okay with rates paid to them through AutoReturn. In some cases those rates were higher than paid before AutoReturn came onto the scene.

The second fear among those who towed for the police was that AutoReturn would come into a city and mess with an established rotation list. Over the years these fears have largely proven unfounded.

As to the issue of upsetting an established rotation in a city, Carnahan has this to say, “We don’t want to upset the status quo. For example, if a city has four towers in the rotation and it’s working well and the city is happy with that, we take that approach.” One of the specific tower concerns had been that AutoReturn would flood an area by adding more towers to a rotation list and dispatch strictly to the truck closest to the breakdown, overriding the tower who was up on the rotation.

“The law enforcement agency,” says Carnahan, “determines if ◀

Brother, Mel Carnahan (inset) and Dad, Gene Carnahan, circa 2017.

the call goes rotation, closest to the scene or a hybrid model. We can and do work with all three. Some use closest to scene to speed response, some prefer rotation and a few use rotation and closest to dispatch with a priority call when they want the vehicles cleared quickly. The facts prove a model allowing a closest to dispatch can drastically improve response times, but, as I have said, we work with whichever model the city requires.”

‘The city,’ says Carnahan, “besides managing the tow rates, sets the service level requirements.”

AutoReturn provides the cities a quantified level of accountability. “AutoReturn measures everything,” said Carnahan. “And we provide comprehensive data on service performance. Response times are critical for reducing secondary crashes and saving lives.”

Carnahan believes that AutoReturn and towers have mutual interests and AutoReturn has been a positive force for towers in the cities they dispatch for. “In my estimation,” said Carnahan, “the biggest issues facing towers is spiraling costs, unfair competition and unprofessional tow operations. We strive to help communities run smoothly by connecting law enforcement, towers and vehicle owners to keep traffic moving and officers and tow truck operators safe.”

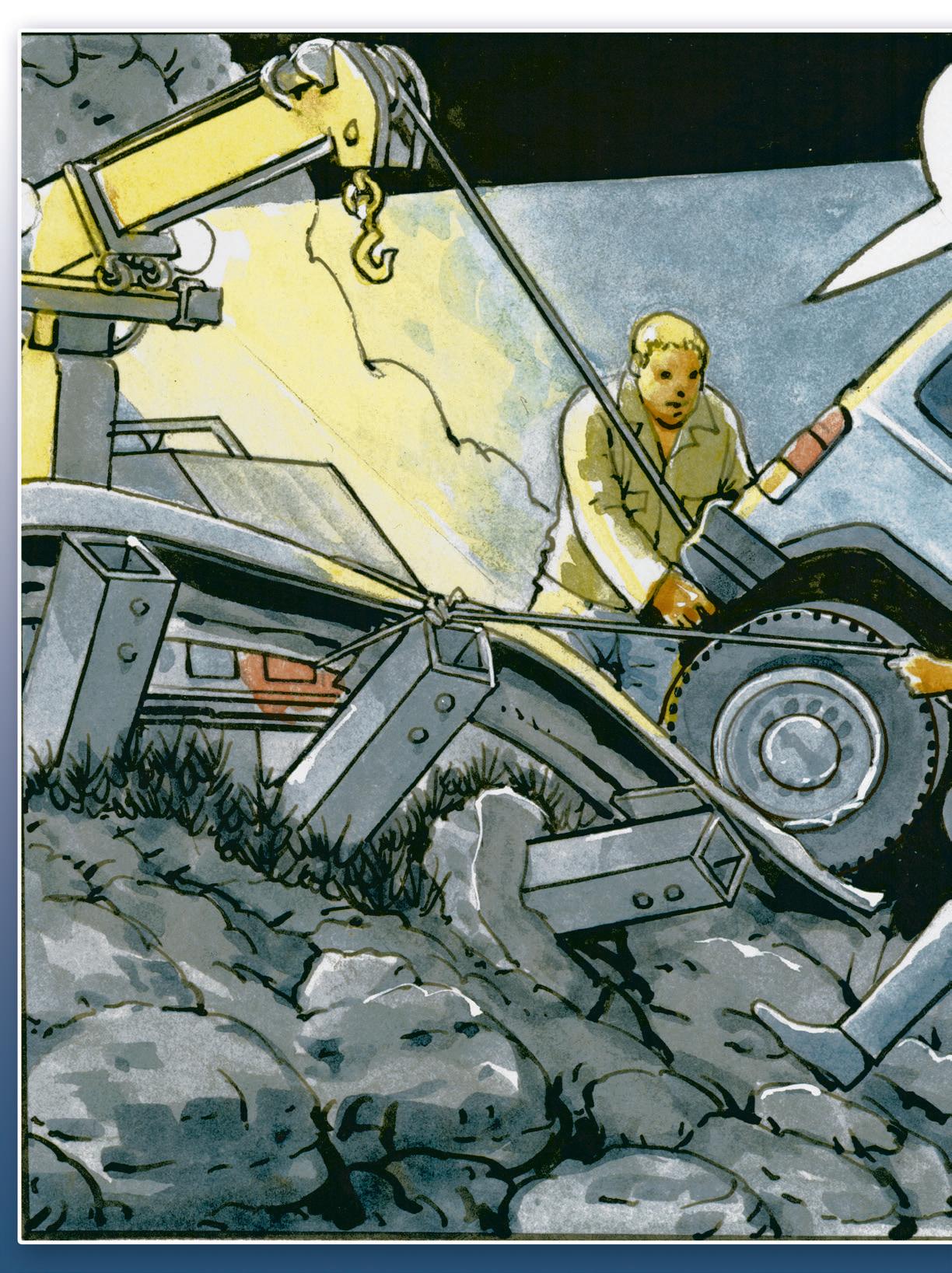

Up the Cliff

By Josh Mast

142 feet from the cliff to ocean floor.

On February 12th, 2021 a geo stabilization company was contracted with Oregon DOT to reinforce and stabilize the narrow portion of highway 101 on the cliffs, seventeen miles north of Florence, OR. The machine was a Komatsu 200 c with an air compressor and drill unit on the end of stick; to bore and insert threaded pins into the rock face of the cliffs and anchor the highway in the places it was sliding. During installation one of the old historic retaining walls collapsed, the highway gave way and the machine weighing 60,000 pounds, and the operator, tumbled 142 feet down the cliffs to the ocean floor below.

Mast Bros. was contacted by the general manager of the company after being referred by a number of people and crane companies for the recovery. Over the next few weeks the company engineers, ODOT and others had to reinforce and stabilize the road prior to us retrieving the unit. After the collapse on February 12th the highway was closed entirely from 7am to 7pm with only one lane open with 24 hour flagging for local residents that had to get home.

After a few weeks of road prep the company contacted us again and had me come look at the repairs and see if it was suitable for the large trucks to recover the unit. We made plans to upright, and prep the unit for removal on February 25th. We arrived in the morning at 7am and began the prep work, removed the compressor unit from the rear in order to gain access for attachment points, and unbolted the drill head for the steep near-

vertical incline it had to go back up. Hydraulic hoses were wrapped and secured in place, loose items strapped to the unit.

We uprighted the unit by placing a strap on the rocks beyond the machine, hanging the block off it, then connecting the line to the upper track rail. This pulled the

Winds were at 60 miles per hour

unit down to its tracks, we then secured the lines to the back and turned the machine in line with the rock cliffs to complete the removal the following day.

It was nearing dark and we had to have all the trucks disconnected and the road clear by 7pm. We made the decision to return the following morning to finish the removal but upon arrival a storm had come in that night and the high surf advisory was making conditions hazardous; the waves were hitting the tracks on the machine and high tide was not even for four more hours. Winds were at 60 miles per hour on the peak of the cliffs and it was hailing sideways. We decided to come back after the storm passed. On February 27th we left our base shop at 5:30am, arrived on scene just before 7am and had to wait for ODOT to close the road. The weather was decent and we began set up. Trucks were placed into position, lines were pulled out and connected back to the rigging that we left in place. We began pulling on the machine at 9am and at 12:30pm the unit landed on the highway. We spent the next few hours bringing debris out and loading the machine onto our Versamax trailer.

We arrived back home and unloaded by 7:43pm. About Mast Bros UNITS (page 42):

Mast Bros Enterprise, Inc. covers an area of almost 8,000 square miles from six locations up and down the Oregon coast, operating 26 trucks. • Lower wrecker: 2002 Kenworth

T2000 325” wheelbase with a Vulcan 940 recovery unit 45 ton primary and 35 ton secondary winches • Middle wrecker, positioned parallel: 2018 Peterbilt 567, 373” wheelbase twin steer 5 axle with a Jerr-Dan 50/60 hdl 1000 jfb rotator unit with 50k primary winches, 25k secondary winches and a 35k drag winch • Top unit: 1995 Peterbilt sleeper 305” wheelbase with a Jerr-Dan hdl 600 /350 30 ton wrecker unit • Further down the road Mast used a 1999 Kenworth T2000 tractor with a 2020 versa max 50 ton, 53 ft extendable trailer to load the machine and parts to transport back to the yard.

A harsh Wisconsin winter leads to severe road conditions and multiple semi accidents.

On February 1st, 2021 Lanser Garage & Towing was called by the Wisconsin State Patrol for a wrecked tractor-trailer. Third generation tower Jamon Ingelse advised, “This was an empty T/T unit out on I43 northbound at 138 MM in Cleveland, Wisconsin. The Volvo tractor tandem bent 90° to the cab around a tree. The trailer stayed attached.”

A Century 9055 50-ton, front, and a Vulcan V100 50-ton, in back, teamed up on the recovery.

Jamon responded with his 2009 Mack with a Vulcan V100 50-ton equipped with a SP850 Side Puller unit, along with operator Scott Winkle in their 2018 Mack with a Century 9055 50-ton and operator Hunter Gottschalk with their 2018 IHC 12 Series rollback.

Jamon informed, “This accident happened two days prior to us doing the job in negative temperatures and wind chill to -40 degrees. Multiple semi accidents were left to do scheduled recoveries throughout the entire county in cooperation/ coordination with the Wisconsin State Patrol, Manitowoc Sheriffs and Highway departments. Recovery day had a high temperature below zero.”

The semi was northbound and due to wind, ice and blinding conditions lost control, slid down the hill jack-knifing and hit the tree on the passenger side ahead of the tandem. At the point of impact the tandem bent 90° around the tree with the trailer still attached behind the tree. The entire unit was approximately 60 feet down a hill with the trailer parallel to the interstate.

The Lanser recovery team positioned the Century 9055 forward of the wreck to winch out after it was removed from the tree. The Vulcan V100 turned around and faced the opposite direction of traffic to be in the correct position to remove the wreck from the tree and be in the right position to tow back to Lanser’s holding facility.

“The V100 was rigged to the front axle area and to the fifth wheel area with separate lines to straighten the

and wind chill to -40 degrees.

Volvo out and “unwrap” it from the tree,” said Jamon. “After it was cleared of the tree, our 9055 rigged to winch the unit to the interstate as the V100 stayed hooked to the fifth wheel plate area and re-rigged

the second line to the rear of the trailer.”

As the entire unit approached the interstate the Vulcan V100 winched the rear of the trailer onto the shoulder of the interstate. They used the Century 9055 to separate the units and re-positioned to tow the trailer. The V100 then backed up to the rear of the Volvo.

Using a cutoff saw, the crew removed broken, bent and twisted metal and plastic to assist with the tow to Lanser’s. The Volvo was chained together from the rear tandems to the transmission cross members with support blocking under cross members and frame rails to make it possible to keep it together during transport.

Jamon explained, “The unit was towed approximately 35 miles to our storage/holding facility where a salvage yard contracted through the insurance came and cut the unit into manageable pieces for transport to Minnesota. Total time was 3 hours and only one lane was closed for this recovery. Great work with everyone involved.”

Read more towing news at

towman.com

Find us on Facebook

About Lanser Garage & Towing Inc

Lanser Garage & Towing, based in Belgium, Wisconsin, was founded by George and Grace Lanser in 1951. The family owned company is currently owned by George’s daughter Donna and son-in-law, Randy Ingelse, with their son, Jamon Ingelse, representing the very involved third generation.

Lanser handles light- and heavy-duty towing and recovery, local and long distance and also offers forklift sales, rental and service. They are proud members of the Wisconsin Towing Associaton.